Design and Optimization of High-Responsivity High-Speed Ge/Si Avalanche Photodiode in the C+L Band

Abstract

:1. Introduction

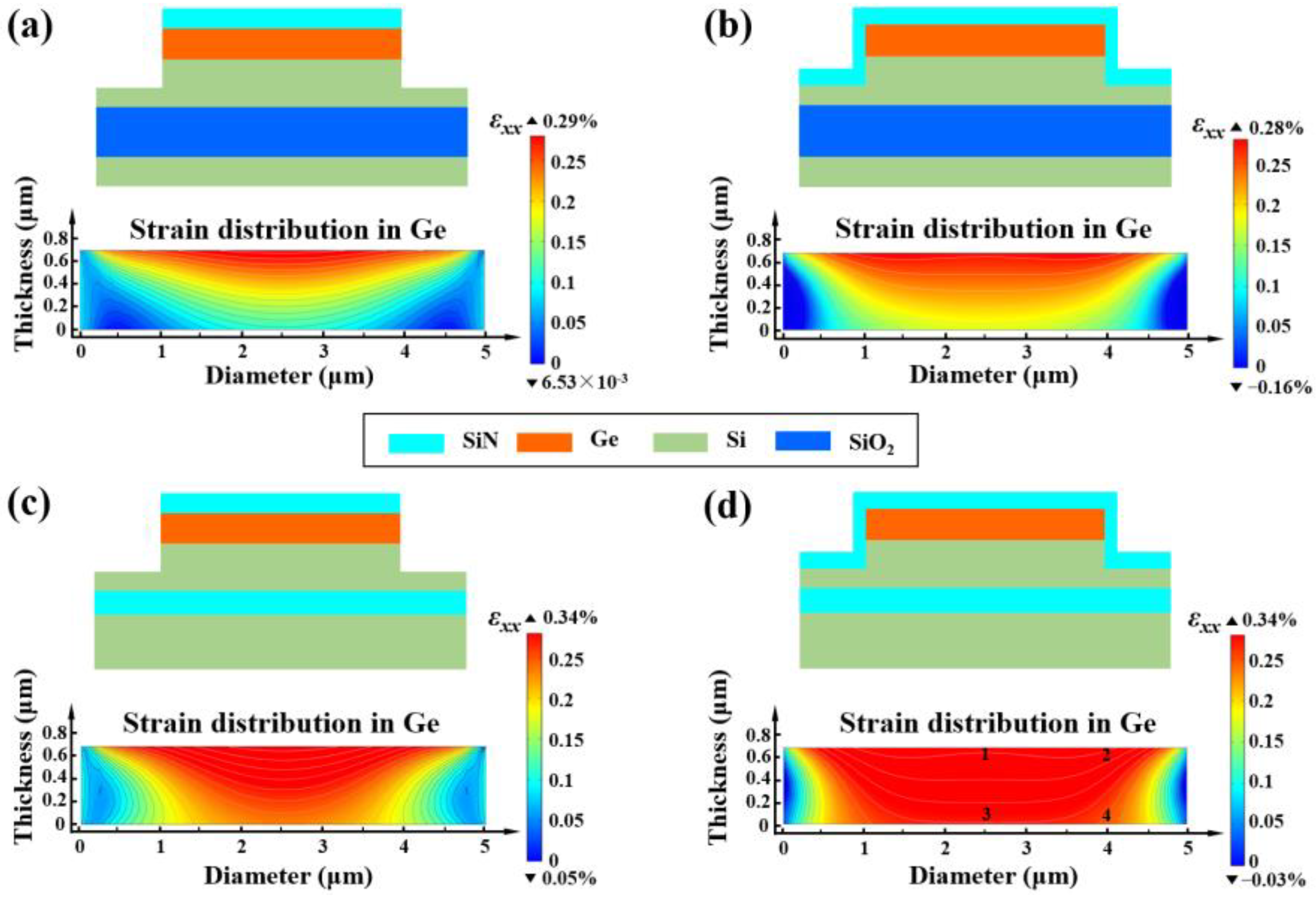

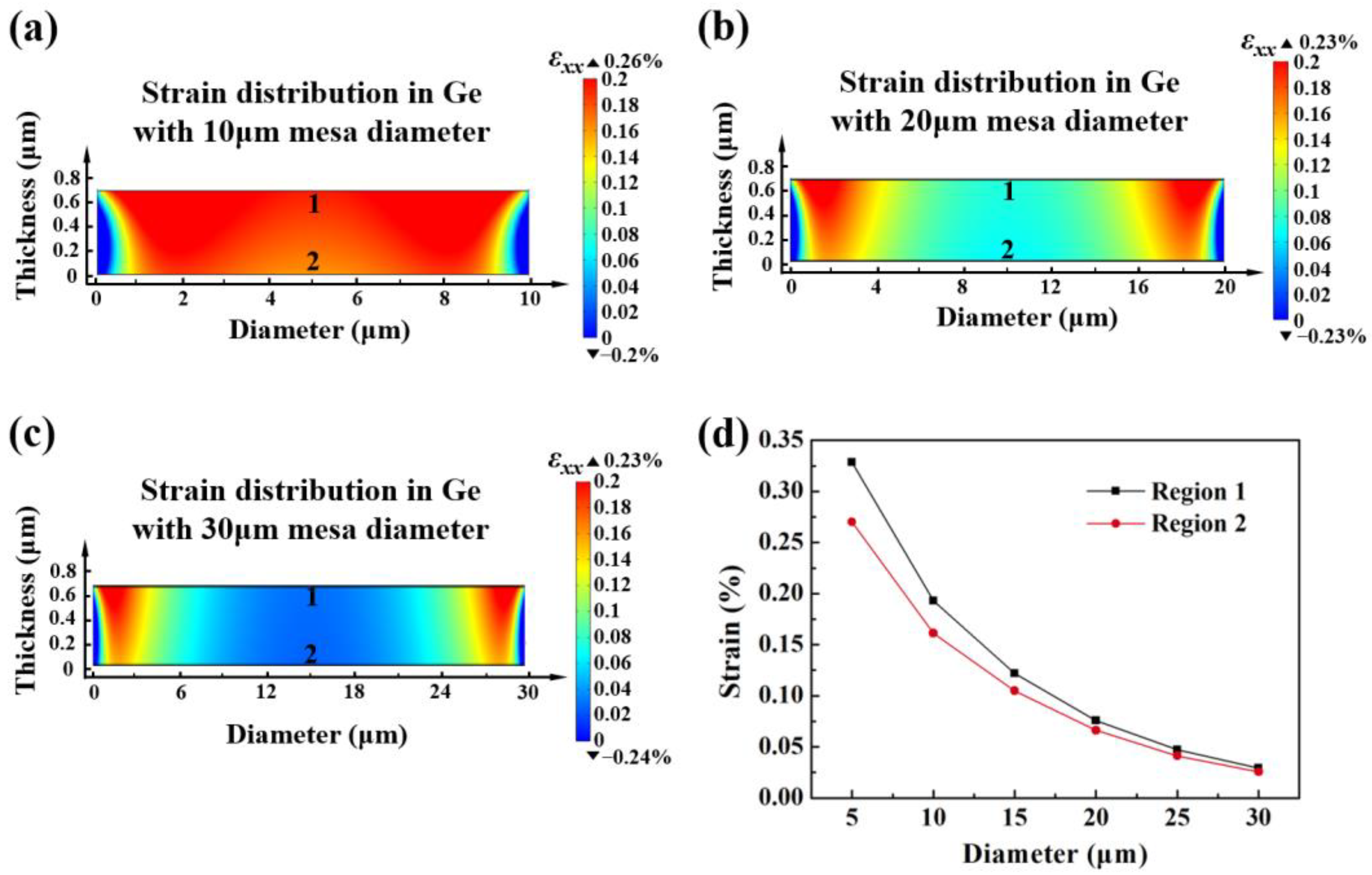

2. Design of Si-Based Strained Ge APD

3. Results and Discussion

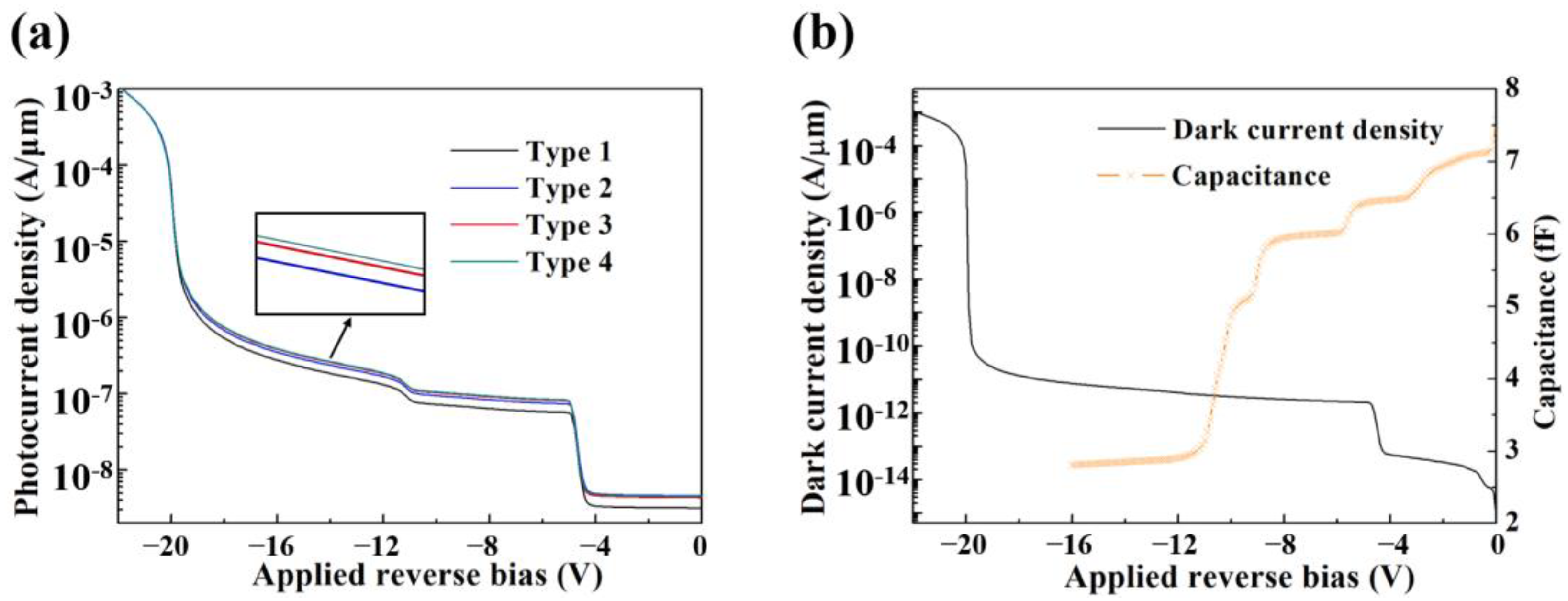

3.1. IV Characteristics

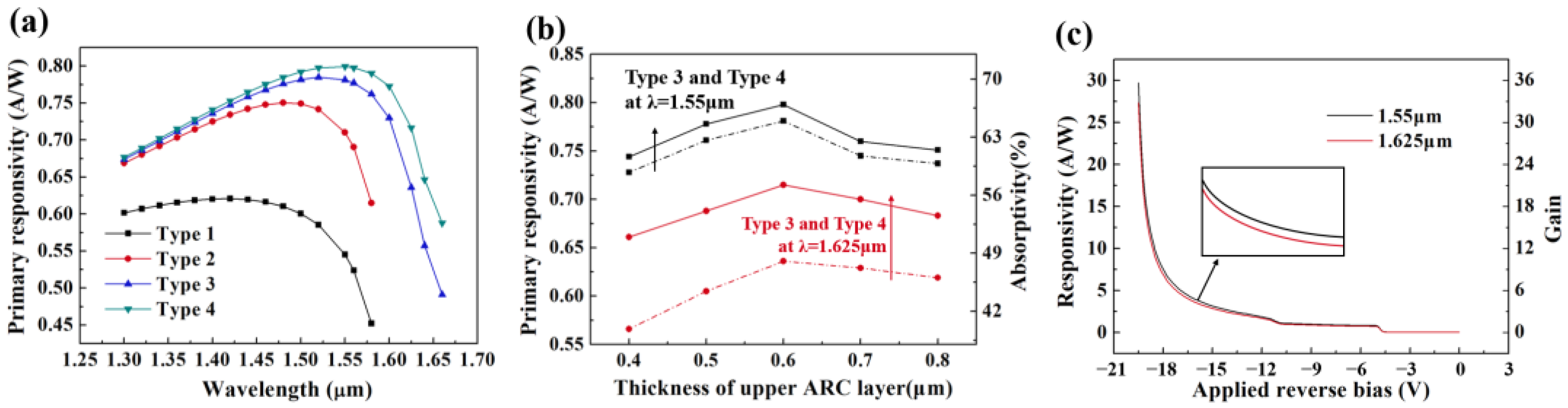

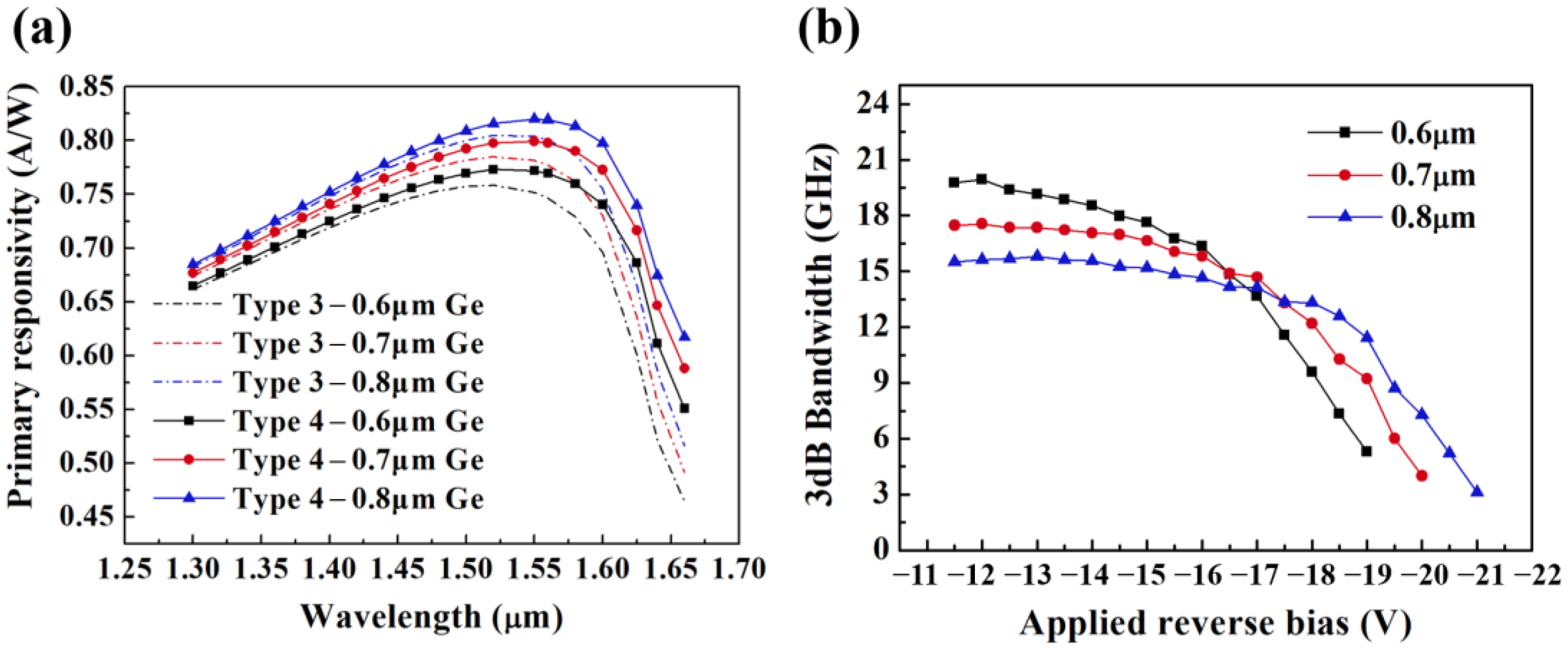

3.2. Responsivity Characteristics

3.3. Trade-Off between Responsivity and Bandwidth

