Analysis of the Severity and Cause and Effect of Occupational Accidents in South Korea

Abstract

:1. Introduction

1.1. Background of the Study

1.2. Literature Review

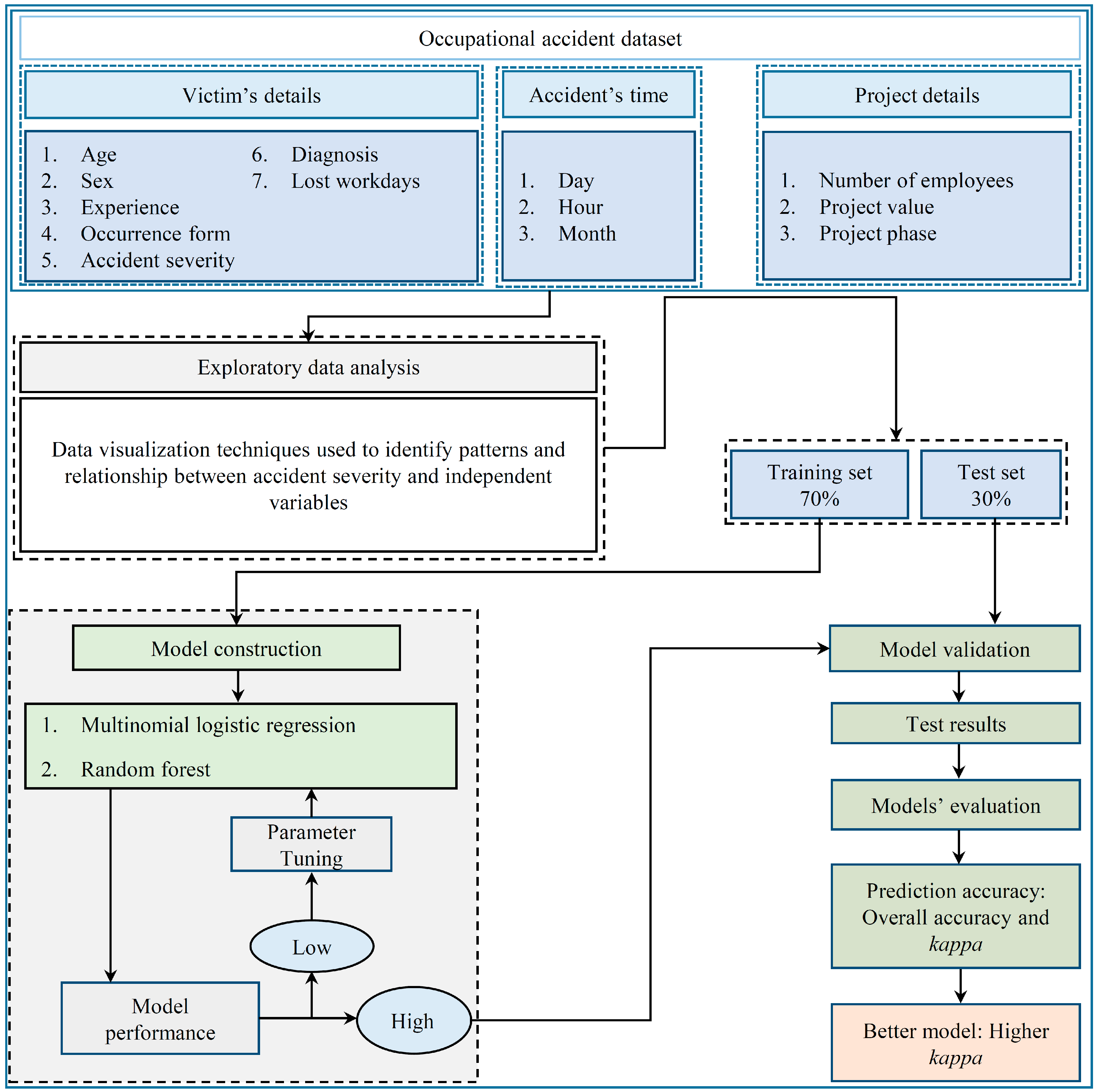

2. Data and Methodology

2.1. Data Description

2.2. Methods

2.2.1. Exploratory Data Analysis Techniques

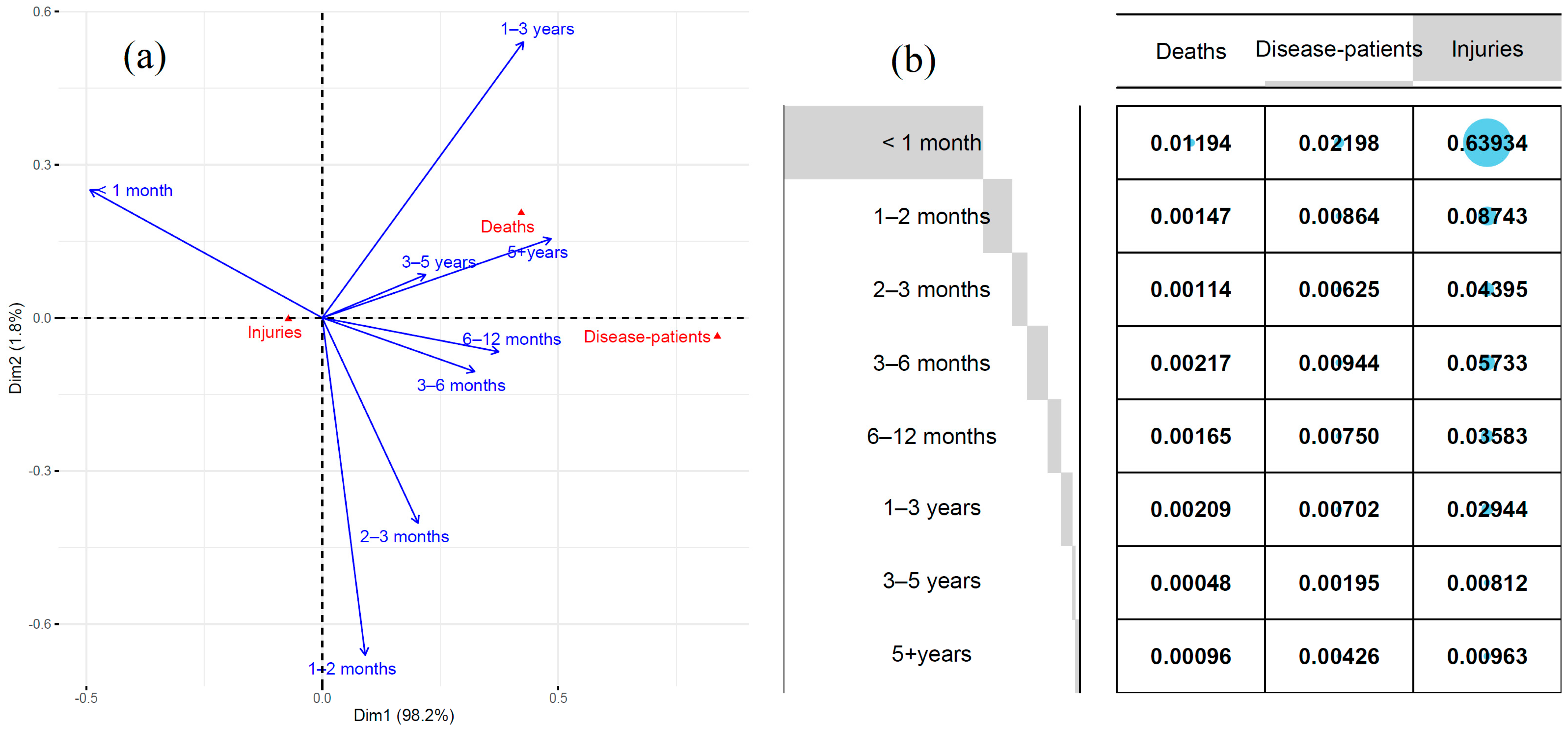

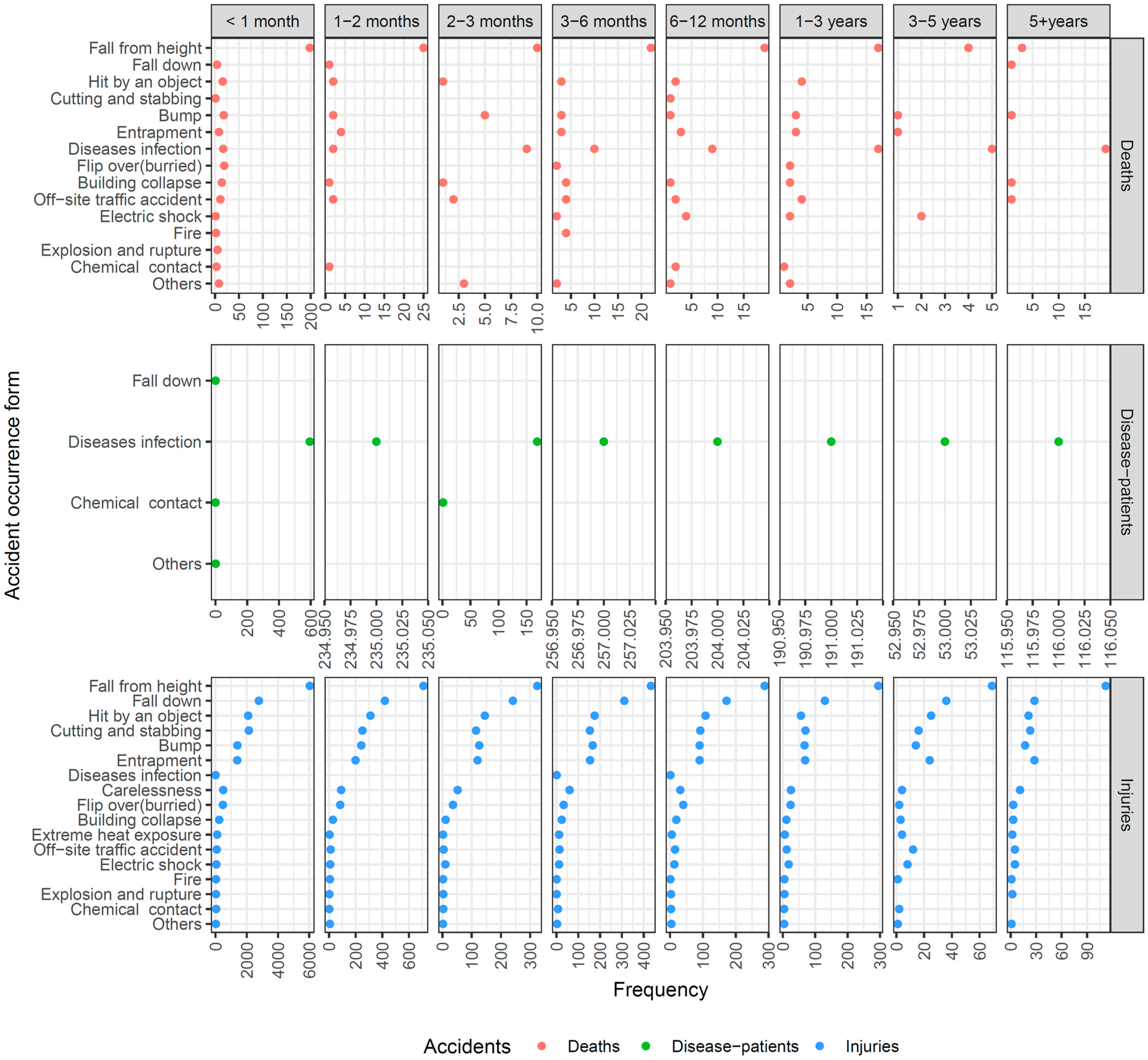

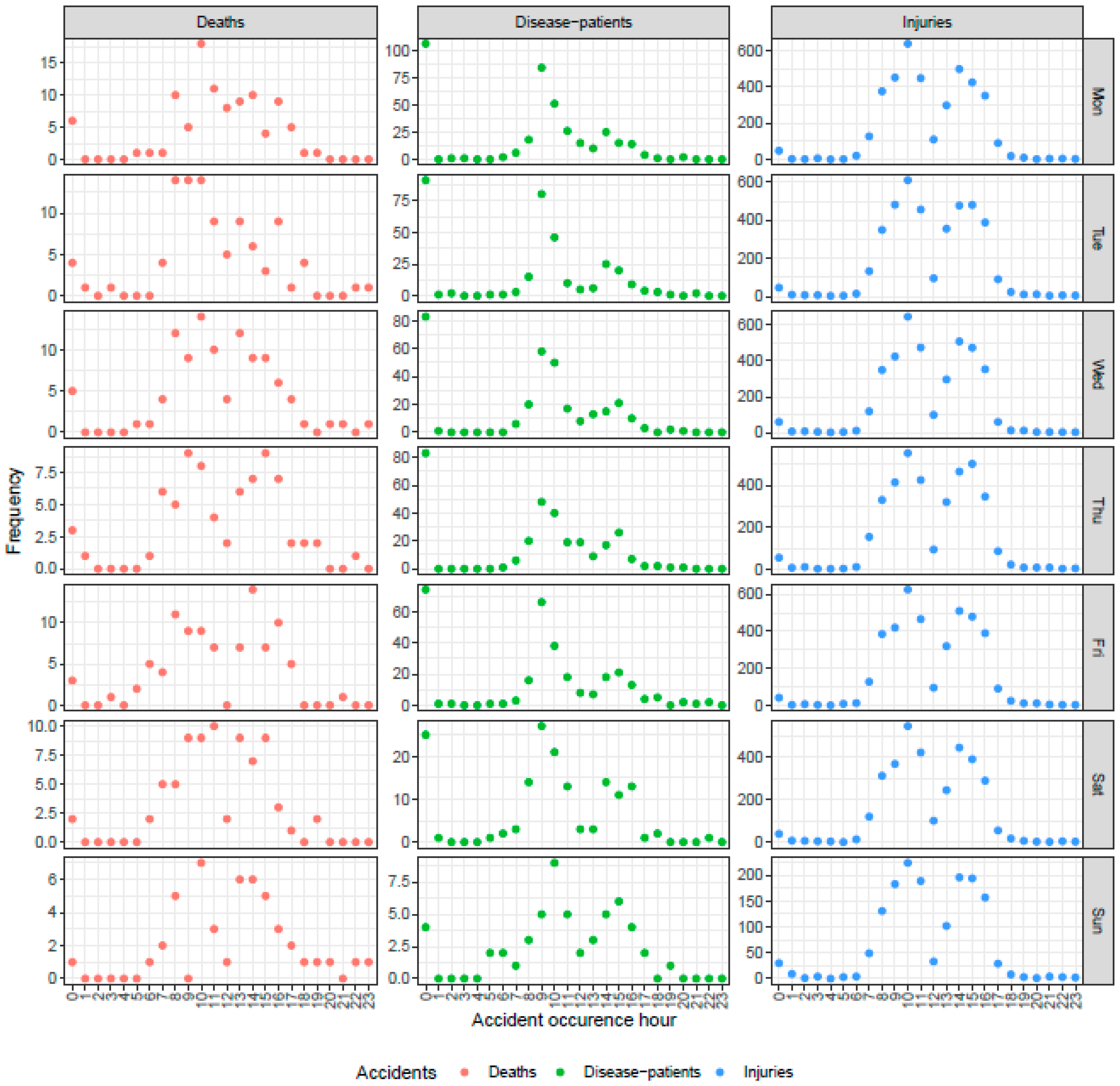

- Cleveland dot: The Cleveland dot plot is better at reducing the visual cutter in the plot and makes it easier to view patterns in the data on the graph [30].

- Balloon plot: It graphically represents the contingency (matrix) table with a size dot corresponding to the entry value in the matrix in the categorical data. The balloon plot serves as an analogy for the correlation matrix when analyzing correlations in the context of continuous variables [31].

- Correspondence analysis: It facilitates the visualization of cross-tabulated data that are on the same scale while considering the weight of factors. It enables a visual representation that takes into account the relative importance or weight of the factors being analyzed [32]. The category with more weight tends