A Quantitative Method for Prediction of Environmental Aspects in Construction Sites of Residential Buildings

Abstract

:1. Introduction

1.1. Systems of Certification of Buildings and the Local Context

1.2. Environmental Performance Assessment Methodologies

1.3. Problem and Purpose of the Article

- Survey of the international scientific literature and Brazilian to identify the main environmental aspects of construction sites and its main regulatory marks.

- Analysis of the ordinary cost bases in construction and selecting quantitative indicators towards to reduce the subjectivity in the environmental aspects evaluation

- Evaluating the predictive method through a case study

- Definition of the mathematical representation of the environmental aspect predictive method.

2. An Overview of the Environmental Impacts of Construction Sites in Brazil

Local Impacts of Construction Sites and Their Main Regulatory Standards

3. Materials and Methods

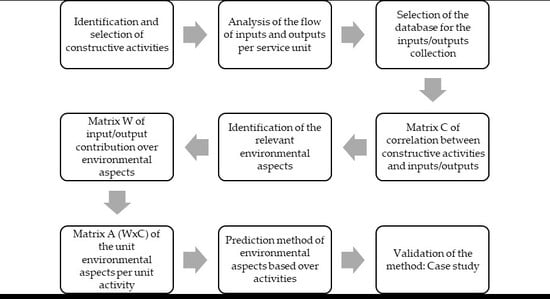

4. Development of the Environmental Aspects Prediction Method (EAPM)

4.1. Context and Delimitation of the Object under Analysis

4.2. Construction Activities Selection

4.3. Analysis of Inputs and Outputs of Constructive Activities

4.3.1. Selection of Input and Output Variables and Their Units of Measure

4.3.2. Database Selection for the Collection of the Inputs and Outputs per Service Unit

4.3.3. Data Collection of Inputs and Outputs per Service Unit (Matrix C)

4.4. Estimating of Environmental Aspects by Service Unit

4.4.1. Identification and Selection of Significant Environmental Aspects

4.4.2. Contribution of Inputs and Outputs to Environmental Aspects (Matrix W)

4.4.3. Environmental Aspects per Unit of Services (Matrix A)

4.5. Estimating of the Global Environmental Aspects of the Construction Sites

4.5.1. Quantitative Services of the Construction Site

4.5.2. Global Environmental Aspects (Matrix G)

4.5.3. Comparing the Environmental Performance of Construction Sites

5. Case Study

Data Collected from Selected Buildings

6. Results and Discussion

6.1. Resources Consumption

6.2. Waste Generation

6.3. Pollution Emission

6.4. Public Services and Transport

6.5. Land Use

6.6. Health and Safety

6.7. Comparing the Estimated Generation Rate of Environmental Aspects from the Construction Sites

7. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| EU | European Union |

| CDW | construction and demolition waste |

| EMAS | Eco-Management and Audit Scheme |

| BOQ | bill of quantities |

| MGI | Mckinsey Global Institute |

| BREEAM | British Building Research Establishment Environmental Assessment Method |

| LEED | Leadership in Energy and Environmental Design |

| CASBEE | Comprehensive Assessment System for Built Environment |

| HQE | Haute Qualité Environnementale |

| AQUA | Alta Qualidade Ambiental |

| EMS | Environmental Management Systems |

| CPI | Construction Pollution Index |

| BDC | Base de Datos de la Construcción de la Comunidad de Madrid |

| BCCA | Base de Costes de la Construcción de Andalucía |

| SINAPI | National System of Costs Survey and Indices of Civil Construction |

| TCPO | Table of Compositions of Prices for Budgets |

Appendix A. Inputs and Outputs per Service Unit (Related to Matrix C)

Appendix B. Contribution of Inputs and Outputs to Environmental Aspects (Related to Matrix W)

Appendix C. Environmental Aspects per Unit of Services (Findings from Matrix A)

Appendix D. Global Environmental Aspects from Construction Site 1

Appendix E. Global Environmental Aspects from Construction Site 2

Appendix F. The Generation Rate of Environmental Aspects from the Construction Sites

References

- Kourtit, K.; Nijkamp, P.; Reid, N. The new urban world: Challenges and policy. Appl. Geogr. 2014, 49, 1–3. [Google Scholar] [CrossRef]

- United Nations (ONU). World Urbanization Prospects: The 2014 Revision; ONU: New York, NY, USA, 2014; ISBN 9789211515176. [Google Scholar]

- Cadena, A.; Remes, J.; Manyika, J.; Dobbs, R.; Roxburgh, C.; Elstrodt, H.-P.; Chaia, A.; Restrepo, A. Building Globally Competitive Cities: The Key to Latin American Growth _ Summary; McKinsey Global Institute: Seoul, Korea, 2011. [Google Scholar]

- Dobbs, R.; Smit, S.; Remes, J.; Manyika, J.; Roxburgh, C.; Restrepo, A. Urban World: Mapping the Economic Power of Cities; McKinsey Global Institute: Seoul, Korea, 2011; ISBN 0983179662. [Google Scholar]

- Banias, G.; Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Tarsenis, S. Assessing multiple criteria for the optimal location of a construction and demolition waste management facility. Build. Environ. 2010, 45, 2317–2326. [Google Scholar] [CrossRef]

- Ameen, R.F.M.; Mourshed, M.; Li, H. A critical review of environmental assessment tools for sustainable urban design. Environ. Impact Assess. Rev. 2015, 55, 110–125. [Google Scholar] [CrossRef]

- Energy and Air Pollution (IEA). World Energy Outlook—Special Report; IEA: Paris, France, 2016. [Google Scholar]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Alwan, Z.; Jones, P.; Holgate, P. Strategic sustainable development in the UK construction industry, through the framework for strategic sustainable development, using Building Information Modelling. J. Clean. Prod. 2015. [Google Scholar] [CrossRef]

- de Magalhães, R.F.; Danilevicz, Â.M.F.; Saurin, T.A. Reducing construction waste: A study of urban infrastructure projects. Waste Manag. 2017. [Google Scholar] [CrossRef] [PubMed]

