Micro-Dosing of Fine Cohesive Powders Actuated by Pulse Inertia Force

Abstract

:1. Introduction

2. Materials and Methods

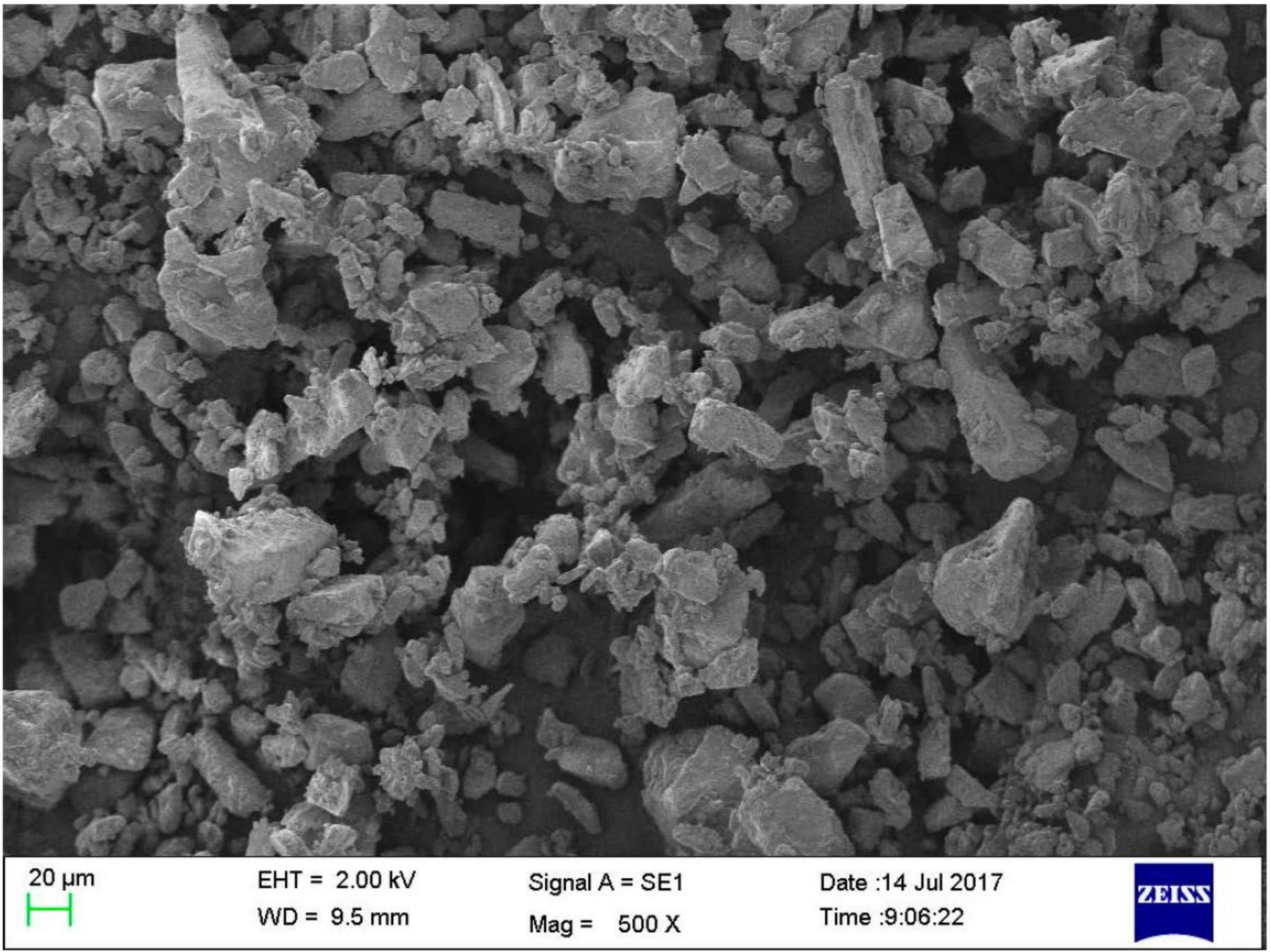

