Three-Dimensional Simulation of DRIE Process Based on the Narrow Band Level Set and Monte Carlo Method

Abstract

:1. Introduction

2. Models of Three-Dimensional DRIE Process

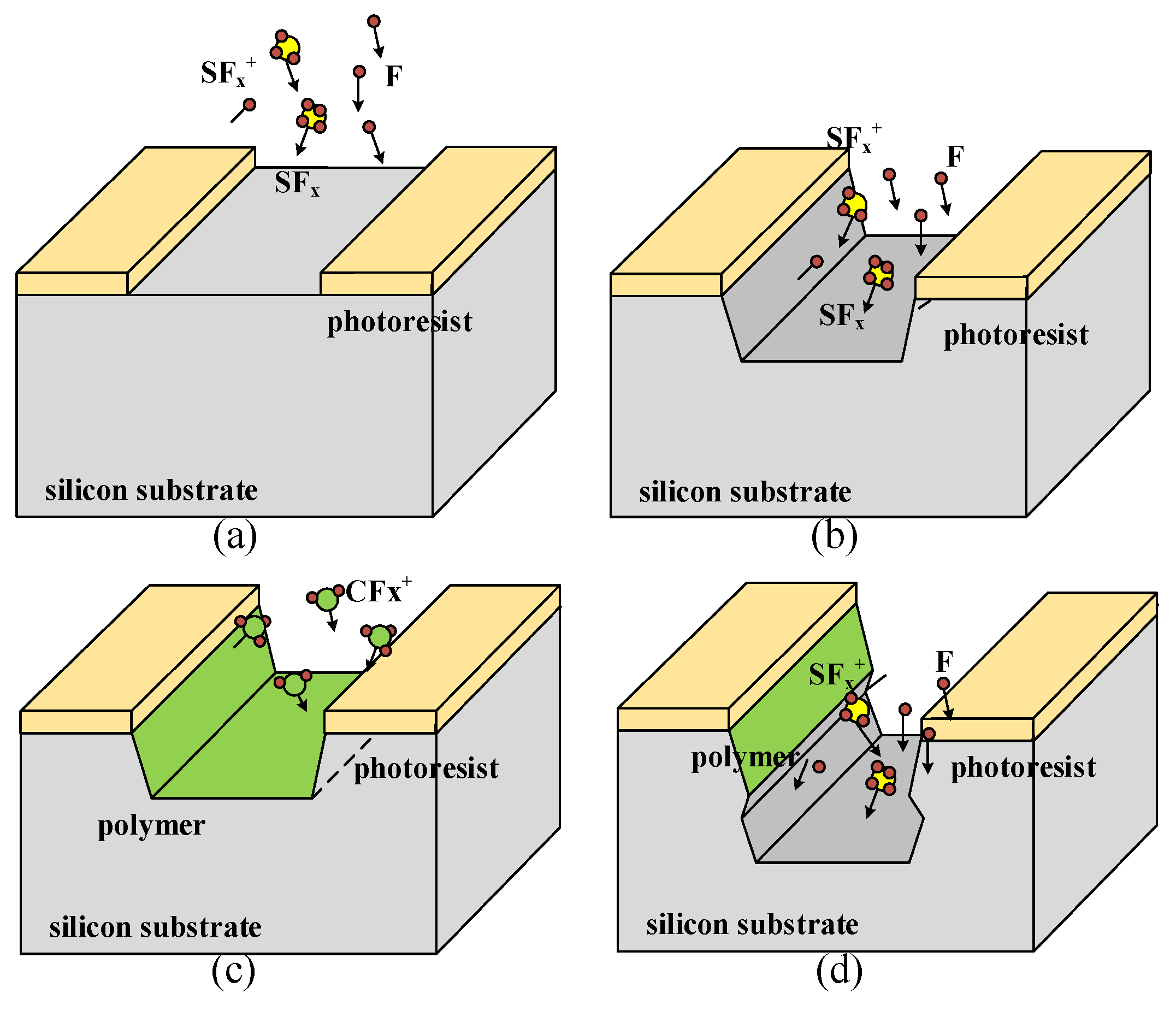

2.1. Theoretical Model of DRIE Process

