Probabilistic Generalization of a Comprehensive Model for the Deterioration Prediction of RC Structure under Extreme Corrosion Environments

Abstract

:1. Introduction

2. Review of the Reliability Model of Combined Deterioration

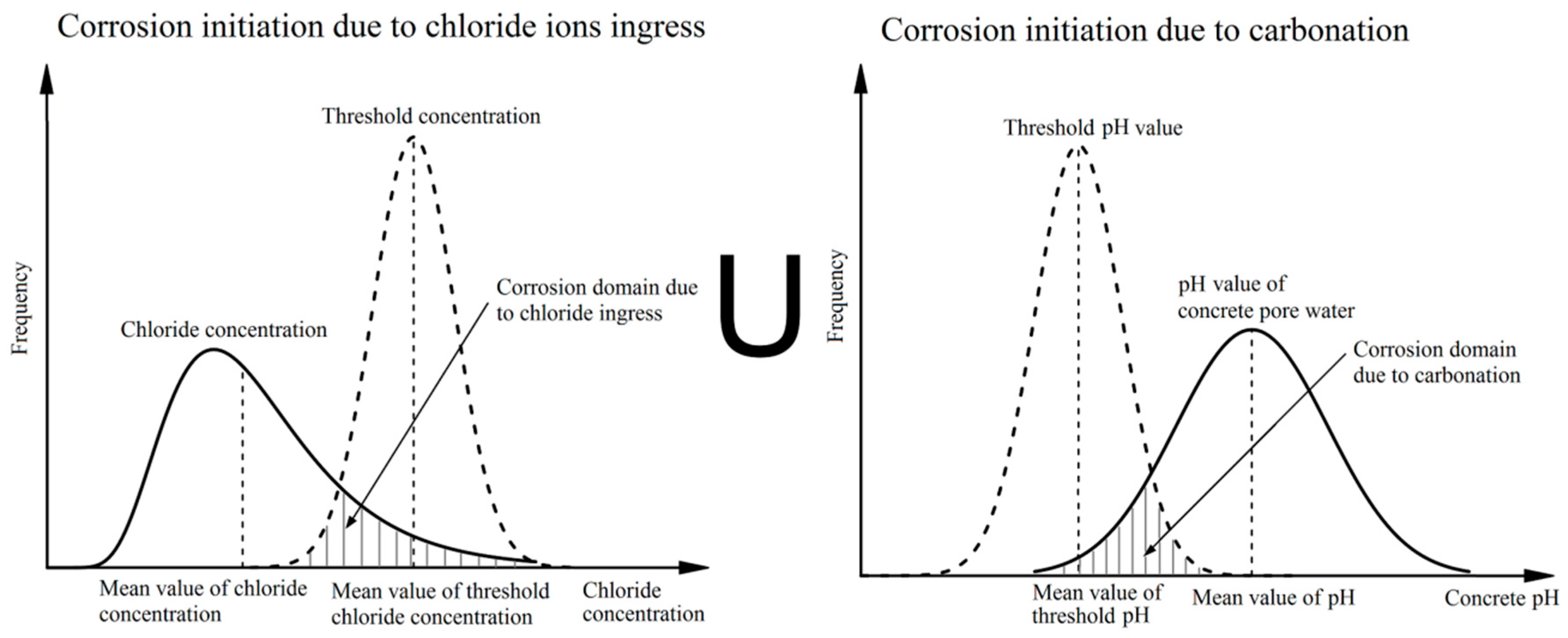

2.1. Governing Equation and Limit State Functions

2.2. Reduced Number of Random Variables

3. Other Further Improvements for the Probabilistic Model of Combined Durability

3.1. Single Limit State Function

3.2. Simplification for the Algorithm of Conventional Solution Procedure

3.3. Response Surface Method

- The probability of corrosion initiation of a reference specimen is calculated using the Monte Carlo method.

- The Monte Carlo result for the above reference specimen is used to build a response surface.

- By changing the mean value of reach random variable, the probabilities of corrosion initiation in other specimens can be calculated by the above mentioned response surface.

