Application of TLS Method in Digitization of Bridge Infrastructures: A Path to BrIM Development

Abstract

:1. Introduction

Aims and Objectives

- Provide a practical methodology for generating a TLS-derived BrIM.

- Elaborate the process to generate a quantitative bridge point cloud using TLS.

- Provide a novel slicing-based method to extract a precise geometric 3D CAD model from the captured bridge point cloud.

- Prove the soundness of the proposed methods in form of a real bridge case study and validating the outcomes by comparing the quality of TLS data, CAD model versus the as-designed CAD drawings, and illustrating the outcome as a BrIM.

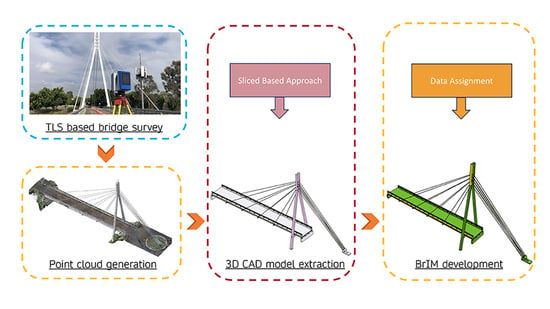

2. TLS-Derived BrIM Methodology

2.1. TLS-Based Bridge Survey and Post-Processing

2.2. Geometric 3D CAD Model Extraction

Point Cloud Slice-Based Approach

2.3. BrIM Development

3. Bridge Case Study

Site Survey and Data Acquisition

4. Results

4.1. Werrington Bridge Point Cloud Generation

4.2. Quality Evaluation of the Generated Point Cloud

4.2.1. Surface Deviation Analysis

4.2.2. Relative Geometric Accuracy Evaluation

4.3. Werrington Bridge 3D CAD Model Extraction

4.4. Werrington Bridge BrIM and Designed Plugin

5. Discussion and Future Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shojaeddin, J. Assessing Load Carrying Capacity of Existing Bridges Using SHM Techniques. Ph.D. Thesis, Queensland University of Technology, Queensland, Australia, 2019. [Google Scholar]

- Wan, C.; Zhou, Z.; Li, S.; Ding, Y.; Xu, Z.; Yang, Z.; Xia, Y.; Yin, F. Development of a Bridge Management System Based on the Building Information Modeling Technology. Sustainability 2019, 11, 4583. [Google Scholar] [CrossRef] [Green Version]

- Horgan, R. Fatal Taiwan Bridge Collapse Is Latest Example of Maintenance Failings. Available online: https://www.newcivilengineer.com/latest/fatal-taiwan-bridge-collapse-is-latest-example-of-maintenance-failings-07-10-2019 (accessed on 22 February 2022).

- Calvi, G.M.; Moratti, M.; O’Reilly, G.J.; Scattarreggia, N.; Monteiro, R.; Malomo, D.; Calvi, P.M.; Pinho, R. Once upon a Time in Italy: The Tale of the Morandi Bridge. Struct. Eng. Int. 2019, 29, 198–217. [Google Scholar] [CrossRef]

- Puž, G.; Radić, J.; Tenžera, D. Visual inspection in evaluation of bridge condition. Građevinar 2012, 64, 717. [Google Scholar] [CrossRef]

- Moore, M.; Phares, B.M.; Graybeal, B.; Rolander, D.; Washer, G. Reliability of Visual Inspection for Highway Bridges, Volume I: Final Report; U.S. Department of Transporation, Federal Highway Administration: Washington, DC, USA, 2001. [Google Scholar]

- Dorafshan, S.; Maguire, M. Bridge inspection: Human performance, unmanned aerial systems and automation. J. Civ. Struct. Health Monit. 2018, 8, 443–476. [Google Scholar] [CrossRef] [Green Version]

- Roads and Traffic Authority of New South Wales. Bridge Inspection Procedure Manual. 2007. Available online: https://roads-waterways.transport.nsw.gov.au/business-industry/partners-suppliers/document-types/guides-manuals/bridge-inspection.html (accessed on 22 February 2022).