- Calvo, N.; Varela-Candamio, L.; Novo-Corti, I. A dynamic model for construction and demolition (C&D) waste management in Spain: Driving policies based on economic incentives and tax penalties. Sustainability 2014, 6, 416. [Google Scholar] [CrossRef]

- de Azevedo, G.O.D.; Kiperstok, A.; Moraes, L.R.S. Construction waste in Salvador: Ways to a sustainable management. Eng. Sanitária e Ambient. 2006, 11, 65–72. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Shen, L. An evaluation framework for the sustainability of urban land use: A study of capital cities and municipalities in China. Habitat Int. 2011, 35, 141–149. [Google Scholar] [CrossRef]

- Lollo, J.; Röhm, S. Land parceling and neighborhood impacts in Brazil. J. Urban Environ. Eng. 2009, 3, 23–31. [Google Scholar] [CrossRef] [Green Version]

- Araújo, I.P.S.; Costa, D.B.; Moraes, R.J.B. de Identification and Characterization of Particulate Matter Concentrations at Construction Jobsites. Sustainability 2014, 6, 7666–7688. [Google Scholar] [CrossRef]

- Ballesteros, M.J.; Fernández, M.D.; Quintana, S.; Ballesteros, J.A.; Gonzá lez, I. Noise emission evolution on construction sites. Measurement for controlling and assessing its impact on the people and on the environment. Build. Environ. 2010, 45, 711–717. [Google Scholar] [CrossRef]

- Lee, W.L. A comprehensive review of metrics of building environmental assessment schemes. Energy Build. 2013, 62, 403–413. [Google Scholar] [CrossRef]

- Chen, Z.; Li, H.; Wong, C.T.C. Environmental Management of Urban Construction Projects in China. J. Constr. Eng. Manag. 2000, 126, 320–324. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Gassó, S.; Forcada, N.; Roca, X.; Fuertes, A. A methodology for predicting the severity of environmental impacts related to the construction process of residential buildings. Build. Environ. 2009, 44, 558–571. [Google Scholar] [CrossRef] [Green Version]

- HK Construction Association. Best Practice Guide for Environmental Protection on Construction Sites; Hong Kong Construction Association: Hong Kong, China, 2013. [Google Scholar]

- Pulaski, M.H.; Horman, M.J.; Riley, D.R.; Dahl, P.; Hickey, A.; Lapinski, A.R.; Magent, C.; Shaltes, N. Field Guide for Sustainable Construction. Pulaski, M.H., Ed.; Pentagon Renovation and Construction Program Office: Arlington, VA, USA, 2004. [Google Scholar]

- Sharifi, A.; Murayama, A. A critical review of seven selected neighborhood sustainability assessment tools. Environ. Impact Assess. Rev. 2013, 38, 73–87. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2009, 9, 189–212. [Google Scholar] [CrossRef]

- Cole, R.J.; Jose Valdebenito, M. The importation of building environmental certification systems: International usages of BREEAM and LEED. Build. Res. Inf. 2013, 41, 662–676. [Google Scholar] [CrossRef]

- Mateus, R.; Bragança, L. Sustainability assessment and rating of buildings: Developing the methodology SBToolPT–H. Build. Environ. 2011, 46, 1962–1971. [Google Scholar] [CrossRef]

- Grünberg, P.R.M.; de Medeiros, M.H.F.; Tavares, S.F. Certificação ambiental de habitações: Comparação entre LEED for Homes, Processo Aqua e Selo Casa Azul. Ambient. Soc. 2014, 17, 195–214. [Google Scholar] [CrossRef]

- Haapio, A.; Viitaniemi, P. A critical review of building environmental assessment tools. Environ. Impact Assess. Rev. 2008, 28, 469–482. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Chen, X.; Wang, X.; Xu, Y.; Chen, P.-H. A review of studies on green building assessment methods by comparative analysis. Energy Build. 2017, 146, 152–159. [Google Scholar] [CrossRef]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Zhang, T.; Tookey, J. A critical comparison of green building rating systems. Build. Environ. 2017, 123, 243–260. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Fuertes, A.; Roca, X. Model for Enhancing Integrated Identification, Assessment, and Operational Control of On-Site Environmental Impacts and Health and Safety Risks in Construction Firms. J. Constr. Eng. Manag. 2013, 138–147. [Google Scholar] [CrossRef]

- ISO 14040. The International Standards Organisation Environmental Management—Life cYcle Assessment—Principles and framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- CEN CEN/TC 350—European Committee for Standardization—Technical Commitee 350. Available online: http://portailgroupe.afnor.fr/public_espacenormalisation/CENTC350/index.html (accessed on 1 December 2017).

- Fuertes, A.; Casals, M.; Gangolells, M.; Forcada, N.; Macarulla, M.; Roca, X. An Environmental Impact Causal Model for improving the environmental performance of construction processes. J. Clean. Prod. 2013, 52, 425–437. [Google Scholar] [CrossRef]

- Mateus, R. Avaliação da Sustentabilidade da Construção: Propostas para o Desenvolvimento de Edifícios mais Sustentáveis. Available online: http://repositorium.sdum.uminho.pt/bitstream/1822/9886/1/Tese%20Doutoramento_Ricardo%20Mateus_2009.pdf (accessed on 26 October 2015).

- Costa, R.J.G.; Bragança, L.; Mateus, R.; Bezerra, J.C. Reabilitação sustentável de edifícios antigos—Contribuição para os edifícios de balanço energético nulo (nZEB) e otimização do nível de sustentabilidade. Rev. Eng. Civ. 2014, 49, 65–80. [Google Scholar]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Chan, K.K. Environmental performance measurement indicators in construction. Build. Environ. 2006, 41, 164–173. [Google Scholar] [CrossRef]

- Shen, L.-Y.; Lu, W.-S.; Yao, H.; Wu, D.-H. A computer-based scoring method for measuring the environmental performance of construction activities. Autom. Constr. 2005, 297–309. [Google Scholar] [CrossRef]

