Abstract

Sustainable development has attracted the increasing attention of both researchers and practitioners. While academicians and practitioners’ focus towards sustainability has shifted to innovation, there is a need to understand how sustainability and innovation are interlinked. Thus, this paper attempts to analyze, first, the bidirectional impact of the firms’ pursuit of sustainability and innovation as the priority, second, the bidirectional impact of the adoption of sustainability innovation action programs and, third, to discern the bidirectional influence of sustainability and innovation performances. The evidence is drawn from a sample of 860 manufacturing plants in 22 countries from the sixth edition of the International Manufacturing Strategy Survey 2013. The survey was conducted using a self-administered questionnaire. Structural equation modelling has been employed to test the model. The results show that sustainability and innovation positively and significantly impact each other in terms of the adoption of their relevant action programs and performance. However, the pursuit of sustainability priority acts as an antecedent of innovation priority.

1. Introduction

Since the release of World Commission on Environment and Development Report in 1987 (commonly known as the ‘Brundtland Commission Report’), research on sustainability has attracted increasing attention. The main concern of sustainability is meeting the needs of the present without compromising the ability of future generations to meet their own needs [1]. Sustainable development encompasses a triple bottom line, a concept developed by [2], which integrates economic, environmental and social issues in operations. While environmental sustainability refers to consuming natural resources in a more advantageous manner and producing less emission to preserve the ecosystem [3], social sustainability refers to the skills’ preservation and enhancing health and quality of life [4]. This study, by adopting the sustainability concept considering both environmental and social perspectives simultaneously, primarily attempts to provide important value to the literature, especially in the operations management literature [5].

Studying sustainability from the Operations Management (OM) field is essential since companies have to consider the footprint left behind in terms of the resources used (e.g., energy) [3]. Moreover, companies are required to operate responsibly for employees’ health and safety and society’s welfare. To conclude, “given the impact of the manufacturing industry on the environment, people and economy, OM gives new opportunities to significantly contribute to sustainability” [6] (p. 1).

Despite the fact that sustainability has been studied extensively for decades, practitioners, as well as academics still interrogate whether or not existing paths of businesses are sustainable [7]. As a result, recently, scholars suggest innovation as one of the possible ways to achieve sustainability, because in order to develop more sustainable products/services, companies need to change their way of doing things: innovate [7]. Accordingly, scholars claim that the incorporation of sustainability issues in innovation is needed [8,9]. Innovation is defined in any form of new products, processes, methods, markets and supply sources [10]. The core perspective of innovation is the novelty and change that must be achieved through a noticeable change from the previous product, process, service or business model [11]. Similar to several previous studies, (e.g., [12]), our notion of innovation is related to the change and novelty of the firm as an institutional context.

Companies require innovative responses, either incremental (doing better) or radical (doing different) [13]. In a similar vein, a broad understanding exits that the sustainability challenges propose meaningful opportunities for innovation [14]. Thus, sustainability challenges act as the source of change and the driver for innovation [15]. Thus, several pieces of evidence are documented on cases where sustainability orientation influences firms to see innovation as a priority or vice versa; the innovation orientation leads firms to consider sustainability as a priority, (e.g., [13,14]). This paper aims at expanding this debate by testing the mutual influence of sustainability and innovation as a business priority in a large sample of firms. To the best of our knowledge, such a large-scale empirical test has not been investigated in the previous studies.

When firms consider sustainability and/or innovation as a priority, they adopt the relevant action programs, (e.g., [14,16]). Moreover, scholars show the positive relationship between the internal sustainability action programs and managing new external insights for sustainability (referred to as external sustainability programs) [3,17]. In this regard, it is argued that environmental and social sustainability development relates to the exploration of product alternatives and, thus, to actions coordinating new product development, (e.g., [18]). The results of the studies propose the impact of the adoption of sustainability programs on innovation programs or vice versa. However, there is a lack of investigation on their simultaneous interaction to shed light on whether firms should focus on one before the other or if they should adopt them at the same time. Additionally, the majority of studies lie in showing successful cases or projects, and there is a lack of generalizable large-scale empirical investigations. That is why we further aim at testing the bidirectional influence of the adoption of sustainability and innovation action programs.

Finally, the adoption of sustainability or innovation programs enhances the business performance, whereas prior investigations on the inter-relationship between sustainability and innovation either lack taking into account the performance perspective or investigate the unidirectional relationship (through showing cases where either one impacts the other) [19]. However, investigating the bidirectional influence of sustainability and innovation performance is important because it can suggest the synergetic effect between them. To satisfy this need, we extend the course of this paper to test empirically the bidirectional influence of innovation and sustainability performance.

To do so, we target firms globally because of the need for the generalizability of the results. Moreover, aligned with Pagell and Gobeli’s recommendation [20], we analyze the data gathered from a sample of individual plants unlike the majority of the previous research that considers a sample of companies [6]. The advantage of scrutinizing individual plants is the ability to study day-to-day decisions and the exact implementation of sustainable and innovative action programs.

To conclude, since the attention of recent sustainability studies has shifted to innovation management as a priority [21,22], the purpose of this study is to investigate on a large and generalizable empirical basis the relationship between sustainability and innovation on three different levels: the firms’ pursuit of sustainability and innovation as the priority, the implementation of their relevant action programs and the performance achieved.

Through this analysis, this paper contributes not only to the sustainability research field, but also to the operation management and innovation fields. Moreover, the study aims at proposing new foundations in further understanding the determinants for sustainable development and innovation management. In particular, while there are fruitful investigations addressing the relationships between sustainability and innovation priorities, programs and performance, they are either focused on a few constructs or demonstrating cases/projects and do not investigate the bidirectional relationships in a generalizable sample of firms. We address this gap and present a more comprehensive study of the relationships between and among sustainability and innovation priorities, action programs and performance.

Moreover, we provide some guidance to managers when deploying sustainability and/or innovation priorities. In particular, the paper gives insights to practitioners on whether they can generally leverage superior sustainability and innovation action programs/performance by taking advantage of their mutual influence.

The structure of this paper is as follows: First, we review the literature on the link between sustainability and innovation. We then present the methodology used. Next, we present and discuss our results. Lastly, we present our conclusions, the limitations of this study, its managerial implications and lines for further research.

