The Mathematical Modeling, Diffusivity, Energy, and Enviro-Economic Analysis (MD3E) of an Automatic Solar Dryer for Drying Date Fruits

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Description of ASD

- Solar Collector: The solar collector is made of angle steel (L) measuring 3 × 3 cm, with dimensions of 300 cm in length and 100 cm in breadth. The solar absorber’s surface comprises galvanized corrugated sheets that are 1.0 mm thick. The surface is coated matte black to optimize sunlight absorption. Sawdust is used as thermal insulation in between the main frame and the adsorbent surface to reduce heat loss.

- Drying Room and Trays: The primary structure of the drying room is built using square metal bars measuring 3.0 × 3.0 cm. The dimensions of the drying room are 45 cm in width, 100 cm in length, and 98 cm in height. The drying room’s sides are clad in two layers of galvanized sheets, each 1.00 mm thick. Sawdust is sandwiched between the layers to prevent heat loss via the sidewalls. Trays are used for placing the date fruit samples within the drying room.

- Automatic Controller: The automatic controller consists of various components, including a channel relay model, an Arduino Uno (ATmega328P, Microchip Technology Inc., Chandler, AZ, USA), a light intensity sensor (model: GL5506, Generic, Chaina), and a weather sensor (model: BME280, Bosch, Gerlingen, Germany). These components help in monitoring and controlling the drying process based on environmental conditions.

- Photovoltaic Solar Panel: A 100 W photovoltaic solar panel is utilized to generate electricity for powering the ASD.

- AC Suction Fan: A 50 W AC suction fan is employed to facilitate air circulation within the drying room, aiding in the drying process.

- Measuring Unit: A DHT-22 measuring unit is used to determine both humidity and air temperature in the drying chamber.

