A Model for External Walls Selection in Hot and Humid Climates

Abstract

:1. Introduction

- What evaluation criterion and methods of assessment should be incorporated in a model for selection of the optimal wall constructions in hot and humid climate?

- What systematic approach and methodology should architects follow for employing suitable wall constructions in hot and humid climate?

- How local construction techniques and materials influence selecting optimal wall constructions for maximum efficiency?

2. Evaluation Criterion Methods of Assessment

2.1. Energy Efficiency

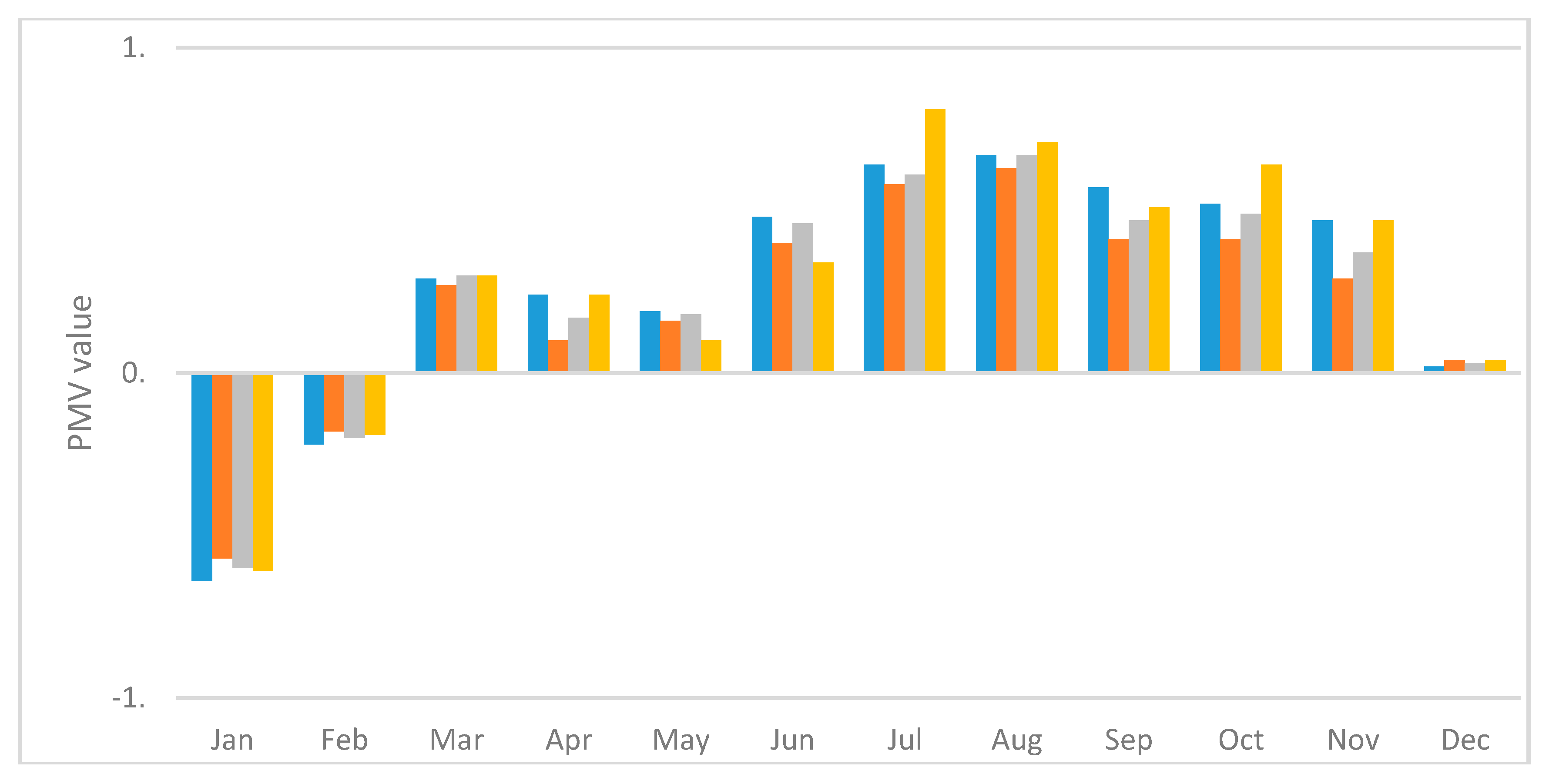

2.2. Thermal Comfort

2.3. Moisture Control

2.4. Cost Efficiency

2.5. Multi-Criteria Evaluation

3. Methodology

3.1. Context Climate Analysis

Defining Active and Passive Design Strategies

3.2. Field Survey

3.3. Localization

- Provide guidance for facilitating and matching the calculation method of the thermal insulation of the building envelope in accordance with the necessities;

- Adding technical data and numerical values needed to calculate the types of thermal bridges in the building external walls;

- Completion of the thermal data related to the materials and products used in the current construction of the country, as well as new products such as multilayered walls, passive wall systems, energy efficient coatings and, etc., to improve the thermal performance of the external walls of the buildings;

- Lack of high level aims and objectives, addressing the characteristics of Iranian buildings;

- Non-separation of rules for buildings in different climatic condition of the country;

- Failure to implement thermal comfort strategies and lack of consideration on user comfort condition.

3.4. Simulation Process

3.4.1. Inputs Setting

3.4.2. Results Validation

3.4.3. Case Study Selection

4. Final Assessment

4.1. Results

4.2. Discussion

5. Conclusions

- What evaluation criterion and methods of assessment should be incorporated in a model for selection of the optimal wall constructions in hot and humid climate?

- What systematic approach and methodology should architects follow for employing suitable wall constructions in hot and humid climate?