2. Literature Review

Scholars propose that sustainability has been emerging in addition to the traditional competitive priorities, (e.g., [23,24]). It is suggested that firms increasingly are integrating sustainability priorities in their business [25]. Furthermore, according to several surveys, the majority of firms take sustainability into account in developing and marketing new products, (e.g., [26]). The fact that sustainable firm pursue innovation as a priority suggests that a sustainability orientation triggers firms to acknowledge innovation as a business priority [14,15]. This argument emerges from two lines of reasoning. First, sustainability introduces additional contemporary visions for new business opportunities [27]; second, sustainability regulations push businesses to be innovative in order to find ways to comply with them without losing money (or even by increasing economic performance) [22,28]. In this regard, sustainability has been seen as a change force that generates new products and processes challenging existing practices in firms [29]. Porter contends that vigorous sustainability strategies would trigger innovation, stating: “properly constructed regulatory standards, which aim at outcomes and not methods, will encourage companies to re-engineer their technology” [30] (p. 96). Porter and van der Linde demonstrate multiple cases where a sustainability orientation leads to enhanced innovativeness in products and processes [31]. Indeed, the quest for sustainability has been shifting the competitive landscape, leading firms to re-think products, processes, if not business models. Particularly in times of economic crisis, the key to re-think products and processes is innovation. Nidumolu, Prahalad and Rangaswami, by scrutinizing longitudinally the sustainability initiatives of 30 large corporations, demonstrate that sustainability is a mother lode of innovations that generates both bottom-line and top-line returns [7], as environmental initiatives are able to decrease costs while generating additional revenues [32]. By pursuing sustainability as a priority, early movers are proven to view compliance as opportunity, make their value chain sustainable, design sustainable new products and processes, develop new business models and create next-practice platforms [7]. This would support also innovation strategies to be sustained in the long-term [33].

On the other hand, extensive practical illustrations are documented where firms’ innovativeness motivates businesses to perceive sustainability as a priority, (e.g., [14,34,35]). In this regard, it is argued that, as innovations are able to target beyond economic goals, through aiming at social and environmental purposes, they trigger business towards sustainability priorities [36]; second, because innovation strategies cannot be sustained long term without being merged with sustainability strategic orientation [37]. We can conclude that, whatever the perspective adopted, it is clear that innovation and sustainability orientation influence each other [13,38,39,40]. What still remains as a gap is whether, on a generalizable sample of firms, the pursuits of sustainability and innovation priority influence each other. Thus, the following hypothesis is formulated:

H1a:

The pursuit of sustainability priority leads to the pursuit of innovation priority.

H1b:

The pursuit of innovation priority leads to the pursuit of sustainability priority.

Business priorities and programs have been proposed as a coupled bundle for strategy deployment [41]. In this regard, there is clear evidence of the pursuit of sustainability priority, which urges firms to adopt relevant action programs, (e.g., [14,16]). However, scholars differentiated between external vs. internal and environmental vs. social action programs, (e.g., [6,42]). In particular, internal environmental action programs are classified into: (1) environmental certifications; (2) energy and water consumption reduction programs; (3) pollution emission reduction and waste recycling programs; and internal social action programs include: (1) social certification; (2) formal sustainability oriented communication, training programs and involvement; (3) a formal occupational health and safety management system; (4) work/life balance policies, (e.g., [6,43]).

Recently, scholars show the positive relationship between the general internal sustainability action programs with external sustainability programs [3]. The majority of these investigations focus on sustainability-oriented supply chain programs [44]. However, fewer studies relate the external sustainability programs to managing new external insights for sustainability, (e.g., [17,45]). It is argued that environmental and social sustainability development relates to the exploration of alternatives and to actions related to the new product development [7,17]. To do so, one common action program is argued to be new product development coordination with the manufacturing processes [18,46,47,48,49]. The results of the studies propose that the adoption of sustainability programs impacts the adoption of innovation programs and vice versa; because coordination programs for product innovation include cross-functional integration, employee involvement and leveraging firms’ ability to generate information, which in return would enhance the adoption of sustainability programs, (e.g., [50,51,52]). In this regard, case-based investigations illustrate that integrating innovation supports firms coping with the challenges of operational processes, particularly of implementing sustainability programs [53,54]. While, the majority of the studies lie in showing successful cases and/or projects, we are not aware of a simultaneous test on a large scale of firms on the bidirectional impact of the adoption of sustainability and innovation action programs. Thus, we hypothesize the following:

H2a:

The adoption of sustainability action programs leads to the adoption of innovation action programs.

H2b:

The adoption of innovation action programs leads to the adoption of sustainability action programs.

The adoption of sustainability and/or innovation action programs enhances the business performance in different ways [55] and plays a role in achieving business success, (e.g., [49,56,57,58]). Whereas prior investigations mostly lie on how sustainability performance impacts economic performance or organizational performance, (e.g., [17]), there are few investigations on the link between sustainability and innovation performance. It is argued that sustainability performance impacts product innovations [59] because ultimately, the sustainability contribution will be achieved when a viable new product is provided [40,60,61]. In this regard, for improving sustainability performance, a regular plan for all of the products is needed, leading to enhanced new product development performance [62].

On the other hand, it is argued that firms with higher innovation performance tend to achieve higher sustainability performance [26,48,63]. To conclude, while the literature highlights the critical role of examining performance in operational studies, prior research on the inter-relationship between sustainability and innovation lacks taking into account the performance dimension or investigating the unidirectional relationship [19]. In other words, few prior research that considers the performance dimension of sustainability and innovation focused on examples where either one impacts the other. However, we argue that taking into account the bidirectional influence of sustainability and innovation performance brings an understanding of the possible existence of the synergetic effect between them. Since there is a need to discern how innovation and sustainability performance would mutually contribute to each other on a generalizable scale [39], we hypothesize:

H3a:

Sustainability performance positively impacts innovation performance.

H3b:

Innovation performance positively impacts sustainability performance.

3. Methodology

A survey research methodology is congruent with the aim of this study because although the operation management literature is quite rich on each of the constructs of sustainability and innovation, previous studies lack generalizable investigations on their mutual inter-relationship. Moreover, a survey research methodology is aligned with other studies published in the managerial literature on sustainability action programs and performance [6,64,65].

To test the above research hypothesis, we used data collected in the sixth edition of the International Manufacturing Strategy Survey (IMSS VI), a research project carried out in 2013–2014 by a global network. The IMSS project, originally launched in 1992 by the London Business School and Chalmers University of Technology, studies manufacturing and supply chain strategies within the assembly industry (25–30 classifications of International Standard Industrial Classification (ISIC)—25, manufacture of rubber and plastics products; 26, manufacture of other non-metallic mineral products; 27, manufacture of basic metals; 28, manufacture of fabricated metal products, except machinery and equipment; 29, manufacture of machinery and equipment not elsewhere classified; 30, manufacture of office, accounting and computing machinery). It is carried out through a detailed questionnaire administered simultaneously in many countries by local research groups. The first section of the questionnaire is related to the general information about the business unit, while the other sections advise on the dominant activities of the plant (particularly focusing on business, strategies, action programs and performance). The unit of analysis is the plant to avoid issues related to diverse working manners of multiple plants of a business unit. To ensure alignment with the most recent trends in operations strategies, part of the questionnaire is redesigned in each edition. The update is performed by a design team composed of a pool of international researchers bypassing country biases of the team [66]. Aligned with the majority of the studies on priorities, programs and performances, we used responses from a single manager within each plant (e.g., operations, manufacturing, general or technical) [60]. This implies the assumption that such a manager has adequate and precise related information [67]. Responses have been gathered in a unique global database [68]. The sample consists of 931 manufacturing plants from 22 different countries, with an average response rate of 36 percent (Table 1). Data have been collected from May 2013–March 2014. Firms have been selected through three different ways: convenience sampling, random sampling and firms that participated in previous versions of the surveys.

