The Significance of a Building’s Energy Consumption Profiles for the Optimum Sizing of a Combined Heat and Power (CHP) System—A Case Study for a Student Residence Hall

Abstract

1. Introduction

- no data are available at all for both electricity and gas consumption;

- only yearly electricity and gas consumption data are available;

- monthly electricity and gas consumption data are available.

2. Methodology

2.1. Site Selection

2.2. Electricity and Gas Consumption

2.3. Weather Normalization of Energy Usage

- Step-1: establishment of a relationship between five years average HDDs and actual monthly electricity consumption through linear regression.

- Step-2: determination of a slope and intercept of a linear regression line.

- Step-3: use of actual HDDs instead of five years average HDDs in the equation of linear regression along with its slope and intercept values, to calculate the monthly normalized electricity consumption. The aforementioned process of weather normalization was used in order to normalize the monthly electricity and gas consumption of McLaren House.

2.3.1. Normalization of Monthly Gas Consumption

2.3.2. Normalization of Monthly Electricity Consumption

2.4. Development of Hourly Thermal and Electrical Demand Profiles

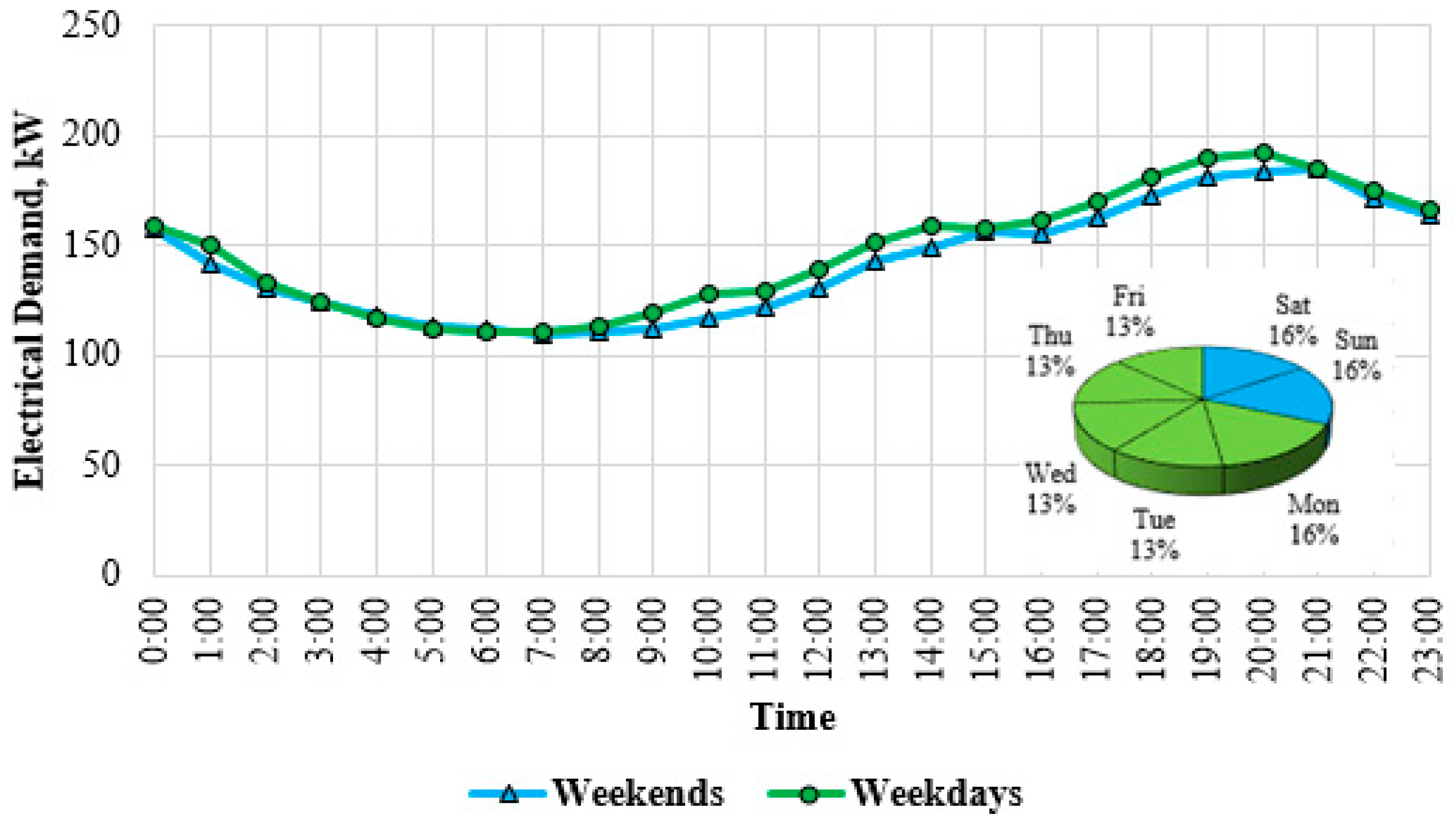

2.4.1. Electrical Demand Profiles

- Hourly electricity consumption remains fairly the same on weekdays and weekends with slightly higher consumption on the weekdays.

- Electricity consumption on a typical weekend is nearly 3% higher than that on a weekday.

- During winter months, base load remains 100 kW, whereas peak load occurs during evening when the kitchen equipment is under use. The value for the peak load could be as high as 190 kW.

- During summer months, the base load remains 62 kW, whereas the peak load occurs during evening when the kitchen equipment is under use. The value for the peak load could be as high as 80 kW.

- During the whole year, the hourly electricity demand remains within 62 kW and 190 kW.

2.4.2. Thermal Demand Profiles

- Hourly thermal demand remains fairly the same on weekdays and weekends with a slightly higher demand on the weekdays during day period.

- Thermal demand on a typical weekend is nearly 3% higher than that on a weekday.

- During winter months, boilers start at 5 a.m. during the whole week. Thermal load remains as high as 630 kW due to high space heating and hot water demand.

- During summer months, the base load remains between 130–150 kW as there is only hot water demand.

- During the whole year, hourly thermal demand remains within 130 kW and 700 kW.

2.5. Optimum Sizing of CHP

- CHP should have minimum 5500 running hours operating between 75% and 100% load;

- higher net present value (NPV);

- higher internal rate of return (IRR), %; and

- lower payback period.

