Safety Risk Identification Method for Railway Construction in Complex and Dangerous Areas

Abstract

:1. Introduction

2. The Safety Risk Identification Method Based on the G–T–WBS–RBS Matrix

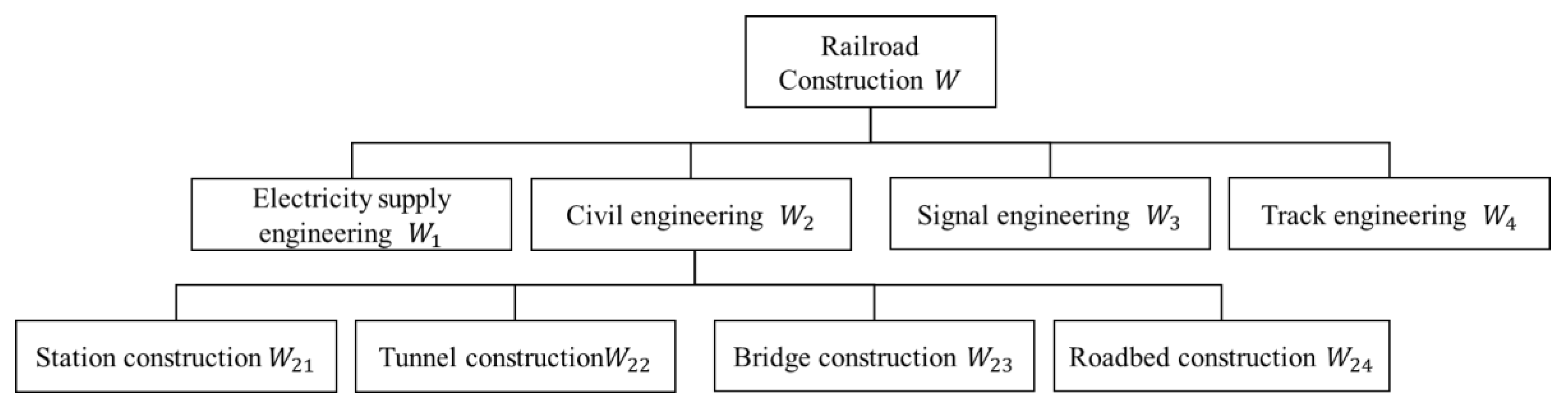

- Use the WBS to analyze railway projects and form the corresponding WBS tree. Based on the characteristics of the construction activities, form the railway construction safety risk identification grid.