- How local construction techniques and materials influence selecting optimal wall constructions for maximum efficiency?

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 9, 2265–2300. [Google Scholar] [CrossRef]

- Cena, K.; de Dear, R. Thermal comfort and behavioural strategies in office buildings located in a hot-arid climate. J. Therm. Biol. 2001, 26, 409–414. [Google Scholar] [CrossRef]

- Sozer, H. Improving energy efficiency through the design of the building envelope. Build. Environ. 2010, 45, 2581–2593. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive building energy savings: A review of building envelope components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Friess, W.A.; Rakhshan, K. A review of passive envelope measures for improved building energy efficiency in the UAE. Renew. Sustain. Energy Rev. 2017, 72, 485–496. [Google Scholar] [CrossRef]

- Ozel, M. Effect of insulation location on dynamic heat-transfer characteristics of building external walls and optimization of insulation thickness. Energy Build. 2014, 72, 288–295. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M.; Fazio, A.; Laforgia, D. Multi-objective optimization analysis for high efficiency external walls of zero energy buildings (ZEB) in the Mediterranean climate. Energy Build. 2014, 84, 483–492. [Google Scholar] [CrossRef]

- Hudobivnik, B.; Pajek, L.; Kunič, R.; Košir, M. FEM thermal performance analysis of multi-layer external walls during typical summer conditions considering high intensity passive cooling. Appl. Energy 2016, 178, 363–375. [Google Scholar] [CrossRef]

- Vollaro, R.D.L.; Guattari, C.; Evangelisti, L.; Battista, G.; Carnielo, E.; Gori, P. Building energy performance analysis: A case study. Energy Build. 2015, 87, 87–94. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M. High performance precast external walls for cold climate by a multi-criteria methodology. Energy 2016, 115, 561–576. [Google Scholar] [CrossRef]

- Wang, B.L.; Takigawa, T.; Yamasaki, Y.; Sakano, N.; Wang, D.H.; Ogino, K. Symptom definitions for SBS (sick building syndrome) in residential dwellings. Int. J. Hyg. Environ. Health 2008, 211, 114–120. [Google Scholar] [CrossRef] [PubMed]

