Status and Prospects of the Development of Deep-Sea Polymetallic Nodule-Collecting Technology

Abstract

:1. Introduction

2. Development Status

2.1. Time Phases and Progress

2.2. Progress Made by Countries and Institutions

2.2.1. OMI, OMA, and OMCO

2.2.2. Japan Oil, Gas & Metals National Corp (JOGMEC), Japan

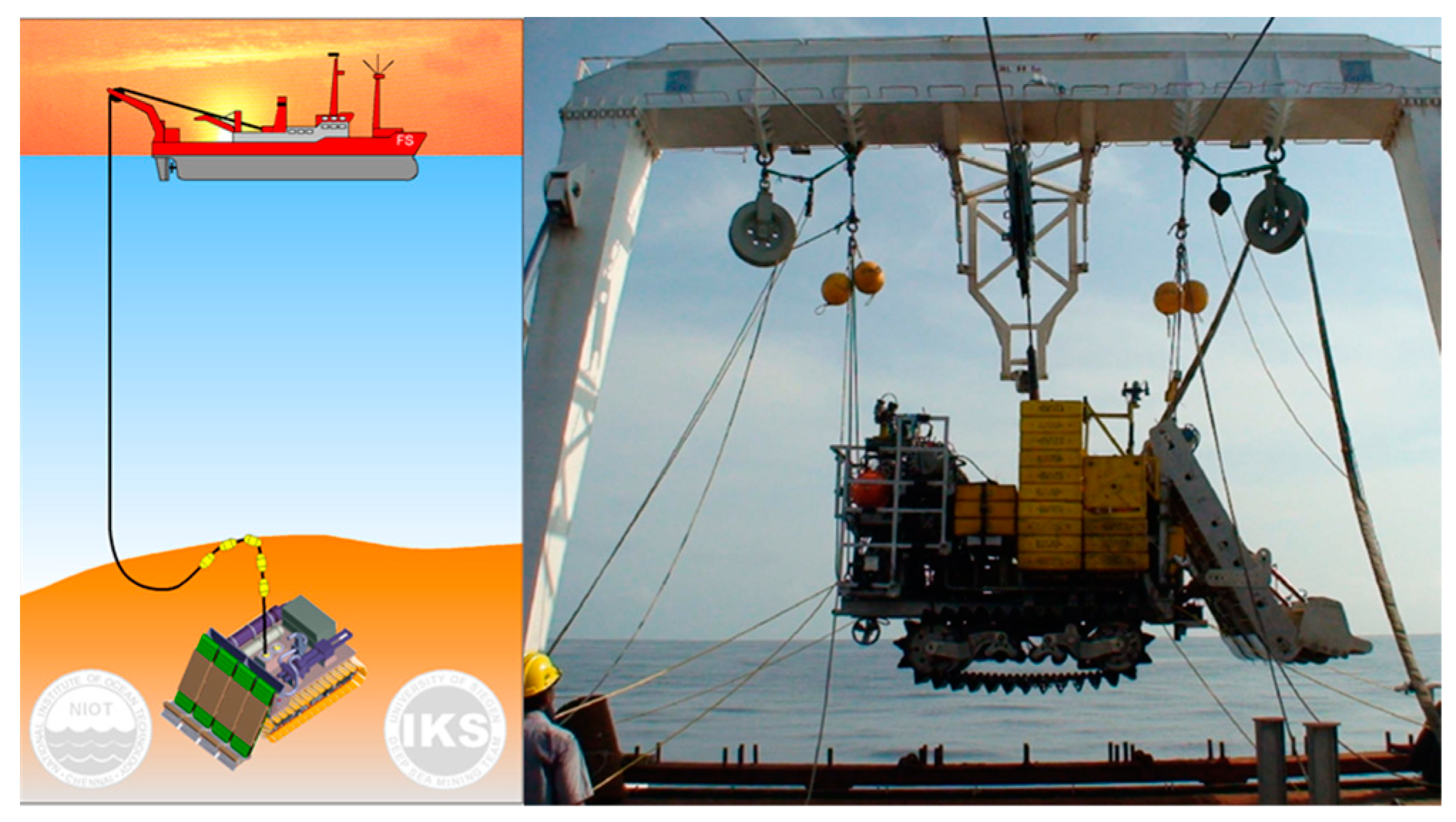

2.2.3. National Institute of Ocean Technology (NIOT), India

2.2.4. Korea Institute of Ocean Science and Technology (KIOST)

2.2.5. Global Sea Mineral Resources (GSR), Belgium

2.2.6. Changsha Research Institute of Mining and Metallurgy, China

2.2.7. The Metals Company (TMC), Canada

3. Technical Difficulties of Commercial Mining

3.1. Efficiency and Disturbance

3.2. Walking Technology on the Submarine Substrate

3.3. Positioning and Navigation Technology

3.4. Power Transmission Technology

3.5. Cooperative Control Technology

3.6. Deployment and Recovery Technology

3.7. Large-Scale Sea Trials

4. Trends and Prospects

4.1. High Demand in the New Energy Market

4.2. Environmental Impact Assessment

4.3. Guaranteed Collection Efficiency

4.4. Low Disturbance Operation Technology

4.5. Enhanced Accuracy and Intelligence Requirements

4.6. Efficient and Safe Deployment and Recovery Operations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peteren, S.; Kraeschell, A.; Augustin, N. News from the seabed—Geological characteristics and resource potential of deep-sea mineral resources. Mar. Policy 2016, 70, 175–187. [Google Scholar] [CrossRef]

- Hein, J.R.; Mizell, K.; Koschinsky, A.; Conrad, T.A. Deep-ocean mineral deposits as a source of critical metals for high- and green-technology applications: Comparison with land-based resources. Ore Geol. Rev. 2013, 51, 1–14. [Google Scholar] [CrossRef]

- Hein, J.R.; Koschinsky, A.; Kuhn, T. Deep-ocean polymetallic nodules as a resource for critical materials. Nat. Rev. Earth Environ. 2020, 1, 158–169. [Google Scholar] [CrossRef] [Green Version]