to be in the center of the graph, while the categories with few counts tend to be far from the center. Correlated categories are located on the same side of the hyperplane, while negatively correlated categories are placed on opposite sides of the axis.

2.2.2. Modeling Techniques

3. Results and Discussion

3.1. Results

3.1.1. Exploratory Data Analysis

3.1.2. Accident Severity Prediction and Model Validation

3.2. Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ILO. Global Trends on Occupational Accidents and Diseases; World Day Safe Health Work; International Labour Organization: Geneva, Switzerland, 2015; Volume 1, pp. 1–7. [Google Scholar]

- Jeong, B.Y. Characteristics of occupational accidents in the manufacturing industry of South Korea. Int. J. Ind. Ergon. 1997, 20, 301–306. [Google Scholar] [CrossRef]

- Fontaneda, I.; Camino López, M.A.; González Alcantara, O.J.; Greiner, B.A. Construction accidents in Spain: Implications for an aging workforce. BioMed Res. Int. 2022, 2022, 9952118. [Google Scholar] [CrossRef]

- Rajak, R.; Chattopadhyay, A.; Maurya, P. Accidents and injuries in workers of iron and steel industry in West Bengal, India: Prevalence and associated risk factors. Int. J. Occup. Saf. Ergon. 2022, 28, 2533–2540. [Google Scholar] [CrossRef]

- Love, P.E.; Teo, P.; Smith, J.; Ackermann, F.; Zhou, Y. The nature and severity of workplace injuries in construction: Engendering operational benchmarking. Ergonomics 2019, 62, 1273–1288. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, H.S. Finding on Preventive Intervention of Fatal Occupational Injuries through Empirical Analysis of Accident Death. J. Korean Soc. Saf. 2019, 34, 83–88. [Google Scholar] [CrossRef]

- Atanasijevic, T.C.; Savic, S.N.; Nikolic, S.D.; Djoki, V.M. Frequency and severity of injuries in correlation with the height of fall. J. Forensic Sci. 2005, 50, 608–612. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.K. The current status and the future of occupational safety and health in Korea. Ind. Health 2012, 50, 12–16. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J. Analysis of the victims characteristics of the industrial accidents in South Korea in 2020. J. Ergon. Soc. Korea 2022, 41, 397–409. [Google Scholar] [CrossRef]

- Al-Abdallat, E.M.; Oqailan AM, A.; Al Ali, R.; Hudaib, A.A.; Salameh, G.A. Occupational fatalities in Jordan. J. Forensic Leg. Med. 2015, 29, 25–29. [Google Scholar] [CrossRef]