2.3. Experimental Procedure

2.4. Calculations and Measurements

2.4.1. Drying Rate

2.4.2. Moisture Ratio

2.4.3. Effective Moisture Diffusivity (EMD)

2.4.4. Drying Constant (k) (Coefficient)

2.4.5. Mathematical Modeling of Date Drying

| No. | Model Name | Model Equation * | References |

|---|---|---|---|

| 1 | Newton (Lewis) | [83] | |

| 2 | Page | [84,85] | |

| 3 | Modified Page III | [29] | |

| 4 | Henderson and Pabis | [59,86] | |

| 5 | Modified Henderson and Pabis | [70] | |

| 6 | Two-term | [87] | |

| 7 | Two-term Exponential | [57,88] | |

| 8 | Approximation diffusion or Diffusion Approach | [89,90] | |

| 9 | Logarithmic | [91] | |

| 10 | Combined Two-term and Page | [92] | |

| 11 | Simplified Fick’s Diffusion | [93] | |

| 12 | Logistics | [94] |

2.5. Economic Analysis

2.6. Environmental Analysis

2.6.1. Specific Energy Consumed (SEC)

2.6.2. Energy Analysis

2.7. Embodied Energy

2.7.1. Time of Energy Payback (Ep)

2.7.2. CO2 Emission

2.7.3. Carbon Mitigation

2.8. Annual Thermal Outputs

3. Results and Discussion

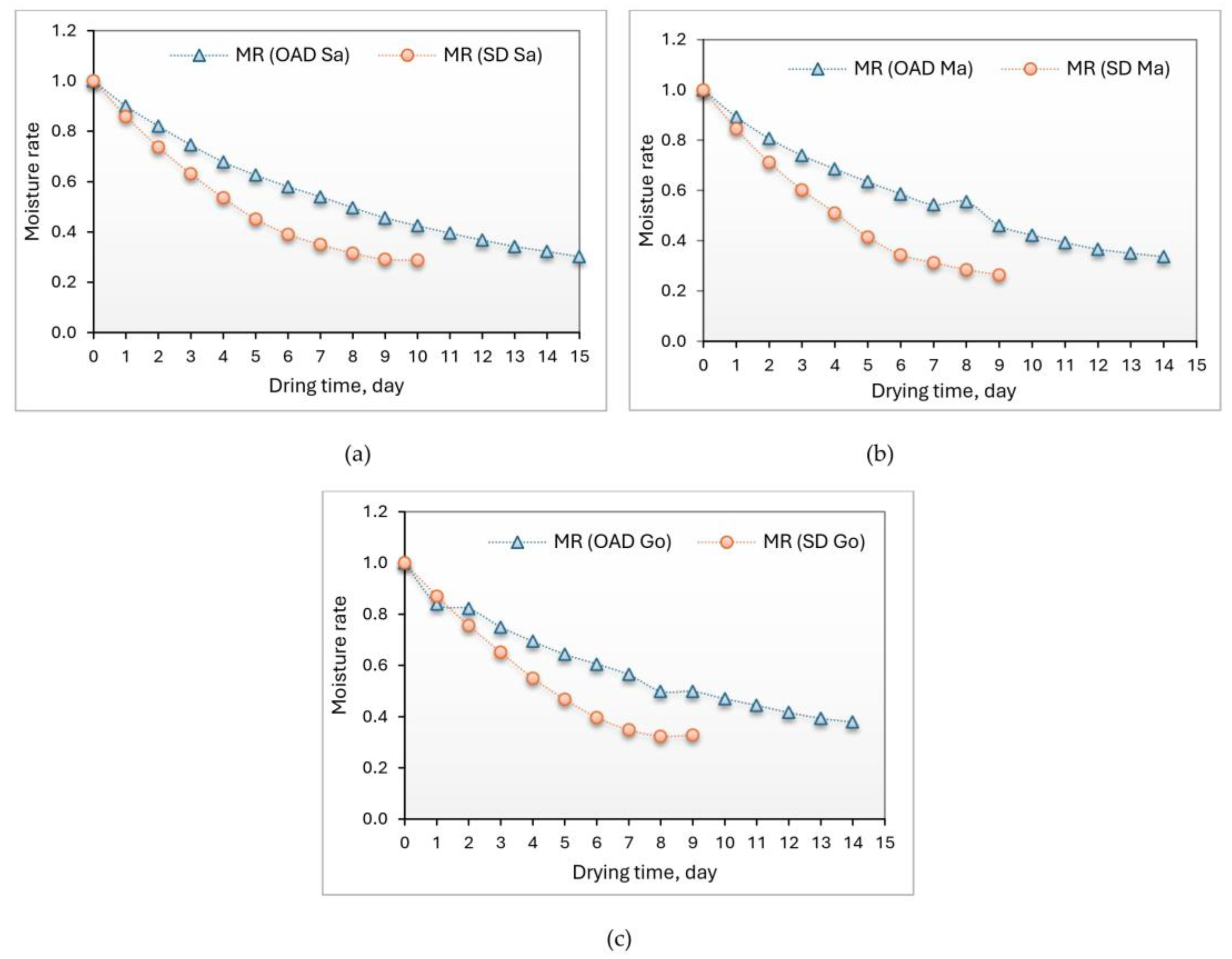

3.1. Moisture Content

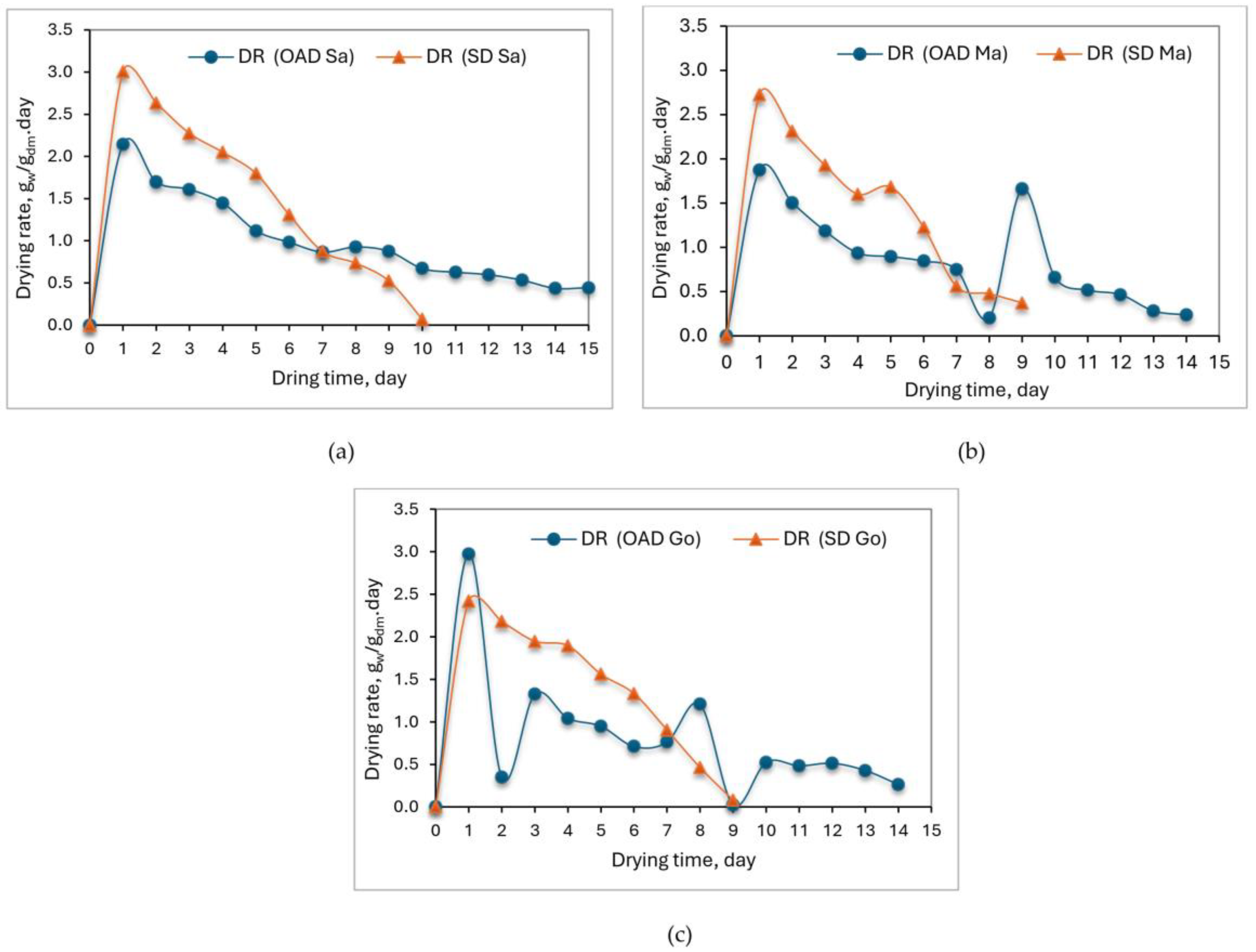

3.2. Drying Rate

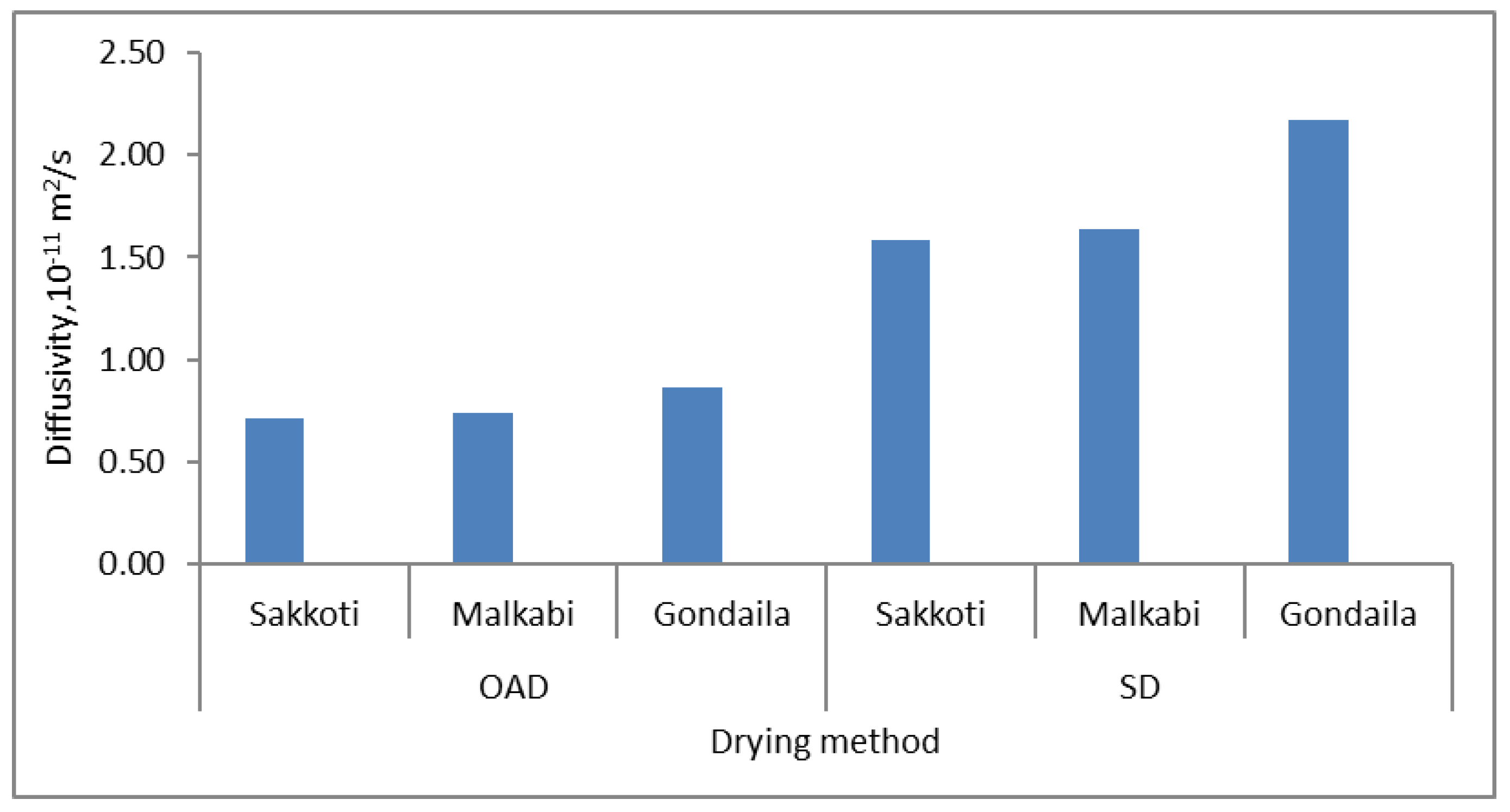

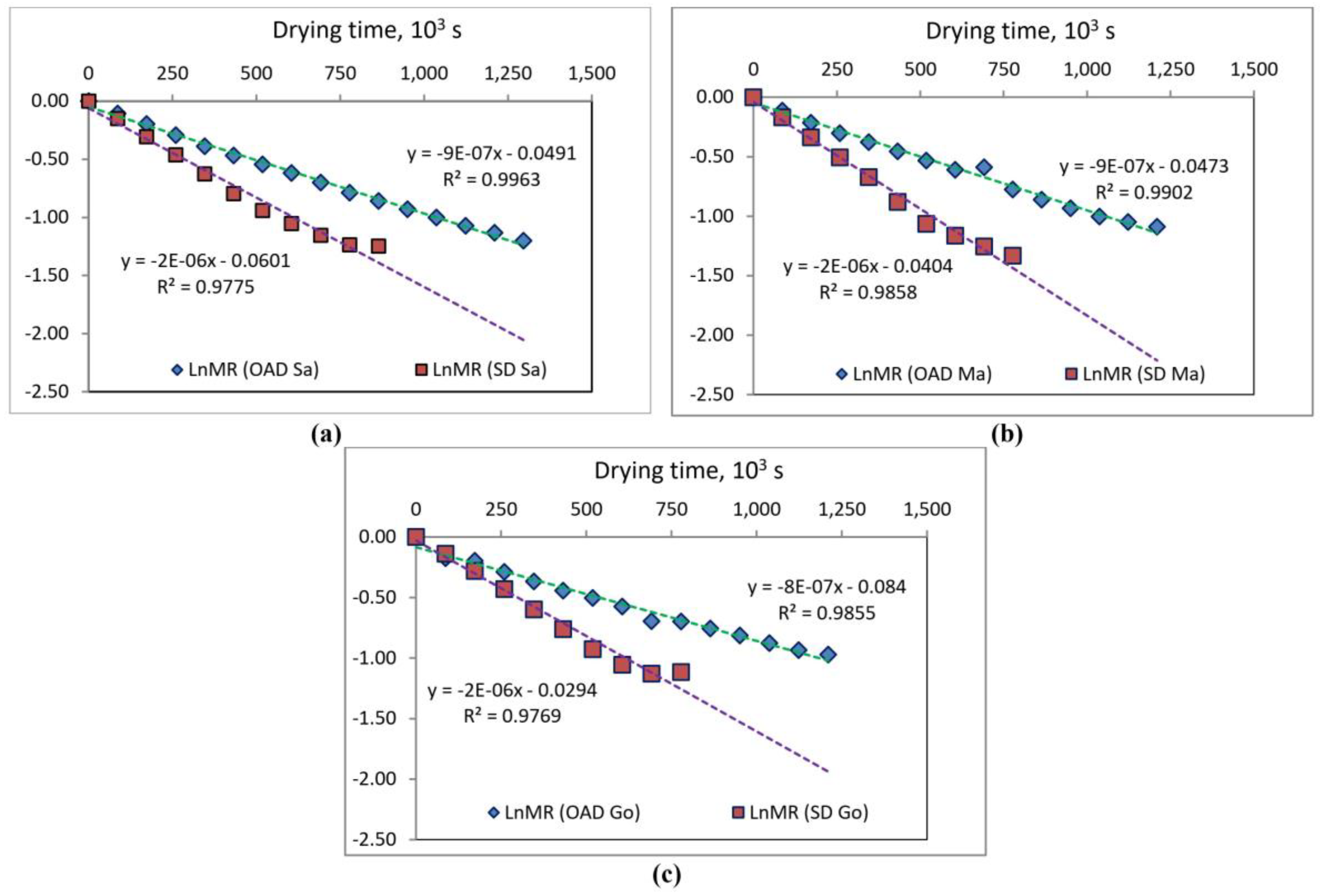

3.3. Effective Moisture Diffusivity (EMD)

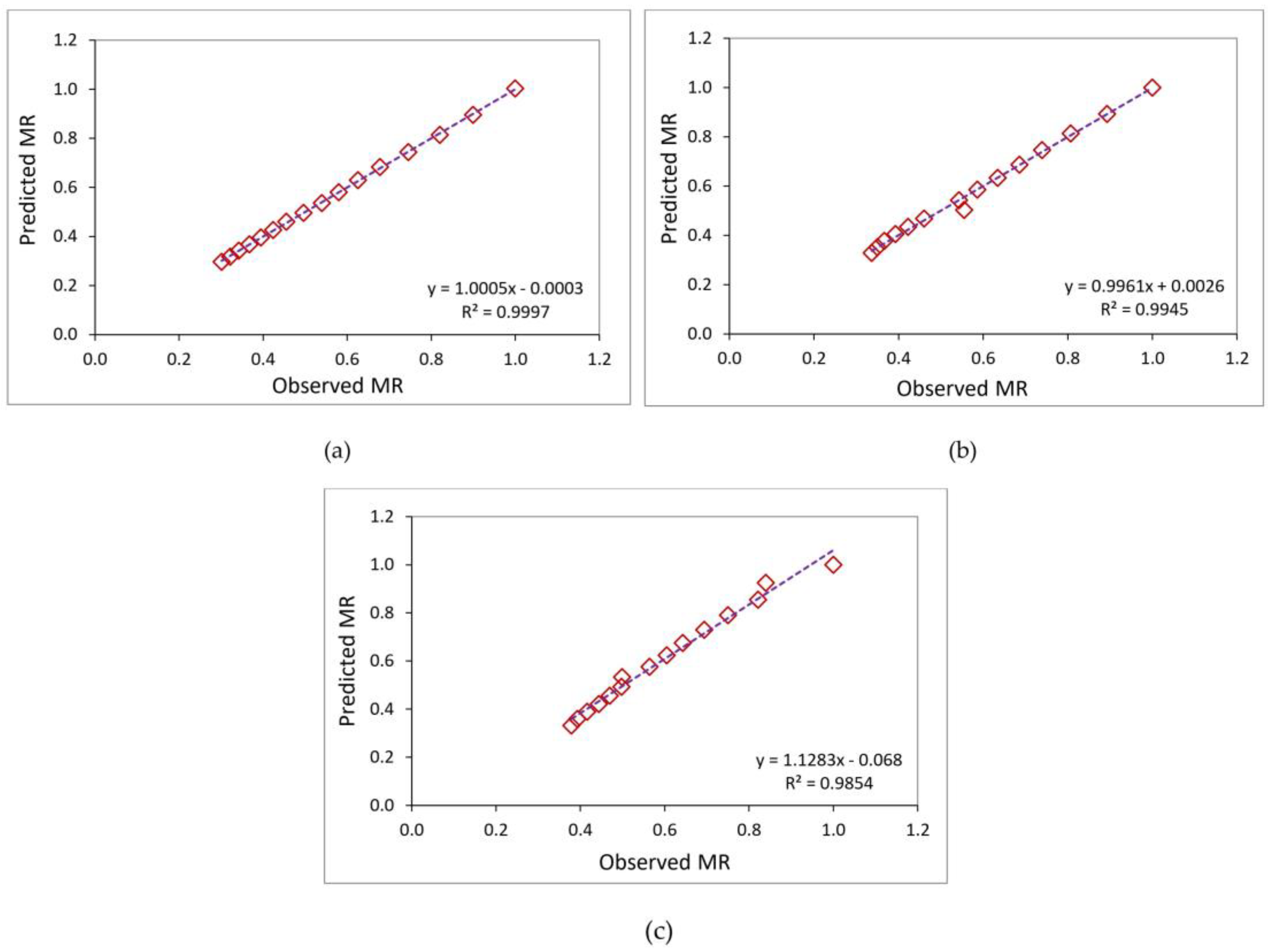

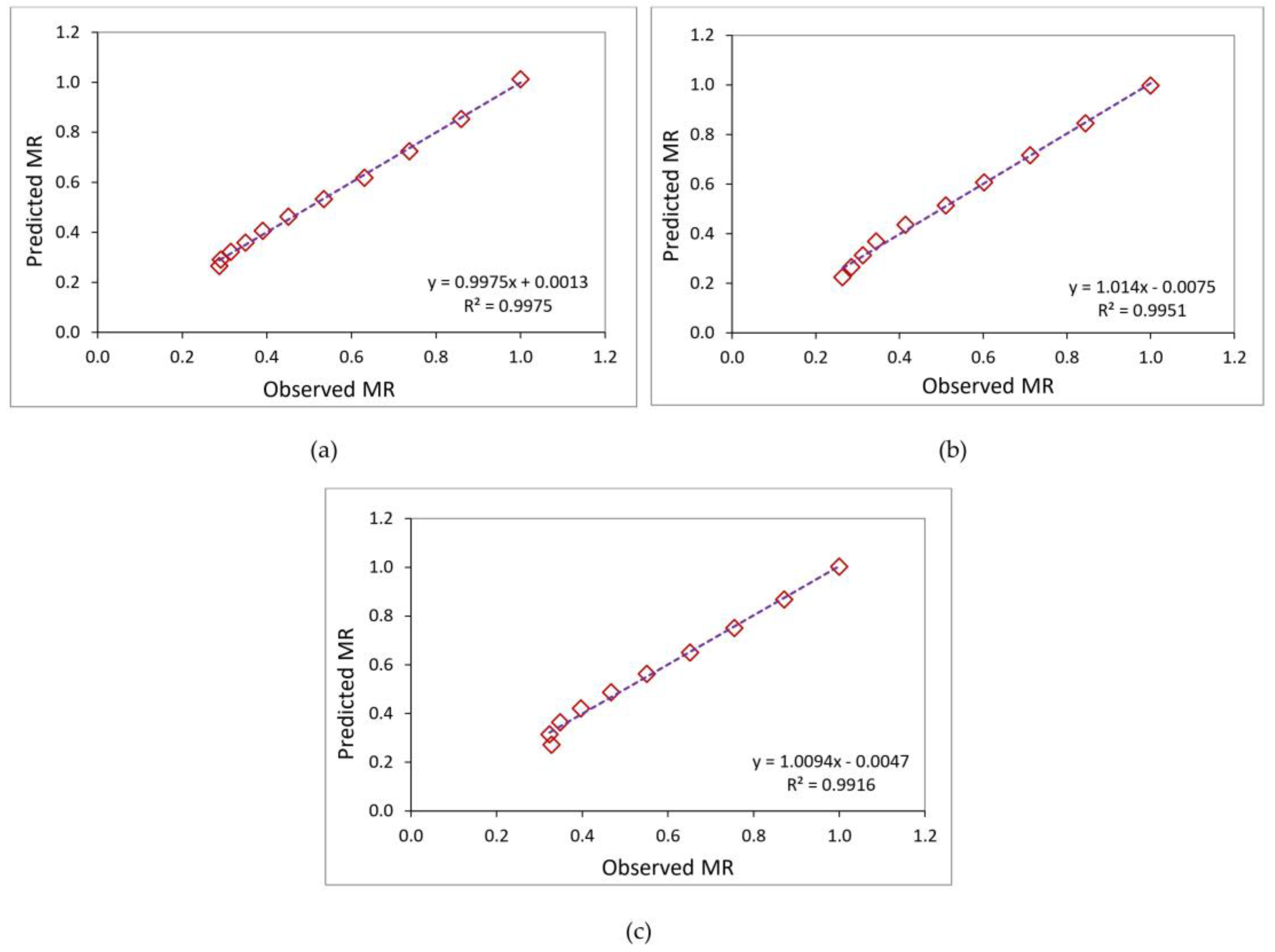

3.4. Evaluation of Drying Models

3.5. Economic Analysis

3.6. Environmental Analysis

4. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elwakeel, A.E.; Wapet, D.E.M.; Mahmoud, W.A.E.M.; Abdallah, S.E.; Mahmoud, M.M.; Ardjoun, S.A.E.M.; Tantawy, A.A. Design and Implementation of a PV-Integrated Solar Dryer Based on Internet of Things and Date Fruit Quality Monitoring and Control. Int. J. Energy Res. 2023, 2023, 7425045. [Google Scholar] [CrossRef]

- Ambawat, S.; Sharma, A.; Saini, R.K. Mathematical Modeling of Thin Layer Drying Kinetics and Moisture Diffusivity Study of Pretreated Moringa oleifera Leaves Using Fluidized Bed Dryer. Processes 2022, 10, 2464. [Google Scholar] [CrossRef]

