Optimization of CI Engine Performance and Emissions Using Alcohol–Biodiesel Blends: A Regression Analysis Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Engine Setup

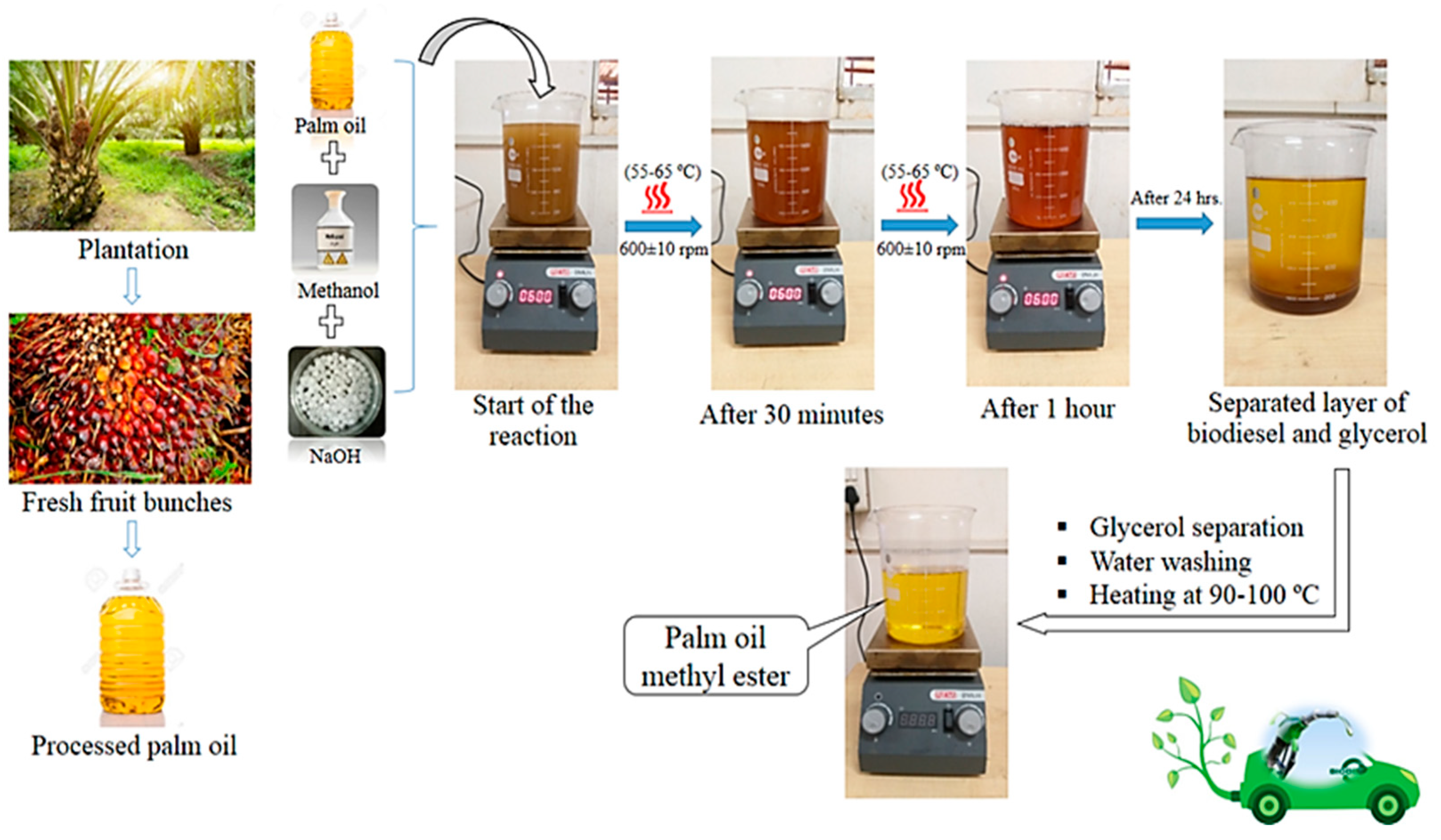

2.2. Experimental Methodology and Fuel Preparation

2.3. Uncertainty of Measurement

3. Results and Discussion

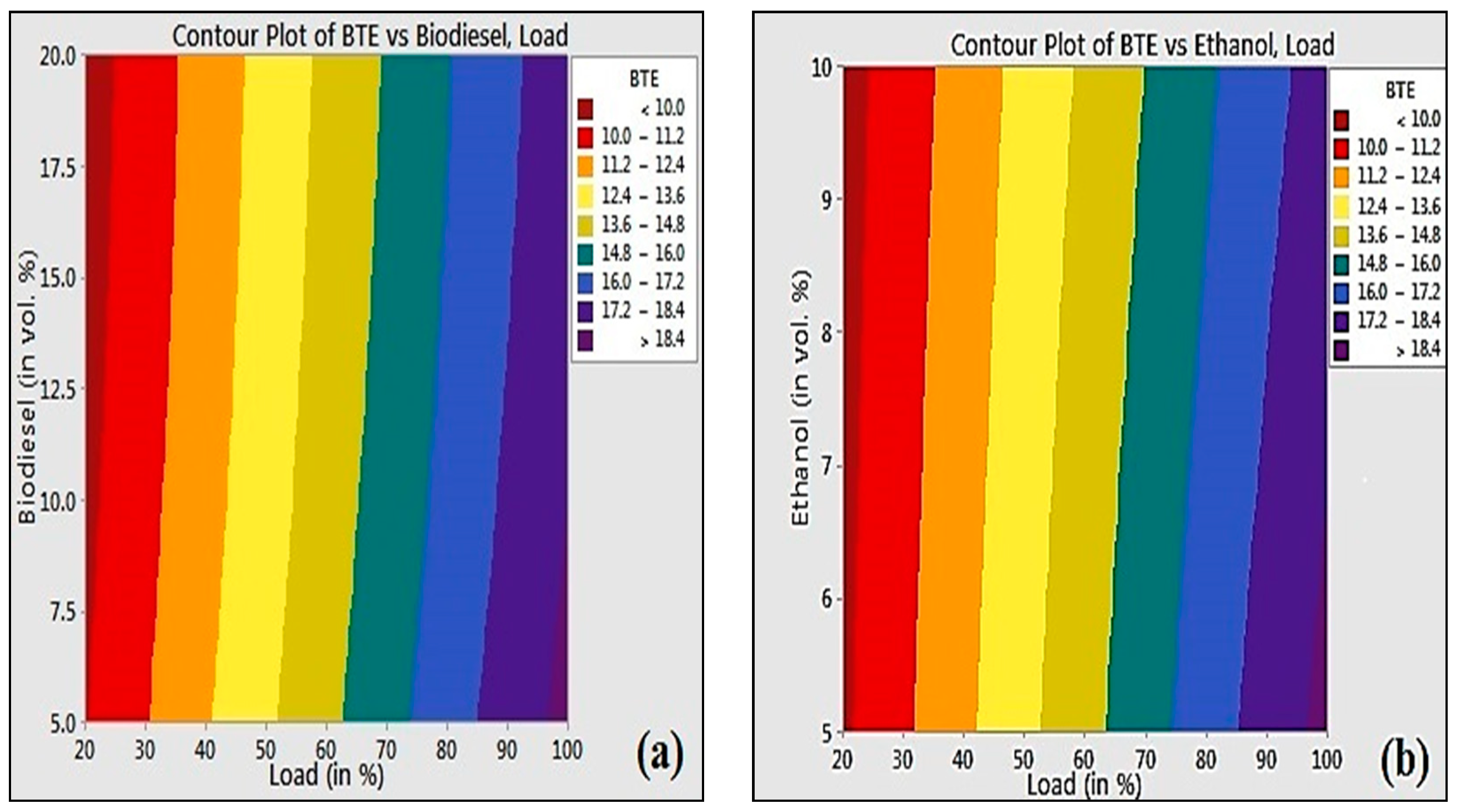

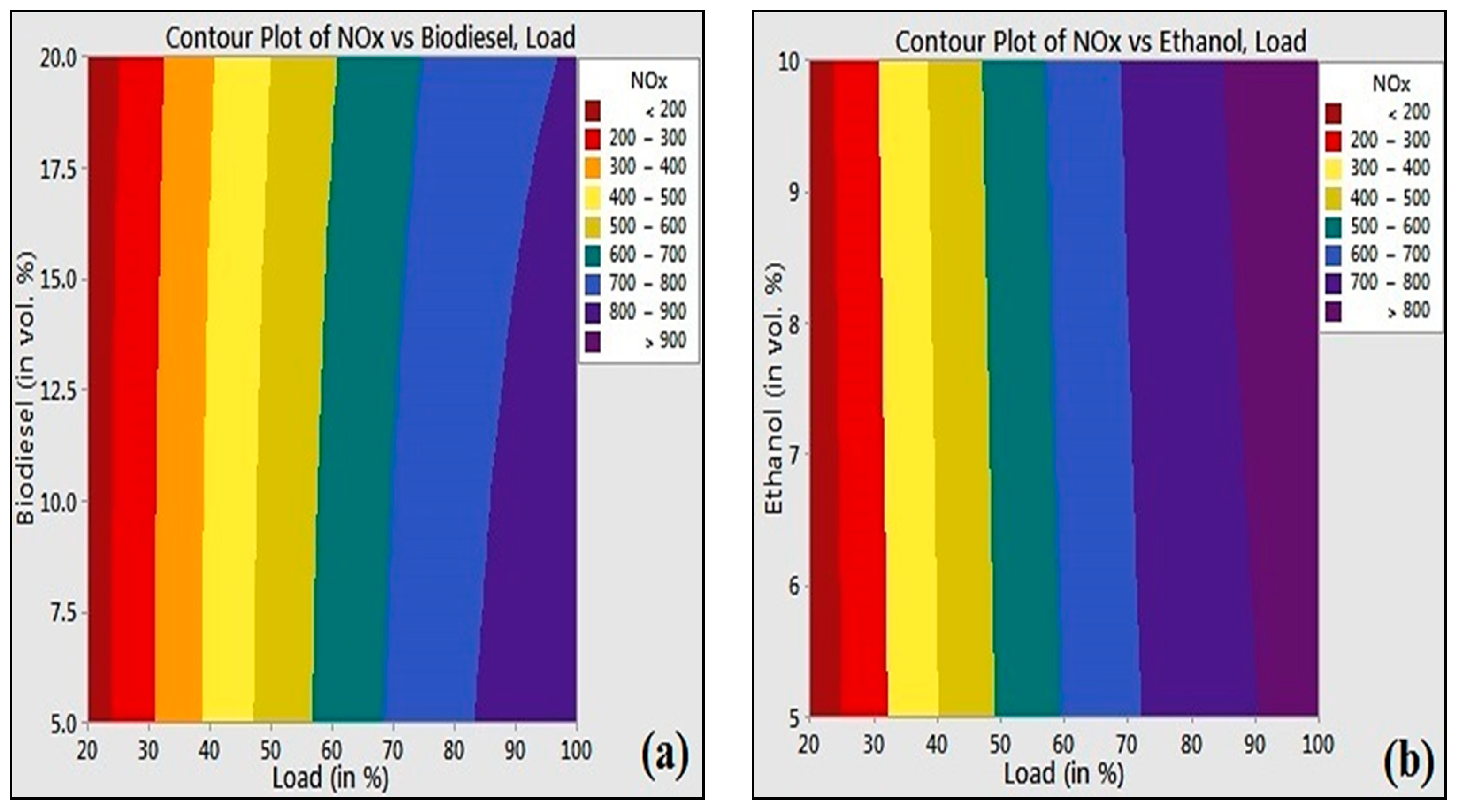

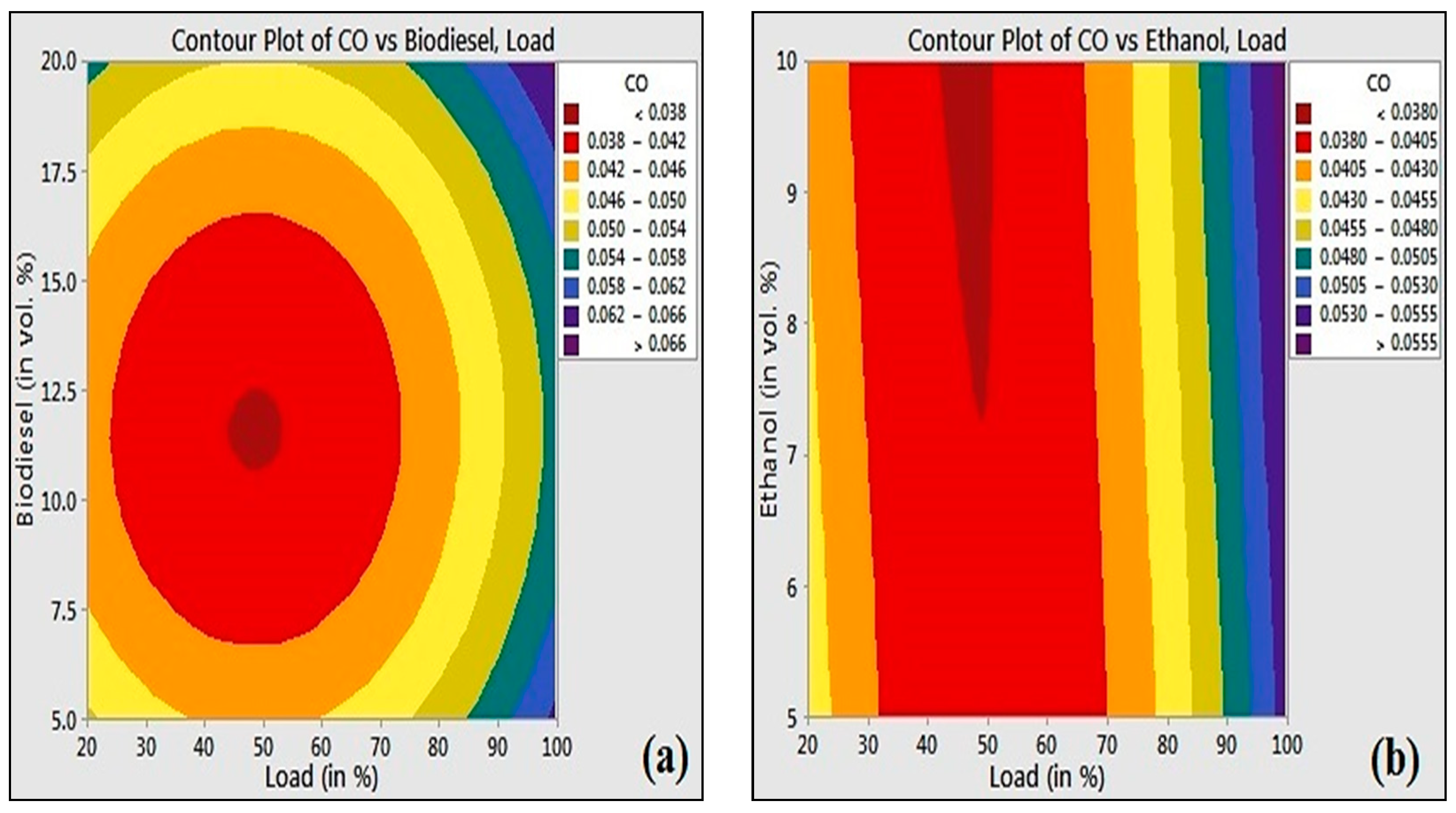

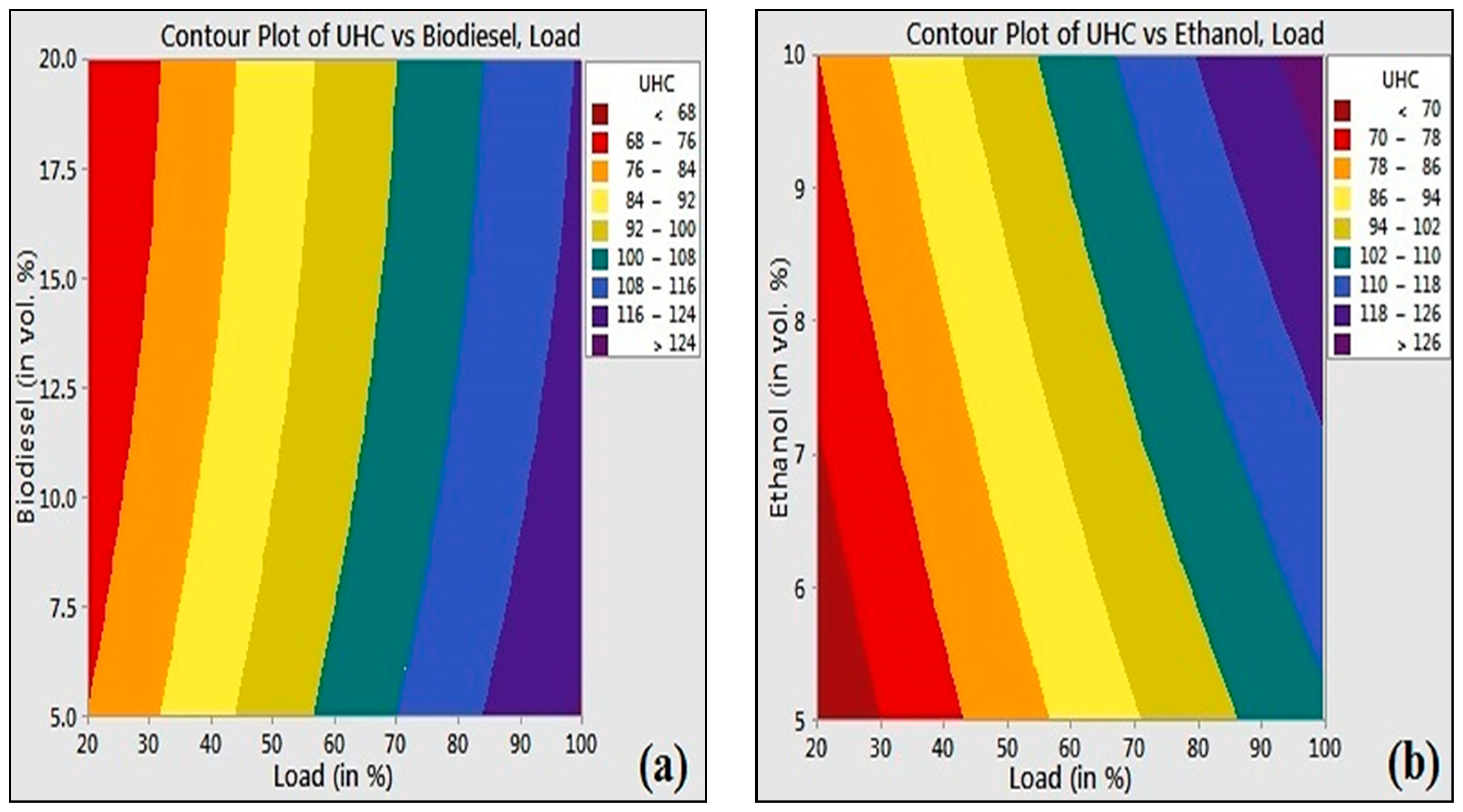

3.1. Effect of Control Factors on Performance and Emission Characteristics

3.2. Non-Linear Regression Analysis

B − 0.000253 A × B − 0.001841 A × C − 0.01048 B × C

B × B + 0.000012 A × C − 0.000144 B × C

0.0396 A × B + 0.0211 A × C − 1.152 B × C

0.00023 A × B + 0.0179 A × C + 0.0636 B × C

3.2.1. Analysis of Variance (ANOVA)

3.2.2. Response Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| 1-C | Single-cylinder |

| 4-S | Four-stroke |

| A | Load (%) |

