From Farm to Fork: Irrigation Management and Cold Storage Strategies for the Shelf Life of Seedless Sugrathirtyfive Table Grape Variety

Abstract

:1. Introduction

2. Material and Methods

2.1. Field Trial and Irrigation Volumes

- Normal Irrigation (NI): empirical irrigation management based on the knowledge and experience of the farmer, tendentially at fixed intervals approximately every 7 days, depending on the occurrence of rain, starting from 24 June (175th Julian day) until the last irrigation intervention on 10 October (283rd Julian day), for a total of 14 watering rounds;

- Smart Irrigation (SI), which restored 100% of crop evapotranspiration. Irrigation occurred when ready water availability was exhausted, according to the methodology of Allen et al. [27]. In particular, the tabulated crop coefficients (Kcinit = 0.15; Kcmed = 0.80; Kcend = 0.40) and depletion fraction value of 0.45 were adopted. Correction of Kcini (for precipitation events), Kcmed and Kcend (for climatic conditions and crop height) was performed according to the methodology of Allen et al. [27].

2.2. Yield and Grapes Quality Parameters

2.3. Preparation of Grape Skin Extracts (GSEs) and Total Phenolic Content (TPF), Total Flavonoids (FLV) and Antioxidant Activity (DPPH)

2.4. Times and Methods of Cold Storage

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results

3.1. Soil Water Content (SWC) and Irrigation Volumes (IVs)

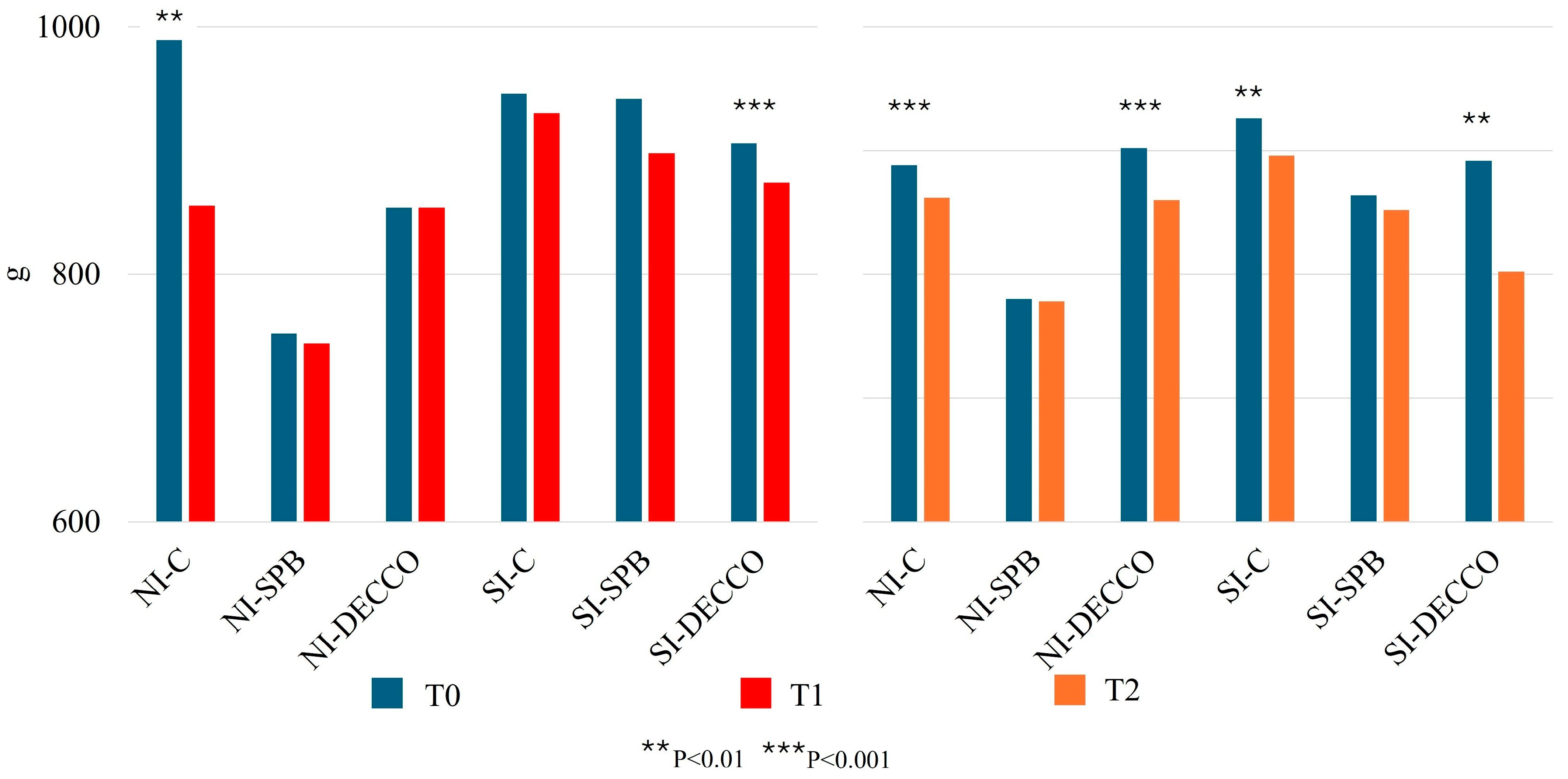

3.2. Univariate Analysis