- Zhang, Q.-A.; Song, Y.; Wang, X.; Zhao, W.-Q.; Fan, X.-H. Mathematical modeling of debittered apricot (Prunus armeniaca L.) kernels during thin-layer drying. CyTA-J. Food 2016, 14, 509–517. [Google Scholar] [CrossRef]

- Mahmoud, W.A.E.-M.; Elwakeel, A. elshawadfy Study on some Properties of Tomato Fruits for Natural Sun Drying. J. Soil Sci. Agric. Eng. 2021, 12, 763–767. [Google Scholar]

- Eissa, A.S.; Gameh, M.A.; Mostafa, M.B.; Elwakeel, A.E. Some Engineering Factors Affecting Utilization of Solar Energy in Drying Tomato Fruits Introduction. Aswan Univ. J. Environ. Stud. 2024, 5, 52–68. [Google Scholar] [CrossRef]

- Senadeera, W.; Adiletta, G.; Önal, B.; Di Matteo, M.; Russo, P. Influence of different hot air drying temperatures on drying kinetics, shrinkage, and colour of persimmon slices. Foods 2020, 9, 101. [Google Scholar] [CrossRef]

- Kishk, S.; El-reheem, S.A.; Elgamal, A. Experimental and mathematical modeling study for solar drying of mint. Misr J. Agric. Eng. 2018, 35, 1327–1344. [Google Scholar] [CrossRef]

- Mahmoud, M.M.; Atia, B.S.; Ratib, M.K.; Aly, M.M.; Elwakeel, A.E.; Abdel-Rahim, A.-M.M. Investigations on OTC-MPPT strategy and FRT capability for PMSG wind system with the support of optimized wind side controller based on GWO technique. Energy 2021, 4, 79–91. [Google Scholar]

- Abd-Allah, Y.S.; Ahmed, T.H.; Metwally, K.A. Evaluation of The Drying Process of Paddy Rice with a Biogas Continuous Rotary Dryer. Misr J. Agric. Eng. 2023, 40, 59–74. [Google Scholar] [CrossRef]

- Sallam, Y.I.; Aly, M.H.; Nassar, A.F.; Mohamed, E.A. Solar drying of whole mint plant under natural and forced convection. J. Adv. Res. 2015, 6, 171–178. [Google Scholar] [CrossRef]

- Sreekumar, A.; Manikantan, P.E.; Vijayakumar, K.P. Performance of indirect solar cabinet dryer. Energy Convers. Manag. 2008, 49, 1388–1395. [Google Scholar] [CrossRef]

