Analysis of Heating and Cooling Loads of Electrochromic Glazing in High-Rise Residential Buildings in South Korea

Abstract

:1. Introduction

1.1. Research Background and Objective

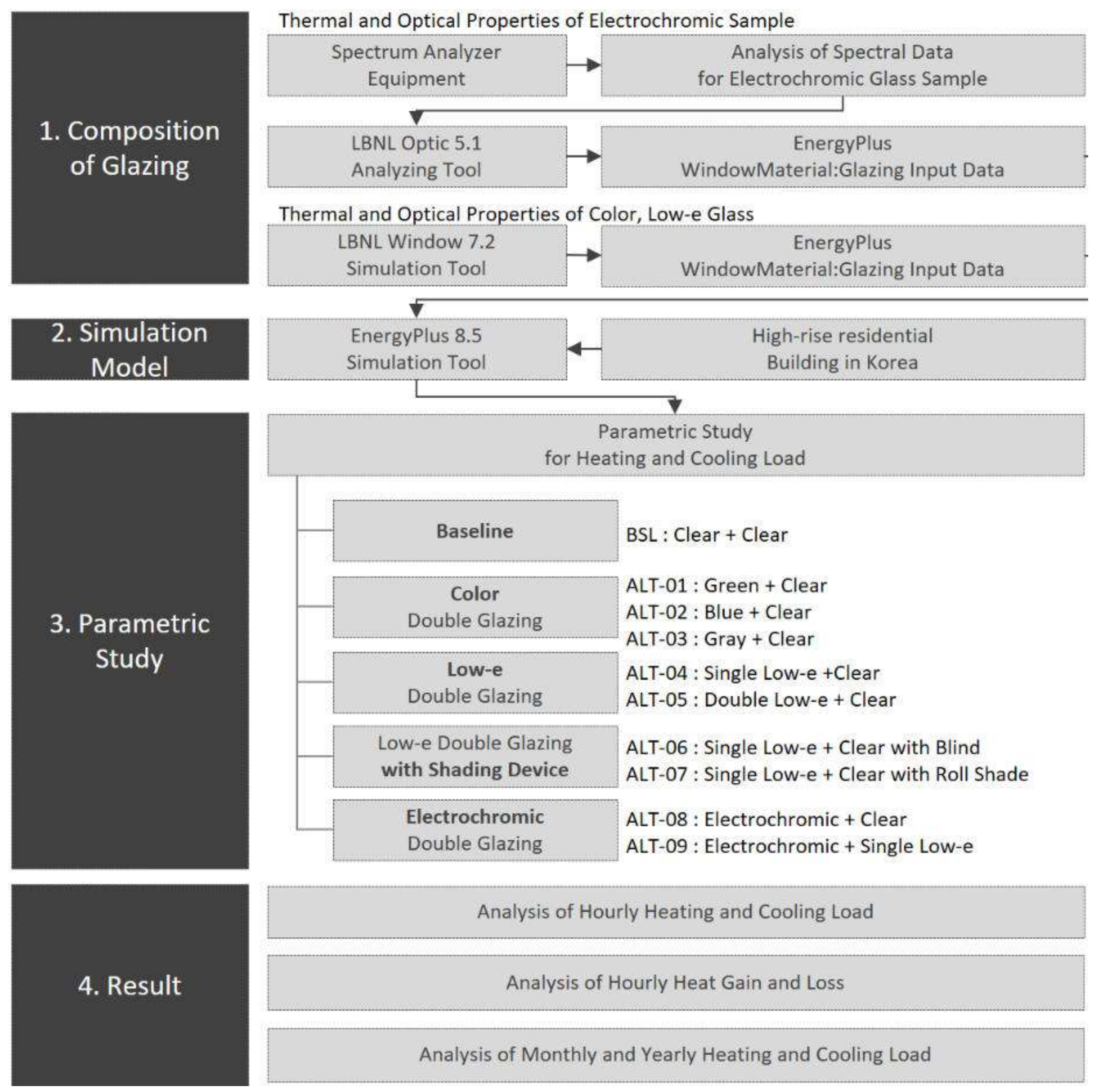

1.2. Research Method and Scope

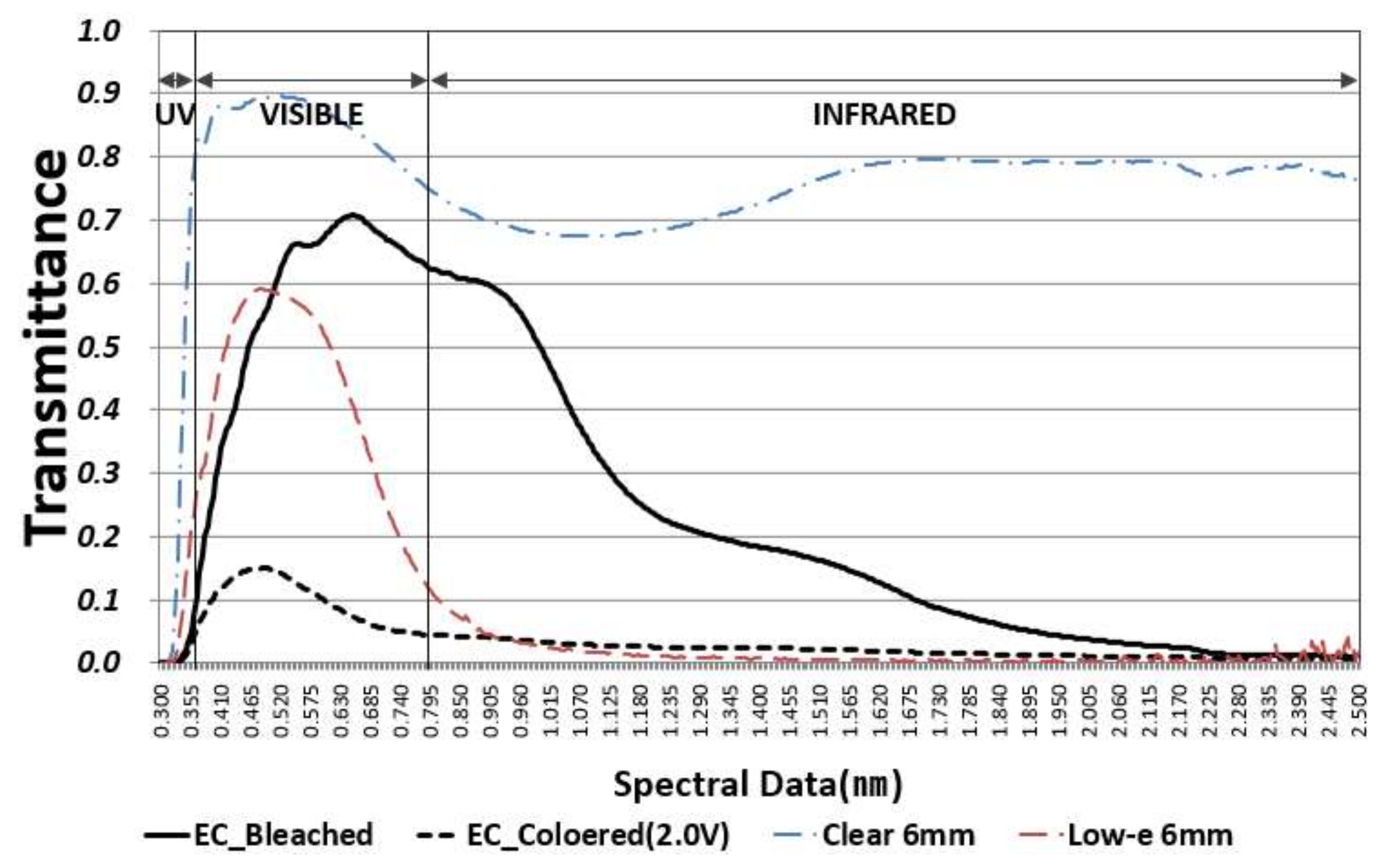

2. Analysis of Optical Properties of Electrochromic Glazing

3. Simulation Conditions

3.1. Overview of Analytical Simulation Model

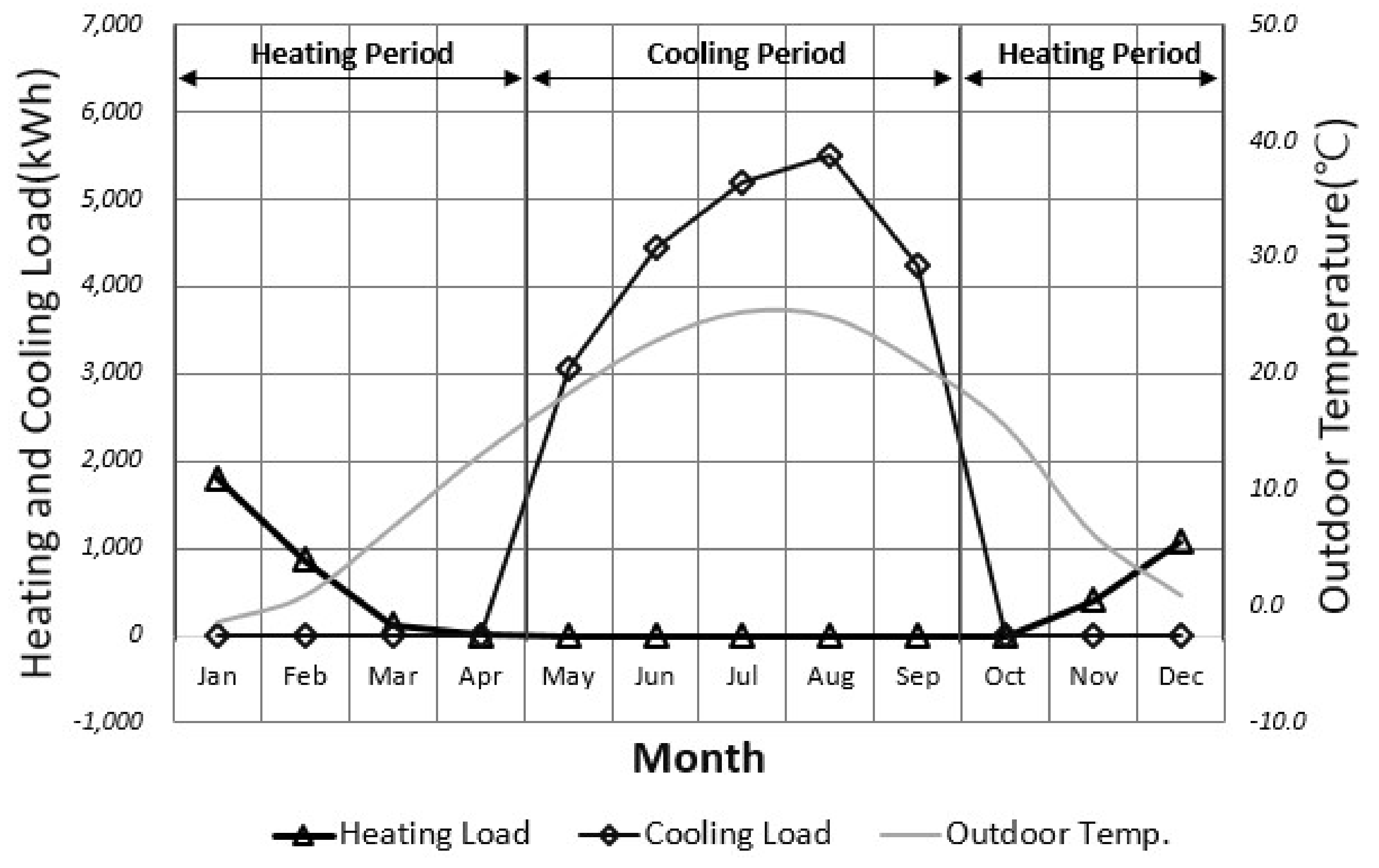

3.2. Analysis of Building Load Characteristics of Analytical Model

3.3. Composition of Double-Glazing and Shading Devices for Comparative Analysis

4. Results and Discussion

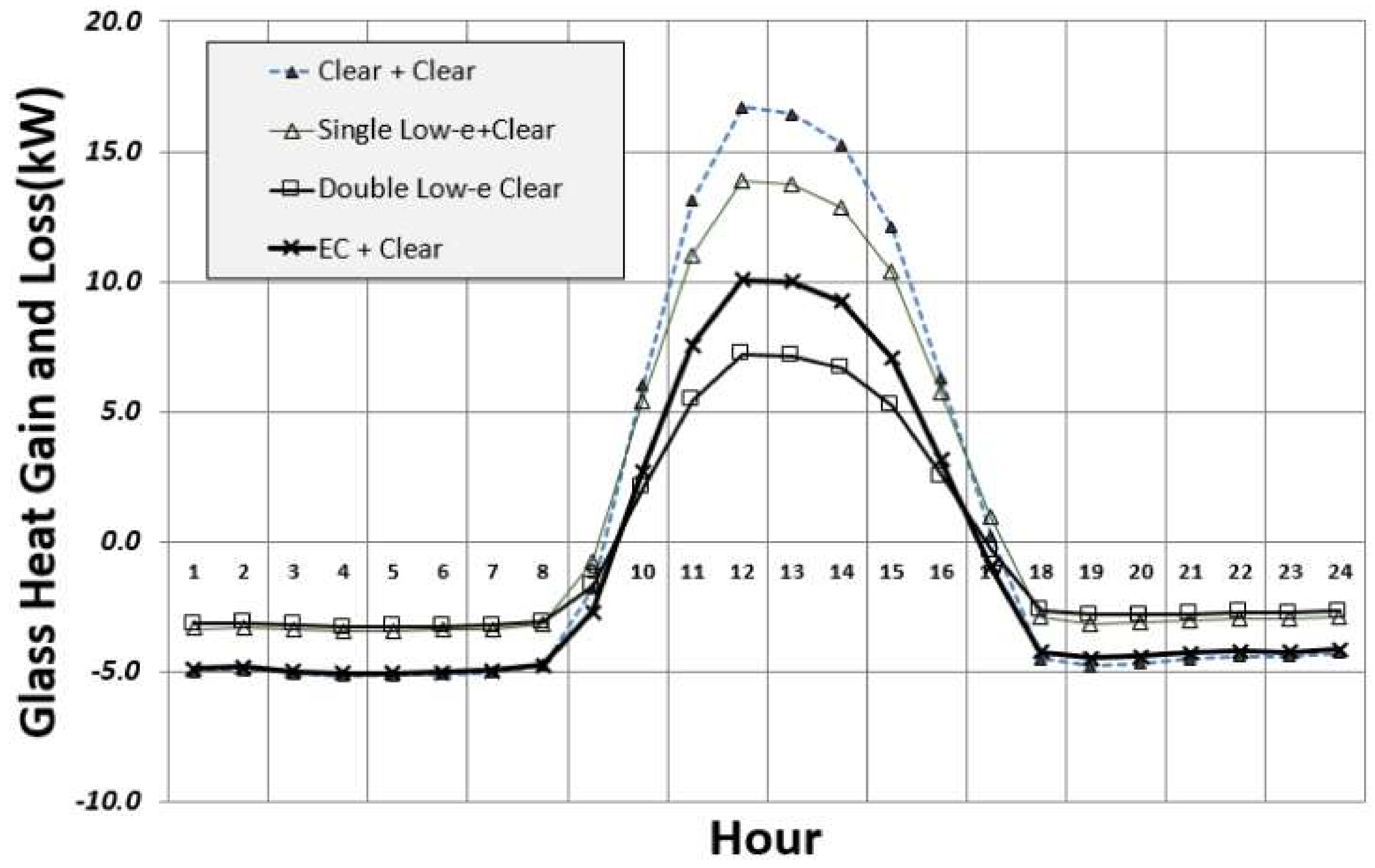

4.1. Performance Evaluation of Hourly Heating and Cooling Loads

4.1.1. Comparative evaluation of hourly heating load performance

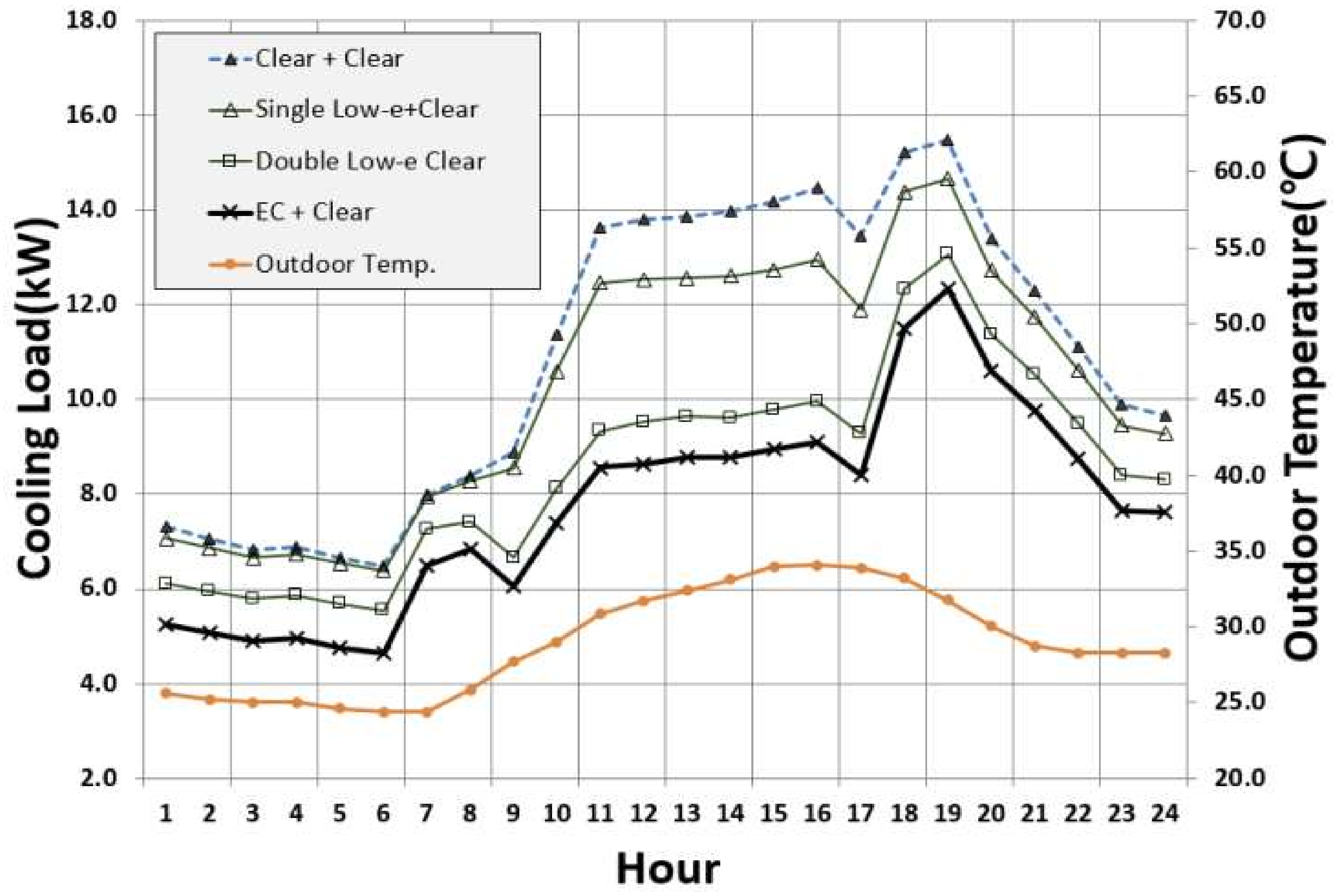

4.1.2. Comparative Evaluation of Hourly Cooling Load Performance

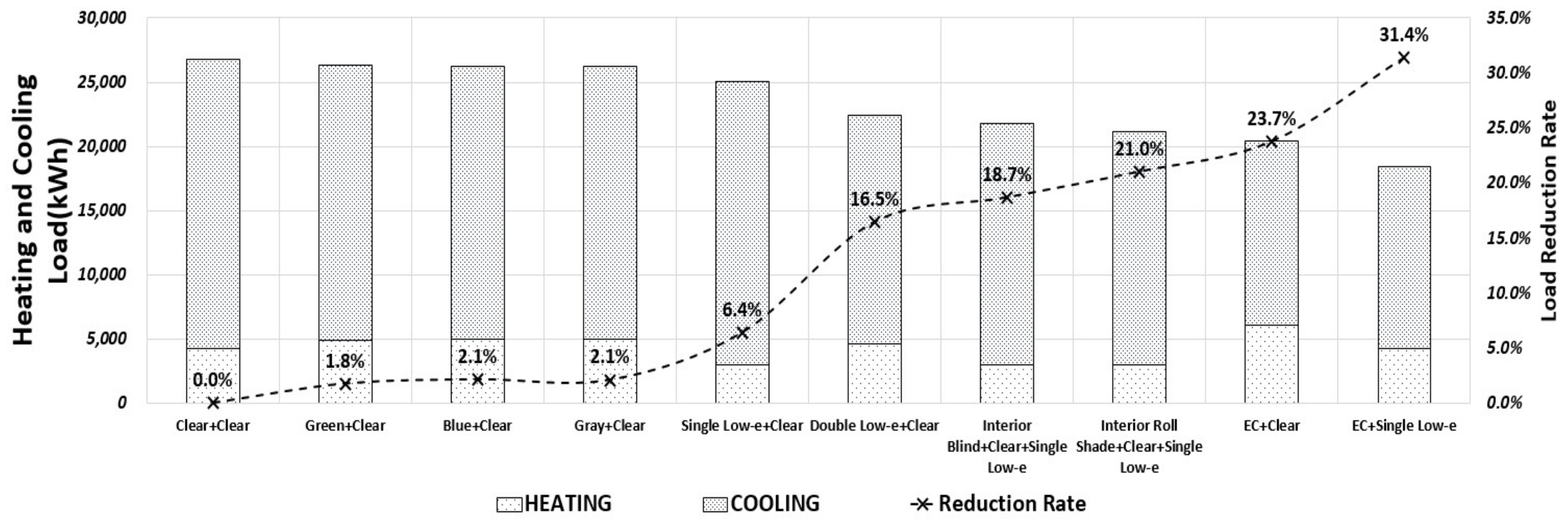