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiang, Y.; Cao, H.; Liu, C.; Dai, D. High-performance waveguide Ge/Si avalanche photodiode with a lateral separate-absorption-charge-multiplication structure. Opt. Express 2022, 30, 11288–11297. [Google Scholar] [CrossRef]

- Park, S.; Malinge, Y.; Dosunmu, O.; Lovell, G.; Slavin, S.; Magruder, K.; Kang, Y.; Liu, A. 50-Gbps Receiver Subsystem Using Ge/Si Avalanche Photodiode and Integrated Bypass Capacitor. In Proceedings of the 2019 Optical Fiber Communications Conference and Exposition (OFC), San Diego, CA, USA, 3–7 March 2019; p. M3A.3. [Google Scholar]

- Huang, M.; Cai, P.; Li, S.; Hou, G.; Zhang, N.; Su, T.-I.; Hong, C.; Pan, D. 56GHz waveguide Ge/Si avalanche photodiode. In Proceedings of the 2018 Optical Fiber Communications Conference and Exposition (OFC), San Diego, CA, USA, 11–15 March 2018; p. W4D.6. [Google Scholar]

- Kang, Y.; Liu, H.D.; Morse, M.; Paniccia, M.J.; Zadka, M.; Litski, S.; Sarid, G.; Pauchard, A.; Kuo, Y.H.; Chen, H.W.; et al. Monolithic germanium/silicon avalanche photodiodes with 340 GHz gain–bandwidth product. Nat. Photonics 2009, 3, 59–63. [Google Scholar] [CrossRef]