- Rashidi, M.; Hoshyar, A.N.; Smith, L.; Bijan, S.; Siddique, R. A comprehensive taxonomy for structure and material deficiencies, preventions and remedies of timber bridges. J. Build. Eng. 2021, 34, 101624. [Google Scholar] [CrossRef]

- Rashidi, M.; Ghodrat, M.; Samali, B.; Kendall, B.; Zhang, C. Remedial Modelling of Steel Bridges through Application of Analytical Hierarchy Process (AHP). Appl. Sci. 2017, 7, 168. [Google Scholar] [CrossRef] [Green Version]

- Javidan, M.M.; Kim, J. Fuzzy-based method for efficient seismic performance evaluation of structures with uncertainty. Comput.-Aided Civ. Infrastruct. Eng. 2021, 1–22. [Google Scholar] [CrossRef]

- Gorji Azandariani, M.; Rousta, A.M.; Mohammadi, M.; Rashidi, M.; Abdolmaleki, H. Numerical and analytical study of ultimate capacity of steel plate shear walls with partial plate-column connection (SPSW-PC). Structures 2021, 33, 3066–3080. [Google Scholar] [CrossRef]

- Waheed, U.; Hudson, W.R.; Ralph, H. Public Infrastructure Asset Management, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Sabrie, S. Sensors Handbook, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2010. [Google Scholar]

- O’Brien, E.; Carey, C.; Keenahan, J. Bridge damage detection using ambient traffic and moving force identification. Struct. Control. Health Monit. 2015, 22, 1396–1407. [Google Scholar] [CrossRef] [Green Version]

- Azim, M.R.; Gül, M. Damage Detection of Steel-Truss Railway Bridges Using Operational Vibration Data. J. Struct. Eng. 2020, 146, 04020008. [Google Scholar] [CrossRef]

- Pourzeynali, S.; Zhu, X.; Ghari Zadeh, A.; Rashidi, M.; Samali, B. Comprehensive Study of Moving Load Identification on Bridge Structures Using the Explicit Form of Newmark-β Method: Numerical and Experimental Studies. Remote Sens. 2021, 13, 2291. [Google Scholar] [CrossRef]

- Yu, Y.; Rashidi, M.; Samali, B.; Mohammadi, M.; Nguyen, T.N.; Zhou, X. Crack detection of concrete structures using deep convolutional neural networks optimized by enhanced chicken swarm algorithm. Struct. Health Monit. 2022. [Google Scholar] [CrossRef]

- Patch, G. Chapter 11—Software Design and Development. In Developing and Managing Embedded Systems and Products; Fowler, K.R., Silver, C.L., Eds.; Newnes: Oxford, UK, 2015; pp. 469–514. [Google Scholar]

- Nicolle, C.; Cruz, C. Semantic Building Information Model and Multimedia for Facility Management. In International Conference on Web Information Systems and Technologies; Springer: Berlin/Heidelberg, Germany, 2011; pp. 14–29. [Google Scholar]

- Chan, B.; Guan, H.; Hou, L.; Jo, J.; Blumenstein, M.; Wang, J. Defining a conceptual framework for the integration of modelling and advanced imaging for improving the reliability and efficiency of bridge assessments. J. Civil. Struct. Health Monit. 2016, 6, 703–714. [Google Scholar] [CrossRef] [Green Version]

- McGuire, B.; Atadero, R.; Clevenger, C.; Ozbek, M. Bridge Information Modeling for Inspection and Evaluation. J. Bridge Eng. 2016, 21, 04015076. [Google Scholar] [CrossRef]

- Barazzetti, L. Parametric as-built model generation of complex shapes from point clouds. Adv. Eng. Inform. 2016, 30, 298–311. [Google Scholar] [CrossRef]

- Brilakis, I.; Lourakis, M.; Sacks, R.; Savarese, S.; Christodoulou, S.; Teizer, J.; Makhmalbaf, A. Toward automated generation of parametric BIMs based on hybrid video and laser scanning data. Adv. Eng. Inform. 2010, 24, 456–465. [Google Scholar] [CrossRef]

- Rashidi, M.; Mohammadi, M.; Sadeghlou Kivi, S.; Abdolvand, M.M.; Truong-Hong, L.; Samali, B. A Decade of Modern Bridge Monitoring Using Terrestrial Laser Scanning: Review and Future Directions. Remote Sens. 2020, 12, 3796. [Google Scholar] [CrossRef]

- Gyetvai, N.; Truong-Hong, L.; Laefer, D.F. Laser Scan-Based Structural Assessment of Wrought Iron Bridges: Guinness Bridge, Ireland. Proc. Inst. Civ. Eng.-Eng. Hist. Herit. 2018, 171, 76–89. [Google Scholar] [CrossRef] [Green Version]

