A New Extension to a Multi-Criteria Decision-Making Model for Sustainable Supplier Selection under an Intuitionistic Fuzzy Environment

Abstract

:1. Introduction

2. Literature Review

2.1. SSS Based on SSCM Practices

2.2. Sustainable Supplier Selection Methods

2.2.1. MCDM Methods for SSS

2.2.2. MCDM methods with IFS for SSS

3. Methodology

3.1. Intuitionistic Fuzzy Set

3.2. The Basic of DANP and VIKOR Methods

3.3. Building an IF-DANP-mV Model for Sustainable Supplier Selection

4. Case Study

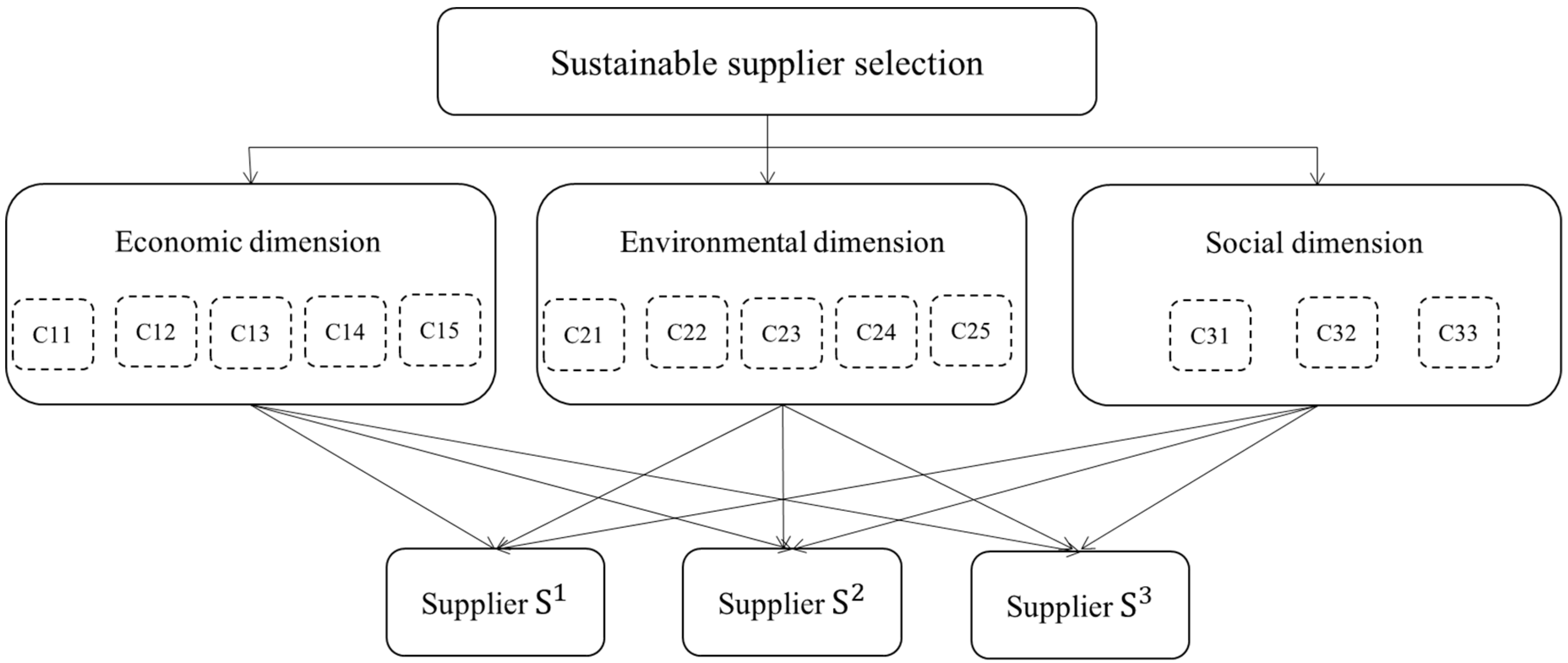

4.1. Problem Description

4.2. Proposed Criteria for SSS-Based SSCM Practices

4.3. Using the IF-DANP-mV Model SSS in a Case Study

4.4. Sensitivity Analysis

4.5. Comparisons with Other Existing Methods

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Govindan, K.; Seuring, S.; Zhu, Q.; Azevedo, S.G. Accelerating the transition towards sustainability dynamics into supply chain relationship management and governance structures. J. Clean. Prod. 2016, 112, 1813–1823. [Google Scholar] [CrossRef]

- Kros, J.F.; Kirchoff, J.F.; Falasca, M. The impact of buyer-supplier relationship quality and information management on industrial vending machine benefits in the healthcare industry. J. Purch. Supply Manag. 2019, 25, 100506. [Google Scholar] [CrossRef]

- Noh, J.; Kim, J.S. Cooperative green supply chain management with greenhouse gas emissions and fuzzy demand. J. Clean. Prod. 2019, 208, 1421–1435. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Li, J.; Fang, H.; Song, W. Sustainable supplier selection based on SSCM practices: A rough cloud TOPSIS approach. J. Clean. Prod. 2019, 222, 606–621. [Google Scholar] [CrossRef]

