A Breakdown Enhanced AlGaN/GaN Schottky Barrier Diode with the T-Anode Position Deep into the Bottom Buffer Layer

Abstract

:1. Introduction

2. Device Structure and Simulation Model

Fabrication Process

- (a)

- Metal organic chemical vapor deposition (MOCVD) was adopted to grow the base structure including the GaN bottom buffer layer, the GaN middle buffer layer, the GaN channel layer, and the AlGaN barrier layer, and the Si3N4 passivation layer was then deposited using plasma-enhanced chemical vapor deposition (PECVD) [30].

- (b)

- The Si3N4 passivation layer, AlGaN barrier layer, GaN channel layer, and GaN buffer layer were etched through inductively coupled plasma reactive ion etching (ICP RIE), using a BCl3/Cl2 gas mixture [30].

- (c)

- The Si3N4 layer was deposited on the anode region using plasma-enhanced chemical vapor deposition (PECVD) [30].

- (d)

- ICP RIE was adopted to etch the Si3N4 layer of the anode region and kept at a thickness of 20 nm for the Si3N4 layer at the right and bottom side.

- (e)

3. Results and Discussion

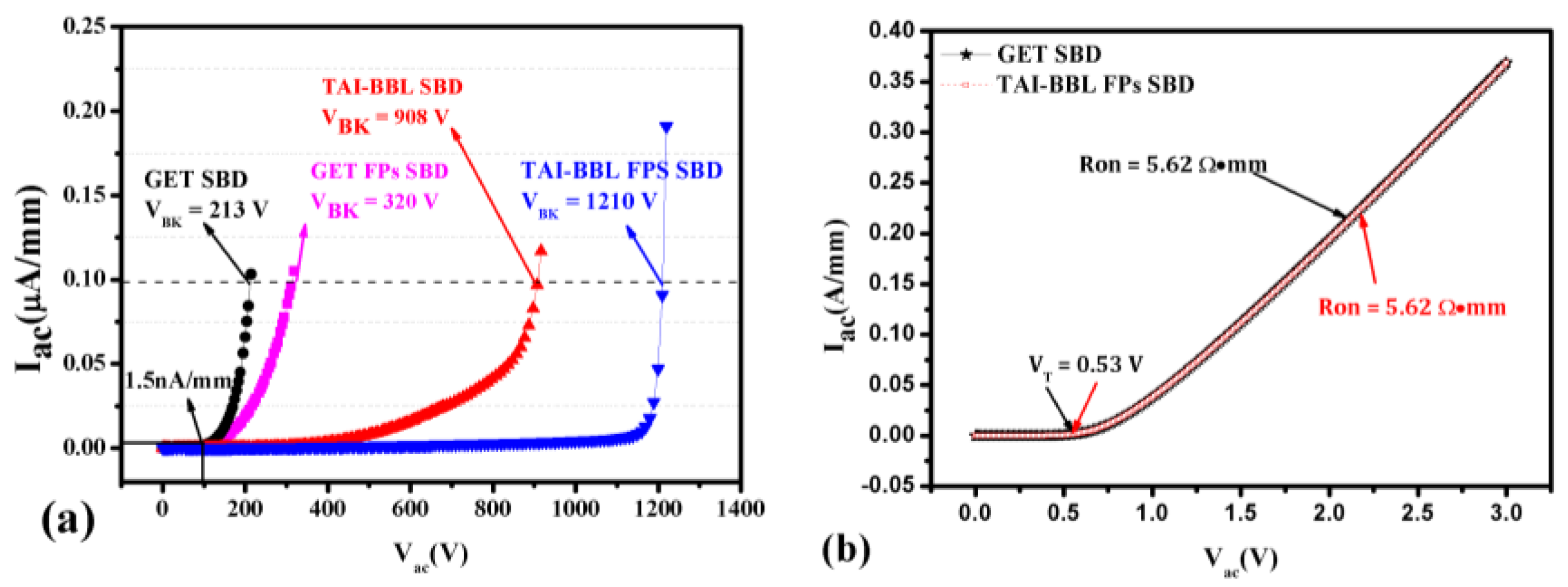

3.1. Forward and Reverse Characteristics

3.2. Equipotential Line and Horizontal Electric Field Distribution

3.3. Electron Concentration Distribution

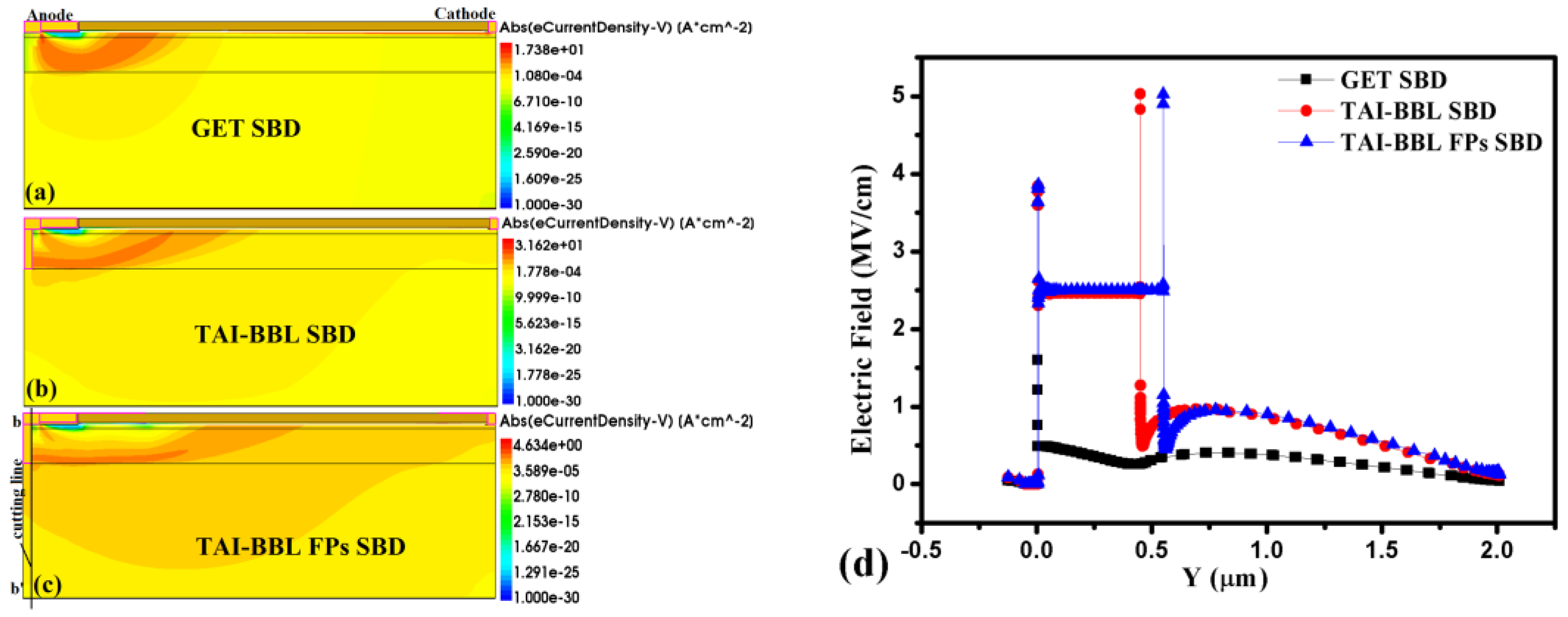

3.4. The Path of the Leakage Current and the Vertical Electric Field Distribution

4. Parameter Optimization

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Holmes, J.; Dutta, M.; Koeck, F.A.; Benipal, M.; Brown, J.; Fox, B.; Hathwar, R.; Johnson, H.; Malakoutian, M.; Saremi, M.; et al. A 4.5-μm PIN diamond diode for detecting slow neutrons. Nucl. Instrum. Methods Phys. Res. Sect. A 2018, 903, 297–301. [Google Scholar] [CrossRef]

