Intelligent Wearable Technologies for Workforce Safety in Built Environment Projects in South Africa

Abstract

:1. Introduction

2. Intelligent Wearable Technology

3. Technology–Organisation–Environment Framework for Assessing the Factors Influencing the Use of Intelligent Wearable Technologies

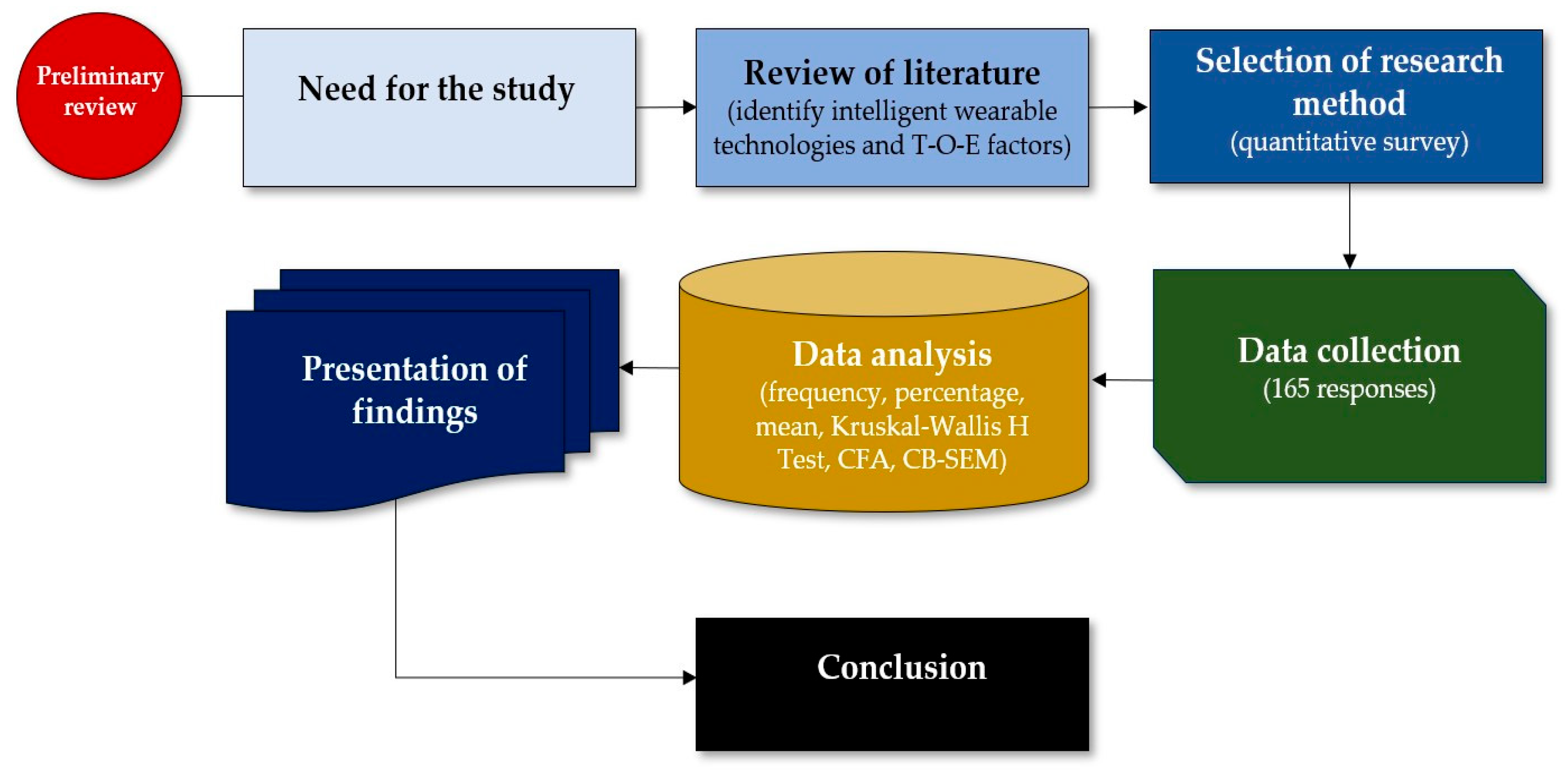

4. Research Methodology

5. Findings and Discussion

5.1. Background Information of Respondents

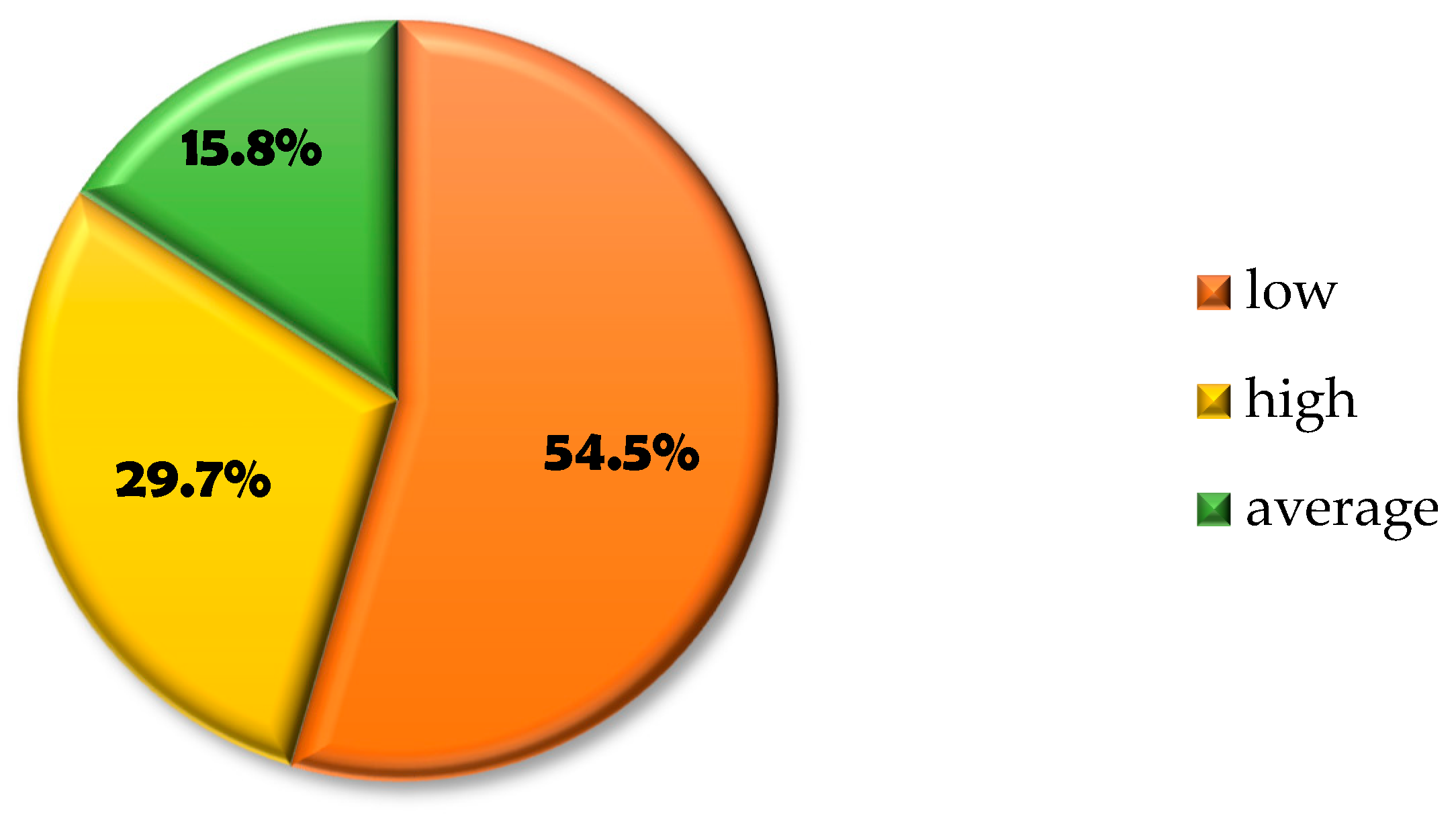

5.2. Use of IWTs for the Effective Safety of Built Environment Projects

5.3. Factors Influencing the Use of IWTs for Effective Safety of Built Environment Project Delivery

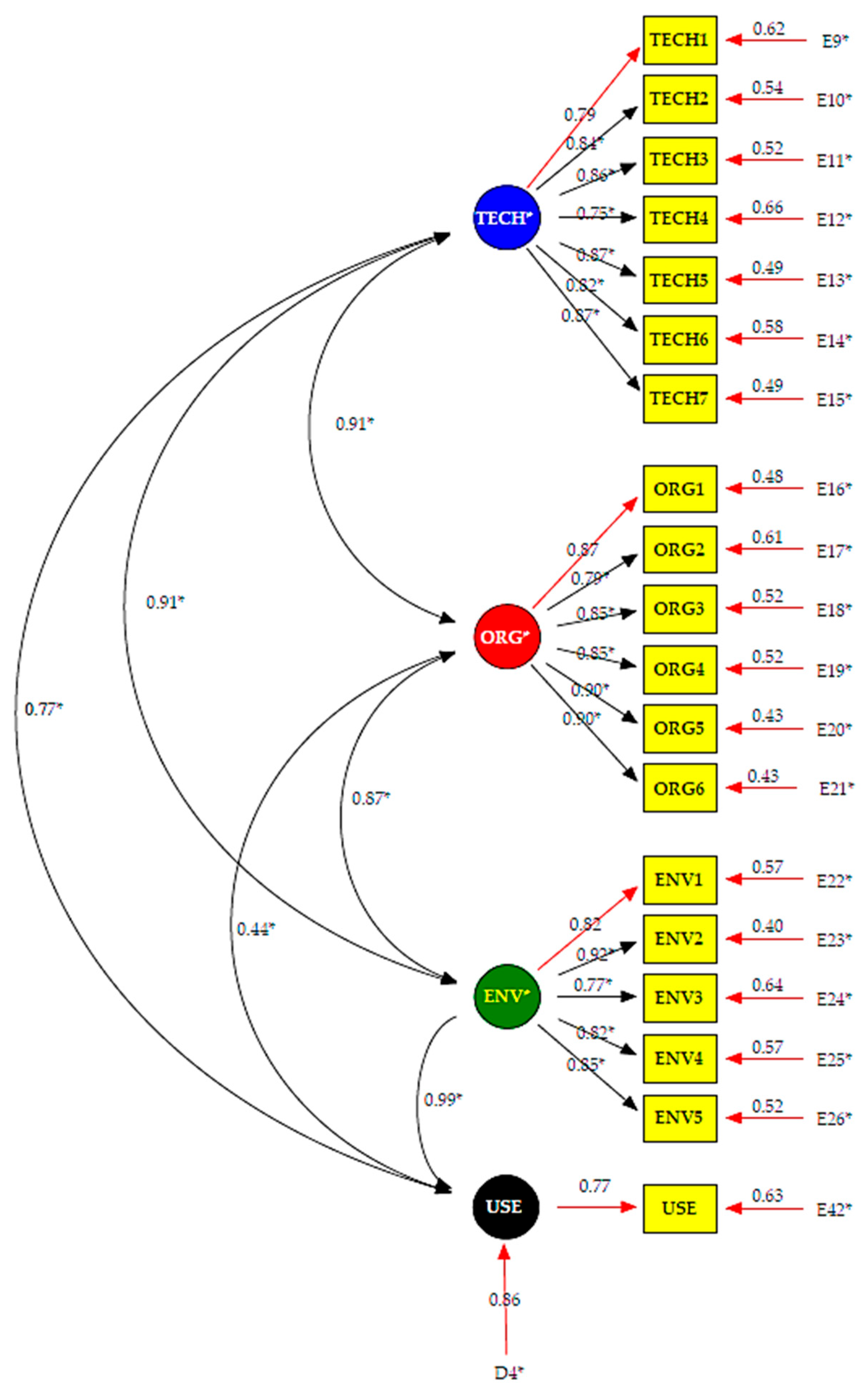

5.3.1. Confirmatory Factor Analysis

5.3.2. Model Fitness

5.3.3. Structural Model Assessment

5.4. Discussion and Implication of Findings