- Laari, S.; Töyli, J.; Ojala, L. Supply chain perspective on competitive strategies and green supply chain management strategies. J. Clean. Prod. 2017, 141, 1303–1315. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. Int. J. Prod. Econ. 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Alikhani, R.; Torabi, S.A.; Altay, N. Strategic supplier selection under sustainability and risk criteria. Int. J. Prod. Econ. 2019, 208, 69–82. [Google Scholar] [CrossRef]

- Xu, Z.; Qin, J.; Liu, J.; Martínez, L. Sustainable supplier selection based on AHPSort II in interval type-2 fuzzy environment. Inf. Sci. 2019, 483, 273–293. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X.; Goh, M.; Zhou, L.; He, Y. Supplier portfolio of key outsourcing parts selection using a two-stage decision making framework for Chinese domestic auto-maker. Comput. Ind. Eng. 2019, 128, 559–575. [Google Scholar] [CrossRef]

- Hong, J.; Zhang, Y.; Ding, M. Sustainable supply chain management practices, supply chain dynamic capabilities, and enterprise performance. J. Clean. Prod. 2018, 172, 3508–3519. [Google Scholar] [CrossRef]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Lean, green and resilient practices influence on supply chain performance: Interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34. [Google Scholar] [CrossRef]

- Chacón Vargas, J.R.; Moreno Mantilla, C.E.; de Sousa Jabbour, A.B.L. Enablers of sustainable supply chain management and its effect on competitive advantage in the Colombian context. Resour. Conserv. Recycl. 2018, 139, 237–250. [Google Scholar] [CrossRef]

- Phochanikorn, P.; Tan, C. An Integrated Multi-Criteria Decision-Making Model Based on Prospect Theory for Green Supplier Selection under Uncertain Environment: A Case Study of the Thailand Palm Oil Products Industry. Sustainability 2019, 11, 1872. [Google Scholar] [CrossRef]

- Lu, Z.; Sun, X.; Wang, Y.; Xu, C. Green supplier selection in straw biomass industry based on cloud model and possibility degree. J. Clean. Prod. 2019, 209, 995–1005. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Z. An Integrated Sustainable Supplier Selection Approach Based on Hybrid Information Aggregation. Sustainability 2018, 10, 2543. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 2010, 124, 252–264. [Google Scholar] [CrossRef]

- Carter, C.R.; Easton, P.L. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. 2015, 41, 46–62. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Schultmann, F. Sustainable supplier management—A review of models supporting sustainable supplier selection, monitoring and development. Int. J. Prod. Res. 2015, 54, 1–31. [Google Scholar] [CrossRef]

- Awaysheh, A.; Klassen, R.D. The impact of supply chain structure on the use of supplier socially responsible practices. Int. J. Oper. Prod. Manag. 2010, 30, 1246–1268. [Google Scholar] [CrossRef]

- Lima-Junior, F.R.; Carpinetti, L.C.R. A multicriteria approach based on fuzzy QFD for choosing criteria for supplier selection. Comput. Ind. Eng. 2016, 101, 269–285. [Google Scholar] [CrossRef]

- Shakourloo, A.; Kazemi, A.; Javad, M.O.M. A new model for more effective supplier selection and remanufacturing process in a closed-loop supply chain. Appl. Math. Model. 2016, 40, 9914–9931. [Google Scholar] [CrossRef]

- Feng, Y.; Hong, Z.; Tian, G.; Li, Z.; Tan, J.; Hu, H. Environmentally friendly MCDM of reliability-based product optimisation combining DEMATEL-based ANP, interval uncertainty and Vlse Kriterijumska Optimizacija Kompromisno Resenje (VIKOR). Inf. Sci. 2018, 442–443, 128–144. [Google Scholar] [CrossRef]

- Saswattecha, K.; Kroeze, C.; Jawjit, W.; Hein, L. Improving environmental sustainability of Thai palm oil production in 2050. J. Clean. Prod. 2017, 147, 572–588. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, M.; Kannan, D. Supplier selection based on corporate social responsibility practices. Int. J. Prod. Econ. 2018, 200, 353–379. [Google Scholar] [CrossRef]

- Allaoui, H.; Guo, Y.; Choudhary, A.; Bloemhof, J. Sustainable agro-food supply chain design using two-stage hybrid multi-objective decision-making approach. Comput. Oper. Res. 2018, 89, 369–384. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Veit, C.; Lambrechts, W.; Quintens, L.; Semeijn, J. The Impact of Sustainable Sourcing on Customer Perceptions: Association by Guilt from Scandals in Local vs. Offshore Sourcing Countries. Sustainability 2018, 10, 2519. [Google Scholar] [CrossRef]

- Paulraj, A.; Chen, I.J.; Blome, C. Motives and Performance Outcomes of Sustainable Supply Chain Management Practices: A Multi-theoretical Perspective. J. Bus. Ethics 2015, 145, 239–258. [Google Scholar] [CrossRef]

- Das, D. The impact of Sustainable Supply Chain Management practices on firm performance: Lessons from Indian organizations. J. Clean. Prod. 2018, 203, 179–196. [Google Scholar] [CrossRef]

- Gören, H.G. A decision framework for sustainable supplier selection and order allocation with lost sales. J. Clean. Prod. 2018, 183, 1156–1169. [Google Scholar] [CrossRef]

- Lo, H.-W.; Liou, J.J.H.; Wang, H.-S.; Tsai, Y.-S. An integrated model for solving problems in green supplier selection and order allocation. J. Clean. Prod. 2018, 190, 339–352. [Google Scholar] [CrossRef]