- McKenna, W.; Wilkes, M. Optimising sleep for night shifts. BMJ 2018, 360, j5637. [Google Scholar] [CrossRef]

- Mobed, K.; Gold, E.B.; Schenker, M.B. Occupational health problems among migrant and seasonal farm workers. West. J. Med. 1992, 157, 367. [Google Scholar]

- Turan, S.; Kahraman, M.M. Investigation of the seasonality of occupational accidents in mine operations. J. Sci. Rep. 2023, 52, 125–148. [Google Scholar] [CrossRef]

- Szóstak, M. Analysis of occupational accidents in the construction industry with regards to selected time parameters. Open Eng. 2019, 9, 312–320. [Google Scholar] [CrossRef]

- Pellicer, E.; Carvajal, G.I.; Rubio, M.C.; Catalá, J. A method to estimate occupational health and safety costs in construction projects. KSCE J. Civ. Eng. 2014, 18, 1955–1965. [Google Scholar] [CrossRef]

- Lee, J.Y.; Yoon, Y.G.; Oh, T.K.; Park, S.; Ryu, S.I. A study on data pre-processing and accident prediction modeling for occupational accident analysis in the construction industry. Appl. Sci. 2020, 10, 7949. [Google Scholar] [CrossRef]

- Pak, H.; Bahk, J.; Paek, D.; Lee, E.H.; Pak, Y.S. Accidents resulting in disability in vulnerable populations and their consequences: A study of vulnerable worker groups in South Korea. J. Digit. Converg. 2017, 15, 225–232. [Google Scholar] [CrossRef]

- Kim, D.K.; Park, S. Business cycle and occupational accidents in Korea. Saf. Health Work 2020, 11, 314–321. [Google Scholar] [CrossRef] [PubMed]

- Hasebe, T.; Sakai, T. Are elderly workers more likely to die in occupational accidents? Evidence from both industry-aggregated data and administrative individual-level data in Japan. Jpn. World Econ. 2018, 48, 79–89. [Google Scholar] [CrossRef]

- Seok, H.; Yoon, J.H.; Lee, W.; Lee, J.H.; Jung, P.K.; Roh, J.; Won, J.U. The perceived socio-economic status is an important factor of health recovery for victims of occupational accidents in Korea. J. Korean Med. Sci. 2016, 31, 164–170. [Google Scholar] [CrossRef] [PubMed]

- Jo, B.W.; Lee, Y.S.; Kim, J.H.; Asad Khan, R.M. Trend analysis of construction industrial accidents in Korea from 2011 to 2015. Sustainability 2017, 9, 1297. [Google Scholar] [CrossRef]

- Sarkar, S.; Maiti, J. Machine learning in occupational accident analysis: A review using science mapping approach with citation network analysis. Saf. Sci. 2020, 131, 104900. [Google Scholar] [CrossRef]

- Koc, K. Role of National Conditions in Occupational Fatal Accidents in the Construction Industry Using Interpretable Machine Learning Approach. J. Manag. Eng. 2023, 39, 04023037. [Google Scholar] [CrossRef]

- Mutlu, N.G.; Altuntas, S. Analyzing factors influencing the severity of occupational accidents in textile industry using decision tree algorithms. Clust. Comput. 2023, 1–39. [Google Scholar] [CrossRef]

- Kang, K.; Ryu, H. Predicting types of occupational accidents at construction sites in Korea using random forest model. Saf. Sci. 2019, 120, 226–236. [Google Scholar] [CrossRef]

- Kim, K.W.; Park, S.J.; Lim, H.S.; Cho, H.H. Safety climate and occupational stress according to occupational accidents experience and employment type in ship building industry of Korea. Saf. Health Work 2017, 8, 290–295. [Google Scholar] [CrossRef]

- Rafindadi, A.D.U.; Napiah, M.; Othman, I.; Mikić, M.; Haruna, A.; Alarifi, H.; Al-Ashmori, Y.Y. Analysis of the causes and preventive measures of fatal fall-related accidents in the construction industry. Ain Shams Eng. J. 2022, 13, 101712. [Google Scholar] [CrossRef]

- Harrison, J.E.; Weber, S.; Jakob, R.; Chute, C.G. ICD-11: An international classification of diseases for the twenty-first century. BMC Med. Inform. Decis. Mak. 2021, 21, 1–10. [Google Scholar] [CrossRef]

- Gribble, P.A.; Tucker, W.S.; White, P.A. Time-of-day influences on static and dynamic postural control. J. Athl. Train. 2007, 42, 35. [Google Scholar]

- Cleveland, W.S. Graphical methods for data presentation: Full scale breaks, dot charts, and multibased logging. Am. Stat. 1984, 38, 270–280. [Google Scholar]

- Jain, N.; Warnes, G.R. Balloon Plot. The Newsletter of the R Project Volume 6/2, May 2006, 6, 35. Available online: https://journal.r-project.org/articles/RN-2006-014/RN-2006-014.pdf (accessed on 16 October 2023).

- Greenacre, M.J. Correspondence analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 613–619. [Google Scholar] [CrossRef]

- Böhning, D. Multinomial logistic regression algorithm. Ann. Inst. Stat. Math. 1992, 44, 197–200. [Google Scholar] [CrossRef]

- Liaw, A.; Wiener, M. Classification and regression by random forest. R News 2002, 2, 18–22. [Google Scholar]

- Liu, R.; Niang, N.; Saporta, G.; Wang, H. Sparse correspondence analysis for contingency tables. arXiv 2020, arXiv:2012.04271. [Google Scholar] [CrossRef]

- Kamalja, K.K.; Khangar, N.V. Multiple Correspondence Analysis and its applications. Electron. J. Appl. Stat. Anal. 2017, 10, 432–462. [Google Scholar]

- Lin, Y.H.; Chen, C.Y.; Luo, J.L. Gender and age distribution of occupational fatalities in Taiwan. Accid. Anal. Prev. 2008, 40, 1604–1610. [Google Scholar] [CrossRef]

- Bayaga, A. Multinomial Logistic Regression: Usage and Application in Risk Analysis. J. Appl. Quant. Methods 2010, 5. Available online: http://jaqm.ro/issues/volume-5,issue-2/pdfs/bayaga.pdf (accessed on 16 October 2023).