4. Semi-Empirical Approach for the Probabilistic Study of Combined Durability

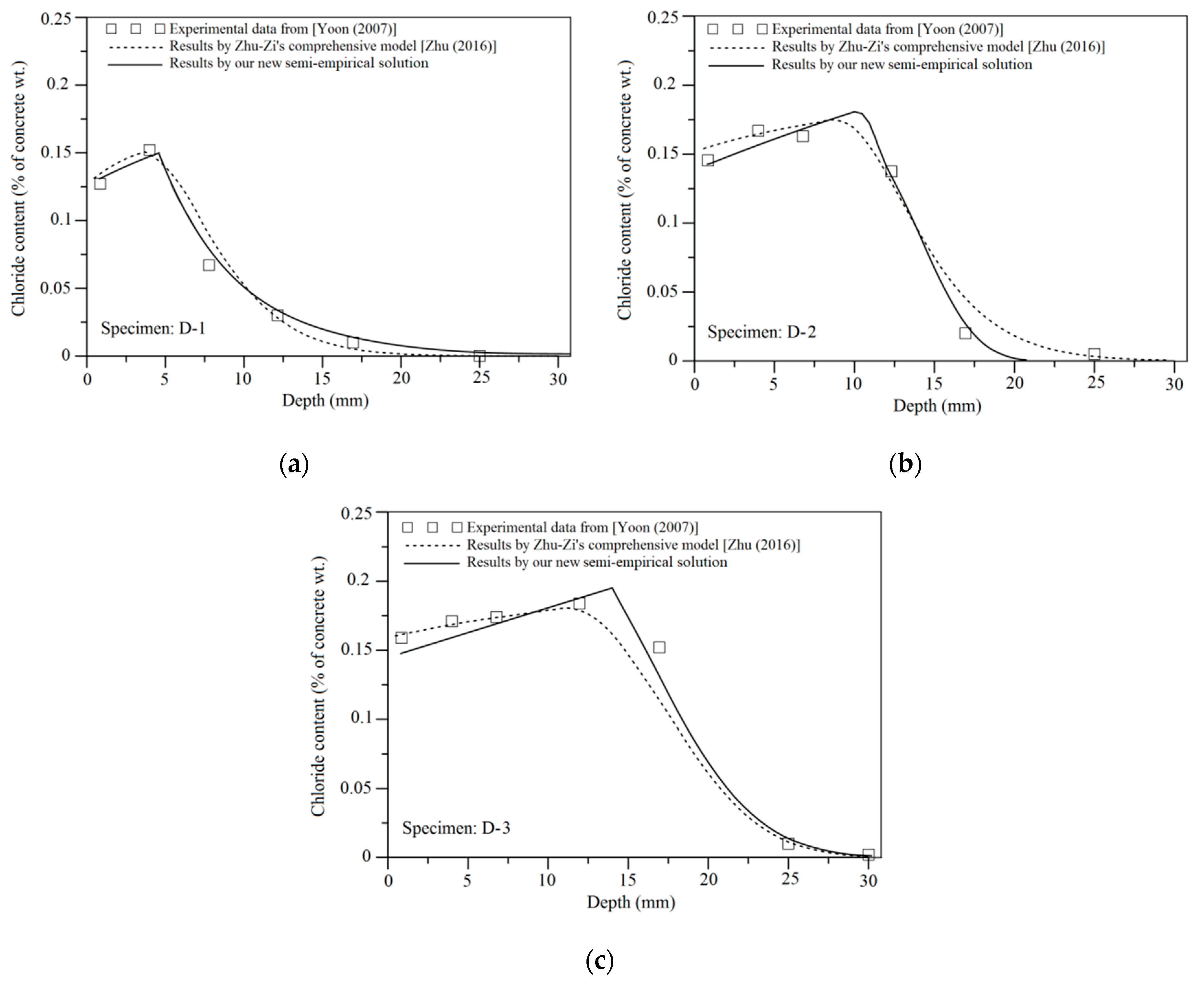

4.1. Concentration Distribution of Free Chloride ions Considering Carbonation

4.2. Experimental Verification and Comparison with the Comprehensive Combined Model for the Semi-Empirical Solution

