1. Introduction

Prefabrication is the practice of assembling the components of a structure in a factory, or other manufacturing locations, and then transporting complete assemblies or sub-assemblies to the construction site where the structure is to be erected. Whereas, traditional building construction takes place on site, prefabrication has gained much interest in recent years, particularly with regard to industrial buildings, for its potential energy saving benefits, as well as improved efficiencies in the construction process. Consequently, the efficiencies gained in the production process of precast components directly enhance the construction time and cost of buildings.

There are several methods to enhance the efficiency of precast components production and to reduce its cost. Generally, these methods involve various stages, including precast component design [

1,

2,

3], material management/transshipment [

4,

5], precast component production planning, precast component inventory control [

6,

7,

8,

9], precast component transportation and site assembly [

10,

11]. It is well established that production planning is the key element in the precast production process and it is closely related to the production time and cost. Planning involves the allocation of resources over a period of time to perform a series of jobs that are subject to known constrains. However, the current practice of designing precast production plans depends primarily on the scheduler’s experience, which has generally proven to be problematic for planners and schedulers [

12]. Inefficient resource utilization and high production cost are common in the precast industry due to unsuitable and inaccurate planning methods [

13,

14]. Therefore, optimizing the production plan is vital in the precast component production process.

Subsequently, this particular area has attracted the interest of many researchers who have proposed various computational techniques to manage planning issues. For example, Dawood developed a scheduling model for the precast industry using the heuristic job scheduling approach. The proposed model was regarded as a factory simulator to automate the planning process which comprised of scheduling rules and the factory’s attributes [

13]. Chan and Hu developed their flow shop sequencing model for precast production scheduling by incorporating actual constraints. They adopted a genetic algorithm approach and compared the proposed method with some well-established heuristic rules [

12]. Benjaoran et al. studied the impact of the quantity of molds on shop floor schedules of precast production and proposed a bespoke precast flow shop scheduling model by using a flow shop sequencing model [

15]. Ko and Wang applied a multiple-objective genetic algorithm to search for optimum solutions with minimum makespan and tardiness penalties. In their model, buffer size between workstations in precast production scheduling was considered for the first time [

14]. Tharmmaphornphilas and Sareinpithak developed a scheduling model to select concrete formulas and schedule jobs to minimize the total product cost and proposed a heuristic approach to solve the model [

16]. Hong and Lee developed algorithms that could promptly establish a production layout plan by considering in situ production factors affecting composite precast concrete members [

17]. Prata et al. proposed a model based on integer linear programming to schedule the production of the beams so as to minimize the losses in a minimal time by taking into account the constraints inherent in the forms and beams [

18]. Yang et al. proposed a flow shop scheduling model of multiple production lines for precast production and developed an optimization approach to facilitate optimized scheduling by using genetic algorithm [

19].

Examining the existing literature on precast production planning, two categories of research can generally be found. The first category focuses on optimizing the specific process for various distinct precast production methods, such as the roll-cutting process of the filigree wide-slab method [

18] and the layout process of composite precast concrete members for precast concrete in situ production [

17]. The second category focuses on traditional precast production methods for optimizing the production plan based on the job shop/flow shop scheduling problem [

12,

13,

14,

15,

16,

19], which mainly emphasize the flow variability between processes under special constrains such as limited labor and mold [

14]. However, strategies for improving the specific production processes for traditional precast production methods are generally neglected in current literature.

This paper evaluates the molding process, a critical process closely related to precast production efficiency and proposes a layout optimization schedule of the components on pallets during the molding process, that (1) improves the utilization rate of the pallets, (2) shortens the manufacturing time, (3) reduces the component manufacturing cost, and (4) saves the resource consumption during the precast production.

2. Problem Description

There are two basic types of precast component production systems in a precast plant, namely, the fixed location production/stationary system and the flow shop production/traveling system [

19,

20,

21]. For fixed location production, all the activities are performed in a particular workstation either by the same team or different teams. In the flow shop production system, pallets are moved on a rolling line from one station to another, with different activities being performed at different stations by a particular team. The two production systems involve the same six main processes: (1) pretreatment, (2) molding, (3) placing of rebars and embedded parts, (4) casting, (5) curing, and, (6) stripping.