- Sprinthall, R.C. Basic Statistical Analysis; Allyn & Bacon, Pearson Education Group: Boston, MA, USA, 2003. [Google Scholar]

- McFadden, D. Conditional logit analysis of qualitative choice behavior. In Frontiers in Econometrics; Zarembka, P., Ed.; Academic Press: Cambridge, MA, USA, 1974; pp. 105–142. [Google Scholar]

- Riefer, D.M.; Batchelder, W.H. Statistical inference for multinomial processing tree models. Math. Psychol. Curr. Dev. 1991, 313–335. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using IBM SPSS Statistics, 4th ed.; Sage Publications: Los Angeles, CA, USA, 2013. [Google Scholar]

- Hastie, T.; Tibshirani, R.; Friedman, J.H.; Friedman, J.H. The Elements of Statistical Learning: Data Mining, Inference, and Prediction; Springer: New York, NY, USA, 2009; Volume 2, pp. 1–758. [Google Scholar]

- Bewick, V.; Cheek, L.; Ball, J. Statistics review 13: Receiver operating characteristic curves. Crit. Care 2004, 8, 1–5. [Google Scholar]

- Altman, D.G.; Bland, J.M. Diagnostic tests 3: Receiver operating characteristic plots. BMJ Br. Med. J. 1994, 309, 188. [Google Scholar] [CrossRef]

- Swaen, G.M.H.; Van Amelsvoort, L.G.P.M.; Bültmann, U.; Kant, I.J. Fatigue as a risk factor for being injured in an occupational accident: Results from the Maastricht Cohort Study. Occup. Environ. Med. 2003, 60, i88–i92. [Google Scholar] [CrossRef]