2.1. Materials

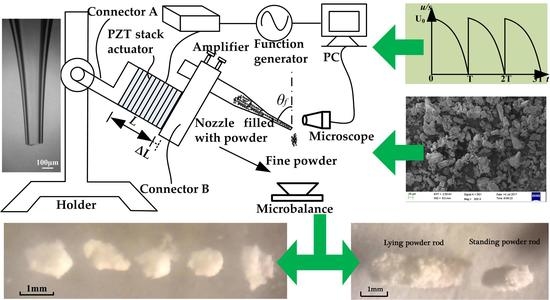

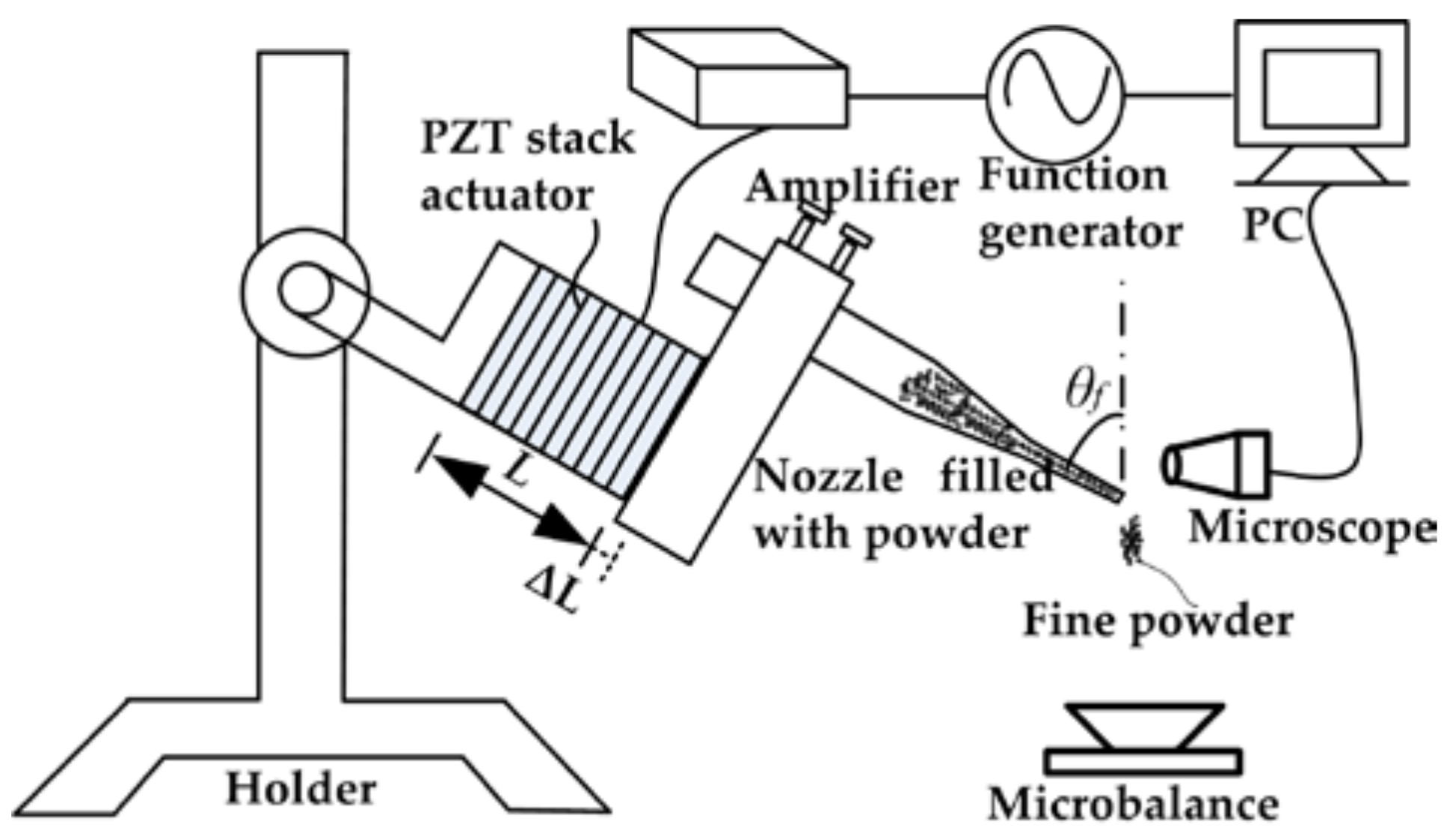

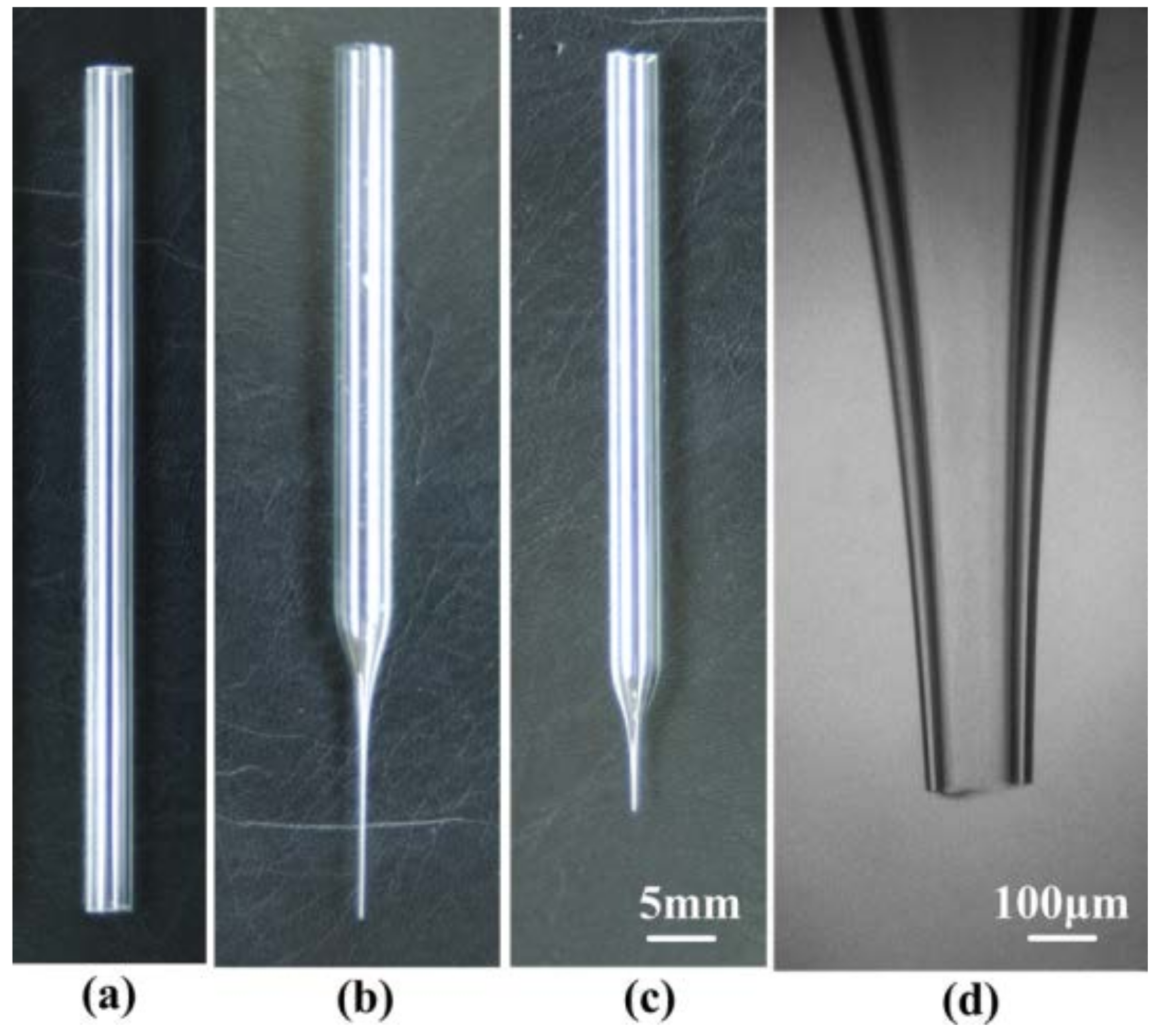