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khalid, U.; Sagoo, A.; Benachir, M. Safety Management System (SMS) framework development—Mitigating the critical safety factors affecting Health and Safety performance in construction projects. Saf. Sci. 2021, 143, 105402. [Google Scholar] [CrossRef]

- World Economic Forum. Shaping the Future of Construction. A Breakthrough in Mindset and Technology. 2016. Available online: http://www3.weforum.org/docs/WEF_Shaping_the_Future_of_Construction_full_report__.pdf (accessed on 28 February 2024).

- Ngwenya, L.M.; Aigbavboa, C. Improvement of productivity and employee performance through an efficient human resource management practice. Adv. Intell. Syst. Comput. 2017, 498, 727–737. [Google Scholar] [CrossRef]

- Chen, H.; Mao, Y.; Xu, Y.; Wang, R. The Impact of Wearable Devices on the Construction Safety of Building Workers: A Systematic Review. Sustainability 2023, 15, 11165. [Google Scholar] [CrossRef]

- Aghimien, L.M.; Aigbavboa, C.O.; Anumba, C.J.; Thwala, W.D. A confirmatory factor analysis of the challenges of effective management of construction workforce in South Africa. J. Eng. Des. Technol. 2021, 21, 1134–1152. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.; Hallowell, M. Wearable technology for personalised construction safety monitoring and trending: Review of applicable devices. Autom. Constr. 2018, 85, 96–106. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Kusoemo, D.; Gosno, R.A. Text mining-based construction site accident classification using hybrid supervised machine learning. Autom. Constr. 2020, 118, 103265. [Google Scholar] [CrossRef]

