Exploring the Feasibility of Using Recycled PET Strips with Palm Leaf Ash for Sustainable Soil Stabilization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials’ Properties

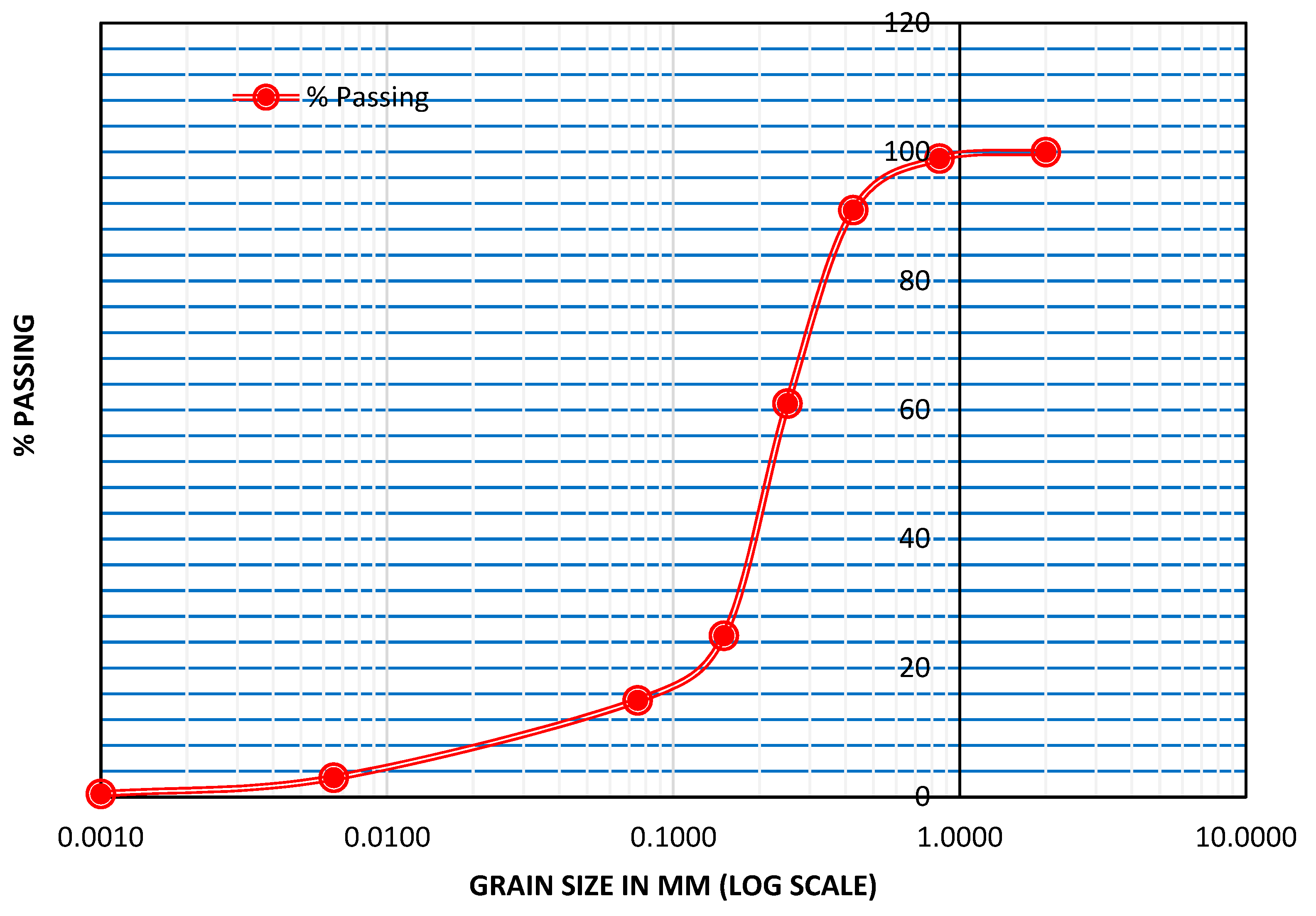

2.1.1. Soil

2.1.2. Recycled PET Strips

2.1.3. Palm Leaves Ash

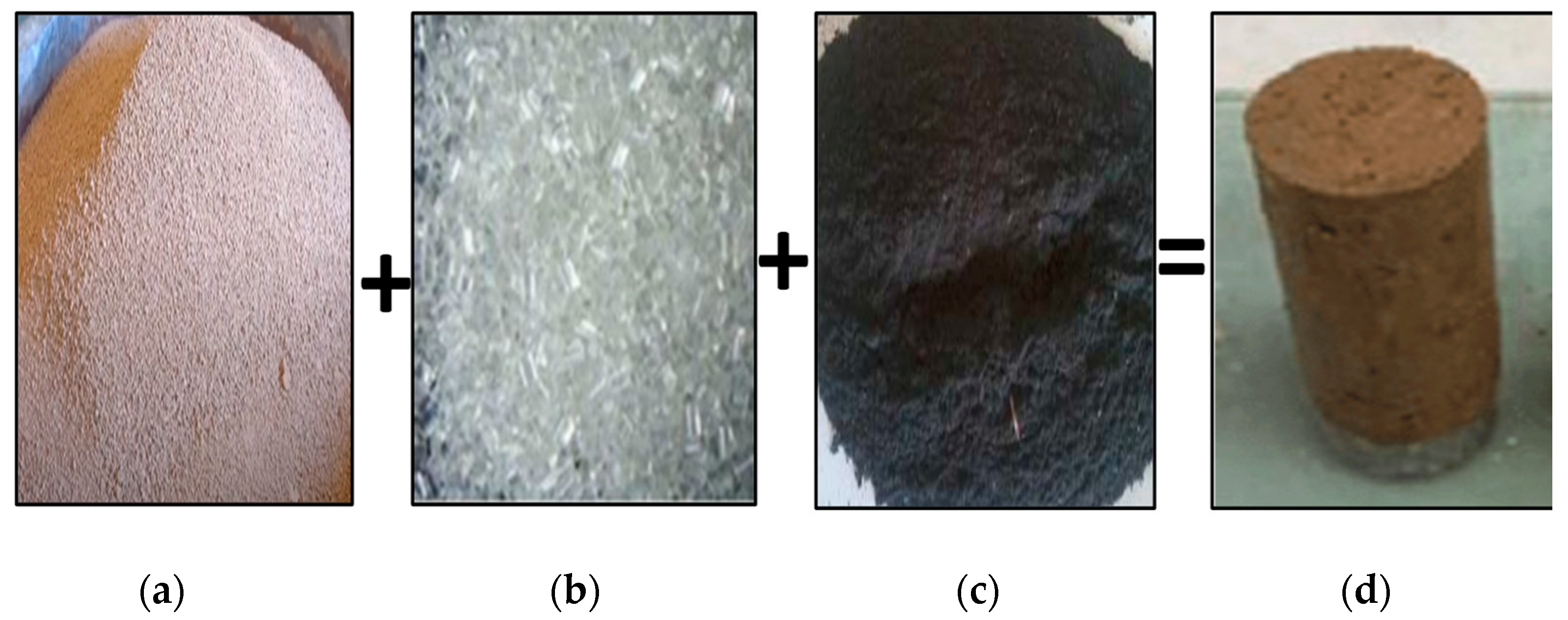

2.2. Preparation of Samples

2.3. Tests Performance