- Lubowiecka, I.; Armesto, J.; Arias, P.; Lorenzo, H. Historic bridge modelling using laser scanning, ground penetrating radar and finite element methods in the context of structural dynamics. Eng. Struct. 2009, 31, 2667–2676. [Google Scholar] [CrossRef]

- Wilford, W. Introduction to Mid-Range Terrestrial Laser Scanning. APT Bull. J. Preserv. Technol. 2020, 51, 1–46. [Google Scholar]

- Spring, A.P. History of Laser Scanning, Part 2: The Later Phase of Industrial and Heritage Applications. Photogramm. Eng. Remote Sens. 2020, 86, 479–501. [Google Scholar] [CrossRef]

- Tang, P.; Akinci, B.; Garrett, J. Laser Scanning for Bridge Inspection and Management. In Proceedings of the IABSE Symposium: Improving Infrastructure Worldwide, Weimar, Germany, 19–21 September 2007; pp. 17–24. [Google Scholar]

- Miśkiewicz, M.; Daszkiewicz, K.; Lachowicz, J.; Tysiac, P.; Jaskula, P.; Wilde, K. Nondestructive methods complemented by FEM calculations in diagnostics of cracks in bridge approach pavement. Autom. Constr. 2021, 128, 103753. [Google Scholar] [CrossRef]

- Artese, S.; Zinno, R. TLS for Dynamic Measurement of the Elastic Line of Bridges. Appl. Sci. 2020, 10, 1182. [Google Scholar] [CrossRef] [Green Version]

- Chen, S. Laser Scanning Technology for Bridge Monitoring; IntechOpen: London, UK, 2012. [Google Scholar]

- Stull, C.J.; Earls, C. A rapid assessment methodology for bridges damaged by truck strikes. Steel Compos. Struct. 2009, 9, 223–237. [Google Scholar] [CrossRef]

- Pérez, J.P.C.; De Sanjosé Blasco, J.J.; Atkinson, A.D.J.; Del Río Pérez, L.M. Assessment of the Structural Integrity of the Roman Bridge of Alcántara (Spain) Using TLS and GPR. Remote Sens. 2018, 10, 387. [Google Scholar] [CrossRef] [Green Version]

- Arbi, A.; Ide, K. The application of terrestrial laser scanner surveys for detailed inspection of bridges. In Proceedings of the 7th Australian Small Bridges Conference, Melbourne, Australia, 23–24 November 2015. [Google Scholar]

- Gawronek, P.; Makuch, M.; Mitka, B.; Gargula, T. Measurements of the Vertical Displacements of a Railway Bridge Using TLS Technology in the Context of the Upgrade of the Polish Railway Transport. Sensors 2019, 19, 4275. [Google Scholar] [CrossRef] [Green Version]

- Mill, T.; Ellmann, A.; Kiisa, M.; Idnurm, J.; Idnurm, S.; Horemuz, M.; Aavik, A. Geodetic monitoring of bridge deformations occurring during static load testing. Balt. J. Road Bridge Eng. 2015, 10, 17–27. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, M.; Rashidi, M.; Mousavi, V.; Karami, A.; Yu, Y.; Samali, B. Quality Evaluation of Digital Twins Generated Based on UAV Photogrammetry and TLS: Bridge Case Study. Remote Sens. 2021, 13, 3499. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rashidi, M.; Mousavi, V.; Karami, A.; Yu, Y.; Samali, B. Case study on accuracy comparison of digital twins developed for a heritage bridge via UAV photogrammetry and terrestrial laser scanning. In Proceedings of the 10th International Conference on Structural Health Monitoring of Intelligent Infrastructure (SHMII 10), Porto, Portugal, 30 June–2 July 2021. [Google Scholar]

- Kwiatkowski, J.; Anigacz, W.; Beben, D. A Case Study on the Noncontact Inventory of the Oldest European Cast-iron Bridge Using Terrestrial Laser Scanning and Photogrammetric Techniques. Remote Sens. 2020, 12, 2745. [Google Scholar] [CrossRef]

- Gawronek, P.; Makuch, M. TLS Measurement during Static Load Testing of a Railway Bridge. ISPRS Int. J. Geo-Inf. 2019, 8, 44. [Google Scholar] [CrossRef] [Green Version]

- Tang, P.; Huber, D.; Akinci, B.; Lipman, R.; Lytle, A. Automatic reconstruction of as-built building information models from laser-scanned point clouds: A review of related techniques. Autom. Constr. 2010, 19, 829–843. [Google Scholar] [CrossRef]

