Laser-Assisted Mist Capillary Self-Alignment

Abstract

:1. Introduction

2. Methods and Materials

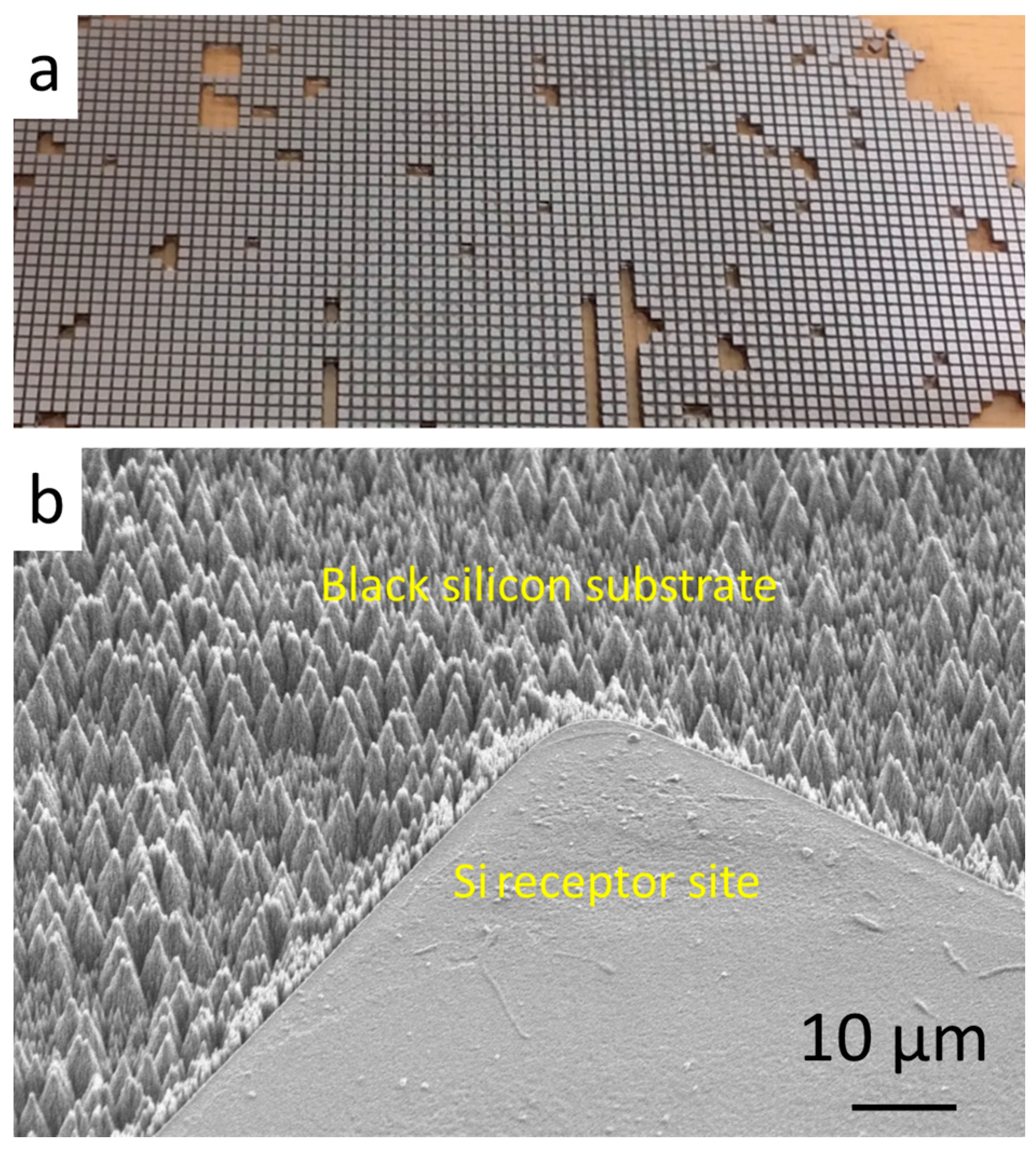

2.1. Materials