4.3. Probability Calculation

5. Illustrative Example and Parametric Study

5.1. Problem Description

5.2. Result Discussion

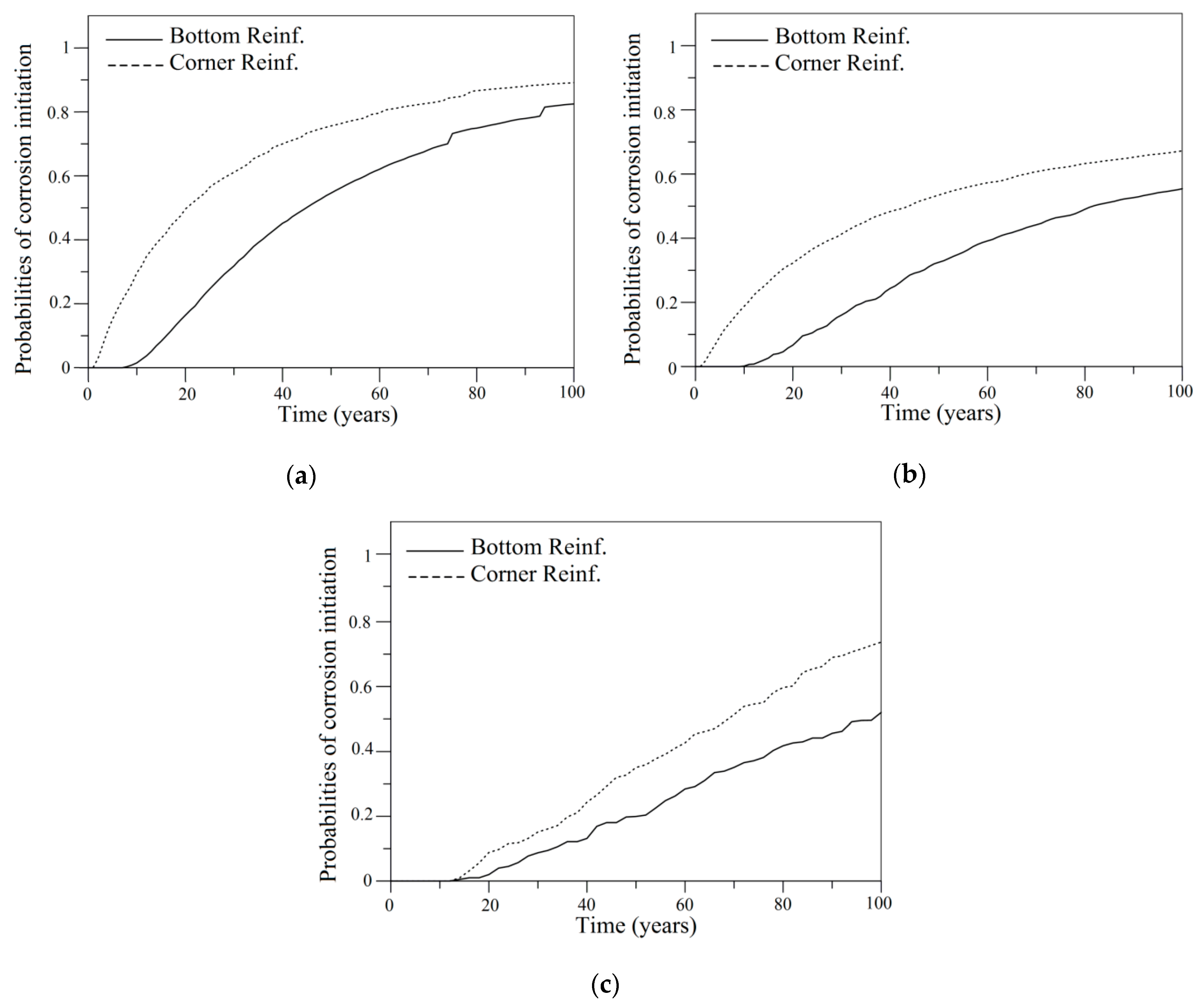

5.2.1. Probability

5.2.2. Effect of Reducing Limit State Functions