- Sáez, P.V.; Porras-Amores, C.; Del Río Merino, M. New quantification proposal for construction waste generation in new residential constructions. J. Clean. Prod. 2015, 102. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Macarulla, M. Predicting on-site environmental impacts of municipal engineering works. Environ. Impact Assess. Rev. 2014, 44, 43–57. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Wang, Y.; Liu, F.; Zhang, Y. Development of a hybrid model to predict construction and demolition waste: China as a case study. Waste Manag. 2017, 59, 350–361. [Google Scholar] [CrossRef] [PubMed]

- Kantová, R. Construction Machines as a Source of Construction noise. Procedia Eng. 2017, 190, 92–99. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Gassó, S.; Forcada, N.; Roca, X.; Fuertes, A. Assessing concerns of interested parties when predicting the significance of environmental impacts related to the construction process of residential buildings. Build. Environ. 2011, 46, 1023–1037. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Chen, Z.; Wong, C.T.C.; Love, P.E.D. A quantitative approach to construction pollution control based on resource levelling. Constr. Innov. 2002, 2, 71–81. [Google Scholar] [CrossRef]

- De Geografia E Estatística (IBGE). Atlas do Censo Demográfico 2010; IBGE: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Paz, D.H.; Lafayette, K.P. Forecasting of construction and demolition waste in Brazil. Waste Manag. Res. 2016, 34, 708–716. [Google Scholar] [CrossRef] [PubMed]

- Instituto Brasileiro de Geografia e Estatística (IBGE). Pesquisa Anual da Indústria da Construção 2014; IBGE: Rio de Janeiro, Brazil, 2014; Volume 42, ISBN 9788524042225. [Google Scholar]

- de Oliveira Holanda, M.J.; da Paz, D.H.F.; Figueredo, C.M.; Lafayette, K.P.V.; Sobral, M.D.C.M. Diagnosis of Irregular Disposal of Construction and Demolition Waste (CDW) in the City of Olinda/PE. Electron. J. Geotech. Eng. 2016, 21, 5115–5128. [Google Scholar]

- Departamento Nacional de Produção Mineral (DNPM). Anuário Mineral Brasileiro 2010; DNPM: Brasília, Brazil, 2010. [Google Scholar]

- Abrelpe. Panorama dos Resíduos Sólidos no Brasil 2016; Associação Brasileira de Empresas de Limpeza Pública e Resíduos Especiais: São Paulo, Brazil, 2017. [Google Scholar]

- Condeixa, K.; Haddad, A.; Boer, D. Material Flow Analysis of the Residential Building Stock at the city of Rio de Janeiro. J. Clean. Prod. 2017, 149, 1249–1267. [Google Scholar] [CrossRef]

- Política Nacional de Resíduos Sólidos, 3nd ed.; Câmara dos Deputados: Brasília, Brazil, 2010; ISBN 978-85-402-0496.

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef] [PubMed]

- Resolução CONAMA no 307/2002. In DOU; 2002. Available online: www.mma.gov.br/port/conama/legiabre.cfm?codlegi=307 (assessed on 30 May 2018).

- Wong, I.L.; Kruger, E. Comparing energy efficiency labelling systems in the EU and Brazil: Implications, challenges, barriers and opportunities. Energy Policy 2017, 109, 310–323. [Google Scholar] [CrossRef]

- de Moraes, R.J.B.; Costa, D.B.; Araújo, I.P.S. Particulate Matter Concentration from Construction Sites: Concrete and Masonry Works. J. Environ. Eng. 2016, 142, 05016004. [Google Scholar] [CrossRef]

- Vazquez, E.; Rola, S.; Martins, D.; Alves, L.; Freitas, M.; Pinguelli Rosa, L. Sustainability in civil construction: Application of an environmental certification process (LEED) during the construction phase of a hospital enterprise—Rio de Janeiro/Brazil. Int. J. Sustain. Dev. Plan. 2013, 8, 1–19. [Google Scholar] [CrossRef]

- Zannin, P.H.T.; de Sant’Ana, D.Q. Noise mapping at different stages of a freeway redevelopment project—A case study in Brazil. Appl. Acoust. 2011, 72, 479–486. [Google Scholar] [CrossRef]

- de Olveira, T.L.C.; Kiperstok, A.; César, S.F. Nuisance in the Neighborhood during Building Construction and Impact of Noise; Federal Univesity of Bahia: Salvador, Brazil, 2016. [Google Scholar]

- ABNT NBR 10151:Acústica-Avaliação do Ruído em Áreas Habitadas 2000; Associação Brasiliera de Normas Técnicas: Rio de Janeiro, Brasil, 2000.

- Cardoso, L. The Politics of Noise Control in São Paulo. J. Lat. Am. Stud. 2016, 1–29. [Google Scholar] [CrossRef]

- de Andrade, F.C.; Sopchaki, L.; Antonio, R.; Padilha, B.; Pereira Silveira, T.; Catai, R.E.; Nagalli, A. Acoustic Mapping of the Central Region of Curitiba -Brazil. Electron. J. Geotech. Eng. 2014, 19, 4301–4319. [Google Scholar]

- López-valcárcel, A.; Lima Júnior, J.M.; Dias, L.A. Segurança e Saúde no Trabalho da Construção: Experiência Brasileira e Panorama Internacional; OIT—Secretaria Internacional do Trabalho: Brasília, Brazil, 2005; ISBN 9228178388. [Google Scholar]

- Silva, C.; Melo De Souza, P.; Antônio, J.; Souza, S. Security Management Benefits at Work in Monitoring Individual Protection Equipment (IPE) and Collective Security Systems (CSS), Procedures and Methods in Industry Construction. Bus. Manag. Dyn. 2017, 6, 19–26. [Google Scholar]

- Brasil Government. Anuário Estatístico de Acidentes do Trabalho—AET 2015; Ministério da Fazenda: Brasília, Brazil, 2015.