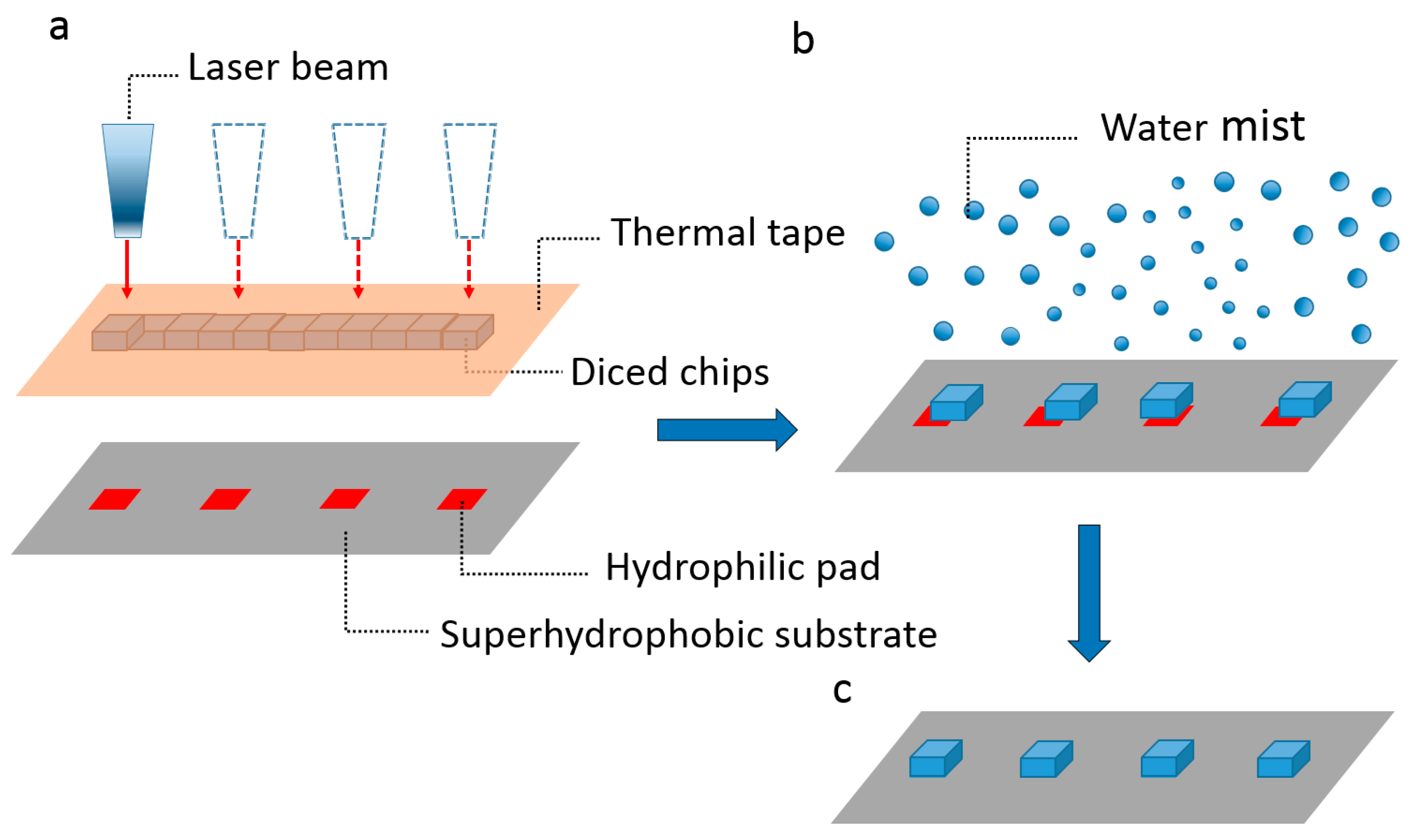

2.2. Method

2.3. Experimental Setup

3. Results

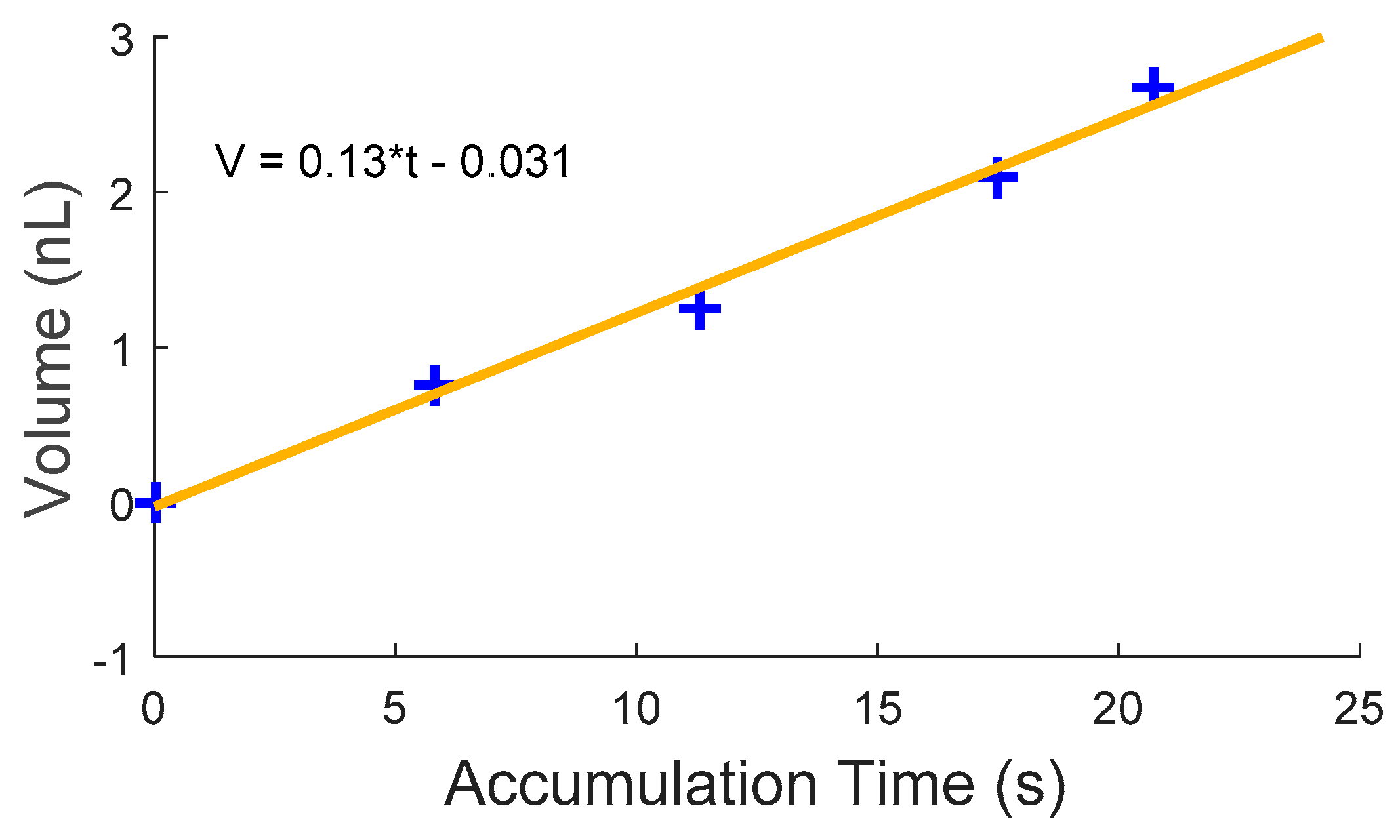

3.1. Laser Beam Diameter Estimation

