Development of Phenol-Enriched Olive Oil with Phenolic Compounds Extracted from Wastewater Produced by Physical Refining

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Reagents

2.3. Preparation of Phenolic Extracts from Wastewater

2.4. Preparation of Phenol-Enriched Oil

2.5. Preparation of Phenolic Extracts from COO and Phenol-Enriched Oil

2.6. Total Phenol Content Determination (Wastewater, Phenolic Extracts from COO, and Phenol-Enriched Oils)

2.7. Bitter Index (BI)

2.8. Antioxidant Capacity of the Olive Oils (COO and Phenol-Enriched Oils) by ABTS Assay

2.9. Cell Culture

2.10. Cell Growth

2.11. Reactive Oxygen Species (ROS) Measurement

2.12. Western Blot

2.13. Statistical Analysis

3. Results and Discussion

3.1. Total Phenol Content of Wastewater and Wastewater Extracts

3.2. Quality Parameters and Total Phenol Content of Enriched Control Olive Oils (COOs)

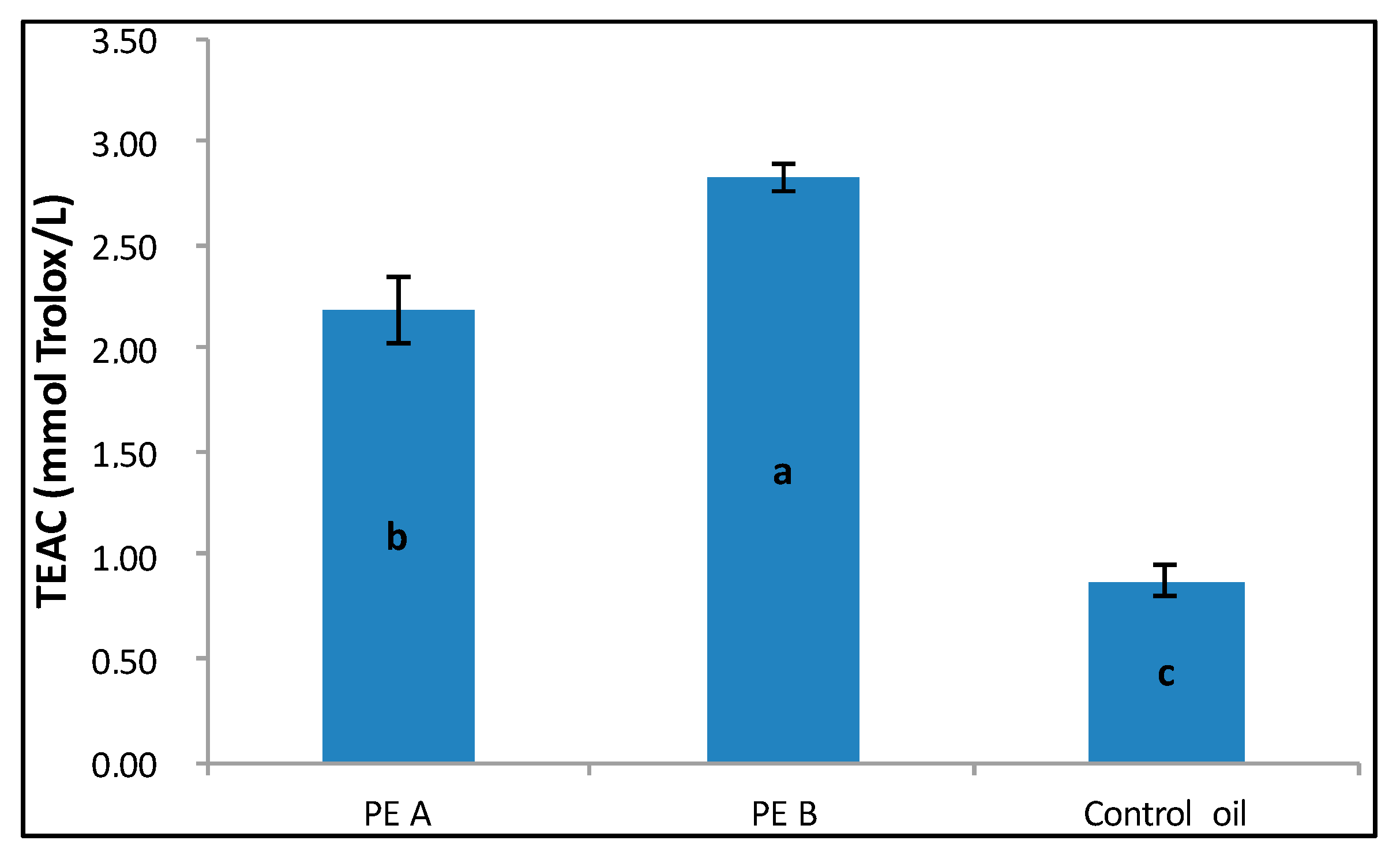

3.3. Antioxidant Capacity of the Olive Oils (COO and Phenol-Enriched Oils) by ABTS Assay

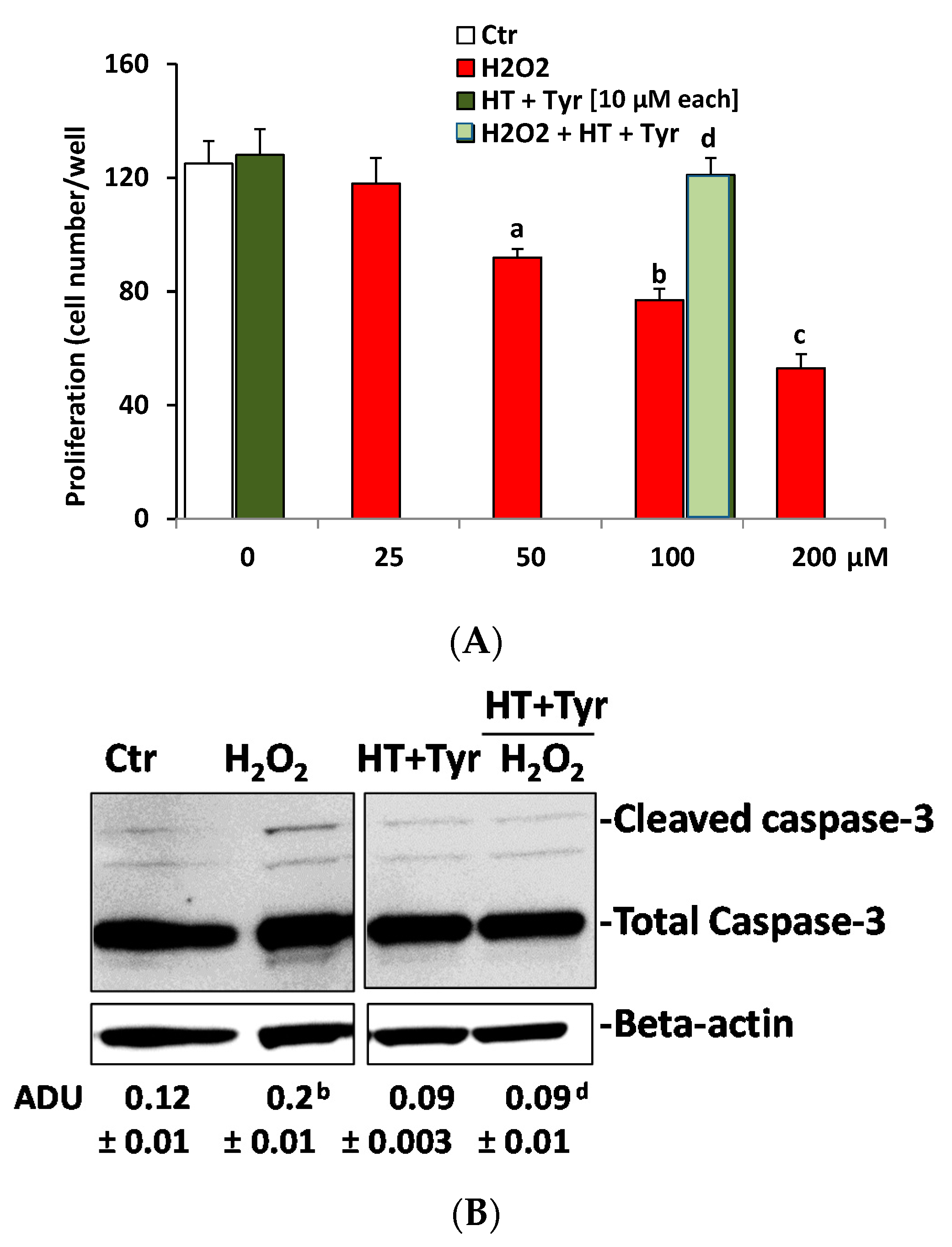