- Yu, C.; Shao, Y.; Wang, K.; Zhang, L. A group decision making sustainable supplier selection approach using extended TOPSIS under interval-valued Pythagorean fuzzy environment. Expert Syst. Appl. 2019, 121, 1–17. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Sen, D.K.; Datta, S.; Mahapatra, S.S. Sustainable supplier selection in intuitionistic fuzzy environment: A decision-making perspective. Benchmark Int. J. 2018, 25, 545–574. [Google Scholar] [CrossRef]

- Khan, S.A.; Kusi-Sarpong, S.; Arhin, F.K.; Kusi-Sarpong, H. Supplier sustainability performance evaluation and selection: A framework and methodology. J. Clean. Prod. 2018, 205, 964–979. [Google Scholar] [CrossRef]

- Wang, X.; Cai, J. A group decision-making model based on distance-based VIKOR with incomplete heterogeneous information and its application to emergency supplier selection. Kybernetes 2017, 46, 501–529. [Google Scholar] [CrossRef]

- dos Santos, B.M.; Godoy, L.P.; Campos, L.M.S. Performance evaluation of green suppliers using entropy-TOPSIS-F. J. Clean. Prod. 2019, 207, 498–509. [Google Scholar] [CrossRef]

- Hamurcu, M.; Eren, T. An Application of Multicriteria Decision-making for the Evaluation of Alternative Monorail Routes. Mathematics 2018, 7, 16. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making with Dependence and Feedback: The Analytic Network Process; RWS Publications: Pittsburgh, PA, USA, 1996. [Google Scholar]

- Liou, J.J.H.; Tamošaitienė, J.; Zavadskas, E.K.; Tzeng, G.-H. New hybrid COPRAS-G MADM Model for improving and selecting suppliers in green supply chain management. Int. J. Prod. Res. 2015, 54, 114–134. [Google Scholar] [CrossRef]

- Chen, V.Y.; Lin, J.C.; Tzeng, G.H. Assessment and improvement of wetlands environmental protection plans for achieving sustainable development. Environ. Res. 2019, 169, 280–296. [Google Scholar] [CrossRef]

- Kannan, D. Role of multiple stakeholders and the critical success factor theory for the sustainable supplier selection process. Int. J. Prod. Econ. 2018, 195, 391–418. [Google Scholar] [CrossRef]

- Awasthi, A.; Govindan, K.; Gold, S. Multi-tier sustainable global supplier selection using a fuzzy AHP-VIKOR based approach. Int. J. Prod. Econ. 2018, 195, 106–117. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Güleryüz, S.; Karpak, B. A new combined IF-DEMATEL and IF-ANP approach for CRM partner evaluation. Int. J. Prod. Econ. 2017, 191, 194–206. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Vafadarnikjoo, A. Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain. Expert Syst. Appl. 2015, 42, 7207–7220. [Google Scholar] [CrossRef]

- Xu, Z. Intuitionistic preference relations and their application in group decision making. Inf. Sci. 2007, 177, 2363–2379. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.-N.; Nguyen, V.T.; Thai, H.T.N.; Tran, N.N.; Tran, T.L.A. Sustainable Supplier Selection Process in Edible Oil Production by a Hybrid Fuzzy Analytical Hierarchy Process and Green Data Envelopment Analysis for the SMEs Food Processing Industry. Mathematics 2018, 6, 302. [Google Scholar] [CrossRef]

- Rashidi, K.; Cullinane, K. A comparison of fuzzy DEA and fuzzy TOPSIS in sustainable supplier selection: Implications for sourcing strategy. Expert Syst. Appl. 2019, 121, 266–281. [Google Scholar] [CrossRef]

- Krishankumar, R.; Ravichandran, K.S.; Saeid, A.B. A new extension to PROMETHEE under intuitionistic fuzzy environment for solving supplier selection problem with linguistic preferences. Appl. Soft. Comput. 2017, 60, 564–576. [Google Scholar]

- Memari, A.; Dargi, A.; Akbari Jokar, M.R.; Ahmad, R.; Abdul Rahim, A.R. Sustainable supplier selection: A multi-criteria intuitionistic fuzzy TOPSIS method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Çalı, S.; Balaman, Ş.Y. A novel outranking based multi criteria group decision making methodology integrating ELECTRE and VIKOR under intuitionistic fuzzy environment. Expert Syst. Appl. 2019, 119, 36–50. [Google Scholar] [CrossRef]

- Atanassov, K.T. Intuitionistic fuzzy sets. Fuzzy Set Syst. 1986, 20, 87–96. [Google Scholar] [CrossRef]

- Wan, S.P.; Li, D.F.; Rui, Z.F. Possibility mean, variance and covariance of triangular intuitionistic fuzzy numbers. J. Intell. Fuzzy Syst. 2013, 24, 847–858. [Google Scholar]

- Liu, P.D.; Jin, F. Interval-valued Intuitionistic Uncertain Linguistic Aggregation Operators and Their Application on Group Decision Making. Appl. Math. Model. 2014, 37, 2430–2444. [Google Scholar] [CrossRef]

- Gigović, L.; Pamučar, D.; Božanić, D.; Ljubojević, S. Application of the GIS-DANP-MABAC multi-criteria model for selecting the location of wind farms: A case study of Vojvodina, Serbia. Renew. Energy 2017, 103, 501–521. [Google Scholar] [CrossRef]