- Penaloza, G.A.; Saurin, T.A.; Formoso, C.T. Identification and assessment of requirements of temporary edge protection systems for buildings. Int. J. Ind. Ergon. 2017, 58, 90–108. [Google Scholar] [CrossRef]

- Engler, M.; Carlos, B.; Formoso, T.; Pellicer, E.; Fabro, F.; Encarnacion, M.; Castello, V.; Soares, M.E.; Resumo, E. Identificação de práticas de gestão da segurança e saúde no trabalho em obras de construção civil Identification of health and safety managerial practices in construction sites. Ambient. Construído 2013, 13, 43–58. [Google Scholar]

- European Commission Regulation (EC). No 1221/2009 of the European Parliament and of the Council of 25 November 2009 on the Voluntary Participation by Organisations in a Community Eco-Management and Audit Scheme (EMAS); EC: Brussels, Belgium, 2009. [Google Scholar]

- ABNT ISO 14001:2015. Environmental Management Systems—Requirements with Guidance for Use; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Llatas, C. A model for quantifying construction waste in projects according to the European waste list. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef] [PubMed]

- Stoy, C.; Schalcher, H.-R. Residential Building Projects: Building Cost Indicators and Drivers. J. Constr. Eng. Manag. 2007, 133, 139–145. [Google Scholar] [CrossRef]

- de Lassio, J.; França, J.; Espirito Santo, K.; Haddad, A. Case Study: LCA Methodology Applied to Materials Management in a Brazilian Residential Construction Site. J. Eng. 2016, 2016, 8513293. [Google Scholar] [CrossRef]

- Costa, D.; Formoso, C.; Lima, H.; Barth, K. Sistema de Indicadores Para Benchmarking na Construção Civil; UFRGS/PPGEC/NORIE, Ed.; Núcleo Orientado Para a Inovação da Edificação—UFRG: Porto Alegre, Brazil, 2005; ISBN 9780874216561. [Google Scholar]

- Cardoso, F.F.C.; Araujo, V.M. Levantamento do Estado da Arte: Canteiro de Obras; Escola Politécnica da Universidade de São Paulo—USP: São Paulo, Brazil, 2007. [Google Scholar]

- Barreiros, M.A.F.; Abiko, A.K. Avaliação de impactos de vizinhança utilizando matrizes numéricas. Ambient. Construído 2016, 16, 23–38. [Google Scholar] [CrossRef]

- Haddad, A.N.; de Lassio, J.G.G. Life cycle assessment of building construction materials: Case study for a housing complex. Rev. Constr. 2016, 15, 69–77. [Google Scholar] [CrossRef]

- Sáez, P.V.; del Río Merino, M.; Porras-Amores, C. Estimation of construction and demolition waste volume generation in new residential buildings in Spain. Waste Manag. Res. 2012, 30, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Chua, D.K.; Godinot, M. Use of a WBS Matrix to Improve Interface Management in Projects. J. Constr. Eng. Manag. 2006, 132, 67–79. [Google Scholar] [CrossRef]

- Huang, T.; Shi, F.; Tanikawa, H.; Fei, J.; Han, J. Materials demand and environmental impact of buildings construction and demolition in China based on dynamic material flow analysis. Resour. Conserv. Recycl. 2013, 72, 91–101. [Google Scholar] [CrossRef]

- Moldan, B.; Janoušková, S.; Hák, T. How to understand and measure environmental sustainability: Indicators and targets. Ecol. Indic. 2012, 17, 4–13. [Google Scholar] [CrossRef]

- Ness, B.; Urbel-Piirsalu, E.; Anderberg, S.; Olsson, L. Categorising tools for sustainability assessment. Ecol. Econ. 2007, 60, 498–508. [Google Scholar] [CrossRef]

- Dirección General de Arquitectura y Vivienda de la Comunidad de Madrid. Base de Precios de la Construcción de la Comunidad de Madrid—BCC. 2007. Available online: http://www.madrid.org/bdccm/principal.htm (accessed on 29 November 2017).

- Cype Ingenieros Generator prices for construction version Brasil. Available online: http://www.brasil.geradordeprecos.info/ (accessed on 1 December 2017). (In Portuguese).

- Rodríguez Serrano, A.; Porras Álvarez, S. Life Cycle Assessment in Building: A Case Study on the Energy and Emissions Impact Related to the Choice of Housing Typologies and Construction Process in Spain. Sustainability 2016, 8, 287. [Google Scholar] [CrossRef]

- Tadeu, S.; Rodrigues, C.; Tadeu, A.; Freire, F.; Simões, N. Energy retrofit of historic buildings: Environmental assessment of cost-optimal solutions. J. Build. Eng. 2015, 4, 167–176. [Google Scholar] [CrossRef]

- PINI. Tables for Compositions of Prices for Budgets (TCPO); PINI: Rio de Janeiro, Brazil, 2013. (In Portuguese) [Google Scholar]

- Federal government of Brazil. Instrução Normativa no13 de 18 de dezembro de 2012—Lista Brasileira de Resíduos Sólidos. In Diário Oficial da União; Federal government of Brazil: Brasil, 2012; pp. 48–52. [Google Scholar]

- Li, Y.; Zhang, X. Web-based construction waste estimation system for building construction projects. Autom. Constr. 2013, 35, 142–156. [Google Scholar] [CrossRef]

- CBIC. Manual Básico de Indicadores de Produtividade na Construção Civil; Câmara Brasileira da Indústria da Construção: Brasília, Brasil, 2017; Volume 1. [Google Scholar]

- Andalusian Government. BCCA Base de Costes de la Construcción de Andalucia 2017; Consejería de Fomento y Vivienda de la Junta de Andalucía: Andalúcia, Spain, 2017.