- Ng, J.S.; Tan, C.H.; Davide, J.P.R. Avalanche Photodiodes beyond 1.65μm. Proc. of SPIE 2009, 7320, 73200V1–73200V11. [Google Scholar]

- Dong, Y.; Wang, W.; Xu, X.; Gong, X.; Lei, D.; Zhou, Q.; Xu, Z.; Loke, W.K.; Yoon, S.F.; Liang, G.; et al. Germanium-Tin on Si avalanche photodiode: Device design and technology demonstration. IEEE Trans. Electron Devices 2015, 62, 128–135. [Google Scholar] [CrossRef]

- Duan, N.; Liow, T.Y.; Lim, A.E.-J.; Ding, L.; Lo, G.Q. 310 GHz gain-bandwidth product Ge/Si avalanche photodetector for 1550 nm light detection. Opt. Express 2012, 20, 11031–11036. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Liu, X.; Zuo, C.; Yang, W.; Fang, X. Supersaturation-Controlled Growth of Monolithically Integrated Lead-Free Halide Perovskite Single-Crystalline Thin Film for High-Sensitivity Photodetectors. Adv. Mater. 2021, 31, 2103010. [Google Scholar] [CrossRef]

- Zhang, Y.; Loh, J.Y.Y.; Kherani, N.P. Facilely Achieved Self-Biased Black Silicon Heterojunction Photodiode with Broadband Quantum Efficiency Approaching 100%. Adv. Mater. 2022, 9, 2203234. [Google Scholar] [CrossRef]