- Wang, C.; Loo, S.C.; Yap, J.B.H.; Abdul-Rahman, H. Novel Capability-Based Risk Assessment Calculator for Construction Contractors Venturing Overseas. J. Constr. Eng. Manag. 2019, 145, 04019059. [Google Scholar] [CrossRef]

- Chan, D.W.M.; Aghimien, D.O. Safe Working Cycle: Is It a Panacea to Combat Construction Site Safety Accidents in Hong Kong? Sustainability 2022, 14, 894. [Google Scholar] [CrossRef]

- Smallwood, J.J. Optimum cost: The role of health and safety. In Proceedings of the International Cost Engineering Council 4th World Congress, Capetown, South Africa, 17–21 April 2004; pp. 1–10. [Google Scholar]

- Ibrahim, K.; Simpeh, F.; Adebowale, O.J. Benefits and challenges of wearable safety devices in the construction sector. Smart Sustain. Built Environ. 2023. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.Y.; Pelosi, A.; Jia, Y.; Shen, X.; Siddiqui, M.K.; Yang, N. Implementation of technologies in the construction industry: A systematic review. Eng. Constr. Archit. Manag. 2021. [Google Scholar] [CrossRef]

- Golizadeh, H.; Hosseini, M.R.; Edwards, D.J.; Abrishami, S.; Taghavi, N.; Banihashemi, S. Barriers to adoption of RPAs on construction projects: A task–technology fit perspective. Constr. Innov. 2019, 19, 149–169. [Google Scholar] [CrossRef]

- Tharshanapriya, K.; Sagadevan, P.; Jayaramjayaraj, K.; Bhuvaneswari, V. Occupational risk assessment using biochemical and genotoxicity studies among construction painters. Indo Am. J. Pharm. Sci. 2017, 4, 1559–1564. [Google Scholar]

- Abuwarda, Z.; Mostafa, K.; Oetomo, A.; Hegazy, T.; Morita, P. Wearable devices: Cross benefits from healthcare to construction. Autom. Constr. 2022, 142, 104501. [Google Scholar] [CrossRef]

- Nnaji, C.; Awolusi, I.; Park, J.; Albert, A. Wearable sensing devices: Towards the development of a personalised system for construction safety and health risk mitigation. Sensors 2021, 21, 682. [Google Scholar] [CrossRef] [PubMed]

- Düking, P.; Achtzehn, S.; Holmberg, H.C.; Sperlich, B. Integrated Framework of Load Monitoring by a Combination of Smartphone Applications, Wearables and Point-of-Care Testing Provides Feedback that Allows Individual Responsive Adjustments to Activities of Daily Living. Sensors 2018, 18, 1632. [Google Scholar] [CrossRef] [PubMed]

- Ahn, C.R.; Lee, S.; Sun, C.; Jebelli, H.; Yang, K.; Choi, B. Wearable sensing technology applications in construction safety and health. J. Constr. Eng. Manag. 2019, 145, 03119007. [Google Scholar] [CrossRef]

- Lee, W.; Lin, K.; Seto, E.; Migliaccio, G.C. Wearable sensors for monitoring on-duty and off-duty worker physiological status and activities in construction. Autom. Constr. 2017, 83, 341–353. [Google Scholar] [CrossRef]

- Shakerian, S.; Habibnezhad, M.; Ojha, A.; Lee, G.; Liu, Y.; Jebelli, H.; Lee, S. Assessing occupational risk of heat stress at construction: A worker-centric wearable sensor-based approach. Saf. Sci. 2021, 142, 105395. [Google Scholar] [CrossRef]

- Dall’Omo, S. Driving African development through smarter technology. Afr. Digit. Matur. Rep. 2017, 1, 1–45. [Google Scholar]

- Ikuabe, M.; Aghimien, D.O.; Aigbavboa, C.O.; Oke, A.E. Exploring the adoption of digital technology at the different phases of construction projects in South Africa. In Proceedings of the 10th International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 10–12 March 2020; pp. 1553–1561. [Google Scholar]

- Oke, A.E.; Aghimien, D.O.; Aigbavboa, C.O.; Koloko, N. Challenges of Digital Collaboration in The South African Construction Industry. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bandung, Indonesia, 6–8 March 2018; pp. 2472–2482. [Google Scholar]

- Angelia, R.E.; Pangantihon, R.S., Jr.; Villaverde, J. Wireless sensor network for safety tracking of construction workers through hard hat. In Proceedings of the 7th International Conference on Computing and Artificial Intelligence, Tianjin, China, 23–26 April 2021; pp. 412–417. [Google Scholar]

- Wright, R.; Keith, L. Wearable technology: If the tech fits, wear it. J. Electron. Resour. Med. Libr. 2014, 11, 204–216. [Google Scholar] [CrossRef]