- JCR. Best environmental management practice for the building and construction Sector. In Sectoral Reference Documents (SRDs) on Best Environmental Management Practice—EMAS; EcoManagement and Audit Scheme (EMAS): Brussels, Belgium, 2012; p. 611. [Google Scholar]

- Li, Y.; Zhang, X.; Ding, G.; Feng, Z. Developing a quantitative construction waste estimation model for building construction projects. Resour. Conserv. Recycl. 2016, 106, 9–20. [Google Scholar] [CrossRef]

- IBGE. Censo Demográfico 2010—Características da População e dos Domicílios—Resultados do Universo; IBGE: Rio de Janeiro, Brazil, 2011. [Google Scholar]

- Instituto Brasileiro de Geografia e Estatística (IBGE). Cidades@. Available online: https://cidades.ibge.gov.br/ (accessed on 22 February 2018).

| IN No. 13/2012 | Res. 307/2002 | Construction and Demolition Wastes (1) |

|---|---|---|

| 17 01 | Class A | Cement, tiles, tiles and ceramic materials. |

| 17 02 | Class B | Wood, glass, and plastic. |

| 17 03 | Class D | Bituminous mixtures, asphalt and tar products. |

| 17 04 | Class B | Metal scrap (including alloys). |

| 17 05 | Class A | Soils (including soils excavated from contaminated sites), rocks and muds. |

| 17 06 | Class D | Insulation materials and building materials containing asbestos. |

| 17 08 | Class B | Gypsum-based building materials. |

| 17 09 | Class C/D | Other construction and demolition waste |

| Context | Reference | Construction Activities |

|---|---|---|

| China | [18] | foundation; prefabricated concrete piles; steel sheet piles; earthwork; support system building; support system demolition; foundation construction; Reinforced Concrete (RC) work-rebar; RC work-form; RC work-concrete; masonry work; structural steelwork; finish work; wall; celling; floor; transportation work. |

| [37] | earthwork and excavation; formwork; reinforcement concrete; wall; roofing, and isolation; component installation; plumbing and drainage; ornament and painting; surrounding and landscaping; waste treatment. | |

| Europe Union | [69] | site clearing; site earth-work; foundation; structure; masonry; roofing; and painting. |

| Spain | [19] | earthworks, foundations; structures; roofs; partitions and closures; impermeable membranes; insulations; coatings; pavements and door and window closures. |

| Portugal | [25] | by elements: foundation; floor; walls; roofs; windows; doors |

| German | [70] | foundations; structure; external walls; internal walls; floors and ceilings; roofs; other activities |

| Brazil | [72] | preliminary services; foundations; structure; vertical fences (masonry and coatings); horizontal fences (floors, linings, coverings and impermeability); window frames; paintings and systems. |

| [73] | demolition, surface cleaning, foundations, drainage, excavations, structure, masonry, partitions, window frames, roofing, impermeability, vertical coating, painting, flooring, building systems, underground and aerial networks, earthworks, paving and drainage. | |

| [71] | foundations (RC structure); structure (RC structure), masonry; wall covering; flooring; mortar applied; doors and windows; and roofing. | |

| [74] | surface cleaning; earthwork; foundations; structures; fences; equipment; finalizations. | |

| [75] | foundation (RC structure); structure (RC structure); masonry; wall covering; frames (doors and windows); roofing; | |

| [50] | foundation; structure; roof; wall; ceiling; doors and windows; electrical/hydraulic systems. |

| Code | Phase | Code | Activities (Measurement Unit) 1 |

|---|---|---|---|

| P01 | Site preparation | P0101 | Demolition (m3) |

| P0102 | Surface cleaning (m2) | ||

| P0103 | Temporary hoarding (m2) | ||

| P0104 | Temporary facilities (m2) | ||

| P02 | Earthwork | P0201 | Mechanical excavation (m3) |

| P03 | Foundation | P0301 | Precast concrete piles (m) |

| P0302 | Foundation wood forms (m2) | ||

| P0303 | Foundation rebar frames (t) | ||

| P0304 | Foundation concrete (m3) | ||

| P04 | Superstructure | P0401 | Superstructure wood forms (m2) |

| P0402 | Superstructure rebar frames (t) | ||

| P0403 | Superstructure concrete (m3) | ||

| P05 | Specialized services | P0501 | Manufacturing of wood forms (m2) |

| P0502 | Cutting/bending of rebar (t) |

| Category | Resource (Measurement Unit 1) |

|---|---|

| Natural resources | sand (t), gravel (t), timber (t) |

| Manufactured resources | cement (t), ready-mix concrete (t), precast concrete (t), rebar (t) |

| Labor | work at height (mh), work at outside (mh), work at area covered (mh). |

| Facilities | pile driver (pmh), bulldozer/excavator/loader (pmh), ready-mix concrete truck (pmh), pneumatic breaker (pmh), concrete electric mixer (pmh), concrete vibrator (pmh), electric saw (pmh). |

| Waste | excavated soil (t), waste of concrete/masonry (t), waste of wood; waste of rebar (t) |

| Public services | water consumption by the process (m3) water consumption by the worker (m3), electric energy consumption (kWh) |

| Transport services | Loading and unloading time (h), materials trucking (h), waste trucking (h) |

| Category | Code | Resource (Unit) | Indicator | Data Source |

|---|---|---|---|---|

| Natural resources | c1 | Sand (t) | Consumption of resources homogenized by conversion rate (if necessary) by each activity. | CYPE [82] and CBIC [88] |

| c2 | Gravel (t) | |||

| c3 | Timber (t) | |||

| Manufactured resources | c4 | Cement (t) | Consumption of resources homogenized by conversion rate (if necessary) by each activity. | CYPE [82] and CBIC [88] |

| c5 | Rebar (t) | |||

| c6 | Precast concrete (t) | |||

| c7 | Ready-mix concrete (t) | |||

| Labor 1 | c8 | Labor at height (mh) | Labor time in man-hours by activity according to productivity indicators of the Brazilian construction industry. | CYPE [82] and CBIC [88] |

| c9 | Labor with machines/vehicles (mh) | |||

| c10 | Labor with manual tools (mh) | |||

| Facilities | c11 | Pile driver (pmh) | Time estimated of productive machine hour (pmh) by activity according to productivity indicators of the Brazilian construction industry. | CYPE [82] |

| c12 | Bulldozer/excavator (pmh) | |||

| c13 | Ready-mix concrete truck (pmh) | |||

| c14 | Pneumatic breaker (pmh) | |||

| c15 | Concrete electric mixer (pmh) | |||

| c16 | Concrete vibrator (pmh) | |||

| c17 | Electric saw (pmh) | |||

| Wastes | c18 | Excavated soil (t) | Volume of excavated. | CYPE [82] |

| c19 | Waste of concrete/masonry (t) | Estimated waste rate (t.) | CYPE [82] and estimated indirect data. | |