Table 1.

Firms’ descriptive data.

The quality of the global database has been checked for all respondents. Cases with more than 60% of answers missing were deleted. Non-response and late response bias have been checked for all of the countries’ database, except for a few cases: Hungary, around half of the Norway cases and Germany. Two procedures are carried out on the country level for checking the non-response bias (objective measures (obtain sales, number of employees and Standard Industrial Classification code figures for respondents and non-respondents; these figures are normally available in most databases; t-test comparing sales_respondents and sales_nonrespondents; t-test comparing employees_respondents and employees_nonrespondents; test comparing SICCode_respondents and SICCode_nonrespondents) and contact non-respondents (contact non-respondents and ask them a couple of questions that can be important for checking non-response bias, e.g., existence of a formalized manufacturing strategy, manufacturing performance, strategic relevance of the manufacturing function, ongoing restructuring process, etc.; if possible, try to ask for the reason why they do not want to answer the questionnaire)) and one procedure for late-response bias (obtain sales, number of employees and SIC code figures for early respondents and late respondents). In addition, for questionnaires gathered on paper, fault-proof methods have been used for data consistency. Furthermore, in some countries, tests were performed for distinguishing between those answers collected on “paper” and those answers collected via “electronic survey”. No noticeable pattern suggesting a bias was found. Moreover, “since data were collected from a single person at a single point in time, common method variance (CMV) might be a threat to the validity of our results” [6] (p. 153). To control the CMV, in the questionnaire and research design, the following measures were considered [69]: (1) respondent anonymity/confidentiality was protected; (2) the questions are designed to be as clear and concise as possible; (3) constructs’ questions were distributed in different sections of the questionnaire [70,71,72]. In particular, questions on action programs are asked in different sections of the questionnaire, and these programs are separated from priorities and performances.

To ensure the validity of the survey variables, the project team assessed content validity. The content validity analysis is carried out through: (1) a review of questions for face validity; (2) the process of variable construction [73,74]. The team thoroughly reviewed the existing literature to establish appropriate domains and to extend them (the data were collected in 1992, 1996, 2001, 2005, 2009 and 2013–2014; the sixth version). Thus, the questions are formulated by a discussion of several academicians.

In addition, the confirmatory factor analysis of the SEM method is applied to confirm the convergent and discriminant validity (through testing the relations among the observables and the uni-dimensionality of the constructs) [73].

In the next step, the quality of the part of the database used particularly for this study has been checked. Missing data replacement was carried out in two steps: first, responses lacking one or more complete construct are eliminated (860 valid respondents remained); second, within these responses, the missing values were replaced with the mean of the series [75]; finally, the coherency of the replaced values with the other responses was checked. The distribution of the sample, in terms of country and valid response, rates is shown in Table 2.

Table 2.

Sample descriptive data.

Data have been tested primarily for the normality check by the skewness and kurtosis tests. The results reveal that the normality assumption is rejected for almost all of the variables. Even though the samples are ordinal and shown to be non-normal, maximum likelihood (ML) is considered despite its assumption of a continuous and normal sample, since previous scholars contend that treating ordinal data as continuous will result in negligible the underestimation of path coefficients, factor loadings and correlations [76]. We did not control for industry, because the sample of the IMSS survey is being restricted to what is called as assembly industries (ISIC 25–30), meaning that the examined industries are already homogeneous in nature. However, we controlled for size, perceived trend of environmental/social pressure and technological change. Following, the summary statistics of the dataset are reported (Table 3).

Table 3.

Summary statistics of the dataset.

4. Operationalization of the Variables

The variables (observed variables) of all constructs (latent variables) were grounded based on previous research studies. All attributes are measured by a Likert scale of 1–5.

Business priorities: Respondents were asked to rate the importance of the competitive priorities for winning orders from the major customers, on a five-point Likert scale (1 = not important to 5 = very important). According to the literature, sustainability encompasses both environmental [6] and social [77] perspectives [3]. In IMSS, both variables are measured. We categorized these priorities into two groups: first, sustainability, which is composed by more environmentally-sound products and processes, a higher contribution to the development and welfare of society, safer and health respectful processes.

According to the literature, innovation has been differentiated mainly between product/process/organizational [78] or radical/incremental [79,80]. However, in IMSS, the attributes relate to the radical/incremental innovations, but are limited to product innovation. The reason lies within the inability to assess process/organizational innovation with measuring the importance of winning the order from the customers’ point of view, (e.g., [81]). Thus, innovation priority has been explored through the priority of offering new products more frequently and offering products that are more innovative, aligned with the way the innovator strategy is generally measured [82].

Action programs: In a similar vein to the course of this paper, we categorized the sets of action programs into two groups:

(1) Sustainability:

Respondents were asked to rate the level of effort put into the implementation of the action programs in the last three years (1 = none to 5 = high), (e.g., [6,83,84]). Following the framework developed in [5], both environmental and social internal programs are assessed for measuring sustainability action programs.

Environmental programs include, (e.g., [6,20,85,86,87,88,89]):

- Environmental certifications (e.g., Eco-Management and Audit Scheme (EMAS)or International Organization for Standardization-ISO 14001)

- Energy and water consumption reduction programs

- Pollution emission reduction and waste recycling programs.

Social programs include [6,90,91,92] (an adaptation of the scale used by [93]):

- Social certifications (e.g., SA8000 or OHSAS 18000)

- Formal sustainability-oriented communication, training programs and involvement

- Formal occupational health and safety management system

- Work/life balance policies

(2) Innovation:

Respondents were asked to indicate the effort in the last three years put into implementing action programs to coordinate the new product development and manufacturing processes [94]. Following prior investigations [95,96], the innovation programs investigated in this survey are:

- Informal mechanisms, such as direct, face-to-face communication, informal discussions and ad hoc meetings

- Design integration between product development and manufacturing through, e.g., platform design, standardization and modularization, design for manufacturing, design for assembly

- Organizational integration between product development and manufacturing through, e.g., cross-functional teams, job rotation, co-location, role combination, secondment and coordinating managers

- Technological integration between product development and manufacturing through, e.g., CAD-CAM, CAPP, CAE, product lifecycle management

- Integrating tools and techniques, such as failure mode and effect analysis, quality function deployment and rapid prototyping

- Communication technologies, such as teleconferencing, web meetings, intranet and social media

Forms of process standardization, such as a stage-gate process, design reviews and performance management.Performance: Respondents were asked to rate the level of change in manufacturing performance over the last three years (1 = decrease −5% or worse, 2 = stayed about the same −5%–+5%, 3 = slightly increased +5%–+15%, 4 = increased = 15%–25%, 5 = strongly increased +25% or better). Aligned with the previous measurements of sustainability and innovation, their performances are measured. In particular, sustainability performance is measured in terms of environmental performance (materials, water and/or energy consumption, pollution emission and waste production levels) [83,97,98] and social performance (workers’ motivation and satisfaction and health and safety conditions) [4,6,20,77]. Innovation performance is measured through a bundle of product customization ability and new product introduction ability [95,99].

