Influence of Waste Brick Powder in the Mechanical Properties of Recycled Aggregate Concrete

Abstract

:1. Introduction

2. Methods and Materials

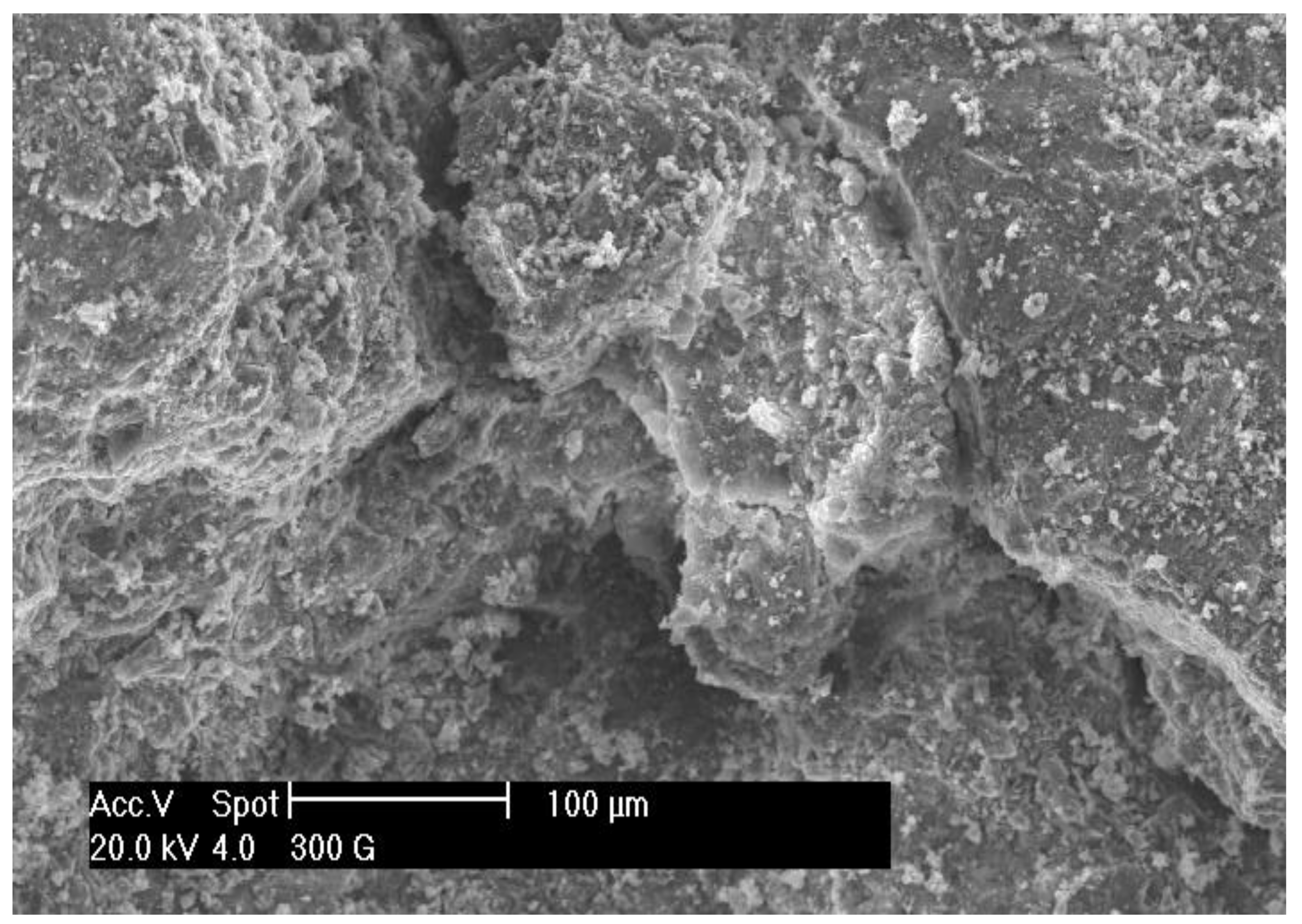

2.1. Cement and CBP

2.2. Natural and Recycled Aggregates

2.3. Sample Preparation

3. Results and Discussion

