Energy-Economic Assessment of Islanded Microgrid with Wind Turbine, Photovoltaic Field, Wood Gasifier, Battery, and Hydrogen Energy Storage

Abstract

:1. Introduction

2. Materials and Methods

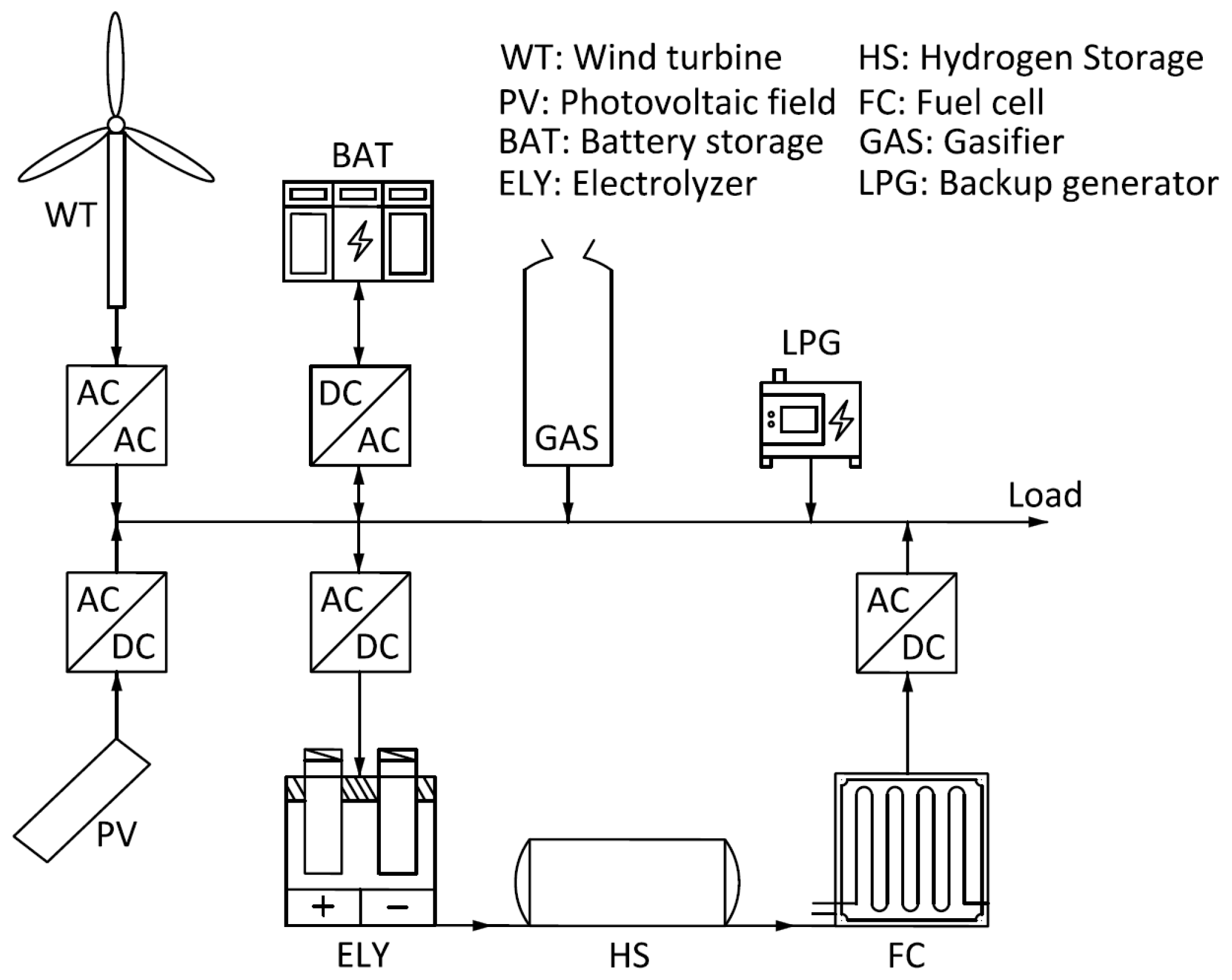

2.1. Layout and Control Strategy

- Monocrystalline type Photovoltaic Field (PV) with a three-phase inverter, producing electrical energy from solar radiation, which is directed to the AC line;

- Direct drive horizontal axis wind turbine with AC/AC regulator, converting the wind energy into electrical power, which is directed to the AC line;

- Gasifier with an internal combustion engine, using a thermochemical conversion of wooden chips to produce low-heating value gas, which is directed to the turbine;

- Lithium-ion battery with AC/DC converter used as energy storage when production from renewable energy sources exceeds the power need of the load, and as a power source when the load exceeds production from renewables;

- Hydrogen loop with an electrolyzer, hydrogen storage, and fuel cell, which is used as energy storage when power from renewables exceeds user needs and battery possibilities, and power source when needed.

2.2. Energy and Economic Model

- Energy curtailed is defined as the energy which cannot be utilized or stored in the energy system;

- Time of the gasifier operation;

- LPG consumption is equal to the number of cubic meters of natural gas utilized during backup generator operation;

- Normalized equivalent hours of operation of WT, defined as the ratio between the sum of energy generated by the turbine annually and the amount of energy produced at the same time at nominal conditions;

- Normalized equivalent hours of operation of PV, defined as the ratio between the sum of energy generated by the PV annually and the amount of energy produced at the same time at nominal conditions;

- Simple payback time is defined as a period when the value of the energy produced by the system exceeds the initial costs of the system.