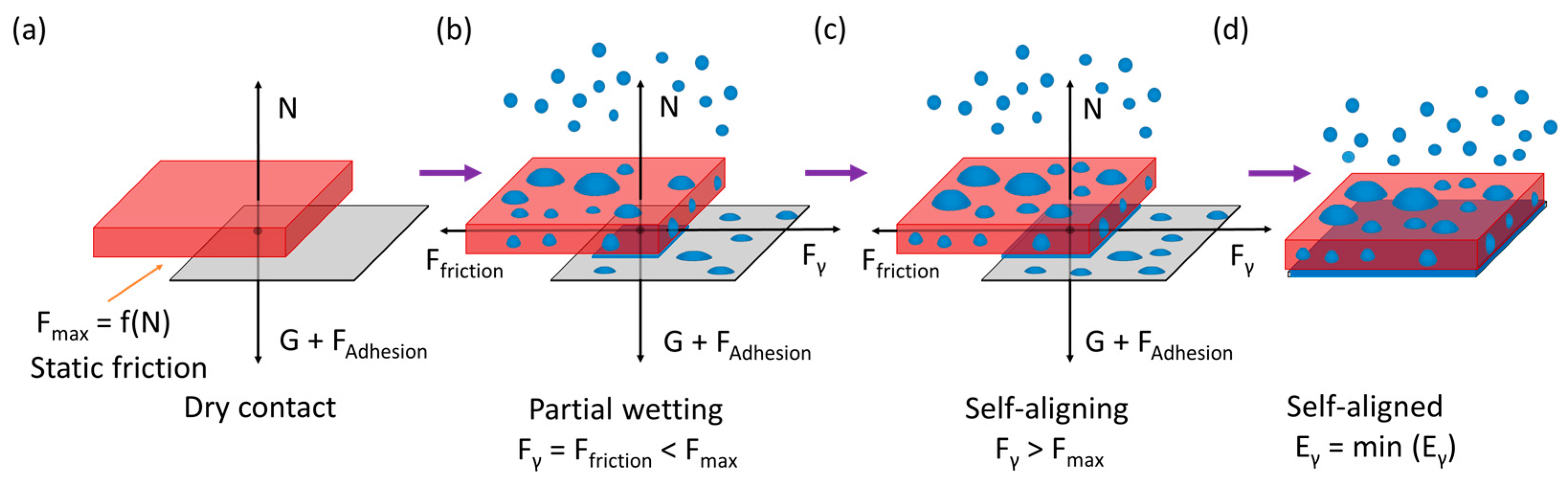

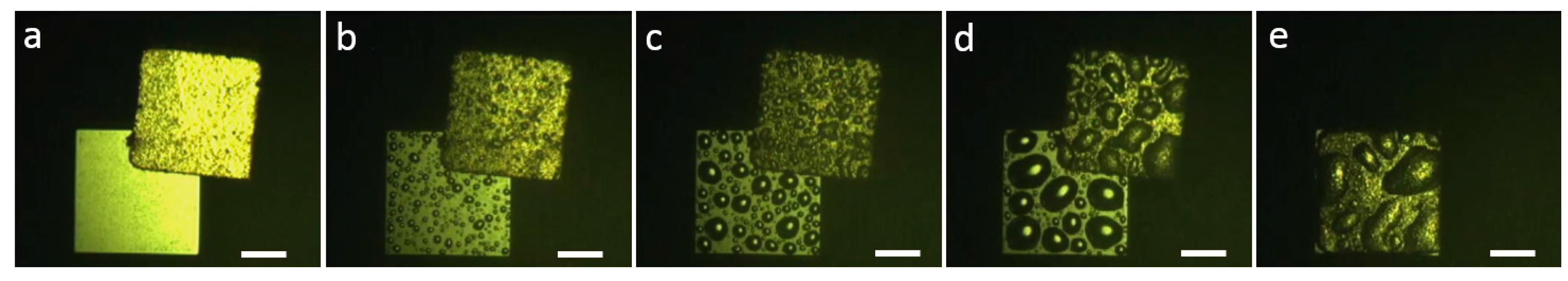

3.2. Mist Capillary Self-Alignment Process

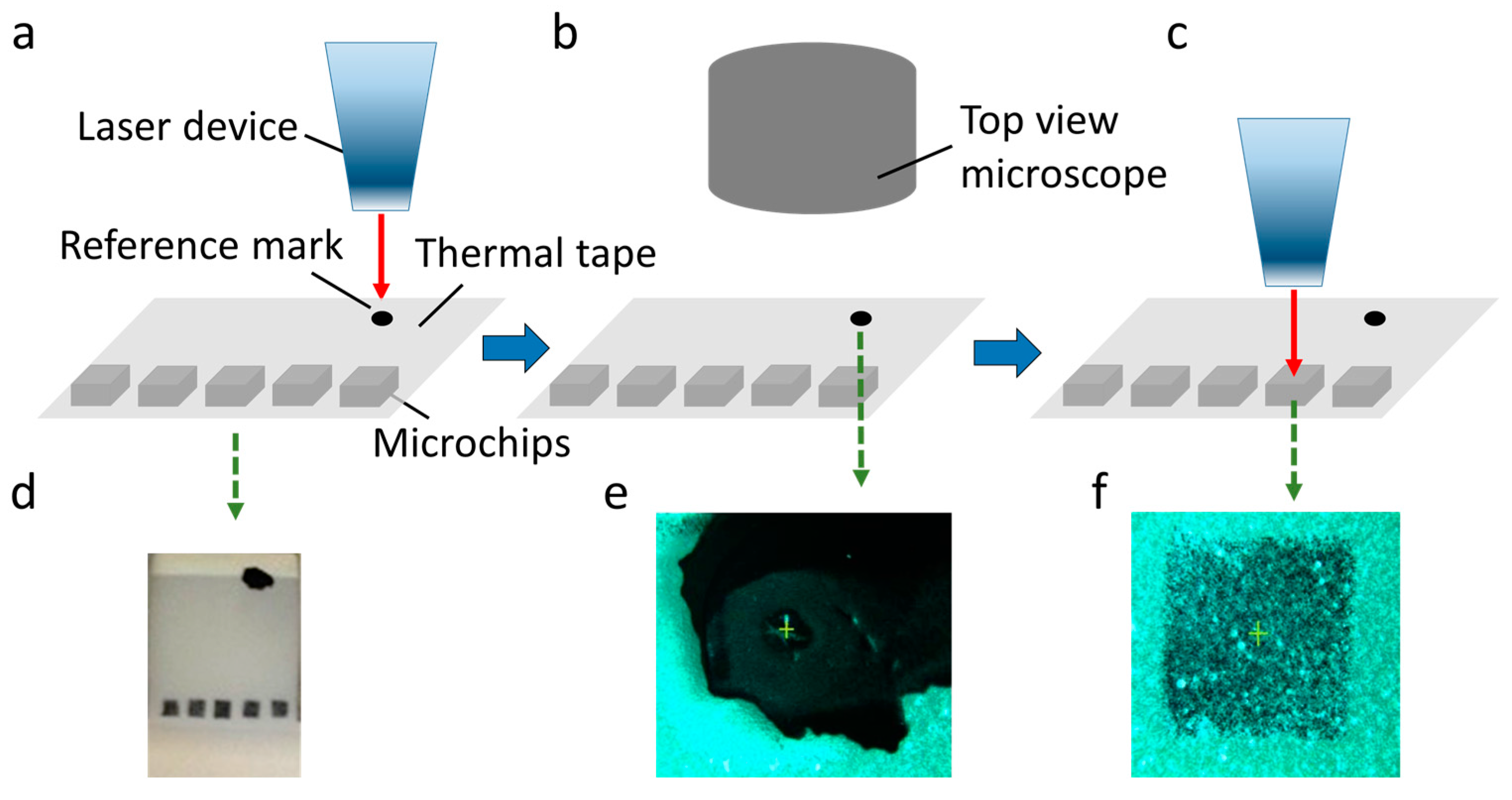

3.3. Laser Die Releasing Procedure

3.4. Mist Capillary Self-Alignment

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fang, J.; Böhringer, K.F. Parallel micro component-to-substrate assembly with controlled poses and high surface coverage. J. Micromech. Microeng. 2006, 16, 721–730. [Google Scholar] [CrossRef]