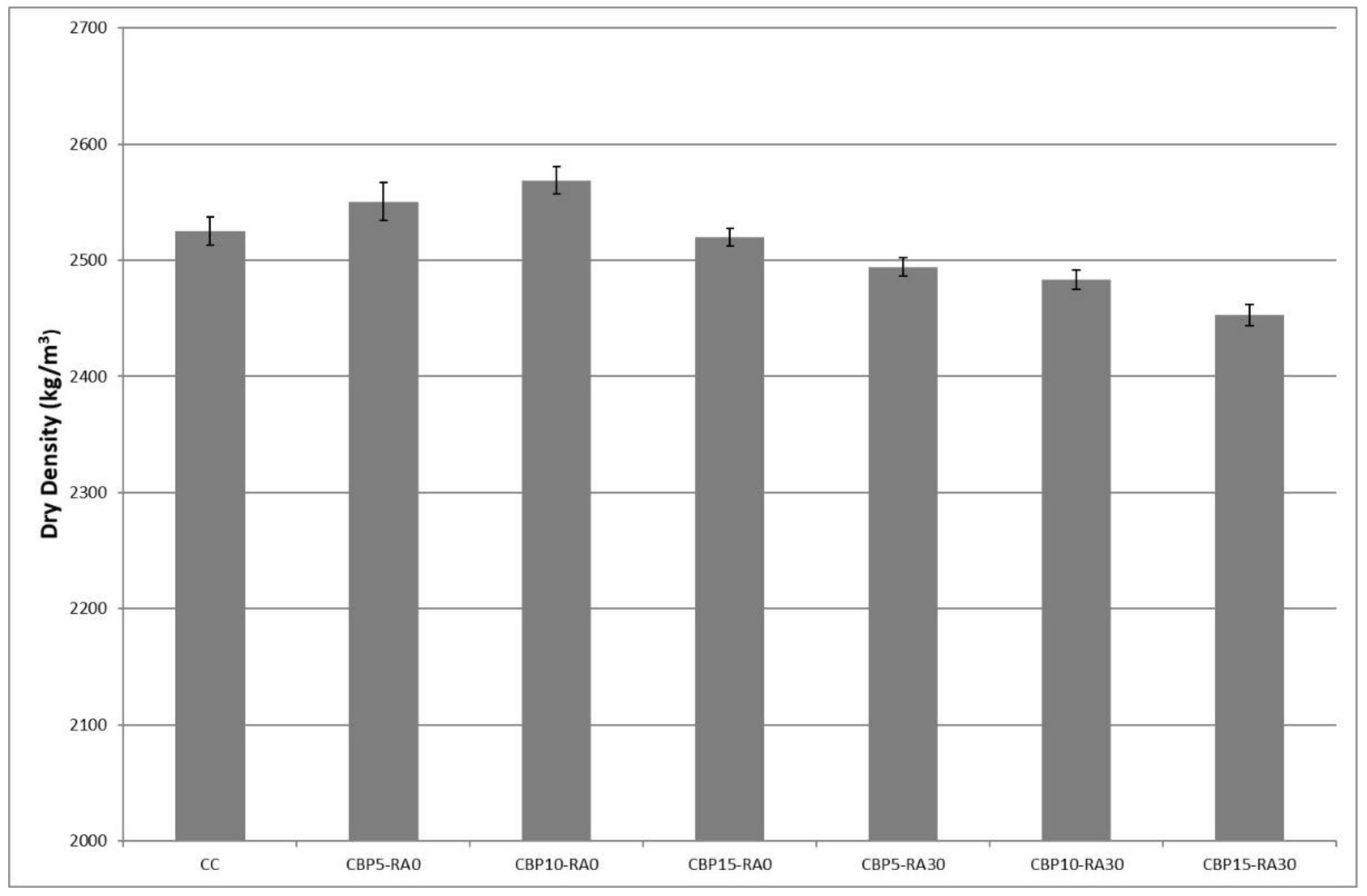

3.1. Density

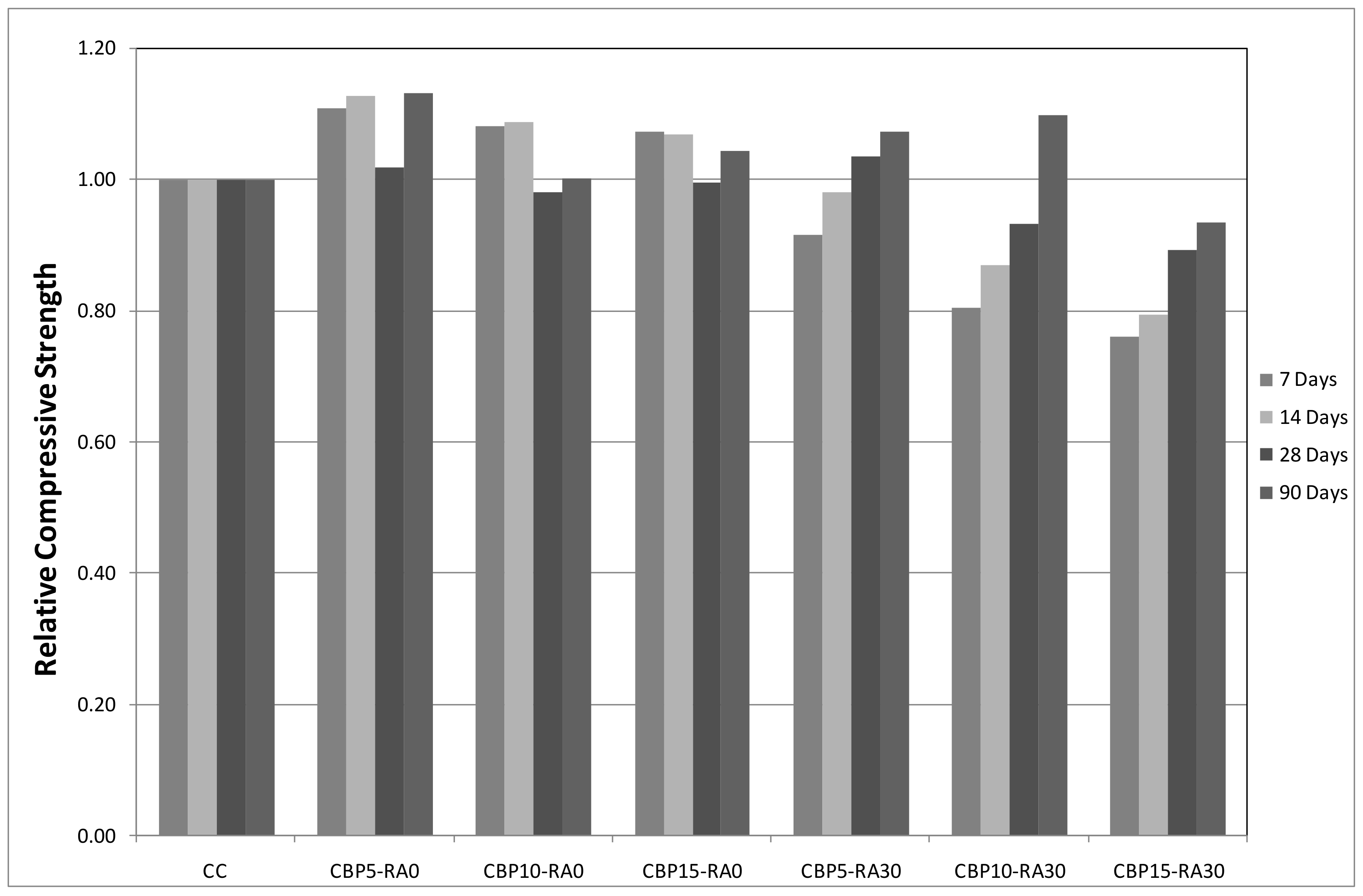

3.2. Compressive Strength

3.3. Flexural Strength

3.4. Static Elastic Modulus

3.5. Comparison with Normative

4. Conclusions

- Replacing up to 15% of cement with CBP does not alter significantly the compressive strength of concretes with natural coarse aggregates or with up to 30% RA replacement if enough curing days are considered.

- The use of a small percentage of CBP together with RA strengthens the concrete matrix, compensating for the strength losses due to the use of RA.