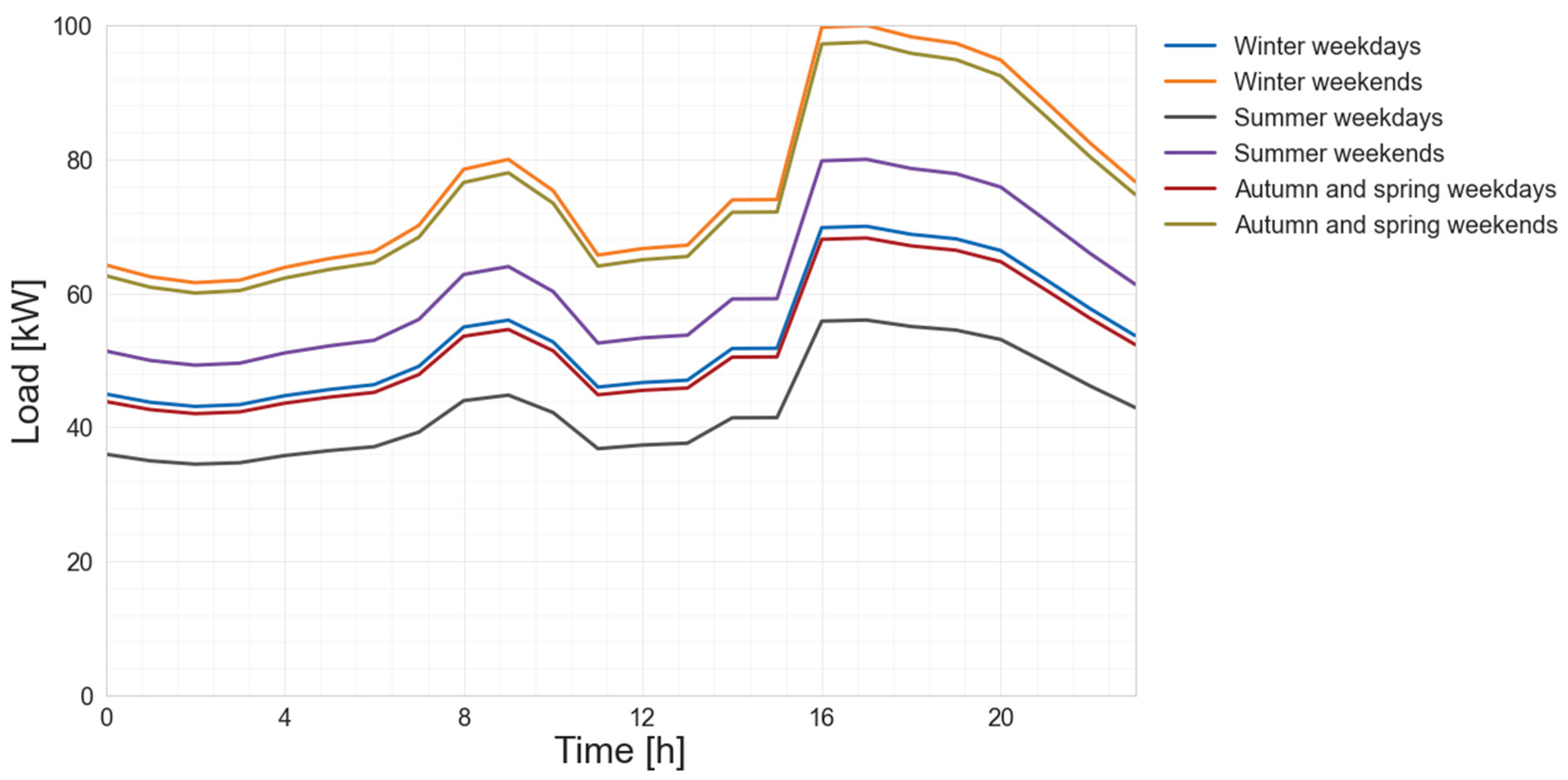

2.3. Case Study

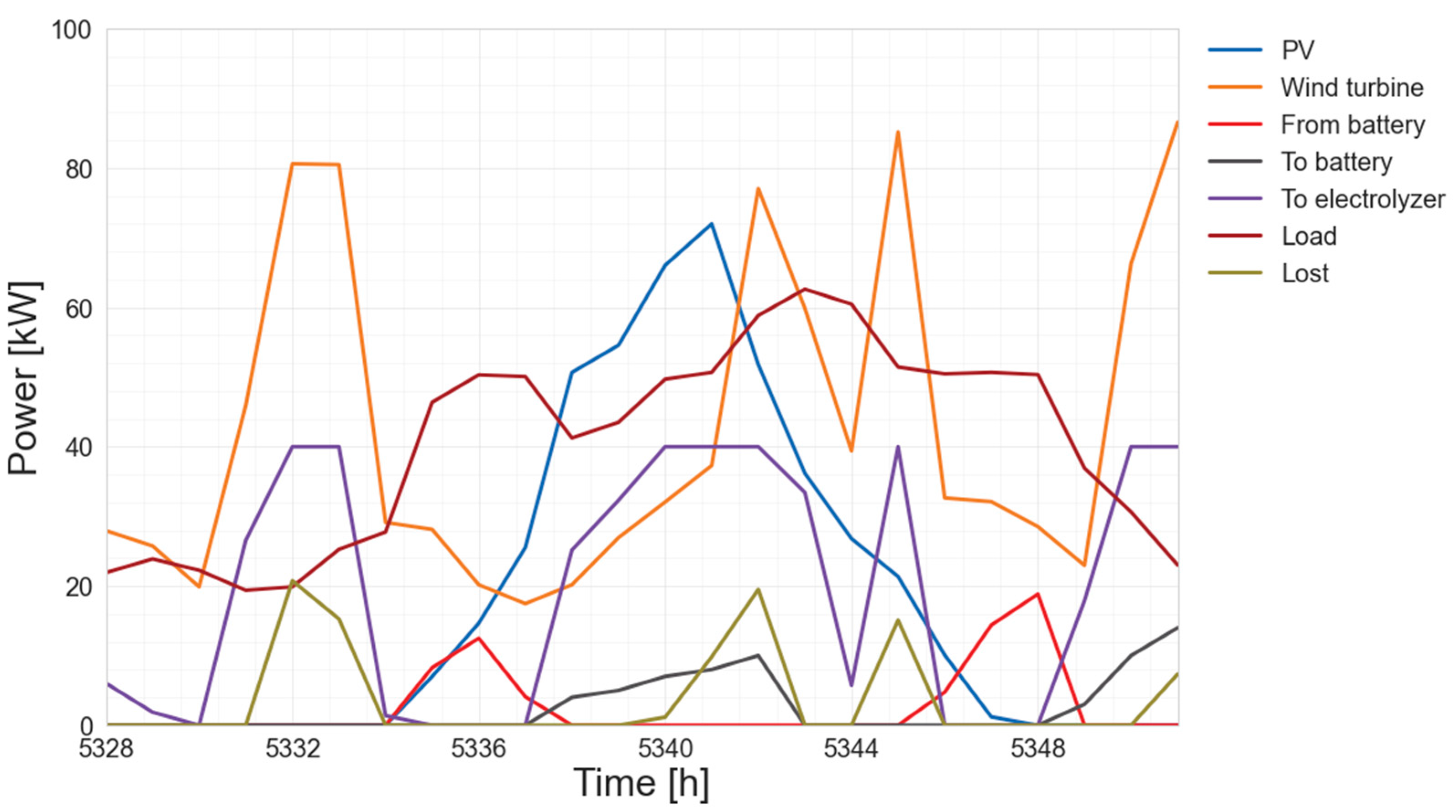

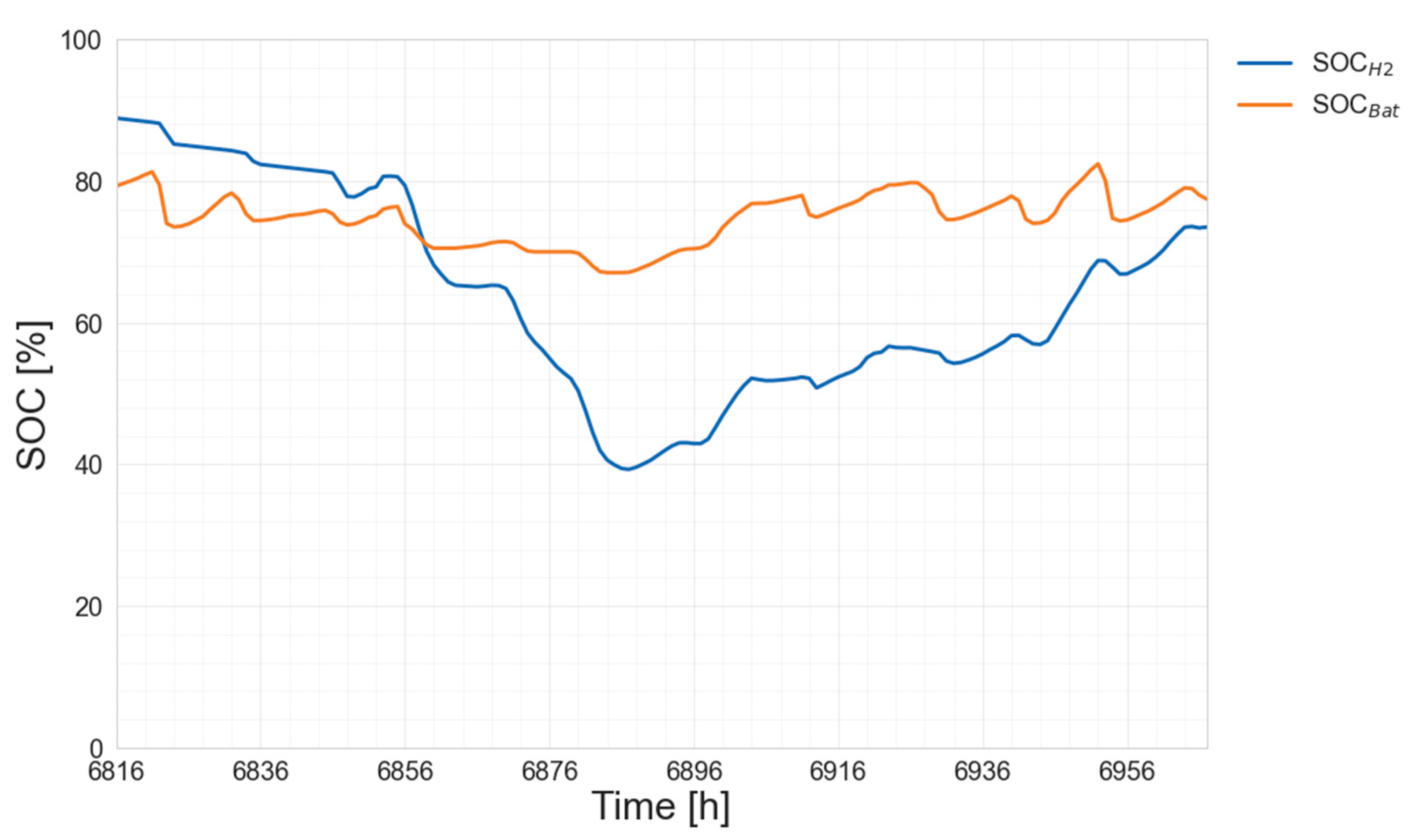

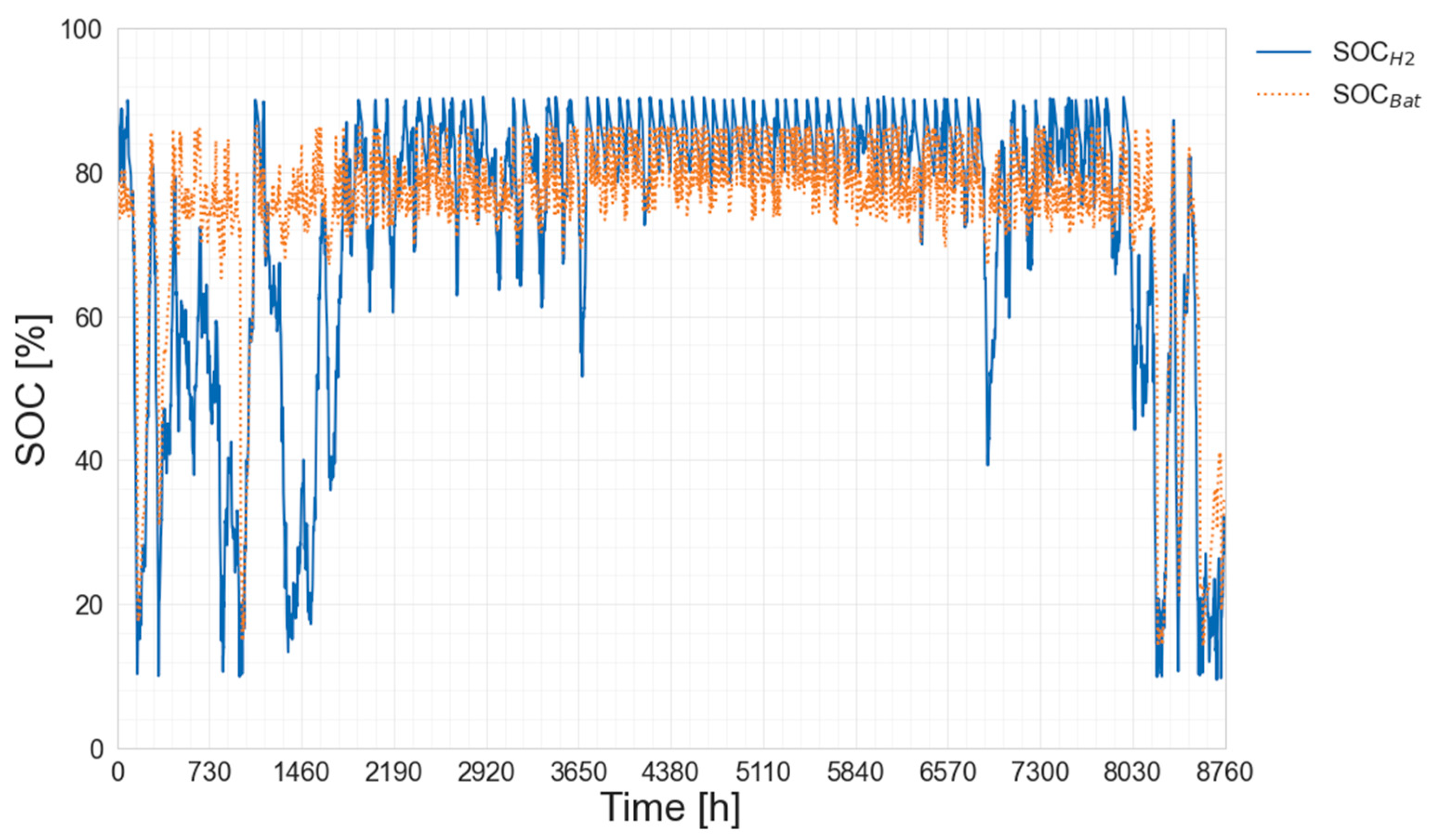

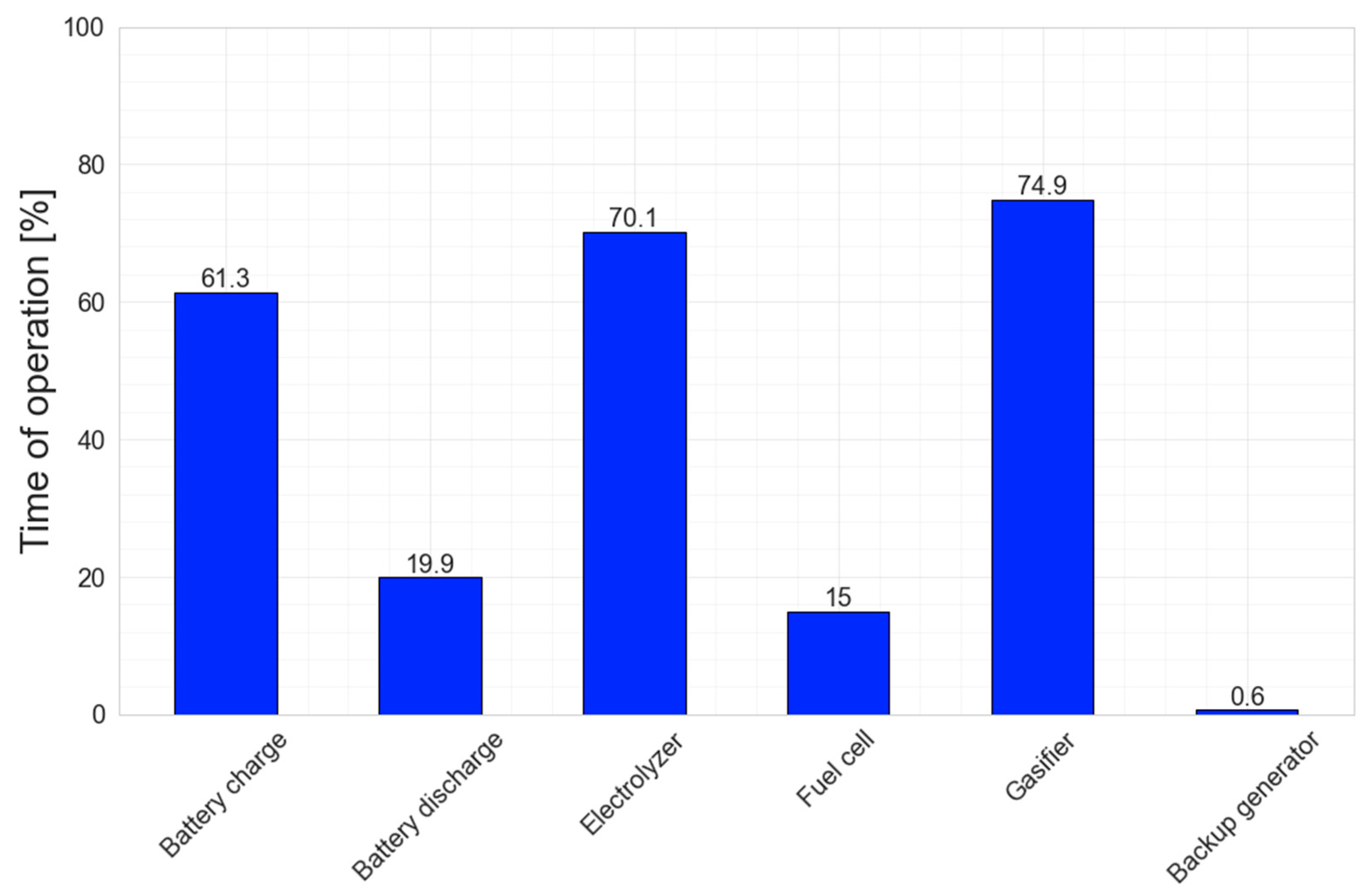

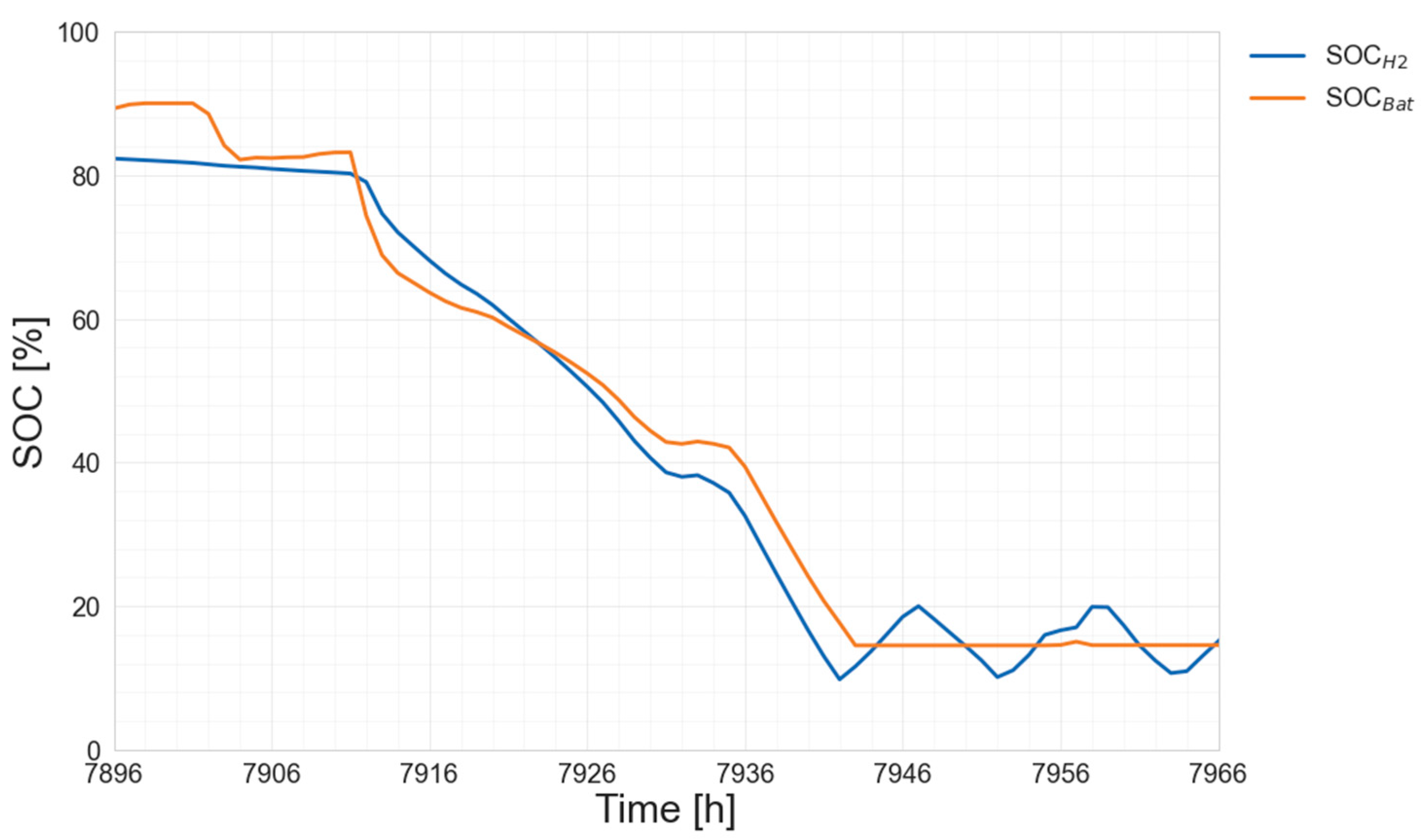

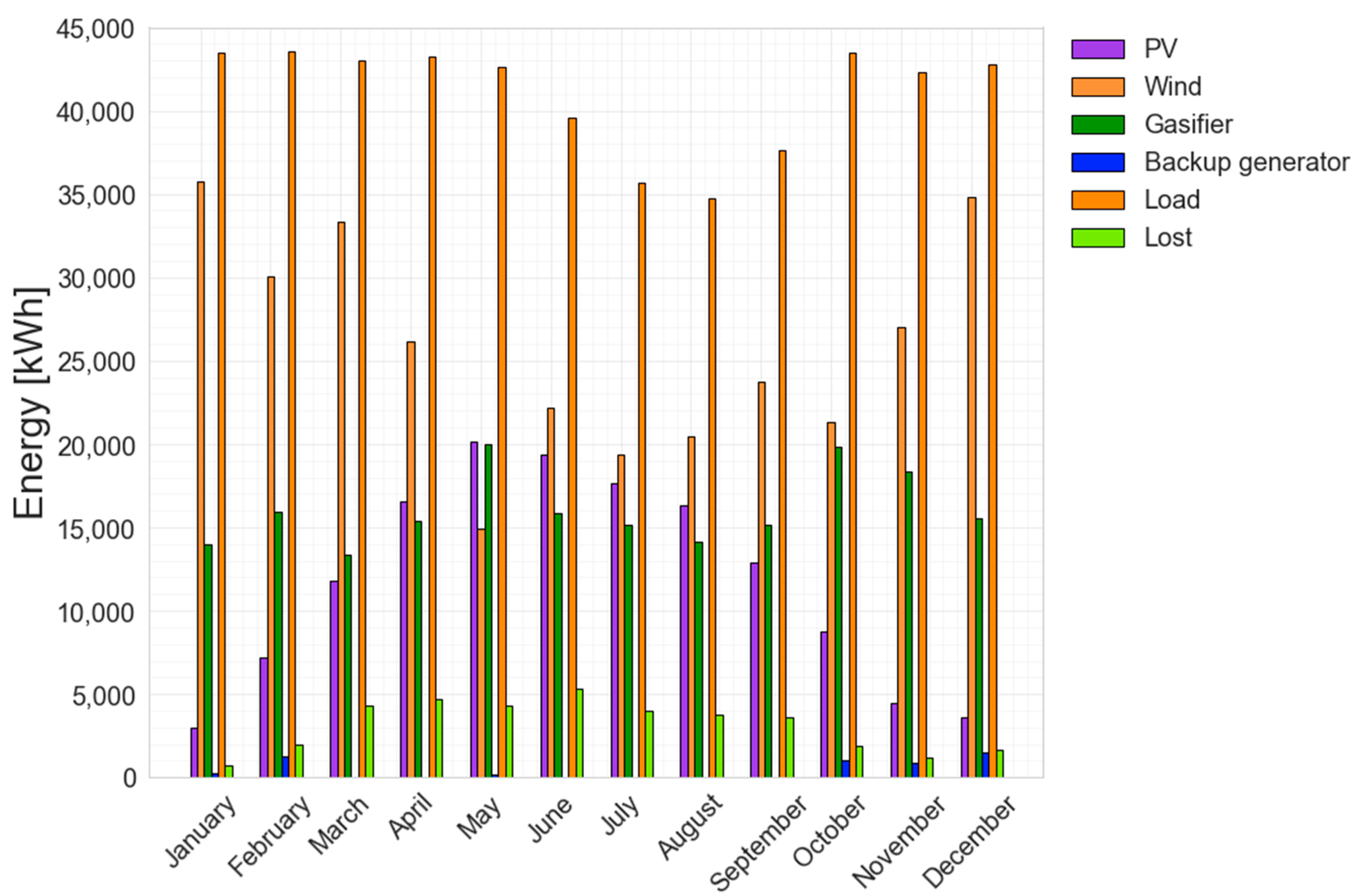

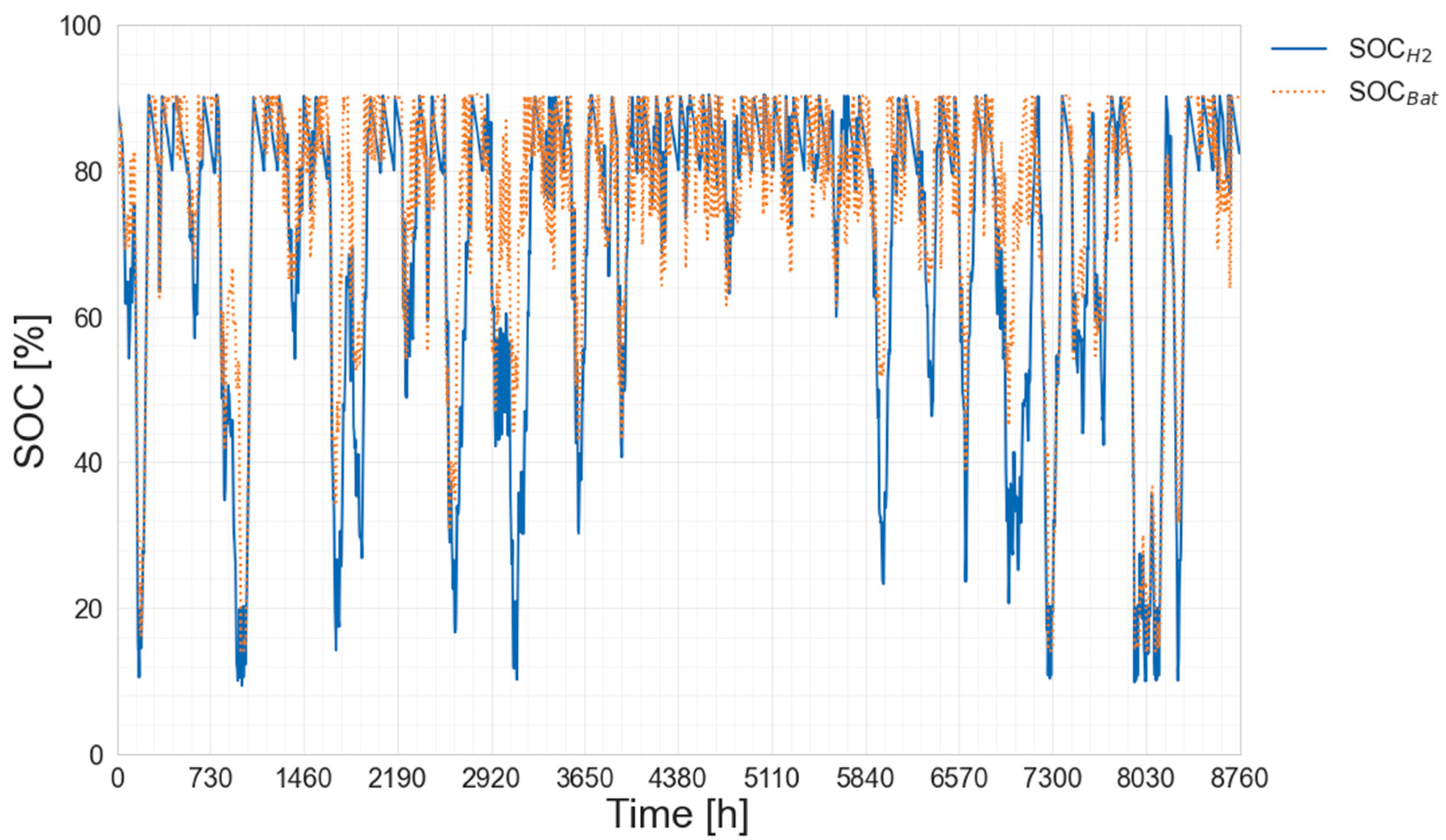

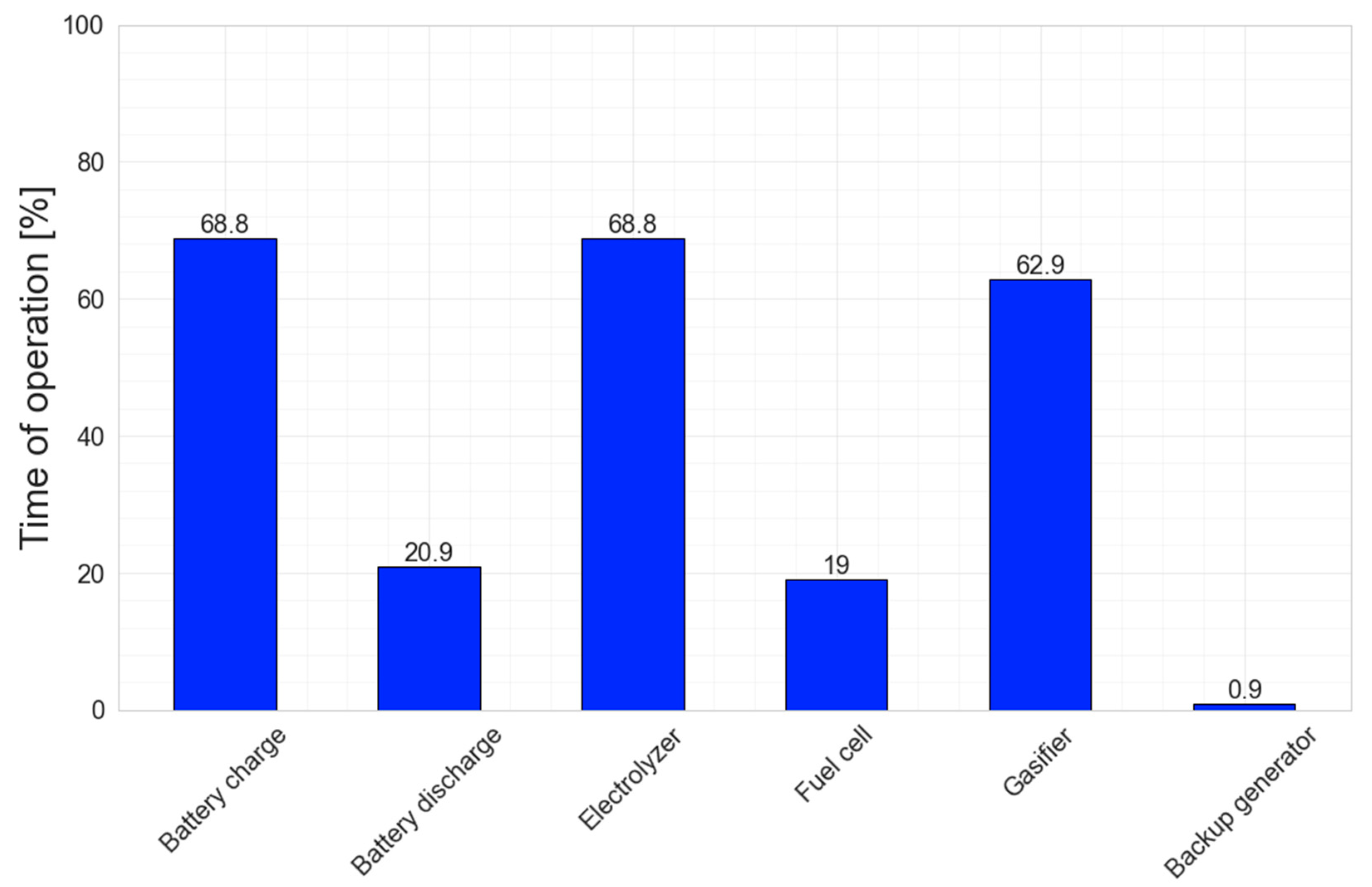

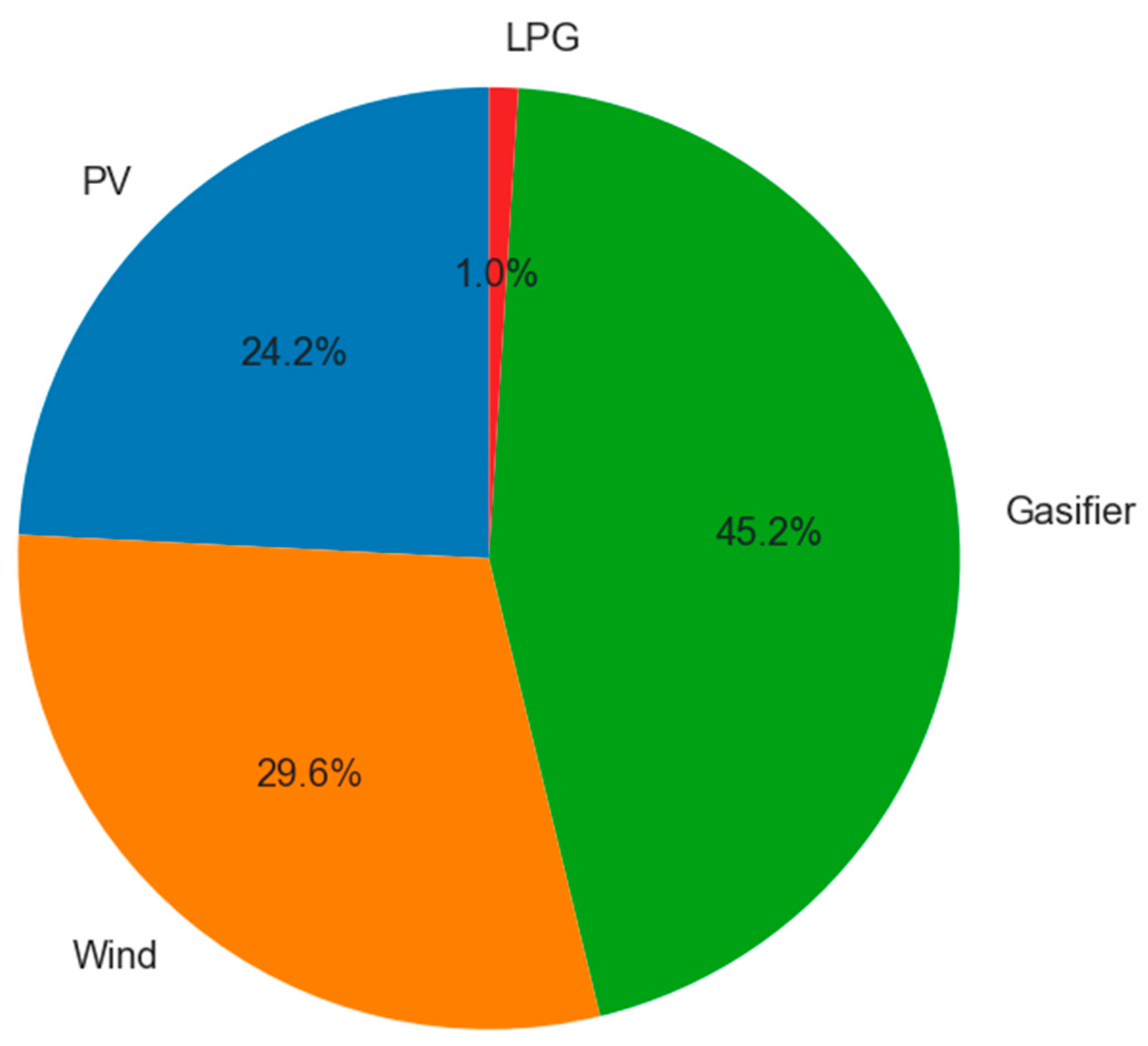

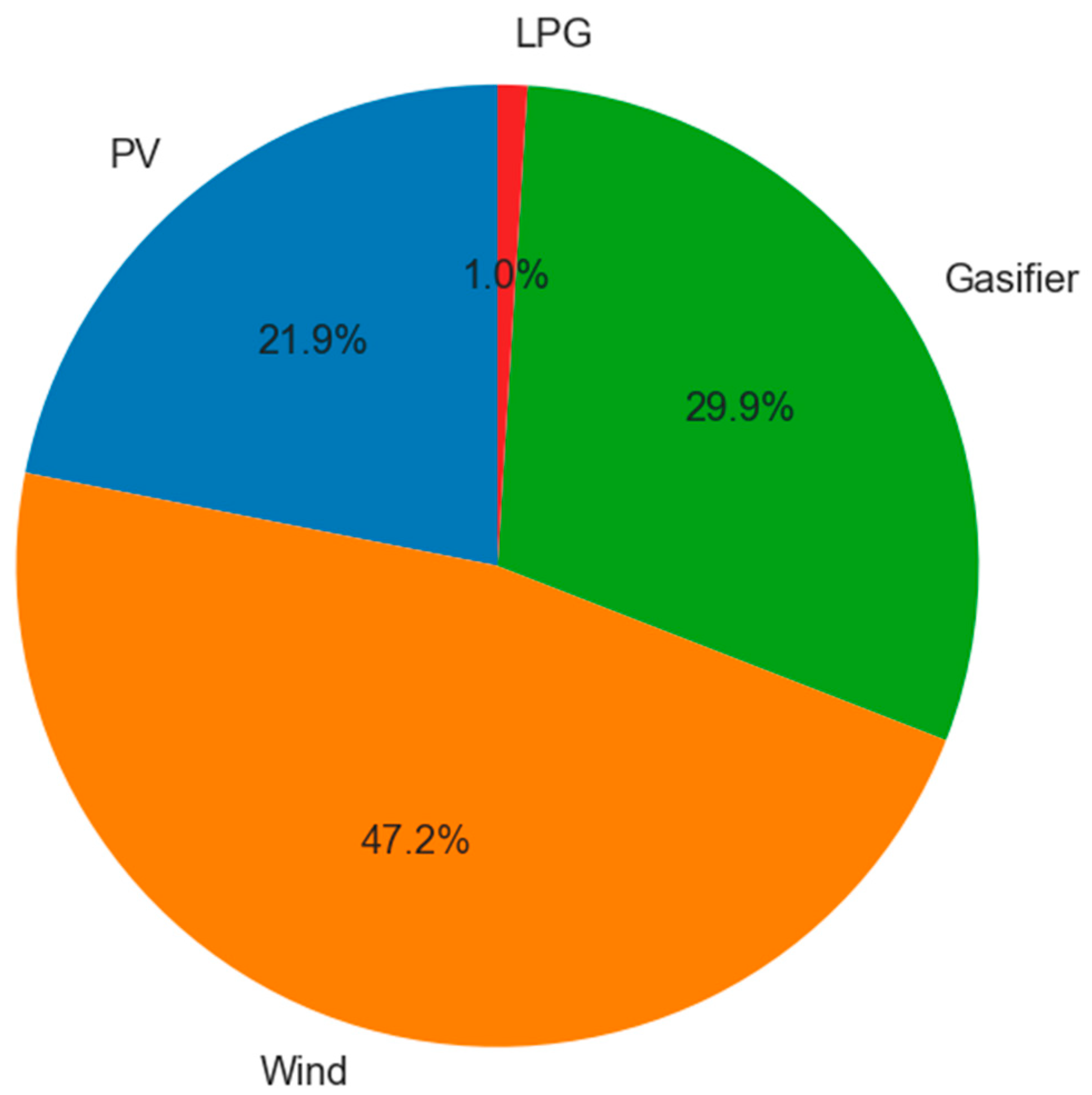

3. Results and Discussion

4. Conclusions

- Despite the availability of long-term energy storage, the energy safety of the presented system is highly dependent on access to wind energy. Due to higher user demand, Gdansk is able to operate in low-wind conditions only for about 3 days, while Agkistro empties its storage in 7 days;