- Gao, F.; Wang, J.H.; Watzinger, H.; Hu, H.; Rancic, M.J.; Zhang, J.Y.; Wang, T.; Yao, Y.; Wang, G.L.; Kukucka, J.; et al. Site-Controlled Uniform Ge/Si Hut Wires with Electrically Tunable Spin-Orbit Coupling. Adv. Mater. 2020, 32, 1906523. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, X.; Choy, W.C.H.; Xie, F.; Duan, C.; Wang, C.; He, W.; Huang, F.; Cao, Y. A study of optical properties enhancement in low-bandgap polymer solar cells with embedded PEDOT:PSS gratings. Sol. Energy Mater. Sol. Cells 2012, 99, 327–332. [Google Scholar] [CrossRef]

- Lin, L.; Ou, Y.; Zhu, X.; Stamate, E.; Wu, K.; Liang, M.; Liu, Z.; Yi, X.; Herstrom, B.; Boisen, A.; et al. InGaN/GaN ultraviolet LED with a graphene/AZO transparent current spreading layer. Opt. Mater. Express 2018, 8, 1818–1826. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Huang, Z.; Zeng, X.; Liang, D.; Sorin, W.V.; Fiorentino, M.; Beausoleil, R.G. High Responsivity Si-Ge Waveguide Avalanche Photodiodes Enhanced by Loop Reflector. IEEE J. Sel. Top. Quantum Electron 2021, 28, 1–8. [Google Scholar] [CrossRef]

- Tani, K.; Oda, K.; Okumura, T.; Takezaki, T.; Kasai, J.-i.; Mine, T.; Ido, T. Enhanced Electroluminescence from Germanium Waveguides by Local Tensile Strain with Silicon Nitride Stressors. In Proceedings of the 2013 International Conference on Solid State Devices and Materials (SSDM), Fukuoka, Japan, 23–27 September 2013; pp. 1032–1033. [Google Scholar]

- Saito, S.; Gardes, F.Y.; Al-Attili, A.Z.; Tani, K.; Oda, K.; Suwa, Y.; Ido, T.; Ishikawa, Y.; Kako, S.; Iwamoto, S.; et al. Group IV Light Sources to Enable the Convergence of Photonics and Electronics. Front. Mater. 2014, 1, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Xiong, W.; Wang, G.; Li, J.; Zhao, C.; Wang, W.; Radamson, H.H. SiN-based platform toward monolithic integration in photonics and electronics. J Mater Sci: Mater. Electron. 2021, 32, 1–18. [Google Scholar] [CrossRef]

- Millar, R.W.; Gallacher, K.; Frigerio, J.; Ballabio, A.; Bashir, A.; MacLaren, I.; Isella, G.; Paul, D.J. Analysis of Ge micro-cavities with in-plane tensile strains above 2%. Opt. Express 2016, 24, 4365–4374. [Google Scholar] [CrossRef] [Green Version]

- Kurdi, M.E.; Prost, M.; Ghrib, A.; Sauvage, S.; Checoury, X.; Beaudoin, G.; Sagnes, I.; Picardi, G.; Ossikovski, R.; Boucaud, P. Direct Band Gap Germanium Microdisks Obtained with Silicon Nitride Stressor Layers. ACS Photonics 2016, 3, 443–448. [Google Scholar] [CrossRef]

- Lin, Y.; Ma, D.; Lee, K.H.; Wen, R.T.; Syaranamual, G.; Kimerling, L.C.; Tan, C.S.; Michel, J. PIC-integrable, uniformly tensile-strained Ge-on-insulator photodiodes enabled by recessed SiNx stressor. Photonics Res. 2021, 9, 1255–1263. [Google Scholar] [CrossRef]

- Van de Walle, C.G. Band lineups and deformation potentials in the model-solid theory. Phys. Rev. B. 1989, 39, 1871–1883. [Google Scholar]

- Liu, J.; Cannon, D.D.; Wada, K.; Ishikawa, Y.; Danielson, D.T.; Jongthammanurak, S.; Michel, J.; Kimerling, L.C. Deformation potential constants of biaxially tensile stressed Ge epitaxial films on Si (100). Phys. Rev. B. 2004, 70, 155309. [Google Scholar] [CrossRef]