| Categories | Accidents (in 100% of 27,211 Cases) | ||||

|---|---|---|---|---|---|

| Deaths | Disease Patients | Injuries | Total | ||

| Variables | % of victims | 2.19 | 6.7 | 91.11 | 100 |

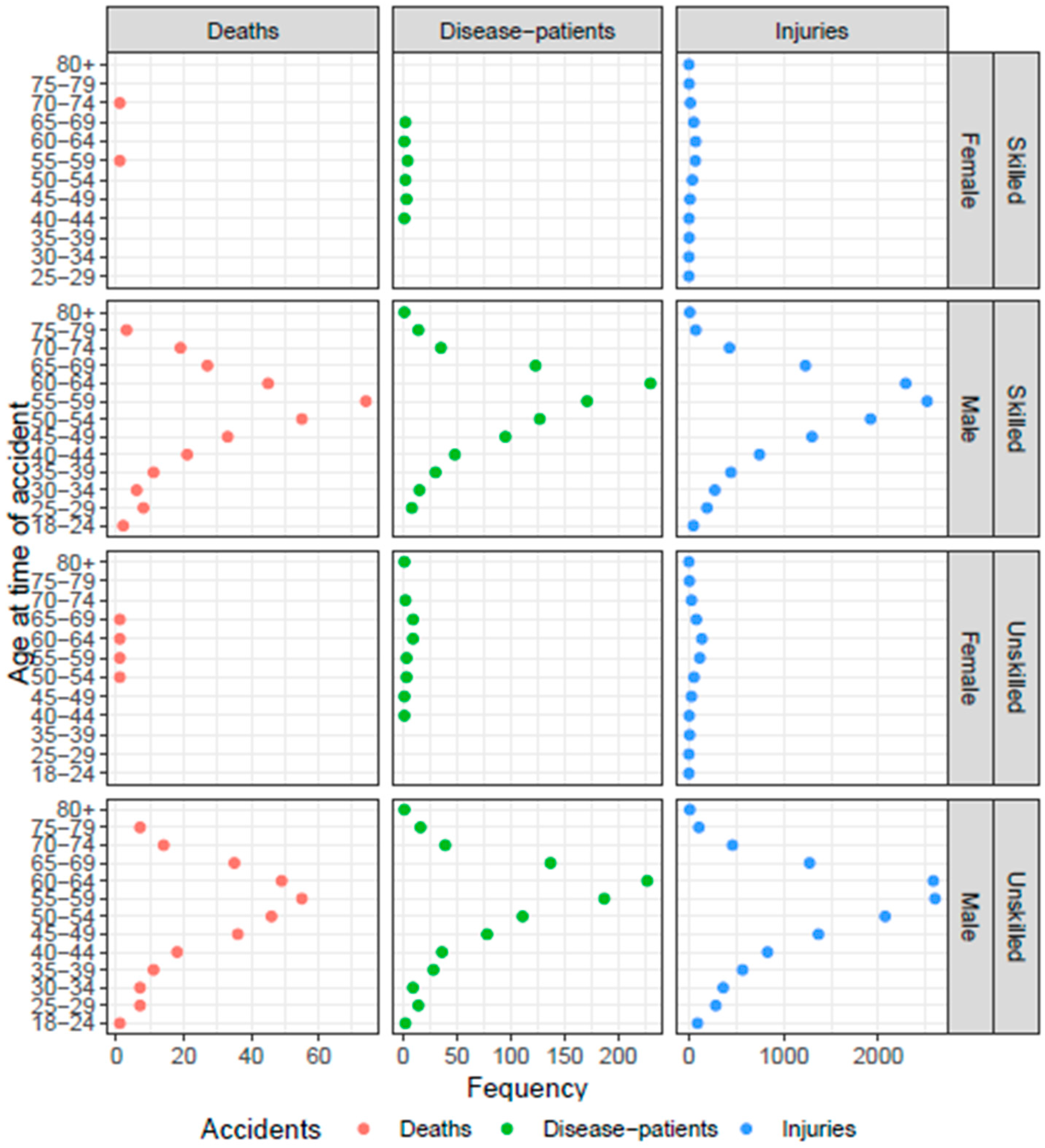

| Sex | Female | 0.02 | 0.15 | 2.69 | 2.87 |

| Male | 2.17 | 6.55 | 88.42 | 97.13 | |

| Age (Years) | 18–24 | 0.01 | 0.01 | 0.51 | 0.53 |

| 25–29 | 0.06 | 0.08 | 1.76 | 1.89 | |

| 30–34 | 0.05 | 0.09 | 2.34 | 2.48 | |

| 35–39 | 0.08 | 0.21 | 3.76 | 4.05 | |

| 40–44 | 0.14 | 0.32 | 5.81 | 6.27 | |

| 45–49 | 0.25 | 0.65 | 9.94 | 10.85 | |

| 50–54 | 0.37 | 0.89 | 14.99 | 16.26 | |

| 55–59 | 0.48 | 1.34 | 19.46 | 21.28 | |

| 60–64 | 0.35 | 1.72 | 18.65 | 20.72 | |

| 65–69 | 0.23 | 1 | 9.68 | 10.91 | |

| 70–74 | 0.12 | 0.28 | 3.43 | 3.83 | |

| 75–79 | 0.04 | 0.11 | 0.69 | 0.84 | |

| 80+ | 0 | 0.01 | 0.08 | 0.09 | |

| Worker skills | Skilled | 1.12 | 3.34 | 43.11 | 47.58 |

| Unskilled | 1.07 | 3.36 | 48 | 52.42 | |

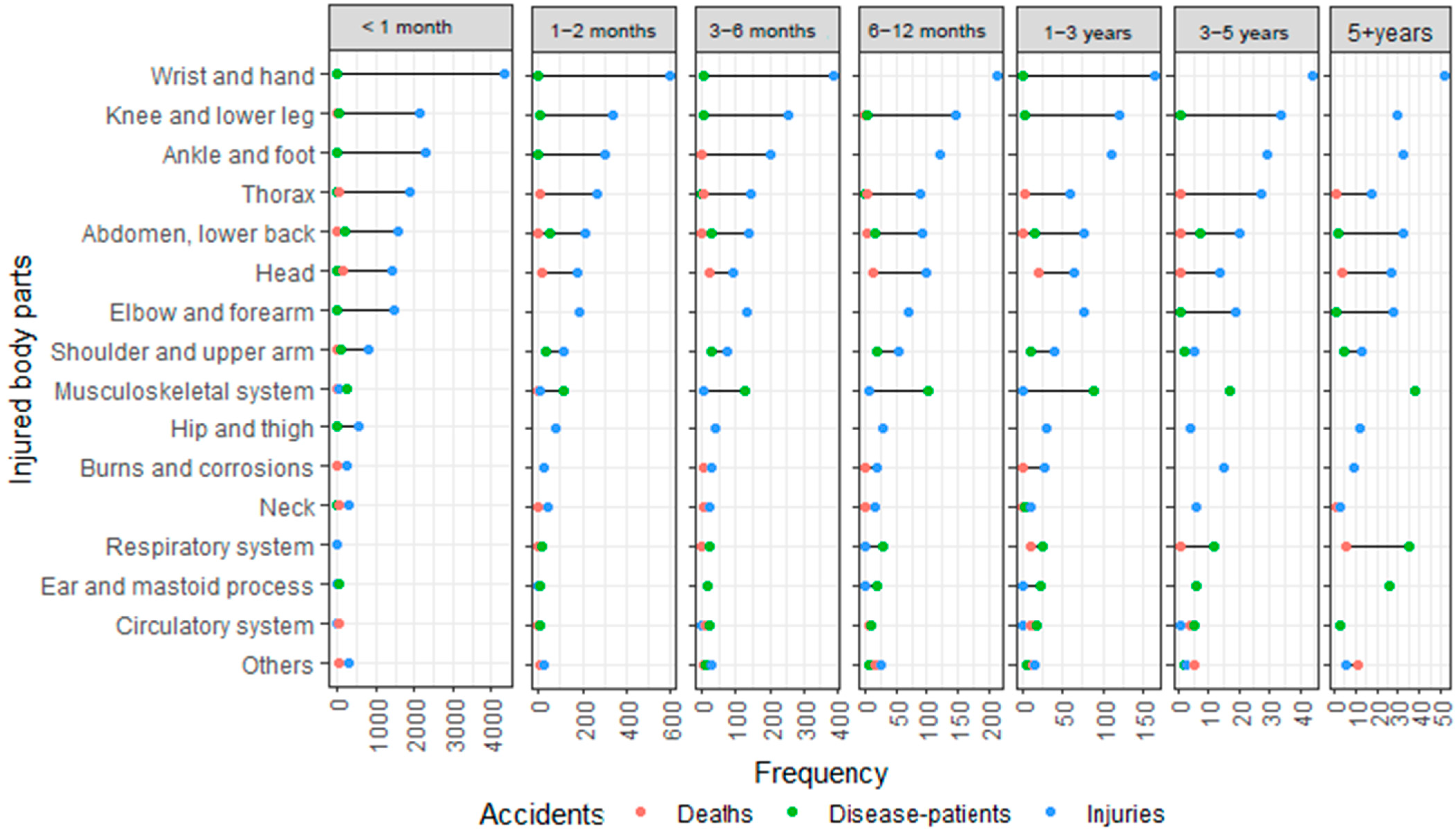

| Work experience | <1 month | 1.19 | 2.2 | 63.93 | 67.33 |

| 1–2 months | 0.15 | 0.86 | 8.74 | 9.75 | |

| 2–3 months | 0.11 | 0.62 | 4.4 | 5.13 | |

| 3–6 months | 0.22 | 0.94 | 5.73 | 6.89 | |

| 6–12 months | 0.17 | 0.75 | 3.58 | 4.5 | |

| 1–3 years | 0.21 | 0.7 | 2.94 | 3.86 | |

| 3–5 years | 0.05 | 0.19 | 0.81 | 1.05 | |

| 5+ years | 0.1 | 0.43 | 0.96 | 1.48 | |

| Diagnosis (injured part or infected organs of the victim) | Abdomen, lower back | 0.08 | 1.14 | 8.39 | 9.61 |