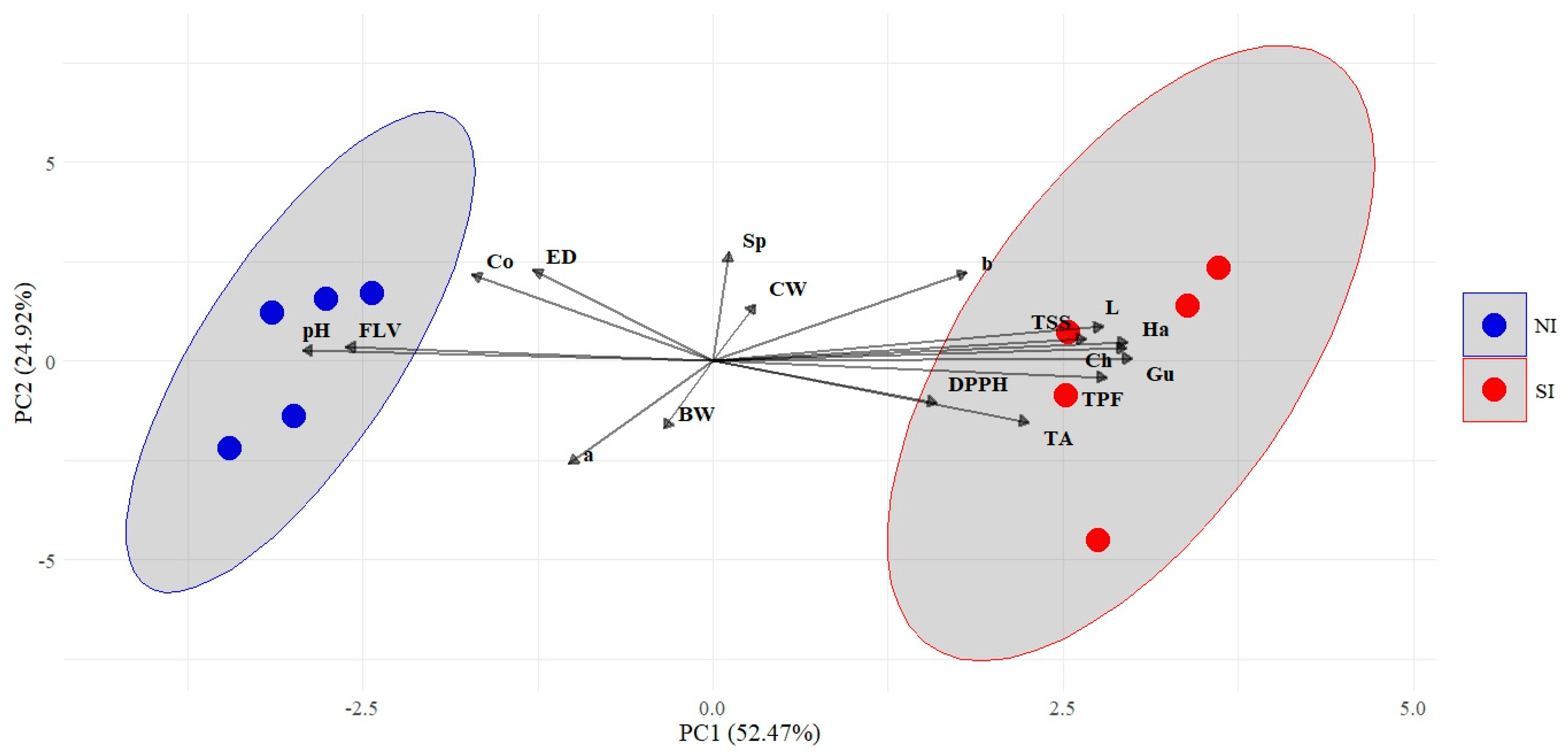

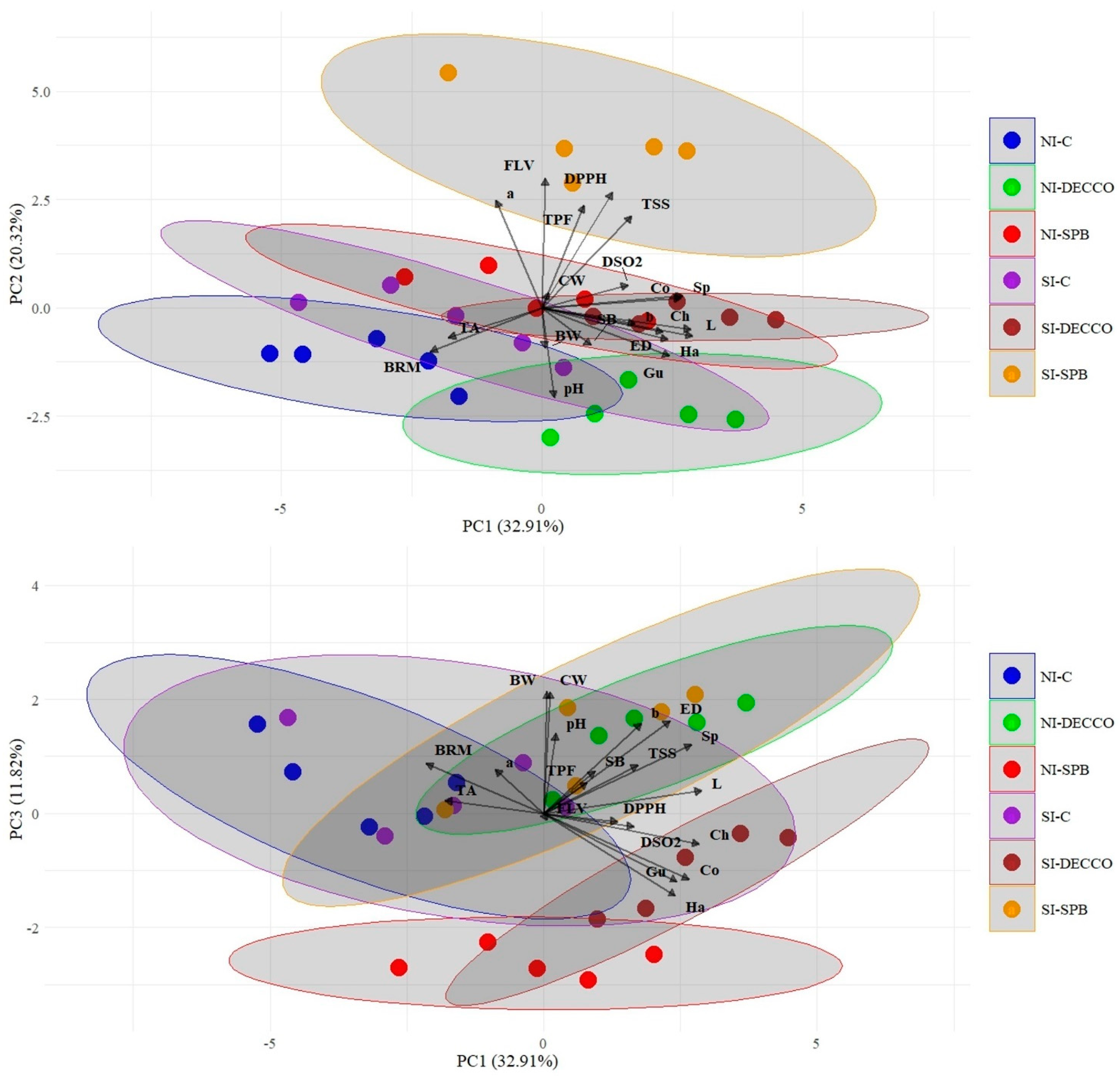

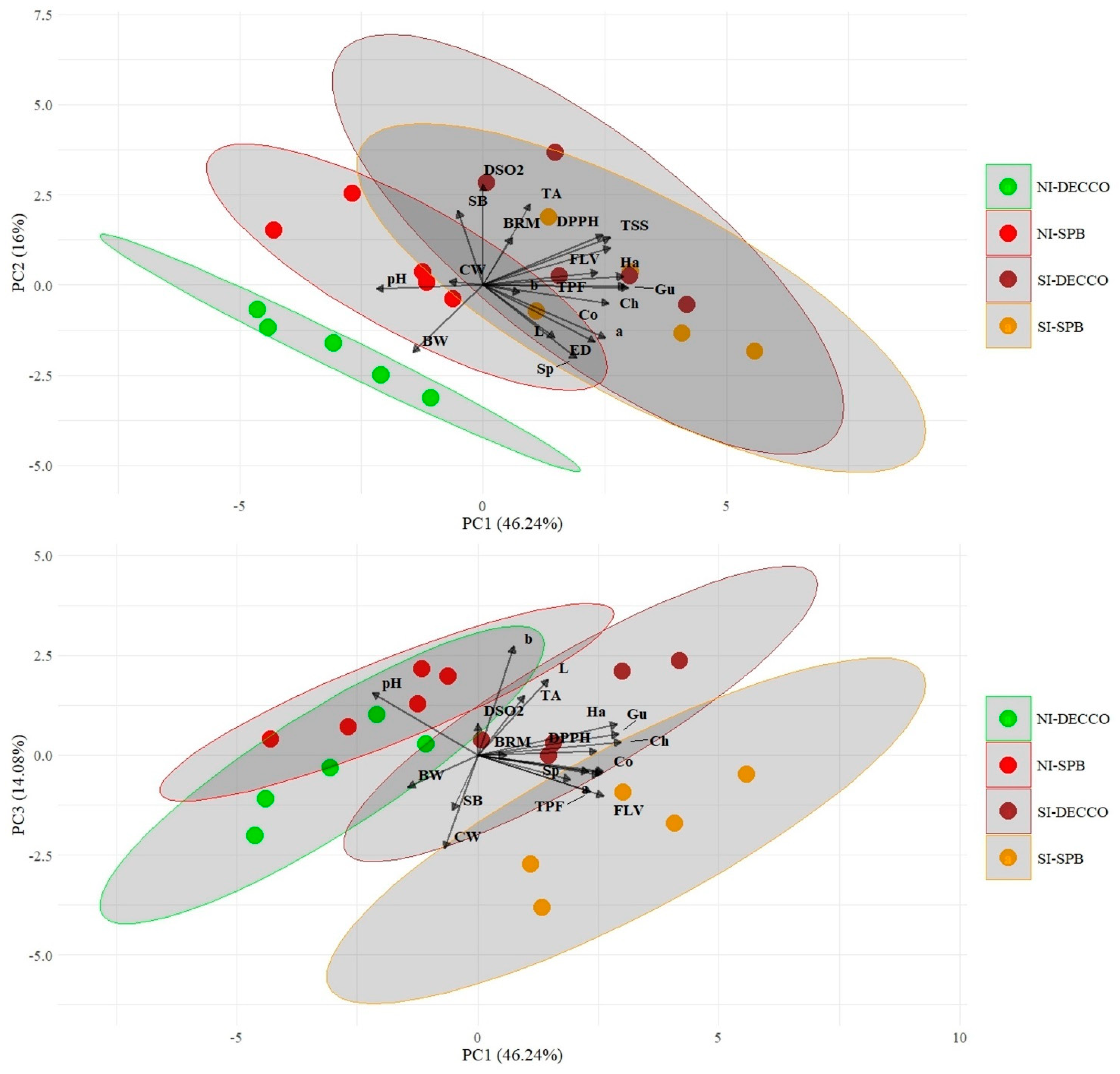

3.3. Multivariate Analysis

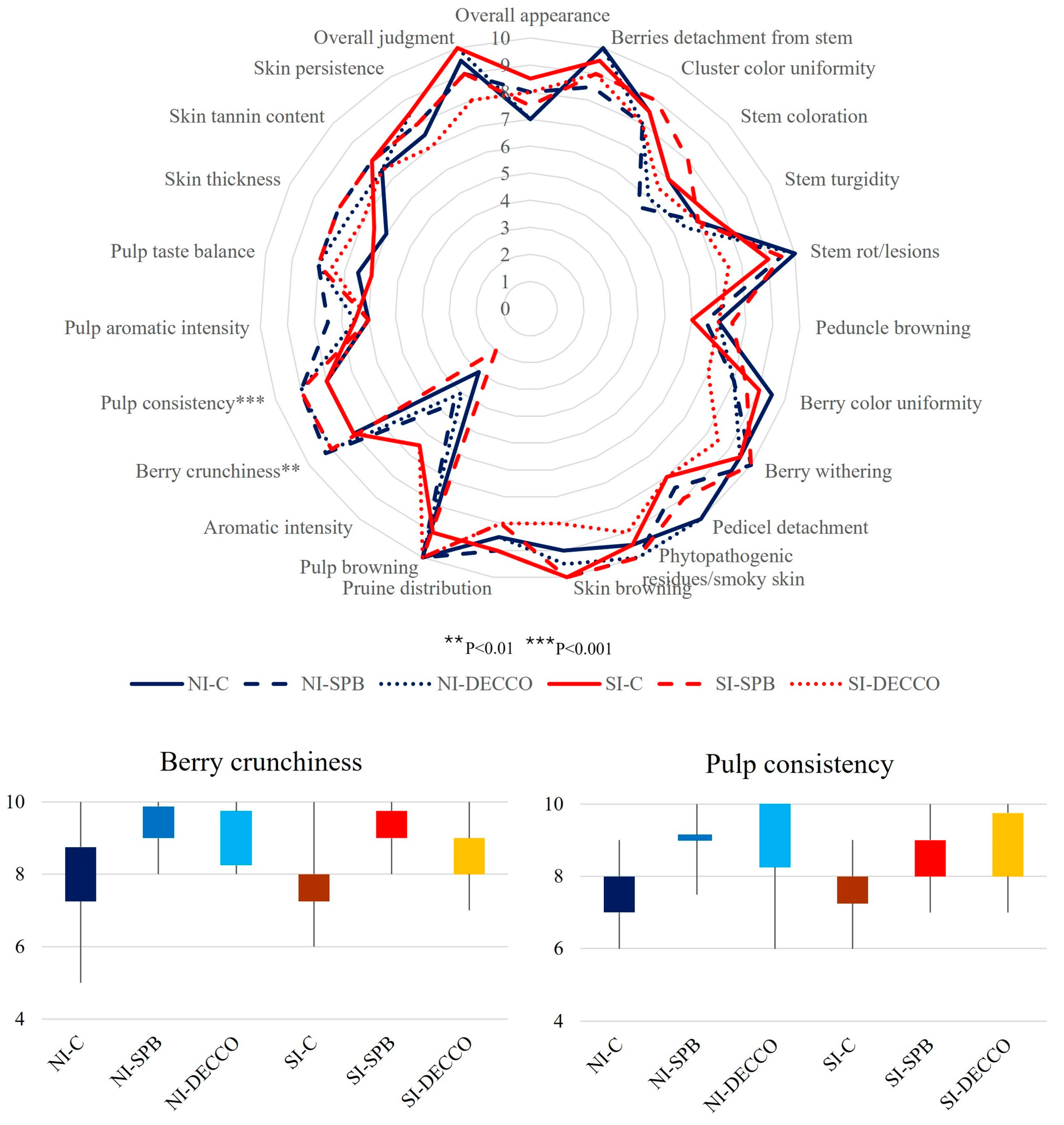

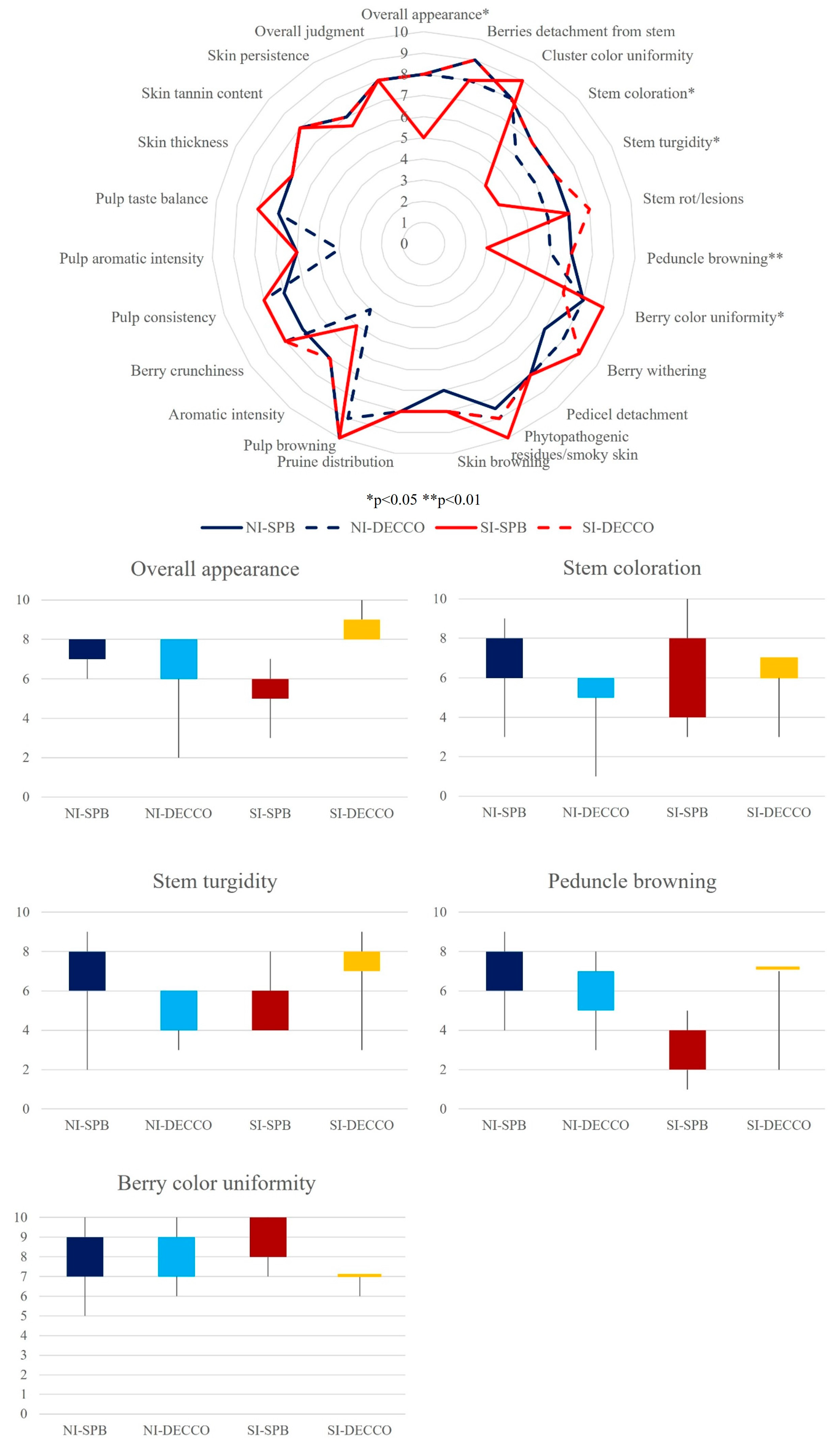

3.4. Sensory Analysis of Grapes

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lionello, P.; Scarascia, L. The relation between climate change in the Mediterranean region and global warming. Reg. Environ. Chang. 2018, 18, 1481–1493. [Google Scholar] [CrossRef]

- Pizarro, E.; Galleguillos, M.; Barría, P.; Callejas, R. Irrigation management or climate change? Which is more important to cope with water shortage in the production of table grape in a Mediterranean context. Agric. Water Manag. 2022, 263, 107467. [Google Scholar] [CrossRef]

- Medrano, H.; Tomás, M.; Martorell, S.; Escalona, J.M.; Pou, A.; Fuentes, S.; Flexas, J.; Bota, J. Improving water use efficiency of vineyards in semi-arid regions. A review. Agron. Sustain. Dev. 2015, 35, 499–517. [Google Scholar] [CrossRef]

- Cotecchia, V. Le Acque Sotterranee e l’Intrusione Marina in Puglia: Dalla Ricerca all’Emergenza Nella Salvaguardia Della Risorsa. In Memorie Descrittive Della Carta Geologica d’Italia; ISPRA Servizio Geologico d’Italia: Rome, Italy, 2014; Volume 92, pp. 338–369. ISBN 978-88-9311-003-7. Available online: https://www.isprambiente.gov.it/files2017/pubblicazioni/periodici-tecnici/memorie-descrittive-della-carta-geologica-ditalia/volume-92?b_start:int=0 (accessed on 18 April 2024).