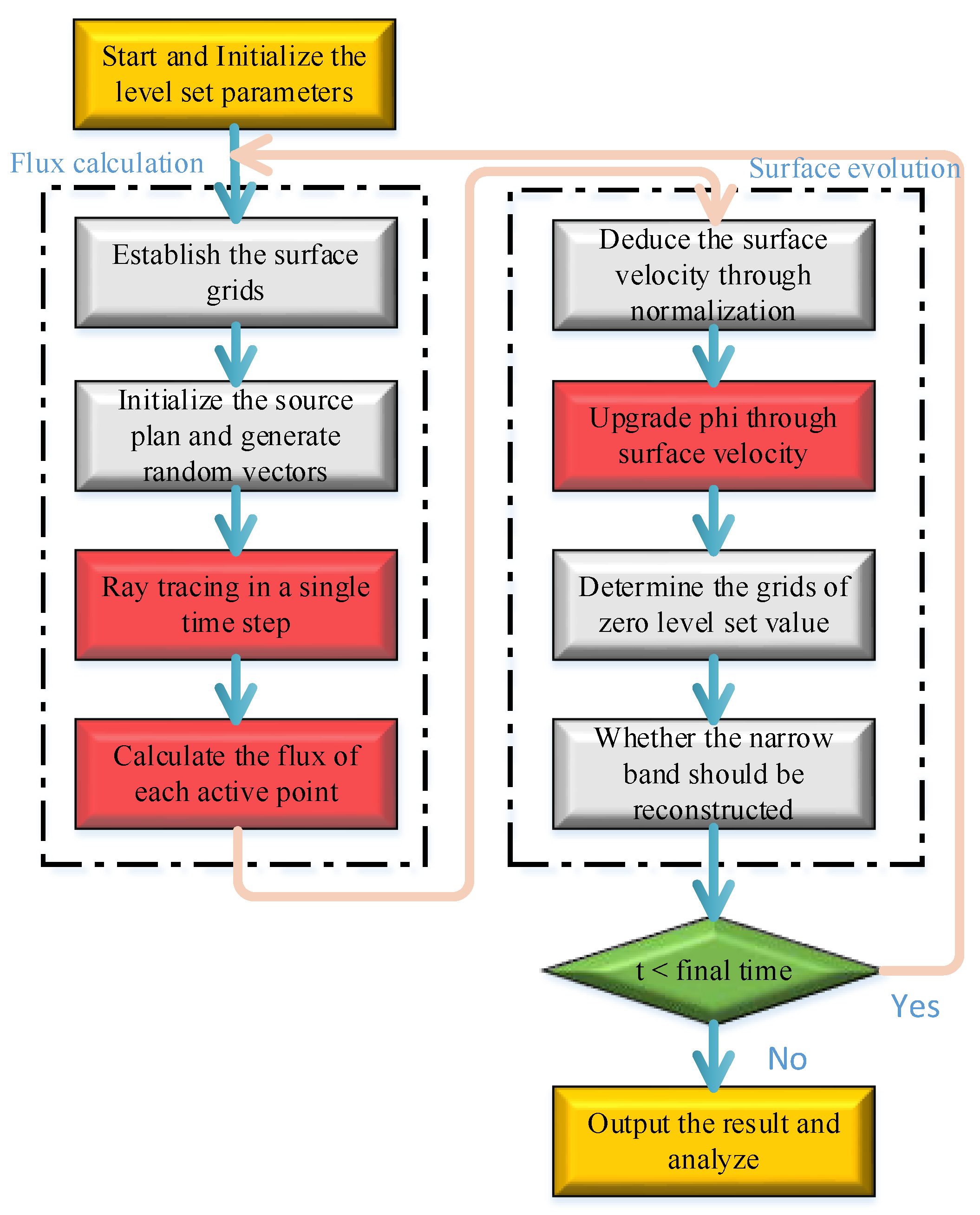

2.2. The Main Steps of Simulation

3. Simulation Methods

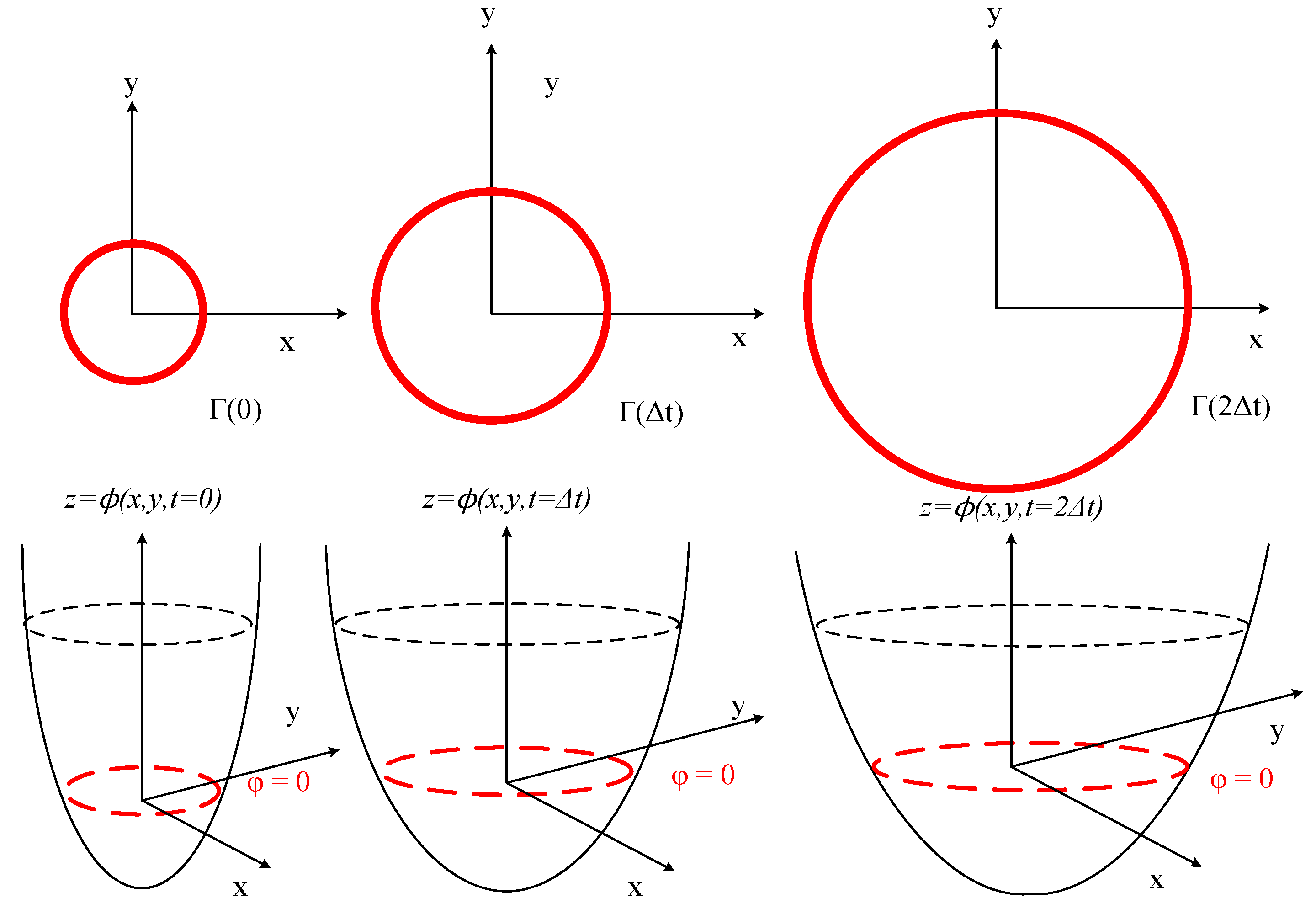

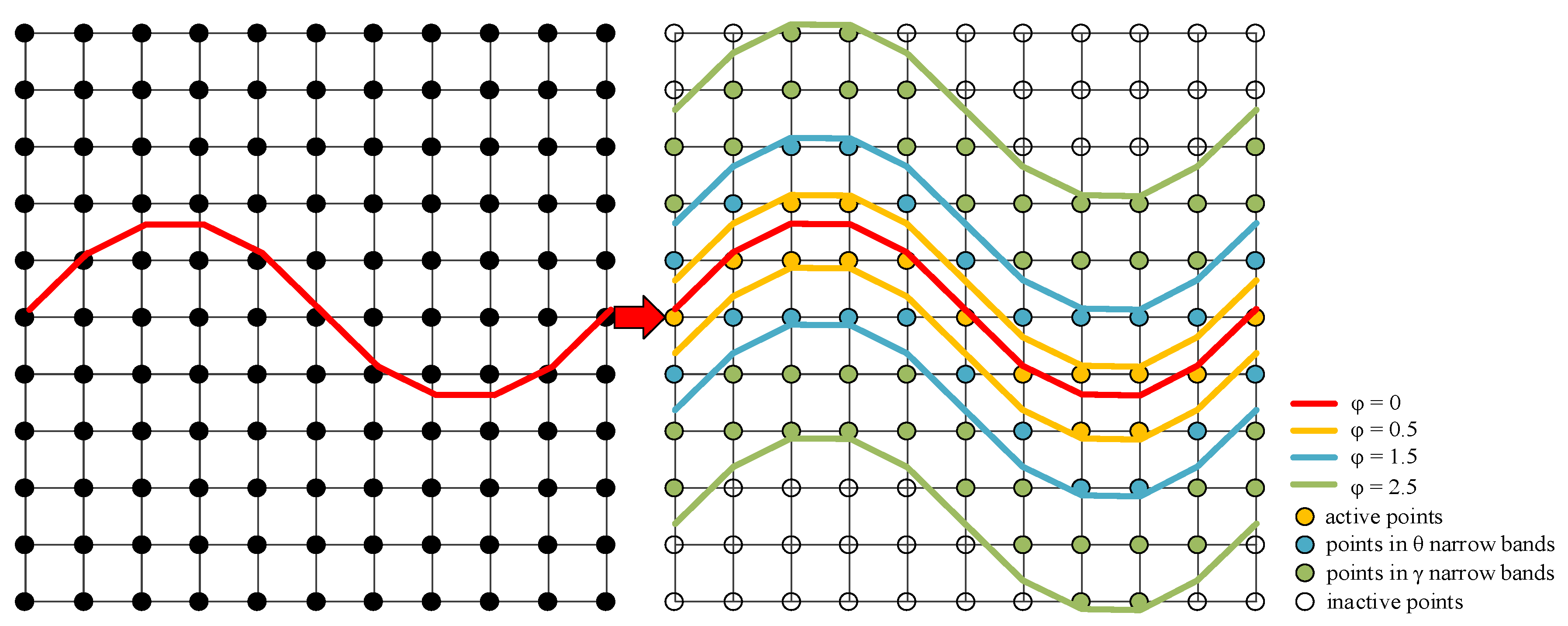

3.1. Narrow Band Level Set Method