5. Analysis and Findings

The structural equation modelling (SEM) approach has been employed to test the hypotheses [100]. It is a statistical method with a confirmatory approach [101] in which constructs’ validity (measurement model) and relationships (structural model) are tested in a hypothesized model concurrently. Moreover, the advantage of the SEM method compared to traditional statistical techniques is the fact that it allows the measurement of several variables and their inter-relationship simultaneously, thanks to an indication of model fitness [102,103]. SEM has attracted increasing attention because of the need for testing a complex phenomenon, which consists of several items, respondents, relationships and combined effects (synergies) [104]. Accordingly, in this paper, this method is adopted for its capability in testing the combination of the hypotheses simultaneously with a large number of respondents.

First, the necessary conditions for model identification were assessed. There is p = 25 observable variables; thus, the non-redundant data points in the sample variance covariance matrix is given by: p = (p(p + 1))/2 = 325. The number of parameters to be estimated is 62, so the model has the necessary condition and can be over identified. The second tested condition is related to the measurement portions of the model. The first regression coefficient of each construct is constrained to one for establishing the scale of factors.

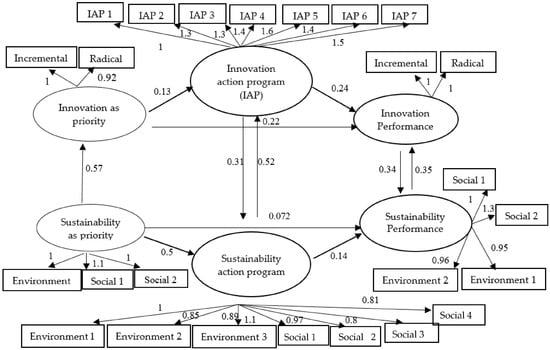

Finally, we specified a model based on our hypothesized framework providing also the parameter values for significant paths (Figure 1 and Table 4). The overall fit for the path model was acceptable ( = 263). Even though the overall fitness of the model was acceptable, we used modification indices to enhance the model with respect to the theoretical considerations. Significantly, covariance between two measurements for each sustainability action program and performance were suggested: energy/material and water consumption (reduction programs) and pollution emission reduction and waste recycling programs/production level). Subsequently, further theoretical investigation of the variables shows that the correlations are justifiable based on the theoretical background due to the fact that both measurements are targeting environmental sustainability programs. Based on previous studies, the environmental programs may be correlated in a sense that firms with proactive environmental strategies engage typically to enhance diverse type of environmental programs [105,106]. As a consequence, the covariance of the environmental programs is considered in the final model with improved overall fit ( = 262; Table 4).

Figure 1.

Structural equation model based on our second hypothesized model.

Table 4.

Overall fit of the model and values of the hypothesized relationships.

As already widely proven by the literature, the pursuit of priorities positively impacts firms’ performance with the mediating role of the adoption of action programs. This is supported, in the model, with the proof of a partial mediation role for innovation and a fully mediating role for sustainability (considering a 99% confidence interval) (partial mediating role for both sustainability and innovation considering a 95% confidence interval).

The results of the analyses provide mixed support to the hypotheses.

Hypothesis 1a, stating that the pursuit of sustainability priority positively impacts innovation priority, is fully supported. However, Hypothesis 1b, stating that the pursuit of innovation priority positively impacts sustainability priority, is not supported. In other words, if the bidirectional relationship is considered, both fall into insignificant. However, when unidirectional relationships are considered, only the impact of sustainability as priority on innovation priority falls into significant and positive.

Hypothesis 2a,b stating that the adoption of sustainability action programs impacts the adoption of innovation action programs to coordinate new product development and manufacturing processes is fully supported. This means that on the level of effort firms provide for the adoption of innovation and sustainability action programs, not only innovation programs are functional to adopt more sustainability programs, but also sustainability programs enhance the adoption of innovation programs.

In a similar vein, Hypothesis 3a,b, stating that sustainability performance positively impacts innovation performance and vice versa, is also fully supported: innovation and sustainability performance improvement are highly correlated and show combined (synergetic) effects.

6. Discussion and Future Research

The results obtained by testing of the research hypotheses can be summarized in the framework depicted in Figure 2.

Figure 2.

Framework for the relationship of innovation and sustainability.

The results reveal appealing insight about the relationship between sustainability and innovation as priorities. This study shows that the pursuit of sustainability as a priority predicts pursuing innovation as a priority according to a generalizable sample of firms; meaning that innovation becomes an order winner when it is driven by sustainable orientation. Our results added value, thanks to its generalizability, to previous proposals of scholars through some cases that sustainability acts a driver of innovation (e.g., based on 30 big corporations in [7]). Our results suggest that innovating without sustainability consideration is no longer a strong competitive priority for firms. Thus, we propose that the sustainable product innovation (as a result of interaction between sustainability and innovation) is emerging as a competitive priority in practice. In this regard, the environmental (green/eco) product innovation is well-studied in the literature [107,108,109]. However, we argue that the social product innovations also turn out to be a business priority [110]. Accordingly, we suggest further research extending the debate of social product innovations as a business priority. The results, suggesting that the innovation priorities do not directly impact sustainability priorities, imply the fact that firms should anticipate sustainability priorities over innovation priorities.

Second, looking at the adoption of action programs, the results of our study confirm on a wider scale the positive correlation between sustainability and innovation action programs [9]. Therefore, we argue that the adoption of sustainability and innovation action programs positively and significantly impacts one another [53]; because coordination programs for product innovation include organizational integration (and cross-functional teams), which in return would enhance the adoption of sustainability programs, (e.g., [50,111,112]). Moreover, the coordination programs for product innovation enhance the employee involvement which in return is a critical element for implementing sustainability programs [51,87,92,113,114,115]. Pagell and Wu contributed to this debate by arguing that innovative firms leverage their ability to generate beneficial information, which supports establishing new sustainability programs [52]. To conclude, our results confirm many case-based studies arguing that innovative firms integrating innovation with manufacturing processes allow businesses to face fewer obstacles to the operational processes of implementing sustainability programs and are better equipped to cope with the challenges [53,54].

To conclude, the adoption of innovation coordination programs enhances the adoption and implementation of sustainability programs [7,30,52,54,116]. However, the majority of the above studies focuses on environmental programs. This study shows that innovation programs act as a predictor also for social sustainability management ([116], based on case data). This preliminary evidence call for further empirical investigation on the relationship between innovation and social sustainability programs may be from the process innovation perspective [54].