| ANOVA | Analysis of variance |

| ASTM | American Society for Testing and Materials |

| B | Palm biodiesel (vol.%) |

| BTE | Brake thermal efficiency |

| BP | Brake power |

| BSFC | Brake-specific fuel consumption |

| BSEC | Brake-specific energy consumption |

| C | Ethanol (vol.%) |

| CO | Carbon monoxide, ppm or % |

| CO2 | Carbon dioxide, % |

| CI | Compression ignition |

| CR | Compression ratio |

| D | Diesel |

| DAQ | Data acquisition |

| DOE | Design of experiments |

| DI | Direct injection |

| D90B5E5 | 90% Diesel + 5% palm biodiesel + 5% ethanol |

| D85B10E5 | 85% Diesel + 10% palm biodiesel + 5% ethanol |

| D80B15E5 | 80% Diesel + 15% palm biodiesel + 5% ethanol |

| D75B20E5 | 75% Diesel + 20% palm biodiesel + 5% ethanol |

| D85B5E10 | 85% Diesel + 5% palm biodiesel + 10% ethanol |

| D80B10E10 | 80% Diesel + 10% palm biodiesel + 10% ethanol |

| D75B15E10 | 75% Diesel + 15% palm biodiesel + 10% ethanol |

| D70B20E10 | 70% Diesel + 20% palm biodiesel + 10% ethanol |

| E | Ethanol |

| EGT | Exhaust gas temperature, °C |

| GUI | Graphical user interface |

| LPH | Liters per hour |

| NDIR | Non-dispersive infrared |

| NI | National instruments |

| NOx | Nitrogen oxides, ppm |

| O2 | Oxygen, % |

| rpm | Revolutions per minute |

| RMS | Root mean square |

| RSM | Response surface methodology |

| R2 | Coefficient of determination |

| TDC | Top dead center |

| UHC | Unburnt hydrocarbon, ppm |

| VCR | Variable compression ratio |

References

- Hasan, A.O.; Osman, A.I.; Al-Muhtaseb, A.H.; Al-Rawashdeh, H.; Abu-Jrai, A.; Ahmad, R.; Gomaa, M.R.; Deka, T.J.; Rooney, D.W. An experimental study of engine characteristics and tailpipe emissions from modern DI diesel engine fuelled with methanol/diesel blends. Fuel Process. Technol. 2021, 220, 106901. [Google Scholar] [CrossRef]