- After 28 curing days, the flexural strength does not present losses when up to 15% of cement is replaced by CBP, if no RA are used. At 90 days, the series show differences between 6% and 11% compared to control concrete.

- Flexural strength is mainly affected by the use of RA, observing losses of up to 16% after 28 curing days when it is combined with the reuse of CBP. At 90 days, these losses are kept between 8% and 15%.

- The use of CBP as a cement replacement without RA affected the elastic modulus with losses between 1% and 9%, due to the low elastic modulus of the bricks.

- The use of CBP together with RA increases the loss in the elastic modulus between 9% and 12%.

- Equations proposed by the different technical regulations tested in this analysis to calculate the flexural strength and the static elastic modulus are not always able to predict conservatively enough the behavior of recycled concretes. Performing further studies is suggested to re-evaluate these regulations when reused materials are included in concrete manufacturing.

- Further studies are suggested to evaluate if a certain proportion of RA and CBP can optimize the performance of the recycled concrete. The results suggest that the internal curing of the RA due to the presence of a certain amount of CBP may lead to an optimal combination of both.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lin, K.-L.; Chang, J.-C. Feasibility of recycling waste diatomite and fly ash cosintered as porous ceramics. Environ. Prog. Sustain. Energy 2013, 32, 25–34. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Recycling of waste aggregate in cement bound mixtures for road pavement bases and sub-bases. Constr. Build. Mater. 2016, 108, 112–118. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Experimental analysis of hydraulically bound mixtures made with waste foundry sand and steel slag. Mater. Struct. 2015, 48, 2489–2503. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Common carbon metric for measuring energy use and reporting greenhouse gas emissions from building operations 2009. Available online: http://wedocs.unep.org/handle/20.500.11822/7922 (accessed on 8 March 2018).

- Liu, Q.; Tong, T.; Liu, S.; Yang, D.; Yu, Q. Investigation of using hybrid recycled powder from demolished concrete solids and clay bricks as a pozzolanic supplement for cement. Constr. Build. Mater. 2014, 73, 754–763. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Rivera, J.F.; Mejía de Gutiérrez, R. Alkali-activated building materials made with recycled construction and demolition wastes. Constr. Build. Mater. 2017, 149, 130–138. [Google Scholar] [CrossRef]

- Rakhimova, N.R.; Rakhimov, R.Z. Alkali-activated cements and mortars based on blast furnace slag and red clay brick waste. Mater. Des. 2015, 85, 324–331. [Google Scholar] [CrossRef]

- Medina, C.; Banfill, P.F.G.; Sánchez De Rojas, M.I.; Frías, M. Rheological and calorimetric behaviour of cements blended with containing ceramic sanitary ware and construction/demolition waste. Constr. Build. Mater. 2013, 40, 822–831. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Petek Gursel, A.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Experimental characterization of binary and ternary blended-cement concretes containing ultrafine residual rice husk and sugar cane bagasse ashes. Constr. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Influence of environmental conditions on durability of slag cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 277–287. [Google Scholar]

- Pastor, J.L.; Ortega, J.M.; Flor, M.; López, M.P.; Sánchez, I.; Climent, M.A. Microstructure and durability of fly ash cement grouts for micropiles. Constr. Build. Mater. 2016, 117, 47–57. [Google Scholar] [CrossRef]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Sánchez, I. Microstructural Effects of Sulphate Attack in Sustainable Grouts for Micropiles. Materials 2016, 9, 905. [Google Scholar] [CrossRef] [PubMed]

- Williams, M.; Ortega, J.M.; Sánchez, I.; Cabeza, M.; Climent, M.A. Non-Destructive Study of the Microstructural Effects of Sodium and Magnesium Sulphate Attack on Mortars Containing Silica Fume Using Impedance Spectroscopy. Appl. Sci. 2017, 7, 648. [Google Scholar] [CrossRef]

- Böke, H.; Akkurt, S.; Ipekoğlu, B.; Uğurlu, E. Characteristics of brick used as aggregate in historic brick-lime mortars and plasters. Cem. Concr. Res. 2006, 36, 1115–1122. [Google Scholar] [CrossRef]