- Zhu, H.; Hwang, B.G.; Ngo, J.; Tan, J.P.S. Applications of smart technologies in construction project management. J. Constr. Eng. Manag. 2022, 148, 04022010. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Y.; Yin, Z. Low-power soft transistors triggering revolutionary electronics. Innovation 2024, 5, 1–2. [Google Scholar] [CrossRef] [PubMed]

- Pal, A.; Hsieh, S.H. Deep-learning-based visual data analytics for smart construction management. Autom. Constr. 2021, 131, 103892. [Google Scholar] [CrossRef]

- Xu, M.; Nie, X.; Li, H.; Cheng, J.C.; Mei, Z. Smart construction sites: A promising approach to improving on-site HSE management performance. J. Build. Eng. 2022, 49, 104007. [Google Scholar] [CrossRef]

- Dehghani, M.; Kim, K.J.; Dangelico, R.M. Will smartwatches last? Factors contributing to intention to keep using smart wearable technology. Telemat. Inform. 2018, 35, 480–490. [Google Scholar] [CrossRef]

- Bangaru, S.S.; Wang, C.; Aghazadeh, F. Data quality and reliability assessment of wearable EMG and IMU sensor for construction activity recognition. Sensors 2020, 20, 5264. [Google Scholar] [CrossRef]

- Aryal, A.; Ghahramani, A.; Becerik-Gerber, B. Monitoring fatigue in construction workers using physiological measurements. Autom. Constr. 2017, 82, 154–165. [Google Scholar] [CrossRef]

- Choi, B.; Hwang, S.; Lee, S. What drives construction workers’ acceptance of wearable technologies in the workplace? indoor localisation and wearable health devices for occupational safety and health. Autom. Constr. 2017, 84, 31–41. [Google Scholar] [CrossRef]

- Hwang, S.; Seo, J.; Jebelli, H.; Lee, S. Feasibility analysis of heart rate monitoring of construction workers using a photoplethysmography (PPG) sensor embedded in a wristband-type activity tracker. Autom. Constr. 2016, 71, 372–381. [Google Scholar] [CrossRef]

- Guo, H.; Yu, Y.; Xiang, T.; Li, H.; Zhang, D. The availability of wearable-device-based physical data for the measurement of construction workers’ psychological status on site: From the perspective of safety management. Autom. Constr. 2017, 82, 207–217. [Google Scholar] [CrossRef]

- Babbie, E. The Practice of Social Research, 13th ed.; Wadsworth Publishing: Belmont, CA, USA, 2013. [Google Scholar]

- Hwang, S.; Lee, S. Wristband-type wearable health devices to measure construction workers’ physical demands. Autom. Constr. 2017, 83, 330–340. [Google Scholar] [CrossRef]

- Lee, G.; Choi, B.; Jebelli, H.; Lee, S. Assessment of construction workers’ perceived risk using physiological data from wearable sensors: A machine learning approach. J. Build. Eng. 2021, 42, 102824. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, T.; Zhou, Y.; Lai, P.; Haung, Y. Wearable ultrasound bioelectronics for healthcare monitoring. Innovation 2023, 4, 100447. [Google Scholar] [CrossRef]

- Yang, X.; Yu, Y.; Shirowzhan, S.; Li, H. Automated PPE-Tool pair check system for construction safety using smart IoT. J. Build. Eng. 2020, 32, 101721. [Google Scholar] [CrossRef]

- Keshetty, S.K. Construction wearable technology-smart work boots. Int. J. Adv. Res. Innov. Ideas Educ. 2021, 7, 889–894. [Google Scholar]

- Al Naabi, M.; Al Harthi, K. Developing a Smart Hard Hat for Employees Who Work on Construction Sites. J. Stud. Res. 2023, 1–5. Available online: https://www.jsr.org/index.php/path/article/view/2312 (accessed on 18 April 2024).

- Bhavesh, B.; Rahul, C. A Comprehensive Review of Smart Glasses Technology-Future of Eyewear. Turk. J. Comput. Math. Educ. 2021, 12, 15–26. [Google Scholar]

- Moon, S.; Seo, J. Integration of Smart Glass Technology for Information Exchange at Construction Sites. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction, Oulu, Finland, 15–18 June 2015. [Google Scholar]

- Noghabaei, M.; Heydarian, A.; Balali, V.; Han, K. Trend Analysis on Adoption of Virtual and Augmented Reality in the Architecture, Engineering, and Construction Industry. Data 2020, 5, 26. [Google Scholar] [CrossRef]

- Awa, H.O.; Ojiabo, O.O.; Orokor, L.E. Integrated technology-organisation-environment (T-O-E) taxonomies for technology adoption. J. Enterp. Inf. Manag. 2017, 30, 893–921. [Google Scholar] [CrossRef]