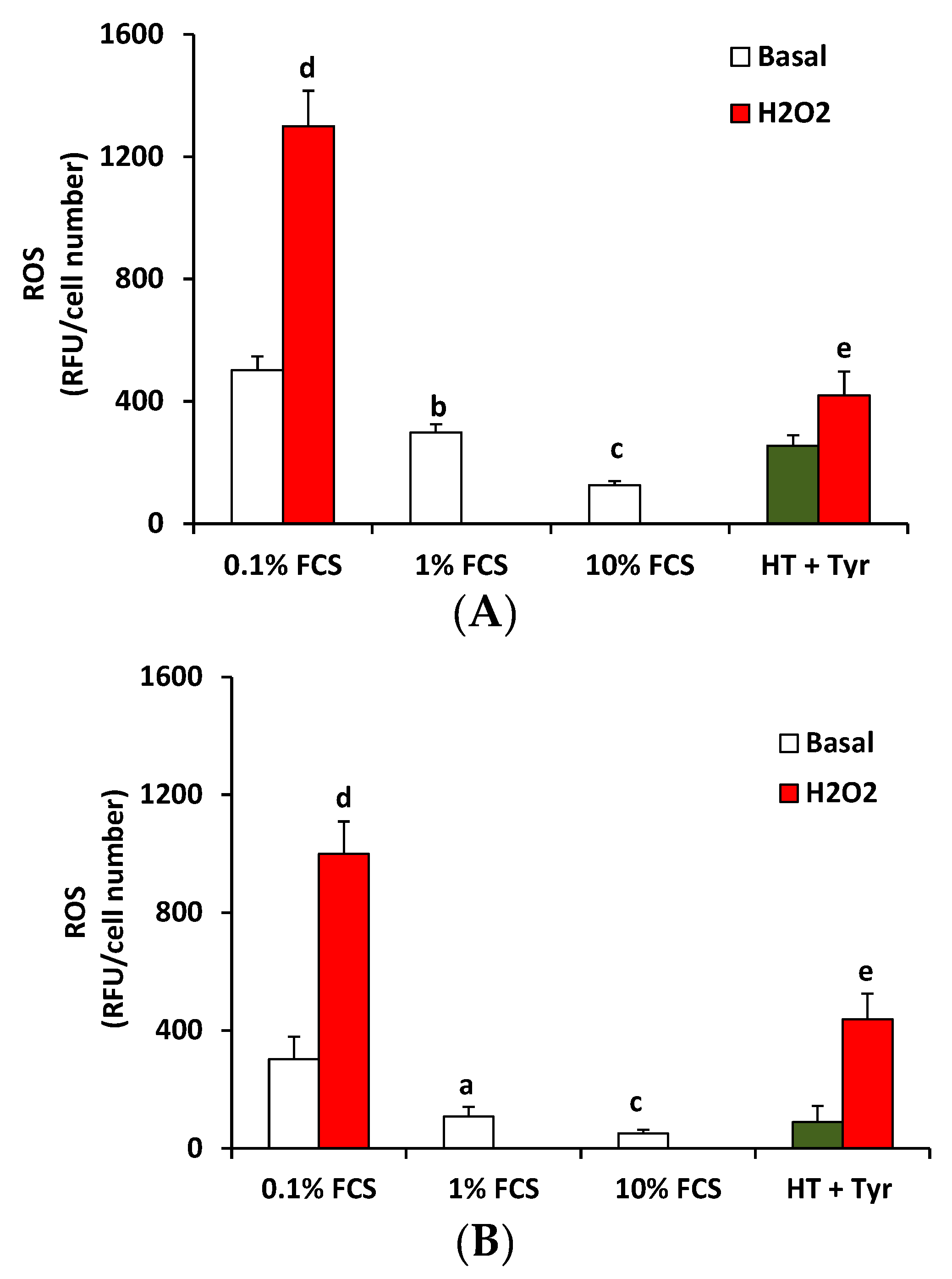

3.4. Polyphenols Recovery H2O2—Impaired Endothelial Cell Viability

3.5. The Recovering Effects of Polyphenols are Linked to the Expression of Antioxidant Enzymes in Endothelium

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- López-Miranda, J.; Pérez-Jiménez, F.; Ros, E.; De Caterina, R.; Badimón, L.; Covas, M.I.; Escrich, E.; Ordovás, J.M.; Soriguer, F.; Abiá, R.; et al. Olive oil and health: Summary of the II international conference on olive oil and health consensus report, Jaén and Córdoba (Spain) 2008. Nutr. Metab. Cardiovasc. Dis. 2010, 20, 284–294. [Google Scholar] [CrossRef] [PubMed]

- Covas, M.I. Olive oil and cardiovascular system. Pharmacol. Res. 2007, 55, 175–186. [Google Scholar] [CrossRef] [PubMed]

- Fitó, M.; De la Torre, R.; Covas, M.I. Olive oil and oxidative stress. Mol. Nutr. Food Res. 2007, 51, 1215–1224. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the substantiation of health claims related to polyphenols in olive oil and protection of LDL particles from oxidative damage. EFSA J. 2011, 9, 2033–2058. [Google Scholar]