- Puertas, F.; Barba, A.; Gazulla, M.F.; Gómez, M.P.; Palacios, M.; Martínez-ramírez, S. Ceramic wastes as raw materials in portland cement clinker fabrication: Characterization and alkaline activation. Mater. Constr. 2006, 56, 73–84. [Google Scholar] [CrossRef] [Green Version]

- Vieira, T.; Alves, A.; de Brito, J.; Correia, J.R.; Silva, R.V. Durability-related performance of concrete containing fine recycled aggregates from crushed bricks and sanitary ware. Mater. Des. 2016, 90, 767–776. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd-Elmoaty, A.-E.M.; Hassan, H.H. Utilization of crushed clay brick in concrete industry. Alexandria Eng. J. 2014, 53, 151–168. [Google Scholar] [CrossRef]

- Letelier, V.; Tarela, E.; Muñoz, P.; Moriconi, G. Combined effects of recycled hydrated cement and recycled aggregates on the mechanical properties of concrete. Constr. Build. Mater. 2017, 132, 365–375. [Google Scholar] [CrossRef]

- Serpell, R.; Lopez, M. Reactivated cementitious materials from hydrated cement paste wastes. Cem. Concr. Compos. 2013, 39, 104–114. [Google Scholar] [CrossRef]

- Kulovaná, T.; Vejmelková, E.; Keppert, M.; Rovnaníková, P.; Keršner, Z.; Černý, R. Mechanical, durability and hygrothermal properties of concrete produced using Portland cement-ceramic powder blends. Struct. Concr. 2016, 17, 105–115. [Google Scholar] [CrossRef]

- Katzer, J. Strength performance comparison of mortars made with waste fine aggregate and ceramic fume. Constr. Build. Mater. 2013, 47, 1–6. [Google Scholar] [CrossRef]

- Lavat, A.E.; Trezza, M.A.; Poggi, M. Characterization of ceramic roof tile wastes as pozzolanic admixture. Waste Manag. 2009, 29, 1666–1674. [Google Scholar] [CrossRef] [PubMed]

- Ge, Z.; Gao, Z.; Sun, R.; Zheng, L. Mix design of concrete with recycled clay-brick-powder using the orthogonal design method. Constr. Build. Mater. 2012, 31, 289–293. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, Y.; Sun, R.; Wu, X.; Guan, Y. Influence of ground waste clay brick on properties of fresh and hardened concrete. Constr. Build. Mater. 2015, 98, 128–136. [Google Scholar] [CrossRef]

- Gonçalves, J.P.; Tavares, L.M.; Toledo Filho, R.D.; Fairbairn, E.M.R. Performance evaluation of cement mortars modified with metakaolin or ground brick. Constr. Build. Mater. 2009, 23, 1971–1979. [Google Scholar] [CrossRef]

- Schackow, A.; Stringari, D.; Senff, L.; Correia, S.L.; Segadães, A.M. Influence of fired clay brick waste additions on the durability of mortars. Cem. Concr. Compos. 2015, 62, 82–89. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M.; Ng, K.M. Physio-chemical reactions in recycle aggregate concrete. J. Hazard. Mater. 2009, 163, 823–828. [Google Scholar] [CrossRef] [PubMed]

- Ismail, S.; Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 2013, 44, 464–476. [Google Scholar] [CrossRef]

- Lee, G.C.; Choi, H.B. Study on interfacial transition zone properties of recycled aggregate by micro-hardness test. Constr. Build. Mater. 2013, 40, 455–460. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Mechanical strength and drying shrinkage properties of concrete containing treated coarse recycled concrete aggregates. Constr. Build. Mater. 2014, 68, 726–739. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Seo, D.S.; Choi, H.B. Effects of the old cement mortar attached to the recycled aggregate surface on the bond characteristics between aggregate and cement mortar. Constr. Build. Mater. 2014, 59, 72–77. [Google Scholar] [CrossRef]

- González, A.; Etxeberria, M. Experimental analysis of properties of high performance recycled aggregate concrete. Constr. Build. Mater. 2014, 52, 227–235. [Google Scholar] [CrossRef]