- Tang, P.; Akinci, B. Automatic execution of workflows on laser-scanned data for extracting bridge surveying goals. Adv. Eng. Inform. 2012, 26, 889–903. [Google Scholar] [CrossRef]

- Tang, P.; Akinci, B. Formalization of workflows for extracting bridge surveying goals from laser-scanned data. Autom. Constr. 2012, 22, 306–319. [Google Scholar] [CrossRef]

- Kasireddy, V.; Akinci, B. Challenges in generation of as-is bridge information model: A case study. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction and Mining: Connected to the Future, Oulu, Finland, 15–18 June 2015. [Google Scholar]

- Hinks, T.; Carr, H.; Truong-Hong, L.; Laefer, D.F. Point Cloud Data Conversion into Solid Models via Point-Based Voxelization. J. Surv. Eng. 2013, 139, 72–83. [Google Scholar] [CrossRef] [Green Version]

- Bitelli, G.; Castellazzi, G.; D’Altri, A.M.; De Miranda, S.; Lambertini, A.; Selvaggi, I. Automated voxel model from point clouds for structural analysis of cultural heritage. ISPRS 2016, 41, 191–197. [Google Scholar]

- Castellazzi, G.; D’Altri, A.M.; de Miranda, S.; Ubertini, F. An innovative numerical modeling strategy for the structural analysis of historical monumental buildings. Eng. Struct. 2017, 132, 229–248. [Google Scholar] [CrossRef]

- Conde-Carnero, B.; Riveiro, B.; Arias, P.; Caamaño, J.C. Exploitation of geometric data provided by laser scanning to create FEM structural models of bridges. J. Perform. Constr. Facil. 2016, 30, 04015053. [Google Scholar] [CrossRef]

- Mehranfar, M.; Arefi, H.; Alidoost, F. Knowledge-based 3D reconstruction of bridge structures using UAV-based photogrammetric point cloud. J. Appl. Remote Sens. 2021, 15, 044503. [Google Scholar] [CrossRef]

- Truong-Hong, L.; Laefer, D.F. Laser Scanning for Bridge Inspection. In Laser Scanning: An Emerging Technology in Structural Engineering; CRC Press: Boca Raton, FL, USA, 2019; pp. 189–214. [Google Scholar]

- Heidari Mozaffar, M.; Varshosaz, M. Optimal Placement of a Terrestrial Laser Scanner with an Emphasis on Reducing Occlusions. Photogramm. Rec. 2016, 31, 374–393. [Google Scholar] [CrossRef]

- Song, M.; Shen, Z.; Tang, P. Data Quality-oriented 3D Laser Scan Planning. In Construction Research Congress 2014: Construction in a Global Network; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 984–993. [Google Scholar]

- Mahmood, S.; Majid, Z.; Idris, K.M. Terrestrial LiDAR sensor modeling towards optimal scan location and spatial density planning for 3D surveying. Appl. Geomat. 2020, 12, 467–480. [Google Scholar] [CrossRef]

- Biswas, H.K.; Bosché, F.; Sun, M. Planning for Scanning Using Building Information Models: A Novel Approach with Occlusion Handling. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction and Mining (ISARC 2015), Oulu, Finland, 15–18 June 2015; pp. 1–8. [Google Scholar]

- Jia, F.; Lichti, D.D. A Model-Based Design System for Terrestrial Laser Scanning Networks in Complex Sites. Remote Sens. 2019, 11, 1749. [Google Scholar] [CrossRef] [Green Version]

- Rebolj, D.; Pučko, Z.; Babič, N.Č.; Bizjak, M.; Mongus, D. Point cloud quality requirements for Scan-vs-BIM based automated construction progress monitoring. Autom. Constr. 2017, 84, 323–334. [Google Scholar] [CrossRef]

- Dai, F.; Rashidi, A.; Brilakis, I.; Vela, P. Comparison of Image-Based and Time-of-Flight-Based Technologies for Three-Dimensional Reconstruction of Infrastructure. J. Constr. Eng. Manag. 2013, 139, 69–79. [Google Scholar] [CrossRef]

- Genechten, B.V. Theory and Practice on Terrestrial Laser Scanning: Training Material Based on Practical Applications; Universidad Politecnica De Valencia: Valencia, Spain, 2008. [Google Scholar]

- Western Sydney University. Week 13: The Werrington South Site. Available online: https://www.westernsydney.edu.au/uws25/25_year_history/25_years_in_25_weeks/blog_posts/week_13 (accessed on 22 February 2022).