- Saremi, M.; Hathwar, R.; Dutta, M.; Koeck, F.A.M. Analysis of the reverse I-V characteristics of diamond-based PIN diodes. Appl. Phys. Lett. 2017, 111, 043507. [Google Scholar] [CrossRef]

- Mahabadi, S.E.J.; Moghadam, H.A. Comprehensive study of a 4H–SiC MES–MOSFET. Phys. E 2015, 74, 25–29. [Google Scholar] [CrossRef]

- Moghadam, H.; Dimitrijev, S.; Han, J.; Han, J.; Haasmann, D.; Aminbeidokhti, A. Transient-current method for measurement of active near-interface oxide traps in 4H-SiC MOS capacitors and MOSFETs. IEEE Trans. Electron Devices 2015, 62, 2670–2674. [Google Scholar] [CrossRef]

- Shen, X.Q.; Matsuhata, H.; Okumura, H. Reduction of the threading dislocation density in GaN films grown on vicinal sapphire (0001) substrates. Appl. Phys. Lett. 2005, 86, 021912. [Google Scholar] [CrossRef]

- Anthony, T.R.; Banholzer, W.F.; Fleischer, J.F.; Wei, L.; Kuo, P.K.; Thomas, R.L.; Pryor, R.W. Thermal diffusivity of isotopically enriched 12C diamond. Phys. Rev. B 1990, 42, 1104–1111. [Google Scholar] [CrossRef]

- Liu, J.; Ohsato, H.; Wang, X.; Liao, M.; Koide, Y. Design and fabrication of high-performance diamond triple-gate field-effect transistors. Sci. Rep. 2016, 6, 1–8. [Google Scholar] [CrossRef]

- Min, W.H.; Seung, C.L.; Young, H.C.; Soo, S.K.; Min, K.H. New GaN Schottky barrier diode employing a trench on AlGaN/GaN heterostructure. Superlattices Microstruct. 2006, 40, 567–573. [Google Scholar] [CrossRef]

- Zhu, M.; Song, B.; Qi, M.; Hu, Z.Y.; Nomoto, K.; Yan, X.D.; Cao, Y.; Johnson, W.; Kohn, E.; Jena, D.; et al. 1.9-kV AlGaN/GaN Lateral Schottky Barrier Diodes on Silicon. IEEE Electron Device Lett. 2015, 36, 375–377. [Google Scholar] [CrossRef]

- Jie, H.; Steve, S.; Ming, Z.; Andrea, N.T.; Isabella, R.; Matteo, M.; Xuan, W.K.; Benoit, B.; Denis, M.; Ben, K.; et al. Time-dependent breakdown mechanisms and reliability improvement in edge terminated AlGaN/GaN Schottky diodes under HTRB tests. IEEE Electron Device Lett. 2017, 38, 371–374. [Google Scholar] [CrossRef]

- Jun, M.; Elison, M. High-voltage and low-leakage AlGaN/GaN tri-anode Schottky diodes with integrated tri-gate transistors. IEEE Electron Device Lett. 2017, 38, 83–86. [Google Scholar] [CrossRef]

- Chuan, W.T.; Kai, P.W.; Yi, W.L.; Shawn, S.H.H. 2.07-kV AlGaN/GaN Schottky barrier diodes on silicon with high Baliga’s figure-of-merit. IEEE Electron Device Lett. 2016, 37, 70–73. [Google Scholar] [CrossRef]

- Treidel, E.B.; Oliver, H.; Rimma, Z.; Andreas, W.; Chafik, M.; Joachim, W.; Günther, T. Fast-Switching GaN-Based Lateral Power Schottky Barrier Diodes With Low Onset Voltage and Strong Reverse Blocking. IEEE Electron Device Lett. 2012, 33, 357–359. [Google Scholar] [CrossRef]