- Liu, J.; Sun, X.; Pan, D.; Wang, X.; Kimerling, L.C.; Koch, T.L.; Michel, J. Tensile-strained, n-type Ge as a gain medium for monolithic laser integration on Si. Opt. Express 2007, 15, 11272–11277. [Google Scholar] [CrossRef]

- Yurasov, D.V.; Bobrov, A.I.; Daniltsev, V.M.; Novikov, A.V.; Pavlov, D.A.; Skorokhodov, E.V.; Shaleev, M.V.; Yunin, P.A. Impact of growth and annealing conditions on the parameters of Ge/Si (001) relaxed layers grown by molecular beam epitaxy. Semiconductors 2015, 49, 1415–1420. [Google Scholar] [CrossRef]

- Capellini, G.; Seta, M.D.; Zaumseil, P.; Kozlowski, G.; Schroeder, T. High temperature x ray diffraction measurements on Ge/Si (001) heterostructures: A study on the residual tensile strain. J. Appl. Phys. 2012, 111, 073518. [Google Scholar] [CrossRef]

- Novikov, A.V.; Yurasov, D.V.; Morozova, E.E.; Skorohodov, E.V.; Verbus, V.A.; Yablonskiy, A.N.; Baidakova, N.A.; Gusev, N.S.; Kudryavtsev, K.E.; Nezhdanov, A.V.; et al. Formation and Properties of Locally Tensile Strained Ge Microstructures for Silicon Photonics. Semiconductors 2018, 52, 1442–1447. [Google Scholar] [CrossRef]

- Cheng, B.W.; Li, C.B.; Yao, F.; Xue, C.L.; Zhang, J.G.; Mao, R.W.; Zuo, Y.H.; Luo, L.P.; Wang, Q.M. Silicon membrane resonant-cavity-enhanced photodetector. Appl. Phys. Lett. 2005, 87, 061111. [Google Scholar] [CrossRef]

- Li, G.; André, N.; Poncelet, O.; Gérard, P.; Ali, S.Z.; Udrea, F.; Francis, L.A.; Zeng, Y.; Flandre, D. Operation of Suspended Lateral SOI PIN Photodiode with Aluminum Back Gate. In Proceedings of the 2016 Joint International EUROSOI Workshop and International Conference on Ultimate Integration on Silicon (EUROSOI-ULIS), Vienna, Austria, 25–27 January 2016; pp. 155–158. [Google Scholar]

- Huang, M.; Li, S.; Cai, P.; Hou, G.; Su, T.I.; Chen, W.; Hong, C.Y.; Pan, D. Germanium on Silicon Avalanche Photodiode. IEEE J. Sel. Top. Quantum Electron 2018, 24, 1–11. [Google Scholar] [CrossRef]

- Kang, Y.; Zadka, M.; Litski, S.; Sarid, G.; Morse, M.; Paniccia, M.J.; Kuo, Y.H.; Bowers, J.; Beling, A.; Liu, H.D.; et al. Epitaxially-grown Ge/Si avalanche photodiodes for 1.3μm light detection. Opt. Express 2008, 16, 9365–9371. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Mu, J. High-speed Si-Ge avalanche photodiodes. PhotoniX 2022, 3, 1–22. [Google Scholar] [CrossRef]

- Huang, Z.; Li, C.; Liang, D.; Yu, K.; Santori, C.; Fiorentino, M.; Sorin, W.; Palermo, S.; Beausoleil, R.G. A 25Gbps low-voltage waveguide Si-Ge avalanche photodiode. Optica 2016, 3, 793–798. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Li, Y.; Li, Y.; Zhi, Z.; Tao, M.; Chen, B.; Zhang, L.; Guo, P.; Lo, G.; et al. Three-terminal germanium-on-silicon avalanche photodiode with extend p-charge layer for dark current reduction. Photonics Res. 2022, 10, 1956–1963. [Google Scholar] [CrossRef]