2.2. Experiment Apparatus

2.3. Powder Dosing Principle

3. Results and Discussion

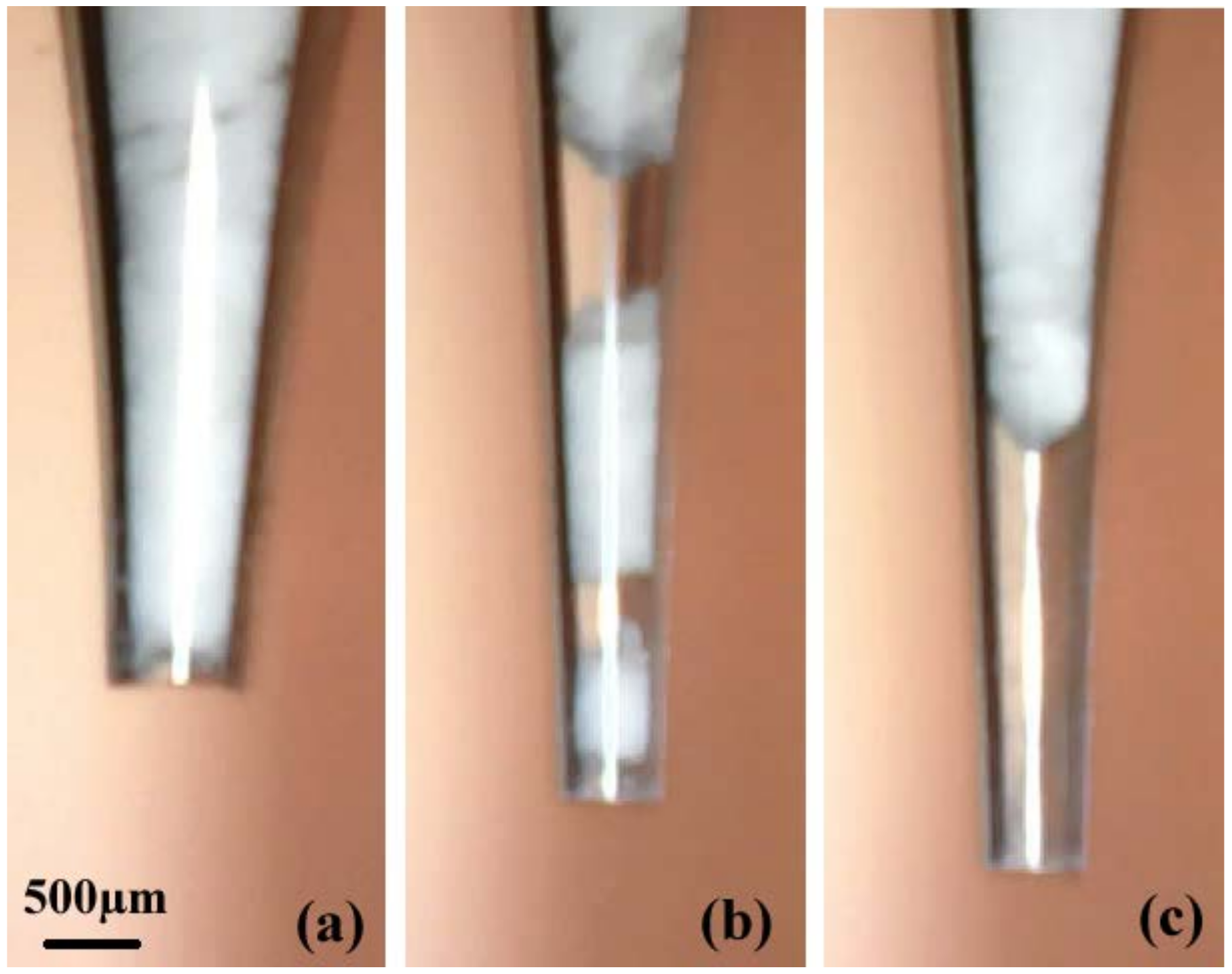

3.1. Aggregation Phenomena