- Park, S.C.; Fang, J.; Biswas, S.; Mozafari, M.; Stauden, T.; Jacobs, H.O. A first implementation of an automated reel-to-reel fluidic self-assembly machine. Adv. Mater. 2014, 26, 5942–5949. [Google Scholar] [CrossRef] [PubMed]

- Chang, B.; Shah, A.; Zhou, Q.; Ras, R.H.A.; Hjort, K. Self-transport and self-alignment of microchips using microscopic rain. Sci. Rep. 2015, 5, 14966. [Google Scholar] [CrossRef] [PubMed]

- Mastrangeli, M.; Zhou, Q.; Sariola, V.; Lambert, P. Surface tension-driven self-alignment. Soft Matter 2017, 13, 304–327. [Google Scholar] [CrossRef] [PubMed]

- Lambert, P.; Mastrangeli, M.; Valsamis, J.B.; Degrez, G. Spectral analysis and experimental study of lateral capillary dynamics for flip-chip applications. Microfluid. Nanofluid. 2010, 9, 797–807. [Google Scholar] [CrossRef]

- Boote, J.J.; Critchley, K.; Evans, S.D. Surfactant mediated assembly of gold nanowires on surfaces. J. Exp. Nanosci. 2006, 1, 125–142. [Google Scholar] [CrossRef]

- Whitesides, G.M.; Grzybowski, B.A.; Stone, H.A. Dynamic self-assembly of magnetized, millimetre-sized objects rotating at a liquid–air interface. Nature 2000, 405, 1033–1036. [Google Scholar]

- Chang, B.; Routa, I.; Sariola, V.; Zhou, Q. Self-alignment of RFID dies on four-pad patterns with water droplet for sparse self-assembly. J. Micromech. Microeng. 2011, 21, 095024. [Google Scholar] [CrossRef]

- Gracias, D.H. Forming Electrical Networks in Three Dimensions by Self-Assembly. Science 2000, 289, 1170–1172. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, H.O. Fabrication of a Cylindrical Display by Patterned Assembly. Science 2002, 296, 323–325. [Google Scholar] [CrossRef] [PubMed]

- Knuesel, R.J.; Jacobs, H.O. Self-assembly of microscopic chiplets at a liquid-liquid-solid interface forming a flexible segmented monocrystalline solar cell. Proc. Natl. Acad. Sci. USA 2010, 107, 993–998. [Google Scholar] [CrossRef] [PubMed]

- Chung, S.E.; Park, W.; Shin, S.; Lee, S.A.; Kwon, S. Guided and fluidic self-assembly of microstructures using railed microfluidic channels. Nat. Mater. 2008, 7, 581–587. [Google Scholar] [CrossRef] [PubMed]

- Sato, K.; Hata, S.; Shimokohbe, A. Self-Alignment for Microparts Assembly Using Water Surface Tension. In Proceedings of the Device and Process Technologies for MEMS and Microelectronics, Gold Coast, Australia, 1 October 1999; Volume 3892, pp. 321–329. [Google Scholar]

- Chang, B.; Sariola, V.; Jääskeläinen, M.; Zhou, Q. Self-alignment in the stacking of microchips with mist-induced water droplets. J. Micromech. Microeng. 2011, 21, 015016. [Google Scholar] [CrossRef]

- Leong, T.G.; Lester, P.A.; Koh, T.L.; Call, E.K.; Gracias, D.H. Surface tension-driven self-folding polyhedra. Langmuir 2007, 23, 8747–8751. [Google Scholar] [CrossRef] [PubMed]

- Gracias, D.H.; Kavthekar, V.; Love, J.C.; Paul, K.E.; Whitesides, G.M. Fabrication of micrometer-scale, patterned polyhedra by self-assembly. Adv. Mater. 2002, 14, 235–238. [Google Scholar] [CrossRef]