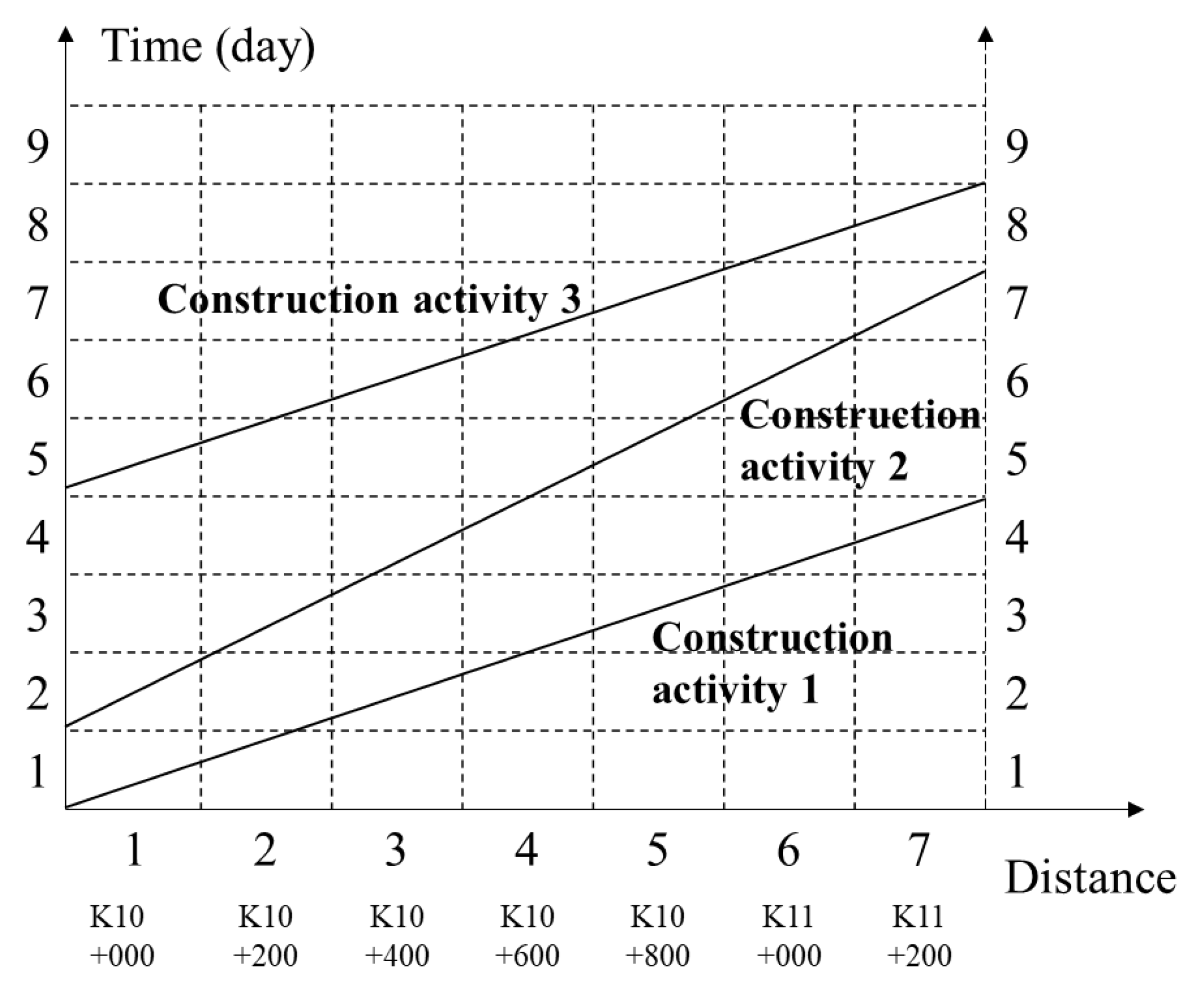

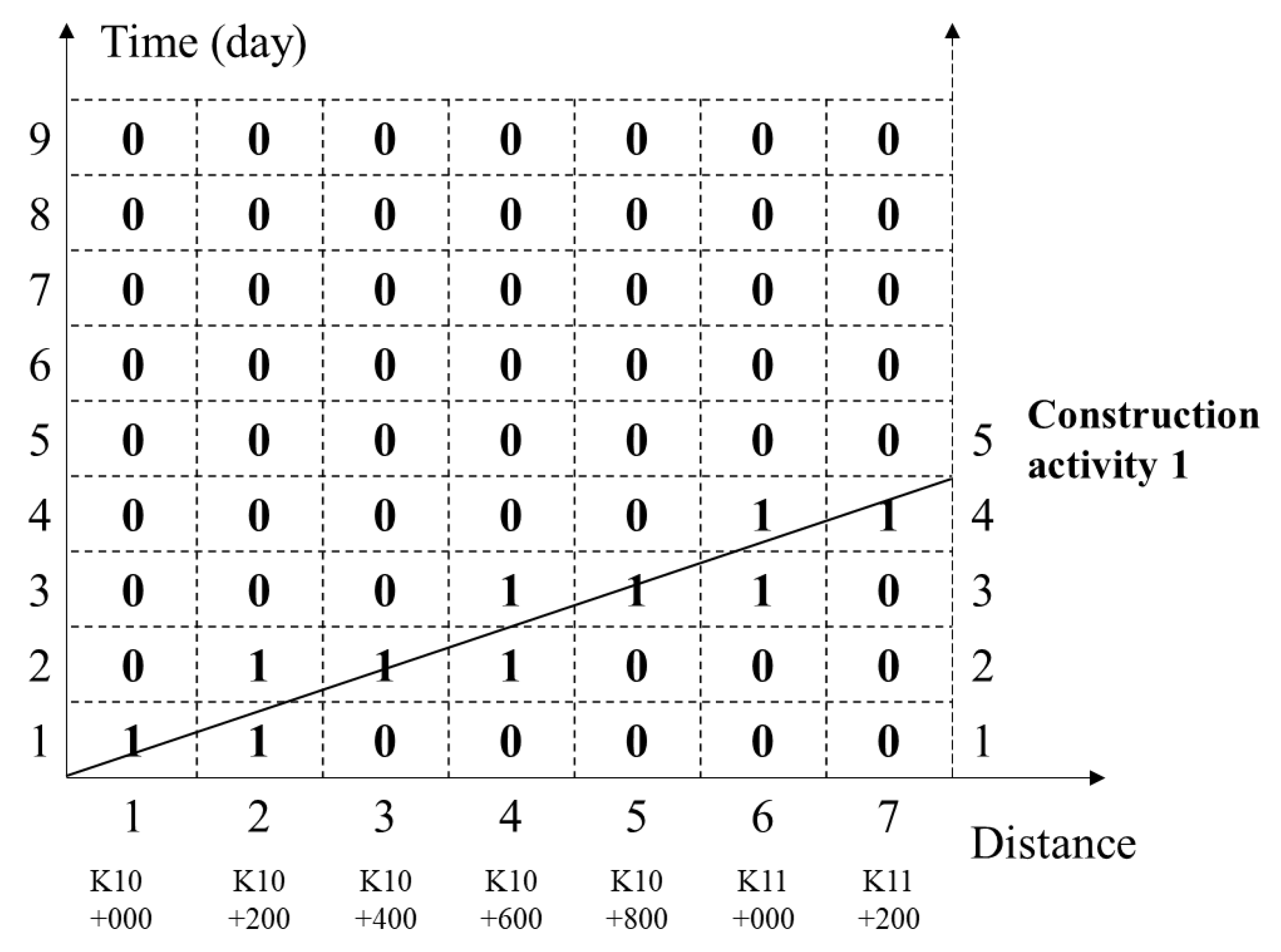

- Find the temporal location relationship between the WBS trees and the railway construction safety risk identification grid and build the G–T–WBS (grid–time–WBS) matrix.

- Identify and sort the risks and form the RBS trees, then cross the G–T–WBS matrix and the RBS tree to form the G–T–WBS–RBS matrix.

- Identify the construction activities and associated risks in each grid, then analyze the spatial and temporal distribution characteristics of the safety risks of RCCDA.