- Li, Y.; Yong, H.; Zhang, X.; Yong, D.; Mahadevan, S. An evidential DEMATEL method to identify critical success factors in emergency management. Appl. Soft. Comput. 2014, 22, 504–510. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Saswattecha, K.; Kroeze, C.; Jawjit, W.; Hein, L. Options to reduce environmental impacts of palm oil production in Thailand. J. Clean. Prod. 2016, 137, 370–393. [Google Scholar] [CrossRef]

- Hu, K.-H.; Chen, F.-H.; Tzeng, G.-H. Evaluating the Improvement of Sustainability of Sports Industry Policy Based on MADM. Sustainability 2016, 8, 606. [Google Scholar] [CrossRef]

- Feng, Z.; Tan, C. Pricing, Green Degree and Coordination Decisions in a Green Supply Chain with Loss Aversion. Mathematics 2019, 7, 239. [Google Scholar] [CrossRef]

- Kannan, D.; Govindan, K.; Rajendran, S. Fuzzy Axiomatic Design approach based green supplier selection: A case study from Singapore. J. Clean. Prod. 2015, 96, 194–208. [Google Scholar] [CrossRef]

| Dimension | Criteria | Description |

|---|---|---|

| Economic (C1) | Product quality improvement (C11) Process capability (C12) Cost reduction activities (C13) Supply capability (C14) Delivery and service of product (C15) | This section focuses on engaging the supply base in reference to the optimal means to reduce the cost and total price in terms of inputs/raw materials. For example, the lead time should include sufficient preparation and delivery times to enable the supplier to provide the purchasers with recycled materials. |

| Environmental (C2) | Green image (C21) Environmental friendly materials (C22) Environmental policies (C23) Environmental planning (C24) Implementation and operation (C25) | Suppliers and consumers should form organizations in which they can share environmental best management practices and knowledge in order to promote green initiatives, reduce environmental impacts, recycling, reduction, or elimination of all types of wastes, such as water and energy as well as ensure future development and cooperation. |

| Social (C3) | Employer rights and welfare (C31) Safety and health system (C32) Stakeholder relationship (C33) | By assessing the social aspect, the enterprises provide a safe and healthy policy for employer as well as increase workers’ satisfaction such as wages, training, education. Moreover, the enterprise can also collaborate with stakeholders to improve the market shares which can enhance the image among the group of sector operators. |

| Linguistic Terms | Abbreviation | IFS |

|---|---|---|

| No Influence | N | (0.00, 1.00, 0.00) |

| Low Influence | L | (0.35, 0.60, 0.05) |

| Medium Influence | M | (0.50, 0.45, 0.05) |

| High Influence | H | (0.75, 0.20, 0.05) |

| Very High Influence | VH | (0.90, 0.10, 0.00) |

| Criteria | C11 | C12 | C13 | C14 | C15 | C21 | C22 | C23 | C24 | C25 | C31 | C32 | C33 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C11 | N | M | H | N | VH | H | L | M | VH | VH | H | M | H |

| C12 | L | N | VH | N | H | L | H | H | M | L | M | H | VH |

| C13 | M | L | N | H | M | H | L | VH | VH | H | M | N | M |

| C14 | H | VH | H | N | M | L | M | H | VH | M | L | L | M |

| C15 | VH | H | L | M | N | M | VH | L | H | H | VH | M | H |

| C21 | M | VH | H | M | H | N | L | H | VH | N | L | H | L |

| C22 | H | VH | M | M | H | L | N | H | VH | M | M | H | VH |

| C23 | M | L | H | VH | VH | H | M | N | H | H | M | VH | M |

| C24 | H | H | L | M | H | VH | VH | M | N | M | H | M | H |

| C25 | M | L | H | M | L | H | VH | M | N | N | H | M | M |

| C31 | H | VH | VH | M | H | VH | H | M | N | L | N | H | VH |

| C32 | L | H | M | H | VH | H | L | N | M | H | VH | N | M |

| C33 | H | VH | M | L | L | M | H | M | VH | VH | M | L | N |

| Criteria | C11 | C12 | C13 | C14 | C15 | C21 | C22 | C23 | C24 | C25 | C31 | C32 | C33 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C11 | 0 | 0.052 | 0.039 | 0 | 0.054 | 0.021 | 0.063 | 0.022 | 0.082 | 0.043 | 0.012 | 0.033 | 0.055 |