- Mabrouk, H. The use of water potentials in irrigation management of table grape grown under semiarid climate in Tunisia. OENO One 2014, 48, 123–133. [Google Scholar] [CrossRef]

- Schilling, T.; Müller, R.; Ellwart, T.; Antoni, C.H. Context-dependent preferences for a decision support system’s level of automation. Comp. Hum. Behav. Rep. 2024, 13, 100350. [Google Scholar] [CrossRef]

- Centofanti, T.; Bañuelos, G.S.; Ayars, J.E. Fruit nutritional quality under deficit irrigation: The case of table grapes in California. J. Sci. Food Agric. 2019, 99, 2215–2225. [Google Scholar] [CrossRef] [PubMed]

- Pinillos, V.; Ibáñez, S.; Cunha, J.M.; Hueso, J.J.; Cuevas, J. Postveraison Deficit Irrigation Effects on Fruit Quality and Yield of “Flame Seedless” Table Grape Cultivated under Greenhouse and Net. Plants 2020, 9, 1437. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Liu, B.; Guan, X.; Wang, Z.; Wang, B.; Zhao, S.; Song, Y.; Zhao, Y.; Bi, J. Proper deficit irrigation applied at various stages of growth can maintain yield and improve the comprehensive fruit quality and economic return of table grapes grown in greenhouses. Irrig. Drain. 2021, 70, 1056–1072. [Google Scholar] [CrossRef]

- Temnani, A.; Conesa, M.R.; Ruiz, M.; López, J.A.; Berríos, P.; Pérez-Pastor, A. Irrigation Protocols in Different Water Availability Scenarios for ‘Crimson Seedless’ Table Grapes under Mediterranean Semi-Arid Conditions. Water 2021, 13, 22. [Google Scholar] [CrossRef]

- Conesa, M.R.; Berríos, P.; Temnani, A.; Pérez-Pastor, A. Assessment of the Type of Deficit Irrigation Applied during Berry Development in ‘Crimson Seedless’ Table Grapes. Water 2022, 14, 1311. [Google Scholar] [CrossRef]

- de Palma, L.; Limosani, P.; Marasovic, I.; Pati, S.; Vox, G.; Schettini, E.; Novello, V. Vineyard protection with rain-shelter: Relationships between radiometric properties of plastic covers and table grape quality. BIO Web Conf. 2019, 13, 04007. [Google Scholar] [CrossRef]

- OIV. The Sustainable Use of Water in Winegrape Vineyards. OIV Collective Expertise Document, 1st ed.; OIV Publications: Paris, France, 2021; ISBN 978-2-85038-023-5. Available online: https://www.oiv.int/the-sustainable-use-of-water-in-winegrape-vineyards (accessed on 18 April 2024).

- Yu, J.M.; Ahmedna, M. Functional components of grape pomace: Their composition, biological properties and potential applications. Int. J. Food Sci. Technol. 2013, 48, 221–237. [Google Scholar] [CrossRef]

- Park, E.; Edirisinghe, I.; Choy, Y.Y.; Waterhouse, A.; Burton-Freeman, B. Effects of grape seed extract beverage on blood pressure and metabolic indices in individuals with pre-hypertension: A randomised, double-blinded, two-arm, parallel, placebo-controlled trial. Br. J. Nutr. 2016, 115, 226–238. [Google Scholar] [CrossRef]

- Lu, R.; Song, M.; Wang, Z.; Zhai, Y.; Hu, C.; Perl, A.; Ma, H. Independent flavonoid and anthocyanin biosynthesis in the flesh of a red-fleshed table grape revealed by metabolome and transcriptome co-analysis. BMC Plant Biol. 2023, 23, 361. [Google Scholar] [CrossRef]

- Conesa, M.R.; de la Rosa, J.M.; Artés-Hernández, F.; Dodd, I.C.; Domingo, R.; Pérez-Pastor, A. Long-term impact of deficit irrigation on the physical quality of berries in ‘Crimson Seedless’ table grapes. J. Sci. Food Agric. 2015, 95, 2510–2520. [Google Scholar] [CrossRef]

- Roberto, S.; Junior, O.; Muhlbeier, D.; Koyama, R.; Ahmed, S.; Dominguez, A. Post-harvest conservation of “Benitaka” table grapes with different SO2−generating pads and plastic liners under cold storage. BIO Web Conf. 2019, 15, 01003. [Google Scholar] [CrossRef]

- Piazzolla, F.; Amodio, M.L.; Pati, S.; Colelli, G. Evaluation of Quality and Storability of “Italia” Table Grapes Kept on the Vine in Comparison to Cold Storage Techniques. Foods 2021, 10, 943. [Google Scholar] [CrossRef]

- Ginsburg, L.; Combrink, J.C.; Truter, A.B. Long and short term storage of table grapes. Int. J. Refrig. 1978, 1, 137–142. [Google Scholar] [CrossRef]

- Burger, D.A.; Jacobs, G.; Huysamer, M.; Taylor, M.A. The Influence of Storage Duration and Elevation of Storage Temperature on the Development of Berry Split and Berry Abscission in Vitis vinifera L. cv. Thompson Seedless Table Grapes. South Afr. J. Enol. Vitic. 2005, 26, 68–70. [Google Scholar] [CrossRef]

- Chironi, S.; Sortino, G.; Allegra, A.; Saletta, F.; Caviglia, V.; Ingrassia, M. Consumer assessment on sensory attributes of fresh table grapes cv ‘italia’ and ‘red globe’ after long cold storage treatment. Chem. Eng. Trans. 2017, 58, 421–426. [Google Scholar] [CrossRef]

- Leng, F.; Wang, C.; Sun, L.; Li, P.; Cao, J.; Wang, Y.; Zhang, C.; Sun, C. Effects of Different Treatments on Physicochemical Characteristics of ‘Kyoho’ Grapes during Storage at Low Temperature. Horticulturae 2022, 8, 94. [Google Scholar] [CrossRef]