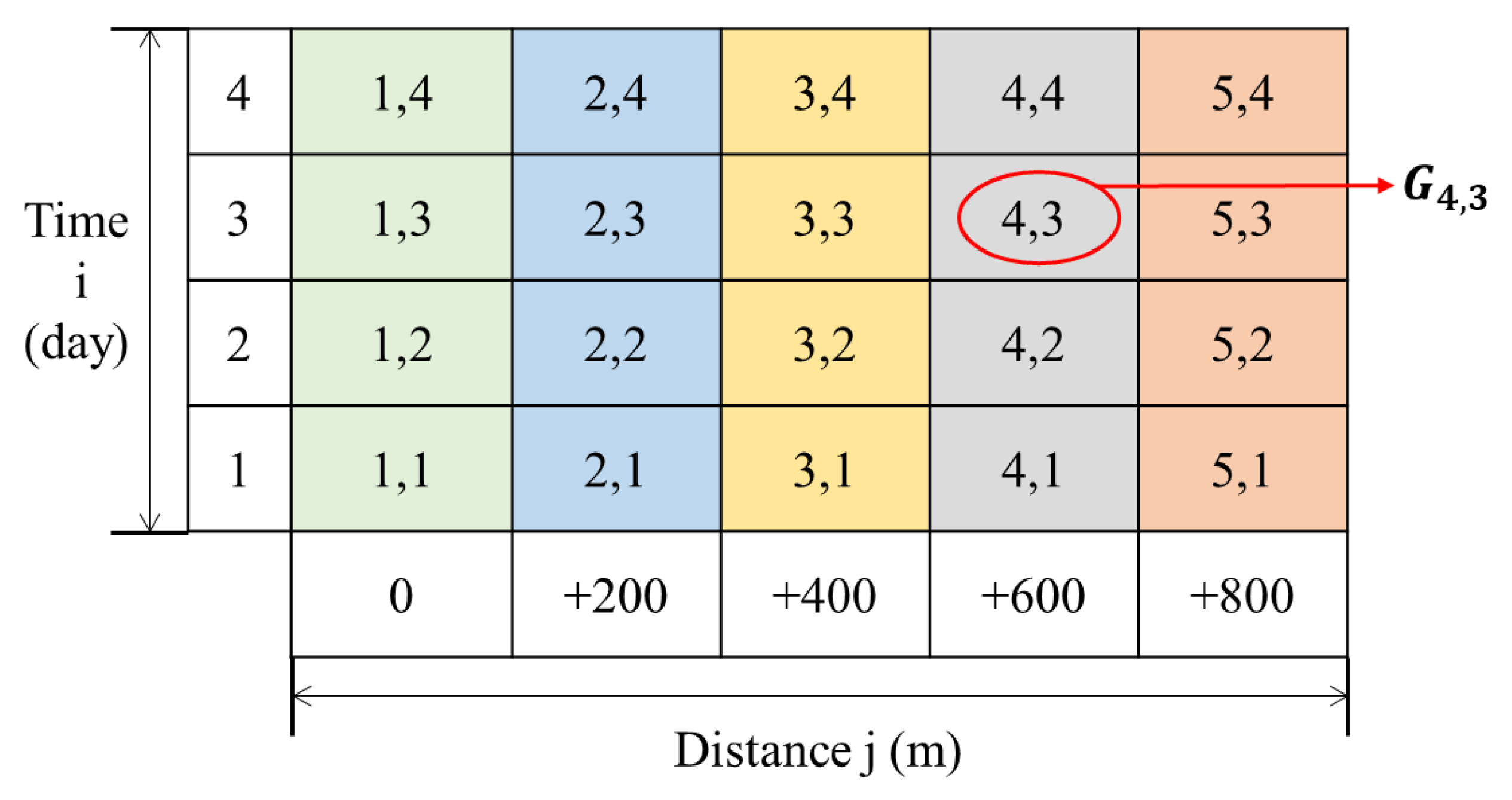

2.1. Safety Risk Management Grid of Railway Construction

- Mileage length division of the railway construction safety risk identification grid (RCSRIG). According to the characteristics of railways, such as long lines, many points, wide areas, and clear land boundaries, the RCSRIG should be divided according to the length of the mileage. According to the characteristics of railway construction and previous studies [30], the RCSRIG uses a line section of 200 m as the basic mileage length unit.

- Time length division of the RCSRIG. Railway construction is a continuous activity. Once the project starts, no special circumstances will interrupt the construction process; construction safety risks have been accompanied by the entire process. In addition, the occurrence of risk has irregularity and suddenness. Therefore, the management of construction safety risks is equally continuous and lasting. At the same time, railway construction can be divided into stages such as construction preparation, main construction section, completion, and acceptance. Each stage has a certain time zone, corresponding to different safety risks. In addition, the project schedule is prepared in accordance with the days, and the actual construction is also in accordance with the daily plan. So, the RCSRIG uses a day as the basic time length unit.

2.2. Railway Construction WBS and RBS

2.3. The Safety Risk Identification Method Based on G–T–WBS–RBS

3. Case Study

4. Discussions

5. Conclusions

- During the construction of the A Railway, bridge construction, station construction, and roadbed construction are most likely to receive climate hazards, while tunnel construction is more likely to be affected by geological hazards. Because of the intense geological activities along the railway line, it is necessary to take precautionary measures against seismic hazards during the construction process. Diseases represented by plague and occupational diseases are prone to occur during the construction of stations or tunnels where the construction site is crowded, or the air is closed. Based on the interrelation between subprojects and their risks, project managers can develop targeted risk prevention measures during the construction process. For climate hazards, managers can build perfect climate monitoring and early warning means and take effective risk control measures before the emergence of extreme climate. For geological hazards, managers should do a good job of geological prediction in the construction process of tunnel engineering and predict the possible geological disasters in time. For diseases, managers should always keep the environment of the construction site healthy to avoid the generation and transmission of diseases.