| c20 | Waste of wood (t) | |||

| c21 | Waste of rebar (t) | |||

| Public services | c22 | Water for workers (m3) | Water consumption (m3) per man-hour (mh) per activity considering daily water consumption per worker about 80 L/day. | |

| c23 | Water to process (m3) | Estimated water consumption by activity (m3) according to water/cement ratio or water/service ratio. | water/cement ratio in CYPE [82] and consumption in BCCA [89] | |

| c24 | Electric energy (kWh) | Estimated electricity consumption according to the productive machine hour (PMH) | CYPE [82] and estimated indirect data. | |

| Transport services | c25 | Loading/unloading of materials (h) | Time of loading or unloading obtained on the auxiliary compositions. | CYPE [82] |

| c26 | Trucking of materials /waste(h) |

| Category | Environmental Aspect | Unit 1 | Contributory Inputs/Outputs 2 (Table 5) |

|---|---|---|---|

| Resources consumption | consumption of mineral resources | t | c1, c2, c6, c7 |

| consumption of renewable resources | t | c3 | |

| consumption of manufactured resources | t | c4, c5, c6, c7 | |

| Waste generation | generation of wastes soil/concrete/masonry | t | c18, c19 |

| generation of wastes of wood or metals | t | c20, c21 | |

| Pollution emission | handling involving dust or particulate matter | t | c1, c2, c4, c6, c18, c19, c20 |

| use of fuel-powered mechanical equipment | h | c11, c12, c13 | |

| use of noise/vibration emission equipment | h | c11, c12, c13, c14, c15, c16, c17, c25 | |

| Public services | consumption of water | m3 | c22, c23 |

| consumption of electricity | kwh | c24 | |

| Transport services | circulation of machines/vehicles on the local | h | c11, c12, c13, c25 |

| circulation of machines/vehicles in the city | h | c26 | |

| Land Use | withdrawal and movement of soil | t | c18 |

| storage of unpacked materials | t | c1, c2, c3, c5, c6 | |

| storage of packed materials | t | c4 | |

| Health and safety | labor exposed to machinery | h | c9 |

| labor exposed to fall of height | h | c8 | |

| labor exposed to falling objects | h | c10 |

| Characteristic | CS1 | CS2 |

|---|---|---|

| 1. Segment | residential building | residential building |

| 2. Floor numbers | 29 | 23 |

| Number of parking floors | 3 | 2 |

| Number of collective area floors | 1 | 1 |

| Number of dwelling floors | 25 | 20 |

| 3. Land area (m2) | 1844.62 | 2210.74 |

| 4. Construction area (m2) | 15,448.11 | 12,906.05 |

| Area of the parking floors (m2) | 3667.88 | 3565.02 |

| Area of the collective floors (m2) | 1774.98 | 1792.43 |

| Area of the dwelling floors (m2) | 10,005.25 | 7548.60 |

| 5. Dwelling area (m2) | 148.31 | 141.18 |

| Number of dwelling per floor | 2 | 2 |

| Number of dwellings | 50 | 40 |

| 6. Number of parking space | 153 | 140 |

| private parking space | 150 | 133 |

| parking space for visitors | 3 | 7 |

| 7. Current stage (in collecting) | Superstructure work | Coating work |

| Construction Activity | Construction Site 1 (CS1) | Construction Site 2 (CS2) |

|---|---|---|

| Demolition (m3) | 42.94 | 12.00 |

| Surface cleaning (m2) | 1481.00 | 1777.93 |

| Temporary hoarding (m2) | 245.36 | 70.40 |

| Temporary facilities (m2) | 210.00 | 270.00 |

| Mechanical excavation (m3) | 3430.00 | 2933.58 |

| Precast concrete piles (m) | 4235.00 | 3584.00 |

| Foundation wood forms (m2) | 216.81 | 765.00 |

| Foundation rebar frames (t) | 7.90 | 34.24 |

| Foundation concrete (m3) | 106.13 | 230.92 |

| Superstructure wood forms (m2) | 44,946.67 | 20,803.06 |

| Superstructure rebar frames (t) | 449.28 | 212.14 |

| Superstructure concrete (m3) | 3771.27 | 2139.59 |

| Manufacturing of forms (m2) | 45,163.48 | 21,568.06 |

| Cutting/bending of rebar (t) | 457.18 | 246.38 |

| Resources Consumption | ||||||||

|---|---|---|---|---|---|---|---|---|

| Construction Site 1 | Construction Site 2 | |||||||

| Construction Activity | Consumption of Mineral Resources (t) | Consumption of Renewable Resources (t) | Consumption of Manufactured Resources (t) | Overall Consumption of Resources by Activity | Consumption of Mineral Resources (t) | Consumption of Renewable Resources (t) | Consumption of Manufactured Resources (t) | Overall Consumption of Resources by Activity |

| Demolition (m3) | - | - | - | - | - | - | - | - |

| Surface cleaning (m2) | - | - | - | - | - | - | - | - |

| Temporary hoarding (m2) | - | 2.98 | - | 2.98 | - | 0.86 | - | 0.86 |

| Temporary facilities (m2) | 29.43 | 5.95 | 5.15 | 40.52 | 37.84 | 7.65 | 6.62 | 52.10 |

| Mechanical excavation (m3) | - | - | - | - | - | - | - | - |

| Precast concrete piles (m) | 529.27 | - | 58.81 | 588.08 | 447.91 | - | 49.77 | 497.68 |

| Foundation wood forms (m2) | - | 1.50 | - | 1.50 | - | 5.30 | - | 5.30 |

| Foundation rebar frames (t) | - | - | 8.29 | 8.29 | - | - | 35.95 | 35.95 |

| Foundation concrete (m3) | 262.67 | - | 29.19 | 291.86 | 571.53 | - | 63.50 | 635.03 |

| Superstructure wood forms (m2) | - | 311.56 | - | 311.56 | - | 144.20 | - | 144.20 |

| Superstructure rebar frames (t) | - | - | 471.74 | 471.74 | - | - | 222.75 | 222.75 |

| Superstructure concrete (m3) | 9333.89 | - | 1037.10 | 10,370.99 | 5295.49 | - | 588.39 | 5883.87 |