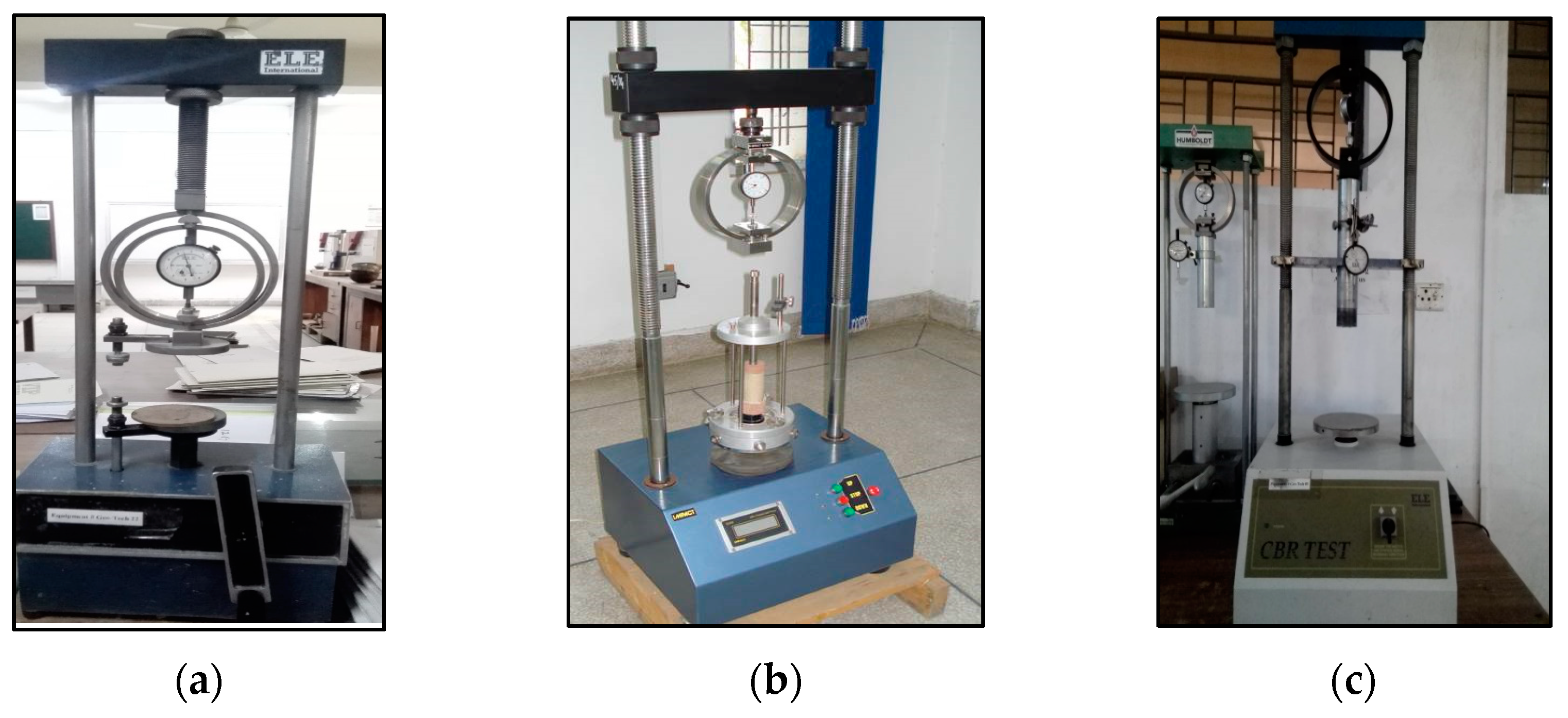

2.3.1. Unconfined Compressive Strength

2.3.2. Triaxial Test

2.3.3. California Bearing Ratio

3. Results and Discussion

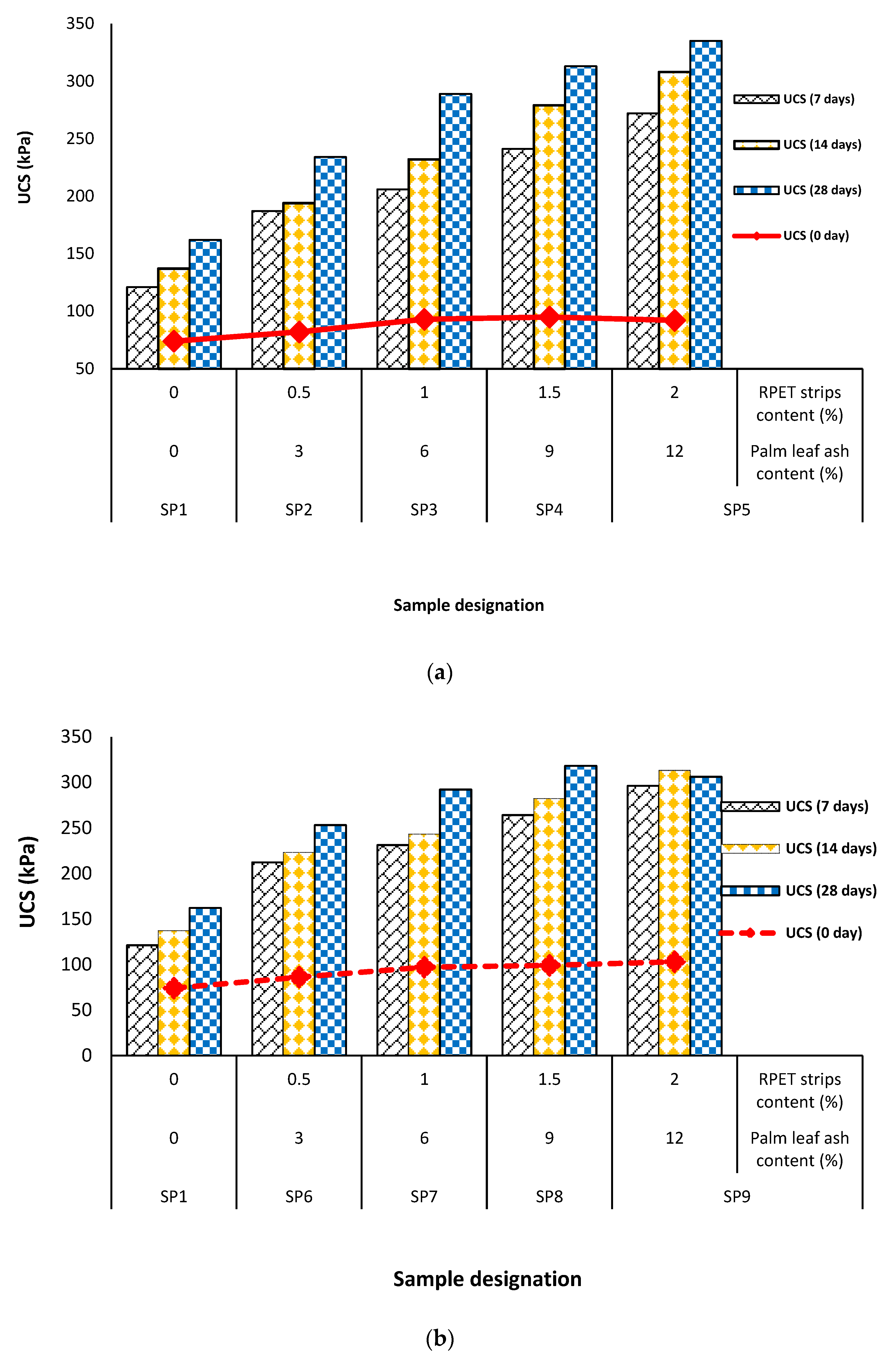

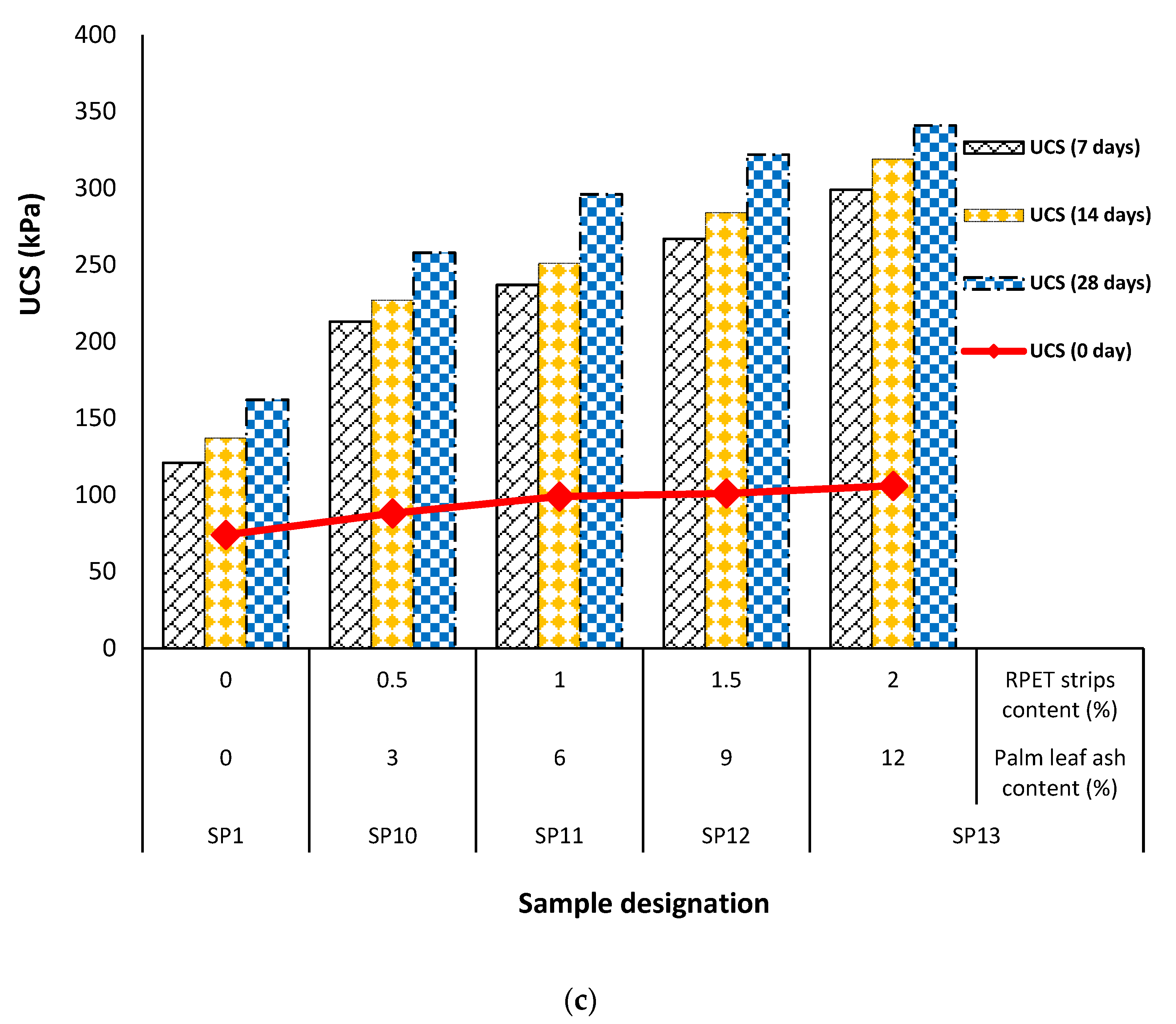

3.1. Influence of Recycled PET strips with PLA on UCS of Soil

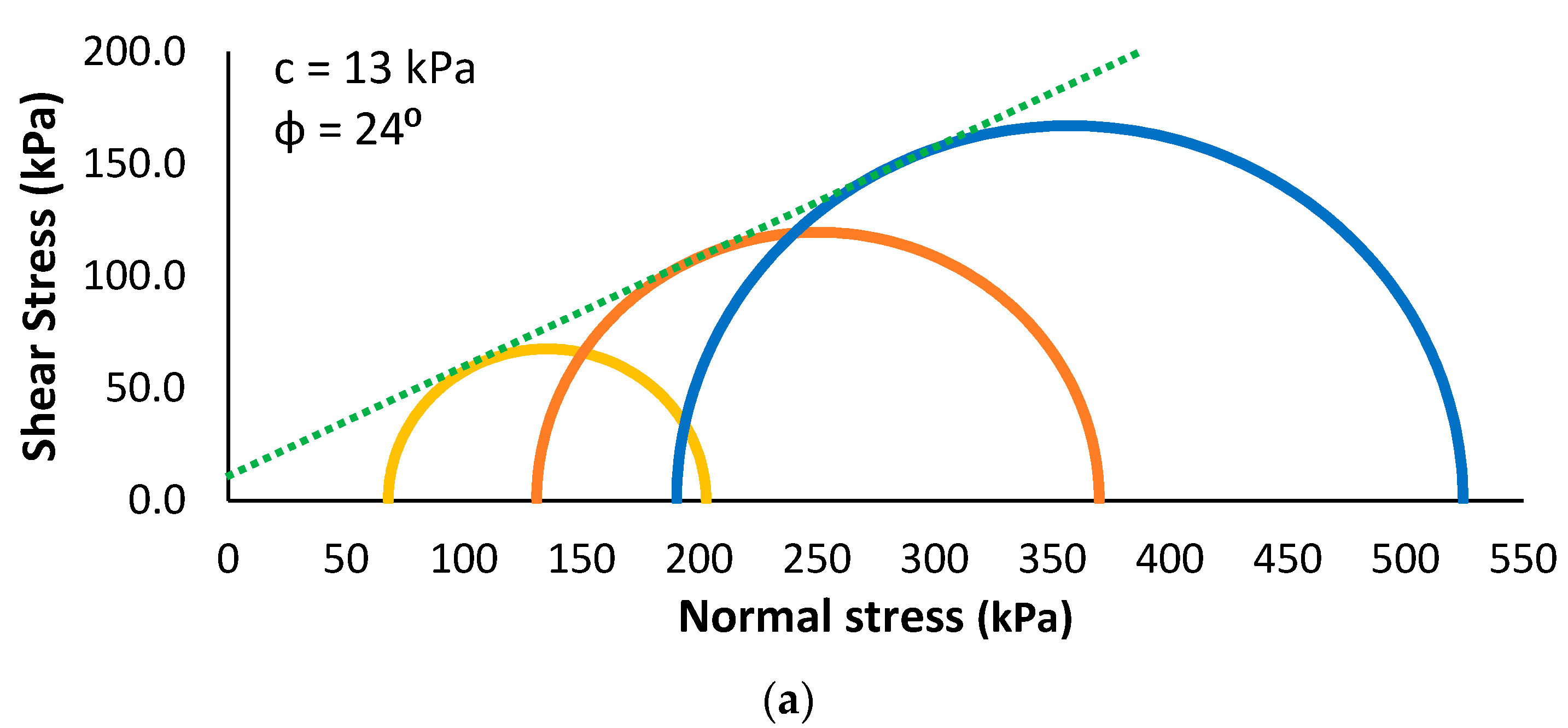