- Presented energy systems are both producing excess energy—Gdansk 31% and Agkistro 43%. Amounts of lost energy are highest in the summer months, which justifies future research to improve the control algorithm, e.g., by disconnecting the gasifier in the summer;

- The operation costs related to the consumption of fuels (LPG and biomass) is different among the selected locations due to the different availability of wind and solar energy sources and capacity of components. The gasifier is more frequently activated in Agkistro compared to Gdansk, which leads to a 19.3% higher cost of exploitation. Conversely, the cost for LPG is higher in the case of Gdansk with respect to Agkistro (30%);

- The proposed system is not profitable in the case of Agkistro, since a Simple Pay Back period of over 22 years is achieved. In the case of Gdansk, this index achieves a value of 12.5 years, which shows that such investment may be profitable. It is worth noticing, that the presented system satisfies less than 1% of its needs from fossil fuels, which makes it possible to reduce initial costs in future research by omitting the gas infrastructure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hirsch, A.; Parag, Y.; Guerrero, J. Microgrids: A Review of Technologies, Key Drivers, and Outstanding Issues. Renew. Sustain. Energy Rev. 2018, 90, 402–411. [Google Scholar] [CrossRef]

- Baccioli, A.; Orecchini, F.; Peloriadi, K.; Iliadis, P.; Boutikos, P.; Atsonios, K.; Grammelis, P.; Nikolopoulos, A. Technoeconomic