- Rabha, D.K.; Muthukumar, P.; Somayaji, C. Experimental investigation of thin layer drying kinetics of ghost chilli pepper (Capsicum Chinense Jacq.) dried in a forced convection solar tunnel dryer. Renew. Energy 2017, 105, 583–589. [Google Scholar] [CrossRef]

- Kassem, R.; Mahmoud, M.M.; Ibrahim, N.F.; Alkuhayli, A.; Khaled, U.; Beroual, A.; Saleeb, H. A Techno-Economic-Environmental Feasibility Study of Residential Solar Photovoltaic / Biomass Power Generation for Rural Electrification: A Real Case Study. Sustainability 2024, 16, 2036. [Google Scholar] [CrossRef]

- Elwakeel, A.E.; Tantawy, A.A.; Alsebiey, M.M.; Elliby, A.K. The date fruit drying systems: Acritical over review. Al-Azhar J. Agric. Eng. 2022, 2, 26–36. [Google Scholar] [CrossRef]

- Elwakeel, A.E.; Gameh, M.A.; Eissa, A.S.; Mostafa, M.B. Recent Advances in Solar Drying Technology for Tomato Fruits: A Comprehensive Review. Int. J. Appl. Energy Syst. 2024, 6, 37–44. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Historical review and recent trends in solar drying systems. Int. J. Green Energy 2013, 10, 690–738. [Google Scholar] [CrossRef]

- Sharma, A.; Chen, C.R.; Lan, N.V. Solar-energy drying systems: A review. Renew. Sustain. Energy Rev. 2009, 13, 1185–1210. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Aboul-Enein, S.; Ramadan, M.R.I.; El-Gohary, H.G. Experimental investigation of an indirect type natural convection solar dryer. Energy Convers. Manag. 2002, 43, 2251–2266. [Google Scholar] [CrossRef]

- Santos, B.M.; Queiroz, M.R.; Borges, T.P.F. A solar collector design procedure for crop drying. Braz. J. Chem. Eng. 2005, 22, 277–284. [Google Scholar] [CrossRef]

- Metwally Mahmoud, M. Improved current control loops in wind side converter with the support of wild horse optimizer for enhancing the dynamic performance of PMSG-based wind generation system. Int. J. Model. Simul. 2022, 43, 952–966. [Google Scholar] [CrossRef]

- Sekyere, C.K.K.; Forson, F.K.; Adam, F.W. Experimental investigation of the drying characteristics of a mixed mode natural convection solar crop dryer with back up heater. Renew. Energy 2016, 92, 532–542. [Google Scholar] [CrossRef]

- El-Beltagy, A.; Gamea, G.R.; Essa, A.H.A. Solar drying characteristics of strawberry. J. Food Eng. 2007, 78, 456–464. [Google Scholar] [CrossRef]

- Keey, R.B. Drying: Principles and Practice; Elsevier: Amsterdam, The Netherlands, 2013; Volume 13, ISBN 1483146332. [Google Scholar]

- Klemes, J.; Smith, R.; Kim, J.-K. Handbook of Water and Energy Management in Food Processing; Elsevier: Amsterdam, The Netherlands, 2008; ISBN 1845694678. [Google Scholar]

- Onwude, D.I.; Hashim, N.; Janius, R.B.; Nawi, N.M.; Abdan, K. Modeling the thin-layer drying of fruits and vegetables: A review. Compr. Rev. food Sci. food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef] [PubMed]

- Kadam, D.M.; Goyal, R.K.; Singh, K.K.; Gupta, M.K. Thin layer convective drying of mint leaves. J. Med. Plants Res. 2011, 5, 164–170. [Google Scholar]

- Ronoh, E.K.; Kanali, C.L.; Mailutha, J.T.; Shitanda, D. Thin layer drying kinetics of amaranth (Amaranthus cruentus) grains in a natural convection solar tent dryer. Afr. J. Food Agric. Nutr. Dev. 2010, 10. [Google Scholar] [CrossRef]

- Omid, M.; Yadollahinia, A.R.; Rafiee, S. A thin-layer drying model for paddy dryer. In Proceedings of the International Conference on Innovations in Food and Bioprocess Technologies, AIT, Pathumthani, Thailand, 12–14 December 2006. [Google Scholar]

- Ertekin, C.; Firat, M.Z. A comprehensive review of thin-layer drying models used in agricultural products. Crit. Rev. Food Sci. Nutr. 2017, 57, 701–717. [Google Scholar] [CrossRef] [PubMed]

- Marinos-Kouris, D.; Maroulis, Z.B. Transport properties in the drying of solids. Handb. Ind. Dry. 2020, 2, 113–159. [Google Scholar]

- Carteri Coradi, P.; de Castro Melo, E.; Pereira da Rocha, R. Modelación matemática de la cinética de secado de las hojas de hierba de limón (Cymbopogon citratus Stapf) y sus efectos sobre la calidad. Idesia 2014, 32, 43–56. [Google Scholar] [CrossRef]

- Sukmawaty, S.; Putra, G.M.D.; Setiawati, D.A.; Kurniawan, H.; Reinhart, I.E.P. The application of mathematical model drying of galangal (Alpiniagalanga L.) using hybrid dryer equipment with rotary type of rack. AIP Conf. Proc. 2019, 2199, 030001. [Google Scholar]

- Younis, M.; Abdelkarim, D.; El-abdein, A.Z. Saudi Journal of Biological Sciences Kinetics and mathematical modeling of infrared thin-layer drying of garlic slices. Saudi J. Biol. Sci. 2018, 25, 332–338. [Google Scholar] [CrossRef]

- Yogendrasasidhar, D.; Setty, Y.P. Engineering Science and Technology, an International Journal Experimental studies and thin layer modeling of pearl millet using continuous multistage fluidized bed dryer staged externally. Eng. Sci. Technol. Int. J. 2019, 22, 428–438. [Google Scholar] [CrossRef]

- Quality, E. Mathematical Modeling of Thin-Layer Drying Kinetics of Tomato Peels: Influence of Drying Temperature on the Energy Requirements and Extracts Quality. Foods 2023, 12, 3883. [Google Scholar] [CrossRef]

- Badaoui, O.; Hanini, S.; Djebli, A.; Haddad, B.; Benhamou, A. Experimental and modelling study of tomato pomace waste drying in a new solar greenhouse: Evaluation of new drying models. Renew. Energy 2019, 133, 144–155. [Google Scholar] [CrossRef]

- Gürlek, G.; Özbalta, N.; Güngör, A. Solar tunnel drying characteristics and mathematical modelling of tomato. J. Therm. Sci. Technol. 2009, 29, 15–23. [Google Scholar]

- Sacilik, K.; Keskin, R.; Elicin, A.K. Mathematical modelling of solar tunnel drying of thin layer organic tomato. J. Food Eng. 2006, 73, 231–238. [Google Scholar] [CrossRef]

- Hussein, J.B.; Filli, K.B.; Oke, M.O. Thin layer modelling of hybrid, solar and open sun drying of tomato slices. Res. J. Food Sci. Nutr. 2016, 1, 15–27. [Google Scholar] [CrossRef]

- Azeez, L.; Adebisi, S.A.; Oyedeji, A.O.; Adetoro, R.O.; Tijani, K.O. Bioactive compounds’ contents, drying kinetics and mathematical modelling of tomato slices influenced by drying temperatures and time. J. Saudi Soc. Agric. Sci. 2019, 18, 120–126. [Google Scholar] [CrossRef]

- Benseddik, A.; Azzi, A.; Zidoune, M.N.; Allaf, K. Engineering in Agriculture, Environment and Food Mathematical empirical models of thin-layer air fl ow drying kinetics of pumpkin slice. Eng. Agric. Environ. Food 2018, 11, 220–231. [Google Scholar] [CrossRef]

- Azadbakht, M.; Aghili, H.; Ziaratban, A.; Torshizi, M.V. Application of arti fi cial neural network method to exergy and energy analyses of fl uidized bed dryer for potato cubes. Energy 2017, 120, 947–958. [Google Scholar] [CrossRef]

- Petru, C.; Marius, B.; Rat, R.; Arsenoaia, V.N.; Ros, G.R. Drying Process Modeling and Quality Assessments Regarding an Innovative Seed Dryer. Agriculture 2023, 13, 328. [Google Scholar] [CrossRef]

- Mehran, S.; Nikian, M.; Ghazi, M.; Zareiforoush, H.; Bagheri, I. Experimental investigation and energy analysis of a solar-assisted fluidized- bed dryer including solar water heater and solar-powered infrared lamp for paddy grains drying. Sol. Energy 2019, 190, 167–184. [Google Scholar] [CrossRef]

- Akpinar, E.K. Drying of mint leaves in a solar dryer and under open sun: Modelling, performance analyses. Energy Convers. Manag. 2010, 51, 2407–2418. [Google Scholar] [CrossRef]

- Kaveh, M.; Amiri, R.; Golpour, I. Food and Bioproducts Processing Evaluation of exergy performance and onion drying properties in a multi-stage semi-industrial continuous dryer: Artificial neural networks (ANNs) and ANFIS models. Food Bioprod. Process. 2021, 127, 58–76. [Google Scholar] [CrossRef]

- Province, S.; Lumpur, K.; Province, S. Evaluation of Thin-layer Models for Kinetic Analysis in Unbleached Kraft Pulpboard Drying. Iran. J. Chem. Chem. Eng. 2022, 41, 1022–1033. [Google Scholar]

- Kaleta, A.; Górnicki, K. Evaluation of drying models of apple (var. McIntosh) dried in a convective dryer. Int. J. Food Sci. Technol. 2010, 45, 891–898. [Google Scholar] [CrossRef]

- Yogendrasasidhar, D.; Setty, Y.P. Drying kinetics, exergy and energy analyses of Kodo millet grains and Fenugreek seeds using wall heated fluidized bed dryer. Energy 2018, 151, 799–811. [Google Scholar] [CrossRef]