| C12 | 0.081 | 0 | 0.090 | 0 | 0.071 | 0.032 | 0.071 | 0.094 | 0.080 | 0.068 | 0.034 | 0.040 | 0.060 |

| C13 | 0.072 | 0.043 | 0 | 0.034 | 0.055 | 0.067 | 0.057 | 0.051 | 0.042 | 0.044 | 0.066 | 0 | 0.012 |

| C14 | 0.050 | 0.020 | 0.031 | 0 | 0.013 | 0.021 | 0.081 | 0.060 | 0.055 | 0.029 | 0.087 | 0.011 | 0.055 |

| C15 | 0.040 | 0.054 | 0.043 | 0.055 | 0 | 0.029 | 0.092 | 0.033 | 0.075 | 0.043 | 0.080 | 0.082 | 0.009 |

| C21 | 0.023 | 0.073 | 0.067 | 0.018 | 0.010 | 0 | 0.070 | 0.011 | 0.059 | 0 | 0.023 | 0.078 | 0.090 |

| C22 | 0.035 | 0.053 | 0.071 | 0.049 | 0.036 | 0.043 | 0 | 0.044 | 0.011 | 0.064 | 0.020 | 0.092 | 0.019 |

| C23 | 0.045 | 0.040 | 0.071 | 0.011 | 0.060 | 0.066 | 0.081 | 0 | 0.040 | 0.036 | 0.044 | 0.014 | 0.043 |

| C24 | 0.039 | 0.066 | 0.003 | 0.073 | 0.090 | 0.058 | 0.030 | 0.067 | 0 | 0.070 | 0.051 | 0.035 | 0.012 |

| C25 | 0.041 | 0.038 | 0.048 | 0.048 | 0.014 | 0.089 | 0.048 | 0.051 | 0 | 0 | 0.063 | 0.016 | 0.088 |

| C31 | 0.033 | 0.081 | 0.090 | 0.090 | 0.035 | 0.094 | 0.061 | 0.022 | 0 | 0.022 | 0 | 0.031 | 0.030 |

| C32 | 0.067 | 0.062 | 0.011 | 0.012 | 0.049 | 0.030 | 0.030 | 0 | 0.059 | 0.013 | 0.054 | 0 | 0.019 |

| C33 | 0.044 | 0.082 | 0.021 | 0.026 | 0.038 | 0.014 | 0.091 | 0.033 | 0.060 | 0.045 | 0.022 | 0.004 | 0 |

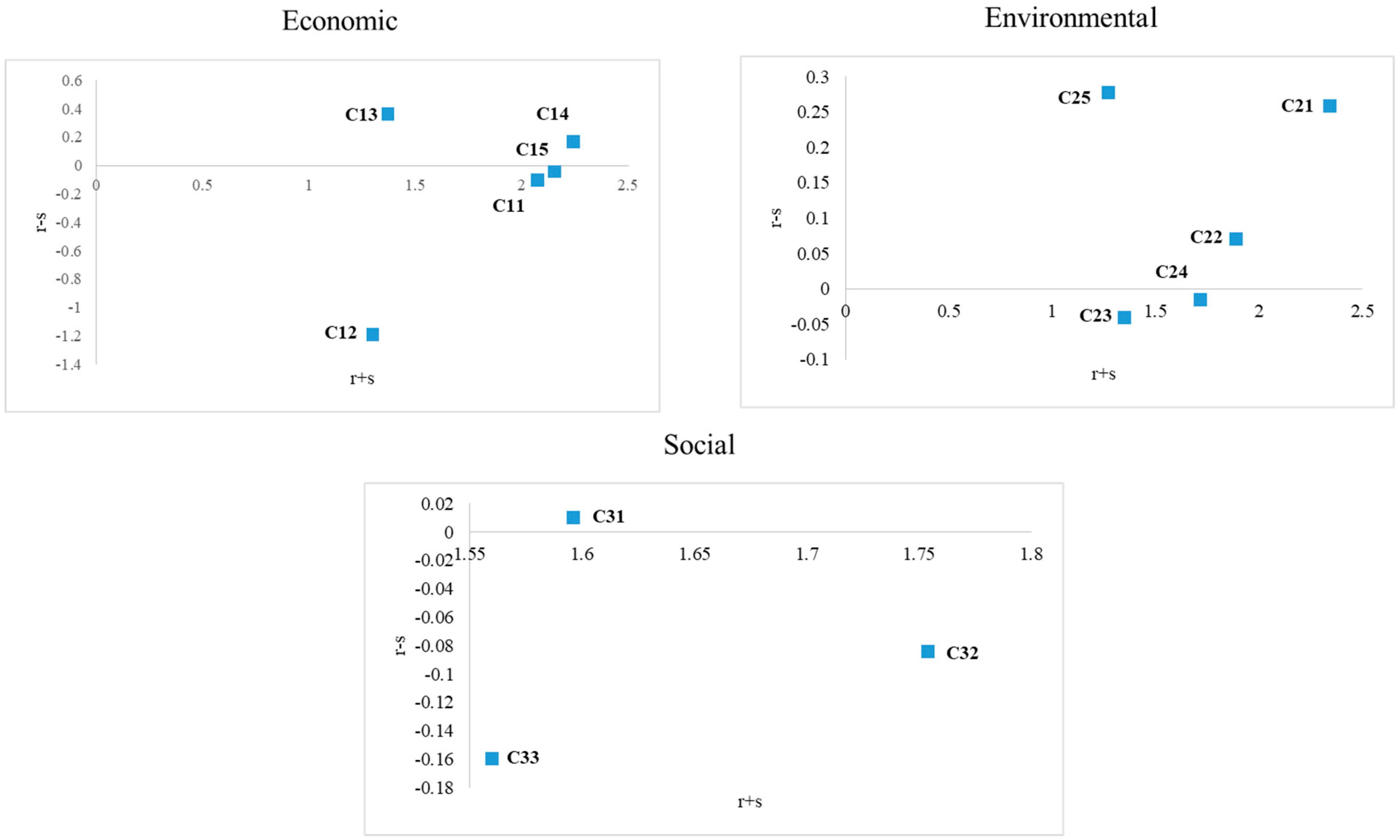

| TD | TC | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dimension | ri | si | ri + si | ri − si | Criteria | ri | si | ri + si | ri − si |