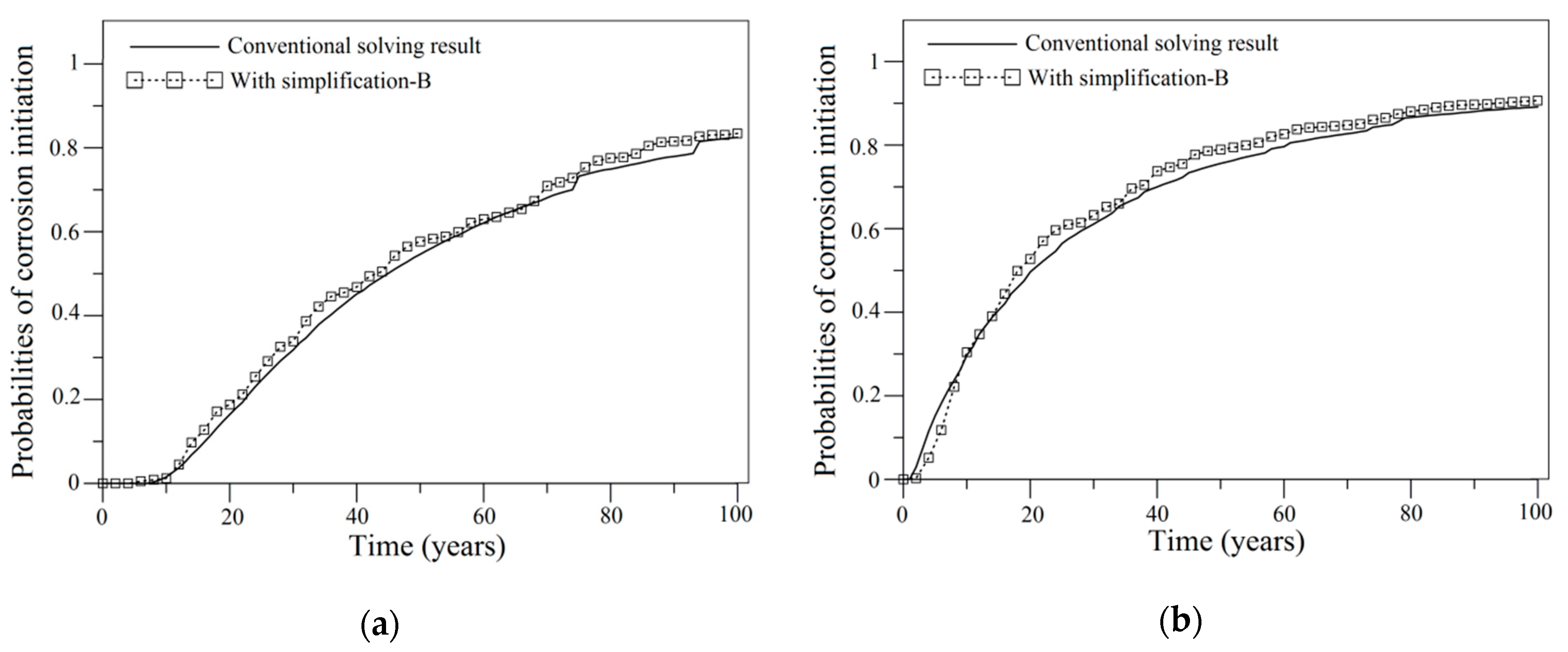

5.2.3. Effect of Simplified Solution Procedure

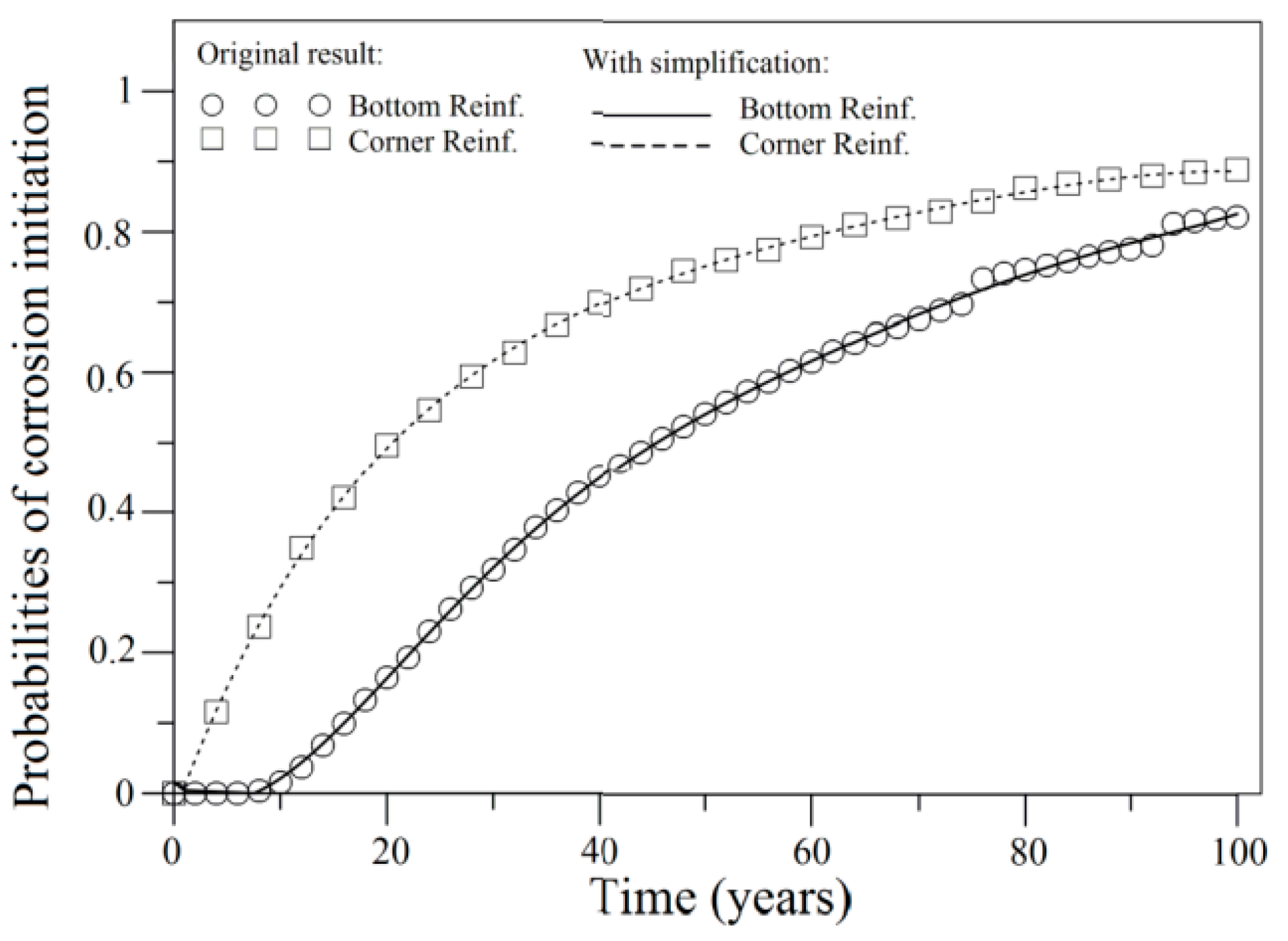

5.2.4. Application of the Response Surface Method

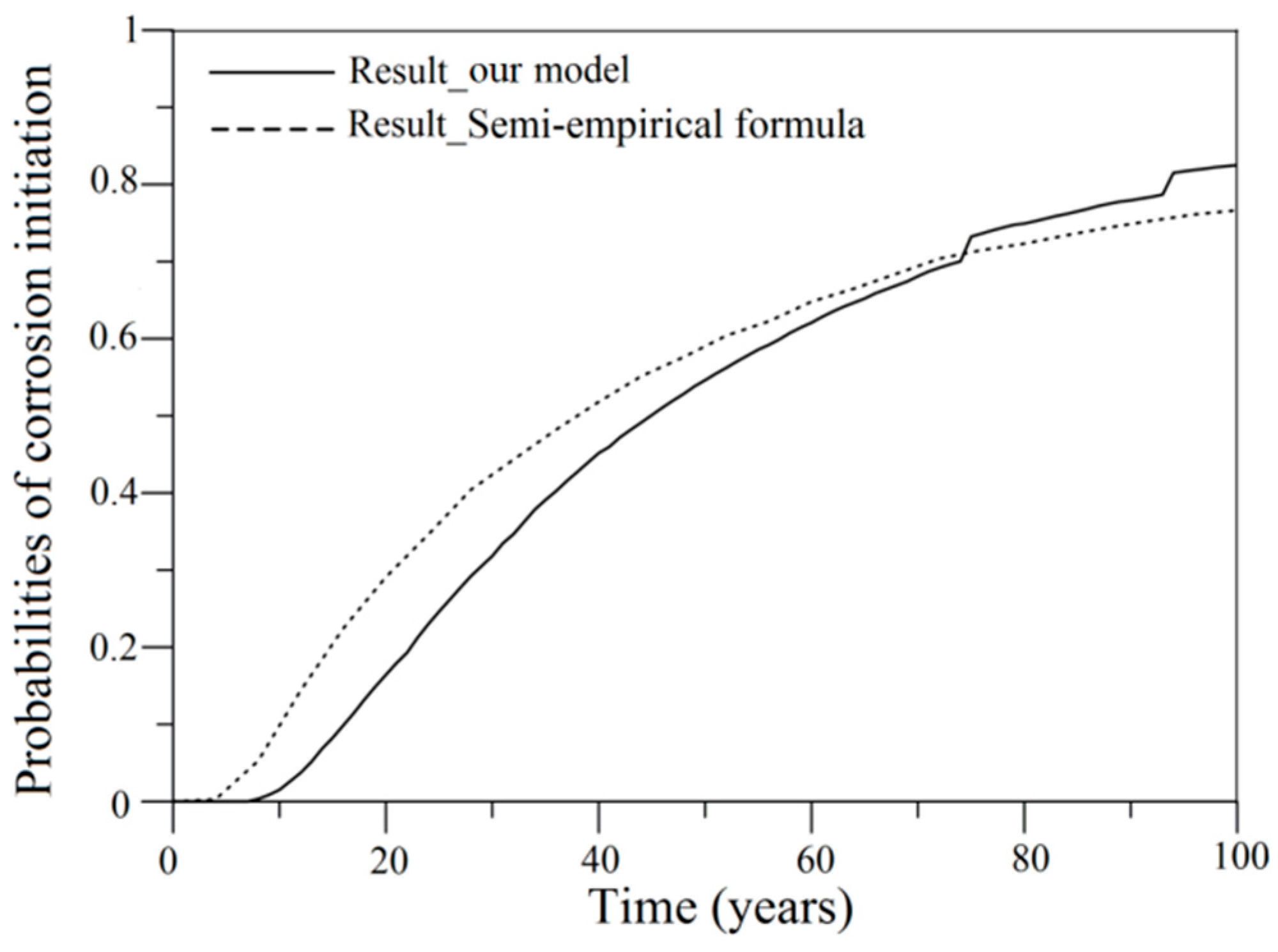

5.2.5. Discussion for the Semi-Empirical Probabilistic Model