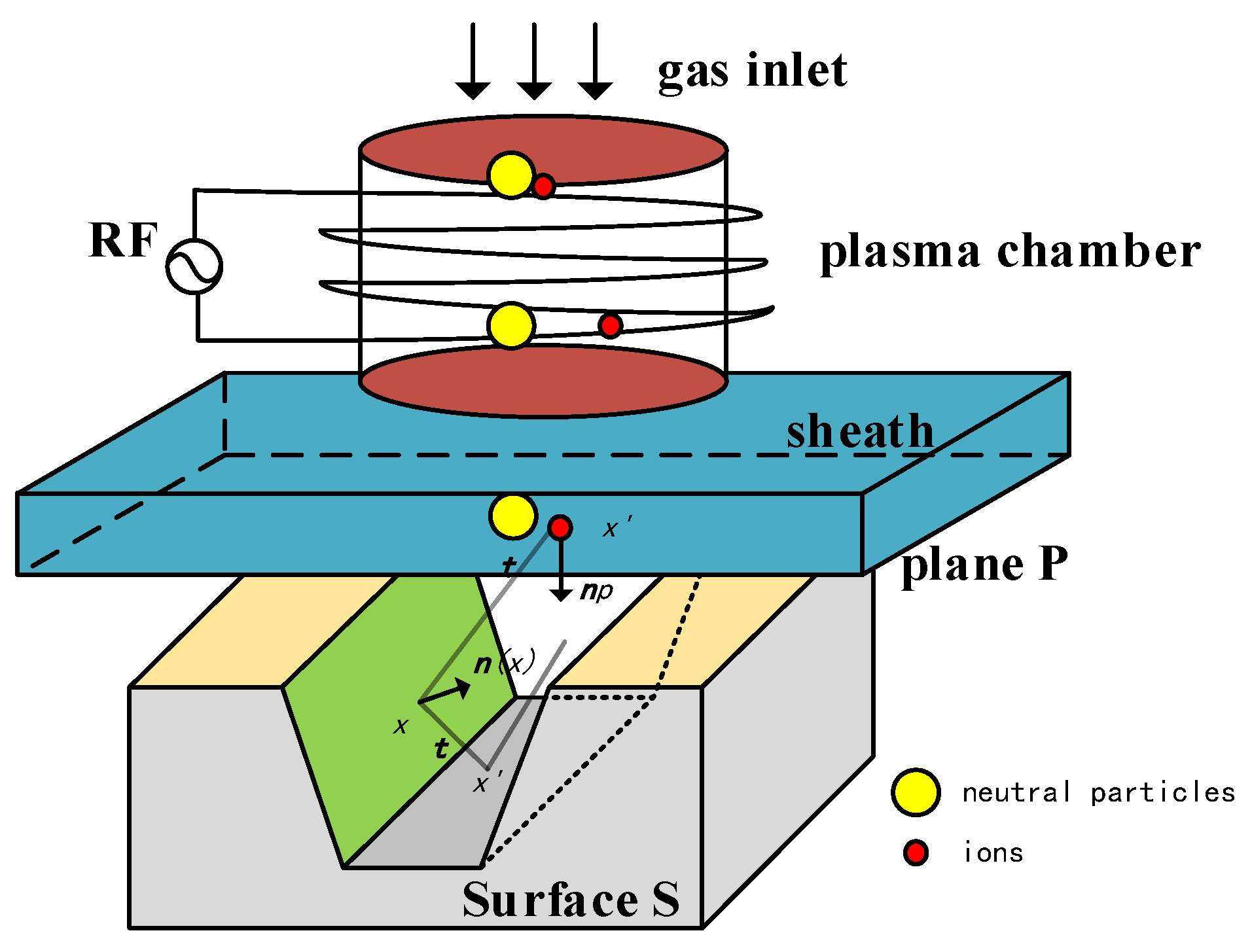

3.2. Monte Carlo Method Accelerated by Ray Tracing

- Step 1: Calculate the distance d1 between origin x′ and center x.

- Step 2: Calculate the closest distance d2 between ray and center x.

- Step 3: Find square of half chord intersection distance d3.

- Step 4: Test if square is negative (no intersection).

- Step 5: Compare the distance d1 and choose the minimum (first intersection).

- Step 6: Find the normal vector.

- Step 7: Calculate the reflective direction.