- Yusuf, A.A.; Ampah, J.D.; Veza, I.; Atabani, A.; Hoang, A.T.; Nippae, A.; Powoe, M.T.; Afrane, S.; Yusuf, D.A.; Yahuza, I. Investigating the influence of plastic waste oils and acetone blends on diesel engine combustion, pollutants, morphological and size particles: Dehalogenation and catalytic pyrolysis of plastic waste. Energy Convers. Manag. 2023, 291, 117312. [Google Scholar] [CrossRef]

- Khan, E.; Ozaltin, K.; Spagnuolo, D.; Bernal-Ballen, A.; Piskunov, M.V.; Di Martino, A. Biodiesel from Rapeseed and Sunflower Oil: Effect of the Transesterification Conditions and Oxidation Stability. Energies 2023, 16, 657. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Lin, K.-H. Comparison of the Engine Performance of Soybean Oil Biodiesel Emulsions Prepared by Phase Inversion Temperature and Mechanical Homogenization Methods. Processes 2023, 11, 907. [Google Scholar] [CrossRef]

- Gavhane, R.S.; Kate, A.M.; Soudagar, M.E.M.; Wakchaure, V.D.; Balgude, S.; Fattah, I.M.R.; Nik-Ghazali, N.-N.; Fayaz, H.; Khan, T.M.Y.; Mujtaba, M.A.; et al. Influence of Silica Nano-Additives on Performance and Emission Characteristics of Soybean Biodiesel Fuelled Diesel Engine. Energies 2021, 14, 1489. [Google Scholar] [CrossRef]

- Phromphithak, S.; Meepowpan, P.; Shimpalee, S.; Tippayawong, N. Transesterification of palm oil into biodiesel using ChOH ionic liquid in a microwave heated continuous flow reactor. Renew. Energy 2020, 154, 925–936. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Shafay, A.S.; Abu Hashish, H.M. Assessment of diesel engine performance, emissions and combustion characteristics burning biodiesel blends from jatropha seeds. Process. Saf. Environ. Prot. 2021, 147, 518–526. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Waly, M.S.; He, Z.; El-Batsh, H.M.; Nasser, A.; El-Zoheiry, R.M. Enhancement of the combustion and stability aspects of diesel-methanol-hydrous methanol blends utilizing n-octanol, diethyl ether, and nanoparticle additives. J. Clean. Prod. 2022, 371, 133673. [Google Scholar] [CrossRef]