- Valls, R.M.; Farràs, M.; Suárez, M.; Fernández-Castillejo, S.; Fitó, M.; Konstantinidou, V.; Fuentes, F.; López-Miranda, J.; Giralt, M.; Covas, M.I.; et al. Effects of functional olive oil enriched with its own phenolic compounds on endothelial function in hypertensive patients. A randomized controlled trial. Food Chem. 2015, 167, 30–35. [Google Scholar] [CrossRef] [PubMed]

- European Communities (EC). Commission Regulation (EC) No. 1989/2003 of 6 November 2003. Off. J. Eur. Commun. 2003, 295, 57–77. [Google Scholar]

- Garcia, R.; Martins, N.; Cabrita, M.J. Putative markers of adulteration of extra virgin olive oil with refined olive oil: Prospects and limitations. Food Res. Int. 2013, 54, 2039–2044. [Google Scholar] [CrossRef]

- International Olive Oil Council (IOOC). Trade Standard Applying to Olive Oils and Olive-Pomace Oils 2011; COI/T.15/NC No. 3/Rev; 6 November 2011; International Olive Oil Council: Madrid, Spain, 2011; pp. 1–17. Available online: http://www.internationaloliveoil.org/estaticos/view/222-standards (accessed on 8 June 2017).

- Garcìa, A.; Ruiz-Mendez, M.V.; Romero, C.; Brenes, M. Effect of refining on the phenolic composition of crude olive oils. J. Am. Oil Chem. Soc. 2006, 83, 159–164. [Google Scholar] [CrossRef]

- Bouaziz, M.; Fki, I.; Jemai, H.; Ayadi, M.; Sayadi, S. Effect of storage on refined and husk olive oils composition: Stabilization by addition of natural antioxidants from Chemlali olive leaves. Food Chem. 2008, 108, 253–262. [Google Scholar] [CrossRef]

- Zinnai, A.; Venturi, F.; Sanmartin, C.; Taglieri, I.; Andrich, G. The utilization of solid carbon dioxide in the extraction of extra-virgin olive oil. Agro Food Ind. Hi Tech. 2015, 26, 24–26. [Google Scholar]

- Zinnai, A.; Sanmartin, C.; Taglieri, I.; Andrich, G.; Venturi, F. Supercritical fluid extraction from microalgae with high content of LC-PUFAs. A case of study: Sc-CO2 oil extraction from Schizochytrium sp. J. Supercrit. Fluids 2016, 116, 126–131. [Google Scholar] [CrossRef]