| Manufacturing of forms (m2) | - | - | - | - | - | - | - | - |

| Cutting/bending of rebar (t) | - | - | - | - | - | - | - | - |

| Overall quantities (absolute) | 10,155.27 | 322.00 | 1610.28 | 12,087.54 | 6352.76 | 158.01 | 966.97 | 7477.74 |

| Overall quantities (relative) | 84% | 3% | 13% | 100% | 85% | 2% | 13% | 100% |

| Waste Generation | ||||||

|---|---|---|---|---|---|---|

| Construction Site 1 | Construction Site 2 | |||||

| Construction Activity | Generation of Wastes of Soil/Concrete (t) | Generation of Wastes of Wood/Metals (t) | Overall Generation of Waste by Activity (t) | Generation of Wastes of Soil/Concrete (t) | Generation of Wastes of Wood/Metals (t) | Overall Generation of Waste by Activity (t) |

| Demolition (m3) | 64.41 | - | 64.41 | 18.00 | - | 18.00 |

| Surface cleaning (m2) | 555.38 | - | 555.38 | 666.72 | - | 666.72 |

| Temporary hoarding (m2) | - | 2.98 | 2.98 | - | 0.86 | 0.86 |

| Temporary facilities (m2) | 34.57 | 5.95 | 40.52 | 44.45 | 7.65 | 52.10 |

| Mechanical excavation (m3) | 4287.50 | - | 4287.50 | 3666.98 | - | 3666.98 |

| Precast concrete piles (m) | - | - | - | - | - | - |

| Foundation wood forms (m2) | - | 1.50 | 1.50 | - | 5.30 | 5.30 |

| Foundation rebar frames (t) | - | 0.41 | 0.41 | - | 1.80 | 1.80 |

| Foundation concrete (m3) | 5.84 | - | 5.84 | 12.70 | - | 12.70 |

| Superstructure wood forms (m2) | - | 311.56 | 311.56 | - | 144.20 | 144.20 |

| Superstructure rebar frames (t) | - | 23.59 | 23.59 | - | 11.14 | 11.14 |

| Superstructure concrete (m3) | 207.42 | - | 207.42 | 117.68 | - | 117.68 |

| Manufacturing of forms (m2) | - | - | - | - | - | - |

| Cutting/bending of rebar (t) | - | - | - | - | - | - |

| Overall quantities (absolute) | 5155.11 | 346.00 | 5501.11 | 4526.54 | 170.94 | 4697.48 |

| Overall quantities (relative) | 94% | 6% | 100% | 96% | 4% | 100% |

| Pollution Emission | ||||||

|---|---|---|---|---|---|---|

| Construction Site 1 | Construction Site 2 | |||||

| Construction Activity | Generation of Wastes of Soil/Concrete (t) | Generation of Wastes of Wood/Metals (t) | Generation of Waste by Activity (t) | Generation of Wastes of Soil/Concrete (t) | Generation of Wastes of Wood/Metals (t) | Generation of Waste by Activity (t) |

| Demolition (m3) | 64.41 | 0.64 | 26.58 | 18.00 | 0.18 | 7.43 |

| Surface cleaning (m2) | 555.38 | 22.22 | 22.22 | 666.72 | 26.67 | 26.67 |

| Temporary hoarding (m2) | 2.98 | - | 5.16 | 0.86 | - | 1.48 |

| Temporary facilities (m2) | 75.09 | - | 11.37 | 96.55 | - | 14.62 |

| Mechanical excavation (m3) | 4287.50 | 483.63 | 483.63 | 3666.98 | 413.64 | 413.64 |

| Precast concrete piles (m) | 588.08 | 194.81 | 243.82 | 497.68 | 164.86 | 206.34 |

| Foundation wood forms (m2) | 1.50 | - | 0.13 | 5.30 | - | 0.44 |

| Foundation rebar frames (t) | - | - | 0.69 | - | - | 3.00 |

| Foundation concrete (m3) | 5.84 | 5.62 | 33.39 | 12.70 | 12.24 | 72.65 |

| Superstructure wood forms (m2) | 311.56 | - | 37.60 | 144.20 | - | 17.40 |

| Superstructure rebar frames (t) | - | - | 39.31 | - | - | 18.56 |

| Superstructure concrete (m3) | 207.42 | 316.79 | 1303.35 | 117.68 | 179.73 | 739.44 |

| Manufacturing of forms (m2) | - | - | 1896.87 | - | - | 905.86 |

| Cutting/bending of rebar (t) | - | - | - | - | - | - |

| Overall quantities (absolute) | 6099.77 | 1023.71 | 4104.09 | 5226.68 | 797.31 | 2427.51 |

| Public Services | Transport Services | |||||||

|---|---|---|---|---|---|---|---|---|

| CS1 | CS2 | CS1 | CS2 | |||||

| Construction Activity | Consumption of Water (m3) | Consumption of Electricity (kWh) | Consumption of Water (m3) | Consumption of Electricity (kWh) | Circulation of Machines and Vehicles on the Local (h) | Circulation of Machines and Vehicles in the City (h) | Circulation of Machines and Vehicles on the Local (h) | Circulation of Machines and Vehicles in the City (h) |

| Demolition (m3) | 0.92 | 38.90 | 0.26 | 10.87 | 0.64 | 10.22 | 0.18 | 2.86 |

| Surface cleaning (m2) | 1.07 | - | 1.28 | - | 22.22 | 88.12 | 26.67 | 105.79 |

| Temporary hoarding (m2) | 2.94 | 2.94 | 0.84 | 0.84 | 0.25 | 0.95 | 0.07 | 0.27 |

| Temporary facilities (m2) | 33.23 | 10.24 | 42.73 | 13.16 | 2.02 | 12.86 | 2.60 | 16.53 |

| Mechanical excavation (m3) | 6.89 | - | 5.90 | - | 483.63 | 680.28 | 413.64 | 581.83 |

| Precast concrete piles (m) | 11.14 | - | 9.43 | - | 243.82 | 93.31 | 206.34 | 78.97 |

| Foundation wood forms (m2) | 1.60 | - | 5.65 | - | 0.13 | 0.48 | 0.44 | 1.68 |

| Foundation rebar frames (t) | 0.86 | - | 3.73 | - | 0.69 | 1.38 | 3.00 | 5.99 |