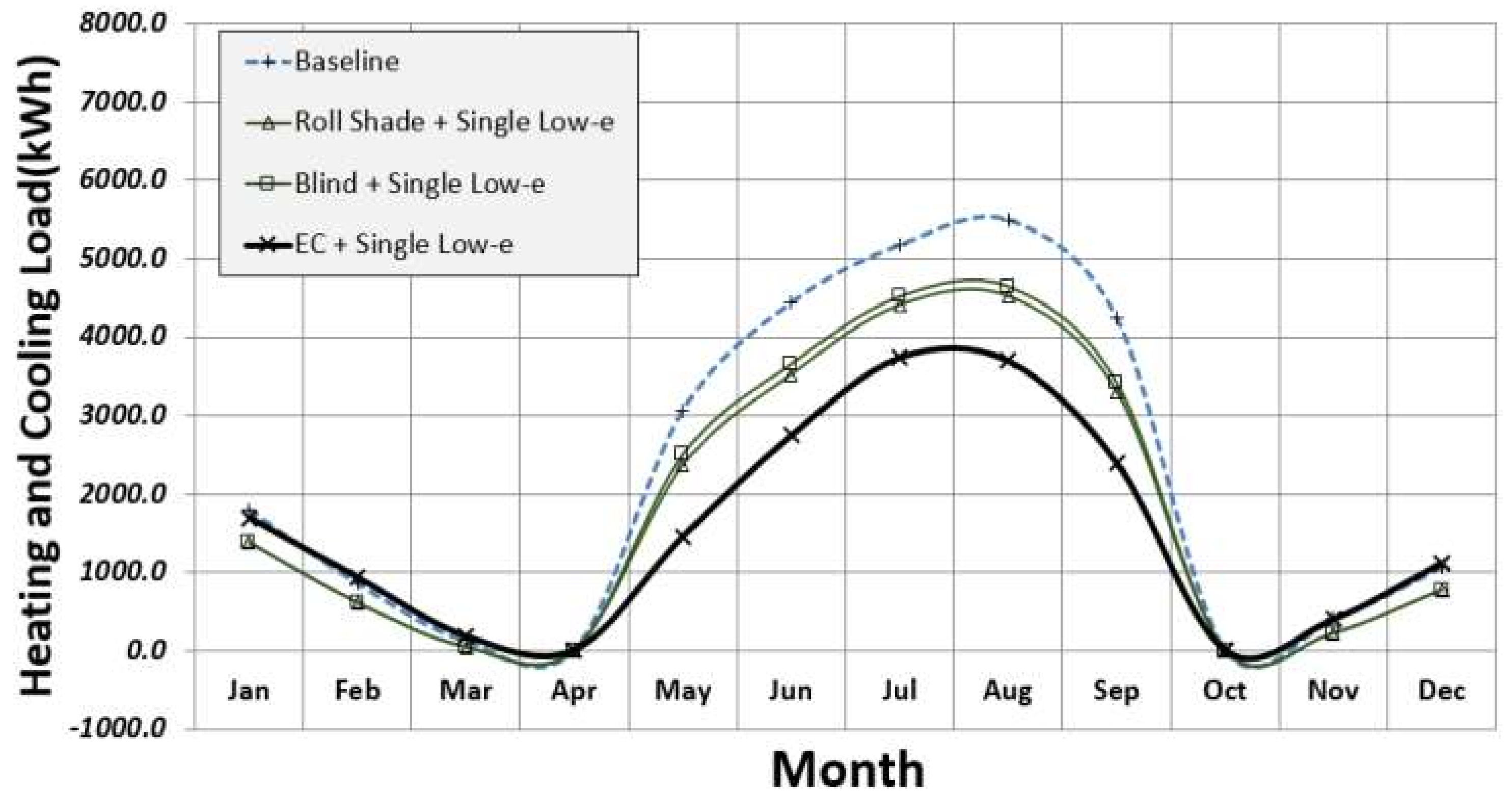

4.2. Monthly and Annual Changes in Heating and Cooling Loads

5. Conclusions

- (1)

- To test the hypothesis that the cooling load of the high-rise residential buildings was high, we analyzed the annual load using an analytical model on the EnergyPlus simulation tool. Heating and cooling loads comprised 84.0% and 16.0% of the total load, respectively, with the load pattern focused more on cooling.

- (2)

- We hypothesized that the load reduction performance of electrochromic glazing with variable solar control and high solar radiation rejection is better than that of double-glazing products and shading devices, and analyzed the cooling and heating loads for each type of double glazing.

- (3)

- In South Korea, which has different weather conditions in summer and winter, controlling solar radiation is important. The analysis of optical properties of electrochromic glazing showed