- Venturi, F.; Sanmartin, C.; Taglieri, I.; Andrich, G.; Zinnai, A. A simplified method to estimate Sc-CO2 extraction of bioactive compounds from different matrices: Chili pepper vs. tomato by-products. Appl. Sci. 2017, 7, 361. [Google Scholar] [CrossRef]

- Fki, I.; Allouche, N.; Sayadi, S. The use of polyphenolic extract, purified hydroxytyrosol and 3,4-dihydroxyphenyl acetic acid from olive mill wastewater for the stabilization of refined oils: A potential alternative to synthetic antioxidants. Food Chem. 2005, 93, 197–204. [Google Scholar] [CrossRef]

- Hou, D.X. Potential mechanisms of cancer hemoprevention by anthocyanins. Curr. Mol. Med. 2003, 3, 149–159. [Google Scholar] [CrossRef] [PubMed]

- Prior, R.L. Absorption and metabolism: Potential health effect. In Phytochemicals: Mechanism of Action, 1st ed.; Meskin, M., Bidlack, W.R., Davies, A.J., Lewis, D.S., Randolph, R.K., Eds.; CRC Press: Boca Raton, FL, USA, 2003; pp. 1–18. [Google Scholar]

- Yanishlieva, N.V.; Marinova, E.M. Stabilization of edible oils with natural antioxidants. Eur. J. Lipid Sci. Tech. 2001, 103, 752–767. [Google Scholar] [CrossRef]

- Suárez, M.; Romero, M.P.; Motilva, M.J. Development of a phenol enriched olive oil with phenolic compounds from olive cake. J. Agric. Food Chem. 2010, 58, 10396–10403. [Google Scholar] [CrossRef] [PubMed]

- Caporaso, N.; Formisano, D.; Genovese, A. Use of phenolic compounds from olive mill wastewater as valuable ingredients for functional foods. Crit. Rev. Food Sci. Nutr. 2017. [Google Scholar] [CrossRef] [PubMed]

- Caporaso, N.; Genovese, A.; Burke, R.; Barry-Ryan, C.; Sacchi, R. Physical and oxidative stability of functional olive oil-in-water emulsions formulated using olive mill wastewater biophenols and whey proteins. Food Funct. 2016, 7, 227–238. [Google Scholar] [CrossRef] [PubMed]

- Caporaso, N.; Genovese, A.; Burke, R.; Barry-Ryan, C.; Sacchi, R. Effect of olive mill wastewater phenolic extract, whey protein isolate and xanthan gum on the behavior of olive O/W emulsions using response surface methodology. Food Hydrocoll. 2016, 61, 66–76. [Google Scholar] [CrossRef]

- Tzia, C.; Giannou, V.; Polychniatou, V.; Chanioti, S. Fat and oil processing technology. In Handbook of Food Processing: Food Safety, Quality, and Manufacturing Processes, 1st ed.; Varzakas, T., Tzia, C., Eds.; CRC Press: Boca Raton, FL, USA, 2015; pp. 381–424. [Google Scholar]

- Montedoro, G.; Servili, M.; Baldioli, M.; Miniati, E. Simple and hydrolyzable phenolic compounds in virgin olive oil. 1. Their extraction, separation, and quantitative and semiquantitative evaluation by HPLC. J. Agric. Food Chem. 1992, 40, 1571–1578. [Google Scholar] [CrossRef]

- Zinnai, A.; Venturi, F.; Andrich, G. Time evolution of phenols extractions from Sangiovese grapes with and without the addition of solid carbon dioxide. Agrochimica 2011, 55, 193–202. [Google Scholar]

- Folin, O.; Ciocalteau, V. On tyrosine and tryptophan determination in protein. J. Biol. Chem. 1927, 73, 627–650. [Google Scholar]

- Gutiérrez Rosales, F.; Perdiguero, S.; Gutierrez, R.; Olias, J.M. Evaluation of the bitter taste in virgin olive oil. J. Am. Oil Chem. Soc. 1992, 69, 394–395. [Google Scholar] [CrossRef]

- Sgherri, C.; Micaelli, F.; Andreoni, N.; Baldanzi, M.; Ranieri, A. Retention of phenolic compounds and antioxidant properties in potato bread obtained from a dough enriched with a powder from the purple cv. Vitelotte. Agrochimica 2016, 60, 312–328. [Google Scholar] [CrossRef]