3. Results

4. Sensitivity Analysis

4.1. Effect of Estimated Energy Demand Profiles on the CHP System’s Sizing and Economics

4.2. Effect of Variation in Electricity and Fuel Prices

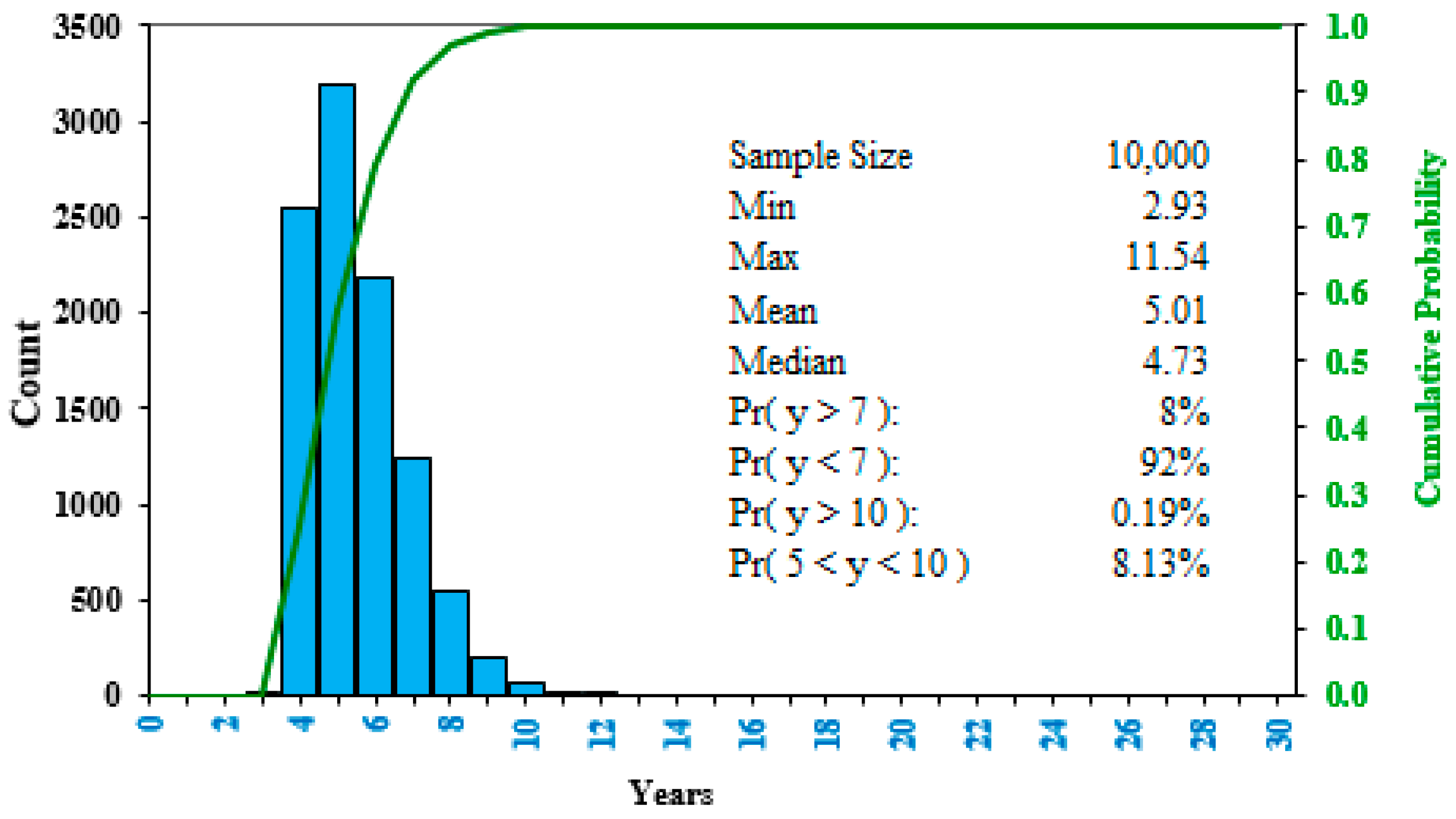

4.3. Significant Parameters (Monte Carlo Analysis)

5. Conclusions

- Availability of real hourly electricity and thermal demand profiles is crucial for the optimum sizing of a CHP system.

- CHP sizing based on estimated energy profiles, monthly energy consumption figures or based on the existing boilers capacity may result in an undersized or oversized CHP system.

- Weather normalization of real hourly energy consumption data is mandatory for finding the optimum size of CHP.

- Under-sizing of a CHP system is better than over-sizing.

- Variation in electricity and fuel prices could affect the project’s economics.

- Increase in electricity price will decrease the payback period of the project and will strengthen its economics over its life period.

- Electricity price has the strongest relationship (R2 = 0.75) with the project’s payback period.

- Variation in CCL tax, VAT tax and O&M price has the minimal effect on the project’s economics.

- An optimum sized CHP is a suitable solution for student residence hall type buildings and could generate considerable financial and environmental savings for the university sector.

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviation

| BMS | Building Management System |

| CCL | Climate Change Levy |

| CHP | Combined Heat and Power |

| CRC | Carbon Reduction Commitment |

| IRR | Internal Rate of Return |

| kW | Kilowatts |

| kWh | Kilo Watts Hour |

| LSBU | London South Bank University |

| NPV | Net Present Value |

| O&M | Operations and Maintenance |

| UK | United Kingdom |

| WACC | Weighted Average Cost of Capital |

References

- Higher Education Funding Council for England (HEFCE). Carbon Reduction Target and Strategy for Higher Education in England. Available online: http://www.hefce.ac.uk/pubs/year/2010/201001/ (accessed on 11 September 2012).

- Higher Education Statistics Agency. Environmental Information, Estates Management Statistics Tables. Available online: https://www.hesa.ac.uk/index.php?option=com_heicontacts&Itemid=87 (accessed on 10 October 2016).