- Bryan, J.D.; Zuva, T. A review on TAM and TOE framework progression and how these models integrate. Adv. Sci. Technol. Eng. Syst. J. 2021, 6, 137–145. [Google Scholar] [CrossRef]

- Abed, S.S. Social commerce adoption using TOE framework: An empirical investigation of Saudi Arabian SMEs. Int. J. Inf. Manag. 2020, 53, 102–118. [Google Scholar] [CrossRef]

- Baker, J. The technology–organisation–environment framework. In Information Systems Theory. Integrated Series in Information Systems; Dwivedi, Y., Wade, M., Schneberger, S., Eds.; Springer: New York, NY, USA, 2012. [Google Scholar] [CrossRef]

- Lumsden, J.R.I.; Gutierrez, A. Understanding the determinants of cloud computing adoption within the UK. In Proceedings of the European, Mediterranean & Middle East Conference on Information System, Windsor, UK, 17–18 October 2013; pp. 1–16. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations; The Free Press: New York, NY, USA, 2003. [Google Scholar]

- Smallwood, J.; Deacon, C. Occupational Health (OH) Practices in South African Construction. MATEC Web Conf. 2020, 312, 03003. [Google Scholar] [CrossRef]

- Parveen, F.; Sulaiman, A. Technology complexity, personal innovativeness and intention to use wireless internet using mobile devices in Malaysia. Int. Rev. Bus. Res. Pap. 2008, 4, 1–10. [Google Scholar]

- Asiaei, A.; Rahim, N.Z.A. A multifaceted framework for adoption of cloud computing in Malaysian SMEs. J. Sci. Technol. Policy Manag. 2019, 10, 708–750. [Google Scholar] [CrossRef]

- Oliveira, T.; Thomas, M.; Espadanal, M. Assessing the determinants of cloud computing adoption: An analysis of the manufacturing and services sectors. Inf. Manag. 2014, 51, 497–510. [Google Scholar] [CrossRef]

- Gupta, P.; Seetharaman, A.; Raj, J. The usage and adoption of cloud computing by small and medium businesses. Int. J. Inf. Manag. 2013, 33, 861–874. [Google Scholar] [CrossRef]

- Low, C.; Chen, Y.; Wu, M. Understanding the determinants of cloud computing adoption. Ind. Manag. Data Syst. 2011, 111, 1006–1023. [Google Scholar] [CrossRef]

- Gutierrez, A.; Boukrami, A.; Lumsden, R. Technological, organisational and environmental factors influencing managers’ decision to adopt cloud computing in the UK. J. Enterp. Inf. Manag. 2015, 28, 788–807. [Google Scholar] [CrossRef]

- Gangwar, H.; Date, H.; Ramaswamy, R. Understanding determinants of cloud computing adoption using an integrated TAM-TOE model. J. Enterp. Inf. Manag. 2015, 28, 107–130. [Google Scholar] [CrossRef]

- Aghimien, D.; Aigbavboa, C.; Oke, A.; Aghimien, L. Latent institutional environment factors influencing construction digitalisation in South Africa. Int. J. Constr. Educ. Res. 2022, 18, 142–158. [Google Scholar] [CrossRef]

- Hsu, P.-F.; Ray, S.; Li-Hsieh, Y.-Y. Examining cloud computing adoption intention, pricing mechanism, and deployment model. Int. J. Inf. Manag. 2014, 34, 474–488. [Google Scholar] [CrossRef]

- Liu, H.; Ke, W.; Wei, K.K.; Gu, J.; Chen, H. The role of institutional pressures and organisational culture in the firm’s intention to adopt internet-enabled supply chain management systems. J. Oper. Manag. 2010, 28, 372–384. [Google Scholar] [CrossRef]

- Aghimien, D.O.; Aghimien, E.I.; Fadiyimu, A.O.; Adegbemo, T.F. Survival strategies for construction related organisations in a challenging economy. Eng. Constr. Archit. Manag. 2018, 25, 861–876. [Google Scholar] [CrossRef]

- Yigitbasioglu, O.M. The role of institutional pressures and top management support in the intention to adopt cloud computing solutions. J. Enterp. Inf. Manag. 2015, 28, 579–594. [Google Scholar] [CrossRef]

- Senyo, P.K.; Effah, J.; Addae, E. Preliminary insight into cloud computing adoption in a developing country. J. Enterp. Inf. Manag. 2016, 29, 505–524. [Google Scholar] [CrossRef]

- Robson, C. Real World Research. In A Resource for Social Scientists and Practitioner-Researchers, 2nd ed.; Blackwell: Oxford, UK; Malden, MA, USA, 2002. [Google Scholar]