that the solar transmittance values were 48.1% and 6.5% in the bleached and colored states, respectively. This indicates that allowing and blocking solar radiation during winter and summer, respectively, are effective for reducing the heating and cooling loads in buildings.

- (4)

- Colored electrochromic glazing had a higher solar radiation rejection than colored glass double glazing and low-e double glazing. Thus, it is effective for reducing cooling load. Moreover, it was observed to be excellent in terms of cooling load reduction compared with shading devices (blinds and roll shades), because such devices are installed indoors. Thus, the solar radiation that penetrates through the glass is partly absorbed by the shading devices, and flows indoors in the form of long-wave radiation, thereby reducing the heat gain due to convection and radiation. However, electrochromic glazing is applied to the outermost part to reduce the inflow of solar radiation.

- (5)

- Electrochromic glazing was found to be more effective for reducing the cooling loads compared with the heating loads. However, in buildings with dominant cooling loads, similar to the analytical model used in this study, it exhibited the best performance in terms of reducing the total annual load.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reilly, S.; Arasteh, D.; Selkowitz, S.E. Thermal and optical analysis of switchable window glazings. Sol. Energy Mater. 1991, 22, 1–14. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Daylighting performance and glare calculation of a suspended particle device switchable glazing. Sol. Energy 2016, 132, 114–128. [Google Scholar] [CrossRef]

- Ghosh, A.; Mallick, T.K. Evaluation of colour properties due to switching behaviour of a PDLC glazing for adaptive building integration. Renew. Energy 2018, 120, 126–133. [Google Scholar] [CrossRef]

- Rezaei, S.D.; Shannigrahi, S.; Ramakrishna, S. A review of conventional, advanced, and smart glazing technologies and materials for improving indoor environment. Sol. Energy Mater. Sol. Cells 2017, 159, 26–51. [Google Scholar] [CrossRef]

- Ihara, T.; Gustavsen, A.; Jelle, B.P. Effect of facade components on energy efficiency in office buildings. Appl. Energy 2015, 158, 422–432. [Google Scholar] [CrossRef]

- Piccolo, A.; Pennisi, F. Daylighting performance of an electrochomic window in a small-scale test-cell. Sol. Energy 2009, 83, 832–844. [Google Scholar] [CrossRef]

- Tavares, P.F.; Gaspar, A.R.; Martins, A.G.; Frontini, F. Evaluation of electrochromic windows impact in the energy performance of buildings in Mediterranean climates. Energy Policy 2014, 67, 68–81. [Google Scholar] [CrossRef]

- Elizabeth, P.; Leidy, J. Passive Design Strategies for Building Envelopes in Different Orientation. Int. J. Sustain. Build. Technol. Urban Dev. 2017, 8, 201–227. [Google Scholar]