- Amber, K.P.; Parkin, J. Barriers to the uptake of combined heat and power technology in the UK higher education sector. Int. J. Sustain. Energy 2015, 34, 406–416. [Google Scholar] [CrossRef]

- Raine, R.D.; Sharifi, V.N.; Swithenbank, J. Optimisation of combined heat and power production for buildings using heat storage. Energy Convers. Manag. 2014, 87, 164–174. [Google Scholar] [CrossRef]

- Amber, K.P.; Day, T.; Ratyal, N.I.; Kiani, A.K.; Ahmad, R. Techno, Economic and Environmental Assessment of a Combined Heat and Power (CHP) System—A Case Study for a University Campus. Energies 2018, 11, 1133. [Google Scholar] [CrossRef]

- Chen, H.; Xu, J.; Xiao, Y.; Qi, Z.; Xu, G.; Yang, Y. An Improved Heating System with Waste Pressure Utilization in a Combined Heat and Power Unit. Energies 2018, 11, 1515. [Google Scholar] [CrossRef]

- Franco, A.; Versace, M. Optimum sizing and operational strategy of CHP plant for district heating based on the use of composite indicators. Energy 2017, 124, 258–271. [Google Scholar] [CrossRef]

- Amber, K.P.; Aslam, M.W.; Mahmood, A.; Kousar, A.; Younis, M.Y.; Akbar, B.; Chaudhary, G.Q.; Hussain, S.K. Energy Consumption Forecasting for University Sector Buildings. Energies 2017, 10, 1579. [Google Scholar] [CrossRef]

- Wu, Q.; Ren, H.; Gao, W.; Ren, J. Multi-criteria assessment of building combined heat and power systems located in different climate zones: Japan-China comparison. Energy 2016, 103, 502–512. [Google Scholar] [CrossRef]

- Amber, K.P.; Aslam, W.; Bashir, M.A. Development of a Typical Hourly Electricity Consumption Profile for Student Residence Halls Based on Central Tendency Method. Nucleus 2016, 53, 14–25. [Google Scholar]

- Athawale, R.; Felder, F.A.; Goldman, L.A. Do Combined Heat and Power plants perform? Case study of publicly funded projects in New York. Energy Policy 2016, 97, 618–627. [Google Scholar] [CrossRef]

- NewEnCo, Benefits of CHP. Available online: http://www.newenco.co.uk/combined-heat-power/benefits-of-chp (accessed on 13 November 2012).

- Amber, K.P. Development of a Combined Heat and Power Sizing Model for the Higher Education Sector of the United Kingdom. Ph.D. Thesis, London South Bank University, London, UK, 2013. [Google Scholar]

- Taljan, G.; Verbič, G.; Pantoš, M.; Sakulin, M.; Fickert, L. Optimal sizing of biomass-fired Organic Rankine Cycle CHP system with heat storage. Renew. Energy 2012, 41, 29–38. [Google Scholar] [CrossRef]

- Ren, H.; Gao, W.; Ruan, Y. Optimal sizing for residential CHP system. Appl. Therm. Eng. 2008, 28, 514–523. [Google Scholar] [CrossRef]

- Amber, K.P.; Aslam, M.W.; Ikram, F.; Kousar, A.; Ali, H.M.; Akram, N.; Afzal, K.; Mushtaq, H. Heating and Cooling Degree-Days Maps of Pakistan. Energies 2018, 11, 94. [Google Scholar] [CrossRef]

- Büyükalaca, O.; Bulut, H.; Yılmaz, T. Analysis of variable-base heating and cooling degree-days for Turkey. Appl. Energy 2001, 69, 269–283. [Google Scholar] [CrossRef]

- Martinaitis, V.; Bieksa, D.; Miseviciute, V. Degree-days for the exergy analysis of buildings. Energy Build. 2010, 42, 1063–1069. [Google Scholar] [CrossRef]

- Soldo, B. Forecasting natural gas consumption. Appl. Energy 2012, 92, 26–37. [Google Scholar] [CrossRef]

- Olofsson, T.; Andersson, S.; Östin, R. Energy load predictions for buildings based on a total demand perspective. Energy Build. 1998, 28, 109–116. [Google Scholar] [CrossRef]

- Olofsson, T.; Andersson, T. Long-term energy demand predictions based on short-term measured data. Energy Build. 2001, 33, 85–91. [Google Scholar]

- Heating and Cooling Degree Days. Available online: http://www.degreedays.net/ (accessed on 21 November 2012).

- Charter Institute of Building Services Engineers (CIBSE). TM41 Degree Days: Theory and Application, 2008. Available online: http://www.ihs.com/info/st/e/info4education.aspx (accessed on 22 September 2014).