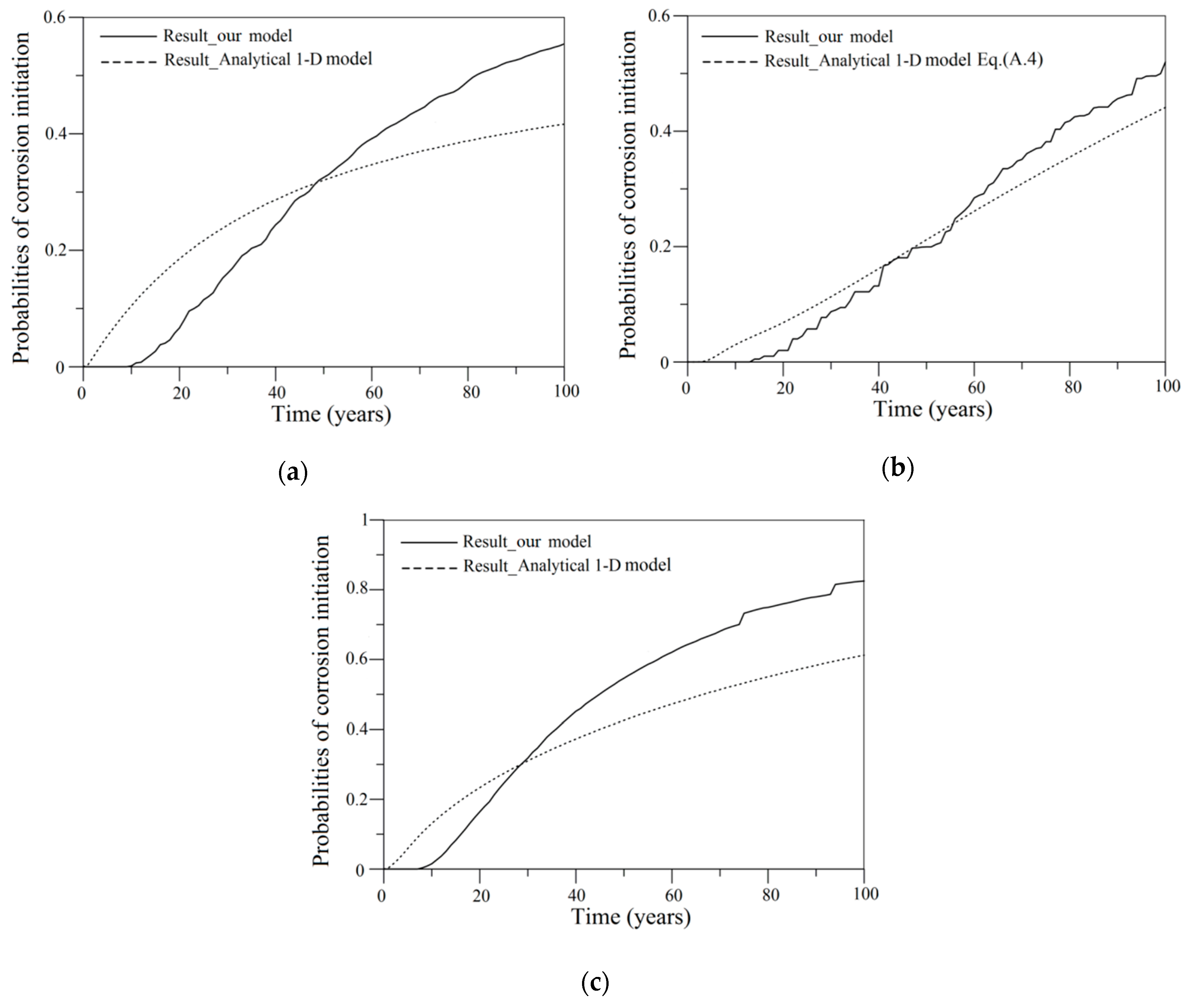

5.2.6. Comparison with the Conventional One-Dimensional Solution

6. Conclusions

- A comprehensive model is reviewed to calculate the reliability of corrosion deterioration due to carbonation, chloride penetration, and their combined effect.