Assessment of LNG-Fueled Solid Oxide Fuel Cells in Small Island Systems: The Patmos Island Case Study. Energies 2022, 15, 3892. [Google Scholar]

- Yadav, D.; Singh, R.; Kumar, A.; Sarkar, B. Reduction of Pollution through Sustainable and Flexible Production by Controlling By-Products. J. Environ. Inform. 2022, in press. [Google Scholar] [CrossRef]

- Khodaei, H.; Hajiali, M.; Darvishan, A.; Sepehr, M.; Ghadimi, N. Fuzzy-Based Heat and Power Hub Models for Cost-Emission Operation of an Industrial Consumer Using Compromise Programming. Appl. Therm. Eng. 2018, 137, 395–405. [Google Scholar] [CrossRef]

- Abedinia, O.; Zareinejad, M.; Doranehgard, M.H.; Fathi, G.; Ghadimi, N. Optimal Offering and Bidding Strategies of Renewable Energy Based Large Consumer Using a Novel Hybrid Robust-Stochastic Approach. J. Clean. Prod. 2019, 215, 878–889. [Google Scholar] [CrossRef]

- Ghadimi, N.; Akbarimajd, A.; Shayeghi, H.; Abedinia, O. Two Stage Forecast Engine with Feature Selection Technique and Improved Meta-Heuristic Algorithm for Electricity Load Forecasting. Energy 2018, 161, 130–142. [Google Scholar] [CrossRef]

- Żołądek, M.; Filipowicz, M.; Sornek, K.; Figaj, R. Energy Performance of the photovoltaic system in urban area—Case study. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012123. [Google Scholar] [CrossRef]

- Kasaeian, A.; Nouri, G.; Ranjbaran, P.; Wen, D. Solar Collectors and Photovoltaics as Combined Heat and Power Systems: A Critical Review. Energy Convers Manag. 2018, 156, 688–705. [Google Scholar] [CrossRef]