- Salem, R.; Bahadori-Jahromi, A.; Mylona, A.; Godfrey, P.; Cook, D. Comparison and evaluation of the potential energy, carbon emissions, and financial impacts from the incorporation of CHP and CCHP systems in existing UK hotel buildings. Energies 2018, 11, 1219. [Google Scholar] [CrossRef]

- Yu, D.; Meng, Y.; Yan, G.; Mu, G.; Li, D.; Blond, S.L. Sizing Combined Heat and Power Units and Domestic Building Energy Cost Optimisation. Energies 2017, 10, 771. [Google Scholar] [CrossRef]

- ENERG—A Guide to CHP Unit Sizing. Available online: http://www.energ-group.com/combined-heat-and-power/cogeneration/essential-guide-to-chp/ (accessed on 21 November 2012).

- Amber, K.P.; Dunn, A.; Parkin, J.; Day, A.R. Development of a combined heat and power sizing model for higher education buildings in the United Kingdom. Energy Build. 2018, 172, 537–553. [Google Scholar] [CrossRef]

- Maurovich-Horvat, L.; Rocha, P.; Siddiqui, A.S. Optimal operation of combined heat and power under uncertainty and risk aversion. Energy Build. 2016, 110, 415–425. [Google Scholar] [CrossRef]

- Teymouri-Hamzehkolaei, F.; Sattari, S. Technical and economic feasibility study of using Micro CHP in the different climate zones of Iran. Energy 2011, 36, 4790–4798. [Google Scholar] [CrossRef]

- Wickart, M.; Madlener, R. Optimal technology choice and investment timing: A stochastic model of industrial cogeneration vs. heat-only production. Energy Econ. 2007, 29, 934–952. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Electricity day tariff | 7.875 p/kWh |

| Electricity night tariff | 4.801 p/kWh |

| Electricity fixed charges | £12,000 |

| Natural gas tariff | 2.375 p/kWh |

| CCL charges on electricity usage | 0.524 p/kWh |

| CCL charges on gas usage | 0.182 p/kWh |

| Boiler’s efficiency | 78% |

| VAT charge | @20% |

| CRC cost | £12/t/CO2 |

| CO2 emission factor for electricity | 0.541 kg/kWh |

| CO2 emission factor for natural gas | 0.194 kg/kWh |

| O&M cost per kWh at 100% load | £0.01/kWh |

| O&M cost per kWh at 100% load | £0.012/kWh |

| O&M cost per kWh at 100% load | £0.013/kWh |

| Weighted average cost of capital (WACC) | 5% |

| Annual inflation rate | 5% |

| Project Life | 15 years |

| CHP asset cost | £200,000 |

| Infrastructure Cost | 50% of CHP cost |

| Switch room modification | 10% of CHP cost |

| G59 Application fee | 2% of CHP cost |

| In-house project management fee | 5% of CHP cost |

| Out-sourced project management fee | 5% of CHP cost |

| BMS connection fee | 2% of CHP cost |

| Other costs | 5% of CHP cost |

| Contractor’s preliminaries | 5% of CHP cost |

| Project contingency | 7% of CHP cost |

| CHP Size (kW) | Total Running Hours | Running Hours >75% | Payback Period, Years | NPV (£) | IRR (%) | CO2 Savings t/CO2 | Reduction in Grid Electricity (%) | Increase in Gas Consumption (%) | QI |

|---|---|---|---|---|---|---|---|---|---|

| 70 | 8668 | 8636 | 8.7 | 138,888 | 12 | 180 | 53.26 | 19.33 | 125 |

| 90 | 8635 | 8004 | 7.8 | 215,849 | 14 | 238 | 65.01 | 20.97 | 127 |

| 100 | 8551 | 6946 | 7.6 | 226,300 | 15 | 244 | 69.13 | 23.60 | 125 |

| 110 | 8635 | 6505 | 6.9 | 279,735 | 16 | 272 | 74.06 | 23.72 | 128 |

| 122 | 8512 | 5896 | 6.8 | 293,574 | 17 | 281 | 77.48 | 25.30 | 128 |

| 135 | 7975 | 5387 | 7.5 | 268,150 | 15 | 282 | 77.98 | 25.64 | 129 |

| 150 | 7263 | 4293 | 8.4 | 224,476 | 13 | 271 | 76.53 | 25.95 | 129 |

| 165 | 6281 | 3293 | 9.9 | 152,267 | 10 | 245 | 71.85 | 25.72 | 125 |

| 185 | 5903 | 2492 | 10.2 | 145,153 | 10 | 252 | 71.18 | 24.18 | 129 |

| Error, % | Optimum CHP Size, kW | Total Running Hours | Running Hours >75% | Pay- Back Period, Years | NPV (£) | IRR (%) | CO2 Saving t/CO2 | Reduction in Grid Electricity (%) | Increase in Gas Consumption (%) | QI |