- Saleh, H.E.; Selim, M.Y.E. Improving the performance and emission characteristics of a diesel engine fueled by jojoba methyl ester-diesel-ethanol ternary blends. Fuel 2017, 207, 690–701. [Google Scholar] [CrossRef]

- Gnanamoorthi, V.; Murugan, M. Effect of DEE and MEA as additives on a CRDI diesel engine fueled with waste plastic oil blend. Energy Sources Part A Recover. Util. Environ. Eff. 2022, 44, 5016–5031. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Mamat, R.; Yusop, A.F.; Idris, D.M.N.D.; Yusaf, T.; Rasul, M.; Najafi, G. Study of a Diesel Engine Performance with Exhaust Gas Recirculation (EGR) System Fuelled with Palm Biodiesel. Energy Procedia 2017, 110, 26–31. [Google Scholar] [CrossRef]

- Appavu, P.; Madhavan, V.R.; Jayaraman, J.; Venu, H. Palm oil-based biodiesel as a novel alternative feedstock for existing unmodified DI diesel engine. Int. J. Ambient. Energy 2019, 43, 222–228. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, Q.; Liang, J.; Yang, C. The performance and emissions characteristics of diesel/biodiesel/alcohol blends in a diesel engine. Energy Rep. 2021, 7, 1016–1024. [Google Scholar] [CrossRef]

- Sathish, T.; Mohanavel, V.; Arunkumar, M.; Rajan, K.; Soudagar, M.E.M.; Mujtaba, M.; Salmen, S.H.; Al Obaid, S.; Fayaz, H.; Sivakumar, S. Utilization of Azadirachta indica biodiesel, ethanol and diesel blends for diesel engine applications with engine emission profile. Fuel 2022, 319, 123798. [Google Scholar] [CrossRef]

- Devarajan, Y.; Munuswamy, D.B.; Mahalingam, A.; Nagappan, B. Performance, Combustion, and Emission Analysis of Neat Palm Oil Biodiesel and Higher Alcohol Blends in a Diesel Engine. Energy Fuels 2017, 31, 13796–13801. [Google Scholar] [CrossRef]

- Thakkar, K.; Kachhwaha, S.S.; Kodgire, P.; Srinivasan, S. Combustion investigation of ternary blend mixture of biodiesel/n-butanol/diesel: CI engine performance and emission control. Renew. Sustain. Energy Rev. 2021, 137, 110468. [Google Scholar] [CrossRef]

- Uslu, S.; Aydın, M. Effect of operating parameters on performance and emissions of a diesel engine fueled with ternary blends of palm oil biodiesel/diethyl ether/diesel by Taguchi method. Fuel 2020, 275, 117978. [Google Scholar] [CrossRef]

- Sakthivel, G.; Sivakumar, R.; Saravanan, N.; Ikua, B.W. A decision support system to evaluate the optimum fuel blend in an IC engine to enhance the energy efficiency and energy management. Energy 2017, 140, 566–583. [Google Scholar] [CrossRef]

- Dhole, A.E.; Yarasu, R.B.; Lata, D.B.; Baraskar, S.S. Mathematical modeling for the performance and emission parameters of dual fuel diesel engine using hydrogen as secondary fuel. Int. J. Hydrogen Energy 2014, 39, 12991–13001. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, A.; Tiwari, S.; Singla, A. Optimization of diesel engine performance and emission parameters employing cassia tora methyl esters-response surface methodology approach. Energy 2019, 168, 909–918. [Google Scholar] [CrossRef]

- Dey, S.; Reang, N.M.; Majumder, A.; Deb, M.; Das, P.K. A hybrid ANN-Fuzzy approach for optimization of engine operating parameters of a CI engine fueled with diesel-palm biodiesel-ethanol blend. Energy 2020, 202, 117813. [Google Scholar] [CrossRef]

- Sakthivel, G.; Sivaraja, C.M.; Ikua, B.W. Prediction OF CI engine performance, emission and combustion parameters using fish oil as a biodiesel by fuzzy-GA. Energy 2019, 166, 287–306. [Google Scholar] [CrossRef]

- Bendu, H.; Deepak, B.B.V.L.; Murugan, S. Multi-objective optimization of ethanol fuelled HCCI engine performance using hybrid GRNN–PSO. Appl. Energy 2017, 187, 601–611. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, A.; Singh, G.K.; Singla, A.; Singh, N.K. Optimization of performance and emission parameters of direct injection diesel engine fuelled with pongamia methyl esters-response surface methodology approach. Ind. Crops Prod. 2018, 126, 218–226. [Google Scholar] [CrossRef]

- ICEngineSoft_9.0_SetupBuild.zip—Google Drive n.d. Available online: https://drive.google.com/file/d/0BxpHpyYTEWVdMm5oQ0VGamMzVGs/view?resourcekey=0-Nbcv1ozQKZ-Ro1S5U5IuUQ (accessed on 19 September 2023).