This study also shows the significant impact of the adoption of sustainability programs on innovation programs, which has been rarely investigated [117]. This finding can be justified as sustainability is proposed to be a facilitator of the product design integration [117]. Alternatively, the implementation of sustainability programs is argued to be more than just a technical process and also requires organizational redesign [118,119]. Moreover, it is argued that through adopting sustainability programs (e.g., certifications), firms can establish innovative technologies [119].

Finally, this study contributes to the literature on the interrelationship between sustainability and innovation performance, (e.g., [6,83,97,98]). The results demonstrate the positive and significant correlation of these two performance dimensions. Thus, we argue that organizations with higher sustainability performance are more innovative and vice versa [120]. Accordingly, plants that simultaneously pursue exploratory innovative programs and exploitative sustainability programs are able to enhance sustainability in existing systems and are able to develop new products [17]. This is aligned with previous scholars suggesting that innovative companies perform best at sustainability [7,52]. Gualandris and Kalchschmidt contributed to this debate by suggesting that high innovation performance may not be sufficient to guarantee high sustainability performance, but its absence may hinder it [53]. Our results, based on large-scale and multi-national empirics, confirm that innovation is not only critical for operational performances (e.g., cost and/or quality), but also it is valuable for environmental and social benefits.

We believe this study drives several valuable contributions: first, we analyze the bidirectional impact of sustainability and innovation; second, by considering both environmental and social perspectives of sustainability, as well as the performances of sustainability and innovation (we are not aware of any clear test that simultaneously does so), so filling a gap in the existing literature. In addition, by scrutinizing the impact of sustainability performance on innovation performance, we propose a new area where enhancing sustainability performance is paid back to the firms.

The paper provides managers with clear evidence of the necessity for sustainability as a priority and endeavors for enhanced innovation at the operational level. Moreover, the study proposes new foundations in further understanding the determinants for sustainable development and innovation. It can support firms to implement sustainability action programs within their operational processes by empirically analyzing how innovation, and in particular, innovation coordination programs, can increase environmental and social sustainability performance.

While this study provides a compelling contribution to the sustainability and innovation literature and possesses valuable implications for practice, there are some limitations and opportunities for future studies. First, the applied measurement items to measure environmental, social and innovation as the priority, program and performance may be considered as a limitation of this study, since the team was required to keep the IMSS questionnaire to a reasonable length, which made the researchers select only the most relevant items. Thus, we suggest using different measurements. Moreover, since sustainability and innovation interlinks evolve over time, examining the patterns in a longitudinal study will be advantageous. Future studies can also extend this paper’s scope by considering other industries. Moreover, we suggest future research to investigate possible differences between plants placed in various continents when it comes to sustainable development and innovation management. Finally, innovation measurements in this study are limited to new product developments, while future research needs to take into account other taxonomies of innovation, including new processes, management systems or business models.

Acknowledgments

This paper is produced as part of the Erasmus Mundus Joint Doctorates (EMJDs) Programme, European Doctorate in Industrial Management (EDIM), funded by the European Commission, Erasmus Mundus Action 1. For their enormous effort in gathering the data, we acknowledge all members of the IMSS project, sixth version.

Author Contributions

All authors have designed the research and conclusions. Both authors contributed to performing the IMSS project as part of the Politecnico di Milano group, with Raffaella Cagliano as the main contributor. Sarah Behnam was the main contributor in reviewing the literature and analyzing the data. Raffaella Cagliano guided the paper editing. All authors read and approved the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- WCED (World Commission on Environment and Development), United Nations. Our Common Future; World Commission on Environment and Development Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century; Capstone Publishing Ltd.: Oxford, UK, 1997. [Google Scholar]

- Kleindorfer, P.R.; Kalyan, S.; Luk, N.W. Sustainable operations management. Prod. Oper. Manag. 2005, 14, 482–492. [Google Scholar] [CrossRef]

- McKenzie, S. Social Sustainability: Towards Some Definitions; Hawke Research Institute: Magill, Australia, 2004. [Google Scholar]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Cagliano, R.; Golini, R.; Longoni, A. The Role of NFWO in Sustainability Strategies: An OM Perspective; Sousa, R., Ed.; Catholic University of Portugal: Porto, Portugal, 2010; pp. 1–10. [Google Scholar]

- Nidumolu, R.; Prahalad, C.K.; Rangaswami, M.R. Why sustainability is now the key driver of innovation. Harv. Bus. Rev. 2009, 87, 56–64. [Google Scholar]

- De Medeiros, J.F.; Ribeiro, J.L.D.; Cortimiglia, M.N. Success factors for environmentally sustainable roduct innovation: A systematic literature review. J. Clean. Prod. 2014, 65, 76–86. [Google Scholar] [CrossRef]

- Gmelin, H.; Seuring, S. Determinants of a sustainable new product development. J. Clean. Prod. 2014, 69, 1–9. [Google Scholar] [CrossRef]

- Schumpeter, J.A. Business Cycles; McGraw-Hill: New York, NY, USA, 1939; Volume 1. [Google Scholar]

- Harper, S.M.; Selwyn, W.B. On the leading edge of innovation: A comparative study of innovation practices. South. Bus. Rev. 2004, 29, 1. [Google Scholar]

- Kemp, R.; Peter, P. Measuring Eco-Innovation; United Nations University: Maastricht, The Netherlands, 2008. [Google Scholar]

- Seebode, D.; Sally, J.; John, B. Managing innovation for sustainability. R&D Manag. 2012, 42, 195–206. [Google Scholar]

- Hansen, E.G.; Friedrich, G.-D.; Ralf, R. Sustainability innovation cube—A framework to evaluate sustainability-oriented innovations. Int. J. Innov. Manag. 2009, 13, 683–713. [Google Scholar] [CrossRef]

- Noci, G.; Verganti, R. Managing ‘green’ product innovation in small firms. R&D Manag. 1999, 29, 3–15. [Google Scholar]

- Adamczyk, S.; Hansen, E.G.; Reichwald, R. Measuring Sustainability by Environmental Innovativeness: Results from Action Research at a Multinational Corporation in Germany. In Proceedings of the International Conference and Doctoral Consortium on Evaluation Metrics of Corporate Social and Environmental Responsibility, Lyon, France, 8–10 June 2009.