- Risk events are generated by the coupling of risk factors, so the interrelationship of risk factors can reflect the evolutionary process of risk to some extent. By analyzing the interrelationship between the safety risks of the A Railway civil engineering, it can be found that rain, snow, strong winds, and scaffolding instability always happen in the same space and time, and they have a strong mutual relationship, which indicates that bad weather is an important cause of scaffolding instabilities. Similarly, rain, snow, mudslides, and dangerous rock falls have the same interrelationship. Based on the results of this study, managers can strengthen scaffolding and support structures before extreme weather events occur. In addition, it is also necessary to organize the construction personnel to avoid the natural hazards caused by the extreme weather in time. By focusing on the distribution of risk factors in space and time and finding risk factors with strong interrelationships, the analysis results can provide an important theoretical basis for risk evolution analysis.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meng, Q.F.; Peng, Q.Y.; Li, Z.; Hu, X. Big Data Technology in Construction Safety Management: Application Status, Trend and Challenge. Buildings 2022, 12, 533. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M.; Khosravi, Y. Factors influencing safety performance on construction projects: A review. Saf. Sci. 2018, 109, 382–397. [Google Scholar] [CrossRef]

- Kaczorek, K.; Krzeminski, M.; Ibadov, N. The problem of choosing risk management methodology at the example of railway construction. In Proceedings of the 26th R-S-P Seminar on Theoretical Foundation of Civil Engineering (RSP), Warsaw, Poland, 21–25 August 2017; p. 117. [Google Scholar]

- Wang, W.D.; Li, J.Y.; Han, Z. Comprehensive assessment of geological hazard safety along railway engineering using a novel method: A case study of the Sichuan-Tibet railway, China. Geomat. Nat. Hazards Risk 2020, 11, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.H.; Li, H.J.; Wang, Y.G.; Cheng, B.Q. A Comprehensive Assessment Approach for Water-Soil Environmental Risk during Railway Construction in Ecological Fragile Region Based on AHP and MEA. Sustainability 2020, 12, 7910. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, M.J.; Oseth, O.; Ronnquist, A. Wind deflection analysis of railway catenary under crosswind based on nonlinear finite element model and wind tunnel test. Mech. Mach. Theory 2022, 168, 104608. [Google Scholar] [CrossRef]

- Magalhaes, H.; Pombo, J.; Ambrosio, J.; Madeira, J.F.A. Rail vehicle design optimization for operation in a mountainous railway track. Innov. Infrastruct. Solut. 2017, 2, 31. [Google Scholar] [CrossRef] [Green Version]

- Dong, S.C.; Yang, Y.; Li, F.J.; Cheng, H.; Li, J.N.; Bilgaev, A.; Li, Z.H.; Li, Y. An evaluation of the economic, social, and ecological risks of China-Mongolia-Russia high-speed railway construction and policy suggestions. J. Geogr. Sci. 2018, 28, 900–918. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.R.; Shang, C.; Wang, C.; Song, R.; Wang, X.H. Real-Time Safety Risk Identification Model during Metro Construction Adjacent to Buildings. J. Constr. Eng. Manag. 2019, 145, 04019034. [Google Scholar] [CrossRef]

- Goh, Y.M.; Chua, D.K.H. Case-Based Reasoning Approach to Construction Safety Hazard Identification: Adaptation and Utilization. J. Constr. Eng. Manag.-Asce 2010, 136, 170–178. [Google Scholar] [CrossRef]

- Hamidi, J.K.; Shahriar, K.; Rezai, B.; Rostami, J.; Bejari, H. Risk assessment based selection of rock TBM for adverse geological conditions using Fuzzy-AHP. Bull. Eng. Geol. Environ. 2010, 69, 523–532. [Google Scholar] [CrossRef]