- Mero, J.L. A Preliminary Report on the Economics of Mining and Processing Deep-Sea Manganese Nodules; Institute of Marine Resources: Los Angeles, CA, USA, 1959; pp. 14–86. [Google Scholar]

- Glasby, G.; Li, J.; Sun, Z. Deep-sea nodules and Co-rich Mn crusts. Mar. Georesources Geotechnol. 2015, 33, 72–78. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, D.; Huang, H.; Wang, C.S.; Qian, P.Y.; Wang, Z.L.; Shi, X.P.; Song, C.B. Progress of environmental research and management related to mineral resources in international seabed. Trans. Nonferrous Met. Soc. China 2021, 31, 2722–2737. [Google Scholar]

- Yang, N.; Chen, G.G. A review of the current status of mining technology for deep-sea mineral resources. Min. Mach. 2010, 38, 4–9. [Google Scholar]

- Dai, Y.; Zhang, Y.Y.; Bian, J.N.; Ma, W.B.; Chen, X. Research of hydrodynamic characteristics of propeller of subsea mining vehicle. Chin. J. Nonferrous Met. 2021, 31, 2771–2781. [Google Scholar]

- Yang, J.M.; Liu, L.; Lyu, H.N.; Lin, Z.Q. Deep-Sea Mining Equipment in China: Current status and prospect. Strateg. Study CAE 2020, 22, 1–9. [Google Scholar] [CrossRef]

- Liu, S.; Hu, J.; Zhang, R.; Dai, Y.; Yang, H. Development of mining technology and equipment for seafloor massive sulfide deposits. Chin. J. Mech. Eng. 2016, 29, 863–870. [Google Scholar] [CrossRef]

- Mero, J.L. The Mineral Resources of the Sea; Elsevier Oceanography Series: Amsterdam, The Netherlands, 1965. [Google Scholar]

- Van Wijk, J.M. Vertical Hydraulic Transport for Deep Sea Mining: A Study into Flow Assurance. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2016. [Google Scholar]

- Chung, J.S. Deep-ocean mining technology: Development II. In Proceedings of the Proc 6th ISOPE Ocean Mining Symposium, Changsha, China, 9–13 October 2005; pp. 1–6. [Google Scholar]