- Tan, W.C.K. Practical Research Methods; Pearson Custom: Singapore, 2011. [Google Scholar]

- Pallant, J. SPSS Survival Manual, 4th ed.; Allen & Unwin Publishers: Crow’s Nest, Australia, 2011. [Google Scholar]

- Aigbavboa, C. An Integrated Beneficiary Centred Satisfaction Model for Publicly Funded Housing Schemes in South Africa. Ph.D. Thesis, Post Graduate School of Engineering Management, University of Johannesburg, Johannesburg, South Africa, 2013. [Google Scholar]

- Cheung, M.W.L. Meta-Analysis: A Structural Equation Modelling Approach; Wiley: Chichester, UK, 2015. [Google Scholar]

- Williams, L.J.; Vandenberg, R.J.; Edwards, J.R. 12 structural equation modelling in management research: A guide for improved analysis. Acad. Manag. Ann. 2009, 3, 543–604. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y. Specification, evaluation, and interpretation of structural equation models. J. Acad. Mark. Sci. 2012, 40, 8–34. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modelling, 3rd ed.; The Guilford Press: New York, NY, USA, 2010. [Google Scholar]

- Oke, A.E.; Ogunsemi, D.R. Structural equation modelling of construction bond administration. J. Financ. Manag. Prop. Constr. 2016, 21, 192–211. [Google Scholar] [CrossRef]

- Byrne, B.M. Structural Equation Modeling with EQS: Basic Concepts, Applications, and Programming; Lawrence Erlbaum Associates: Mahwah, NJ, USA, 2008. [Google Scholar]

- Hulland, J. Use of partial least squares (PLS) in strategic management research: A review of four recent studies. Strateg. Manag. J. 1999, 20, 195–204. [Google Scholar] [CrossRef]

- Cepeda-Carrion, G.; Cegarra-Navarro, J.-G.; Cillo, V. Tips to use partial least squares structural equation modelling (PLS-SEM) in knowledge management. J. Knowl. Manag. 2019, 23, 67–89. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Hu, L.T.; Bentler, P.M. Cut-off criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Model. A Multidiscip. J. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Doloi, H.; Iyer, K.C.; Sawhney, A. Structural equation model for assessing impacts of contractor’s performance on project success. Int. J. Proj. Manag. 2011, 29, 687–695. [Google Scholar] [CrossRef]

- Singh, R. Does my structural model represent the real phenomenon? A review of the appropriate use of structural equation modelling model fit indices. Mark. Rev. 2009, 9, 199–212. [Google Scholar] [CrossRef]

- Zack, J. Trends in Construction Technology: The Potential Impact on Project Management and Construction Claims, A Research Perspective, The Navigant Construction Forum™. 2016. Available online: https://www.navigant.com/insights/construction/2016/trends-in-construction-technology (accessed on 28 February 2024).

- Goodrum, P.M.; Haas, C.T.; Caldas, C.; Zhai, D.; Yeiser, J.; Homm, D. Model to predict the impact of a technology on construction productivity. J. Constr. Eng. Manag. 2011, 137, 678–688. [Google Scholar] [CrossRef]

- Haikio, J.; Kallio, J.; Makela, S.M.; Keranen, J. IoT-based safety monitoring from the perspective of construction site workers. Int. J. Occup. Environ. Saf. 2020, 4, 1–14. [Google Scholar] [CrossRef]

| K-W | ||||

|---|---|---|---|---|

| Intelligent Wearable Technologies | Rank | χ2 | p-Value | |

| Smart safety vest embedded with indoor GPS/sensors | 3.21 | 1 | 9.469 | 0.051 |

| Smartwatch and wristband biosensors | 3.13 | 2 | 1.806 | 0.771 |

| Smart safety helmet | 3.10 | 3 | 13.340 | 0.010 ** |

| Smart boots | 3.08 | 4 | 9.620 | 0.047 ** |

| Smart glasses | 3.01 | 5 | 3.777 | 0.437 |

| Chest wearable sensors | 2.96 | 6 | 2.923 | 0.571 |

| Smart gloves | 2.84 | 7 | 5.429 | 0.246 |

| Overall | 3.05 | |||

| K-W | ||||

|---|---|---|---|---|

| T–O–E Factors | Rank | χ2 | p-Value | |

| Technology | ||||

| Ability of devices to ensure workers safety (Tech 6) | 3.60 | 1 | 5.971 | 0.201 |