| Foundation concrete (m3) | 0.93 | 31.84 | 2.02 | 69.28 | 12.16 | 47.23 | 26.46 | 102.77 |

| Superstructure wood (m2) | 332.16 | - | 153.73 | - | 37.60 | 98.87 | 17.40 | 45.76 |

| Superstructure rebar (t) | 48.97 | - | 23.12 | - | 39.31 | 78.59 | 18.56 | 37.11 |

| Superstructure concrete (m3) | 223.37 | 1131.38 | 126.73 | 641.88 | 549.10 | 1678.44 | 311.52 | 952.25 |

| Manufacturing of forms (m2) | 185.17 | 1138.12 | 88.43 | 543.52 | - | - | - | - |

| Cutting/bending of rebar (t) | 109.72 | - | 59.13 | - | - | - | - | - |

| Overall quantities | 958.98 | 2353.42 | 522.98 | 1279.55 | 1391.56 | 2790.73 | 1026.88 | 1931.80 |

| Rate per construction area | 0.06 | 0.15 | 0.04 | 0.10 | 0.09 | 0.18 | 0.08 | 0.15 |

| Rate per land area | 0.52 | 1.28 | 0.24 | 0.58 | 0.75 | 1.51 | 0.46 | 0.87 |

| Land Use | ||||||

|---|---|---|---|---|---|---|

| Construction Site 1 | Construction Site 2 | |||||

| Construction Activity | Withdrawal and Movement of Soil (t) | Storage of Unpacked Materials (t) | Storage of Packed Materials (t) | Withdrawal and Movement of Soil (t) | Storage of Unpacked Materials (t) | Storage of Packed Materials (t) |

| Demolition (m3) | - | 64.41 | - | - | 18.00 | - |

| Surface cleaning (m2) | 555.38 | - | - | 666.72 | - | - |

| Temporary hoarding (m2) | - | 5.94 | - | - | 1.71 | - |

| Temporary facilities (m2) | - | 75.90 | 5.15 | - | 97.58 | 6.62 |

| Mechanical excavation (m3) | 4287.50 | - | - | 3666.98 | - | - |

| Precast concrete piles (m) | - | 588.08 | - | - | 497.68 | - |

| Foundation wood forms (m2) | - | 3.01 | - | - | 10.61 | - |

| Foundation rebar frames (t) | - | 8.71 | - | - | 37.75 | - |

| Foundation concrete (m3) | - | 5.84 | - | - | 12.70 | - |

| Superstructure wood forms (m2) | - | 623.13 | - | - | 288.41 | - |

| Superstructure rebar frames (t) | - | 495.33 | - | - | 233.88 | - |

| Superstructure concrete (m3) | - | 207.42 | - | - | −117.68 | - |

| Manufacturing of forms (m2) | - | - | - | - | - | - |

| Cutting/bending of rebar (t) | - | - | - | - | - | - |

| Overall quantities (absolute) | 4842.88 | 2077.79 | 5.15 | 4333.70 | 1316.00 | 6.62 |

| Rate per construction area | 0.31 | 0.13 | 0.00 | 0.34 | 0.10 | 0.00 |

| Rate per land area | 2.62 | 1.13 | 0.00 | 1.96 | 0.60 | 0.00 |

| Health and Safety | ||||||

|---|---|---|---|---|---|---|

| Construction Site 1 | Construction Site 2 | |||||

| Construction Activity | Labor Exposed to Machinery (h) | Labor Exposed to Fall of Height (h) | Labor Exposed to Falling Objects (h) | Labor Exposed to Machinery (h) | Labor Exposed to Fall of Height (h) | Labor Exposed to Falling Objects (h) |

| Demolition (m3) | 91.59 | - | - | 25.60 | - | - |

| Surface cleaning (m2) | 106.63 | - | - | 128.01 | - | - |

| Temporary hoarding (m2) | - | - | 294.43 | - | - | 84.48 |

| Temporary facilities (m2) | - | - | 3066.00 | - | - | 3942.00 |

| Mechanical excavation (m3) | 689.43 | - | - | 589.65 | - | - |

| Precast concrete piles (m) | 1113.81 | - | - | 942.59 | - | - |

| Foundation wood forms (m2) | - | - | 116.86 | - | - | 412.34 |

| Foundation rebar frames (t) | - | - | 86.10 | - | - | 373.19 |

| Foundation concrete (m3) | - | - | 18.68 | - | - | 40.64 |

| Superstructure wood forms (m2) | - | 24,226.26 | - | - | 11,212.85 | - |

| Superstructure rebar frames (t) | - | 4897.16 | - | - | 2312.32 | - |

| Superstructure concrete (m3) | - | 19,697.34 | - | - | 11,175.08 | - |

| Manufacturing of forms (m2) | - | - | 18,517.03 | - | - | 8842.91 |

| Cutting/bending of rebar (t) | - | - | 10,970.32 | - | - | 5913.03 |

| Overall quantities (absolute) | 2001.45 | 48,820.76 | 33,071.41 | 1685.85 | 24,700.24 | 19,608.58 |

| Overall quantities (relatives) | 2% | 58% | 39% | 4% | 54% | 43% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borja, L.C.A.; César, S.F.; Cunha, R.D.A.; Kiperstok, A. A Quantitative Method for Prediction of Environmental Aspects in Construction Sites of Residential Buildings. Sustainability 2018, 10, 1870. https://doi.org/10.3390/su10061870

Borja LCA, César SF, Cunha RDA, Kiperstok A. A Quantitative Method for Prediction of Environmental Aspects in Construction Sites of Residential Buildings. Sustainability. 2018; 10(6):1870. https://doi.org/10.3390/su10061870

Chicago/Turabian StyleBorja, Luis Claudio A., Sandro Fábio César, Rita Dione A. Cunha, and Asher Kiperstok. 2018. "A Quantitative Method for Prediction of Environmental Aspects in Construction Sites of Residential Buildings" Sustainability 10, no. 6: 1870. https://doi.org/10.3390/su10061870