It is worth noting that two of the processes, mold setting and curing, have a significant impact on the component production efficiency and cost. In regards to the flow shop production, several pallets are cured in a kiln during the curing process, where the concrete mix undergoes an accelerated but expensive process. For the curing of the precast concrete, water is consumed by the curing kiln, which is driven by electricity. The curing kiln is limited by a fixed pallet capacity and it takes some hours to cure the precast components loaded on the pallets. Therefore, if more components can be accommodated in the kiln during the curing process, the average curing cost and resource (electricity and resource) consumption for each component are lowered and an increased efficiency of component production can be achieved. In the mold setting process, molds are placed onto the pallets according to the component production layout plan, which determines the number of components on each pallet. The pallet is generally made of steel and can be used a few hundred times. Obviously, the more components loaded on a pallet, the higher utilization rate of pallet, the lower the average curing cost for each component, and the larger the efficiency of component production. Thus, cost and efficiency of component production is directly responsive to the configuration of the mold setting process. Furthermore, from the perspective of the environment, an intensive molding layout could enable lower energy and material consumption (e.g., electricity, water and steel pallet consumption) during the curing process. Similarly, for fixed location production, which normally uses a steam curing method in its curing process, a much more efficient layout plan also helps to reduce the number of pallet cycles. Accordingly, production efficiency can be improved and the resource consumption, production time and curing cost can be reduced as well.

In contrast to the manufacturing industry, such as in car, electronics or machine production where automated scheduling decision systems are used, precast concrete component production generally relies on subjective decision systems. While the knowledge and experience of managers may be sufficient to handle normal workloads, there is limited emphasis on optimizing the use of the pallet. This leaves the production facility unable to maximize output in peak periods. Indeed, it leaves the production facility unable to gauge what its maximum production capacity is.

Figure 1 shows an example of a typical production layout plan of precast components. It includes a large area inside an unused pallet. Not only does this reduce the pallet utilization rate, but this also causes a waste of production capacity. Consequently, this results in extended production cycles and increased curing costs.

In summary, concrete components are laid out on pallets based on existing practices and the judgment of the manager, which can be sub-optimal. This leads to a lower utilization rate of the pallets and curing kiln, and consequently imposes higher costs and resource consumption and reduces production rates. If production efficiency is to be improved, a structured, scientific approach to the laying-out of the precast molds needs to be adopted. The aim of this study is to propose such a structured approach.

3. Proposed Model

Precast components are usually rectangular and workers normally arrange the molds in a regular way (horizontal or vertical). These assumptions will be incorporated and inform the model developed here. There are three such assumptions: (1) the shape of the production component is to be contained within an envelope rectangle of the smallest possible size, (2) the edge of the component is to be arranged parallel or perpendicular to the edge of the mold, regardless of the diagonal layout, and, (3) the amount of mold available is unlimited. The relevant notions used in developing the model, along with their corresponding definitions, are shown in

Table 1.

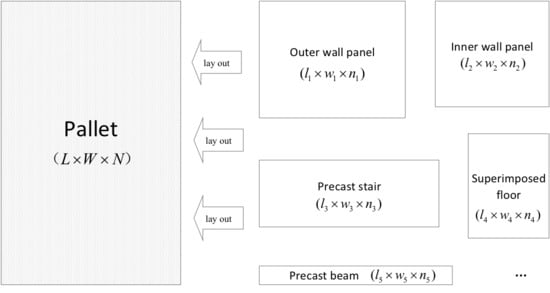

Figure 2 shows an example of a general order. Here, the production plan is determined by the order contract to be delivered within a certain amount of time. Moreover, there are various sizes of components needed to be produced, with the demand for the components designated as

d1,

d2,

d3, ...,

di, respectively. All these will be laid out on the pallets.

N describes the number of pallet cycles required. As layout plans vary,

N will vary as well. The aim is to minimize

N (all else being equal), and in doing so, to reduce the component production cost and time.

The layout optimization model is formulated using the following mathematical equations

s.t.

In the model, the objective function in Equation (1) represents the average utilization of the pallets. By computing this equation for the highest value, the highest utilization rate can be determined, with the number of pallet cycles consequently minimized. In turn, reduction of the pallet cycles will increase the production capacity, shorten the production time, and reduce the number of the pallets that need curing, thereby reducing overall production cost.

The constraint introduced in Equation (2) ensures that the number of components required to meet the order agreement are achieved. As shown in

Table 1, in a production plan, there are

j layout schemes in total. Where

xj stands for the number of pallets using the

jth layout scheme, and,

aij is the number of the

ith component on a pallet using the

jth layout scheme. So, the product of

aij and

xj needs to meet the

ith component’s demand

di.The constraint in Equations (3) and (4) ensures that the component layout will be limited within the pallet size. As shown in

Figure 3, components could be placed either horizontal or perpendicular to meet the parallel requirement. As shown in

Table 2, we adopt a coordinate constraint to achieve this condition, considering the convert of component placement. In order for the components to be arranged within the pallet dimensions, the formulas in the table will need to be satisfied.

The constraint in Equation (5) assures that the component layouts do not overlap. There are four non-overlap situations in total, as shown in

Figure 4. Each formula in (5) represents a non-overlap situation of the

P,

Q components, and the corresponding coordinate constraints were given, which are presented in

Table 3. Therefore, if the component layouts do not overlap with each other, at least one of the formulas in (5) will be satisfied. Constraints in Equation (6) indicate the placement method for components, where

r = 0 means that the components are laid in a transverse direction, and

r = 1 means that the members are placed in a longitudinal direction. Constraints in equations (7) are constraints of decision variables.