- Yang, R.; Meng, X.; Xiang, Z.; Li, Y.; You, Y.; Zeng, H. Establishment of a New Quantitative Evaluation Model of the Targets’ Geometry Distribution for Terrestrial Laser Scanning. Sensors 2020, 20, 555. [Google Scholar] [CrossRef] [Green Version]

- Zoller + Fröhlich GmbH. Z+F IMAGER® 5016, 3D Laser Scanner. Available online: https://www.zofre.de/en/laser-scanners/3d-laser-scanner/z-f-imagerr-5016 (accessed on 22 February 2022).

- Zoller + Fröhlich GmbH. Z+F LaserControl® Scout Manual; Zoller + Fröhlich GmbH Company: Wangen, Germany, 2019; Volume 9.1. [Google Scholar]

- Besl, P.J.; McKay, N.D. A method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure and Verband Der Elektrotechnik. VDI/VDE 2634 BLATT 3, Optical 3D-Measuring Systems—Multiple View Systems Based on Area Scanning; VDI: Düsseldorf, Germany, 2008. [Google Scholar]

- Mousavi, V.; Khosravi, M.; Ahmadi, M.; Noori, N.; Haghshenas, S.; Hosseininaveh, A.; Varshosaz, M. The performance evaluation of multi-image 3D reconstruction software with different sensors. Measurement 2018, 120, 1–10. [Google Scholar] [CrossRef]

- GOM Gmbh Company. Gom Inspect SUITE Software; Braunschweig, Germany, 2020. Available online: https://www.gom.com/en/products/gom-suite/gom-inspect-pro?gclid=EAIaIQobChMI_43d-Z3f8gIVSteWCh2ltQ9MEAAYAyAAEgKGd_D_BwE (accessed on 22 February 2022).

- Trimble Solutions Corporation. Tekla Structures Software. Available online: https://www.tekla.com/products/tekla-structures (accessed on 22 February 2022).

- Koch, C.; Firmenich, B. An approach to distributed building modeling on the basis of versions and changes. Adv. Eng. Inform. 2011, 25, 297–310. [Google Scholar] [CrossRef]

- Yu, Y.; Rashidi, M.; Samali, B.; Mohammadi, M.; Nguyen, A. Computer vision-based classification of cracks on concrete bridges using machine learning techniques. In Proceedings of the the 10th International Conference on Structural Health Monitoring of Intelligent Infrastructure (SHMII 10), Porto, Portugal, 30 June–2 July 2021. [Google Scholar]

- Liu, J.; Mohammadi, M.; Zhan, Y.; Zheng, P.; Rashidi, M.; Mehrabi, P. Utilizing Artificial Intelligence to Predict the Superplasticizer Demand of Self-Consolidating Concrete Incorporating Pumice, Slag, and Fly Ash Powders. Materials 2021, 14, 6792. [Google Scholar] [CrossRef]

- Rashidi, M.; Samali, B.; Sharafi, P. A new model for bridge management: Part B: Decision support system for remediation planning. Aust. J. Civ. Eng. 2016, 14, 46–53. [Google Scholar] [CrossRef] [Green Version]

- Zinno, R.; Artese, S.; Clausi, G.; Magarò, F.; Meduri, S.; Miceli, A.; Venneri, A. Structural Health Monitoring (SHM). In The Internet of Things for Smart Urban Ecosystems; Cicirelli, F., Guerrieri, A., Mastroianni, C., Spezzano, G., Vinci, A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 225–249. [Google Scholar]