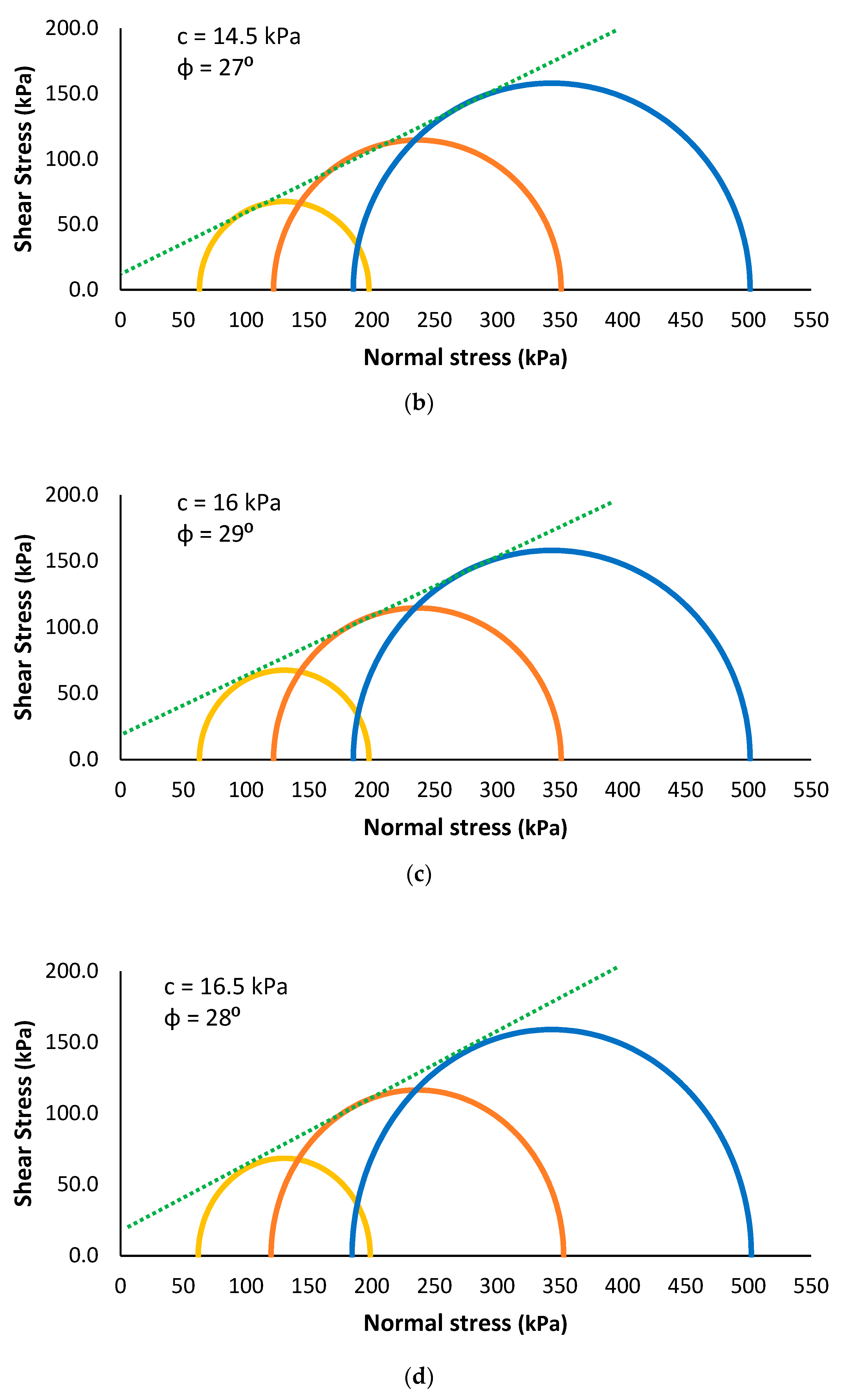

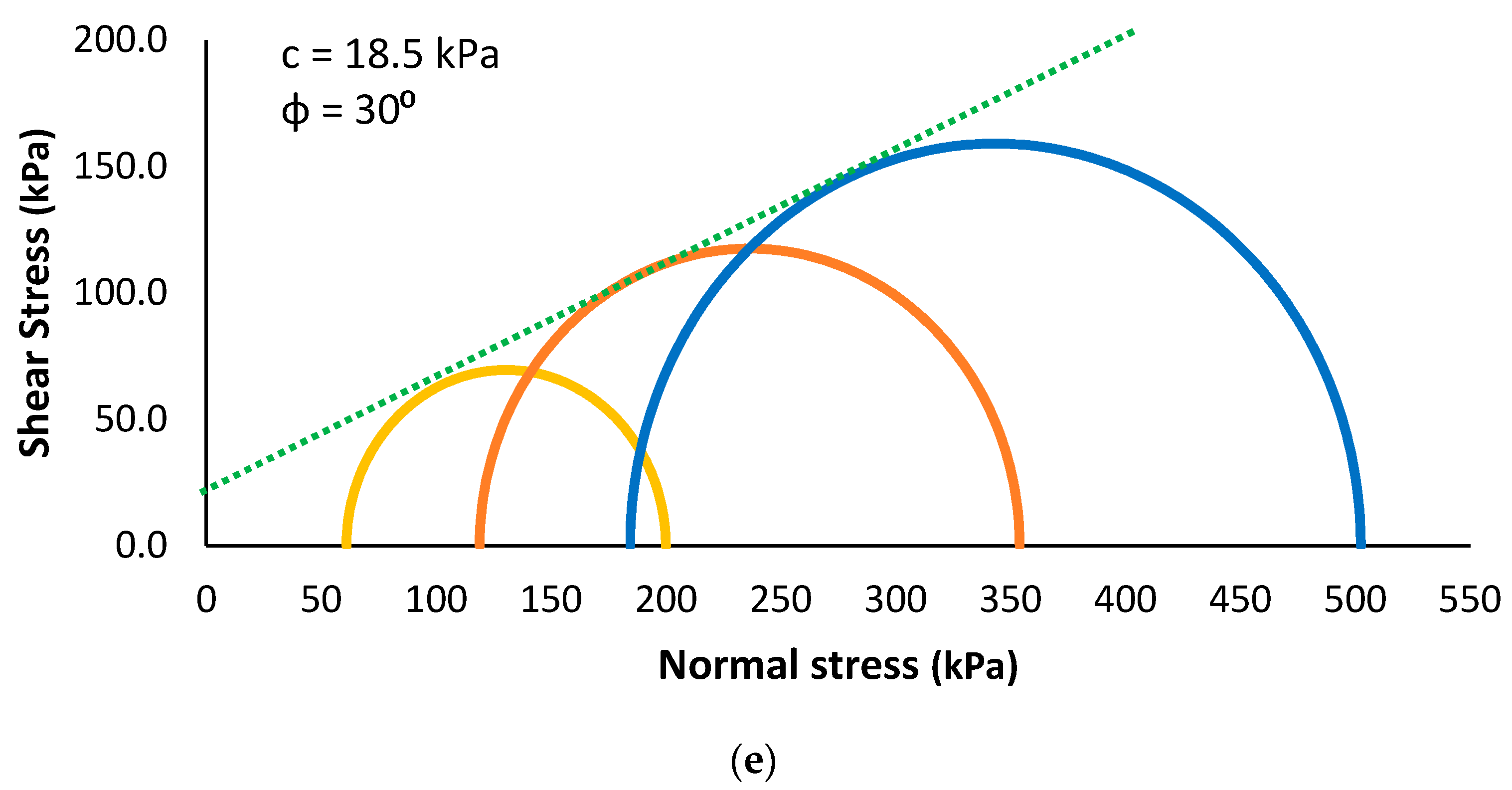

3.2. Influence of Recycled PET Strips with PLA on Shear Strength Parameters of Soil

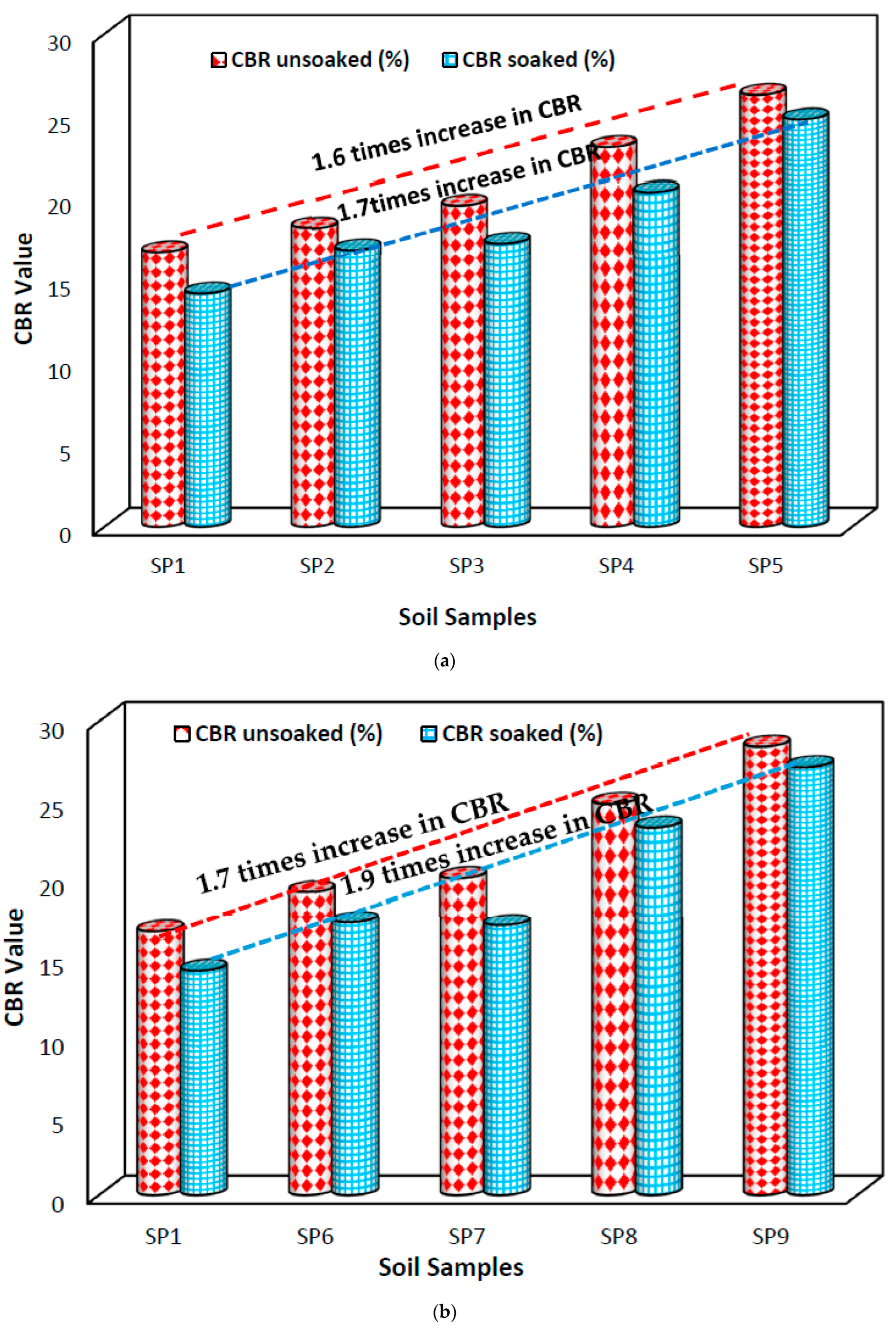

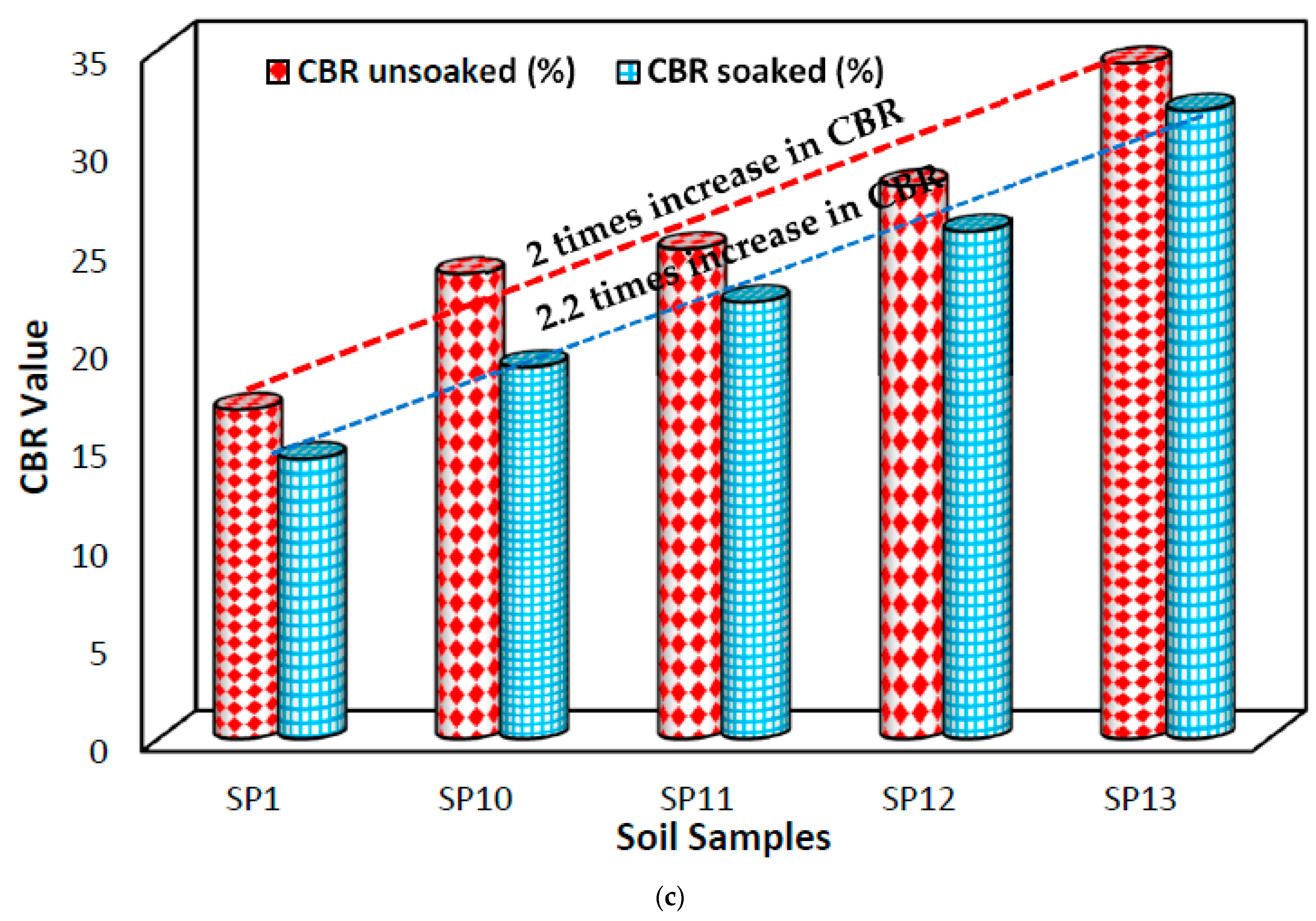

3.3. Influence of Recycled PET Strips with PLA on CBR Value of Soil

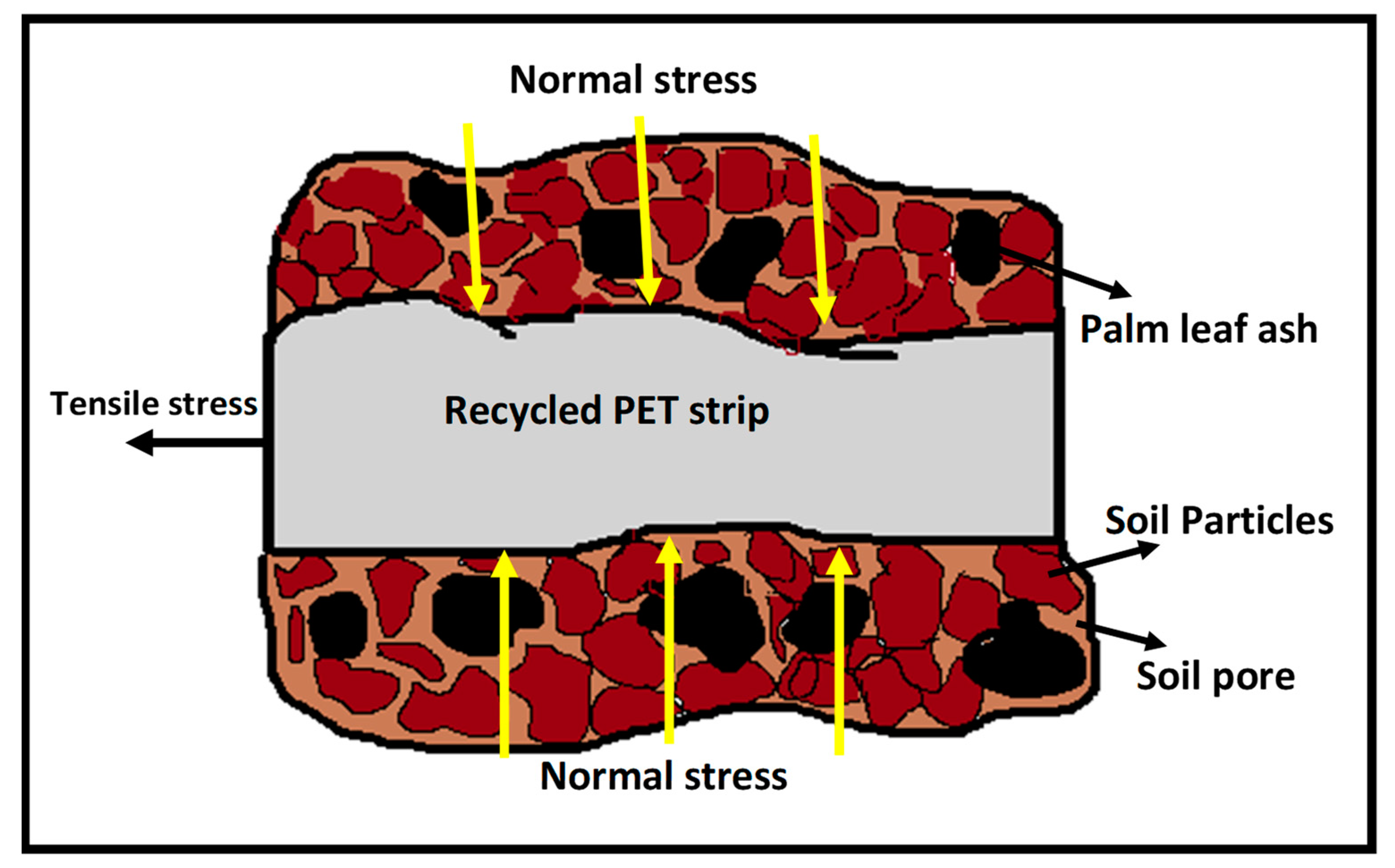

4. Interaction Mechanism between Recycled PET, PLA, and Soil

5. Conclusions

- Reinforcing SC soil with recycled PET strips of 10 mm, 20 mm, and 30 mm lengths, ranging from 0% to 2% content for PET and 0% to 12% for PLA, resulted in notable improvements in UCS. The SP4 sample exhibited the most significant increase of around 28% in UCS with 10 mm strips at day 0. Subsequently, SP5 demonstrated the highest enhancements after 7, 14, and 28 days. Using 20 mm PET strips, the SP9 sample showed a remarkable 39% enhancement on 0 days, with notable UCS increases at 7 and 14 days, while SP8 displayed substantial improvements after 28 days. For 30 mm PET strips, the initial 43% increase in UCS was most prominent in the SP13 sample, followed by significant improvements at 7, 14, and 28 days.

- At a strain of 10%, it was noted that the apparent cohesion of the soil increased by around 1.42 times when comparing unreinforced soil to soil containing 2% PET strips (30 mm in length) and 12% palm leaf ash (referred to as S13). Similarly, the apparent friction angle also exhibited an increase of roughly 1.21 times in the same comparison.