- Ngcobo, M.E.K.; Delele, M.A.; Opara, U.L.; Meyer, C.J. Performance of multi-packaging for table grapes based on airflow, cooling rates and fruit quality. J. Food Eng. 2013, 116, 613–621. [Google Scholar] [CrossRef]

- Ahmed, S.; Roberto, S.R.; Domingues, A.R.; Shahab, M.; Junior, O.J.C.; Sumida, C.H.; De Souza, R.T. Effects of Different Sulfur Dioxide Pads on Botrytis Mold in ‘Italia’ Table Grapes under Cold Storage. Horticulturae 2018, 4, 29. [Google Scholar] [CrossRef]

- Yuan, Y.; Wei, J.; Xing, S.; Zhang, Z.; Wu, B.; Guan, J. Sulfur dioxide (SO2) accumulation in postharvest grape: The role of pedicels of four different varieties. Postharvest Biol. Technol. 2022, 190, 111953. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration. Guidelines for Computing Crop Water Requirements; FAO Irrigation and Drainage Paper No. 56; FAO—Food and Agriculture Organization of the United Nations: Rome, Italy, 1998; Available online: https://www.fao.org/3/x0490e/x0490e00.htm (accessed on 7 March 2024).

- Di Stefano, R.; Cravero, M.C. Metodi per lo studio dei polifenoli dell’uva. Riv. Vitic. Enol. 1991, 44, 37–45. [Google Scholar]

- Waterhouse, A.L. Determination of Total Phenolics. Curr. Protoc. Food Anal. Chem. 2002, 6, I1.1.1–I1.1.8. [Google Scholar]

- Ayoola, G.A.; Ipav, S.S.; Solidiya, M.O.; Adepoju-Bello, A.A.; Coker, H.A.B.; Odugbemi, T.O. Phytochemical screening and free radical scavenging activities of the fruits and leaves of allanblackia floribunda olive (Guttiferae). Int. J. Health Res. 2008, 1, 81–93. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 1995, 1, 25–30. [Google Scholar] [CrossRef]

- ISO 8589:2007; Sensory Analysis: General Guidance for Design of Test Rooms. International Organization for Standardization: Genèva, Switzerland, 2007.

- OIV. OIV General form for the Sensorial Analysis of Table Grape. Resolution OIV/VITI 371/2010. 2010. Available online: https://www.oiv.int/public/medias/385/viti-2010-2-en.pdf (accessed on 30 January 2024).

- OIV. Annual Assessment of the World Vine and Wine Sector in 2021. 2021. Available online: https://www.oiv.int/sites/default/files/documents/OIV_Annual_Assessment_of_the_World_Vine_and_Wine_Sector_in_2021.pdf (accessed on 18 April 2024).

- Romero, P.; Navarro, J.M.; Botía Ordaz, P. Towards a sustainable viticulture: The combination of deficit irrigation strategies and agroecological practices in Mediterranean vineyards. A review and update. Agric. Water Manag. 2022, 259, 107216. [Google Scholar] [CrossRef]

- Kang, C.; Diverres, G.; Karkee, M.; Zhang, Q.; Keller, M. Decision-support system for precision regulated deficit irrigation management for wine grapes. Comput. Electron. Agric. 2023, 208, 107777. [Google Scholar] [CrossRef]

- Ribera-Fonseca, A.; Palacios-Peralta, C.; González-Villagra, J.; Diaz, M.R.; Serra, I. How Could Cover Crops and Deficit Irrigation Improve Water Use Efficiency and Oenological Properties of Southern Chile Vineyards? J. Soil Sci. Plant Nutr. 2023, 23, 6851–6865. [Google Scholar] [CrossRef]

- Permanhani, M.; Costa, J.M.; Conceição, M.A.F.; de Souza, R.T.; Vasconcellos, M.A.S.; Chaves, M.M. Deficit irrigation in table grape: Eco-physiological basis and potential use to save water and improve quality. Theor. Exp. Plant Phys. 2016, 28, 85–108. [Google Scholar] [CrossRef]

- Campi, P.; Modugno, F.; Palumbo, A.D.; Mastrorilli, M. Dimensioning the Irrigation Variables for Table Grape Vineyards in Litho-soils. Ital. J. Agron. 2010, 4, 315–321. [Google Scholar] [CrossRef]

- Çolak, Y.B.; Yazar, A. Evaluation of crop water stress index on Royal table grape variety under partial root drying and conventional deficit irrigation regimes in the Mediterranean Region. Sci. Hortic. 2017, 224, 384–394. [Google Scholar] [CrossRef]

- Vox, G.; Schettini, E.; Scarascia-Mugnozza, G.; Tarricone, L.; Gentilesco, G. Crimson seedless table grape grown under plastic film: Ecophysiological parameters and grape characteristics as affected by the irrigation volume. In Proceedings of the International Conference of Agricultural Engineering, Zurich, Switzerland, 6–10 July 2014; EurAgEng: Bedford, UK, 2014. Ref: C0354. pp. 1–8. Available online: https://www.geyseco.es/geystiona/adjs/comunicaciones/304/C03540001.pdf (accessed on 7 March 2024).

- Mirás-Avalos, J.M.; Intrigliolo, D.S. Grape Composition under Abiotic Constrains: Water Stress and Salinity. Front. Plant Sci. 2017, 8, 851. [Google Scholar] [CrossRef] [PubMed]

- Conesa, M.R.; Falagán, N.; de la Rosa, J.M.; Aguayo, E.; Domingo, R.; Pérez Pastor, A. Post-veraison deficit irrigation regimes enhance berry coloration and health-promoting bioactive compounds in ‘Crimson Seedless’ table grapes. Agric. Water Manag. 2016, 163, 9–18. [Google Scholar] [CrossRef]

- Temnani, A.; Berríos, P.; Conesa, M.R.; Pérez-Pastor, A. Modelling the Impact of Water Stress during Post-Veraison on Berry Quality of Table Grapes. Agronomy 2022, 12, 1416. [Google Scholar] [CrossRef]

- Pisciotta, A.; Planeta, D.; Giacosa, S.; Paissoni, M.A.; Di Lorenzo, R.; Rolle, L. Quality of Grapes Grown Inside Paper Bags in Mediterranean Area. Agronomy 2020, 10, 792. [Google Scholar] [CrossRef]