- Dey, S.; Reang, N.M.; Deb, M.; Das, P.K. Study on performance-emission trade-off and multi-objective optimization of diesel-ethanol-palm biodiesel in a single cylinder CI engine: A Taguchi-fuzzy approach. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 42, 1–21. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Kosmadakis, G.M.; Papagiannakis, R.G. Experimental comparative assessment of butanol or ethanol diesel-fuel extenders impact on combustion features, cyclic irregularity, and regulated emissions balance in heavy-duty diesel engine. Energy 2019, 174, 1145–1157. [Google Scholar] [CrossRef]

- Pan, M.; Huang, R.; Liao, J.; Jia, C.; Zhou, X.; Huang, H.; Huang, X. Experimental study of the spray, combustion, and emission performance of a diesel engine with high n-pentanol blending ratios. Energy Convers. Manag. 2019, 194, 1–10. [Google Scholar] [CrossRef]

- Atmanlı, A.; Yüksel, B.; İleri, E.; Karaoglan, A.D. Response surface methodology based optimization of diesel–n-butanol –cotton oil ternary blend ratios to improve engine performance and exhaust emission characteristics. Energy Convers. Manag. 2015, 90, 383–394. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yilmaz, N. Optimization of diesel–butanol–vegetable oil blend ratios based on engine operating parameters. Energy 2016, 96, 569–580. [Google Scholar] [CrossRef]

- Sakthivel, R.; Ramesh, K.; Marshal, S.J.J.; Sadasivuni, K.K. Prediction of performance and emission characteristics of diesel engine fuelled with waste biomass pyrolysis oil using response surface methodology. Renew. Energy 2019, 136, 91–103. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P. Optimization of engine parameters in a bio diesel engine run with honge methyl ester using response surface methodology. Measurement 2018, 125, 224–231. [Google Scholar] [CrossRef]

- Najafi, G.; Ghobadian, B.; Yusaf, T.; Ardebili, S.M.S.; Mamat, R. Optimization of performance and exhaust emission parameters of a SI (spark ignition) engine with gasoline–ethanol blended fuels using response surface methodology. Energy 2015, 90, 1815–1829. [Google Scholar] [CrossRef]

- Awad, O.I.; Mamat, R.; Ali, O.M.; Azmi, W.H.; Kadirgama, K.; Yusri, I.M.; Leman, A.M.; Yusaf, T. Response surface methodology (RSM) based multi-objective optimization of fusel oil-gasoline blends at different water content in SI engine. Energy Convers. Manag. 2017, 150, 222–241. [Google Scholar] [CrossRef]

| Parameters | Specifications |

|---|---|

| Engine | 1-C, 4-S, VCR (variable compression ratio) diesel engine |

| Product code | 234 |

| Dynamometer | Eddy-current-type |

| Cooling type | Water-cooled |

| Data acquisition system | NI USB-6210, 16-bit, 250 kS/s |

| Crank angle sensor | 1° resolution, speed 5500 rpm with TDC pulse |

| Temperature sensor | RTD, PT100, and K-type thermocouple |

| Load sensor | Strain-gauge-type (range 0–50 Kg) |

| Rotameter | Engine cooling (40–400 LPH); calorimeter (25–250 LPH) |

| Stroke | 110 mm |

| Bore | 87.5 mm |

| Displacement | 661 cc |

| Compression Ratio | 17.5:1 |

| Output power | 3.5 kW |

| Speed | constant 1500 rpm |

| Fuel Injection pressure | 220 bar |

| Samples | Density at 20 °C (kg/m3) | Cetane Number | Kinematic Viscosity at 40 °C (cSt) | Calorific Value (kJ/kg) | Flashpoint (°C) |

|---|---|---|---|---|---|

| ASTM D-1298 | ASTM D-613 | ASTM D-445 | ASTM D-240 | ASTM D-93 | |

| Diesel | 836 | 49 | 2.45 | 42,800 | 100 |

| Palm Biodiesel | 925 | 62 | 4.56 | 39,849 | 167 |

| Ethanol | 789 | 8 | 1.09 | 29,700 | 16.60 |

| D90B5E5 | 838.1 | 47.6 | 2.49 | 41,998 | 99.2 |

| D85B10E5 | 842.6 | 48.3 | 2.59 | 41,850 | 102.8 |

| D80B15E5 | 847 | 48.9 | 2.7 | 41,702 | 105.9 |

| D75B20E5 | 851.5 | 49.6 | 2.8 | 41,555 | 109.2 |

| D85B5E10 | 835.8 | 45.6 | 2.42 | 41,343 | 95 |

| D80B10E10 | 840.2 | 46.2 | 2.53 | 41,195 | 98.4 |

| D75B15E10 | 844.7 | 46.9 | 2.63 | 41,047 | 101.7 |

| D70B20E10 | 849.1 | 47.5 | 2.7 | 40,900 | 105.1 |

| % measurement uncertainty | ±0.3 | ±0.15 | ±0.22 | ±0.75 | ±0.2 |

| Performance Parameter | Measured Variables | Instrument Involved in the Measurement | % Uncertainty of the Instrument | Calculation | Total % Uncertainty of Parameters |

|---|---|---|---|---|---|

| BP | Load, RPM | Load sensor, load indicator, speed measuring unit | 0.2, 0.1, 0.9 | 0.9 | |