| C1 | 1.994 | 1.751 | 3.745 | 0.243 | C11 | 0.985 | 1.087 | 2.072 | −0.102 |

| C12 | 0.053 | 1.245 | 1.298 | −1.192 | |||||

| C13 | 0.866 | 0.504 | 1.370 | 0.362 | |||||

| C14 | 1.204 | 1.036 | 2.240 | 0.168 | |||||

| C15 | 1.056 | 1.098 | 2.154 | −0.042 | |||||

| C2 | 1.908 | 1.984 | 4.892 | −0.076 | C21 | 1.300 | 1.041 | 2.341 | 0.259 |

| C22 | 0.981 | 0.910 | 1.891 | 0.071 | |||||

| C23 | 0.654 | 0.694 | 1.348 | −0.040 | |||||

| C24 | 0.851 | 0.866 | 1.717 | −0.015 | |||||

| C25 | 0.774 | 0.496 | 1.270 | 0.278 | |||||

| C3 | 1.854 | 1.878 | 3.732 | −0.024 | C31 | 0.803 | 0.793 | 1.596 | 0.010 |

| C32 | 0.835 | 0.919 | 1.754 | −0.084 | |||||

| C33 | 0.699 | 0.861 | 1.560 | −0.162 | |||||

| Criteria | C11 | C12 | C13 | C14 | C15 | C21 | C22 | C23 | C24 | C25 | C31 | C32 | C33 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C11 | 0.071 | 0.062 | 0.082 | 0.066 | 0.08 | 0.062 | 0.052 | 0.063 | 0.056 | 0.052 | 0.049 | 0.054 | 0.068 |

| C12 | 0.067 | 0.051 | 0.063 | 0.062 | 0.077 | 0.073 | 0.084 | 0.074 | 0.058 | 0.073 | 0.063 | 0.053 | 0.058 |

| C13 | 0.058 | 0.063 | 0.056 | 0.053 | 0.048 | 0.079 | 0.058 | 0.048 | 0.073 | 0.056 | 0.078 | 0.069 | 0.069 |

| C14 | 0.082 | 0.074 | 0.082 | 0.074 | 0.052 | 0.071 | 0.081 | 0.084 | 0.054 | 0.072 | 0.059 | 0.078 | 0.048 |

| C15 | 0.062 | 0.072 | 0.08 | 0.062 | 0.067 | 0.081 | 0.066 | 0.071 | 0.076 | 0.061 | 0.071 | 0.082 | 0.052 |

| C21 | 0.069 | 0.08 | 0.071 | 0.079 | 0.07 | 0.065 | 0.072 | 0.058 | 0.069 | 0.075 | 0.085 | 0.055 | 0.075 |

| C22 | 0.086 | 0.081 | 0.081 | 0.061 | 0.08 | 0.085 | 0.055 | 0.065 | 0.061 | 0.088 | 0.058 | 0.085 | 0.075 |

| C23 | 0.061 | 0.061 | 0.051 | 0.077 | 0.063 | 0.041 | 0.04 | 0.049 | 0.067 | 0.066 | 0.065 | 0.063 | 0.066 |

| C24 | 0.074 | 0.074 | 0.051 | 0.074 | 0.073 | 0.058 | 0.06 | 0.07 | 0.074 | 0.071 | 0.061 | 0.055 | 0.061 |

| C25 | 0.053 | 0.065 | 0.058 | 0.055 | 0.055 | 0.058 | 0.078 | 0.074 | 0.065 | 0.068 | 0.07 | 0.068 | 0.068 |

| C31 | 0.083 | 0.083 | 0.083 | 0.073 | 0.073 | 0.063 | 0.073 | 0.073 | 0.073 | 0.083 | 0.085 | 0.073 | 0.083 |

| C32 | 0.058 | 0.058 | 0.068 | 0.064 | 0.064 | 0.058 | 0.059 | 0.059 | 0.064 | 0.061 | 0.071 | 0.058 | 0.058 |

| C33 | 0.056 | 0.046 | 0.046 | 0.046 | 0.058 | 0.066 | 0.072 | 0.072 | 0.056 | 0.046 | 0.056 | 0.067 | 0.069 |

| Criteria | C11 | C12 | C13 | C14 | C15 | C21 | C22 | C23 | C24 | C25 | C31 | C32 | C33 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (IF-DANP) | 0.062 | 0.072 | 0.065 | 0.081 | 0.080 | 0.082 | 0.073 | 0.072 | 0.083 | 0.070 | 0.055 | 0.053 | 0.060 |