- Leitner, B. A General Model for Railway Systems Risk Assessment with the Use of Railway Accident Scenarios Analysis. In Proceedings of the 10th International Scientific Conference on Transportation Science and Technology (TRANSBALTICA), Vilnius, Lithuania, 4–5 May 2017; pp. 150–159. [Google Scholar]

- Vishwas, H.S.; Gidwani, G.D. Hazards Identification and Risk Assessment in Metro Railway Line Construction Project at Hyderabad. Int. J. Eng. Tech. Res. 2017, V6, 8. [Google Scholar] [CrossRef]

- Liu, Q.L.; Peng, Y.M.; Li, Z.Y.; Zhao, P.; Qiu, Z.X. Hazard identification methodology for underground coal mine risk management—Root-State Hazard Identification. Resour. Policy 2021, 72, 102052. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Z.; Peng, F. Causality-Network-Based Critical Hazard Identification for Railway Accident Prevention: Complex Network-Based Model Development and Comparison. Entropy 2021, 23, 864. [Google Scholar] [CrossRef] [PubMed]

- Lekan, A.; Clinton, A.; Fayomi, O.S.I.; James, O. Lean Thinking and Industrial 4.0 Approach to Achieving Construction 4.0 for Industrialization and Technological Development. Buildings 2020, 10, 221. [Google Scholar] [CrossRef]

- Ding, L.Y.; Yu, H.L.; Li, H.; Zhou, C.; Wu, X.G.; Yu, M.H. Safety risk identification system for metro construction on the basis of construction drawings. Autom. Constr. 2012, 27, 120–137. [Google Scholar] [CrossRef]

- Shi, D.H.; Guan, J.; Zurada, J.; Manikas, A. A Data-Mining Approach to Identification of Risk Factors in Safety Management Systems. J. Manag. Inf. Syst. 2017, 34, 1054–1081. [Google Scholar] [CrossRef]

- Aliyari, M.; Ashrafi, B.; Ayele, Y.Z. Hazards identification and risk assessment for UAV-assisted bridge inspections. Struct. Infrastruct. Eng. 2022, 18, 412–428. [Google Scholar] [CrossRef]

- Ji, T.; Liu, J.W.; Li, Q.F. Safety Risk Evaluation of Large and Complex Bridges during Construction Based on the Delphi-Improved FAHP-Factor Analysis Method. Adv. Civ. Eng. 2022, 2022, 5379032. [Google Scholar] [CrossRef]

- Zhang, L.; Li, H.B. Construction Risk Assessment of Deep Foundation Pit Projects Based on the Projection Pursuit Method and Improved Set Pair Analysis. Appl. Sci. 2022, 12, 1922. [Google Scholar] [CrossRef]

- Kuang, X.; Yi, D.Q.; Wang, C.L. Study on Construction Risk Assessment Method of Deep Buried Tunnels. In Proceedings of the 2nd International Conference on Civil, Architectural and Hydraulic Engineering (ICCAHE 2013), Zhuhai, China, 27–28 July 2013; pp. 1305–1308. [Google Scholar]

- Miao, J.X.; Huang, D.C.; He, Z.Q. Social Risk Assessment and Management for Major Construction Projects in China Based on Fuzzy Integrated Analysis. Complexity 2019, 2019, 2452895. [Google Scholar] [CrossRef]

- Zhang, L.M.; Wu, X.G.; Ding, L.Y.; Skibniewski, M.J.; Lu, Y.J. BIM-based risk identification system in tunnel construction. J. Civ. Eng. Manag. 2016, 22, 529–539. [Google Scholar] [CrossRef] [Green Version]

- Huang, R.Q.; Li, Y.R.; Qu, K.; Wang, K. Engineering geological assessment for route selection of railway line in geologically active area: A case study in China. J. Mt. Sci. 2013, 10, 495–508. [Google Scholar] [CrossRef] [Green Version]

- Chatziioannou, A.A.; Kanaris, I.; Doukas, C.; Moulos, P.; Kolisis, F.N.; Maglogiannis, I. GRISSOM Platform: Enabling Distributed Processing and Management of Biological Data Through Fusion of Grid and Web Technologies. IEEE Trans. Inf. Technol. Biomed. 2011, 15, 83–92. [Google Scholar] [CrossRef] [PubMed]