- Maletic, M.; Maletic, D.; Dahlgaard, J.J.; Dahlgaard-Park, S.M.; Gomiscek, B. Sustainability exploration and sustainability exploitation: From a literature review towards a conceptual framework. J. Clean. Prod. 2014, 79, 182–194. [Google Scholar] [CrossRef]

- Schaltegger, S.; Beckmann, M.; Hansen, E.G. Transdisciplinarity in corporate sustainability: Mapping the field. Bus. Strategy Environ. 2013, 22, 219–229. [Google Scholar] [CrossRef]

- Pujari, D. Eco-innovation and new product development: Understanding the influences on market performance. Technovation 2006, 26, 76–85. [Google Scholar] [CrossRef]

- Pagell, M.; David, G. How plant managers’ experiences and attitudes toward sustainability relate to operational performance. Prod. Oper. Manag. 2009, 18, 278–299. [Google Scholar] [CrossRef]

- Hart, S.L.; Sharma, S. Engaging fringe stakeholders for competitive imagination. Acad. Manag. Executive 2004, 18, 7–18. [Google Scholar] [CrossRef]

- Hockerts, K.; Morsing, M. A Literature Review on Corporate Social Responsibility in the Innovation Process; Center for Corporate Social Responsibility, Copenhagen Business School (CBS): Frederiksberg, Denmark, 2008; pp. 1–28. [Google Scholar]

- De Burgos, J.J.; Jose, J.C.L. Environmental performance as an operations objective. Int. J. Oper. Prod. Manag. 2001, 21, 1553–1572. [Google Scholar] [CrossRef]

- Porter, M.; Kramer, M.R. The link between competitive advantage and corporate social responsibility. Harv. Bus. Rev. 2006, 84, 1–24. [Google Scholar]

- McKinsey Global Institute. The Business of Sustainability; McKinsey Global Institute: New York, NY, USA, 2013. [Google Scholar]

- May, G.; Taisch, M.; Kerga, E. Assessment of sustainable practices in new product development. In IFIP International Conference on Advances in Production Management Systems; Springer: Berlin/Heidelberg, Germany, 2011; pp. 437–447. [Google Scholar]

- Hart, S.L. Beyond greening: Strategies for a sustainable world. Harv. Bus. Rev. 1997, 75, 66–76. [Google Scholar]

- Preuss, L. Contribution of purchasing and supply management to ecological innovation. Int. J. Innov. Manag. 2007, 11, 515–537. [Google Scholar] [CrossRef]

- Martina, B.-K.; Hussain, S.S. Innovation and corporate sustainability: An investigation into the process of change in the pharmaceuticals industry. Bus. Strategy Environ. 2001, 10, 300. [Google Scholar]

- Porter, M.E. Towards a dynamic theory of strategy. Strateg. Manag. J. 1991, 12, 95–117. [Google Scholar] [CrossRef]

- Porter, M.E.; Van der Linde, C. Toward a new conception of the environment-competitiveness relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Bos-Brouwers, H.E.J. Corporate sustainability and innovation in SMEs: Evidence of themes and activities in practice. Bus. Strategy Environ. 2010, 19, 417–435. [Google Scholar] [CrossRef]

- Hall, J. Environmental innovation (Editorial). J. Clean. Prod. 2003, 11, 343–346. [Google Scholar] [CrossRef]

- Hart, S.L.; Mark, B.M. Global sustainability and the creative destruction of industries. MIT Sloan Manag. Rev. 1999, 41, 23. [Google Scholar]

- Westley, F.; Harrie, V. Interorganizational collaboration and the preservation of global biodiversity. Organ. Sci. 1997, 8, 381–403. [Google Scholar] [CrossRef]

- Adams, R.; Jeanrenaud, S.; Besant, J.; Denyer, D.; Overy, P. Sustainability-oriented innovation: A systematic review. Int. J. Manag. Rev. 2015, 18, 180–205. [Google Scholar] [CrossRef]

- Steiner, G. Supporting sustainable innovation through stakeholder management: A systems view. Int. J. Innov. Learn. 2008, 5, 595–616. [Google Scholar] [CrossRef]

- Pujari, D.; Wright, G.; Peattie, K. Green and competitive: Influences on environmental new product development performance. J. Bus. Res. 2003, 56, 657–671. [Google Scholar] [CrossRef]

- Longoni, A.; Cagliano, R. Environmental and social sustainability priorities: Their integration in operations strategies. Int. J. Oper. Prod. Manag. 2015, 35, 216–245. [Google Scholar] [CrossRef]

- Gomez-Conde, J. Examining the link between outsourcing and performance: The leverage effect of the interactive use of management accounting and control systems. Span. J. Financ. Account./Rev. Esp. Financ. Contab. 2015, 44, 298–325. [Google Scholar] [CrossRef]

- Longoni, A.; Golini, R.; Cagliano, R. The role of New Forms of Work Organization in developing sustainability strategies in operations. Int. J. Prod. Econ. 2014, 147, 147–160. [Google Scholar] [CrossRef]

- Quesada, G.; Rachamadugu, R.; Gonzalez, M.; Luis Martinez, J. Linking order winning and external supply chain integration strategies. Supply Chain Manag. 2008, 13, 296–303. [Google Scholar] [CrossRef]

- Van Kleef, J.A.G.; Roome, N.J. Developing capabilities and competence for sustainable business management as innovation: A research agenda. J. Clean. Prod. 2007, 15, 38–51. [Google Scholar] [CrossRef]

- Biondi, V.; Iraldo, F.; Meredith, S. Achieving sustainability through environmental innovation: The role of SMEs. Int. J. Technol. Manag. 2002, 24, 612–626. [Google Scholar] [CrossRef]

- Alblas, A.A.; Peters, K.; Wortmann, J.C. Fuzzy sustainability incentives in new product development: An empirical exploration of sustainability challenges in manufacturing companies. Int. J. Oper. Prod. Manag. 2014, 34, 513–545. [Google Scholar] [CrossRef]

- Endris, K.; Marco, T.; Sergio, T.; Gokan, M. Integration of sustainability in NPD process: Italian Experiences. In Proceedings of the IFIP WG 5.1 8th International Conference on Product lifecycle Management (PLM2011), Eindhoven, The Netherlands, 11–13 July 2011.

- Fish, L. Recommendations for Implementing Sustainability in New Product Development for Supply Chain Management; Business Research Consortium of Western New York: New York, NY, USA, 2015; p. 119. [Google Scholar]

- Schaltegger, S.; Marcus, W. Managing the Business Case for Sustainability; Greenleaf Publishing: Sheffield, UK, 2006. [Google Scholar]

- Wagner, M.; Schaltegger, S. How does sustainability performance relate to business competitiveness? Greener Manag. Int. 2003, 44, 5–16. [Google Scholar] [CrossRef]

- Koufteros, X.A.; Nahm, A.Y.; Edwin Cheng, T.C.; Lai, K. An empirical assessment of a nomological network of organizational design constructs: From culture to structure to pull production to performance. Int. J. Prod. Econ. 2007, 106, 468–492. [Google Scholar] [CrossRef]

- Hanna, M.D.; Newman, W.R.; Pamela, J. Linking operational and environmental improvement through employee involvement. Int. J. Oper. Prod. Manag. 2000, 20, 148–165. [Google Scholar] [CrossRef]

- Pagell, M.; Wu, Z. Building a more complete theory of sustainable supply chain management using case studies of 10 exemplars. J. Supply Chain Manag. 2009, 45, 37–56. [Google Scholar] [CrossRef]

- Gualandris, J.; Kalchschmidt, M. Customer pressure and innovativeness: Their role in sustainable supply chain management. J. Purch. Supply Manag. 2014, 20, 92–103. [Google Scholar] [CrossRef]

- Christmann, P. Effects of “best practices” of environmental management on cost advantage: The role of complementary assets. Acad. Manag. J. 2000, 43, 663–680. [Google Scholar] [CrossRef]

- Schaltegger, S.; Marcus, W. Managing the business case for sustainability. In Proceedings of the EMAN-EU 2008 Conference, Budapest, Hungary, 6–7 October 2008; Volume 7.