- Rolle, L.; Giacosa, S.; Gerbi, V.; Novello, V. Comparative Study of Texture Properties, Color Characteristics, and Chemical Composition of Ten White Table-Grape Varieties. Am. J. Enol. Vitic. 2011, 62, 49–56. [Google Scholar] [CrossRef]

- Castillo-Munoz, N.; Gomez-Alonso, S.; Garcia-Romero, E.; Hermosin-Gutierrez, I. Flavonol profiles of Vitis vinifera white grape cultivars. J. Food Compos. Anal. 2010, 23, 699–705. [Google Scholar] [CrossRef]

- Šikuten, I.; Štambuk, P.; Andabaka, Ž.; Tomaz, I.; Marković, Z.; Stupić, D.; Maletić, E.; Kontić, J.K.; Preiner, D. Grapevine as a Rich Source of Polyphenolic Compounds. Molecules 2020, 25, 5604. [Google Scholar] [CrossRef] [PubMed]

- Gambetta, G.A.; Herrera, J.C.; Dayer, S.; Feng, Q.; Hochberg, U.; Castellarin, S.D. The physiology of drought stress in grapevine: Towards an integrative definition of drought tolerance. J. Exp. Bot. 2020, 71, 4658–4676, Erratum in J. Exp. Bot. 2020, 71, 5717. [Google Scholar] [CrossRef]

- Palai, G.; Caruso, G.; Gucci, R.; D’Onofrio, C. Berry flavonoids are differently modulated by timing and intensities of water deficit in Vitis vinifera L. cv. Sangiovese. Front. Plant Sci. 2022, 13, 1040899. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Tang, G.Y.; Zhao, C.N.; Feng, X.L.; Xu, X.Y.; Cao, S.Y.; Meng, X.; Li, S.; Gan, R.Y.; Li, H.B. Comparison of Antioxidant Activities of Different Grape Varieties. Molecules 2018, 23, 2432. [Google Scholar] [CrossRef] [PubMed]

- Giovinazzo, G.; Grieco, F. Functional Properties of Grape and Wine Polyphenols. Plant Foods Hum. Nutr. 2015, 70, 454–462. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Trujillo, J.P.; Obando-Ulloa, J.M.; Baró, R.; Martínez, J.A. Quality of two table grape guard cultivars treated with single or dual-phase release SO2 generators. J. Appl. Bot. Food Qual. 2008, 82, 1–8. [Google Scholar]

- Peña-Neira, A.; Cortiella, M.G.I.; Ubeda, C.; Pastenes, C.; Villalobos, L.; Contador, L.; Infante, R.; Gómez, C. Phenolic, polysaccharides composition, and texture properties during ripening and storage time of new table grape cultivars in Chile. Plants 2023, 12, 2488. [Google Scholar] [CrossRef]

- de Aguiar, A.C.; Higuchi, M.T.; Yamashita, F.; Roberto, S.R. SO2-Generating Pads and Packaging Materials for Postharvest Conservation of Table Grapes: A Review. Horticulturae 2023, 9, 724. [Google Scholar] [CrossRef]

| Factors | Interactions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IV | SGP | CSD | IV × SGP | IV × CSD | SGP × CSD | IV × SGP × CSD | ||||||

| NI | SI | C † | SPB | DECCO | T0 | T1 | T2 † | |||||

| 20 berries’ weight (g) | 244.4 | 241.5 | 246.8 | 239.2 | 243.0 | 250.9 | 238.3 | 246.1 | ns | ns | * | ns |

| Equatorial diameter (mm) | 24.9 | 25.1 | 24.7 | 24.9 | 25.3 | 25.2 | 24.7 | 25.3 | ** | ns | ns | ns |

| Total Soluble Solids (°Brix) | 15.7 b | 17.3 a | 15.7 b | 17.2 a | 16.6 ab | 16.0 | 16.7 | 16.5 | *** | *** | * | *** |

| pH | 3.75 a | 3.63 b | 3.63 b | 3.70 ab | 3.75 a | 3.57 b | 3.70 b | 3.74a | * | ns | *** | *** |

| TA (g/L tartaric acid) | 4.1 | 4.0 | 4.1 | 4.1 | 4.0 | 4.1 | 4.0 | 4.1 | ** | *** | ** | *** |

| L* | 39.90 b | 40.91 a | 40.26 ab | 39.88 b | 41.07 a | 41.17 a | 40.51 ab | 39.86 b | ns | ns | ns | ns |

| a* | –3.48 b | –3.22 a | –3.35 ab | –3.24 a | –3.47 b | –3.36 | –3.40 | –3.27 | ** | ns | *** | ns |

| b* | 9.15 | 9.37 | 9.20 | 9.15 | 9.42 | 8.68 b | 8.79 b | 9.79 a | ns | ns | ns | *** |

| Hardness (N) | 14.38 b | 16.25 a | 15.74 | 14.81 | 15.40 | 17.61 a | 15.13 b | 14.44 b | ns | ns | ns | ns |

| Springiness (mm) | 4.97 | 5.01 | 4.94 | 4.98 | 5.05 | 5.04 | 4.93 | 5.05 | ** | ns | ns | ns |

| Cohesiveness (adim) | 0.65 | 0.65 | 0.62 b | 0.67 a | 0.66 a | 0.63 b | 0.65 b | 0.68 a | ns | ns | ns | * |

| Chewiness (mj) | 46.51 b | 53.06 a | 48.61 | 49.8 | 50.95 | 55.07 | 47.99 | 49.84 | ns | ** | ns | ns |

| Gumminess (N) | 9.34 b | 10.64 a | 9.78 | 9.95 | 10.23 | 10.90 | 9.79 | 9.84 | ns | * | ns | ns |

| TPF mg/kg fresh grape GAE | 90.42 b | 103.61 a | 91.99 b | 109.88 a | 89.17 b | 97.57 | 99.17 | 93.51 | ** | ns | ns | * |

| FLV g RE/kg | 0.51 b | 0.70 a | 0.52 ab | 0.78 a | 0.50 b | 0.44 | 0.73 | 0.49 | ns | ns | ** | ns |

| DPPH μmol TE /kg | 452.86 b | 502.40 a | 437.20 | 502.29 | 463.41 | 468.13 ab | 501.88 a | 446.01 b | ns | ns | ns | ns |

| % berries damaged by SO2 | 0.5% | 0.5% | 0.0% b | 0.9% a | 0.9% a | 0.0% b | 0.0% b | 1.2% a | ns | ns | * | ns |