| Plane | STD | Mean Absolute Error | Max Absolute Error | RMSE |

|---|---|---|---|---|

| P1-S | 1.779 | 1.059 | 12.300 | 1.453 |

| P1-N | 2.452 | 1.889 | 8.800 | 1.560 |

| P1-E | 1.765 | 1.212 | 14.700 | 1.283 |

| P1-W | 3.040 | 2.749 | 6.060 | 1.212 |

| P2-S | 2.356 | 1.793 | 7.378 | 1.529 |

| P2-N | 2.478 | 1.323 | 18.900 | 2.096 |

| P2-E | 10.386 | 7.777 | 10.294 | 6.884 |

| P2-W | 6.815 | 4.047 | 44.620 | 5.483 |

| Average | 3.883 | 2.731 | 15.381 | 2.687 |

| Cylinder | TLS | As-Designed Diameter | Measurement Absolute Error | |||

|---|---|---|---|---|---|---|

| STD | Mean Absolute Error | MAX ABSOLUTE ERROR | Diameter | |||

| Cable 1 | 1.401 | 0.912 | 14.791 | 62.822 | 60.300 | 2.522 |

| Cable 2 | 1.473 | 4.231 | 12.134 | 62.614 | 60.300 | 2.314 |

| Cable 3 | 1.102 | 2.021 | 13.231 | 62.167 | 60.300 | 1.867 |

| Cable 4 | 1.321 | 0.601 | 15.221 | 62.212 | 60.300 | 1.912 |

| Cable 5 | 4.745 | 2.935 | 25.753 | 52.628 | 48.300 | 4.328 |

| Cable 6 | 4.291 | 2.922 | 23.424 | 52.061 | 48.300 | 3.761 |

| Cable 7 | 4.881 | 3.334 | 27.521 | 52.879 | 48.300 | 4.579 |

| Cable 8 | 4.692 | 2.981 | 29.332 | 47.218 | 48.300 | 1.082 |

| Average | 2.988 | 2.492 | 20.175 | - | - | 2.795 |

| Cross-Sectional Profiles | TLS-Based Measurements | As-Is Measurements | Measurement Absolute Error | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | |

| Sec A1-A1 | 5507 | 386 | 355 | 5498 | 388 | 352 | 9 | 2 | 3 |

| Sec A2-A2 | 5504 | 387 | 352 | 5496 | 389 | 348 | 8 | 2 | 4 |

| Sec A3-A3 | 5503 | 387 | 357 | 5493 | 388 | 353 | 10 | 1 | 4 |

| Sec A4-A4 | 5492 | 388 | 343 | 5486 | 391 | 346 | 6 | 3 | 3 |

| Average | 5501 | 387 | 352 | 5493 | 389 | 349 | 8 | 2 | 3 |

| Cross-Sectional Profiles | TLS-Based Measurements | As-Designed Dimensions | Measurement Absolute Error | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | A | B | C | D | A | B | C | D | |

| Sec A1-A1 | 5507 | 386 | 355 | 566 | 5500 | 385 | 350 | 560 | 7 | 1 | 5 | 6 |

| Sec A2-A2 | 5504 | 387 | 352 | 568 | 5500 | 385 | 350 | 560 | 4 | 2 | 2 | 8 |

| Sec A3-A3 | 5503 | 387 | 357 | 566 | 5500 | 385 | 350 | 560 | 3 | 2 | 7 | 6 |

| Sec A4-A4 | 5492 | 388 | 343 | 559 | 5500 | 385 | 350 | 560 | 8 | 3 | 7 | 1 |

| Average | 5501 | 387 | 352 | 565 | - | - | - | - | 5 | 2 | 5 | 5 |

| Sliced-Based CAD Model | Mesh-Based CAD Model | TLS-Based Point Cloud | ||||||

|---|---|---|---|---|---|---|---|---|

| STD | Mean | RMSE | MAE | STD | Mean | RMSE | MAE | |

| Part A | 4.11 | 3.90 | 5.23 | 2.17 | 3.40 | 4.51 | 4.57 | 3.32 |

| Part B | 5.12 | 5.72 | 6.26 | 4.44 | 5.12 | 5.78 | 6.22 | 4.58 |

| Average | 4.62 | 4.81 | 5.75 | 3.31 | 4.26 | 5.15 | 5.40 | 3.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadi, M.; Rashidi, M.; Mousavi, V.; Yu, Y.; Samali, B. Application of TLS Method in Digitization of Bridge Infrastructures: A Path to BrIM Development. Remote Sens. 2022, 14, 1148. https://doi.org/10.3390/rs14051148

Mohammadi M, Rashidi M, Mousavi V, Yu Y, Samali B. Application of TLS Method in Digitization of Bridge Infrastructures: A Path to BrIM Development. Remote Sensing. 2022; 14(5):1148. https://doi.org/10.3390/rs14051148

Chicago/Turabian StyleMohammadi, Masoud, Maria Rashidi, Vahid Mousavi, Yang Yu, and Bijan Samali. 2022. "Application of TLS Method in Digitization of Bridge Infrastructures: A Path to BrIM Development" Remote Sensing 14, no. 5: 1148. https://doi.org/10.3390/rs14051148