3.2. Micro-Dosing Mass

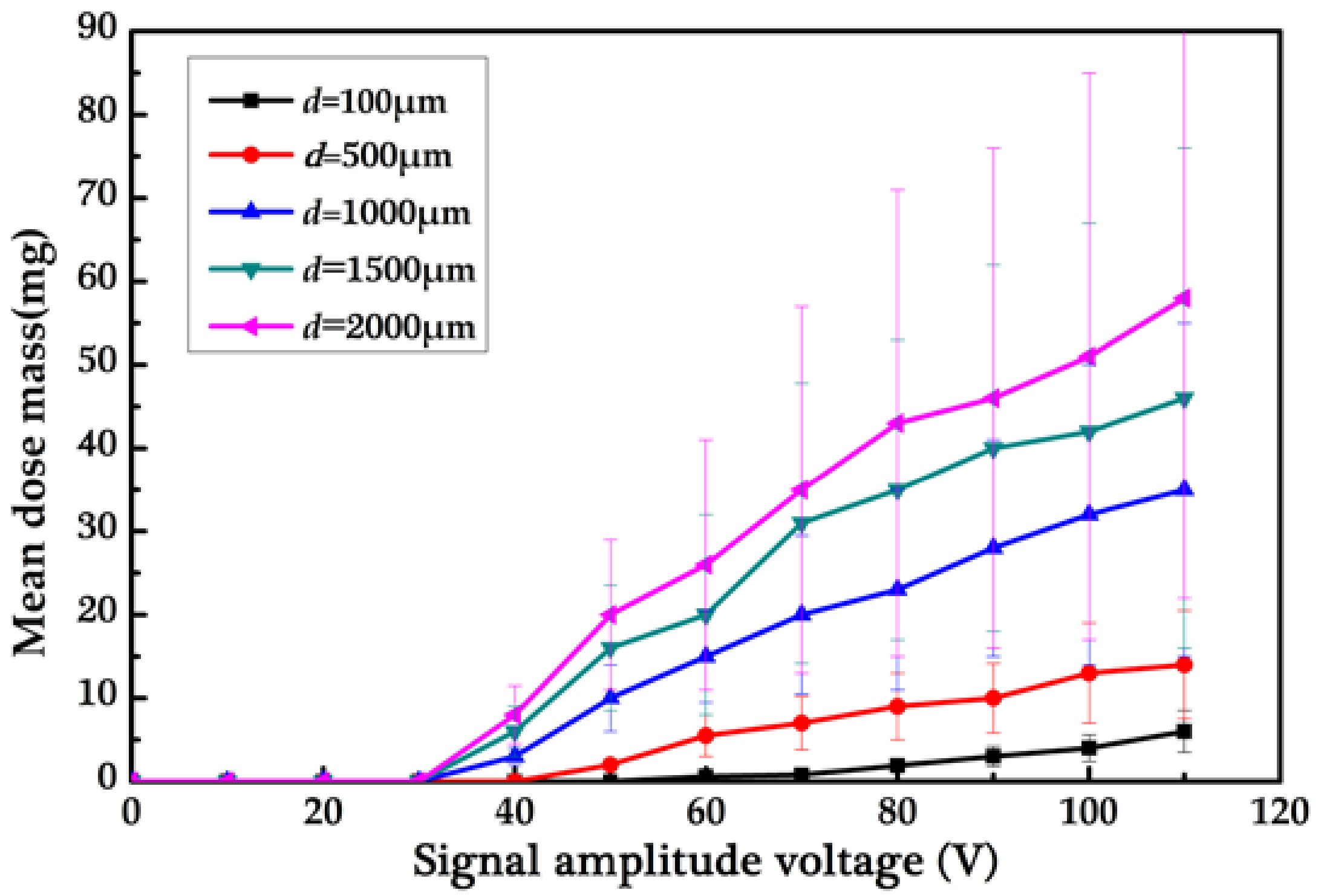

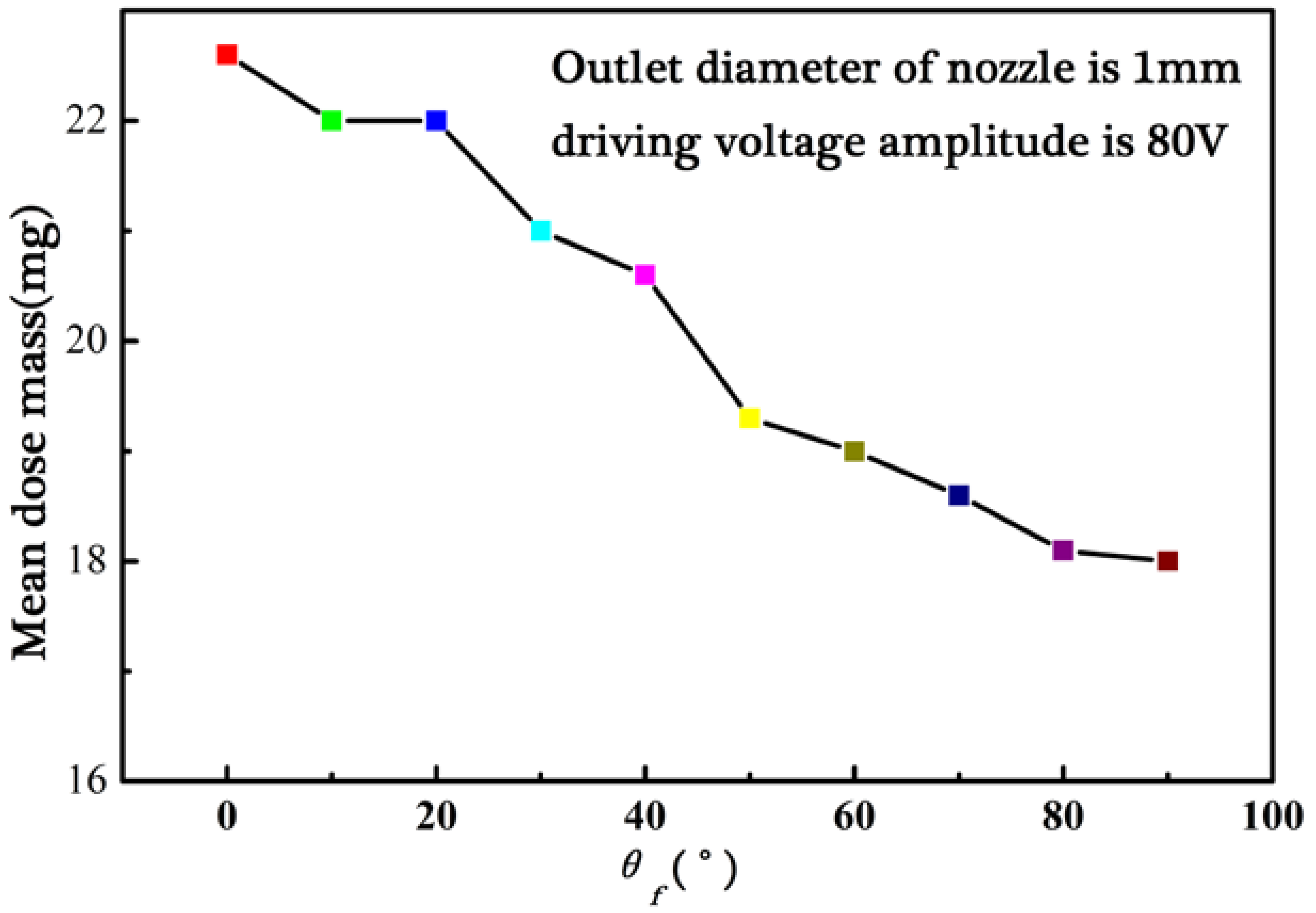

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Karg, M.C.H.; Ahuja, B.; Wiesenmayer, S.; Kuryntsev, S.V.; Schmidt, M. Effects of process conditions on the mechanical behavior of aluminium wrought alloy EN AW-2219 (AlCu6Mn) additively manufactured by laser beam melting in powder bed. Micromachines 2017, 8, 23. [Google Scholar] [CrossRef]