- Pellegrini, N.; Re, R.; Yang, M.; Rice-Evans, C. Screening of dietary carotenoids and carotenoid-rich fruit extracts for antioxidant activities applying 2,2′-azinobis[3-ethylenebenzothiazoline-6-sulfonic acid] radical cation decolorization assay. Methods Enzymol. 1999, 299, 379–389. [Google Scholar] [CrossRef]

- D.M. 21 July 1998. Production Specifications for Protected Geographical Indication of “Toscano” Extra Virgin Olive Oil. Gazz. Uff. N. 243. 17 October 1998. Available online: http://www.oliotoscanoigp.it/cms/doc/DisciplinareOlioToscanoIGP.pdf (accessed on 8 June 2017).

- Irani, K. Oxidant signaling in vascular cell growth, death and survival. A review of the roles of reactive oxygen species in smooth muscle and endothelial cell mitogenic and apoptotic signaling. Circ. Res. 2000, 87, 179–183. [Google Scholar] [CrossRef] [PubMed]

- De la Puerta, R.; Ruiz Gutierrez, V.; Hoult, J.R. Inhibition of leukocyte 5-lipoxygenase by phenolics from virgin olive oil. Biochem. Pharmacol. 1999, 57, 445–449. [Google Scholar] [CrossRef]

- Tripoli, E.; Giammanco, M.; Tabacchi, G.; Di Majo, D.; Giammanco, S.; La Guardia, M. The phenolic compounds of olive oil: Structure, biological activity and beneficial effects on human health. Nutr. Res. Rev. 2005, 18, 98–112. [Google Scholar] [CrossRef] [PubMed]

- Terzuoli, E.; Giachetti, A.; Ziche, M.; Donnini, S. Hydroxytyrosol, a product from olive oil, reduces colon cancer growth by enhancing epidermal growth factor receptor degradation. Mol. Nutr. Food Res. 2016, 60, 519–529. [Google Scholar] [CrossRef] [PubMed]

- Corona, G.; Tzounis, X.; Assunta Dessì, M.; Deiana, M.; Debnam, E.S.; Visioli, F.; Spencer, J.P. The fate of olive oil polyphenols in the gastrointestinal tract: Implications of gastric and colonic microflora-dependent biotransformation. Free Radic. Res. 2006, 40, 647–658. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Bolaños, J.G.; López, O.; Fernández-Bolanos, J.; Rodríguez-Gutiérrez, G. Hydroxytyrosol and derivatives: Isolation, synthesis, and biological properties. Curr. Org. Chem. 2008, 12, 442–463. [Google Scholar] [CrossRef]

- Cantara, S.; Donnini, S.; Giachetti, A.; Thorpe, P.E.; Ziche, M. Exogenous BH4/Bcl-2 peptide reverts coronary endothelial cell apoptosis induced by oxidative stress. J. Vasc. Res. 2004, 41, 202–207. [Google Scholar] [CrossRef] [PubMed]

- Le Bras, M.; Clement, M.V.; Pervaiz, S.; Brenner, C. Reactive oxygen species and the mitochondrial signaling pathway of cell death. Histol. Histopathol. 2005, 20, 205–219. [Google Scholar] [CrossRef] [PubMed]

- Carrasco-Pancorbo, A.; Cerretani, L.; Bendini, A.; Segura-Carretero, A.; Del Carlo, M.; Gallina-Toschi, T.; Lercker, G.; Compagnone, D.; Fernández-Gutiérrez, A. Evaluation of the antioxidant capacity of individual phenolic compounds in virgin olive oil. J. Agric. Food Chem. 2005, 53, 8918–8925. [Google Scholar] [CrossRef] [PubMed]

- Visioli, F.; Galli, C.; Galli, G.; Varuso, D. Biological activities and metabolic fate of olive oil phenols. Eur. J. Lipid Sci. Technol. 2002, 104, 677–684. [Google Scholar] [CrossRef]

- Morbidelli, L. Polyphenol-based nutraceuticals for the control of angiogenesis: Analysis of the critical issues for human use. Pharmacol. Res. 2016, 111, 384–393. [Google Scholar] [CrossRef] [PubMed]