| BSFC | SFC (Liquid Fuel), BP | Fuel measuring unit, fuel flow transmitter, as For BP measurement | 0.05, 1.5, 0.92 | 1.8 | |

| BSEC | SFC (Liquid Fuel), BP | As for SFC measurement, as for BP measurement | 1.84, 0.92 | 2 |

| Measured Parameter | Measurement Principle | Measuring Range | Resolution | Accuracy | % Uncertainty in Sampling |

|---|---|---|---|---|---|

| CO | NDIR | 0–10% vol. | 0.01% vol. | <0.6% vol.: ±0.03% vol.; ≥0.6% vol.: ± 5% of value | ±0.2 ± 0.3 |

| CO2 | NDIR | 0–20% vol. | 0.1% vol. | <10% vol.: ±0.5% vol.; ≥10% vol: ±5% of value | ±0.15 ±0.2 |

| HC | NDIR | 0–20,000 ppm vol. (n-hexane equivalent) | ≤2000:1 ppm vol. >2000:10 ppm vol. | <200 ppm vol.: ±10 ppm; ≥200 ppm vol.: ±5% of value | ±0.1 ±0.2 |

| O2 | Electro chemical sensor | 0–22%vol. | 0.01% vol. | <2% vol.: ±0.1% vol.; ≥2% vol.: ±5% of value. | ±0.2 ±0.3 |

| NO | Electro chemical sensor | 0–5000 ppm vol. | 1 ppm vol. | <500 ppm vol: ±50 ppm vol ≥500 ppm vol: ±10% of value | ±0.2 ±0.9 |

| Factors | Symbolic Representation | Levels | ||||

|---|---|---|---|---|---|---|

| Load (%) | A | 20 | 40 | 60 | 80 | 100 |

| Palm Biodiesel (vol.%) | B | 5 | 10 | 15 | 20 | - |

| Ethanol (vol.%) | C | 5 | 10 | - | - | - |

| Source | BTE | NOx | CO | UHC | ||||

|---|---|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| Regression | 746.21 | 0.000 | 957.45 | 0.000 | 4.86 | 0.001 | 39.30 | 0.000 |

| A | 229.39 | 0.000 | 795.38 | 0.000 | 6.57 | 0.015 | 5.72 | 0.023 |

| B | 0.06 | 0.814 | 9.42 | 0.004 | 3.36 | 0.077 | 1.50 | 0.229 |

| C | 4.90 | 0.034 | 21.57 | 0.000 | 0.48 | 0.494 | 1.36 | 0.252 |

| A × A | 2.60 | 0.117 | 325.54 | 0.000 | 12.24 | 0.001 | 0.41 | 0.527 |

| B × B | 0.91 | 0.348 | 0.63 | 0.434 | 11.00 | 0.002 | 0.30 | 0.585 |

| A × B | 1.01 | 0.322 | 4.55 | 0.041 | 0.00 | 0.951 | 0.00 | 0.974 |

| A × C | 10.70 | 0.003 | 0.26 | 0.614 | 0.48 | 0.495 | 1.30 | 0.263 |

| B × C | 13.55 | 0.001 | 30.14 | 0.000 | 2.47 | 0.126 | 0.64 | 0.429 |

| R-sq. | 99.48 | 99.49 | 55.66 | 91.02 | ||||

| R-sq. (adj.) | 99.35 | 99.23 | 44.21 | 88.71 | ||||

| Engine Output Parameters | Experimental (Input Variables: 40% Engine Load, 10% Palm Biodiesel, 5% Ethanol) | Optimized (Input Variables: 43% Engine Load, 11% Palm Biodiesel, 5% Ethanol) |

|---|---|---|

| BTE (%) | 12.52 | 12.57 |

| NOx (ppm) | 401 | 436.2 |

| UHC (ppm) | 87 | 79.24 |

| CO (vol.%) | 0.05 | 0.037 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dey, S.; Singh, A.P.; Gajghate, S.S.; Pal, S.; Saha, B.B.; Deb, M.; Das, P.K. Optimization of CI Engine Performance and Emissions Using Alcohol–Biodiesel Blends: A Regression Analysis Approach. Sustainability 2023, 15, 14667. https://doi.org/10.3390/su152014667

Dey S, Singh AP, Gajghate SS, Pal S, Saha BB, Deb M, Das PK. Optimization of CI Engine Performance and Emissions Using Alcohol–Biodiesel Blends: A Regression Analysis Approach. Sustainability. 2023; 15(20):14667. https://doi.org/10.3390/su152014667

Chicago/Turabian StyleDey, Suman, Akhilendra Pratap Singh, Sameer Sheshrao Gajghate, Sagnik Pal, Bidyut Baran Saha, Madhujit Deb, and Pankaj Kumar Das. 2023. "Optimization of CI Engine Performance and Emissions Using Alcohol–Biodiesel Blends: A Regression Analysis Approach" Sustainability 15, no. 20: 14667. https://doi.org/10.3390/su152014667