- Significant improvements in CBR values were witnessed through the CBR test. With a 10 mm PET strip length, the CBR value increased by 1.6 times in unsoaked and 1.7 times in soaked conditions for SP5 soil, compared to unreinforced soil. Increasing the strip length to 20 mm led to a 1.7 times increase in unsoaked and a 1.9 times increase in soaked conditions for SP9 soil. Further, transitioning from 20 mm to 30 mm strip length resulted in a 2 times increase in unsoaked and 2.2 times increase in soaked conditions for SP13 soil, relative to unreinforced soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fouad, A.K. Planning Mitigation Measures against Flash Floods in Egyptian Cities. Master’s Thesis, Cairo University, Giza, Egypt, 2022. [Google Scholar]

- Schandl, H.; Fischer-Kowalski, M.; West, J.; Giljum, S.; Dittrich, M.; Eisenmenger, N.; Geschke, A.; Lieber, M.; Wieland, H.; Schaffartzik, A. Global material flows and resource productivity: Forty years of evidence. J. Ind. Ecol. 2018, 22, 827–838. [Google Scholar] [CrossRef]

- Cohen, B. Urbanization in developing countries: Current trends, future projections, and key challenges for sustainability. Technol. Soc. 2006, 28, 63–80. [Google Scholar] [CrossRef]

- Habib, S.H.; Saha, S. Burden of non-communicable disease: Global overview. Diabetes Metab. Syndr. Clin. Res. Rev. 2010, 4, 41–47. [Google Scholar] [CrossRef]

- Zeng, Y.; Cao, Y.; Qiao, X.; Seyler, B.C.; Tang, Y. Air pollution reduction in China: Recent success but great challenge for the future. Sci. Total Environ. 2019, 663, 329–337. [Google Scholar] [CrossRef] [PubMed]

- Wei, R.; Zimmermann, W. Biocatalysis as a green route for recycling the recalcitrant plastic polyethylene terephthalate. Microb. Biotechnol. 2017, 10, 1302. [Google Scholar] [CrossRef]

- Bharadwaj, A.; Yadav, D.; Varshney, S. Non-biodegradable waste–its impact & safe disposal. Int. J. Adv. Technol. Eng. Sci. 2015, 3, 184–191. [Google Scholar]

- Davis, G.; Song, J. Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind. Crops Prod. 2006, 23, 147–161. [Google Scholar] [CrossRef]

- Kanwal, A.; Zhang, M.; Sharaf, F.; Li, C. Polymer pollution and its solutions with special emphasis on Poly (butylene adipate terephthalate (PBAT)). Polym. Bull. 2022, 79, 9303–9330. [Google Scholar] [CrossRef]

- Weiland, S.; Hickmann, T.; Lederer, M.; Marquardt, J.; Schwindenhammer, S. The 2030 agenda for sustainable development: Transformative change through the sustainable development goals? Politics Gov. 2021, 9, 90–95. [Google Scholar] [CrossRef]

- Singh, R.; Embrandiri, A.; Ibrahim, M.; Esa, N. Management of biomass residues generated from palm oil mill: Vermicomposting a sustainable option. Resour. Conserv. Recycl. 2011, 55, 423–434. [Google Scholar] [CrossRef]

- Lim, S.L.; Wu, T.Y.; Lim, P.N.; Shak, K.P.Y. The use of vermicompost in organic farming: Overview, effects on soil and economics. J. Sci. Food Agric. 2015, 95, 1143–1156. [Google Scholar] [CrossRef] [PubMed]

- Theisen, M.S. The role of geosynthetics in erosion and sediment control: An overview. Geotext. Geomembr. 1992, 11, 535–550. [Google Scholar] [CrossRef]

- Emmanuel, E.; Yong, L.L.; Fogne Appiah, N.; Gawu, S. Response surface methodology: A tool to optimise the contents of lime and polyethylene terephthalate (PET) fiber for stabilising a residual soil. Geomech. Geoengin. 2022, 17, 1516–1535. [Google Scholar] [CrossRef]

- Dandin, S.; Kulkarni, M. Effect of isolated footing on fly ash subgrade reinforced with PET bottles: An experimental and analytical study. Constr. Build. Mater. 2022, 353, 129095. [Google Scholar] [CrossRef]

- Bozyigit, I.; Bulbul, F.; Alp, C.; Altun, S. Effect of randomly distributed pet bottle strips on mechanical properties of cement stabilized kaolin clay. Eng. Sci. Technol. Int. J. 2021, 24, 1090–1101. [Google Scholar] [CrossRef]

- Mostafaei, H.; Bahmani, H.; Mostofinejad, D.; Wu, C. A novel development of HPC without cement: Mechanical properties and sustainability evaluation. J. Build. Eng. 2023, 76, 107262. [Google Scholar] [CrossRef]

- Koohmishi, M.; Palassi, M. Mechanical properties of clayey soil reinforced with PET considering the influence of lime-stabilization. Transp. Geotech. 2022, 33, 100726. [Google Scholar] [CrossRef]

- Mishra, B.; Gupta, M.K. Use of randomly oriented polyethylene terephthalate (PET) fiber in combination with fly ash in subgrade of flexible pavement. Constr. Build. Mater. 2018, 190, 95–107. [Google Scholar] [CrossRef]

- Sengul, T.; Akray, N.; Vitosoglu, Y. Investigating the effects of stabilization carried out using fly ash and polypropylene fiber on the properties of highway clay soils. Constr. Build. Mater. 2023, 400, 132590. [Google Scholar] [CrossRef]

- Uniyal, S. Comparative Study of Soil Properties by Stabilizing Soil Using Plastic in the Form of Strips and Crushed Pieces; National Institute of Technology Kurukshetra: Thanesar, India, 2021. [Google Scholar]

- Silveira, M.R.; Lodi, P.C.; Correia, N.d.S.; Rodrigues, R.A.; Giacheti, H.L. Effect of recycled polyethylene terephthalate strips on the mechanical properties of cement-treated lateritic sandy soil. Sustainability 2020, 12, 9801. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, M. Effect of NaOH Treated Polyethylene Terephthalate (PET) Plastic Bottle Strips on Stabilization of Soil; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2023; p. 012013. [Google Scholar]

- ASTM D3282; Materials in ASTM D3282: Standard Practice for Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes, 2015. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D2487; Rock, Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System) 1. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D7928; Standard Test Method for Particle-Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D698; Rock, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 Ft-Lbf/Ft3 (2,700 KN-M/M3)) 1. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- Osman, N.S.; Sapawe, N. Optimization of silica (SiO2) synthesis from acid leached oil palm frond ash (OPFA) through sol-gel method. Mater. Today Proc. 2020, 31, 232–236. [Google Scholar] [CrossRef]

- Younesi, H.; Sanati, A.M.; Ghorbani, F. The potential of date-palm leaf ash as low-cost adsorbent for the removal of Pb (II) ion from aqueous solution. Int. J. Eng. 2012, 25, 269–278. [Google Scholar]

- Prabakar, J.; Dendorkar, N.; Morchhale, R. Influence of fly ash on strength behavior of typical soils. Constr. Build. Mater. 2004, 18, 263–267. [Google Scholar] [CrossRef]

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D4767; Standard Test Method for Consolidated Undrained Triaxial Compression test for Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM D1883; Standard Test Method for California Bearing Ratio (CBR) of Laboratory Compacted Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- Roustaei, M.; Tavana, J.; Bayat, M. Influence of adding waste polyethylene terephthalate plastic strips on uniaxial compressive and tensile strength of cohesive soil. Geopersia 2022, 12, 39–51. [Google Scholar]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Hoque, M.I.; Hasan, M.; Datta, S.D. Effect of Waste Plastic Strip On The Shear Strength And Permeability Characteristics of Black Cotton Soil. J. Appl. Sci. Eng. 2019, 27, 2019–2028. [Google Scholar]