- Yao, R.; Costanzo, V.; Li, X.; Zhang, Q.; Li, B. The effect of passive measures on thermal comfort and energy conservation. A case study of the hot summer and cold winter climate in the Yangtze River region. J. Build. Eng. 2018, 15, 298–310. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Ushak, S.; Cabeza, L.F. Passive cooling of buildings with phase change materials using whole-building energy simulation tools: A review. Renew. Sustain. Energy Rev. 2017, 80, 1239–1255. [Google Scholar] [CrossRef]

- Pisello, A.L.; D’Alessandro, A.; Sambuco, S.; Rallini, M.; Ubertini, F.; Asdrubali, F.; Cotana, F. Multipurpose experimental characterization of smart nanocomposite cement-based materials for thermal-energy efficiency and strain-sensing capability. Sol. Mater. 2017, 161, 77–88. [Google Scholar] [CrossRef]

- Wu, F.; Zhu, J. Study on the construction of the database of energy-saving building wall’s thermal performance in Hangzhou. Energy 2012, 14, 943–948. [Google Scholar] [CrossRef]

- Radhi, H. Viability of autoclaved aerated concrete walls for the residential sector in the United Arab Emirates. Energy Build. 2011, 43, 2086–2092. [Google Scholar] [CrossRef]

- Abanto, G.A.; Karkri, M.; Lefebvre, G.; Horn, M.; Solis, J.L.; Gómez, M.M. Thermal properties of adobe employed in Peruvian rural areas: Experimental results and numerical simulation of a traditional bio-composite material. Case Stud. Constr. Mater. 2017, 6, 177–191. [Google Scholar] [CrossRef]

- Sambou, V.; Lartigue, B.; Monchoux, F.; Adj, M. Thermal optimization of multilayered walls using genetic algorithms. Energy Build. 2009, 41, 1031–1036. [Google Scholar] [CrossRef]

- Stazi, F.; Vegliò, A.; Di Perna, C.; Munafò, P. Experimental comparison between 3 different traditional wall constructions and dynamic simulations to identify optimal thermal insulation strategies. Energy Build. 2013, 60, 429–441. [Google Scholar] [CrossRef]

- Hens, H.; Janssens, A.; Depraetere, W.; Carmeliet, J.; Lecompte, J. Brick cavity walls: A performance analysis based on measurements and simulations. J. Build. Phys. 2007, 31, 95–124. [Google Scholar] [CrossRef]

- Ozel, M. Influence of glazing area on optimum thickness of insulation for different wall orientations. Appl. Therm. Eng. 2019, 147, 770–780. [Google Scholar] [CrossRef]

- Ozel, M.; Pihtili, K. Optimum location and distribution of insulation layers on building walls with various orientations. Build. Environ. 2007, 42, 3051–3059. [Google Scholar] [CrossRef]

- Pekdogan, T.; Basaran, T. Thermal performance of different exterior wall structures based on wall orientation. Appl. Therm. Eng. 2017, 112, 15–24. [Google Scholar] [CrossRef]

- Asan, H. Investigation of wall’s optimum insulation position from maximum time lag and minimum decrement factor point of view. Energy Build. 2000, 32, 197–203. [Google Scholar] [CrossRef]

- Bond, D.E.; Clark, W.W.; Kimber, M. Configuring wall layers for improved insulation performance. Appl. Energy 2013, 112, 235–245. [Google Scholar] [CrossRef]

- Hansen, T.K.; Bjarløv, S.P.; Peuhkuri, R.H.; Harrestrup, M. Long term in situ measurements of hygrothermal conditions at critical points in four cases of internally insulated historic solid masonry walls. Energy Build. 2018, 172, 235–248. [Google Scholar] [CrossRef]

- Halawa, E.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Trombley, J.; Hassan, N.; Baig, M.; Ismail, M.A. A review on energy conscious designs of building façades in hot and humid climates: Lessons for (and from) Kuala Lumpur and Darwin. Renew. Sustain. Energy Rev. 2018, 82, 2147–2161. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Hasan, A. Optimizing insulation thickness for buildings using life cycle cost. Appl. Energy 1999, 63, 115–124. [Google Scholar] [CrossRef]