- Yi, W.L.; Yu, S.L.; Jui, M.Y.; Chih, H.C.; Shawn, S.H.H. AlGaN/GaN Schottky Barrier Diodes on Silicon Substrates With Selective Si Diffusion for Low Onset Voltage and High Reverse Blocking. IEEE Electron Device Lett. 2013, 34, 981–983. [Google Scholar] [CrossRef]

- Chang, T.F.; Huang, C.F.; Yang, T.Y.; Chiu, C.W.; Huang, T.Y.; Lee, K.Y.; Zhao, F. Low turn-on voltage dual metal AlGaN/GaN Schottky barrier diode. Solid-State Electron. 2015, 105, 12–15. [Google Scholar] [CrossRef]

- Eldad, B.T.; Frank, B.; Oliver, H.; Eunjung, C.; Joachim, W.; Günther, T. AlGaN/GaN/GaN:C Back-Barrier HFETs With Breakdown Voltage of Over 1 kV and Low RON × A. IEEE Trans. Electron Devices 2010, 57, 3050–3058. [Google Scholar] [CrossRef]

- Xin, L.; Ying, W.; Fei, C.; Cheng, H.Y.; Xin, X.F. A breakdown enhanced AlGaN/GaN MISFET with source-connected P-buried layer. Superlattices Microstruct. 2017, 112, 517–527. [Google Scholar] [CrossRef]

- Chiu, H.C.; Chen, S.C.; Chiu, J.W.; Li, B.H.; Wang, H.Y.; Peng, L.Y.; Wang, H.C.; Hsueh, K.P. AlGaN/GaN Schottky barrier diodes on silicon substrates with various Fe doping concentrations in the buffer layers. Microelectron. Reliab. 2018, 83, 238–241. [Google Scholar] [CrossRef]

- Jing, N.G.; Mao, J.W.; Rui, Y.Y.; Shao, F.L.; Cheng, P.W.; Jin, Y.W.; Wen, G.W.; Yi, L.H.; Yu, F.J.; Bo, S. Schottky-MOS Hybrid Anode AlGaN/GaN Lateral Field-Effect Rectifier With Low Onset Voltage and Improved Breakdown Voltage. IEEE Trans. Electron Devices 2017, 38, 1425–1428. [Google Scholar] [CrossRef]

- Jie, H.; Steve, S.; Silvia, L.; Brice, D.J.; Nicolò, R.; Andrea, N.T.; Dirk, W.; Shu, Z.Y.; Benoit, B.; Guido, G.; et al. Statistical Analysis of the Impact of Anode Recess on the Electrical Characteristics of AlGaN/GaN Schottky Diodes With Gated Edge Termination. IEEE Trans. Electron Devices 2016, 63, 3451–3458. [Google Scholar] [CrossRef]

- Tang, C.; Xie, G.; Zhang, L.; Guo, Q.; Wang, T.; Sheng, K. Electric field modulation technique for high-voltage AlGaN/GaN Schottky barrier diodes. Chin. Phys. B 2013, 22, 106107:1–106107:6. [Google Scholar] [CrossRef]

- Ying, W.; Zhi, Y.L.; Yue, H.; Xin, L.; Jun, P.F.; Ya, C.M.; Cheng, H.Y.; Fei, C. Evaluation by Simulation of AlGaN/GaN Schottky Barrier Diode (SBD) With Anode-Via Vertical Field Plate Structure. IEEE Trans. Electron Devices 2018, 65, 2552–2557. [Google Scholar] [CrossRef]

- Hua, M.; Zhang, Z.; Wei, J.; Lei, J.; Tang, G.; Fu, K.; Cai, Y.; Zhang, B.; Chen, K.J. Integration of LPCVD-SiNx gate dielectric with recessed-gate E-mode GaN MIS-FETs: Toward high performance, high stability and long TDDB lifetime. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; p. 10. [Google Scholar] [CrossRef]