- Wagner, M.; Schaltegger, S.; Wehrmeyer, W. The relationship between the environmental and economic performance of firms: What does theory propose and what does empirical evidence tell us? Greener Manag. Int. 2001, 34, 95–108. [Google Scholar] [CrossRef]

- Totterdell, P.; Leach, D.; Birdi, K.; Clegg, C.; Wall, T. An investigation of the contents and consequences of major organizational innovations. Int. J. Innov. Manag. 2002, 6, 343–368. [Google Scholar] [CrossRef]

- Zhang, Q.; Doll, W.J. The fuzzy front end and success of new product development: A causal model. Eur. J. Innov. Manag. 2001, 4, 95–112. [Google Scholar] [CrossRef]

- Ottman, J.A. Green Marketing: Challenges and Opportunities; NTC Business Books: Linclonwood, IL, USA, 1994. [Google Scholar]

- Pujari, D.; Wright, G. Integrating environmental issues into product development: Understanding the dimensions of perceived driving forces. J. Eur. Mark. 1999, 7, 43–63. [Google Scholar] [CrossRef]

- Pujari, D.; Wright, G. Management of environmental new product development in charter. In Greener Marketing, 2nd ed.; Charter, M., Polonsky, M., Eds.; Greenleaf Publishing: London, UK, 1999. [Google Scholar]

- Charter, M. Sustainable Consumption & Production, Business and Innovation. In Perspectives on Radical Changes to Sustainable Consumption and Production (SCP); Sustainable Consumption Research Exchange: Copenhagen, Denmark, 2006; Volume 20, p. 243. [Google Scholar]

- Boons, F.; Montalvo, C.; Quist, J.; Wagner, M. Sustainable innovation, business models and economic performance: An overview. J. Clean. Prod. 2013, 45, 1–8. [Google Scholar] [CrossRef]

- Searcy, C. Corporate sustainability performance measurement systems: A review and research agenda. J. Bus. Ethics 2012, 107, 239–253. [Google Scholar] [CrossRef]

- Crowe, D.; Brennan, L. Environmental considerations within manufacturing strategy: An international study. Bus. Strategy Environ. 2007, 16, 266–289. [Google Scholar] [CrossRef]

- Van de Vijver, F.J.R.; Kwok, L. Methods and Data Analysis for Cross-Cultural Research; Sage: Riverside County, CA, USA, 1997; Volume 1. [Google Scholar]

- Szwejczewski, M.; Mapes, J.; New, C. Delivery and trade-offs. Int. J. Prod. Econ. 1997, 53, 323–330. [Google Scholar] [CrossRef]

- Lindberg, P.; Voss, C.A.; Blackmon, K. International Manufacturing Strategies. Context, Content, and Change; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1998. [Google Scholar]

- Conway, J.M.; Charles, E.L. What reviewers should expect from authors regarding common method bias in organizational research. J. Bus. Psychol. 2010, 25, 325–334. [Google Scholar] [CrossRef]

- Chang, S.J.; Van Witteloostuijn, A.; Eden, L. From the editors: Common method variance in international business research. J. Int. Bus. Stud. 2010, 41, 178–184. [Google Scholar] [CrossRef]

- Malhotra, N.K.; Kim, S.S.; Patil, A. Common method variance in IS research: A comparison of alternative approaches and a reanalysis of past research. Manag. Sci. 2006, 52, 1865–1883. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behaveral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Nunnally, J. Psychometric Methods; McGraw-Hill: New York, NY, USA, 1978. [Google Scholar]

- Widener, S.K. An empirical analysis of the levers of control framework. Account. Organ. Soc. 2007, 32, 757–788. [Google Scholar] [CrossRef]

- Downey, R.G.; King, C.V. Missing data in Likert ratings: A comparison of replacement methods. J. Gen. Psychol. 1998, 125, 175–191. [Google Scholar] [CrossRef] [PubMed]

- West, S.G.; Finch, J.F.; Curran, P.J. Structural Equation Models with Nonnormal Variables: Problems and Remedies; Sage Publications: Riverside County, CA, USA, 1995. [Google Scholar]

- Maxwell, D.; van der Vorst, R. Developing sustainable products and services. J. Clean. Prod. 2003, 11, 883–895. [Google Scholar] [CrossRef]

- Gritti, P.; Leoni, R. High Performance Work Practices, Industrial Relations and Firm Propensity for Innovation. In Advances in the Economic Analysis of Participatory and Labor-Managed Firms; Bryson, A., Ed.; Emerald Group Publishing Limited: Bingley, UK, 2012; Volume 13, pp. 267–309. [Google Scholar]

- Hult, G.; Tomas, M.; Robert, F.H.; Gary, A.K. Innovativeness: Its Antecedents and Impact on Business Performance. Ind. Mark. Manag. 2004, 33, 429–438. [Google Scholar] [CrossRef]

- Jay, S.K.; Peter, A. Manufacturing Competence and Business Performance: A Framework and Empirical Analysis. Int. J. Oper. Prod. Manag. 1993, 13, 4–25. [Google Scholar]

- Bisbe, J.; Otley, D. The effects of the interactive use of management control systems on product innovation. Account. Organ. Soc. 2004, 29, 709–737. [Google Scholar] [CrossRef]

- Miller, J.; Roth, A. A taxonomy of manufacturing strategies. Manag. Sci. 1994, 40, 285–304. [Google Scholar] [CrossRef]

- Zhu, Q.; Joseph, S. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Zhu, Q.; Joseph, S.; Kee-hung, L. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Berkhout, F.; Verbong, G.; Wieczorek, A.J.; Raven, R.; Lebel, L.; Bai, X. Sustainability experiments in Asia: Innovations shaping alternative development pathways? Environ. Sci. Policy 2010, 13, 261–271. [Google Scholar] [CrossRef]

- Klassen, R.D.; Whybark, D.C. The Impact of Environmental Technologies on Manufacturing Performance. Acad. Manag. J. 1999, 42, 599–615. [Google Scholar] [CrossRef]