| Dimensions | Criteria | Weight | Gap of Aspired Level | ||

|---|---|---|---|---|---|

| S1 | S2 | S3 | |||

| C1 | C11 | 0.062 | 0.985 | 1.087 | 2.072 |

| C12 | 0.072 | 0.053 | 1.245 | 1.298 | |

| C13 | 0.065 | 0.866 | 0.504 | 1.370 | |

| C14 | 0.081 | 1.204 | 1.036 | 2.240 | |

| C15 | 0.080 | 1.056 | 1.098 | 2.154 | |

| C2 | C21 | 0.082 | 1.300 | 1.041 | 2.341 |

| C22 | 0.073 | 0.981 | 0.910 | 1.891 | |

| C23 | 0.072 | 0.654 | 0.694 | 1.348 | |

| C24 | 0.083 | 0.851 | 0.866 | 1.717 | |

| C25 | 0.070 | 0.774 | 0.496 | 1.270 | |

| C3 | C25 | 0.070 | 0.774 | 0.496 | 1.270 |

| C31 | 0.052 | 0.803 | 0.793 | 1.596 | |

| C32 | 0.053 | 0.835 | 0.919 | 1.754 | |

| C33 | 0.060 | 0.699 | 0.861 | 1.560 | |

| Total Gap Performance | 2.541(3) | 2.582(2) | 3.095(1) | ||

| Scores(Ranking) | |||||

| 0.566(3) | 0.493(2) | 0.453(1) | |||

| 0.050(3) | 0.055(2) | 0.031(1) | |||

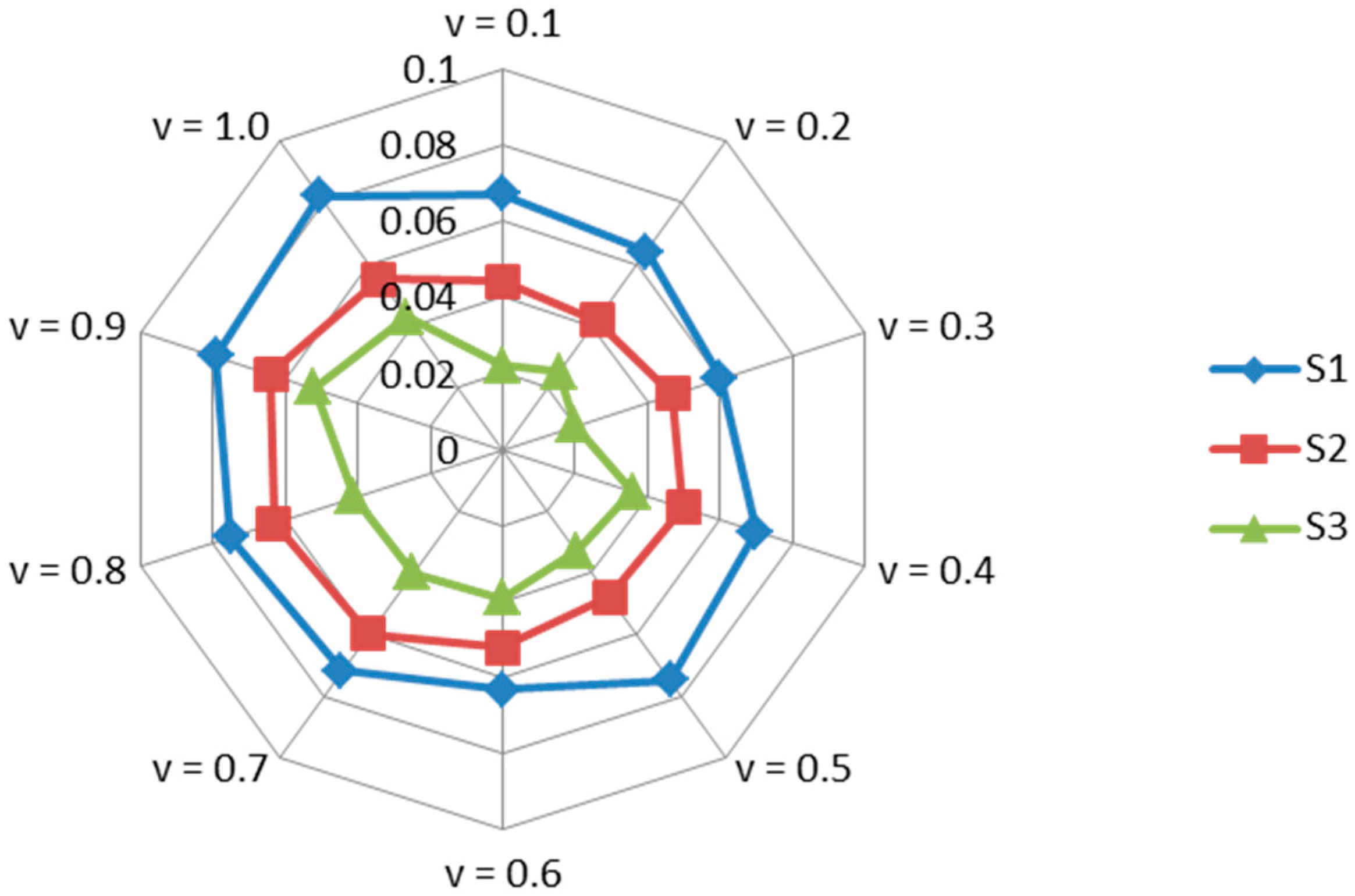

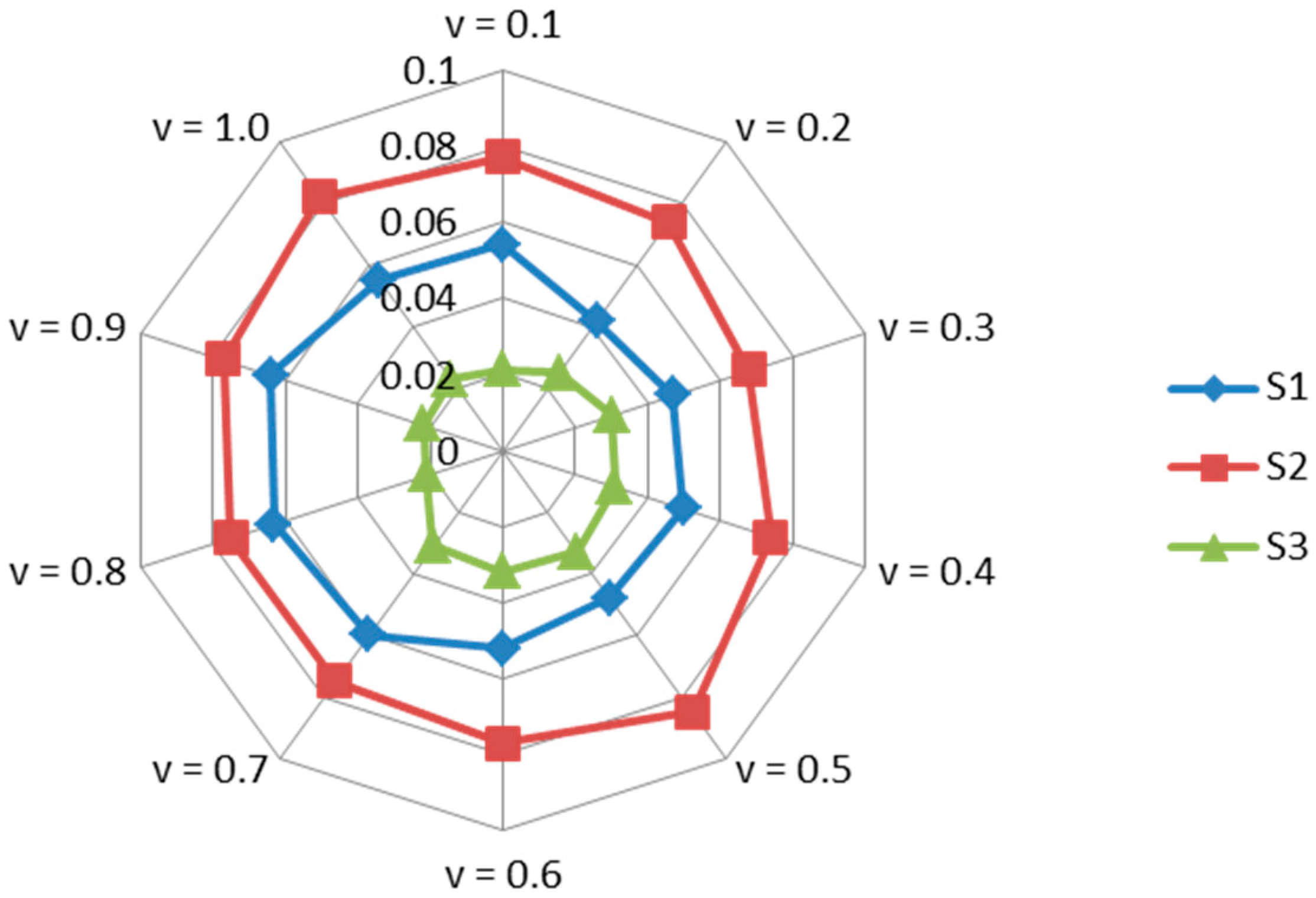

| Alternatives | v = 0.1 | Rank | v = 0.2 | Rank | v = 0.3 | Rank | v = 0.4 | Rank | v = 0.5 | Rank |

| S1 | 0.030 | 3 | 0.038 | 3 | 0.040 | 3 | 0.055 | 3 | 0.061 | 3 |

| S2 | 0.024 | 2 | 0.032 | 2 | 0.031 | 2 | 0.050 | 2 | 0.043 | 2 |