| % berries with gray rot/mold | 16.3% | 15.0% | 36.3 a | 0.6% b | 1.9% b | 0.0% b | 7.9% b | 27.6% a | ns | ns | * | ns |

| % stem browning | 6.2% | 4.7% | 3.8% | 7.0% | 6.2% | 0.0% b | 2.1% b | 10.2% a | ns | ns | ns | ns |

| NI-C T0 | NI-C T1 | NI-C T2 | SI-C T0 | SI-C T1 | SI-C T2 | NI-SPB T1 | NI-SPB T2 | SI-SPB T1 | SI-SPB T2 | NI-DECCO T1 | NI-DECCO T2 | SI-DECCO T1 | SI-DECCO T2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 berry weight (g) | 252.3 | 238.5 | - | 249.5 | 246.8 | - | 223.1 | 252.1 | 233.5 | 248.0 | 243.9 | 256.7 | 243.7 | 227.5 |

| Equatorial diameter (mm) | 25.4 | 24.2 | - | 25.1 | 24.3 | - | 24.1 | 24.6 | 25.1 | 25.9 | 25.6 | 25.5 | 24.8 | 25.3 |

| TSSs (°Brix) | 15.6 | 15.1 | - | 16.4 *** | 15.9 | - | 16.2 *** | 15.8 | 18.8 *** | 18.0 *** | 17.0 *** | 14.4 *** | 16.9 *** | 17.9 *** |

| pH | 3.61 | 3.77 *** | - | 3.52 *** | 3.62 | - | 3.64 | 3.84 *** | 3.64 | 3.66 * | 3.86 *** | 3.78 *** | 3.66 * | 3.69 *** |

| TA (g/L tartaric acid) | 4.1 | 4.2 | - | 4.2 | 4.0 | - | 4.2 | 4.2 | 4.0 | 3.9 | 4.1 | 3.7 | 3.5 ** | 4.7 *** |

| L* | 39.94 | 38.73 | - | 42.40 * | 39.98 | - | 39.79 | 39.57 | 40.64 | 39.51 | 41.68 | 39.66 | 42.24 * | 40.69 |

| a* | −3.33 | –3.45 | - | –3.40 | –3.24 | - | –3.52 | –3.46 | –2.93 * | –3.04 | –3.78 ** | –3.36 | –3.51 | –3.22 |

| b* | 8.20 | 10.12 ** | - | 9.16 | 9.34 | - | 8.82 | 9.23 | 10.25 ** | 8.31 | 10.29 ** | 8.24 | 9.80 * | 9.37 |

| Hardness (N) | 13.67 | 13.54 | - | 21.55 *** | 14.18 | - | 15.85 | 13.89 | 13.74 | 15.76 | 16.73 | 12.60 | 16.75 | 15.50 |

| Springiness (mm) | 5.08 | 4.83 | - | 5.01 | 4.85 | - | 4.81 | 4.90 | 5.02 | 5.17 | 5.12 | 5.08 | 4.96 | 5.05 |

| Cohesiveness (adim) | 0.63 | 0.62 | - | 0.62 | 0.62 | - | 0.66 | 0.67 | 0.65 | 0.70 *** | 0.64 | 0.68 | 0.66 | 0.68 |

| Chewiness (mI) | 43.20 | 41.01 | - | 66.93 *** | 43.30 | - | 50.96 | 45.42 | 45.34 | 57.48 | 55.29 | 43.20 | 52.07 | 53.25 |

| Gumminess (N) | 8.52 | 8.46 | - | 13.29 *** | 8.87 | - | 10.53 | 9.26 | 8.92 | 11.10 | 10.77 | 8.52 | 11.17 | 10.49 |

| DPPH umol TE /kg | 451.23 | 436.58 | - | 485.03 | 495.98 | - | 513.43 | 444.31 | 538.90 ** | 472.50 | 473.12 | 398.49 | 513.26 | 468.74 |

| FLV g RE/kg | 0.55 | 0.62 | - | 0.34 | 0.58 | - | 0.77 | 0.40 | 0.88 *** | 0.66 | 0.34 | 0.35 | 0.77 | 0.55 |

| TPF mg/kg fresh grape GAE | 82.10 | 96.47 | - | 113.03 *** | 76.35 | - | 101.33 | 91.73 | 133.94 *** | 112.53** | 93.56 | 77.31 | 93.34 | 92.46 |

| % berries damages SO2 | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 1.8% * | 0.0% | 1.8% * | 0.0% | 1.8% * | 0.0% | 1.8% * | 0.0% |

| % berries with rot/mold | 0.0% | 32.0% *** | 76.0% *** | 0.0% | 15.0%** | 80.0% *** | 0.0% | 0.8% | 0.0% | 1.6% | 0.2% | 1.8% | 0.2% | 5.4% |

| % stem browning | 0.0% | 0.0% | 13.0%** | 0.0% | 0.4% | 8.0% ** | 2.0% | 12.0% ** | 2.0% | 12.0% ** | 7.0% * | 8.0% ** | 1.2% | 8.4% ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alba, V.; Russi, A.; Forte, G.; Milella, R.A.; Roccotelli, S.; Campi, P.; Modugno, A.F.; Pipoli, V.; Gentilesco, G.; Tarricone, L.; et al. From Farm to Fork: Irrigation Management and Cold Storage Strategies for the Shelf Life of Seedless Sugrathirtyfive Table Grape Variety. Sustainability 2024, 16, 3543. https://doi.org/10.3390/su16093543

Alba V, Russi A, Forte G, Milella RA, Roccotelli S, Campi P, Modugno AF, Pipoli V, Gentilesco G, Tarricone L, et al. From Farm to Fork: Irrigation Management and Cold Storage Strategies for the Shelf Life of Seedless Sugrathirtyfive Table Grape Variety. Sustainability. 2024; 16(9):3543. https://doi.org/10.3390/su16093543

Chicago/Turabian StyleAlba, Vittorio, Alessandra Russi, Giovanna Forte, Rosa Anna Milella, Sabino Roccotelli, Pasquale Campi, Anna Francesca Modugno, Vito Pipoli, Giovanni Gentilesco, Luigi Tarricone, and et al. 2024. "From Farm to Fork: Irrigation Management and Cold Storage Strategies for the Shelf Life of Seedless Sugrathirtyfive Table Grape Variety" Sustainability 16, no. 9: 3543. https://doi.org/10.3390/su16093543