- Filipowicz, M.; Żołądek, M.; Goryl, W.; Sornek, K. Urban Ecological Energy Generation on the Example of Elevation Wind Turbines Located at Center of Energy AGH. E3S Web Conf. 2018, 49, 00023. [Google Scholar] [CrossRef]

- Li, H.; Campana, P.E.; Tan, Y.; Yan, J. Feasibility Study about Using a Stand-Alone Wind Power Driven Heat Pump for Space Heating. Appl. Energy 2018, 228, 1486–1498. [Google Scholar] [CrossRef]

- Breault, R.W. Gasification Processes Old and New: A Basic Review of the Major Technologies. Energies 2010, 3, 216–240. [Google Scholar] [CrossRef] [Green Version]

- Jankowski, M.; Borsukiewicz, A.; Hooman, K. Development of Decision-Making Tool and Pareto Set Analysis for Bi-Objective Optimization of an ORC Power Plant. Energies 2020, 13, 5280. [Google Scholar] [CrossRef]

- Sornek, K. Study of Operation of the Thermoelectric Generators Dedicated to Wood-Fired Stoves. Energies 2021, 14, 6264. [Google Scholar] [CrossRef]

- Tschiggerl, K.; Sledz, C.; Topic, M. Considering Environmental Impacts of Energy Storage Technologies: A Life Cycle Assessment of Power-to-Gas Business Models. Energy 2018, 160, 1091–1100. [Google Scholar] [CrossRef]

- Sarkar, B.; Mridha, B.; Pareek, S. A Sustainable Smart Multi-Type Biofuel Manufacturing with the Optimum Energy Utilization under Flexible Production. J. Clean. Prod. 2022, 332, 129869. [Google Scholar] [CrossRef]

- Habib, M.S.; Omair, M.; Ramzan, M.B.; Chaudhary, T.N.; Farooq, M.; Sarkar, B. A Robust Possibilistic Flexible Programming Approach toward a Resilient and Cost-Efficient Biodiesel Supply Chain Network. J. Clean. Prod. 2022, 366, 132752. [Google Scholar] [CrossRef]

- Garai, A.; Sarkar, B. Economically Independent Reverse Logistics of Customer-Centric Closed-Loop Supply Chain for Herbal Medicines and Biofuel. J. Clean. Prod. 2022, 334, 129977. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Abeykoon, C.; Nasser, A.; Turan, A.; Ume, C.S. Prospects of Integrated Photovoltaic-Fuel Cell Systems in a Hydrogen Economy: A Comprehensive Review. Energies 2021, 14, 6827. [Google Scholar] [CrossRef]

- Khan, Z.A.; Imran, M.; Altamimi, A.; Diemuodeke, O.E.; Abdelatif, A.O. Assessment of Wind and Solar Hybrid Energy for Agricultural Applications in Sudan. Energies 2021, 15, 5. [Google Scholar] [CrossRef]

- Akter, H.; Howlader, H.O.R.; Nakadomari, A.; Islam, M.R.; Saber, A.Y.; Senjyu, T. A Short Assessment of Renewable Energy for Optimal Sizing of 100% Renewable Energy Based Microgrids in Remote Islands of Developing Countries: A Case Study in Bangladesh. Energies 2022, 15, 1084. [Google Scholar] [CrossRef]

- Hidalgo-Leon, R.; Amoroso, F.; Urquizo, J.; Villavicencio, V.; Torres, M.; Singh, P.; Soriano, G. Feasibility Study for Off-Grid Hybrid Power Systems Considering an Energy Efficiency Initiative for an Island in Ecuador. Energies 2022, 15, 1776. [Google Scholar] [CrossRef]

- Tarife, R.; Nakanishi, Y.; Chen, Y.; Zhou, Y.; Estoperez, N.; Tahud, A. Optimization of Hybrid Renewable Energy Microgrid for Rural Agricultural Area in Southern Philippines. Energies 2022, 15, 2251. [Google Scholar] [CrossRef]

- Dimou, A.; Vakalis, S. Technoeconomic Analysis of Green Energy Transitions in Isolated Grids: The Case of Ai Stratis—Green Island. Renew. Energy 2022, 195, 66–75. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Forzano, C.; Giuzio, G.F.; Palombo, A. Increasing Renewable Energy Penetration and Energy Independence of Island Communities: A Novel Dynamic Simulation Approach for Energy, Economic, and Environmental Analysis, and Optimization. J. Clean. Prod. 2021, 311, 127558. [Google Scholar] [CrossRef]

- Hoseinzadeh, S.; Astiaso Garcia, D. Techno-Economic Assessment of Hybrid Energy Flexibility Systems for Islands’ Decarbonization: A Case Study in Italy. Sustain. Energy Technol. Assess. 2022, 51, 101929. [Google Scholar] [CrossRef]

- Cabrera, P.; Carta, J.A.; Lund, H.; Thellufsen, J.Z. Large-Scale Optimal Integration of Wind and Solar Photovoltaic Power in Water-Energy Systems on Islands. Energy Convers Manag. 2021, 235, 113982. [Google Scholar] [CrossRef]

- Figaj, R. Performance Assessment of a Renewable Micro-Scale Trigeneration System Based on Biomass Steam Cycle, Wind Turbine, Photovoltaic Field. Renew. Energy 2021, 177, 193–208. [Google Scholar] [CrossRef]

- Figaj, R.; Sornek, K.; Podlasek, S.; Żołądek, M. Operation and Sensitivity Analysis of a Micro-Scale Hybrid Trigeneration System Integrating a Water Steam Cycle and Wind Turbine under Different Reference Scenarios. Energies 2020, 13, 5697. [Google Scholar] [CrossRef]

- Klein, S.A. TRNSYS 18: A Transient System Simulation Program; Solar Energy Laboratory, University of Wisconsin: Madison, WI, USA, 2017. [Google Scholar]

- Calise, F. High Temperature Solar Heating and Cooling Systems for Different Mediterranean Climates: Dynamic Simulation and Economic Assessment. Appl. Therm. Eng. 2012, 32, 108–124. [Google Scholar] [CrossRef]

- Calise, F.; Figaj, R.; Vanoli, L. Energy and Economic Analysis of Energy Savings Measures in a Swimming Pool Centre by Means of Dynamic Simulations. Energies 2018, 11, 2182. [Google Scholar] [CrossRef]

- Figaj, R.; Żołądek, M.; Gory, W. Dynamic Simulation and Energy Economic Analysis of a Household Hybrid Ground-Solar-Wind System Using TRNSYS Software. Energies 2020, 13, 3523. [Google Scholar] [CrossRef]

- Hummer H25.0-100KW—100,00 KW—Wind Turbine. Available online: https://en.wind-turbine-models.com/turbines/1682-hummer-h25.0-100kw (accessed on 11 August 2022).

- Waste to Energy Companies—Ankur Scientific. Available online: https://www.ankurscientific.com/ (accessed on 11 August 2022).

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1991. [Google Scholar]

- Hyman, E.A. Phenomenological Cell Modelling: A Tool for Planning and Analyzing Battery Testing at the BEST Facility; U. S. Department of Energy: Newark, NJ, USA, 1977.

- HYDROGEMS. Hydrog En E Nergy M Odel S; Institute for Energy Technology: Kjeller, Norway, 1995. [Google Scholar]

- Ulleberg, Ø. Modeling of Advanced Alkaline Electrolyzers: A System Simulation Approach. Int. J. Hydrogen Energy 2003, 28, 21–33. [Google Scholar] [CrossRef]

- Çengel, Y.A.; Boles, M.A.; Kanoğlu, M. Thermodynamics: An Engineering Approach, 9th ed.; McGraw-Hill Education: New York, NY, USA, 2019; p. 1009. [Google Scholar]

- Lloyd, C.R. Assessment of Diesel Use in Remote Area Power Supply; Internal report prepared for the Australian Greenhouse Office; Energy Strategies: Canberra, Australia, 1999. [Google Scholar]

- Figaj, R.; Żołądek, M. Experimental and Numerical Analysis of Hybrid Solar Heating and Cooling System for a Residential User. Renew. Energy 2021, 172, 955–967. [Google Scholar] [CrossRef]

- International LNG Prices by Select Region 2021 | Statista. Available online: https://www.statista.com/statistics/252984/landed-prices-of-liquefied-natural-gas-in-selected-regions-worldwide/ (accessed on 11 August 2022).

- Woodfuel Economics—Forest Research. Available online: https://www.forestresearch.gov.uk/tools-and-resources/fthr/urban-regeneration-and-greenspace-partnership/greenspace-in-practice/benefits-of-greenspace/woodfuel-economics/ (accessed on 11 August 2022).