- Pedro, D.; De Brito, J.; Evangelista, L. Influence of the use of recycled concrete aggregates from different sources on structural concrete. Constr. Build. Mater. 2014, 71, 141–151. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Wang, K.; Tam, C.M. Assessing relationships among properties of demolished concrete, recycled aggregate and recycled aggregate concrete using regression analysis. J. Hazard. Mater. 2008, 152, 703–714. [Google Scholar] [CrossRef] [PubMed]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in China. Part II. Structural behaviour of recycled aggregate concrete and engineering applications. Resour. Conserv. Recycl. 2009, 53, 107–112. [Google Scholar] [CrossRef]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Letelier, V.; Tarela, E.; Moriconi, G. Mechanical Properties of Concretes with Recycled Aggregates and Waste Brick Powder as Cement Replacement. Procedia Eng 2017, 171, 627–632. [Google Scholar] [CrossRef]

- Pereira-De-Oliveira, L.A.; Castro-Gomes, J.P.; Santos, P.M.S. The potential pozzolanic activity of glass and red-clay ceramic waste as cement mortars components. Constr. Build. Mater. 2012, 31, 197–203. [Google Scholar] [CrossRef]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.B.; Martinelli, E. Alternative processing procedures for recycled aggregates in structural concrete. Constr. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Harbi, R.; Derabla, R.; Nafa, Z. Improvement of the properties of a mortar with 5% of kaolin fillers in sand combined with metakaolin, brick waste and glass powder in cement. Constr. Build. Mater. 2017, 152, 632–641. [Google Scholar] [CrossRef]

- Silva, J.; Brito, J.D.; Veiga, R. Incorporation of fine ceramics in mortars. Constr. Build. Mater. 2009, 23, 556–564. [Google Scholar] [CrossRef]

- Naceri, A.; Hamina, M.C. Use of waste brick as a partial replacement of cement in mortar. Waste Manag. 2009, 29, 2378–2384. [Google Scholar] [CrossRef] [PubMed]

- O’Farrell, M.; Wild, S.; Sabir, B.B. Pore size distribution and compressive strength of waste clay brick mortar. Cem. Concr. Compos. 2001, 23, 81–91. [Google Scholar] [CrossRef]

- Nassar, R.-U.-D.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Letelier, V.; Tarela, E.; Muñoz, P.; Moriconi, G. Assessment of the mechanical properties of a concrete made by reusing both: Brewery spent diatomite and recycled aggregates. Constr. Build. Mater. 2016, 114, 492–498. [Google Scholar] [CrossRef]

- RILEM TC 37-DRC. Demolition and Reuse of Concrete; E & FN Spon: London, UK, 1992. [Google Scholar]

- Ikeda, T.; Yamane, S.; Sakamoto, A. Strengths of concrete containing recycled concrete aggregate. In Demolition and Reuse of Concrete and Masonry; Kasai, Y., Ed.; Chapman and Hall: Tokyo, Japan, 1988; pp. 585–594. [Google Scholar]

| Composition | Cement | CBP |

|---|---|---|

| SiO2 | 38.06% | 41.47% |

| Al2O3 | 8.88% | 39.05% |

| CaO | 40.92% | 0.63% |

| Fe2O3 | 2.83% | 12.73% |

| SO3 | 2.33% | 1.59% |

| MgO | 1.59% | - |

| Na2O | 1.75% | - |

| K2O | 1.62% | 2.81% |

| TiO2 | - | 1.03% |

| CuO | - | 0.70% |

| Density | 2688 kg/m3 | 2660 kg/m3 |

| Blaine surface area | 4610 m2/kg | 6485 m2/kg |

| Aggregates | Size(mm) | Bulk Specific Gravity (Saturated Surface Dry, SSD) (kg/m3) | Bulk Specific Gravity (kg/m3) | Apparent Specific Gravity (kg/m3) | Absorption(%) |

|---|---|---|---|---|---|

| NA | 6.3–9.5 | 2678 | 2629 | 2765 | 1.9 |

| 9.5–12.5 | 2687 | 2642 | 2767 | 1.7 | |

| 12.5–19.3 | 2699 | 2661 | 2765 | 1.4 | |

| RA | 6.3–9.5 | 2510 | 2390 | 2720 | 5.0 |

| 9.5–12.5 | 2530 | 2430 | 2720 | 4.4 | |

| 12.5–19.3 | 2530 | 2440 | 2700 | 4.0 |

| Series | NA (2.36–19.0 mm) (kg) | RA (6.3–19.0 mm) (kg) | Cement (kg) | CBP (kg) | Sand (kg) | Water (L) | Slump (cm) |