- Lee, E.S.; Tavil, A. Energy and visual comfort performance of electrochromic windows with overhangs. Build Environ. 2009, 42, 2439–2449. [Google Scholar] [CrossRef]

- Lee, E.S.; Yazdanian, M.; Selkowitz, S. The Energy-Savings Potential of Electrochromic Windows in the US Commercial Buildings Sector; University of California: Oakland, CA, USA, 2004. [Google Scholar]

- Papaefthimiou, S.; Syrrakou, E.; Yianoulis, P. Energy performance assessment of an electrochromic window. Thin Solid Films 2006, 502, 257–264. [Google Scholar] [CrossRef]

- Fernandes, L.L.; Lee, E.S.; Ward, G. Lighting energy savings potential of split-pane electrochromic windows controlled for daylighting with visual comfort. Energy Build. 2013, 61, 8–20. [Google Scholar] [CrossRef]

- Ajaji, Y.; André, P. Thermal comfort and visual comfort in an office building equipped with smart electrochromic glazing: An experimental study. Energy Proc. 2015, 78, 2464–2469. [Google Scholar] [CrossRef]

- DeForest, N.; Shehabi, A.; Garcia, G.; Greenbalt, J.; Masanet, E.; Lee, E.S.; Selkowitz, S.; Milliron, D.J. Regional performance targets for transparent near-infrared switching electrochromic window glazings. Build. Environ. 2013, 61, 160–168. [Google Scholar] [CrossRef]

- Cannavale, G.E.; Eperon, P.; Cossari, A.; Abate, H.J.; Snaith, G.; Gigli, P. Photovoltachromic cells for building integration. Energy Environ. Sci. 2015, 8, 1578–1584. [Google Scholar] [CrossRef]

- Sage Glass. Available online: https://www.sageglass.com (accessed on 22 February 2018).

- Granqvist, C.G.; Bayrak Pehlivan, I.; Niklasson, G.A. Electrochromics on a roll: Web-coating and lamination for smart windows. Surf. Coat. Technol. 2017, 6–11. [Google Scholar] [CrossRef]

- Rottmann, M.; Kraft, A.; Heckner, K.H.; Hausler, T.; Fischer, U.; Stenzel, H. Large-area electrochromic safety glass; switching behaviour and transmission control of solar radiation. In Proceedings of the 9th International Glass Conference on Glass Processing Days, Tampere, Finland, 17–20 June 2005. [Google Scholar]

- Tavares, P.; Bernardo, H.; Gaspar, A.; Martin, A. Control criteria of electrochromic glasses for energy savings in Mediterranean buildings refurbishment. Sol. Energy 2016, 134, 236–250. [Google Scholar] [CrossRef]

- HALIO Glass, Asahi Glass Co. (AGC). Available online: https://halioglass.com (accessed on 22 February 2018).

- EnergyPlus. EnergyPlus Engineering Reference. The Reference to EnergyPlus Calculation. Available online: http://www.energyplus.gov (accessed on 22 February 2018).

- Winkelmann, F. Modeling windows in EnergyPlus. In Proceedings of the 7th International IBPSA Conference, Rio di Janeiro, Brazil, 13–15 August 2001. [Google Scholar]

- Arasteh, D.K.; Reilly, M.S.; Rubin, M.D. A versatile procedure for calculating heat transfer through windows, American Society of Heating, Refrigeration and Air-Conditioning Engineers. ASHRAE Trans. 1989, 95, 755–765. [Google Scholar]

- Finlayson, E.U.; Arasteh, D.K.; Huizenga, C.; Rubin, M.D.; Reilly, M.S. WINDOW 4.0: Documentation of Calculation Procedures, Lawrence Berkeley National Laboratory Report LBL-33943; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1993. [Google Scholar]

- Arasteh, D.K.; Kohler, J.C.; Griffith, B.T. Draft, Modeling Windows in EnergyPlus with only U, SHGC, and Optionally VT. Lawrence Berkeley National Laboratory Report; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2009. [Google Scholar]

- Winkelmann, F.; Selkowitz, S. Day-Lighting Simulation in DOE-2: Theory, Validation and Applications. Lawrence Berkeley National Laboratory Report; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1985. [Google Scholar]

- Lomanowski, B.A.; Wright, J.L. Modeling fenestration with shading devices in building energy simulation: a practical approach. In Proceedings of the 11th International IBPSA Conference, Glasgow, Scotland, 27–30 July 2009. [Google Scholar]

- Chantrasrisalai, C.; Fisher, D.E. Comparative analysis of one-dimensional slat type blind models. In Proceedings of the SimBuild 2004, Boulder, CO, USA, 4–6 August 2004. [Google Scholar]

- International Organization for Standardization. ISO 15099, Thermal Performance of Windows, Doors, and Shading Devices—Detailed Calculations; International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

- The Korean Ministry of Land, Transport and Maritime Affairs. Standard for Energy Saving Design in Buildings; The Korean Ministry of Land, Transport and Maritime Affairs: Gwacheon, Korea, 2017.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. ASHRAE Fundamentals Handbook; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2009. [Google Scholar]

- EnergyPlus. EnergyPlus Input Output Reference. The Encyclopedic Reference to EnergyPlus Input and Output. Available online: http://www.energyplus.gov (accessed on 22 February 2018).