4. Algorithm

This paper develops an optimization approach to maximizing the average utilization rate of pallets with extra constraints, such as the size of molds and the order demand. A heuristic algorithm is developed to solve the proposed problem. In this algorithm, components needed to be placed to compromise the elements of production sequences, with the position of the elements corresponding to the order of component placement (the earlier the component is located in the sequence, the earlier it is placed). Additionally, different component production sequences represent different production schedules, which can lead to different layout schemes of the pallets. Therefore, the algorithm aims to identify the best layout sequence with the maximum utilization of pallets among numerous feasible sequences, thus identifying the optimal schedule. As shown in

Figure 5, the algorithm can be described according to the following three interrelated stages: (1) generate a set of feasible sequences, (2) calculate the utilization of an extracted sequence, (3) identify the optimal layout sequence. The following section describes the three stages in detail.

Table 4 shows the notions used in the heuristic algorithm.

Stage 1: Generate a set of feasible sequences.

Stage 1 is used to generate a set of feasible sequences. If the number of the component types is

i, the maximum number of production sequences is

i!. Assume there are three component types (A, B, C), thus a total of 3! = 6 feasible sequences can be generated as follows: ABC, ACB, BAC, BCA, CAB, CBA. However, if the number of the component types becomes large (being greater than eight in this case), an enormous number of sequences would be created, which would result in a high computational cost. In order to reduce the unnecessary computation time of this algorithm, a classification method is presented. Notably, as shown in

Figure 6, a small component is more capable of being be placed into the remaining positions than a large one, which can improve the utilization of the pallet. Therefore, sequences where small components are at the back can generally achieve better solutions. According to this, we equally divide all the components into two groups: small and large, with the large group always being in the front of the sequence. The number of these two groups’ component types are

a = int(

i/2) and

b =

i-int(

i/2), respectively. For each group, the sequences are generated via random permutations. For example, nine kinds of components in total need to be produced. We firstly divide them into two groups, where the large group contains

a = int(9/2) = 4 kinds of components while the small group contains

b = 9-int(9/2) = 5, then 4! = 24 permutations for the large group and 5! = 120 for the small group can be generated. Thus a total number of 4! × 5! = 2880 sequences are finally created, which has declined exponentially in comparison to the result of 9! = 362,880 for the ungrouped method. In short, in this stage, the feasible sequences are generated by the following rules: if the number of the component types

i is greater than eight, then

, where

a(

b) is the large(small) group’s component type, and

a +

b =

i; otherwise

.

Stage 2: Calculate the utilization rate of an extracted sequence.

Stage 2 is used to calculate the utilization rate of the selected sequence from Stage 1. This algorithm establishes an updating principle to place the components in the sequence (see Step 3). Also, the two placement strategies (horizontally and vertically) of components are considered. The specific procedural steps are outlined below.

Input: The kth sequence Tk.

Output: The number of pallet cycles according to kth sequence Nk, the average utilization rate according to kth sequence Uk, and the kth layout plan Fk.

Step 1: Initialize. Let Fk = Ø, Nk = 1, Uk = 0; k = 1.

Step 2: Calculate v.

Step 3: Search available components by the order of the sequence. Define the placement strategy of components as r. r = 0 means that the component is arranged horizontally, r = 1 means that the component is arranged vertically.

If v is longer than the long side of the component then r = 0;

If v is longer than the short side, but shorter than the long side then r = 1;

If v is shorter than the short side then r = −1.

Step 4: Search for the value of r in sequence Tk. Check whether there r ≥ 0 exists.

If true, then place the component with the first minimal value of r to the left side, go to Step 5; otherwise update the lowest available space, go to Step 2 (the updating principle for the lowest available space is to raise its height to the penultimate lowest space when it is compared to the current one).

Step 5: Compare H with W;

If H<W then accept the component, add the component into Fk; and remove it from Tk, go to Step 6; otherwise, Nk = Nk + 1; go to Step 2;

Step 6: Check whether Tk = Ø.

If true, save Nk and calculate Uk, go to Step 6; otherwise, go to Step 2.

Step 7: Return Fk, Nk, Uk.

For understanding how Stage 2 runs and how the updating principle works, a demo sequence (sequence

T1) is proposed to test it. Nine components in total are needed for arrangement, and the size and order of components in

T1 are given in

Figure 7.