- Routa, I.; Chang, B.; Shah, A.; Zhou, Q. Surface tension-driven self-alignment of microchips on low-precision receptors. J. Microelectromech. Syst. 2014, 23, 819–828. [Google Scholar] [CrossRef]

- Meitl, M.A.; Zhu, Z.-T.; Kumar, V.; Lee, K.J.; Feng, X.; Huang, Y.Y.; Adesida, I.; Nuzzo, R.G.; Rogers, J.A. Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat. Mater. 2006, 5, 33–38. [Google Scholar] [CrossRef]

- Karlitskaya, N.S. Study of laser die release by Q-switched Nd:YAG laser pulses. In Proceedings of the Society of Photo-Optical Instrumentation Engineers, Taos, NM, USA, 20 September 2004; Volume 5448, pp. 935–943. [Google Scholar]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Zhang, Y.; Jia, L.; Mathewson, K.E.; Jang, K.-I.; Kim, J.; Fu, H.; Huang, X.; Chava, P.; Wang, R.; et al. Soft Microfluidic Assemblies of Sensors, Circuits, and Radios for the Skin. Science 2014, 344, 70–74. [Google Scholar] [CrossRef] [PubMed]

- Marinov, V.R.; Swenson, O.; Atanasov, Y.; Schneck, N. Laser-assisted ultrathin die packaging: Insights from a process study. Microelectron. Eng. 2013, 101, 23–30. [Google Scholar] [CrossRef]

- Chang, B.; Koverola, M.; Ge, Z.; Zhou, Q. Hybrid Microassembly combining Laser Die Transfer and Capillary Self-alignment. In Proceedings of the 2017 International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Montreal, QC, Canada, 17–21 July 2017; pp. 38–41. [Google Scholar]

- Shah, A.; Chang, B.; Suihkonen, S.; Zhou, Q.; Lipsanen, H. Surface-Tension-Driven Self-Alignment of Microchips on Black-Silicon-Based Hybrid Template in Ambient Air. J. Microelectromech. Syst. 2013, 22, 739–746. [Google Scholar] [CrossRef]

- Karlitskaya, N. Laser Die Transfer: Laser-Induced Transfer of Microcomponents; University of Twente: Enschede, The Netherlands, 2011. [Google Scholar]

- Brakke, K.A. The Surface Evolver. Exp. Math. 1992, 1, 141–165. [Google Scholar] [CrossRef]

- Zhou, Q.; Liimatainen, V.; Routa, I. Microsystem integration using hybrid microassembly. In Proceedings of the 2014 5th Electronics System-Integration Technology Conference ESTC, Helsinki, Finland, 16–18 September 2014; pp. 4–9. [Google Scholar]

| Test | Inner Diameter (μm) | Outer Diameter (μm) |

|---|---|---|

| # 1 | 240.54 | 316.22 |

| # 2 | 253.15 | 330.63 |

| # 3 | 263.06 | 315.32 |

| Average | 252.58 | 320.72 |

| Test | Average Releasing Time | Success Rate |

|---|---|---|

| # 1 | 390.3 ms | 4/5 |

| # 2 | 380.4 ms | 5/5 |

| # 3 | 398.1 ms | 3/5 |

| # 4 | 300.2 ms | 5/5 |

| # 5 | 357.3 ms | 4/5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, B.; Zhu, Z.; Koverola, M.; Zhou, Q. Laser-Assisted Mist Capillary Self-Alignment. Micromachines 2017, 8, 361. https://doi.org/10.3390/mi8120361

Chang B, Zhu Z, Koverola M, Zhou Q. Laser-Assisted Mist Capillary Self-Alignment. Micromachines. 2017; 8(12):361. https://doi.org/10.3390/mi8120361

Chicago/Turabian StyleChang, Bo, Zhaofei Zhu, Mikko Koverola, and Quan Zhou. 2017. "Laser-Assisted Mist Capillary Self-Alignment" Micromachines 8, no. 12: 361. https://doi.org/10.3390/mi8120361