| Ankle and foot | 0 | 0.01 | 11.84 | 11.86 | |

| Burns and corrosions | 0.05 | 0 | 1.37 | 1.43 | |

| Circulatory system | 0.23 | 0.32 | 0.03 | 0.59 | |

| Ear and mastoid process | 0 | 0.49 | 0.04 | 0.53 | |

| Elbow and forearm | 0 | 0.02 | 7.68 | 7.7 | |

| Head | 0.93 | 0.01 | 7.35 | 8.29 | |

| Hip and thigh | 0 | 0 | 2.79 | 2.79 | |

| Knee and lower leg | 0.01 | 0.13 | 11.86 | 12 | |

| Musculoskeletal system | 0.01 | 2.98 | 0.27 | 3.26 | |

| Neck | 0.1 | 0.03 | 1.54 | 1.66 | |

| Others | 0.47 | 0.26 | 1.57 | 2.3 | |

| Respiratory system | 0.09 | 0.57 | 0.04 | 0.7 | |

| Shoulder and upper arm | 0.01 | 0.67 | 4.37 | 5.05 | |

| Thorax | 0.21 | 0.06 | 9.56 | 9.83 | |

| Wrist and hand | 0 | 0.03 | 22.39 | 22.42 | |

| Accident occurrence form | Building collapse | 0.09 | 0 | 1.23 | 1.32 |

| Bump | 0.12 | 0 | 7.8 | 7.92 | |

| Carelessness | 0 | 0 | 2.81 | 2.81 | |

| Chemical contact | 0.03 | 0.01 | 0.24 | 0.27 | |

| Cutting and stabbing | 0.01 | 0 | 10.49 | 10.5 | |

| Disease infection | 0.32 | 6.68 | 0.02 | 7.03 | |

| Electric shock | 0.04 | 0 | 0.48 | 0.52 | |

| Entrapment | 0.08 | 0 | 7.62 | 7.7 | |

| Explosion and rupture | 0.02 | 0 | 0.18 | 0.2 | |

| Extreme heat exposure | 0 | 0 | 0.52 | 0.52 | |

| Fall down | 0.02 | 0 | 15.12 | 15.14 | |

| Fall from height | 1.1 | 0 | 30.38 | 31.48 | |

| Fire | 0.02 | 0 | 0.18 | 0.21 | |

| Flip over (buried) | 0.08 | 0 | 2.55 | 2.63 | |

| Hit by an object | 0.1 | 0 | 10.77 | 10.87 | |

| Off-site traffic accident | 0.1 | 0 | 0.56 | 0.65 | |

| Others | 0.06 | 0.01 | 0.16 | 0.22 | |

| Project phase (% rate of completion) | 0–20 | 0.47 | 0.69 | 15.49 | 16.65 |

| 20–40 | 0.38 | 1.01 | 18.31 | 19.7 | |

| 40–60 | 0.46 | 1.36 | 20.05 | 21.87 | |

| 60–80 | 0.43 | 1.62 | 19.97 | 22.02 | |

| 80+ | 0.45 | 2.02 | 17.29 | 19.76 | |

| Number of workers | <5 | 0.76 | 1.9 | 37.76 | 40.42 |

| 5–9 | 0.25 | 0.72 | 11.85 | 12.82 | |

| 10–15 | 0.18 | 0.49 | 8.15 | 8.83 | |

| 16–29 | 0.17 | 0.76 | 10.4 | 11.33 | |

| 30–99 | 0.36 | 1 | 11.88 | 13.25 | |

| 100–499 | 0.36 | 1.34 | 8.54 | 10.24 | |

| 500+ | 0.1 | 0.49 | 2.52 | 3.11 | |

| Project value (in million KRW) | 10–20 | 0.32 | 0.52 | 11.87 | 12.71 |

| 20–40 | 0.17 | 0.38 | 6.22 | 6.77 | |

| 40–100 | 0.16 | 0.4 | 8.28 | 8.84 | |

| 100–500 | 0.36 | 1 | 18.06 | 19.42 | |

| 500–1000 | 0.18 | 0.44 | 7.95 | 8.57 | |

| 1000–5000 | 0.32 | 1.16 | 16.85 | 18.33 | |

| 5000–10,000 | 0.12 | 0.47 | 6.1 | 6.69 | |

| 10,000–50,000 | 0.22 | 0.67 | 6.12 | 7 | |

| 50,000+ | 0.35 | 1.67 | 9.65 | 11.67 | |

| Month of accident | January | 0.15 | 0.57 | 6 | 6.73 |

| February | 0.12 | 0.42 | 4.68 | 5.22 | |

| March | 0.21 | 0.58 | 7.31 | 8.1 | |

| April | 0.15 | 0.55 | 7.76 | 8.46 | |

| May | 0.18 | 0.63 | 8.59 | 9.4 | |

| June | 0.2 | 0.62 | 7.77 | 8.58 | |

| July | 0.24 | 0.64 | 8.31 | 9.19 | |

| August | 0.22 | 0.6 | 8.5 | 9.33 | |