- Two simplified approaches for the solution procedure of this probabilistic model are provided.

- A semi-empirical method is developed to approximately predict the concentration distribution of chloride ions, and swiftly calculate the probability of combined deterioration.

- Comparison to the original non-simplified model shows that all of these improved approaches can greatly simplify the computational cost, and that the accuracies are acceptable.

Author Contributions

Funding

Conflicts of Interest

Appendix A. Mechanism of Chemical Link between Carbonation and Chloride Movement

Appendix B. Calculation of Average Error e

References

- Böhni, H. (Ed.) Corrosion in Reinforced Concrete Structures; Woodhead Publishing: Oxford, UK, 2005. [Google Scholar]

- Bazant, Z.P. Physical model for steel corrosion in concrete sea structures-theory. ASCE J. Struct. Div. 1979, 105, 1137–1153. [Google Scholar]

- Safehian, M.; Ramezanianpour, A.A. Prediction of RC structure service life from field long term chloride diffusion. Comput. Concr. 2015, 15, 589–606. [Google Scholar] [CrossRef]

- Kwon, S.J.; Kim, S.C. Concrete mix design for service life of RC structures exposed to chloride attack. Comput. Concr. 2012, 10, 587–607. [Google Scholar] [CrossRef]

- Ho, D.W.S.; Lewis, R.K. Carbonation of concrete and its prediction. Cem. Concr. Res. 1987, 17, 489–504. [Google Scholar] [CrossRef]

- Demis, S.; Papadakis, V. Software-assisted comparative assessment of the effect of cement type on concrete carbonation and chloride ingress. Comput. Concr. 2012, 10, 391–407. [Google Scholar] [CrossRef]

- Na, O.; Cai, X.; Xi, Y. Corrosion prediction with parallel finite element modeling for coupled hygro-chemo transport into concrete under chloride-rich environment. Materials 2017, 10, 350. [Google Scholar] [CrossRef] [PubMed]

- Isteita, M.; Xi, Y. The effect of temperature variation on chloride penetration in concrete. Constr. Build. Mater. 2017, 156, 73–82. [Google Scholar] [CrossRef]

- Homan, L.; Ababneh, A.; Xi, Y. The effect of moisture transport on chloride penetration in concrete. Constr. Build. Mater. 2016, 125, 1189–1195. [Google Scholar] [CrossRef] [Green Version]

- Ozbolt, J.; Orsanic, F.; Balabanic, G.; Kuster, M. Modeling damage in concrete caused by corrosion of reinforcement: Coupled 3D FE model. Int. J. Fract. 2012, 178, 233–244. [Google Scholar] [CrossRef]

- Ozbolt, J.; Balabanic, G.; Kuster, M. 3D Numerical modelling of steel corrosion in concrete structures. Corros. Sci. 2011, 53, 4166–4177. [Google Scholar] [CrossRef]

- Cao, C.; Cheung, M.; Chan, B. Modelling of interaction between corrosion-induced concrete cover crack and steel corrosion rate. Corros. Sci. 2013, 69, 97–109. [Google Scholar] [CrossRef]

- Pantazopoulou, S.; Papoulia, K. Modeling cover-cracking due to reinforcement corrosion in RC structures. J. Eng. Mech.-ASCE 2001, 127, 342–351. [Google Scholar] [CrossRef]

- Zhu, X.; Zi, G. A 2D mechano-chemical model for the simulation of reinforcement corrosion and concrete damage. Constr. Build. Mater. 2017, 137, 330–344. [Google Scholar] [CrossRef]

- Saassouh, B.; Lounis, Z. Probabilistic modeling of chloride-induced corrosion in concrete structures using first-and second-order reliability methods. Cem. Concr. Comp. 2012, 34, 1082–1093. [Google Scholar] [CrossRef]

- Shin, K.; Kim, J.; Lee, K. Probability-based durability design software for concrete structures subjected to chloride exposed environments. Comput. Concr. 2011, 8, 511–524. [Google Scholar] [CrossRef]

- Kong, J.; Ababneh, A.; Frangopol, D.; Xi, Y. Reliability analysis of chloride penetration in saturated concrete. Probabl. Eng. Mech. 2002, 17, 305–315. [Google Scholar] [CrossRef]

- Stewart, M.; Mullard, J. Spatial time-dependent reliability analysis of corrosion damage and the timing of first repair for RC structures. Eng. Struct. 2007, 29, 1457–1464. [Google Scholar] [CrossRef]

- Stewart, M.; Suo, Q. Extent of spatially variable corrosion damage as an indicator of strength and time-dependent reliability of RC beams. Eng. Struct. 2009, 31, 198–207. [Google Scholar] [CrossRef]

- Ryan, P.; O’Connor, A. Probabilistic analysis of the time to chloride induced corrosion for different self-compacting concretes. Constr. Build. Mater. 2013, 47, 1106–1116. [Google Scholar] [CrossRef]

- Nogueira, C.; Leonel, E. Probabilistic models applied to safety assessment of reinforced concrete structures subjected to chloride ingress. Eng. Fail. Anal. 2013, 31, 76–89. [Google Scholar] [CrossRef]