- Sandeepa, K.; Rao, S.R.M. Studies on Drying of Sorghum Seeds in a Fluidized Bed Dryer. In Proceedings of the 14th International Conference on Fluidization—From Fundamentals to Products, Noordwijkerhout, The Netherlands, 26–31 May 2013. [Google Scholar]

- Celma, A.R.; Rojas, S.; Lopez-Rodriguez, F. Mathematical modelling of thin-layer infrared drying of wet olive husk. Chem. Eng. Process. Process Intensif. 2008, 47, 1810–1818. [Google Scholar] [CrossRef]

- Panchariya, P.C.; Popovic, D.; Sharma, A.L. Thin-layer modelling of black tea drying process. J. Food Eng. 2002, 52, 349–357. [Google Scholar] [CrossRef]

- Ertekin, Ö.; İpek, Y. Modeling of drying processes of dates (Phoenix, arecaceae) with oven or TGA and microbiological properties of fresh and dried dates. Int. J. Fruit Sci. 2020, 20, S1530–S1538. [Google Scholar] [CrossRef]

- Seerangurayar, T.; Al-Ismaili, A.M.; Janitha Jeewantha, L.H.; Al-Nabhani, A. Experimental investigation of shrinkage and microstructural properties of date fruits at three solar drying methods. Sol. Energy 2019, 180, 445–455. [Google Scholar] [CrossRef]

- Boubekri, A.; Benmoussa, H.; Mennouche, D. Solar drying kinetics of date palm fruits assuming a step-wise air temperature change. J. Eng. Sci. Technol. 2009, 4, 292–304. [Google Scholar]

- Abodunrin, O.D. Mathematical Modelling of Thin Layer Drying Kinetics of Pre-Treated Date Fruits (Phonenix dactylifera L.). Ph.D. Thesis, Federal University of Technology, Akure, Nigeria, 2023. [Google Scholar]

- Midilli, A.; Kucuk, H. Mathematical modeling of thin layer drying of pistachio by using solar energy. Energy Convers. Manag. 2003, 44, 1111–1122. [Google Scholar] [CrossRef]

- Akpinar, E.K.; Bicer, Y. Mathematical modeling and experimental study on thin layer drying of strawberry. Int. J. Food Eng. 2006, 2. [Google Scholar] [CrossRef]

- Akpinar, E.K.; Bicer, Y.; Cetinkaya, F. Modelling of thin layer drying of parsley leaves in a convective dryer and under open sun. J. Food Eng. 2006, 75, 308–315. [Google Scholar] [CrossRef]

- Elhage, H.; Herez, A.; Ramadan, M.; Bazzi, H.; Khaled, M. An investigation on solar drying: A review with economic and environmental assessment. Energy 2018, 157, 815–829. [Google Scholar] [CrossRef]

- Sodha, M.S.; Chandra, R.; Pathak, K.; Singh, N.P.; Bansal, N.K. Techno-economic analysis of typical dryers. Energy Convers. Manag. 1991, 31, 509–513. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A.; Nuntadusit, C. Thermo-environomical and drying kinetics of bitter gourd flakes drying under north wall insulated greenhouse dryer. Sol. Energy 2018, 162, 205–216. [Google Scholar] [CrossRef]

- Anil Kumar, A.K.; Renu Singh, R.S.; Om Prakash, O.P.; Ashutosh, A. Review on global solar drying status. Agric. Eng. Int. CIGR J. 2015, 16, 161–177. [Google Scholar]

- Fudholi, A.; Sopian, K.; Gabbasa, M.; Bakhtyar, B.; Yahya, M.; Ruslan, M.H.; Mat, S. Techno-economic of solar drying systems with water based solar collectors in Malaysia: A review. Renew. Sustain. Energy Rev. 2015, 51, 809–820. [Google Scholar] [CrossRef]

- Tesfaye, A.; Habtu, N.G. Fabrication and performance evaluation of solar tunnel dryer for ginger drying. Int. J. Photoenergy 2022, 2022, 6435080. [Google Scholar] [CrossRef]

- AOAC Int. Official Methods of Analysis of AOAC Int.; AOAC Int.: Gaithersburg, MD, USA, 2007. [Google Scholar]

- Etim, P.J.; Eke, A.B.; Simonyan, K.J. Effect of air inlet duct features and grater thickness on cooking banana drying characteristics using active indirect mode solar dryer. Niger. J. Technol. 2019, 38, 1056–1063. [Google Scholar] [CrossRef]

- Dak, M.; Pareek, N.K. Effective moisture diffusivity of pomegranate arils under going microwave-vacuum drying. J. Food Eng. 2014, 122, 117–121. [Google Scholar] [CrossRef]

- Doymaz, İ. Influence of pretreatment solution on the drying of sour cherry. J. Food Eng. 2007, 78, 591–596. [Google Scholar] [CrossRef]

- Karathanos, V.T. Determination of water content of dried fruits by drying kinetics. J. Food Eng. 1999, 39, 337–344. [Google Scholar] [CrossRef]

- Temple, S.J.; Van Boxtel, A.J.B. Thin layer drying of black tea. J. Agric. Eng. Res. 1999, 74, 167–176. [Google Scholar] [CrossRef]

- Karathanos, V.T.; Belessiotis, V.G. Application of a thin-layer equation to drying data of fresh and semi-dried fruits. J. Agric. Eng. Res. 1999, 74, 355–361. [Google Scholar] [CrossRef]

- Palipane, K.B.; Driscoll, R.H. The thin-layer drying characteristics of macadamia in-shell nuts and kernels. J. Food Eng. 1994, 23, 129–144. [Google Scholar] [CrossRef]

- Pahlavanzadeh, H.; Basiri, A.; Zarrabi, M. Determination of parameters and pretreatment solution for grape drying. Dry. Technol. 2001, 19, 217–226. [Google Scholar] [CrossRef]

- Doymaz, I.; Pala, M. The thin-layer drying characteristics of corn. J. Food Eng. 2003, 60, 125–130. [Google Scholar] [CrossRef]

- Buzrul, S. Reassessment of Thin-Layer Drying Models for Foods: A critical short communication. Processes 2022, 10, 118. [Google Scholar] [CrossRef]

- Elwakeel, A.E.; Mazrou, Y.S.A.; Tantawy, A.A.; Okasha, A.M.; Elmetwalli, A.H.; Elsayed, S.; Makhlouf, A.H. Designing, Optimizing, and Validating a Low-Cost, Multi-Purpose, Automatic System-Based RGB Color Sensor for Sorting Fruits. Agriculture 2023, 13, 1824. [Google Scholar] [CrossRef]

- Elwakeel, A.E.; Mazrou, Y.S.; Eissa, A.S.; Okasha, A.M.; Elmetwalli, A.H.; Makhlouf, A.H.; Metwally, K.A.; Mahmoud, W.A.; Elsayed, S. Design and Validation of a Variable-Rate Control Metering Mechanism and Smart Monitoring System for a High-Precision Sugarcane Transplanter. Agriculture 2023, 13, 2218. [Google Scholar] [CrossRef]

- Elsayed, S.; El-Hendawy, S.; Elsherbiny, O.; Okasha, A.M.; Elmetwalli, A.H.; Elwakeel, A.E.; Memon, M.S.; Ibrahim, M.E.M.; Ibrahim, H.H. Estimating Chlorophyll Content, Production, and Quality of Sugar Beet under Various Nitrogen Levels Using Machine Learning Models and Novel Spectral Indices. Agronomy 2023, 13, 2743. [Google Scholar] [CrossRef]

- Elwakeel, A.E.; Mohamed, S.M.A.; Tantawy, A.A.; Okasha, A.M.; Elsayed, S.; Elsherbiny, O.; Farooque, A.A. Design, construction and field testing of a manually feeding semiautomatic sugarcane dud chipper. Sci. Rep. 2024, 14, 5373. [Google Scholar] [CrossRef]

- Yang, L.; Nasrat, L.S.; Badawy, M.E.; Mbadjoun Wapet, D.E.; Ourapi, M.A.; El-Messery, T.M.; Aleksandrova, I.; Mahmoud, M.M.; Hussein, M.M.; Elwakeel, A.E. A new automatic sugarcane seed cutting machine based on internet of things technology and RGB color sensor. PLoS ONE 2024, 19, e0301294. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, J.; Liao, X.; Chen, F.; Zhao, G.; Wu, J.; Hu, X. Mathematical modeling on hot air drying of thin layer apple pomace. Food Res. Int. 2007, 40, 39–46. [Google Scholar] [CrossRef]

- Lewis, W.K. The rate of drying of solid materials. Ind. Eng. Chem. 1921, 13, 427–432. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Kianmehr, M.H.; Khani, S.; Ghasemi, M. Mathematical modelling of thin-layer drying of carrot. Int. Agrophys. 2009, 23, 313–317. [Google Scholar]

- Page, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers; Purdue University: West Lafayette, IN, USA, 1949; ISBN 1083231995. [Google Scholar]

- Henderson, S.M.; Pabis, S. Grain drying theory. 1. Temperature effect on drying coefficient. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Henderson, S.M. Progress in developing the thin layer drying equation. Trans. ASAE 1974, 17, 1167–1168. [Google Scholar] [CrossRef]

- Sharaf-Eldeen, Y.I.; Blaisdell, J.L.; Hamdy, M.Y. A model for ear-corn drying. Trans. ASAE 1981, 23, 1261–1265. [Google Scholar] [CrossRef]

- Yaldýz, O.; Ertekýn, C. Thin layer solar drying of some vegetables. Dry. Technol. 2001, 19, 583–597. [Google Scholar] [CrossRef]

- Kassem, A.S. Comparative studies on thin layer drying models for wheat. In Proceedings of the 13th International Congress on Agricultural Engineering, Rabat, Morocco, 2–6 February 1998; Volume 6. [Google Scholar]

- Chandra, P.K.; Singh, R.P. Applied Numerical Methods for Food and Agricultural Engineers; CRC Press: Boca Raton, FL, USA, 2017; ISBN 1351465953. [Google Scholar]