| S3 | 0.012 | 1 | 0.011 | 1 | 0.020 | 1 | 0.046 | 1 | 0.033 | 1 |

| Alternatives | v = 0.6 | Rank | v = 0.7 | Rank | v = 0.8 | Rank | v = 0.9 | Rank | v = 1.0 | Rank |

| S1 | 0.063 | 3 | 0.072 | 3 | 0.105 | 3 | 0.010 | 3 | 0.031 | 3 |

| S2 | 0.045 | 2 | 0.060 | 2 | 0.089 | 2 | 0.084 | 2 | 0.055 | 2 |

| S3 | 0.039 | 1 | 0.040 | 1 | 0.071 | 1 | 0.062 | 1 | 0.050 | 1 |

| Methods | Orders of Alternatives |

|---|---|

| IF-DANP-mV | S3 > S2 > S1 |

| DANP-VIKOR | S3 > S1 > S2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phochanikorn, P.; Tan, C. A New Extension to a Multi-Criteria Decision-Making Model for Sustainable Supplier Selection under an Intuitionistic Fuzzy Environment. Sustainability 2019, 11, 5413. https://doi.org/10.3390/su11195413

Phochanikorn P, Tan C. A New Extension to a Multi-Criteria Decision-Making Model for Sustainable Supplier Selection under an Intuitionistic Fuzzy Environment. Sustainability. 2019; 11(19):5413. https://doi.org/10.3390/su11195413

Chicago/Turabian StylePhochanikorn, Patchara, and Chunqiao Tan. 2019. "A New Extension to a Multi-Criteria Decision-Making Model for Sustainable Supplier Selection under an Intuitionistic Fuzzy Environment" Sustainability 11, no. 19: 5413. https://doi.org/10.3390/su11195413