- Kaynakli, O. A review of the economical and optimum thermal insulation thickness for building applications. Renew. Sustain. Energy Rev. 2012, 16, 415–425. [Google Scholar] [CrossRef]

- Bolattürk, A. Determination of optimum insulation thickness for building walls with respect to various fuels and climate zones in Turkey. Appl. Therm. Eng. 2006, 26, 1301–1309. [Google Scholar] [CrossRef]

- Dylewski, R.; Adamczyk, J. Economic and environmental benefits of thermal insulation of building external walls. Build. Environ. 2011, 46, 2615–2623. [Google Scholar] [CrossRef]

- Özel, G.; Açıkkalp, E.; Görgün, B.; Yamık, H.; Caner, N. Optimum insulation thickness determination using the environmental and life cycle cost analyses based entransy approach. Sustain. Energy Technol. Assess. 2015, 11, 87–91. [Google Scholar] [CrossRef]

- Nyers, J.; Kajtar, L.; Tomić, S.; Nyers, A. Investment-savings method for energy-economic optimization of external wall thermal insulation thickness. Energy Build. 2015, 86, 268–274. [Google Scholar] [CrossRef]

- Sun, H.; Lauriat, G.; Nicolas, X. Natural convection and wall condensation or evaporation in humid air-filled cavities subjected to wall temperature variations. Int. J. Therm. Sci. 2011, 50, 663–679. [Google Scholar] [CrossRef] [Green Version]

- Wyrwał, J.; Marynowicz, A. Vapour condensation and moisture accumulation in porous building wall. Build. Environ. 2002, 37, 313–318. [Google Scholar] [CrossRef]

- Aelenei, D.; Henriques, F.M. Analysis of the condensation risk on exterior surface of building envelopes. Energy Build. 2008, 40, 1866–1871. [Google Scholar] [CrossRef]

- Liu, J.; Aizawa, H.; Yoshino, H. CFD prediction of surface condensation on walls and its experimental validation. Build. Environ. 2004, 39, 905–911. [Google Scholar] [CrossRef]

- Vereecken, E.; Van Gelder, L.; Janssen, H.; Roels, S. Interior insulation for wall retrofitting—A probabilistic analysis of energy savings and hygrothermal risks. Energy Build. 2015, 89, 231–244. [Google Scholar] [CrossRef]

- Ibrahim, M.; Wurtz, E.; Biwole, P.H.; Achard, P.; Sallee, H. Hygrothermal performance of exterior walls covered with aerogel-based insulating rendering. Energy Build. 2014, 84, 241–251. [Google Scholar] [CrossRef]

- Bliuc, I.; Lepadatu, D.; Iacob, A.; Judele, L.; Bucur, R.D. Assessment of thermal bridges effect on energy performance and condensation risk in buildings using DoE and RSM methods. Eur. J. Environ. Civil Eng. 2017, 21, 1466–1484. [Google Scholar] [CrossRef]

- European Standards. ISO 13790, Energy Performance of Buildings–Calculation of Energy Use for Space Heating and Cooling; International Standard Organisation (ISO): Geneva, Switzerland, 2008. [Google Scholar]

- The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). Handbook of Fundamentals, American Society of Heating, Refrigeration and Air-Conditioning Engineers; ASHRAE: Atlanta, GA, USA, 2001. [Google Scholar]

- Standard 7730. Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Calculations of the PMV and PPD Indices and Local Thermal Comfort Criteria; The International Organization for Standardization (ISO): Geneva, Switzerland, 2005. [Google Scholar]

- European Standards. EN 15251, Indoor environmental input parameters for design and assessment of energy performance of buildings adressing indoor air quality. In Thermal Environment, Lighting and Acoustics; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- Lucas, F.; Adelard, L.; Garde, F.; Boyer, H. Study of moisture in buildings for hot humid climates. Energy Build. 2002, 34, 345–355. [Google Scholar] [CrossRef]