Figure 8(G1) and

Figure 8(G2) show the updating principle for the lowest available space (Step 4). The width of the lowest available space (

v) in

Figure 8(G1) is equal to 5, which is not enough to accommodate any components, so

v is updated. The updating principle for the lowest available space is to raise its height to the penultimate lowest space when it’s compared to the current one. Thus, the height of the lowest available space (

hv) is raised from 0 (see

Figure 8(G1)) to 45 (see

Figure 8(G2)). The principle can also be illustrated in

Figure 8(I1) and

Figure 8(I2), where the

hv is raised from 45 to 115.

Figure 8J shows component 2–3 placed in a temporary position before Step 5 runs. However, due to

H = 250 >

W = 200, component 2–3 has to be canceled. Then, another pallet to place component 2–3 is required.

Figure 8K shows the last placed component in a second pallet (

N1 = 2). When it is finished, all components in sequence

T1 have been arranged, then the average utilization rate is calculated (

U1 = 45.87%).

Stage 3: Identify the optimal layout sequence.

Stage 3 is used to identify the best precast component layout sequence. The specific approach is to compare the average utilization rates according to Stage 2 and find the optimal one with the highest utilization rate. The specific procedural steps are outlined below.

Input: Pallet size (L, W), component demand (di) and component size (li, wi).

Output: The minimal cycles of pallets N, the maximum average utilization rate U, and the best layout plan F.

Step 1: Initialize. Let F = Ø, U = 0, N = 0, k = 1.

Step 2: k = k + 1. Run sub-process, save Nk and Fk, calculate Uk.

Step 3: Compare Uk with U.

If Uk > U, then U = Uk, N = Nk, F = Fk; otherwise, keep U, N, F unchanged.

Step 4: Check if all the sequences are already arranged.

If T = Ø, then go to step 5; otherwise, go to step 2.

Step 5: Output U, N, F.

Here,

Figure 9 demonstrates the layout result of the second demo sequence

T2 (see

Figure 7), which contains the same components as

T1 does. Although

T2 and

T1 contain the same components, these two layout plans are different due to the different order of the components in the two sequences. In

Figure 9 it can be seen that only one pallet (

N2 = 1) is required and the average utilization rate is 91.73% (

U2 = 91.73%). Therefore, the layout result shown in

Figure 9 is significantly better than that in

Figure 8. Hence, in this case,

T2 is the optimal sequence according to Stage 3.

5. Case Study

As shown in

Table 5, this study collected actual production data from a precast component plant (Plant A) in Chongqing, and the method described here was used successfully to solve the component pallet layout. The optimization problem presented in this paper has general applicability, such that various sizes of precast components, as well as models with different indicators may be used.

As per an order received, the plant management set a certain amount of time for the production quantity, which included eight different types of precast components, such as outer wall panels, inner wall panels and superimposed floors, etc. According to the specification of the precast production line, the length and width of the pallets were 9 m and 4 m, respectively. The curing kiln could simultaneously cure 21 pallets, the curing time required for the components is 8 h, the running cost was 600 RMB per hour, and the power of the machine is 36 kWh. In the original plan, the total number of cycles of the pallets was predicted to be 261, using the curing kiln 13 times, for a total of 104 h.

In this case, Visual C++, on a Windows 7 platform, was used for programming the heuristic algorithm. The final result showed that only 203 cycles were needed to finish the production task, and five different layout schemes were needed.

Figure 10 shows the five layout patterns for the given case.

Table 6 shows the number and types of components of each layout scheme.

Table 7 shows the number of the pallet cycles and the utilization rate of each layout scheme. According to

Table 7, the best layout plan needs five configurations, the average utilization rate is 90.6%. These five configurations reduce the original number of pallet cycles used from 261 to 203, saving 58 pallet cycles and improving efficiency and shortening manufacturing time by 22.2%. Furthermore, the improved plan only uses the curing kiln 10 times, instead of the 13 actually used, which saves (13–10) × 8 × 600 = 14,400 RMB, which represents a 23.1% curing cost saving. Additionally, the improved plan could also enhance the pallet utilization efficiency and lower the energy consumption. There would be a decrease of 3 × 36 × 8 = 864 kWh in the electricity consumption, and the water consumption could be reduced as well.

Additionally, in order to prove the reliability of the method, another six cases were tested. The data for these cases are listed in

Table 8.

Table 9 shows the specific layout schemes for these cases.

Table 10 compares the proposed method with the original method, which reveals that the proposed method cost fewer pallet cycles to arrange all the components. All these cases show at least 20% reduction in the pallet cycles, thus, the resource consumption, production cost and time could be reduced as well.

In summary, these case studies, where experienced managers have been operating ‘Factory A’ over a number of years, utilizing their experience in combination with current best practice, show that this proposed model has genuine applicability to real-world scenarios. The proposed model provides a scientific approach to generating optimized component schedules that are relatively simple to use, while offering significant gains in production efficiency, time saving, resource consumption, and overall cost reduction.