- Estruch, R.; Ros, E.; Salas-Salvadó, J.; Covas, M.I.; Corella, D.; Arós, F.; Gómez-Gracia, E.; Ruiz-Gutiérrez, V.; Fiol, M.; Lapetra, J.; et al. Primary prevention of cardiovascular disease with a Mediterranean diet. N. Engl. J. Med. 2013, 368, 1279–1290. [Google Scholar] [CrossRef] [PubMed]

- Monti, M.; Terzuoli, E.; Ziche, M.; Morbidelli, L. The sulphydryl containing ACE inhibitor Zofenoprilat protects coronary endothelium from Doxorubicin-induced apoptosis. Pharmacol. Res. 2013, 76, 171–181. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Control Olive Oil (COO) | Wastewater (WW) |

|---|---|---|

| Free acidity (% of oleic acid) | 0.12 ± 0.01 | -- |

| Peroxide value (meq O2/kg) | 5.46 ± 0.03 | -- |

| K270 | 0.56 ± 0.03 | -- |

| pH | -- | 3.32 ± 0.02 |

| Density | -- | 1.03 ± 0.01 |

| Dry matter (d.m. %) | -- | 11.53 ± 0.10 |

| Total phenol content (g/L of gallic acid) | 0.025 ± 0.002 | 1.880 ± 0.004 |

| Sample | Total Phenol Content (g/L) as Gallic Acid | % of Non-Flavonoid Phenols |

|---|---|---|

| Wastewater (WW) | 1.880 a | 92% |

| WW Extract A (WW-A) | 0.430 b | -- |

| WW Extract B (WW-B) | 0.292 c | -- |

| Sample | Free Acidity (% of Oleic Acid) | Peroxide Value (meq O2/kg) | K270 | ΔK | K225 | Bitter Index (BI) | Total Phenol Content (g/kg of Gallic Acid) | % of Non-Flavonoid Phenols |

|---|---|---|---|---|---|---|---|---|

| COO | 0.12 a | 5.46 a | 0.56 a | ≤0.15 | 0.10 c | 0.52 c | 0.025 c | 99.4 |

| PE-A | 0.12 a | 5.47 a | 0.57 a | ≤0.15 | 0.15 b | 1.20 b | 0.105 b | 74.9 |

| PE-B | 0.12 a | 5.47 a | 0.57 a | ≤0.15 | 0.18 a | 1.52 a | 0.131 a | 100 |

| Polyphenol Concentration Tested | Ctr | HT | Tyr | HT + Tyr |

|---|---|---|---|---|

| 0 | 121 ± 4 | --- | --- | --- |

| 0.1 µM | --- | 130 ± 7 | 123 ± 6 | --- |

| 1 µM | --- | 126 ± 5 | 124 ± 4 | --- |

| 10 µM | --- | 127 ± 5 | 125 ± 8 | 130 ± 8 |

| 100 µM | --- | 112 ± 6 | 108 ± 10 | --- |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venturi, F.; Sanmartin, C.; Taglieri, I.; Nari, A.; Andrich, G.; Terzuoli, E.; Donnini, S.; Nicolella, C.; Zinnai, A. Development of Phenol-Enriched Olive Oil with Phenolic Compounds Extracted from Wastewater Produced by Physical Refining. Nutrients 2017, 9, 916. https://doi.org/10.3390/nu9080916

Venturi F, Sanmartin C, Taglieri I, Nari A, Andrich G, Terzuoli E, Donnini S, Nicolella C, Zinnai A. Development of Phenol-Enriched Olive Oil with Phenolic Compounds Extracted from Wastewater Produced by Physical Refining. Nutrients. 2017; 9(8):916. https://doi.org/10.3390/nu9080916

Chicago/Turabian StyleVenturi, Francesca, Chiara Sanmartin, Isabella Taglieri, Anita Nari, Gianpaolo Andrich, Erika Terzuoli, Sandra Donnini, Cristiano Nicolella, and Angela Zinnai. 2017. "Development of Phenol-Enriched Olive Oil with Phenolic Compounds Extracted from Wastewater Produced by Physical Refining" Nutrients 9, no. 8: 916. https://doi.org/10.3390/nu9080916