- European Standards. CEN 13788, Hygrothermal performance of building components and building elements. In Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation, Calculation Methods; European Committee for Standardization: Brussels, Belgium, 2001. [Google Scholar]

- Özdeniz, M.B.; Hançer, P. Suitable roof constructions for warm climates—Gazimağusa case. Energy Build. 2005, 37, 643–649. [Google Scholar] [CrossRef]

- Edwards, W.; Barron, F.H. SMARTS and SMARTER: Improved simple methods for multiattribute utility measurement. Organ. Behav. Hum. Decis. Proc. 1994, 60, 306–325. [Google Scholar] [CrossRef]

- Fazelpour, F.; Soltani, N.; Rosen, M.A. Feasibility of satisfying electrical energy needs with hybrid systems for a medium-size hotel on Kish Island, Iran. Energy 2014, 73, 856–865. [Google Scholar] [CrossRef]

- Climate Consultant Software. Available online: http://www.energy-design-tools.aud.ucla.edu/climate-consultant/ (accessed on 7 September 2018).

- Costanzo, V.; Donn, M. Thermal and visual comfort assessment of natural ventilated office buildings in Europe and North America. Energy Build. 2017, 140, 210–223. [Google Scholar] [CrossRef]

- Fayaz, R.; Kari, B.M. Comparison of energy conservation building codes of Iran, Turkey, Germany, China, ISO 9164 and EN 832. Appl. Energy 2009, 86, 1949–1955. [Google Scholar] [CrossRef]

- DesignBuilder. Advanced Modelling Tool for Buildings. Available online: https://www.designbuilder.co.uk/ (accessed on 7 September 2018).

- Meteonorm. Irradiation Data for Every Place on Earth. Available online: https://www.meteonorm.com/ (accessed on 7 September 2018).

- Mohammadi, A.; Saghafi, M.R.; Tahbaz, M.; Nasrollahi, F. The study of climate-responsive solutions in traditional dwellings of Bushehr City in Southern Iran. J. Build. Eng. 2018, 16, 169–183. [Google Scholar] [CrossRef]

- Reddy, B.V.; Jagadish, K.S. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Ünal, O.; Uygunoğlu, T.; Yildiz, A. Investigation of properties of low-strength lightweight concrete for thermal insulation. Build. Environ. 2007, 42, 584–590. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Hago, A.W.; Al-Nuaimi, A.S.; Al-Saidy, A.H. Concrete blocks for thermal insulation in hot climate. Cem. Concr. Res. 2005, 35, 1472–1479. [Google Scholar] [CrossRef]

- Abokhamis Mousavi, S.; Hoşkara, E.; Woosnam, K.M. Developing a Model for Sustainable Hotels in Northern Cyprus. Sustainability 2017, 9, 2101. [Google Scholar] [CrossRef]

- Yuan, J. Impact of Insulation Type and Thickness on the Dynamic Thermal Characteristics of an External Wall Structure. Sustainability 2018, 10, 2835. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. Experimental study of the hygrothermal behaviour of External Thermal Insulation Composite Systems (ETICS). Build. Environ. 2013, 63, 31–39. [Google Scholar] [CrossRef]

- Aflaki, A.; Mahyuddin, N.; Mahmoud, Z.A.C.; Baharum, M.R. A review on natural ventilation applications through building façade components and ventilation openings in tropical climates. Energy Build. 2015, 101, 153–162. [Google Scholar] [CrossRef]

- Lomas, K.J. Architectural design of an advanced naturally ventilated building form. Energy Build. 2007, 39, 166–181. [Google Scholar] [CrossRef]

- Gao, C.F.; Lee, W.L. Evaluating the influence of openings configuration on natural ventilation performance of residential units in Hong Kong. Build. Environ. 2011, 46, 961–969. [Google Scholar] [CrossRef]