- Yi, M.G. Path Exploration of Grid Management of Marine Communities Based on Numerical Assimilation. J. Coast. Res. 2020, 115, 327–332. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Li, Z.Y.; Shahidehpour, M.; Ai, B. Battery-Based Energy Storage Transportation for Enhancing Power System Economics and Security. IEEE Trans. Smart Grid 2015, 6, 2395–2402. [Google Scholar] [CrossRef]

- Geng, X.; Zhang, P.R.; Cai, Y.; Liang, Y.; Wu, Q.L. Comparative Study on Simulation of Grid and Non-grid Management Process of Farmland. In Proceedings of the 4th International Conference on Management Engineering, Software Engineering and Service Sciences (ICMSS), Wuhan, China, 17–19 January 2020; pp. 174–183. [Google Scholar]

- An, R.; Sun, Q.X.; Wang, F.T.; Bai, W.F.; Zhu, X.Y.; Liu, R.K. Improved Railway Track Geometry Degradation Modeling for Tamping Cycle Prediction. J. Transp. Eng. Part A-Syst. 2018, 144. [Google Scholar] [CrossRef]

- Yan, H.Y.; Gao, C.; Elzarka, H.; Mostafa, K.; Tang, W.B. Risk assessment for construction of urban rail transit projects. Saf. Sci. 2019, 118, 583–594. [Google Scholar] [CrossRef]

- Wang, Y.P.; Bai, Z.C.; Zhang, Y.; Qin, Y.X.; Lin, Y.; Li, Y.; Shen, W.J. Using TerraSAR X-Band and Sentinel-1 C-Band SAR Interferometry for Deformation Along Beijing-Tianjin Intercity Railway Analysis. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2021, 14, 4832–4841. [Google Scholar] [CrossRef]

- Lu, C.F.; Cai, C.X. Challenges and Countermeasures for Construction Safety during the Sichuan-Tibet Railway Project. Engineering 2019, 5, 833–838. [Google Scholar] [CrossRef]

- Shen, Z.B.; Zhang, M.J.; Liu, Y.Y.; Jiang, C.L.; IOP. Research on the influence mechanism of safety risk factors on traffic organization of high-speed railway construction. In Proceedings of the 6th International Conference on Advances in Energy Resources and Environment Engineering (ICAESEE), Chongqing, China, 20–22 November 2020; p. 012174. [Google Scholar]

| Risk Factor | Construction Activity 1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| G1,1 | G2,1 | G2,2 | G3,2 | G4,2 | G4,3 | G5,3 | G6,3 | G6,4 | G7,4 | |

| R1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 |

| R2 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 |

| R3 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 |

| Name | Tier 1 Risk Factors | Tier 2 Risk Factors |

|---|---|---|

| The A Railway construction safety risk R | Climate Hazards R1 | Rain and snow R11 |

| Severe cold R12 | ||

| Strong wind R13 | ||

| Thunder and lightning R14 | ||

| Engineering Hazards R2 | Temporary works collapse R21 | |

| Tunnel sudden water and mud R22 | ||

| Bridge/tunnel collapse R23 | ||

| Gas explosion R24 | ||

| Scaffolding instability R25 | ||

| Fall from height R26 | ||

| Mold burst R27 | ||

| Geological Hazards R3 | Mudslide R31 | |

| Avalanche R32 | ||

| Landslide R33 | ||

| Glacial eruption R34 | ||

| Tunnel deformation R35 | ||

| Dangerous rock fall R36 | ||

| High Geothermal R37 | ||

| Karst R38 | ||

| High Temperature Water R39 | ||

| Rock explosion R310 | ||

| Seismic R311 | ||

| Highland Hazards R4 | Occupational disease R41 | |

| Acute/chronic plateau disease R42 | ||

| Diseases of natural epidemic origin R43 | ||

| Other infectious diseases R44 | ||

| Accidental injury R45 | ||

| Plague R46 | ||

| Social Stability Risks R5 | Customs and traditions R51 | |

| Religious beliefs R52 | ||

| Road–land relations R53 |

| Engineering Project | G-T-WBS Matrix |

|---|---|

| The A Railway civil engineering W2 | G1,13, G2,13, G3,13, G4,13, G4,14, G5,14, G5,14, G5,14, G6,15, G7,15, G8,15, G9,15, G10,15 |