- Hii, C.L.; Law, C.L.; Cloke, M. Modelling of thin layer drying kinetics of cocoa beans during artificial and natural drying. J. Eng. Sci. Technol. 2008, 3, 1–10. [Google Scholar]

- Crank, J. The Mathematics of Diffusion; Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Shah, S.; Joshi, M. Modeling microwave drying kinetics of sugarcane bagasse. Int. J. Electron. Eng. 2010, 2, 159–163. [Google Scholar]

- ELkhadraoui, A.; Kooli, S.; Hamdi, I.; Farhat, A. Experimental investigation and economic evaluation of a new mixed-mode solar greenhouse dryer for drying of red pepper and grape. Renew. Energy 2015, 77, 1–8. [Google Scholar] [CrossRef]

- Mohammed, I.A.; Al Dulaimi, M.A.K. An Economic Analysis of The Costs of Producing Tomato Under Greenhouse in Anbar Governorate For the Agricultural Season 2019–2020. IOP Conf. Ser. Earth Environ. Sci. 2021, 904, 012061. [Google Scholar] [CrossRef]

- Singh, P.; Gaur, M.K. Environmental and economic analysis of novel hybrid active greenhouse solar dryer with evacuated tube solar collector. Sustain. Energy Technol. Assessments 2021, 47, 101428. [Google Scholar] [CrossRef]

- Metwally, K.A.; Zaki, R.I.; Fouda, S.S.; Alruhaimi, R.S.; Alqhtani, H.A.; Aldawood, N.; Mahmoud, A.M.; Naiel, M.A.E. Effects of feeding rate and formula fineness degree of ring die pellet mill on mechanical property, physical quality, energy requirements, and production cost of poultry diets. Int. J. Agric. Biol. Eng. 2023, 16, 30–36. [Google Scholar] [CrossRef]

- Radwan, M.E.; Zaki, R.I.; El-Said, A.F.; Metwally, K.A. Impact of Die Surface Holes Distribution Patterns of Fish Feed Extruder on Performance Indicators and Pellets Quality. J. Soil Sci. Agric. Eng. 2021, 12, 337–343. [Google Scholar] [CrossRef]

- Atheaya, D. Economics of Solar Drying. In Solar Drying Technology; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K.; Yazdi, M.H.; Ruslan, M.H.; Gabbasa, M.; Kazem, H.A. Performance analysis of solar drying system for red chili. Sol. Energy 2014, 99, 47–54. [Google Scholar] [CrossRef]

- Bala, B.K.; Janjai, S. Solar Drying of Fish (Bombay Duck) Using Solar Tunnel Dryer. Int. Energy J. 2005, 6, 91–102. [Google Scholar]

- Usub, T.; Lertsatitthanakorn, C.; Poomsa-ad, N.; Wiset, L.; Yang, L.; Siriamornpun, S. Experimental performance of a solar tunnel dryer for drying silkworm pupae. Biosyst. Eng. 2008, 101, 209–216. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Environomical analysis and mathematical modelling for tomato flakes drying in a modified greenhouse dryer under active mode. Int. J. Food Eng. 2014, 10, 669–681. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Solar greenhouse drying: A review. Renew. Sustain. Energy Rev. 2014, 29, 905–910. [Google Scholar] [CrossRef]

- Baird, G.; Alcorn, A.; Haslam, P. The energy embodied in building materials-updated New Zealand coefficients and their significance. Trans. Inst. Prof. Eng. N. Zeal. Civ. Eng. Sect. 1997, 24, 46–54. [Google Scholar]

- Nayak, S.; Naaz, Z.; Yadav, P.; Chaudhary, R. Economic analysis of hybrid photovoltaic-thermal (PVT) integrated solar dryer. Int. J. Eng. Invent. 2012, 1, 21–27. [Google Scholar]

- Eltawil, M.A.; Azam, M.M.; Alghannam, A.O. Energy analysis of hybrid solar tunnel dryer with PV system and solar collector for drying mint (MenthaViridis). J. Clean. Prod. 2018, 181, 352–364. [Google Scholar] [CrossRef]

- Elghazali, M.N.; Tawfeuk, H.Z.; Gomaa, R.A.; Abbas, A.A.; Aml, A. Effect of Dehydration Methods on Physicochemical Properties of Aswan Dry Dates. Assiut J. Agric. Sci. 2020, 51, 50–64. [Google Scholar] [CrossRef]

- Elghazali, M.N.; Tawfeuk, H.Z.; Gomaa, R.A.; Tantawy, A.A. Technological Studies on Aswan Dry Dates Products After Dehydration. Assiut J. Agric. Sci. 2020, 51, 32–49. [Google Scholar] [CrossRef]

- Sengkhamparn, N.; Chanshotikul, N.; Assawajitpukdee, C.; Khamjae, T. Effects of blanching and drying on fiber rich powder from pitaya (Hylocereus undatus) peel. Int. Food Res. J. 2013, 20, 1595. [Google Scholar]

- Deng, L.Z.; Pan, Z.; Mujumdar, A.S.; Zhao, J.H.; Zheng, Z.A.; Gao, Z.J.; Xiao, H.W. High-humidity hot air impingement blanching (HHAIB) enhances drying quality of apricots by inactivating the enzymes, reducing drying time and altering cellular structure. Food Control 2019, 96, 104–111. [Google Scholar] [CrossRef]

- Kamal, M.M.; Ali, M.R.; Shishir, M.R.I.; Mondal, S.C. Thin-layer drying kinetics of yam slices, physicochemical, and functional attributes of yam flour. J. Food Process Eng. 2020, 43, e13448. [Google Scholar] [CrossRef]

- Doymaz, İ. Evaluation of some thin-layer drying models of persimmon slices (Diospyros kaki L.). Energy Convers. Manag. 2012, 56, 199–205. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K.; Winiczenko, R.; Chojnacka, A. Evaluation of drying models of apple (var. Ligol) dried in a fluidized bed dryer. Energy Convers. Manag. 2013, 67, 179–185. [Google Scholar] [CrossRef]

- Meziane, S. Drying kinetics of olive pomace in a fluidized bed dryer. Energy Convers. Manag. 2011, 52, 1644–1649. [Google Scholar] [CrossRef]

- He, C.; Wang, H.; Yang, Y.; Huang, Y.; Zhang, X.; Arowo, M.; Ye, J.; Zhang, N.; Xiao, M. Drying behavior and kinetics of drying process of plant-based enteric hard capsules. Pharmaceutics 2021, 13, 335. [Google Scholar] [CrossRef] [PubMed]

- Dissa, A.O.; Desmorieux, H.; Bathiebo, J.; Koulidiati, J. A comparative study of direct and indirect solar drying of mango. Glob. J. Pure Appl. Sci. 2011, 17, 273–294. [Google Scholar]

- Navale, S.R.; Harpale, V.M.; Mohite, K.C. Comparative study of open sun and cabinet solar drying for fenugreek leaves. Int. J. Renew. Energy Technol. Res. 2015, 4, 1–9. [Google Scholar]

- Manjunatha, S.S.; Ravi, N.; Negi, P.S.; Raju, P.S.; Bawa, A.S. Kinetics of moisture loss and oil uptake during deep fat frying of Gethi (Dioscorea kamoonensis Kunth) strips. J. Food Sci. Technol. IB 2014, 51, 3061–3071. [Google Scholar] [CrossRef]

- Babar, O.A.; Tarafdar, A.; Malakar, S.; Arora, V.K.; Nema, P.K. Design and performance evaluation of a passive flat plate collector solar dryer for agricultural products. J. Food Process Eng. 2020, 43, e13484. [Google Scholar] [CrossRef]

- Etim, P.J.; Eke, A.B.; Simonyan, K.J. Design and development of an active indirect solar dryer for cooking banana. Sci. Afr. 2020, 8, e00463. [Google Scholar] [CrossRef]

- Hossain, M.A.; Amer, B.M.A.; Gottschalk, K. Hybrid solar dryer for quality dried tomato. Dry. Technol. 2008, 26, 1591–1601. [Google Scholar] [CrossRef]

- Song, X.; Zhang, M.; Mujumdar, A.S. Effect of vacuum-microwave predrying on quality of vacuum-fried potato chips. Dry. Technol. 2007, 25, 2021–2026. [Google Scholar] [CrossRef]

- Farag, S.E.-S.; Hassan, S.R.; Younes, O.S.; Taha, S.A. Methods of drying of tomato slices and the effect of the using of its powder on the production and characteristics of extruded snacks. Misr J. Agric. Eng. 2016, 33, 1537–1558. [Google Scholar] [CrossRef]

- Téllez, M.C.; Figueroa, I.P.; Téllez, B.C.; Vidaña, E.C.L.; Ortiz, A.L. Solar drying of Stevia (Rebaudiana Bertoni) leaves using direct and indirect technologies. Sol. Energy 2018, 159, 898–907. [Google Scholar] [CrossRef]

- Ismail, O.; Akyol, E. Open-air sun drying: The effect of pretreatment on drying kinetic of cherry tomato. Sigma J. Eng. Nat. Sci. 2016, 34, 141–151. [Google Scholar]

- Manalu, L.P.; Tambunan, A.H.; Nelwan, L.O.; Hoetman, A.R. The thin layer drying of temu putih herb. In Proceedings of the 6th Asia-Pacific Drying Conference (ADC2009), Bangkok, Thailand, 19–21 October 2009; pp. 402–409. [Google Scholar]

- Touil, A.; Chemkhi, S.; Zagrouba, F. Moisture diffusivity and shrinkage of fruit and cladode of Opuntia ficus-indica during infrared drying. J. food Process. 2014, 2014, 175402. [Google Scholar] [CrossRef]

- Mayor, L.; Sereno, A.M. Modelling shrinkage during convective drying of food materials: A review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Doymaz, İ.; İsmail, O. Drying characteristics of sweet cherry. Food Bioprod. Process. 2011, 89, 31–38. [Google Scholar] [CrossRef]