- Masuda, Y.; Cruickshank, M.J.; Mero, J.L. Continuous bucket-line dredging at 12,000 feet. In Proceedings of the Offshore Technology Conference, Dallas, TX, USA, 18–20 April 1971; pp. 837–841. [Google Scholar]

- Thiel, H. From MESEDA to DISCOL: A new approach to deep-sea mining risk assessment. Mar. Min. 1991, 10, 369–386. [Google Scholar]

- Sharma, R. Deep-Sea Mining: Economic, Technical, Technological, and Environmental Considerations for Sustainable Development. Mar. Technol. Soc. J. 2011, 45, 28–41. [Google Scholar] [CrossRef]

- Kaufman, R.; Latimer, J.; Tolefson, D.; Senni, S. The design and operation of a pacific ocean deep-ocean mining Test Ship: R/V Deepsea Miner 2. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 1985; pp. 33–43. [Google Scholar]

- Huang, X.; Dai, Y.; Su, Q.; Cheng, H.Y.; Zhu, X. Simulation and experimental verification of water impact flow field of deep ocean mining vehicle entering water. Chin. J. Nonferrous Met. 2021, 31, 2782–2794. [Google Scholar]

- Xiao, Y.X.; Yang, L.B.; Cao, L.; Wang, Z.W. Distribution of marine mineral resource and advances of deep-sea lifting pump technology. J. Drain. Irrig. Mach. Eng. 2014, 32, 319–326. [Google Scholar]

- Kang, Y.; Liu, S. The development history and latest progress of deep-sea polymetallic nodule mining technology. Minerals 2021, 11, 1132. [Google Scholar] [CrossRef]

- Tang, D.S.; Yang, N.; Jin, X. Hydraulic lifting technique with vertical pipe for deep-sea coarse mineral particles. Min. Metall. Eng. 2013, 33, 1–8. [Google Scholar]

- Yang, N.; Chen, G.G. Status quo and development trendency of deep sea minerals mining technology. Min. Process. Equip. 2010, 38, 4–9. [Google Scholar]

- Boschen, R.E.; Rowden, A.A.; Clark, M.R.; Gardner, J.P. Mining of deep-sea seafloor massive sulfides: A review of the deposits, their benthic communities, impacts from mining, regulatory frameworks and management strategies. Ocean Coast. Manag. 2013, 84, 54–67. [Google Scholar] [CrossRef] [Green Version]

- Brocktt, F.H.; Huizingh, J.P.; Mcfarlane, J.A.R. Updated analysis of the capital and operating costs of a polymetallic nodule deep ocean mining system developed in the 1970s. In Proceedings of the ISA Workshop on Polymetallic Nodule Mining Technology—Current Status and Challenges Ahead, Chennai, India, 18–22 February 2008; pp. 54–80. [Google Scholar]

- Rajesh, S.; Gnanaraj, A.; Velmurugan, A.; Ramesh, R.; Muthuvel, P.; Babu, M.; Ramesh, N.; Deepak, C.; Atmanand, M. Qualification tests on underwater mining system with manganese nodule collection and crushing devices. In Proceedings of the 9th Ocean Mining Symposium, Maui, HI, USA, 19–24 June 2011; pp. 110–115. [Google Scholar]

- Yamada, H.; Yamazaki, T. Japan’s Ocean test of the nodule mining system. In Proceedings of the 8th International Offshore and Polar Engineering Conference, Montreal, QC, Canada, 24–29 May 1998; pp. 13–19. [Google Scholar]

- Yang, N. Research and development of polymetallic nodule mining technology in China. In Proceedings of the ISA Workshop on Polymetallic Nodule Mining Technology—Current Status and Challenges Ahead, Chennai, India, 18–22 February 2008; pp. 214–226. [Google Scholar]

- Liu, F.; Liu, Y.; Song, C.B.; Li, X.Y.; Luo, Y.; Gao, Y.; Zhang, D. Three decades’ development of China in deep-sea field. Chin. J. Nonferrous Met. 2021, 31, 2613–2623. [Google Scholar]

- Li, J.B.; Wang, Y.J.; Liu, L.; XU, X.W. The development status and prospect of deep-sea mineral resources development technology. Preview Technol. 2022, 1, 92–102. [Google Scholar]