- Strauss, A.; Wendner, R.; Bergmeister, K.; Costa, C. Numerically and experimentally based reliability assessment of a concrete bridge subjected to chloride-induced deterioration. J. Infrastruct. Syst. 2012, 19, 166–175. [Google Scholar] [CrossRef]

- Val, D.; Trapper, P. Probabilistic evaluation of initiation time of chloride-induced corrosion. Reliab. Eng. Syst. Saf. 2008, 93, 364–372. [Google Scholar] [CrossRef]

- Saetta, A.; Scotta, R.; Vitaliani, R. Analysis of chloride diffusion into partially saturated concrete. ACI Mater. J. 1993, 90, 441–451. [Google Scholar]

- Suo, Q.; Stewart, M. Corrosion cracking prediction updating of deteriorating RC structures using inspection information. Reliab. Eng. Syst. Saf. 2009, 94, 1340–1348. [Google Scholar] [CrossRef]

- Bastidas-Arteaga, E.; Schoefs, F.; Stewart, M.; Wang, X. Influence of global warming on durability of corroding RC structures: A probabilistic approach. Eng. Struct. 2013, 51, 259–266. [Google Scholar] [CrossRef] [Green Version]

- Duprat, F.; Vu, N.; Sellier, A. Accelerated carbonation tests for the probabilistic prediction of the durability of concrete structures. Constr. Build. Mater. 2014, 66, 597–605. [Google Scholar] [CrossRef]

- Duprat, F.; Vu, N. Probabilistic threshold for the onset of carbonation-induced corrosion. Eur. J. Environ. Civ. Eng. 2013, 17, 478–495. [Google Scholar] [CrossRef]

- Lollini, F.; Redaelli, E.; Bertolini, L. Analysis of the parameters affecting probabilistic predictions of initiation time for carbonation-induced corrosion of reinforced concrete structures. Mater. Corros. 2012, 63, 1059–1068. [Google Scholar] [CrossRef]

- Mai-Nhu, J.; Sellier, A.; Duprat, F.; Rougeau, P.; Caprad, B.; Hyvert, N.; Francisco, P. Probabilistic approach for durable design of concrete cover: Application to carbonation. Eur. J. Environ. Civ. Eng. 2012, 16, 264–272. [Google Scholar] [CrossRef]

- Huang, T. The Experimental Research on the Interaction between Concrete Carbonation and Chloride Ingress under Loading. Master’s Thesis, Zhejiang University, Hangzhou, China, 2013. [Google Scholar]

- Zhu, X.J.; Zi, G.; Cao, Z.; Cheng, X. Combined effect of carbonation and chloride ingress in concrete. Constr. Build. Mater. 2016, 110, 369–380. [Google Scholar] [CrossRef]

- Zhu, X.J.; Kim, S.; Kwak, D.; Bea, K.; Zi, G. Parametric analysis for the simultaneous carbonation and chloride ion penetration in reinforced con crete sections. J. Korea Inst. Struct. Maint. Insp. 2016, 20, 66–74. [Google Scholar]

- Lee, M.; Jung, S.; Oh, B. Effects of carbonation on chloride penetration in concrete. ACI Mater. J. 2013, 110, 559–566. [Google Scholar] [CrossRef]

- Backus, J.; Mcpolin, D.; Basheer, M.; Long, A.; Holmes, N. Exposure of mortars to cyclic chloride ingress and carbonation. Adv. Cem. Res. 2013, 25, 3–11. [Google Scholar] [CrossRef] [Green Version]

- Tumidajski, P.; Chan, G. Effect of sulfate and carbon dioxide on chloride diffusivity. Cem. Concr. Res. 1996, 26, 551–556. [Google Scholar] [CrossRef]

- Yoon, I. Simple approach to calculate chloride diffusivity of concrete considering carbonation. Comput. Concr. 2009, 6, 1–18. [Google Scholar] [CrossRef]

- Yoon, I. Deterioration of concrete due to combined reaction of carbonation and chloride penetration: Experimental study. Key Eng. Mater. 2007, 348–349, 729–732. [Google Scholar] [CrossRef]

- Yoon, I. Simple approach for computing chloride diffusivity of (non)carbonated concrete. Key Eng. Mater. 2008, 385–387, 281–284. [Google Scholar] [CrossRef]

- Yuan, C.; Niu, D.; Luo, D. Effect of carbonation on chloride diffusion in fly ash concrete. Disaster Adv. 2012, 5, 433–436. [Google Scholar]

- Delnavaz, A.; Ramezanianpour, A. The assessment of carbonation effect on chloride diffusion in concrete based on artificial neural network model. Mag. Concr. Res. 2012, 64, 877–884. [Google Scholar] [CrossRef]

- Ngala, V.; Page, C. Effects of carbonation on pore structure and diffusional properties of hydrated cement pastes. Cem. Concr. Res. 1997, 27, 995–1007. [Google Scholar] [CrossRef]

- CEB-FIP. Fib Model Code for Concrete Structures; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2010. [Google Scholar]

- Zhang, S.; Zhao, B. Research on chloride ion diffusivity of concrete subjected to CO2 environment. Comput. Concr. 2015, 15, 589–606. [Google Scholar]

- Zhu, X.J.; Zi, G.; Lee, W.; Kim, S.; Kong, J. Probabilistic analysis of reinforcement corrosion due to the combined action of carbonation and chloride ingress in concrete. Constr. Build. Mater. 2016, 124, 667–680. [Google Scholar] [CrossRef]