- Oh, M.H.; Lee, K.H.; Yoon, J.H. Automated control strategies of inside slat-type blind considering visual comfort and building energy performance. Energy Build. 2012, 55, 728–737. [Google Scholar] [CrossRef]

| Division | EC Glass (Bleached) | EC Glass (Colored) | |

|---|---|---|---|

| Thickness (mm) | 9 | 9 | |

| Solar Transmittance | front | 0.481 | 0.065 |

| back | 0.481 | 0.065 | |

| Solar Reflectance | front | 0.214 | 0.181 |

| back | 0.190 | 0.168 | |

| Visible Transmittance | front | 0.648 | 0.120 |

| back | 0.648 | 0.120 | |

| Visible Reflectance | front | 0.128 | 0.074 |

| back | 0.111 | 0.062 | |

| Front and back side emissivity | 0.840 | 0.840 | |

| Conductivity (W/mK) | 1.000 | 1.000 | |

| Division | Materials | Thermal Properties |

|---|---|---|

| Exterior wall | 200 mm concrete 155 t insulation 19 mm gypsum board | U-value 0.429 W/m2 K |

| Interior floor | 150 mm concrete 30 mm insulation 40 mm ALC(Autoclaved lightweight concrete) 30 mm mortar | U-value 1.186 W/m2 K |

| Glazing | 24 mm double glazing (6 clear + 12 air + 6 clear) | SHGC 0.695 Tvis 0.777 U-value 2.543 |

| Internal Load Type | Maximum Value |

|---|---|

| Overhead lighting (W/m2) | 10.8 |

| Peak occupancy (m2/person) | 17.0 |

| Equipment (W/m2) | 8.6 |

| Division | Total Load (kWh) | |

|---|---|---|

| Heating | Cooling | |

| Total | 4285.1 | 22,490.0 |

| Rate | 16.0% | 84.0% |

| Division | U-Value | SHGC | Tvis | |||

|---|---|---|---|---|---|---|

| BSL * | Baseline | clear + clear | 2.685 | 0.714 | 0.790 | |

| ALT-01 | Colored glazing | green + clear | 2.685 | 0.632 | 0.671 | |

| ALT-02 | blue + clear | 2.685 | 0.616 | 0.511 | ||

| ALT-03 | gray + clear | 2.685 | 0.618 | 0.393 | ||

| ALT-04 | Low-e glazing | single low-e+ clear | 1.630 | 0.571 | 0.711 | |

| ALT-05 | double low-e + clear | 1.600 | 0.325 | 0.503 | ||

| ALT-06 | Low-e glazing with shading device | interior blind + clear + single low-e | open | 1.630 | 0.571 | 0.711 |

| close | 1.624 | 0.333 | 0.000 | |||

| ALT-07 | interior roll shade + clear + single low-e | open | 1.630 | 0.571 | 0.711 | |

| close | 1.579 | 0.319 | 0.000 | |||

| ALT-08 | Electrochromic glazing (controlled) | EC + clear | bleached | 2.853 | 0.487 | 0.579 |

| colored | 2.853 | 0.191 | 0.107 | |||

| ALT-09 | EC + single low-e | bleached | 1.619 | 0.409 | 0.521 | |

| colored | 1.619 | 0.128 | 0.096 | |||

| Glass Division | Clear | Green | Blue | Gray | EC | |

|---|---|---|---|---|---|---|

| Bleached | ||||||

| Glazing properties | U-Value (W/m2 K) | 2.685 | 2.685 | 2.685 | 2.685 | 2.853 |

| SHGC | 0.714 | 0.632 | 0.616 | 0.618 | 0.487 | |

| Tvis | 0.790 | 0.671 | 0.511 | 0.393 | 0.579 | |

| Heating load (kWh) | 83.0 | 89.7 | 91.0 | 90.9 | 105.0 | |

| ※ Double Glazing—[Clear, Green, Blue, Gray, EC] + Clear Glass | ||||||

| Glass Division | Clear | Green | Blue | Gray | EC |

|---|---|---|---|---|---|

| Bleached | |||||

| Transmitted solar (kWh) | 106.1 | 62.0 | 52.7 | 54.2 | 64.4 |

| Convection heat flow (kWh) | −26.5 | −19.7 | −17.9 | −18.2 | −27.9 |

| Infrared heat flow (kWh) | −70.1 | −45.8 | −41.0 | −41.8 | −61.0 |

| Shortwave heat flow (kWh) | 3.3 | 1.2 | 0.9 | 0.9 | 1.3 |

| Total heat flow (kWh) | 6.2 | −4.8 | −7.0 | −6.8 | −25.8 |

| Glass Division | Clear | Single Low-e | Double Low-e | EC | |

|---|---|---|---|---|---|

| Bleached | |||||

| Glazing properties | U-Value (W/m2 K) | 2.685 | 1.630 | 1.600 | 2.853 |

| SHGC | 0.714 | 0.571 | 0.325 | 0.487 | |

| Tvis | 0.790 | 0.711 | 0.503 | 0.579 | |

| Heating load (kWh) | 83.0 | 65.7 | 86.2 | 105.0 | |

| ※ Double Glazing—[Clear, Single Low-e, Double Low-e, EC] + Clear Glass | |||||

| Glass Division | Clear | Single Low-e | Double Low-e | EC |

|---|---|---|---|---|

| Bleached | ||||

| Transmitted solar (kWh) | 106.1 | 68.3 | 33.3 | 64.4 |

| Convection heat flow (kWh) | −26.5 | −9.8 | −11.6 | −27.9 |

| Infrared heat flow (kWh) | −70.1 | −34.3 | −32.1 | −61.0 |

| Shortwave heat flow (kWh) | 3.3 | 1.5 | 0.4 | 1.3 |

| Total heat flow (kWh) | 6.2 | 22.7 | −10.7 | −25.8 |

| Glass Division | Clear | Blind | Roll Shade | EC | |

|---|---|---|---|---|---|

| Open | Bleached | ||||

| Glazing properties | U-Value (W/m2 K) | 2.685 | 1.630 | 1.630 | 1.619 |

| SHGC | 0.714 | 0.571 | 0.571 | 0.409 | |

| Tvis | 0.790 | 0.711 | 0.711 | 0.521 | |

| Heating load (kWh) | 83.0 | 65.7 | 65.7 | 81.5 | |

| ※ Double Glazing—[Clear, Single Low-e, Double Low-e, EC] + Single Low-e Glass | |||||