- Kentaro, H.; Hiroshi, O.; Hirohumi, T.; Tohru, N.; Tomoyoshi, M. Junction-Barrier Schottky Diodes Fabricated with Very Thin Highly Mg-Doped p + -GaN(20 nm)/n-GaN Layers Grown on GaN Substrates. In Proceedings of the IEEE International Meeting for Future of Electron Devices, Kansai (IMFEDK), Kyoto, Japan, 29–30 June 2017; pp. 50–51. [Google Scholar] [CrossRef]

- Honda, U.; Yamada, Y.; Tokuda, Y.; Shiojima, K. Deep levels in n-GaN doped with carbon studied by deep level and minority carrier transient spectroscopies. Jpn. J. Appl. Phys. 2011, 51, 827–831. [Google Scholar] [CrossRef]

- Lyons, J.L.; Janotti, A.; Walle, C. Carbon impurities and the yellow luminescence in GaN. Appl. Phys. Lett. 2010, 97, 152108:1–152108:3. [Google Scholar] [CrossRef]

- Sentaurus Device User Guide Version I-2013.12; Synopsys Inc.: Mountain View, CA, USA, 2013.

- Stephan, S.; Axel, E.; Tommaso, C.; Denis, M.; Steve, S.; Benoit, B. TCAD methodology for simulation of GaN-HEMT power devices. In Proceedings of the IEEE 26th International Symposium on Power Semiconductor Devices IC’s (ISPSD), Waikoloa, HI, USA, 15–19 June 2014; pp. 257–260. [Google Scholar] [CrossRef]

- Hu, J.; Lenci, S.; Stoffels, S.; Jaeger, B.D.; Groeseneken, G.; Decoutere, S. Leakage-current reduction and improved on-state performance of Au-free AlGaN/GaN-on-Si Schottky diode by embedding the edge terminations in the anode region. Phys. Status Solidi C 2014, 11, 862–865. [Google Scholar] [CrossRef]

- Hyun, S.L.; Dong, Y.J.; Youngrak, P.; Jeho, N.; Hyun, G.J.; Hyoung, S.L.; Chi, H.J.; Junbo, P.; Sang, O.R.; Sang, C.K.; et al. 0.34 VT AlGaN/GaN-on-Si Large Schottky Barrier Diode With Recessed Dual Anode Metal. IEEE Electron Device Lett. 2015, 36, 1132–1134. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Anode length (LA) | 0.2 μm |

| Gated edge length (LGE) | 0.45 μm |

| Cathode length (LC) | 0.1 μm |

| Anode–cathode spacing (LAC) | 5 μm |

| T-anode length (LT) | 0.445–0.945 μm |

| Barrier layer thickness (Tbar) | 25 nm |

| Channel layer thickness (Tchan) | 50 nm |

| Bottom buffer layer thickness (Tbot) | 1.6 μm |

| Middle buffer layer thickness (Tmid) | 0.4 μm |

| Cathode field plate length (Lcfp) | 0.6 μm |

| Anode field plate length (Lafp) | 0.83 μm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Wang, Y.; Tang, J.; Wang, W.; Huang, Y.; Kuang, X. A Breakdown Enhanced AlGaN/GaN Schottky Barrier Diode with the T-Anode Position Deep into the Bottom Buffer Layer. Micromachines 2019, 10, 91. https://doi.org/10.3390/mi10020091

Sun Y, Wang Y, Tang J, Wang W, Huang Y, Kuang X. A Breakdown Enhanced AlGaN/GaN Schottky Barrier Diode with the T-Anode Position Deep into the Bottom Buffer Layer. Micromachines. 2019; 10(2):91. https://doi.org/10.3390/mi10020091

Chicago/Turabian StyleSun, Youlei, Ying Wang, Jianxiang Tang, Wenju Wang, Yifei Huang, and Xiaofei Kuang. 2019. "A Breakdown Enhanced AlGaN/GaN Schottky Barrier Diode with the T-Anode Position Deep into the Bottom Buffer Layer" Micromachines 10, no. 2: 91. https://doi.org/10.3390/mi10020091