- Lee, H.; Kwon, J.; Shin, W.S.; Kim, H.R.; Shin, J.; Cho, H.; Han, S.; Yeo, J.; Hong, S. Large-area compatible laser sintering schemes with a spatially extended focused beam. Micromachines 2017, 8, 153. [Google Scholar] [CrossRef]

- Mirko, K.; Milan, S.; Manja, K.K. Use of wood powder and adhesive as a mixture for 3D printing. Eur. J. Wood Prod. 2016, 74, 123–126. [Google Scholar]

- Michalson, E.T. High potency active pharmaceutical ingredients: An overview of safety and manufacturing concerns. Chim. Oggi 2007, 25, 18–20. [Google Scholar]

- Hertel, M.; Schwarz, E.; Kobler, M.; Hauptstein, S.; Steckel, H. Powder flow analysis: A simple method to indicate the ideal amount of lactose fines in dry powder inhaler formulations. Int. J. Pharm. 2018, 535, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.L.; Zhang, Q.; Huang, C.; Wang, Y.; Yang, C.H.; Wei, F. Validation of surface coating with nanoparticles to improve the flowability of fine cohesive powders. Particuology 2017, 30, 53–61. [Google Scholar] [CrossRef]

- Barletta, D.; Poletto, M. Aggregation phenomena in fluidization of cohesive powders assisted by mechanical vibrations. Powder Technol. 2012, 225, 93–100. [Google Scholar] [CrossRef]

- Kaur, B.; Mittal, A.; Wypych, P.; Mallick, S.S.; Jana, S. On developing improved modelling and scale-up procedures for pneumatic conveying of fine powders. Powder Technol. 2017, 305, 270–278. [Google Scholar] [CrossRef]

- Kovalenko, V.; Yao, J.; Zhang, Q.; Hu, X.; Zhuk, R. Development of Multichannel Gas-powder Feeding System Coaxial with Laser Beam. Procedia CIRP 2016, 42, 96–100. [Google Scholar] [CrossRef]

- Yang, Q.L.; Ma, Y.L.; Zhu, J.; Chow, K.; Shi, K. An update on electrostatic powder coating for pharmaceuticals. Particuology 2017, 31, 1–7. [Google Scholar] [CrossRef]

- Yang, S.; Evans, J.R.G. On the rate of descent of powder in a vibrating tube. Philos. Mag. 2005, 85, 1089–1109. [Google Scholar] [CrossRef]

- Matsusaka, S.; Yamamoto, K.; Masuda, H. Micro-feeding of a fine powder using a vibrating capillary tube. Adv. Powder Technol. 1996, 7, 141–151. [Google Scholar] [CrossRef]

- Qi, L.; Zeng, X.H.; Zhou, J.M.; Luo, J.; Chao, Y.P. Stable micro-feeding of fine powders using a capillary with ultrasonic vibration. Powder Technol. 2011, 214, 237–242. [Google Scholar] [CrossRef]

- Lu, X.S.; Yang, S.F.; Evans, J.L.R.G. Microfeeding with different ultrasonic nozzle designs. Ultrasonics 2009, 49, 514–521. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.S.; Yang, S.F.; Evens, J.R. Studies on ultrasonic microfeeding of fine powders. J. Phys. D Appl. Phys. 2006, 39, 2444–2453. [Google Scholar] [CrossRef]

- Lu, X.S.; Yang, S.F.; Evens, J.L.R.G. Dose uniformity of fine powders in ultrasonic microfeeding. Powder Technol. 2007, 175, 63–72. [Google Scholar] [CrossRef]

- Besenhard, M.O.; Faulhammer, E.; Fathollahi, S.; Reif, G.; Calzolari, V.; Biserni, S.; Ferrari, A.; Lawrence, S.M.; Llusa, M.; Khinast, J.G. Accuracy of micro powder dosing via a vibratory sieve-chute system. Eur. J. Pharm. Biopharm. 2015, 94, 264–272. [Google Scholar] [CrossRef] [PubMed]