| G11,16, G12,16, G13,16, G14,16, G14,17, G15,17, G16,17, G17,17, G17,18, G18,18, G19,18, G20,18 | |

| G21,19, G22,19, G23,19, G24,19, G24,20, G25,20, G26,20, G27,20, G27,21, G28,21, G29,21, G30,21 | |

| G31,22, G32,22, G33,22, G34,22, G34,23, G35,23, G36,23, G37,23, G37,24, G38,24, G39,24, G40,24, | |

| G41,25, G42,25, G43,25, G44,25, G44,26, G45,26, G46,26, G47,26, G47,27, G48,27, G49,27, G50,27 | |

| G51,28, G52,28, G53,28, G54,28, G54,29, G55,29, G56,29, G57,29, G57,30, G58,30, G59,30, G60,30 | |

| G61,31, G62,31, G63,31, G64,31, G64,32, G65,32, G66,32, G67,32, G67,33, G68,33, G69,33, G70,33 |

| Risk Factor | Civil Engineering W2 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G10,30 W21 | G10,31 W21 | G10,32 W21 | G10,33 W21 | G40,30 W22 | G41,70 W22 | G42,110 W22 | G43,150 W22 | G91,40 W23 | G92,50 W23 | G93,60 W23 | G94,70 W23 | G65,35 W24 | G66,40 W24 | G67,45 W24 | G68,50 W24 | ||

| R1 | R11 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R12 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| R13 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | |

| R14 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | |

| R2 | R21 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R22 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R23 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | |

| R24 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R25 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | |

| R26 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | |

| R27 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | |

| R3 | R31 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R32 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | |

| R33 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | |

| R34 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | |

| R35 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R36 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | |

| R37 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R38 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R39 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R310 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R311 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | |

| R4 | R41 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R42 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | |

| R43 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R44 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R45 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| R46 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| R5 | R51 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 |

| R52 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | |

| R53 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | |

| Risk Factor | The A Railway Civil Engineering W2 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G10,30 W21 | G10,31 W21 | G10,32 W21 | G10,33 W21 | G40,30 W22 | G41,70 W22 | G42,110 W22 | G43,150 W22 | G91,40 W23 | G92,50 W23 | G93,60 W23 | G94,70 W23 | G65,35 W24 | G66,40 W24 | G67,45 W24 | G68,50 W24 | ||

| R1 | R11 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R13 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | |

| R2 | R21 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R25 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | |

| R26 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Risk Factor | The A Railway Civil Engineering W2 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G10,30 W21 | G10,31 W21 | G10,32 W21 | G10,33 W21 | G40,30 W22 | G41,70 W22 | G42,110 W22 | G43,150 W22 | G91,40 W23 | G92,50 W23 | G93,60 W23 | G94,70 W23 | G65,35 W24 | G66,40 W24 | G67,45 W24 | G68,50 W24 | ||

| R1 | R11 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R13 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | |

| R3 | R31 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R32 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | |

| R33 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | |

| R34 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | |

| R36 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Wei, Q.; Zhao, G.; Wang, J.; Yin, Y. Safety Risk Identification Method for Railway Construction in Complex and Dangerous Areas. Sustainability 2022, 14, 13698. https://doi.org/10.3390/su142113698

Wang P, Wei Q, Zhao G, Wang J, Yin Y. Safety Risk Identification Method for Railway Construction in Complex and Dangerous Areas. Sustainability. 2022; 14(21):13698. https://doi.org/10.3390/su142113698

Chicago/Turabian StyleWang, Peng, Qiang Wei, Guotang Zhao, Jingchun Wang, and Yang Yin. 2022. "Safety Risk Identification Method for Railway Construction in Complex and Dangerous Areas" Sustainability 14, no. 21: 13698. https://doi.org/10.3390/su142113698