- Marçal, R.; Lodi, P.C.; Correia, N.d.S.; Giacheti, H.L.; Rodrigues, R.A.; McCartney, J.S. Reinforcing effect of polypropylene waste strips on compacted lateritic soils. Sustainability 2020, 12, 9572. [Google Scholar] [CrossRef]

- Kassa, R.B.; Workie, T.; Abdela, A.; Fekade, M.; Saleh, M.; Dejene, Y. Soil stabilization using waste plastic materials. Open J. Civ. Eng. 2020, 10, 55–68. [Google Scholar] [CrossRef]

- Muntohar, A.S.; Widianti, A.; Hartono, E.; Diana, W. Engineering properties of silty soil stabilized with lime and rice husk ash and reinforced with waste plastic fiber. J. Mater. Civ. Eng. 2013, 25, 1260–1270. [Google Scholar] [CrossRef]

- Choudhary, A.; Jha, J.; Gill, K. A study on CBR behavior of waste plastic strip reinforced soil. Emir. J. Eng. Res. 2010, 15, 51–57. [Google Scholar]

- Dutta, R.K. CBR behaviour of waste plastic strip-reinforced stone dust/fly ash overlying saturated clay. Turk. J. Eng. Environ. Sci. 2007, 31, 171–182. [Google Scholar]

- Choudhary, A.; Jha, J.; Gill, K.; Shukla, S.K. Utilization of fly ash and waste recycled product reinforced with plastic wastes as construction materials in flexible pavement. In Proceedings of the Geo-Congress 2014: Geo-Characterization and Modeling for Sustainability, Atlanta, GA, USA, 23–26 February 2014; pp. 3890–3902. [Google Scholar]

- Amena, S. Experimental study on the effect of plastic waste strips and waste brick powder on strength parameters of expansive soils. Heliyon 2021, 7, e08278. [Google Scholar] [CrossRef]

- Amena, S.; Kabeta, W.F. Mechanical behavior of plastic strips-reinforced expansive soils stabilized with waste marble dust. Adv. Civ. Eng. 2022, 2022, 9807449. [Google Scholar] [CrossRef]

- Chebet, F.; Kalumba, D. Laboratory investigation on re-using polyethylene (plastic) bag waste material for soil reinforcement in geotechnical engineering. Civ. Eng. Urban Plan. Int. J. CiVEJ 2014, 1, 67–82. [Google Scholar]

| Properties | Value | Specifications |

|---|---|---|

| Soil Classification (AASHTO) | A-2-6 (0) | ASTM D3282 [24] |

| Soil Classification (USCS) | SC | ASTM D2487 [25] |

| Percent fines (%) | 15 | ASTM D7928 [26] |

| Percent Sand (%) | 85 | ASTM D7928 [26] |

| Maximum dry unit weight (kN/m3) | 19.8 | ASTM D698 [27] |

| Specific gravity, GS | 2.64 | ASTM D854 [28] |

| Liquid limit | 18 | ASTM D4318 [29] |

| Plastic limit | NP | ASTM D4318 [29] |

| Plasticity index | NP | ASTM D4318 [29] |

| Optimum moisture content (%) | 11 | ASTM D698 [27] |

| Parameters | Value Range (Unit) |

|---|---|

| Melting temperature | 250–270 (°C) |

| Intrinsic viscosity | 0.7–0.85 (dL/g) |

| Glass transition temperature | 65–135 (°C) |

| Tensile strength | 57.5–73.2 (MPa) |

| Tensile modulus | 2.5–4.2 (GPa) |

| Flexural strength | 96–125 (MPa) |

| Flexural modulus | 2.3–3.2 (GPa) |

| Impact strength | 13.2–34.7 (J/m) |

| Parameters | Percentage (%) |

|---|---|

| SiO2 | 71.16 |

| Al2O3 | 1.37 |

| Fe2O3 | 1.14 |

| MgO | 2.91 |

| CaO | 9.21 |

| Na2O | 1.73 |

| K2O | 3.04 |

| SO3 | 0.08 |

| P2O5 | 1.49 |

| MnO | 0.04 |

| TiO2 | 0.96 |

| LOI | 3.28 |

| Others | 3.59 |

| SN | Weight-Based Ratios of Soil Combinations | Designation | Soil (%) | Recycled PET Strips (%) | Palm Leaves Ash (%) | Total (%) |

|---|---|---|---|---|---|---|

| Recycled PET strip length 10 mm | ||||||

| 1 | Soil + recycled PET strips 0% + PLA 0% | SP1 | 100 | 0 | 0 | 100 |

| 2 | Soil + recycled PET strips 0.5% + PLA 3% | SP2 | 96.5 | 0.5 | 3 | 100 |

| 3 | Soil + recycled PET strips 1% + PLA 6% | SP3 | 93 | 1 | 6 | 100 |

| 4 | Soil + recycled PET strips 1.5% + PLA 9% | SP4 | 89.5 | 1.5 | 9 | 100 |

| 5 | Soil + recycled PET strips 2% + PLA 12% | SP5 | 86 | 2 | 12 | 100 |

| Recycled PET strip length 20 mm | ||||||

| 7 | Soil + recycled PET strips 0.5% + PLA 3% | SP6 | 96.5 | 0.5 | 3 | 100 |

| 8 | Soil + recycled PET strips 1% + PLA 6% | SP7 | 93 | 1 | 6 | 100 |

| 9 | Soil + recycled PET strips 1.5% + PLA 9% | SP8 | 89.5 | 1.5 | 9 | 100 |

| 10 | Soil + recycled PET strips 2% + PLA 12% | SP9 | 86 | 2 | 12 | 100 |

| Recycled PET strip length 30 mm | ||||||

| 12 | Soil + recycled PET strips 0.5% + PLA 3% | SP10 | 96.5 | 0.5 | 3 | 100 |

| 13 | Soil + recycled PET strips 1% + PLA 6% | SP11 | 93 | 1 | 6 | 100 |

| 14 | Soil + recycled PET strips 1.5% + PLA 9% | SP12 | 89.5 | 1.5 | 9 | 100 |

| 15 | Soil + recycled PET strips 2% + PLA 12% | SP13 | 86 | 2 | 12 | 100 |

| Depth (cm) | Effective Vertical Stress (σv), kPa | Confining Pressure (σc), kPa |

|---|---|---|

| 0 | 0.00 | 0.00 |

| 250 | 58.45 | 58.45 |

| 500 | 123.90 | 123.90 |

| 750 | 182.20 | 182.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalid, B.; Alshawmar, F. Exploring the Feasibility of Using Recycled PET Strips with Palm Leaf Ash for Sustainable Soil Stabilization. Sustainability 2023, 15, 13542. https://doi.org/10.3390/su151813542

Khalid B, Alshawmar F. Exploring the Feasibility of Using Recycled PET Strips with Palm Leaf Ash for Sustainable Soil Stabilization. Sustainability. 2023; 15(18):13542. https://doi.org/10.3390/su151813542

Chicago/Turabian StyleKhalid, Bisma, and Fahad Alshawmar. 2023. "Exploring the Feasibility of Using Recycled PET Strips with Palm Leaf Ash for Sustainable Soil Stabilization" Sustainability 15, no. 18: 13542. https://doi.org/10.3390/su151813542