| Cost-effectiveness (Tech 4) | 3.49 | 2 | 8.005 | 0.091 |

| Reliability of wearables technologies (Tech 2) | 3.47 | 3 | 4.055 | 0.399 |

| Compatibility with existing technologies (Tech 7) | 3.45 | 4 | 1.641 | 0.801 |

| Availability of wearables devices (Tech 1) | 3.42 | 5 | 8.227 | 0.084 |

| Ease of use (Tech 5) | 3.42 | 5 | 2.431 | 0.657 |

| Perceived innovativeness (Tech 3) | 3.28 | 7 | 3.348 | 0.501 |

| Organisation | ||||

| Support from management (Org 2) | 3.47 | 1 | 2.739 | 0.602 |

| Available organisational resources (Org 6) | 3.45 | 2 | 3.585 | 0.465 |

| Organisation’s digital culture (Org 3) | 3.38 | 3 | 5.145 | 0.273 |

| Organisation’s readiness (Org 1) | 3.34 | 4 | 3.652 | 0.455 |

| Organisation size (Org 4) | 3.33 | 5 | 6.886 | 0.142 |

| Available technical expertise (Org 5) | 3.27 | 6 | 5.250 | 0.263 |

| Environment | ||||

| Supporting industry regulations (ENV 2) | 3.47 | 1 | 1.357 | 0.852 |

| Demand from construction clients (ENV 3) | 3.43 | 2 | 3.872 | 0.424 |

| Available legislation (ENV 1) | 3.38 | 3 | 3.392 | 0.494 |

| Competitors pressure (ENV 4) | 3.29 | 4 | 4.085 | 0.395 |

| Trust in suppliers (ENV 5) | 3.19 | 5 | 1.375 | 0.849 |

| Groups | Variable | Standardised λ | Z | Significant at 5% Level? | R2 | Group R2 | α | ρA |

|---|---|---|---|---|---|---|---|---|

| Technology | TECH1 | 0.79 | Yes | 0.62 | 0.69 | 0.967 | 0.975 | |

| TECH 2 | 0.84 | 12.366 | Yes | 0.71 | ||||

| TECH 3 | 0.86 | 12.617 | Yes | 0.73 | ||||

| TECH 4 | 0.75 | 10.642 | Yes | 0.57 | ||||

| TECH 5 | 0.87 | 12.922 | Yes | 0.76 | ||||

| TECH 6 | 0.82 | 11.812 | Yes | 0.67 | ||||

| TECH 7 | 0.87 | 12.926 | Yes | 0.76 | ||||

| Organisation | ORG1 | 0.87 | Yes | 0.77 | 0.75 | |||

| ORG2 | 0.79 | 13.071 | Yes | 0.62 | ||||

| ORG3 | 0.85 | 15.077 | Yes | 0.73 | ||||

| ORG4 | 0.85 | 15.053 | Yes | 0.73 | ||||

| ORG5 | 0.90 | 17.038 | Yes | 0.82 | ||||

| ORG6 | 0.90 | 16.923 | 0.82 | |||||

| Environment | ENV1 | 0.82 | Yes | 0.67 | 0.69 | |||

| ENV2 | 0.92 | 14.933 | Yes | 0.84 | ||||

| ENV3 | 0.77 | 11.359 | Yes | 0.59 | ||||

| ENV4 | 0.82 | 12.563 | Yes | 0.68 | ||||

| ENV5 | 0.85 | 13.291 | Yes | 0.73 | ||||

| Use of IWTs | USE | 0.77 | Yes | 0.60 |

| Fit Indices | Cut-Offs | Value | Remarks |

|---|---|---|---|

| S-Bχ2 | - | 295.44 | - |

| Df | - | 146 | - |

| S-Bχ2/Df | <3—good fit | 2.02 | Good |

| GFI | 0 to 1 (0 = no fit; 1—perfect fit) | 0.786 | Good |

| CFI | 0 to 1 (0 = no fit; 1—perfect fit) | 0.926 | Good |

| NNFI | 0.60 to 1.00—acceptable fit | 0.914 | Good |

| IFI | 0.90 to 1.00—acceptable fit | 0.927 | Good |

| RMSEA | 0.05 to 0.10—acceptable fit | 0.079 | Good |

| SRMR | ≤0.08—acceptable fit | 0.045 | Good |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aghimien, L.; Ngcobo, N.; Aghimien, D. Intelligent Wearable Technologies for Workforce Safety in Built Environment Projects in South Africa. Sustainability 2024, 16, 3498. https://doi.org/10.3390/su16083498

Aghimien L, Ngcobo N, Aghimien D. Intelligent Wearable Technologies for Workforce Safety in Built Environment Projects in South Africa. Sustainability. 2024; 16(8):3498. https://doi.org/10.3390/su16083498

Chicago/Turabian StyleAghimien, Lerato, Ntebo Ngcobo, and Douglas Aghimien. 2024. "Intelligent Wearable Technologies for Workforce Safety in Built Environment Projects in South Africa" Sustainability 16, no. 8: 3498. https://doi.org/10.3390/su16083498