- Lee, G.; Hsieh, F. Thin-layer drying kinetics of strawberry fruit leather. Trans. ASABE 2008, 51, 1699–1705. [Google Scholar] [CrossRef]

- Kaya, A.; Aydin, O.; Demirtas, C.; Akgün, M. An experimental study on the drying kinetics of quince. Desalination 2007, 212, 328–343. [Google Scholar] [CrossRef]

- Doymaz, İ. Effect of pre-treatments using potassium metabisulphide and alkaline ethyl oleate on the drying kinetics of apricots. Biosyst. Eng. 2004, 89, 281–287. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Samimi-Akhijahani, H. Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers. Manag. 2008, 49, 2865–2871. [Google Scholar] [CrossRef]

- Ruiz-Cabrera, M.A.; Flores-Gómez, G.; González-García, R.; Grajales-Lagunes, A.; Moscosa-Santillan, M.; Abud-Archila, M. Water diffusivity and quality attributes of fresh and partially osmodehydrated cactus pear (Opuntia ficus indica) subjected to air-dehydration. Int. J. Food Prop. 2008, 11, 887–900. [Google Scholar] [CrossRef]

- Tireki, S. Effective diffusivity determination of date (Phoenix dactylifera L.) leather in infrared drying: Effect of cooking time. Niğde Ömer Halisdemir Üniversitesi Mühendislik Bilim. Derg. 2023, 12, 1558–1565. [Google Scholar] [CrossRef]

- Inyang, U.E.; Oboh, I.O.; Etuk, B.R. Kinetic models for drying techniques—Food materials. Adv. Chem. Eng. Sci. 2018, 8, 27–48. [Google Scholar] [CrossRef]

- Shrivastava, V.; Kumar, A. Embodied energy analysis of the indirect solar drying unit. Int. J. Ambient Energy 2017, 38, 280–285. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A.; Laguri, V. Performance of modified greenhouse dryer with thermal energy storage. Energy Rep. 2016, 2, 155–162. [Google Scholar] [CrossRef]

| No. | Materials | Embodied Energy | Weight | Embodied Energy (kW·h) | References |

|---|---|---|---|---|---|

| Solar collector | |||||

| 1 | Metal frame | 55.28 (kW·h/kg) | 20.0 (kg) | 1105.6 | [104,105] |

| 2 | Glass cover | 7.28 (kW·h/kg) | 10 (kg) | 72.8 | [106] |

| 3 | Wood dust | 2.0 (kW·h/kg) | 2.0 (kg) | 4.0 | |

| 4 | Paint | 25.11(kW·h/kg) | 1.0 (kg) | 25.11 | |

| 5 | Absorber plate | 9.636 (kW·h/kg) | 10.5 (kg) | 101.18 | |

| Drying room | |||||

| 1 | Metal frame | 55.28 (kW·h/kg) | 25 (kg) | 1382 | [104,105] |

| 2 | Wood dust | 2.0 (kW·h/kg) | 2.0 (kg) | 4.0 | [106] |

| 3 | Paint | 25.11 (kW·h/kg) | 1.0 (kg) | 25.11 | |

| 4 | Hinges | 55.28 (kW·h/kg) | 0.05 (kg) | 2.764 | [104,105] |

| Handel | 55.28 (kW·h/kg) | 0.05 (kg) | 2.764 | ||

| 5 | Suction fan 1. Plastic parts2. Motor and cooper wires | 19.44 (kW·h/kg)19.61(kW·h/kg) | 0.20 (kg)0.20 (kg) | 3.8883.922 | |

| 6 | Drying trays 1. Wire mesh 2. Metal frame | 9.67 (kW·h/kg)55.28 (kW·h/kg) | 3 (kg)5 (kg) | 29.01276.4 | |

| Total embodied energy for ASD (solar collector + drying room) (kWh) | 1932.95 | ||||

| PV system | |||||

| 1 | Metal frame | 55.28 (kW·h/kg) | 4.5 (kg) | 248.76 | [104,105] |

| 2 | PV system | 1130.6 kW·h/m2 | 0.65 m2 | 734.89 | |

| 3 | Battery | 148.4515 | -- | 46.00 | |

| 4 | Battery charger | -- | -- | 33.00 | |

| Total embodied energy for PV system (kWh) | 1062.65 | ||||

| Date Fruit Variety | OAD | ASD | ||

|---|---|---|---|---|

| k | R2 | k | R2 | |

| Sakkoti | 0.079 | 0.9963 | 0.133 | 0.9775 |

| Malkabii | 0.078 | 0.9902 | 0.155 | 0.9858 |

| Gondaila | 0.069 | 0.986 | 0.136 | 0.9769 |

| Reference | Dried Product | EMD, m2/s |

|---|---|---|

| Ambawat et al. [2] | Moringa oleifera leaves | 3.59 × 10−10–2.92 × 10−10 |

| Quality [35] | Tomato | 1.01 × 10−9–1.53 × 10−9 |

| Sandeepa and Rao [50] | Sorghum Seeds | 3.01 × 10−10–5.50 × 10−10 |

| Akpinar and Bicer [58] | Strawberry | 4.52 × 10−10–9.63 × 10−10 |

| Pahlavanzadeh et al. [74] | Grapes | 2.4 × 10−10–6.22 × 10−10 |

| Lee and Hsieh [132] | Strawberry | 2.4 × 10−9–12.1 × 10−9 |

| Kaya et al. [133] | Quince | 0.65 × 10−10–6.92 × 10−10 |

| Doymaz [134] | Apricot | 6.76 × 10−10–12.6 × 10−10 |

| Aghbashlo and Samimi-Akhijahani [135] | Berberis | 3.32 × 10−10–90 × 10−10 |

| Ruiz-Cabrera et al. [136] | Cactus pears | 1.51 × 10−10–5.32 × 10−10 |

| TİREKİ [137] | Date fruit | 1.53 × 10−9–1.74 × 10−9 |

| Current study | Date fruit | 7.14 × 10−12–2.17 × 10−11 |

| Drying Type | OAD | ASD | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model No. | Model Name | Date Fruit Varity | Model Constant * | R2 | RSME | Model Constant | R2 | RSME | |||

| 1. | Newton (Lewis) | Sakkoti | k = 0.08641 | 0.99285 | 0.00036 | 0.01826 | k = 0.14759 | 0.99020 | 0.00067 | 0.02458 | |

| Malkabii | k = 0.08497 | 0.98663 | 0.00065 | 0.02457 | k = 0.16634 | 0.99496 | 0.00039 | 0.01862 | |||

| Gondaila | k = 0.07877 | 0.99632 | 0.00142 | 0.03635 | k = 0.14420 | 0.99209 | 0.00056 | 0.02228 | |||

| 2. | Page | Sakkoti | k = 0.11193 n = 0.88133 | 0.99970 | 0.00002 | 0.00379 | k = 0.17392 n = 0.90575 | 0.99403 | 0.00047 | 0.01942 | |

| Malkabii | k = 0.11294 n = 0.86684 | 0.99473 | 0.00027 | 0.01534 | k = 0.18233 n = 0.94401 | 0.99608 | 0.00035 | 0.01640 | |||

| Gondaila | k = 0.13018 n = 0.76603 | 0.99438 | 0.00024 | 0.01441 | k = 0.15348 n = 0.96291 | 0.99257 | 0.00060 | 0.02158 | |||

| 3. | Modified Page III | Sakkoti | k = 0.97113 d = 2.33661 n = 0.45109 | 0.99617 | 0.00023 | 0.01356 | k = 0.98502 d = 2.01894 n = 0.58914 | 0.99112 | 0.00080 | 0.02370 | |

| Malkabii | k = 0.96601 d = 2.24414 n = 0.40458 | 0.99137 | 0.00045 | 0.01962 | k = 0.99207 d = 1.80709 n = 0.53739 | 0.99513 | 0.00050 | 0.01829 | |||

| Gondaila | k = 0.93937 d = 2.37609 n = 0.39832 | 0.99831 | 0.00077 | 0.02461 | k = 0.99821 d = 1.90394 n = 0.52134 | 0.99210 | 0.00074 | 0.02227 | |||

| 4. | Henderson and Pabis | Sakkoti | k = 0.08262 a = 0.97113 | 0.99617 | 0.00021 | 0.01356 | k = 0.14454 a = 0.98502 | 0.99112 | 0.00070 | 0.02370 | |

| Malkabii | k = 0.08034 a = 0.96601 | 0.99137 | 0.00045 | 0.01962 | k = 0.16456 a = 0.99207 | 0.99513 | 0.00043 | 0.01829 | |||

| Gondaila | k = 0.07055 a = 0.93938 | 0.98355 | 0.00071 | 0.02461 | k = 0.14382 a = 0.99821 | 0.99210 | 0.00064 | 0.02227 | |||

| 5. | Logarithmic | Sakkoti | k = 0.11357 a = 0.84061 c = 0.15245 | 0.99961 | 0.00002 | 0.00431 | k = 0.20565 a = 0.85583 c = 0.15644 | 0.99762 | 0.00022 | 0.01228 | |

| Malkabii | k = 0.10644 a = 0.84005 c = 0.14246 | 0.99352 | 0.00037 | 0.01701 | k = 0.20680 a = 0.90099 c = 0.10759 | 0.99767 | 0.00024 | 0.01265 | |||

| Gondaila | k = 0.12380 a = 0.71555 c = 0.25526 | 0.99230 | 0.00036 | 0.01686 | k = 0.18640 a = 0.88519 c = 0.12941 | 0.99479 | 0.00049 | 0.01810 | |||

| 6. | Two-term | Sakkoti | ko = 0.05115 k1 = 0.16597 a = 0.57410 b = 0.42183 | 0.99979 | 0.00001 | 0.00319 | ko = 0.0000 k1 = 0.20565 a = 0.15644 b = 0.85583 | 0.99762 | 0.00025 | 0.01228 | |