| Glass Division | Clear | Blind | Roll Shade | EC |

|---|---|---|---|---|

| Bleached | ||||

| Transmitted solar (kWh) | 106.1 | 68.3 | 68.3 | 42.4 |

| Convection heat flow (kWh) | −26.5 | −9.8 | −9.8 | −11.9 |

| Infrared heat flow (kWh) | −70.1 | −34.3 | −34.3 | −34.0 |

| Shortwave heat flow (kWh) | 3.3 | 1.5 | 1.5 | 0.6 |

| Total heat flow (kWh) | 6.2 | 22.7 | 22.7 | −4.1 |

| Glass Division | Clear | Green | Blue | Gray | EC | |

|---|---|---|---|---|---|---|

| Colored | ||||||

| Glazing properties | U-Value (W/m2 K) | 2.685 | 2.685 | 2.685 | 2.685 | 2.853 |

| SHGC | 0.714 | 0.632 | 0.616 | 0.618 | 0.191 | |

| Tvis | 0.790 | 0.671 | 0.511 | 0.393 | 0.107 | |

| Cooling Load (kWh) | 262.2 | 252.6 | 250.7 | 251.0 | 185.8 | |

| ※ Double Glazing—[Clear, Green, Blue, Gray, EC] + Clear Glass | ||||||

| Glass Division | Clear | Green | Blue | Gray | EC |

|---|---|---|---|---|---|

| Colored | |||||

| Transmitted solar (kWh) | 106.6 | 61.4 | 52.0 | 53.5 | 8.7 |

| Convection heat flow (kWh) | 9.8 | 20.3 | 22.4 | 22.0 | 13.4 |

| Infrared heat flow (kWh) | 0.7 | 24.4 | 29.3 | 28.4 | 20.6 |

| Shortwave heat flow (kWh) | 2.8 | 1.0 | 0.7 | 0.7 | 0.0 |

| Total heat flow (kWh) | 114.3 | 105.1 | 103.0 | 103.2 | 42.7 |

| Glass Division | Clear | Single Low-e | Double Low-e | EC | |

|---|---|---|---|---|---|

| Colored | |||||

| Glazing properties | U-Value (W/m2 K) | 2.685 | 1.630 | 1.600 | 2.853 |

| SHGC | 0.714 | 0.571 | 0.325 | 0.191 | |

| Tvis | 0.790 | 0.711 | 0.503 | 0.107 | |

| Cooling load (kWh) | 262.2 | 246.2 | 205.1 | 185.8 | |

| ※ Double Glazing—[Clear, Single Low-e, Double Low-e, EC] + Clear Glass | |||||

| Glass Division | Clear | Single Low-e | Double Low-e | EC |

|---|---|---|---|---|

| Bleached | ||||

| Transmitted solar (kWh) | 106.6 | 68.4 | 33.5 | 8.7 |

| Convection heat flow (kWh) | 9.8 | 14.7 | 11.3 | 13.4 |

| Infrared heat flow (kWh) | 0.7 | 14.7 | 13.7 | 20.6 |

| Shortwave heat flow (kWh) | 2.8 | 1.2 | 0.3 | 0.0 |

| Total heat flow (kWh) | 114.3 | 96.5 | 58.2 | 42.7 |

| Glass Division | Clear | Blind | Roll Shade | EC | |

|---|---|---|---|---|---|

| Closed | Colored | ||||

| Glazing properties | U-Value (W/m2 K) | 2.685 | 1.624 | 1.579 | 1.619 |

| SHGC | 0.714 | 0.333 | 0.319 | 0.128 | |

| Tvis | 0.790 | 0.000 | 0.000 | 0.096 | |

| Cooling load (kWh) | 262.2 | 208.8 | 205.4 | 170.6 | |

| ※ Double Glazing—[Clear, Single Low-e, Double Low-e, EC] + Single Low-e Glass | |||||

| Glass Division | Clear | Blind | Roll Shade | EC |

|---|---|---|---|---|

| Bleached | ||||

| Transmitted solar (kWh) | 106.6 | 1.5 | 0.0 | 5.7 |

| Convection heat flow (kWh) | 9.8 | 39.5 | 46.4 | 8.6 |

| Infrared heat flow (kWh) | 0.7 | 19.5 | 11.4 | 13.4 |

| Shortwave heat flow (kWh) | 2.8 | 0.0 | 0.0 | 0.0 |

| Total heat flow (kWh) | 114.3 | 60.5 | 57.7 | 27.7 |

| Glass Division | Heating Load | Cooling Load | Total Load | Reduction Rate |

|---|---|---|---|---|

| Baseline (clear + clear) | 4285.1 | 22,490.0 | 26,775.1 | 0.0% |

| Green + clear | 4895.5 | 21,409.2 | 26,304.7 | −1.8% |

| Blue + clear | 5014.4 | 21,190.0 | 26,204.5 | −2.1% |

| Gray + clear | 4999.5 | 21,215.5 | 26,214.9 | −2.1% |

| Single low-e + clear | 2999.4 | 22,060.6 | 25,060.0 | −6.4% |

| Double low-e + clear | 4654.4 | 17,715.3 | 22,369.6 | −16.5% |

| Single low-e + clear with blind | 2999.4 | 18,775.8 | 21,775.3 | −18.7% |

| Single low-e + clear with roll shade | 2999.4 | 18,148.6 | 21,148.0 | −21.0% |

| EC + clear | 6073.3 | 14,343.0 | 20,416.3 | −23.7% |

| EC + single low-e | 4294.7 | 14,082.1 | 18,376.8 | −31.4% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, M.; Tae, S.; Hwang, S. Analysis of Heating and Cooling Loads of Electrochromic Glazing in High-Rise Residential Buildings in South Korea. Sustainability 2018, 10, 1121. https://doi.org/10.3390/su10041121

Oh M, Tae S, Hwang S. Analysis of Heating and Cooling Loads of Electrochromic Glazing in High-Rise Residential Buildings in South Korea. Sustainability. 2018; 10(4):1121. https://doi.org/10.3390/su10041121

Chicago/Turabian StyleOh, Myunghwan, Sungho Tae, and Sangkun Hwang. 2018. "Analysis of Heating and Cooling Loads of Electrochromic Glazing in High-Rise Residential Buildings in South Korea" Sustainability 10, no. 4: 1121. https://doi.org/10.3390/su10041121