|---|---|---|---|---|---|---|---|

| CC | 920 | - | 382.0 | - | 877 | 203 | 3.0 |

| CBP5-RA0 | 920 | - | 362.9 | 19.1 | 877 | 203 | 3.5 |

| CBP10-RA0 | 920 | - | 343.8 | 38.2 | 877 | 203 | 5.0 |

| CBP15-RA0 | 920 | - | 324.7 | 57.3 | 877 | 203 | 6.5 |

| CBP5-RA30 | 644 | 276 | 362.9 | 19.1 | 877 | 203 | 3.5 |

| CBP10-RA30 | 644 | 276 | 343.8 | 38.2 | 877 | 203 | 4.0 |

| CBP15-RA30 | 644 | 276 | 324.7 | 57.3 | 877 | 203 | 1.0 |

| CC | CBP5-RA0 | CBP10-RA0 | CBP15-RA0 | CBP5-RA30 | CBP10-RA30 | CBP15-RA30 | ||

|---|---|---|---|---|---|---|---|---|

| Compressive Strength (MPa) | 7 days | 19.05 | 21.14 | 20.63 | 20.45 | 17.46 | 15.35 | 14.49 |

| Std% | 2.5 | 0.3 | 1.3 | 0.9 | 1.2 | 3.0 | 3.9 | |

| 14 days | 24.23 | 27.35 | 26.38 | 25.91 | 23.78 | 21.09 | 19.27 | |

| Std% | 4.0 | 2.2 | 3.3 | 6.9 | 3.8 | 1.7 | 3.8 | |

| 28 days | 32.34 | 32.93 | 31.77 | 32.21 | 33.51 | 30.18 | 28.93 | |

| Std% | 2.7 | 5.7 | 4.4 | 2.3 | 2.4 | 0.8 | 3.2 | |

| 90 days | 38.34 | 43.39 | 38.44 | 40.07 | 41.18 | 42.15 | 35.87 | |

| Std% | 1.7 | 5.3 | 2.3 | 2.4 | 6.8 | 4.3 | 3.3 | |

| Flexural Strength (MPa) | 28 days | 3.40 | 3.29 | 3.33 | 3.42 | 3.13 | 3.64 | 2.84 |

| Std% | 1.1 | 4.9 | 7.6 | 4.0 | 0.7 | 1.1 | 2.3 | |

| 90 days | 5.16 | 4.68 | 4.57 | 4.85 | 4.49 | 4.74 | 4.39 | |

| Std% | 2.7 | 3.2 | 4.4 | 4.7 | 2.3 | 2.8 | 1.4 | |

| Static Elastic Modulus, E (MPa) | 28 days | 29,000 | 28,733 | 26,267 | 28,133 | 25,467 | 25,800 | 26,300 |

| Std% | 5.2 | 0.8 | 5.0 | 0.8 | 2.5 | 5.5 | 2.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Letelier, V.; Ortega, J.M.; Muñoz, P.; Tarela, E.; Moriconi, G. Influence of Waste Brick Powder in the Mechanical Properties of Recycled Aggregate Concrete. Sustainability 2018, 10, 1037. https://doi.org/10.3390/su10041037

Letelier V, Ortega JM, Muñoz P, Tarela E, Moriconi G. Influence of Waste Brick Powder in the Mechanical Properties of Recycled Aggregate Concrete. Sustainability. 2018; 10(4):1037. https://doi.org/10.3390/su10041037

Chicago/Turabian StyleLetelier, Viviana, José Marcos Ortega, Pedro Muñoz, Ester Tarela, and Giacomo Moriconi. 2018. "Influence of Waste Brick Powder in the Mechanical Properties of Recycled Aggregate Concrete" Sustainability 10, no. 4: 1037. https://doi.org/10.3390/su10041037

APA StyleLetelier, V., Ortega, J. M., Muñoz, P., Tarela, E., & Moriconi, G. (2018). Influence of Waste Brick Powder in the Mechanical Properties of Recycled Aggregate Concrete. Sustainability, 10(4), 1037. https://doi.org/10.3390/su10041037