- Kim, G.; Lim, H.S.; Lim, T.S.; Schaefer, L.; Kim, J.T. Comparative advantage of an exterior shading device in thermal performance for residential buildings. Energy Build. 2012, 46, 105–111. [Google Scholar] [CrossRef]

- Rosso, F.; Pisello, A.L.; Castaldo, V.L.; Ferrero, M.; Cotana, F. On Innovative Cool-Colored Materials for Building Envelopes: Balancing the Architectural Appearance and the Thermal-Energy Performance in Historical Districts. Sustainability 2017, 9, 2319. [Google Scholar] [CrossRef]

- Corgnati, S.P.; Fabrizio, E.; Filippi, M. The impact of indoor thermal conditions, system controls and building types on the building energy demand. Energy Build. 2008, 40, 627–636. [Google Scholar] [CrossRef]

- Nam, I.; Yang, J.; Lee, D.; Park, E.; Sohn, J.R. A study on the thermal comfort and clothing insulation characteristics of preschool children in Korea. Build. Environ. 2015, 92, 724–733. [Google Scholar] [CrossRef]

- Kim, J.; de Dear, R.; Parkinson, T.; Candido, C. Understanding patterns of adaptive comfort behaviour in the Sydney mixed-mode residential context. Energy Build. 2017, 141, 274–283. [Google Scholar] [CrossRef]

- O’Brien, W.; Gunay, H.B. The contextual factors contributing to occupants’ adaptive comfort behaviors in offices–A review and proposed modeling framework. Build. Environ. 2014, 77, 77–87. [Google Scholar] [CrossRef]

- Habibi, S. Micro-climatization and real-time digitalization effects on energy efficiency based on user behavior. Build. Environ. 2017, 114, 410–428. [Google Scholar] [CrossRef]

- Habibi, S. The promise of BIM for improving building performance. Energy Build. 2017, 153, 525–548. [Google Scholar] [CrossRef]

- Habibi, S. Smart innovation systems for indoor environmental quality (IEQ). J. Build. Eng. 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Masi, R.F.; Mauro, G.M.; Vanoli, G.P. Design of the building envelope: A novel multi-objective approach for the optimization of energy performance and thermal comfort. Sustainability 2015, 7, 10809–10836. [Google Scholar] [CrossRef]

| Dry Bulb Temperature (C°) | Relative Humidity (%) | Global Horizontal Radiation (Wh/sq.m) | Wind Speed (m/s) |

|---|---|---|---|

| 27.2 | 55.6 | 434.6 | 2.4 |

| Months | Active and Passive Strategies | ||||||

|---|---|---|---|---|---|---|---|

| Shading | Natural Ventilation | Air Conditioning | Dehumidification | Thermal Mass | Solar Gain | ||

| Heating | Cooling | ||||||

| Jan. | __ | (12 a.m.–4 p.m.) | (7–10 a.m.) | __ | × | × | × |

| Feb. | __ | (11 a.m.–5 p.m.) | (7–11 a.m.) | __ | × | × | × |

| Mar. | × | (8–11 a.m., 7 p.m.–1 a.m.) | × | E.N.V.P. * | × | × | __ |

| Apr. | × | (10 p.m.–10 a.m.) | __ | E.N.V.P. * | __ | × | __ |

| May | × | __ | __ | × | __ | __ | __ |

| Jun. | × | __ | __ | × | __ | __ | __ |

| Jul. | × | __ | __ | × | __ | __ | __ |

| Aug. | × | __ | __ | × | × | __ | __ |

| Sep. | × | __ | __ | × | × | __ | __ |

| Oct. | × | (12 p.m.–7 a.m.) | __ | E.N.V.P. * | × | × | __ |

| Nov. | × | (7 p.m.–3 a.m., 9–11 a.m.) | __ | E.N.V.P. * | × | × | __ |

| Dec. | __ | (12 a.m.–7 p.m.) | (7–9 a.m.) | __ | × | × | × |

| Project Sample | Structure | Structure Thickness | Wall Construction | Wall Material |