|---|---|---|---|---|---|---|---|---|---|---|

| −20 | 110 | 7873 | 5119 | 4.9 | 507,120 | 24 | 226 | 77.91 | 25.54 | 128 |

| −15 | 110 | 8273 | 5643 | 5.2 | 458,415 | 22 | 242 | 78.17 | 25.36 | 128 |

| −10 | 110 | 8474 | 5896 | 5.6 | 401,754 | 20 | 255 | 77.28 | 24.93 | 128 |

| 0 | 122 | 8512 | 5896 | 6.77 | 293,574 | 17 | 281 | 77 | 25 | 128 |

| +10 | 122 | 8635 | 6438 | 8.7 | 169,902 | 12 | 299 | 74.43 | 24.16 | 128 |

| +15 | 135 | 8626 | 6192 | 10.6 | 104,443 | 9 | 322 | 76.71 | 24.87 | 129 |

| +20 | 135 | 8635 | 6382 | 12.6 | 40,558 | 7 | 329 | 75.05 | 24.27 | 129 |

| −10% | Gas Cost Now | 10% | 20% | 30% | 40% | |

|---|---|---|---|---|---|---|

| −10% | 7.8 | 8.7 | 9.8 | 11.1 | 12.8 | 14.9 |

| Electricity cost now | 6.2 | 6.7 | 7.4 | 8.2 | 9.2 | 10.4 |

| 10% | 5.0 | 5.4 | 5.9 | 6.5 | 7.1 | 7.8 |

| 20% | 4.1 | 4.5 | 4.8 | 5.2 | 5.7 | 6.2 |

| 30% | 3.5 | 3.7 | 4.0 | 4.3 | 4.6 | 5.0 |

| 40% | 3.0 | 3.2 | 3.4 | 3.6 | 3.9 | 4.2 |

| 50% | 2.5 | 2.7 | 2.9 | 3.1 | 3.3 | 3.5 |

| Variable | R | R2 |

|---|---|---|

| Fuel price | 0.33 | 0.10856 |

| Day electricity price | −0.87 | 0.75490 |

| Night electricity price | −0.17 | 0.02838 |

| CRC allowance price | −0.16 | 0.02716 |

| VAT, % for electricity | −0.02 | 0.00053 |

| VAT, % for fuel | 0.01 | 0.00005 |

| O & M Cost | −0.01 | 0.00003 |

| CCL rate for fuel | 0.04 | 0.00148 |

| CCL rate for electricity | −0.06 | 0.00348 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amber, K.P.; Day, A.R.; Ratyal, N.I.; Ahmad, R.; Amar, M. The Significance of a Building’s Energy Consumption Profiles for the Optimum Sizing of a Combined Heat and Power (CHP) System—A Case Study for a Student Residence Hall. Sustainability 2018, 10, 2069. https://doi.org/10.3390/su10062069

Amber KP, Day AR, Ratyal NI, Ahmad R, Amar M. The Significance of a Building’s Energy Consumption Profiles for the Optimum Sizing of a Combined Heat and Power (CHP) System—A Case Study for a Student Residence Hall. Sustainability. 2018; 10(6):2069. https://doi.org/10.3390/su10062069

Chicago/Turabian StyleAmber, Khuram Pervez, Antony R. Day, Naeem Iqbal Ratyal, Rizwan Ahmad, and Muhammad Amar. 2018. "The Significance of a Building’s Energy Consumption Profiles for the Optimum Sizing of a Combined Heat and Power (CHP) System—A Case Study for a Student Residence Hall" Sustainability 10, no. 6: 2069. https://doi.org/10.3390/su10062069

APA StyleAmber, K. P., Day, A. R., Ratyal, N. I., Ahmad, R., & Amar, M. (2018). The Significance of a Building’s Energy Consumption Profiles for the Optimum Sizing of a Combined Heat and Power (CHP) System—A Case Study for a Student Residence Hall. Sustainability, 10(6), 2069. https://doi.org/10.3390/su10062069