- Besenhard, M.O.; Karkala, S.K.; Faulhammer, E.; Fathollahi, S.; Ramachandran, R.; Khinast, J.G. Continuous feeding of low-dose APIs via periodic micro dosing. Int. J. Pharm. 2016, 509, 123–134. [Google Scholar] [CrossRef] [PubMed]

- Besenhard, M.O.; Fathollahi, S.; Siegmann, E.; Slama, E.; Faulhammer, E.; Khinast, J.G. Micro-feeding and dosing of powders via a small-scale powder pump. Int. J. Pharm. 2017, 519, 314–322. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.C.; Hou, L.Y.; Zhang, W.Y. A drop-on-demand droplet generator for coating catalytic materials on microhotplates of micropellistor. Sens. Actuators B Chem. 2013, 183, 342–349. [Google Scholar] [CrossRef]

- Russo, P.; Chirone, R.; Massimilla, L.; Russo, S. The influence of the frequency of acoustic waves on sound-assisted fluidization of beds of fine particles. Powder Technol. 1995, 82, 219–230. [Google Scholar] [CrossRef]

| Name | Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| RespitoseSV003 | Characteristics | X10/μm | X50/μm | X90/μm | Bulk density/g·cm−3 | Tapped density | Carr Index | AoR | AR |

| Sieved | 46.1 | 71.0 | 100.0 | 0.67 | 0.85 | 20.8 | 35.85° | 0.69 | |

| Samples | Voltage | 40 V | 50 V | 60 V | 70 V | 80 V | 90 V | 100 V | 110 V |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 9.3 | 15.2 | 17.6 | 22.6 | 23 | 29.3 | 29.2 | |

| 2 | 3.2 | 10.6 | 14.1 | 21 | 21 | 26.5 | 34.2 | 30.5 | |

| 3 | 3.1 | 10.9 | 16.2 | 23.3 | 23.5 | 31.8 | 28.3 | 38.3 | |

| 4 | 2.9 | 11 | 15.9 | 18.3 | 19.3 | 29.5 | 39.1 | 39 | |

| 5 | 2.8 | 10 | 17 | 19.6 | 25 | 31 | 30.5 | 41.6 | |

| 6 | 2.9 | 10.2 | 15.6 | 21.4 | 24.5 | 32 | 32.2 | 31.2 | |

| 7 | 3 | 10.6 | 14.7 | 17.3 | 18.3 | 24.5 | 26.2 | 39.5 | |

| 8 | 3 | 9.9 | 14.6 | 22.2 | 22.6 | 30.2 | 36.3 | 36.7 | |

| 9 | 2.8 | 10.6 | 13.2 | 22.2 | 18.5 | 24.6 | 36.8 | 35.3 | |

| 10 | 3.1 | 9.2 | 16.2 | 19.5 | 24 | 26.2 | 24.3 | 26.4 | |

| 3.0 | 10.2 | 15.3 | 20.2 | 22.8 | 23 | 31.7 | 34.8 | ||

| C·V | 4.41% | 6.13% | 7.39% | 10.32% | 10.32% | 12% | 15.3% | 14.69% | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhang, T.; Zhao, M.; Chen, R.; Wu, L. Micro-Dosing of Fine Cohesive Powders Actuated by Pulse Inertia Force. Micromachines 2018, 9, 73. https://doi.org/10.3390/mi9020073

Wang H, Zhang T, Zhao M, Chen R, Wu L. Micro-Dosing of Fine Cohesive Powders Actuated by Pulse Inertia Force. Micromachines. 2018; 9(2):73. https://doi.org/10.3390/mi9020073

Chicago/Turabian StyleWang, Hongcheng, Ting Zhang, Miaomiao Zhao, Rangrang Chen, and Liqun Wu. 2018. "Micro-Dosing of Fine Cohesive Powders Actuated by Pulse Inertia Force" Micromachines 9, no. 2: 73. https://doi.org/10.3390/mi9020073