|---|---|---|---|---|

Apartment | Concrete | 25 cm | Masonry | Hollowed brick |

Tower | Concrete | 20 cm | Lightweight | Pumic block |

Villa | Concrete | 25 cm | Masonry | Concrete block |

| Building Category | Occupancy Hours | Height Level (HL) (Storey) |

|---|---|---|

| Villa | 24 | 1 > HL < 3 |

| Apartment | 24 | 3 > HL < 6 |

| Tower | 24 | 7 > HL < 21 |

| Components’ U-Value (W/m2 K) | ||||||

|---|---|---|---|---|---|---|

| Ceiling | Walls | Floor | Door | Window Glazing | Window Frame | Window Shading |

| 1.11 | 1.37 | 1.28 | 5.04 | 4.39 | 4.86 | 5.23 |

| Material | Density (kg/m3) | Conductivity (W/mK) | Specific Heat (kJ/kg K) | Vapour Diffusion (Factor) |

|---|---|---|---|---|

| 1. Gypsum | 1900 | 0.30 | 1200 | 11 |

| 2. Brick | 1800 | 0.39 | 920 | 8.0 |

| 3. Cement Plaster | 2000 | 1.60 | 837 | 6.8 |

| 4. Concrete Block | 700 | 0.18 | 1071 | 6.8 |

| 5. Pumice Block | 720 | 0.20 | 769 | 6.8 |

| 6. Extruded Polystyrene | 1400 | 0.70 | 837 | 59 |

| 7. Gypsum Board | 800 | 0.161 | 1088 | 11 |

| Material | Width (m) | Convection Coefficient (W/m2 °C) | Vapour Diffusion (Factor) |

|---|---|---|---|

| 8. Horizontal Flow Air | 0.02 | 1.66 | 1 |

| Date | 3 Mar | 4 Mar | 5 Mar | 6 Mar | 7 Mar | 8 Mar | 9 Mar | 10 Mar |

|---|---|---|---|---|---|---|---|---|

| Data Logger (°C) | 23.2 | 23.4 | 23.3 | 23.3 | 23.5 | 23.7 | 23.9 | 23.9 |

| Simulated (°C) | 20.9 | 20.8 | 21.7 | 22.1 | 22.2 | 20.8 | 20.7 | 22.1 |

| Error (%) | 9.9 | 11.1 | 6.8 | 5.1 | 5.5 | 12.2 | 13.3 | 7.5 |

| Wall 4 | Wall 5 |

|---|---|

| Amount of Condensed Water: (0.24 kg/m3) | Amount of Condensed Water: (0.18 kg/m3) |

| Wall No. | Criteria | |||||

|---|---|---|---|---|---|---|

| Energy Efficiency | Thermal Comfort | Cost Efficiency | ||||

| Heating | Cooling | PMV Value | Discomfort Hours | Amortization Time | Total Grade | |

| 1 | 4 | 3 | 3 | 2 | 6 | 18 |

| 2 | 7 | 1 | 1 | 3 | 1 | 13 |

| 3 | 6 | 4 | 4 | 4 | 3 | 21 |

| 4 | 1 | 5 | 5 | 5 | 4 | 20 |

| 5 | 5 | 7 | 7 | 7 | 7 | 31 |

| 6 | 2 | 6 | 6 | 6 | 5 | 25 |

| 7 | 3 | 2 | 2 | 1 | 2 | 10 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boostani, H.; Hancer, P. A Model for External Walls Selection in Hot and Humid Climates. Sustainability 2019, 11, 100. https://doi.org/10.3390/su11010100

Boostani H, Hancer P. A Model for External Walls Selection in Hot and Humid Climates. Sustainability. 2019; 11(1):100. https://doi.org/10.3390/su11010100

Chicago/Turabian StyleBoostani, Haleh, and Polat Hancer. 2019. "A Model for External Walls Selection in Hot and Humid Climates" Sustainability 11, no. 1: 100. https://doi.org/10.3390/su11010100