| Malkabii | ko = 0.08034 k1 = 0.08034 a = 0.48300 b = 0.48300 | 0.99137 | 0.00054 | 0.01962 | ko = 0.16456 k1 = 0.16456 a = 0.49603 b = 0.49603 | 0.99513 | 0.00060 | 0.01829 | |||

| Gondaila | ko = 0.07055 k1 = 0.07055 a = 0.46969 b = 0.46969 | 0.98355 | 0.00085 | 0.02461 | ko = 0.14382 k1 = 0.14382 a = 0.49911 b = 0.49911 | 0.99210 | 0.00089 | 0.02227 | |||

| 7. | Two-term Exponential | Sakkoti | k = 0.09870 a = 0.97971 | 0.99898 | 0.00006 | 0.00703 | k = 0.17033 a = 0.98201 | 0.99856 | 0.00011 | 0.00956 | |

| Malkabii | k = 0.08497 a = 1.00000 | 0.99859 | 0.00070 | 0.02457 | k = 0.18296 a = 0.98758 | 0.99967 | 0.00016 | 0.01118 | |||

| Gondaila | k = 0.10231 a = 0.95862 | 0.98730 | 0.00066 | 0.02178 | k = 0.16081 a = 0.98329 | 0.99523 | 0.00038 | 0.01727 | |||

| 8. | Approximation diffusion or Diffusion Approach | Sakkoti | k = 0.08641 a = 1.00000 b = 1.00000 | 0.99312 | 0.00042 | 0.01826 | k = 0.14759 a = 1.00000 b = 1.00000 | 0.99049 | 0.00086 | 0.02458 | |

| Malkabii | k = 0.08497 a = 1.00000 b = 1.00000 | 0.98663 | 0.00077 | 0.02457 | k = 0.16634 a = 1.00000 b = 1.00000 | 0.99496 | 0.00052 | 0.01862 | |||

| Gondaila | k = 0.07877 a = 1.00000 b = 1.00000 | 0.96514 | 0.00168 | 0.03635 | k = 0.14420 a = 1.00000 b = 1.00000 | 0.99209 | 0.00074 | 0.02228 | |||

| 9. | Modified Henderson and Pabis | Sakkoti | k = 0.02618 a = 0.29215 b = 0.34879 c = 0.35322 g = 0.14614 h = 0.10983 | 0.99971 | 0.00002 | 0.00373 | k = 0.14454 a = 0.32834 b = 0.32834 c = 0.32834 g = 0.14454 h = 0.14454 | 0.99112 | 0.00080 | 0.02370 | |

| Malkabii | k = 0.08034 a = 0.32200 b = 0.32200 c = 0.32200 g = 0.08034 h = 0.08034 | 0.99137 | 0.00067 | 0.01962 | k = 0.16456 a = 0.33069 b = 0.33069 c = 0.33069 g = 0.16456 h = 0.16456 | 0.99513 | 0.00100 | 0.01829 | |||

| Gondaila | k = 0.07055 a = 0.31312 b = 0.31312 c = 0.31312 g = 0.07055 h = 0.07055 | 0.98355 | 0.00106 | 0.02461 | k = 0.14382 a = 0.33274 b = 0.33274 c = 0.33274 g = 0.14382 h = 0.14382 | 0.99210 | 0.00149 | 0.02227 | |||

| 10. | Combined Two-term and Page | Sakkoti | k = 0.11429 a = 1.00391 b = 0.00000 h = 0.82522 n = 0.87436 | 0.99973 | 0.00002 | 0.00362 | k = 0.18152 a = 1.01091 b = 0.00000 h = 0.78848 n = 0.88943 | 0.99426 | 0.00073 | 0.01907 | |

| Malkabii | k = 0.11343 a = 0.99892 b = 0.00077 h = 0.77768 n = 0.86410 | 0.99473 | 0.00041 | 0.01534 | k = 0.18902 a = 1.00368 b = 0.00000 h = 0.72906 n = 0.92519 | 0.99608 | 0.00061 | 0.01641 | |||

| Gondaila | k = 0.12499 a = 0.99237 b = 0.00000 h = 0.78021 n = 0.77924 | 0.99452 | 0.00031 | 0.01423 | k = 0.15986 a = 1.00925 b = 0.00000 h = 0.74414 n = 0.94662 | 0.99276 | 0.00102 | 0.02133 | |||

| 11. | Simplified Fick’s Diffusion | Sakkoti | a = 0.97113 c = 0.45109 L = 2.33661 | 0.99617 | 0.00023 | 0.01356 | a = 0.98502 c = 0.45737 L = 1.77887 | 0.99112 | 0.00080 | 0.02370 | |

| Malkabii | a = 0.96601 c = 0.40458 L = 2.24414 | 0.99137 | 0.00049 | 0.01962 | a = 0.99207 c = 0.53739 L = 1.80709 | 0.99513 | 0.00050 | 0.01829 | |||

| Gondaila | a = 0.93937 c = 0.39832 L = 2.37609 | 0.98355 | 0.00077 | 0.02461 | a = 0.99821 c = 0.52134 L = 1.90394 | 0.99210 | 0.00074 | 0.02227 | |||

| 12. | Logistics | Sakkoti | k = 0.08251 a = 154.858 b = 151.019 | 0.99608 | 0.00024 | 0.01373 | k = 0.14519 a = 2434.74 b = 2407.56 | 0.99109 | 0.00081 | 0.02375 | |

| Malkabii | k = 0.08097 a = 43.0337 b = 42.4148 | 0.99113 | 0.00050 | 0.01991 | k = 0.16610 a = 207.685 b = 208.129 | 0.99501 | 0.00051 | 0.01853 | |||

| Gondaila | k = 0.07148 a = 332.550 b = 314.967 | 0.98339 | 0.00078 | 0.02475 | k = 0.145594 a = 86.73296 b = 87.99771 | 0.99194 | 0.00076 | 0.02253 | |||

| Date Variety | OAD | ASD | ||

|---|---|---|---|---|

| The First | The Second | The First | The Second | |

| Sakkoti | Two-term | Combined Two-term and Page | Two-term Exponential | Logarithmic |

| Malkabii | Two-term | Page and Combined Two-term and Page | Newton (Lewis)/Approximation or diffusion or Diffusion Approach | Logistics |

| Gondaila | Modified Page III | Newton (Lewis) | Two-term Exponential | Logarithmic |

| Cost Parameters | ASD | PV System |

|---|---|---|

| Capital cost, USD | 468.75 | 62.5 |

| Lifespan, years | 10 | 20 |

| Annual capital cost, USD | 112.03 | 12.83 |

| Annual maintenance cost, USD | 3.369 | 0.385 |

| Annual salvage value, USD | 8.984 | 1.027 |

| Annualized investment cost, USD | 106.42 | 12.188 |

| The annual cost of the ASD integrated PV system, USD | 118.61 | |

| Economic Parameters | ASD Integrated with PV System |

|---|---|

| Mass of date fruit dried per batch, kg | 35 |

| Quantity of dried date fruit annually, kg | 175 |

| Drying cost per kg of date fruit, USD | 0.677 |

| Cost of 1 kg fresh date fruit, USD | 0.625 |

| Mass of fresh date fruit per batch, kg | 38.5 |

| Cost of fresh date fruit per kg of dried product, USD | 0.687 |

| Cost of 1 kg of crop dried date fruit inside dryer, USD | 1.364 |

| Selling price per kg of date fruit, USD | 3.0 |

| Saving per Kg of date fruit, USD | 1.636 |

| Saving per batch, USD | 57.26 |

| Saving per day, USD | 6.3622 |

| Saving after 1 year, USD | 229.04 |

| Payback time, years | 2.476 |

| Date Fruit Variety | Sakkoti | Malkabii | Gondaila |

|---|---|---|---|

| Specific energy consumed, kW·h/kg | 17.936 | 22.746 | 21.264 |

| Embodied energy, kW·h | 2995.6 | 2995.6 | 2995.6 |

| Annual thermal output, kW·h | 105.16 | 96.719 | 103.458 |

| Total annual thermal output, kW·h | 397.16 | 388.72 | 395.46 |

| Energy payback time, year | 7.54 | 7.71 | 7.58 |

| Net CO2 mitigation over the lifetime, tons | 8.80 | 8.55 | 8.75 |

| CO2 emission | 241.5 | 241.5 | 241.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metwally, K.A.; Oraiath, A.A.T.; Elzein, I.M.; El-Messery, T.M.; Nyambe, C.; Mahmoud, M.M.; Abdeen, M.A.; Telba, A.A.; Khaled, U.; Beroual, A.; et al. The Mathematical Modeling, Diffusivity, Energy, and Enviro-Economic Analysis (MD3E) of an Automatic Solar Dryer for Drying Date Fruits. Sustainability 2024, 16, 3506. https://doi.org/10.3390/su16083506

Metwally KA, Oraiath AAT, Elzein IM, El-Messery TM, Nyambe C, Mahmoud MM, Abdeen MA, Telba AA, Khaled U, Beroual A, et al. The Mathematical Modeling, Diffusivity, Energy, and Enviro-Economic Analysis (MD3E) of an Automatic Solar Dryer for Drying Date Fruits. Sustainability. 2024; 16(8):3506. https://doi.org/10.3390/su16083506

Chicago/Turabian StyleMetwally, Khaled A., Awad Ali Tayoush Oraiath, I. M. Elzein, Tamer M. El-Messery, Claude Nyambe, Mohamed Metwally Mahmoud, Mohamed Anwer Abdeen, Ahmad A. Telba, Usama Khaled, Abderrahmane Beroual, and et al. 2024. "The Mathematical Modeling, Diffusivity, Energy, and Enviro-Economic Analysis (MD3E) of an Automatic Solar Dryer for Drying Date Fruits" Sustainability 16, no. 8: 3506. https://doi.org/10.3390/su16083506