- Kitazawa, S.; Sarkis, J. The relationship between ISO 14001 and continuous source reduction programs. Int. J. Oper. Prod. Manag. 2000, 20, 225–248. [Google Scholar] [CrossRef]

- Russo, M.V. Explaining the impact of ISO 14001 on emission performance: A Dynamic Capabilities Perspective on process learning. Bus. Strategy Environ. 2009, 18, 307–319. [Google Scholar] [CrossRef]

- Sarkis, J. Evaluating environmentally conscious business practices. Eur. J. Oper. Res. 1998, 107, 159–174. [Google Scholar] [CrossRef]

- Florida, R. Lean and green: The move to environmentally conscious manufacturing. Calif. Manag. Rev. 1996, 39, 80–105. [Google Scholar] [CrossRef]

- Longo, M.; Mura, M.; Bonoli, A. Corporate Social Responsibility and Corporate Performance: The Case of Italian SMEs. Corp. Gov. 2005, 5, 28–42. [Google Scholar] [CrossRef]

- Daily, B.F.; Huang, S. Achieving sustainability through attention to human resource factors in environmental management. Int. J. Oper. Prod. Manag. 2001, 21, 1539–1552. [Google Scholar] [CrossRef]

- Pullman, M.E.; Michael, J.M.; Craig, R.C. Food for thought: Social versus environmental sustainability practices and performance outcomes. J. Supply Chain Manag. 2009, 45, 38–54. [Google Scholar] [CrossRef]

- Paashuis, V.; Boer, H. Organizing for concurrent engineering: An integration mechanism framework. Integr. Manuf. Syst. 1997, 8, 79–89. [Google Scholar] [CrossRef]

- Boer, H.E.; Boer, H. Modularization, inter-functional integration and operational performance. In Proceedings of the 15th International CINet Conference on Operating Innovation—Innovating Operations. Continuous Innovation Network (CINet), Budapest, Hungary, 7–9 September 2014.

- Boer, H.; Kuhn, J.; Gertsen, F. Continuous innovation: Managing dualities through co-ordination. In Continuous Innovation Network; CiteseerX: Princeton, NJ, USA, 2006. [Google Scholar]

- Rao, P. Greening the supply chain: A new initiative in South East Asia. Int. J. Oper. Prod. Manag. 2002, 22, 632–655. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Efeoglu, A.; Moller, C.; Serie, M. Corporate Innovation Management Framework Based on Design Thinking. In Proceedings of the International CINet Conference on Operating Innovation—Innovating Operations, Budapest, Hungary, 7–9 September 2014.

- Anderson, J.C.; Gerbing, D.W. Structural equation modeling in practice: A review and recommended two-step approach. Psychol. Bull. 1998, 103, 411. [Google Scholar] [CrossRef]

- Byrne, B.M. Structural equation modeling with AMOS, EQS, and LISREL: Comparative approaches to testing for the factorial validity of a measuring instrument. Int. J. Test. 2001, 1, 55–86. [Google Scholar] [CrossRef]

- Hoe, S.L. Issues and procedures in adopting structural equation modeling technique. J. Appl. Quant. Methods 2008, 3, 76–83. [Google Scholar]

- Schreiber, J.B.; Nora, A.; Stage, F.K.; Barlow, E.A.; King, J. Reporting structural equation modeling and confirmatory factor analysis results: A review. J. Educ. Res. 2006, 99, 323–338. [Google Scholar] [CrossRef]

- Dell’Anno, R.; Schneider, F. A complex approach to estimate shadow economy: The structural equation modelling. In Coping with the Complexity of Economics; Springer: Milan, Italy, 2009; pp. 111–130. [Google Scholar]

- Arbuckle, J.G.; James, M.A.; Miller, M.L.; Sullivan, T.F. Environmental Law Handbook; Government Institutes, Inc.: Washington, DC, USA, 1976.

- Brownell, F.W.; Case, D.R.; Cardwell, R.E. Environmental Law Handbook; Government Institutes: Washington, DC, USA, 2011.

- Dangelico, R.M.; Pujari, D. Mainstreaming green product innovation: Why and how companies integrate environmental sustainability. J. Bus. Ethics 2010, 95, 471–486. [Google Scholar] [CrossRef]

- Rennings, K. Redefining innovation—Eco-innovation research and the contribution from ecological economics. Ecol. Econ. 2000, 32, 319–332. [Google Scholar] [CrossRef]

- Carrillo-Hermosilla, J.; del Gonzalez, P.R.; Konnola, T. What is eco-innovation? In Eco-Innovation; Palgrave Macmillan: London, UK, 2009; pp. 6–27. [Google Scholar]

- Piller, F.T.; Vossen, A.; Ihl, C. From social media to social product development: The impact of social media on co-creation of innovation. Die Unternehm. 2012, 65, 1. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Myers, M.B. Product and employee development in advanced manufacturing: Implementation and impact. Int. J. Prod. Res. 2001, 39, 65–79. [Google Scholar] [CrossRef]

- Russo, M.V.; Paul, A.F. A resource-based perspective on corporate environmental performance and profitability. Acad. Manag. J. 1997, 40, 534–559. [Google Scholar] [CrossRef]

- Bunge, J.; Edward, C.-R.; Antonio, R.-Q. Employee participation in pollution reduction: Preliminary analysis of the Toxics Release Inventory. J. Clean. Prod. 1996, 4, 9–16. [Google Scholar] [CrossRef]

- Hui, I.K.; Alan, H.S.C.; Pun, K.F. A study of the environmental management system implementation practices. J. Clean. Prod. 2001, 9, 269–276. [Google Scholar] [CrossRef]

- Daily, B.F.; James, W.B.; Robert, S. The mediating role of EMS teamwork as it pertains to HR factors and perceived environmental performance. J. Appl. Bus. Res. 2011, 23. [Google Scholar] [CrossRef]

- Klassen, R.D.; Ann, V. Social issues in supply chains: Capabilities link responsibility, risk (opportunity), and performance. Int. J. Prod. Econ. 2012, 140, 103–115. [Google Scholar] [CrossRef]

- Hong, P.; Kwon, H.B.; Jungbae Roh, J. Implementation of strategic green orientation in supply chain: An empirical study of manufacturing firms. Eur. J. Innov. Manag. 2009, 12, 512–532. [Google Scholar] [CrossRef]

- Mohrman, S.A.; Worley, C.G. The organizational sustainability journey: Introduction to the special issue. Organ. Dyn. 2010, 4, 289–294. [Google Scholar] [CrossRef]

- Golini, R.; Longoni, A.; Cagliano, R. Developing sustainability in global manufacturing networks: The role of site competence on sustainability performance. Int. J. Prod. Econ. 2014, 147, 448–459. [Google Scholar] [CrossRef]

- He, Z.-L.; Wong, P.-K. Exploration vs. exploitation: An empirical test of the ambidexterity hypothesis. Organ. Sci. 2004, 15, 481–494. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).