- Hong, S.; Kimg, H.W.; Choi, J.S.; Yeu, T.K.; Park, S.J.; Lee, C.H.; Yoon, S.M. A self-propelled deep-seabed miner and lessons from shallow water tests. In Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010; pp. 1–12. [Google Scholar]

- Hong, S.; Kim, H.W.; Yeu, T.; Choi, J.S.; Lee, T.H.; Lee, J.K. Technologies for safe and sustainable mining of deep-seabed minerals. In Environmental Issues of Deep-Sea Mining; Springer: Cham, Switzerland, 2019; pp. 95–143. [Google Scholar]

- Kang, Y.J.; Liu, S.; Zou, W.; Zhao, H.; Hu, X. Design and analysis of an innovative deep-sea lifting motor pump. Appl. Ocean Res. 2019, 82, 22–31. [Google Scholar] [CrossRef]

- Peng, J.P. Development of research on deep-sea polymetallic nodule mining vehicles in China. Min. Mach. 2020, 48, 8–11. [Google Scholar]

- Global Sea Mineral Resources NV. PATANIA II—Technical Update. 2019. Available online: https://deme-gsr.com/news/pataniaii-technical-update/ (accessed on 15 November 2022).

- Global Sea Mineral Resources NV. Deep-Seabed Mining Robot PATANIA II Successfully Reconnected-Mission Contin-ues. 2021. Available online: https://deme-gsr.com/news/deep-seabed-mining-robot-patania-ii-successfully-reconnected-mis-sion-continues/ (accessed on 16 November 2022).

- Kang, Y.J.; Liu, S.J. Development history and prospect of deep sea polymetallic nodules mining technology. Chin. J. Nonferrous Met. 2021, 31, 2848–2860. [Google Scholar]

- Liu, S.; Yang, N.; Han, Q. Research and development of deep sea mining technology in China. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Shanghai, China, 6–11 June 2010; pp. 163–169. [Google Scholar]

- Janarthanan, C.; Chandran, V.; Sundaramoorthi, V.; Viswanath, B.; Dinesh Kumar, D.; Muthuvel, P.; Rajesh, S.; Gnanaraj, A.; Venkatesan, K.; Muthukrishna, S.B. Development and testing of locomotion trials on soft sea bed soil and system performance checks of experimental undercarriage system. In Proceedings of the Twenty-eighth (2018) International Ocean and Polar Engineering Conference, Sapporo, Japan, 10–15 June 2018; pp. 152–159. [Google Scholar]

- Nguyen, N.D.; Kim, S.K. Navigation and Control of Underwater Tracked Vehicle Using Ultrashort Baseline and Ring Laser Gyro Sensors. Sens. Mater 2019, 31, 1575–1587. [Google Scholar]

- Dai, Y.; Liu, S.H. Researches on deep ocean mining robots: Status and development. Robot 2013, 35, 363–375. [Google Scholar] [CrossRef]

- Teague, J.; Allen, M.J.; Scott, T.B. The potential of low-cost ROV for use in deep-sea mineral, ore prospecting and monitoring. Ocean Eng. 2018, 147, 333–339. [Google Scholar] [CrossRef]

- JOGMEC Conducts World’s First Successful Excavation of Cobalt-Rich Seabed in the Deep Ocean. Available online: https://www.jogmec.go.jp/english/news/release/news_01_000033.html (accessed on 18 November 2022).

- Rao, Q.H.; Liu, Z.L.; Xu, F.; Huang, W.; Ma, W.B. Research progress on characteristics of deep-sea soft sediment and walking performance of mining vehicle. Chin. J. Nonferrous Met. 2021, 31, 2795–2816. [Google Scholar]

- Chen, B.Z. Development and experimental study of crawler mechanism of “Kunlong 500” mining vehicle. Min. Technol. 2019, 19, 132–135. [Google Scholar]

- Hund, K.; Porta, D.L.; Fabregas, T.P.; Laing, T.; Drexhage, J. Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition; The World Bank Group: Washington, DC, USA, 2020; Available online: https://commdev.org/pdf/publications/MineralsforClimateActionTheMineralIntensityoftheCleanEnergyTransition.pdf (accessed on 23 November 2022).