- Srinivasan, S.A.; Berciano, M.; Heyn, P.D.; Lardenois, S.; Pantouvaki, M.; Campenhout, J.V. 27 GHz Silicon-Contacted Waveguide-Coupled Ge/Si Avalanche Photodiode. J. Lightwave Technol. 2020, 38, 3044–3050. [Google Scholar] [CrossRef]

- Benedikovic, D.; Virot, L.; Aubin, G.; Hartmann, J.M.; Amar, F.; Roux, X.L.; Alonso-Ramos, C.; Cassan, E.; Marris-Morini, D.; Crozat, P.; et al. 40 Gbps heterostructure germanium avalanche photo receiver on a silicon chip. Optica 2020, 7, 775–783. [Google Scholar] [CrossRef]

- Zeng, X.; Huang, Z.; Wang, B.; Liang, D.; Fiorentino, M.; Beausoleil, R.G. Silicon–germanium avalanche photodiodes with direct control of electric field in charge multiplication region. Optica 2019, 6, 772–777. [Google Scholar] [CrossRef]

- Hsin, C.L.; Chou, C.H. Buffer-Free Ge/Si by Rapid Melting Growth Technique for Separate Absorption and Multiplication Avalanche Photodetectors. IEEE Electron. Device. Lett. 2019, 40, 945–948. [Google Scholar] [CrossRef]

| Type | Device Structure | RCE | SiN Stressor |

|---|---|---|---|

| 1 | Structure 2 | × | × |

| 2 | Structure 2 | √ | × |

| 3 | Structure 2 | √ | √ |

| 4 | Structure 4 | √ | √ |

| Ref. | λ (μm) | Device Type | Device Structure | Vbr (V) | Id (μA) | Rp (A/W) | Gain | f3-dB (GHz) | GBP (GHz) |

|---|---|---|---|---|---|---|---|---|---|

| [31] | 1.55 | Waveguide-integrated | Vertical SACM | −10 | 1 | 0.75 | 12 | 25 | 276 |

| [33] | 1.55 | Waveguide-integrated | Lateral SACM | −12 | 100 | 0.78 | 36 | 27 | 300 |

| [34] | 1.55 | Waveguide-integrated | Lateral PIN | −11 | 100 | 0.49 | 13 | 16 | 210 |

| [35] | 1.55 | Waveguide-integrated | Three-Terminal | −6 | 1000 | 0.48 | 15 | 18.9 | / |

| [7] | 1.55 | Surface-illuminated | Vertical SACM | −29.0 | 5 | 0.3 | 39 | 13 * | 310 |

| [28] | 1.55 | Surface-illuminated | Vertical SACM | −28.5 | 3 | 0.9 | 12 | 7 (M = 12) | 84 * |

| [36] | 1.55 | Surface-illuminated | Vertical SACM | −27 | 100 | 0.26 | 34.5 | / | / |

| This work | 1.55 | Surface-illuminated | Vertical SACM | −20.2 | 7.85 | 0.80 | 18 | 17.5 | 162 |

| 1.625 | 0.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Li, X.; Cai, Y.; Wang, W.; Yu, M. Design and Optimization of High-Responsivity High-Speed Ge/Si Avalanche Photodiode in the C+L Band. Micromachines 2023, 14, 108. https://doi.org/10.3390/mi14010108

Li C, Li X, Cai Y, Wang W, Yu M. Design and Optimization of High-Responsivity High-Speed Ge/Si Avalanche Photodiode in the C+L Band. Micromachines. 2023; 14(1):108. https://doi.org/10.3390/mi14010108

Chicago/Turabian StyleLi, Chuan, Xinyu Li, Yan Cai, Wei Wang, and Mingbin Yu. 2023. "Design and Optimization of High-Responsivity High-Speed Ge/Si Avalanche Photodiode in the C+L Band" Micromachines 14, no. 1: 108. https://doi.org/10.3390/mi14010108