4. Simulation and Experimental Results

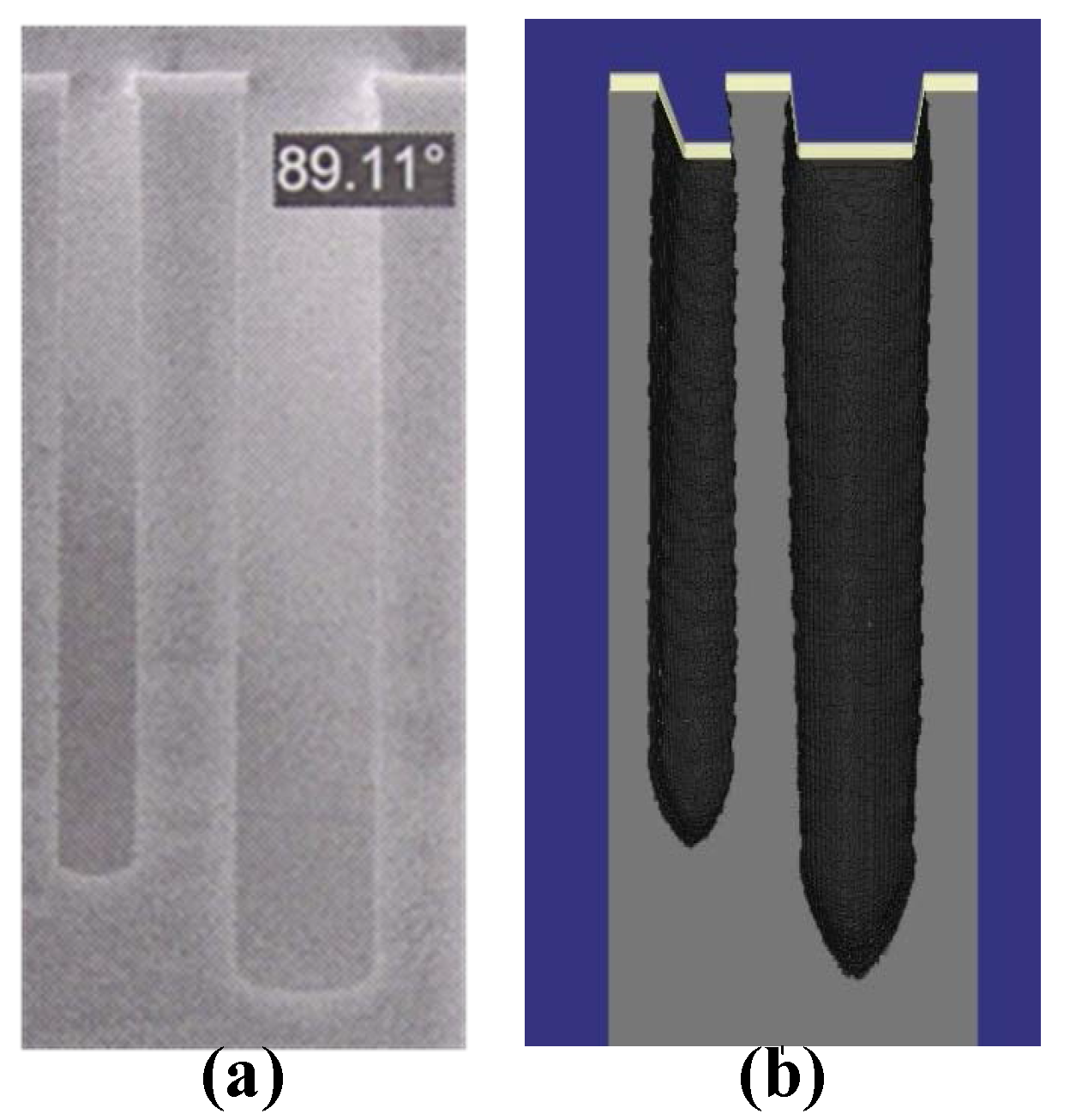

4.1. Qualitative Analysis

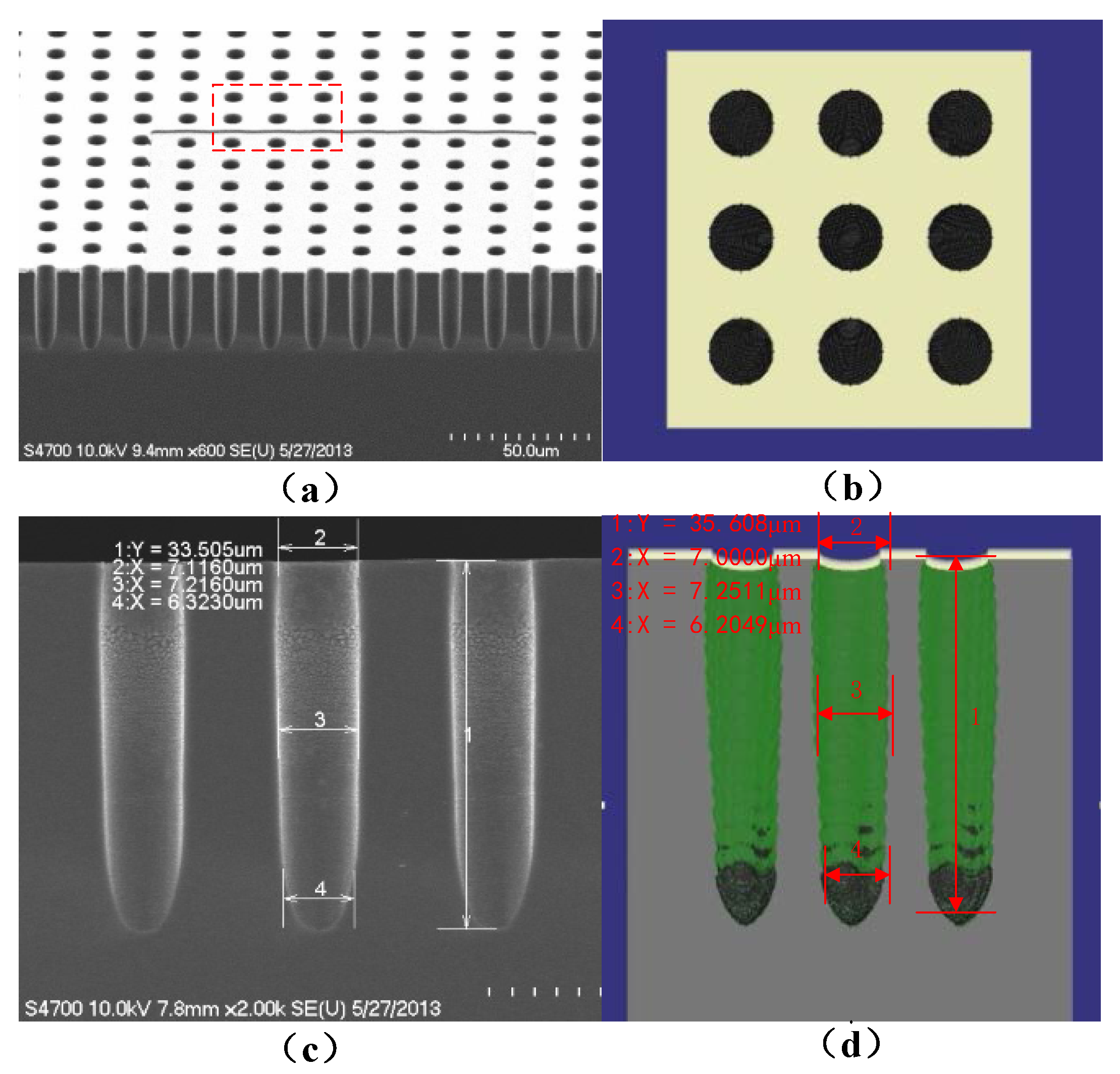

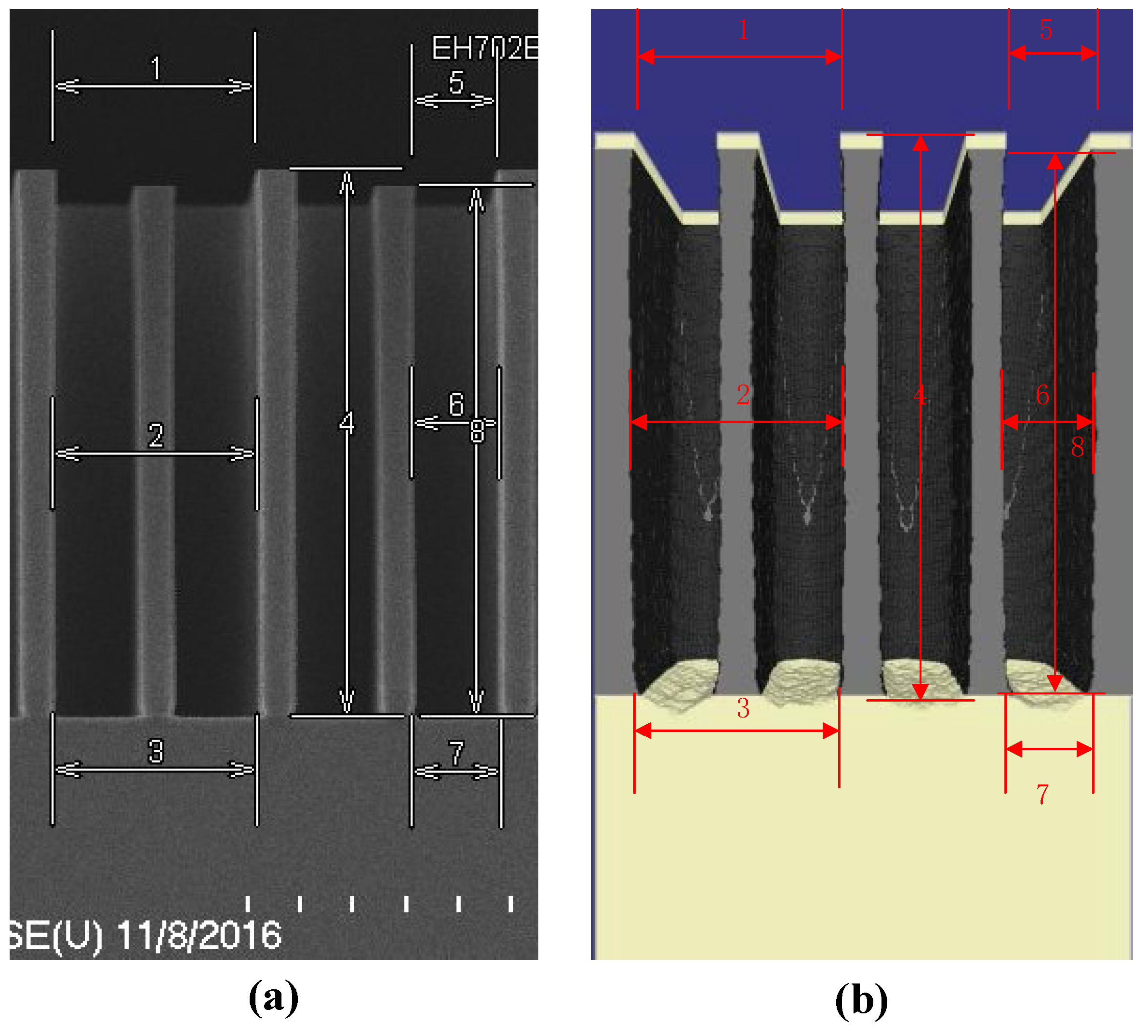

4.2. Quantitative Analysis

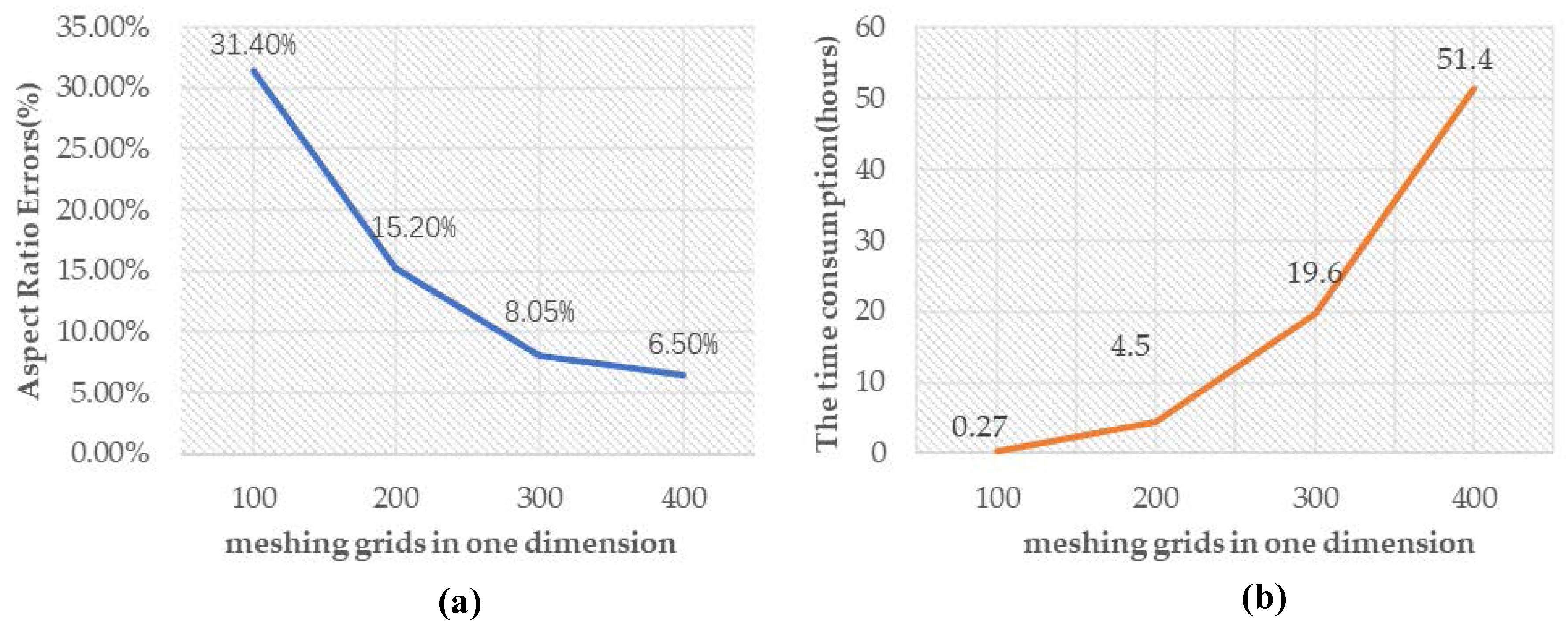

4.3. Accuracy and Runtime

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chang, C.; Wang, Y.-F.; Kanamori, Y.; Shih, J.-J.; Kawai, Y.; Lee, C.-K.; Wu, K.-C.; Esashi, M. Etching submicrometer trenches by using the Bosch process and its application to the fabrication of antireflection structures. J. Micromech. Microeng. 2005, 15, 580. [Google Scholar] [CrossRef]