- How Much Money Does a Wind Turbine Produce From Electricity It Generates?—Anemoi ServicesAnemoi Services. Available online: http://anemoiservices.com/industry-news/how-much-money-does-a-wind-turbine-produce-from-electricity-it-generates/ (accessed on 11 August 2022).

- Solar PV Installation Cost Worldwide 2021 | Statista. Available online: https://www.statista.com/statistics/809796/global-solar-power-installation-cost-per-kilowatt/ (accessed on 11 August 2022).

- Ramasamy, V.; Feldman, D.; Desai, J.; Margolis, R. U.S. Solar Photovoltaic System and Energy Storage Cost Benchmarks: Q1 2021; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2021. [Google Scholar]

- Zauner, A.; Böhm, H.; Rosenfeld, D.; Tichler, R. Innovative Large-Scale Energy Storage Technologies and Power-to-Gas Concepts after Optimization D7.7 Analysis on Future Technology Options and on Techno-Economic Optimization. 2019. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5c58ae3ff&appId=PPGMS (accessed on 9 June 2022).

- Gorre, J.; Ruoss, F.; Karjunen, H.; Schaffert, J.; Tynjälä, T. Cost Benefits of Optimizing Hydrogen Storage and Methanation Capacities for Power-to-Gas Plants in Dynamic Operation. Appl. Energy 2020, 257, 113967. [Google Scholar] [CrossRef]

- Cigolotti, V.; Genovese, M.; Fragiacomo, P. Comprehensive Review on Fuel Cell Technology for Stationary Applications as Sustainable and Efficient Poly-Generation Energy Systems. Energies 2021, 14, 4963. [Google Scholar] [CrossRef]

- Borello, D.; de Caprariis, B.; de Filippis, P.; di Carlo, A.; Marchegiani, A.; Pantaleo, A.M.; Shah, N.; Venturini, P. Thermo-Economic Assessment of a Olive Pomace Gasifier for Cogeneration Applications. Energy Procedia 2015, 75, 252–258. [Google Scholar] [CrossRef]

- Ericson, S.; Olis, D. A Comparison of Fuel Choice for Backup Generators; The Joint Institute for Strategic Energy Analysis: Golden, CO, USA, 2019. [Google Scholar] [CrossRef]

- Karagiorgas, M.; Tsoutsos, T.; Moiá-Pol, A. A Simulation of the Energy Consumption Monitoring in Mediterranean Hotels: Application in Greece. Energy Build 2007, 39, 416–426. [Google Scholar] [CrossRef]

- Ogrodniczuk, J.; Węglarz, A.; Kamieniecka, J. Energia w Obiekcie Turystycznym; Fundacja Instytut na rzecz Ekorozwoju: Warsaw, Poland, 2011. [Google Scholar]

- RYNEK HOTELARSKI W POLSCE—RAPORT 2019 by BROG B2B Sp. z o.o. S.K.—Issuu. Available online: https://issuu.com/brogmarketing/docs/rynek_hotelarski_w_polsce_-_raport_2019 (accessed on 9 June 2022).

- About Us | Krajowa Agencja Poszanowania Energii | KAPE S.A. Available online: https://kape.gov.pl/about-us (accessed on 9 June 2022).

| Technology | Project Scale | Evaluation Tool | Economic Evaluation | Location | Ref. |

|---|---|---|---|---|---|

| PV + wind | 30–480 kWh/year | Homer pro | LCOE = 0.36–1.28 EUR/kWh | Sudan | [19] |

| PV + battery + fuel cell | 31 kW | Matlab | - | Bangladesh | [20] |

| PV + diesel + battery | 50 kW | Homer pro | LCOE = 0.390–0.421 EUR/kWh | Ecuador | [21] |

| PV + diesel + battery + hydroelectric plant | Agriculture processing facility | Matlab | LCOE = 0.197 EUR/kWh | Philippines | [22] |

| PV + wind + battery + diesel | Non-interconnected island | Homer pro | LCOE = 0.148–0.295 EUR/kWh | Greece | [23] |

| PV + wind-power hydro storage + battery + diesel + solar thermal collectors | Non-interconnected island + reverse osmosis plant | TRNSYS | SPBT = 8.9 years | Canary Islands | [24] |

| PV + wind + fuel cell | 2 MW | Homer pro | - | Sicily, Italy | [25] |

| PV + wind + diesel | Non-interconnected island + reverse osmosis plant | EnergyPLAN + Matlab | - | Canary Islands | [26] |

| PV + wind + biomass RC | Zootechnical farm | TRNSYS | SPBT = 10.1 years | Poland | [27] |

| Biomass RC + wind | Zootechnical farm | TRNSYS | SPBT = 5.92 years | Poland | [28] |

| PV + wind + biomass gasifier + battery + fuel cell + LPG | Tourist resort | TRNSYS | SPBT = 12.5/22.5 years | Poland/Greece | Current study |

| Component | Type | Ref. | Component | Type | Ref. |

|---|---|---|---|---|---|

| WT | 90 | [33] | Mini-grid controlling system | 105 | [29] |

| PV | 103b | [35] | Inverter, charge controller | 175, 48 | [29] |

| BAT | 47a | [36] | On/off differential controller | 911 | [29] |

| FC | 173 | [37] | Data plotter | 25c | [29] |

| ELY | 160 | [38] | Data reader | 9a | [29] |

| HS | 164 | [39] | Data integrator | 24 | [29] |

| LPG | 120 | [40] | Weather data processor | 15 | [29] |

| PWT | PPV | PGas | PFC | PEly | CapH2 | Pbat | Capbst | |

|---|---|---|---|---|---|---|---|---|

| Agkistro | 100 | 100 | 35 | 60 | 40 | 1500 | 60 | 500 |

| Gdansk | 70 | 120 | 35 | 50 | 20 | 1500 | 60 | 400 |

| Unit | kW | kW | kW | kW | kW | kWh | kW | kWh |

| Parameter. | Agkistro | Gdansk | Unit |

|---|---|---|---|

| Eload | 354 × 103 | 492 × 103 | kWh/year |

| EWT | 151 × 103 | 309 × 103 | kWh/year |

| EPV | 126 × 103 | 143 × 103 | kWh/year |

| EGas | 229 × 103 | 192 × 103 | kWh/year |

| ERES | 507 × 103 | 645 × 103 | kWh/year |

| Ebackup | 4 × 103 | 5.2 × 103 | kWh/year |

| Ebackup | 1 | 1 | % load |

| Ecurtailed | 152 × 103 | 153 × 103 | kWh/year |

| Ecurtailed | 43 | 31 | % load |

| tgas | 6557 | 5507 | h/year |

| Normalized equivalent hours, WT | 0.172 | 0.503 | - |

| Normalized equivalent hours, PV | 0.144 | 0.136 | - |

| Parameter | Agkistro | Gdansk | Unit | Calculated on the Basis of Ref. |

|---|---|---|---|---|

| CostWT | 600,000 | 420,000 | EUR | [32] |

| CostPV | 88,000 | 105,600 | EUR | [33] |

| CostGAS | 175,000 | 175,000 | EUR | [38] |

| CostBAT | 35,000 | 35,000 | EUR | [34] |

| CostH2circuit | 1,151,000 | 1,073,000 | EUR | [35,36,37] |

| CostLPG | 70,000 | 70,000 | EUR | [39] |

| Costmaintanance | 17,500 | 17,500 | EUR/year | - |

| Biomass cost | 18,618 | 15,610 | EUR/year | [31] |

| LPG cost | 1440 | 1872 | EUR/year | [30] |

| SPBT | 22.5 | 12.5 | years | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żołądek, M.; Kafetzis, A.; Figaj, R.; Panopoulos, K. Energy-Economic Assessment of Islanded Microgrid with Wind Turbine, Photovoltaic Field, Wood Gasifier, Battery, and Hydrogen Energy Storage. Sustainability 2022, 14, 12470. https://doi.org/10.3390/su141912470

Żołądek M, Kafetzis A, Figaj R, Panopoulos K. Energy-Economic Assessment of Islanded Microgrid with Wind Turbine, Photovoltaic Field, Wood Gasifier, Battery, and Hydrogen Energy Storage. Sustainability. 2022; 14(19):12470. https://doi.org/10.3390/su141912470

Chicago/Turabian StyleŻołądek, Maciej, Alexandros Kafetzis, Rafał Figaj, and Kyriakos Panopoulos. 2022. "Energy-Economic Assessment of Islanded Microgrid with Wind Turbine, Photovoltaic Field, Wood Gasifier, Battery, and Hydrogen Energy Storage" Sustainability 14, no. 19: 12470. https://doi.org/10.3390/su141912470