- Ghanem, R.; Spanos, P. Stochastic Finite Elements: A Spectral Approach; Springer: New York, NY, USA, 1991; pp. 15–36. [Google Scholar]

- Xiu, D. Numerical Methods for Stochastic Computations: A Spectral Method Approach; Princeton University Press: Princeton, NJ, USA, 1991; pp. 33–45. [Google Scholar]

- Bazant, Z.P.; Liu, K. Random creep and shrinkage in structures: Sampling. J. Struct. Eng. ASCE 1985, 111, 1113–1134. [Google Scholar] [CrossRef]

- Papadakis, V.; Vayenas, C.; Fardis, M. Fundamental modeling and experimental investigation of concrete carbonation. ACI Mater. J. 1991, 88, 363–373. [Google Scholar]

- Papadakis, V.; Vayenas, C.; Fardis, M. Experimental investigation and mathematical modeling of the concrete carbonation problem. Chem. Eng. Sci. 1991, 46, 1333–1338. [Google Scholar] [CrossRef]

- Angst, U.; Elsener, B.; Larsen, C.; Vennesland, Ø. Critical chloride content in reinforced concrete—A review. Cem. Concr. Res. 2009, 39, 1122–1138. [Google Scholar] [CrossRef]

- Söylev, T.; François, R. Corrosion of reinforcement in relation to presence of defects at the interface between steel and concrete. J. Mater. Civ. Eng. 2005, 17, 447–455. [Google Scholar] [CrossRef]

- Shi, J.; Ming, J. Influence of defects at the steel-mortar interface on the corrosion behaviour of steel. Constr. Build. Mater. 2017, 136, 118–125. [Google Scholar] [CrossRef]

- Horne, T.; Richardson, I.; Brydson, R. Quantitative analysis of the microstructure of interfaces in steel reinforced concrete. Cem. Concr. Res. 2007, 37, 1613–1623. [Google Scholar] [CrossRef]

- Angst, U.; Elsener, B.; Larsen, C.; Vennesland, Ø. Chloride induced reinforcement corrosion: Electrochemical monitoring of initiation stage and chloride threshold values. Corros. Sci. 2011, 53, 1451–1464. [Google Scholar] [CrossRef]

- Zhang, R.; François, R.; Castel, A. Influence of steel-concrete interface defects owing to the top-bar effect on the chloride-induced corrosion of reinforcement. Mag. Concr. Res. 2011, 63, 773–781. [Google Scholar] [CrossRef]

| Variable | Mean Value | COV | Distribution |

|---|---|---|---|

| Cfc,b | 0.75% binder w. t. | 0.2 | Log-Normal |

| CCO2,b | 0.02 mol/m3 of pore air | 0.1 | Normal |

| Cfc,th | 0.4% binder w. t. | 0.2 | Normal |

| ct | 40 mm | 0.2 | Normal |

| Dfc,ref | 6.5 × 10−12 m2/s | 0.2 | Log-Normal |

| ϕhc,0 | 0.5 | 0.3 | Normal |

| [CCaO]0 | 3000 mol/m3 of concrete | 0.05 | Normal |

| d | 0.9 | 0.05 | Normal |

| kϕ | 0.2 | 0.1 | Normal |

| Mix Proportions | Specimen | |||||

|---|---|---|---|---|---|---|

| FAC-1 (Ref.) | OPC-1 | OPC-2 | OPC-3 | FAC-2 | FAC-3 | |

| w/b | 0.45 | 0.35 | 0.35 | 0.55 | 0.45 | 0.45 |

| a/b | 4 | 4 | 6 | 4 | 4 | 4 |

| FA | 0.1 | 0 | 0 | 0 | 0.2 | 0.3 |

| Variable | Mean Value | COV | Distribution |

|---|---|---|---|

| Cfc,b | 0.75% binder w. t. | 0.2 | Log-Normal |

| CCO2,b | 0.02 mol/m3 of pore air | 0.1 | Normal |

| Cfc,th | 0.4% binder w. t. | 0.2 | Normal |

| ct | 40 mm | 0.2 | Normal |

| Dfc,ref | 6.5 × 10−12 m2/s | 0.2 | Log-Normal |

| DCO2 | 3 × 10−8 m2/s | 0.2 | Log-Normal |

| [CCaO]0 | 3000 mol/m3 of concrete | 0.05 | Normal |

| βc | 0.15 | 0.1 | Normal |

| cpar | 15 mm | 0.05 | Normal |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Chen, Z.; Wang, H.; Chen, Y.; Xu, L. Probabilistic Generalization of a Comprehensive Model for the Deterioration Prediction of RC Structure under Extreme Corrosion Environments. Sustainability 2018, 10, 3051. https://doi.org/10.3390/su10093051

Zhu X, Chen Z, Wang H, Chen Y, Xu L. Probabilistic Generalization of a Comprehensive Model for the Deterioration Prediction of RC Structure under Extreme Corrosion Environments. Sustainability. 2018; 10(9):3051. https://doi.org/10.3390/su10093051

Chicago/Turabian StyleZhu, Xingji, Zaixian Chen, Hao Wang, Yabin Chen, and Longjun Xu. 2018. "Probabilistic Generalization of a Comprehensive Model for the Deterioration Prediction of RC Structure under Extreme Corrosion Environments" Sustainability 10, no. 9: 3051. https://doi.org/10.3390/su10093051