| September | 0.17 | 0.36 | 6.41 | 6.93 | |

| October | 0.12 | 0.59 | 9.2 | 9.92 | |

| November | 0.22 | 0.57 | 9.01 | 9.79 | |

| December | 0.21 | 0.56 | 7.58 | 8.35 | |

| Day of accident | Sunday | 0.17 | 0.2 | 5.73 | 6.1 |

| Monday | 0.37 | 1.4 | 14.51 | 16.28 | |

| Tuesday | 0.37 | 1.19 | 14.93 | 16.49 | |

| Wednesday | 0.38 | 1.13 | 14.47 | 15.98 | |

| Thursday | 0.28 | 1.11 | 14.09 | 15.47 | |

| Friday | 0.35 | 1.1 | 14.88 | 16.33 | |

| Saturday | 0.28 | 0.57 | 12.51 | 13.35 | |

| Hour of accident | 0:00 | 0.09 | 1.71 | 1.18 | 2.98 |

| 1:00 | 0.01 | 0.01 | 0.17 | 0.19 | |

| 2:00 | 0 | 0.01 | 0.16 | 0.17 | |

| 3:00 | 0.01 | 0 | 0.12 | 0.13 | |

| 4:00 | 0 | 0 | 0.05 | 0.05 | |

| 5:00 | 0.01 | 0.02 | 0.1 | 0.13 | |

| 6:00 | 0.04 | 0.03 | 0.32 | 0.4 | |

| 7:00 | 0.1 | 0.1 | 3.05 | 3.25 | |

| 8:00 | 0.23 | 0.39 | 8.2 | 8.82 | |

| 9:00 | 0.2 | 1.35 | 10.07 | 11.63 | |

| 10:00 | 0.29 | 0.94 | 14.11 | 15.34 | |

| 11:00 | 0.2 | 0.4 | 10.58 | 11.18 | |

| 12:00 | 0.08 | 0.22 | 2.31 | 2.61 | |

| 13:00 | 0.21 | 0.19 | 7.11 | 7.52 | |

| 14:00 | 0.22 | 0.44 | 11.39 | 12.04 | |

| 15:00 | 0.17 | 0.44 | 10.82 | 11.43 | |

| 16:00 | 0.17 | 0.26 | 8.36 | 8.79 | |

| 17:00 | 0.07 | 0.07 | 1.84 | 1.99 | |

| 18:00 | 0.03 | 0.05 | 0.47 | 0.55 | |

| 19:00 | 0.02 | 0.02 | 0.23 | 0.27 | |

| 20:00 | 0.01 | 0.02 | 0.15 | 0.18 | |

| 21:00 | 0.01 | 0.01 | 0.12 | 0.14 | |

| 22:00 | 0.01 | 0.01 | 0.1 | 0.12 | |

| 23:00 | 0.01 | 0 | 0.08 | 0.1 | |

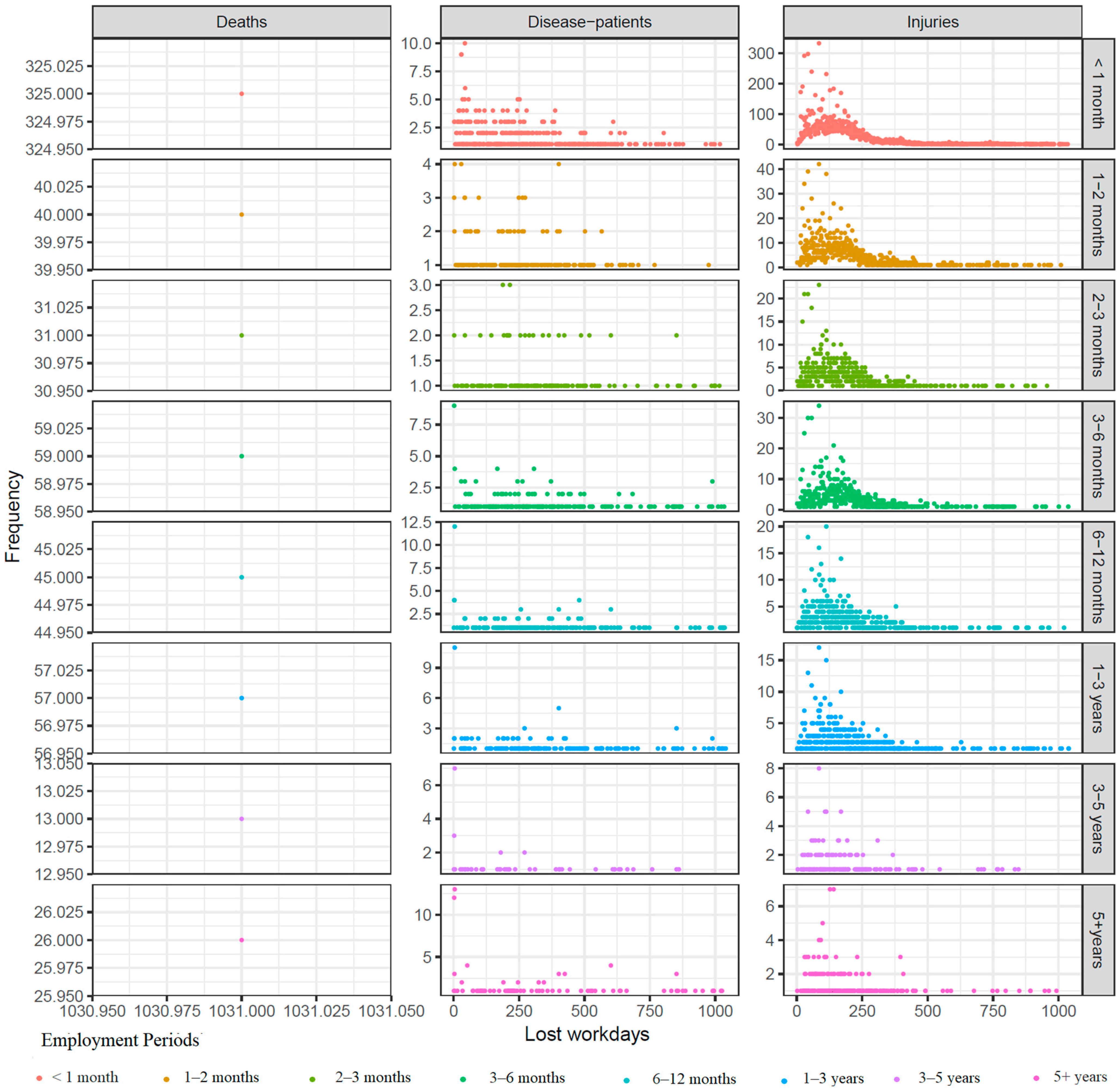

| Lost workdays | Discrete variable | 11.00 | 12.00 | 77.00 | 100 |

| Pseudo R-Squared | Information Criterion | ||||

|---|---|---|---|---|---|

| Models | CoxSnell | Nagelkerke | McFadden | AIC | BIC |

| Null model | 0 | 0 | 0 | 13,325.970 | 13,341.670 |

| Full model | 0.441 | 0.877 | 0.832 | 2670.543 | 4414.290 |

| Optimal model | 0.441 | 0.877 | 0.833 | 2559.036 | 3878.629 |

| Values | Multinomial | Random Forest |

|---|---|---|

| Accuracy | 0.9766 | 0.9738 |

| 95% CI | (0.9731, 0.9798) | (0.9735, 0.9801) |

| No Information Rate | 0.9111 | 0.9111 |

| p-Value [Acc > NIR] | <0.001 | <0.001 |

| Kappa | 0.8463 | 0.8443 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuganishuri, J.; Yum, S.-G.; Adhikari, M.D.; Oh, T.-K. Analysis of the Severity and Cause and Effect of Occupational Accidents in South Korea. Sustainability 2023, 15, 15058. https://doi.org/10.3390/su152015058

Tuganishuri J, Yum S-G, Adhikari MD, Oh T-K. Analysis of the Severity and Cause and Effect of Occupational Accidents in South Korea. Sustainability. 2023; 15(20):15058. https://doi.org/10.3390/su152015058

Chicago/Turabian StyleTuganishuri, Jérémie, Sang-Guk Yum, Manik Das Adhikari, and Tae-Keun Oh. 2023. "Analysis of the Severity and Cause and Effect of Occupational Accidents in South Korea" Sustainability 15, no. 20: 15058. https://doi.org/10.3390/su152015058