- Metals Company. Revolutionizing the Mineral Supply Chain for Fast Growing EV Demand; Metals Company: Vancouver, BC, Canada, 2021; Available online: https://metals.co/investors/ (accessed on 23 November 2022).

- Nautilus Minerals Singapore PTE LTD. Seafloor Haulage System. International Application Published under the Patent Cooperation Treaty (PCT), Wo 2015/178853. A1. 26 November 2015Michael, C. Marine mining: An area of critical national need. Min. Eng. 2011, 5, 89–93. [Google Scholar]

- Alicia, C. Deep Seabed Mining: An Urgent Wake-Up Call to Protect Our Oceans; Greenpeace International: Amsterdam, The Netherlands, 2013. [Google Scholar]

- International Seabed Authority. Draft Standard and Guidelines on the Development and Application of Environmental Management Systems Developed by the Legal and Technical Commission; International Seabed Authority: Kingston, Jamaica, 2020. [Google Scholar]

| Stage | Year | Country/Organization | Depth/m | Representative Content |

|---|---|---|---|---|

| phaseⅠ (1950~2000) | 1978 | US, Canada, Germany, Japan/Ocean Management Institution (OMI) [24] | 5200 | Sea trials of polymetallic nodules |

| 1978 | American/Ocean Mineral Association (OMA) [17] | 4570 | Sea trials of polymetallic nodules | |

| 1979 | American, Dutch/Ocean Mining Corporation (OMCO) [13] | 5000 | Sea trials of polymetallic nodules | |

| 1996 | India/National Institute of Ocean Technology (NIOT); Germany/Sign University [25] | 500 | Mining and mining vehicle walking and collection test | |

| 1997 | Japan/polymetallic tuberculosis mining system research and development project [26] | 2200 | Towing-type mining test | |

| phaseⅡ (2000~2020) | 2001 | China/Changsha Institute of Mining Research, Changsha Research Institute of Mining and Metallurgy [27,28] | 143 | Mining system linkage test |

| 2002 | Japan/Japan Oil,Gas & Metals National Corp (JOGMEC) [9] | 1600 | Walking test of the mining collector | |

| 2006 | India/National Institute of Ocean Technology (NIOT) [25] | 450 | Mining vehicle sea trials | |

| 2012 | Japan/Japan Oil,Gas & Metals National Corp (JOGMEC) [29] | 1600 | Collection and test of the mining vehicle | |

| 2013 | Korea/Korea Institute of Ocean Science and Technology (KIOST) [30,31] | 1370 | Mining vehicle sea trials | |

| 2017 | Belgian/Global Sea Mineral Resources (GSR) [32] | 4571 | Walking test of the mining collector | |

| 2018 | Dutch/Royal IHC Corporation (Royal IHC) [9] | 300 | Mining car walking sea trials | |

| 2018 | China/Changsha Research Institute of Mining and Metallurgy [33] | 514 | Mining vehicle collection and walking sea trials | |

| phase III (2020~) | 2021 | Belgian/Global Sea Mineral Resources (GSR) [34,35] | 4500 | Mining test and environmental impact monitoring |

| 2021 | China/Ocean Association, Changsha Research Institute of Mining and Metallurgy, Changsha Research Mining Institute [36,37] | 1300 | Mining system linkage test and environmental monitoring test | |

| 2022 | Canada/The Metals Corporation TMC | 4400 | Mining system linkage test and environmental impact monitoring |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Dai, Y.; Zhang, Y.; Yang, C.; Liu, C. Status and Prospects of the Development of Deep-Sea Polymetallic Nodule-Collecting Technology. Sustainability 2023, 15, 4572. https://doi.org/10.3390/su15054572

Cheng Y, Dai Y, Zhang Y, Yang C, Liu C. Status and Prospects of the Development of Deep-Sea Polymetallic Nodule-Collecting Technology. Sustainability. 2023; 15(5):4572. https://doi.org/10.3390/su15054572

Chicago/Turabian StyleCheng, Yangrui, Yu Dai, Yanyang Zhang, Caihua Yang, and Chenglong Liu. 2023. "Status and Prospects of the Development of Deep-Sea Polymetallic Nodule-Collecting Technology" Sustainability 15, no. 5: 4572. https://doi.org/10.3390/su15054572