- Lärmer, F.; Schilp, A. Method of Anisotropically Etching Silicon. Patent US5501893 A, 26 March 1996. [Google Scholar]

- Sethian, J.A. Level Set Methods and Fast Marching Methods: Evolving Interfaces in Computational Geometry, Fluid Mechanics, Computer Vision, and Materials Science; Cambridge University Press: Cambridge, UK, 1999; Volume 3. [Google Scholar]

- Sethian, J.A. A fast marching level set method for monotonically advancing fronts. Proc. Natl. Acad. Sci. USA 1996, 93, 1591–1595. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Zhang, H.; Hao, Y.; Zhang, D.; Wang, Y. Simulation of profile evolution in etching-polymerization alternation in drie of silicon with SF6/C4F8. In Proceedings of the IEEE Sixteenth Annual International Conference on Micro Electro Mechanical Systems, Kyoto, Japan, 19–23 January 2003; pp. 161–164. [Google Scholar]

- Li, X.-Q.; Zhou, Z.-F.; Li, W.-H.; Huang, Q.-A. Three-dimensional simulation of surface topography evolution in the bosch process by a level set method. Microsyst. Technol. 2015, 21, 1587–1593. [Google Scholar] [CrossRef]

- Kokkoris, G.; Panagiotopoulos, A.; Goodyear, A.; Cooke, M.; Gogolides, E. A global model for sf6plasmas coupling reaction kinetics in the gas phase and on the surface of the reactor walls. J. Phys. D Appl. Phys. 2009, 42, 055209. [Google Scholar] [CrossRef]

- Picard, A.; Turban, G.; Grolleau, B. Plasma diagnostics of a sf6 radiofrequency discharge used for the etching of silicon. J. Phys. D Appl. Phys. 1986, 19, 991. [Google Scholar] [CrossRef]

- Quirk, M.; Serda, J. Semiconductor Manufacturing Technology; Prentice Hall: Upper Saddle River, NJ, USA, 2001; Volume 1. [Google Scholar]

- Lieberman, M.A.; Lichtenberg, A.J. Principles of Plasma Discharges and Materials Processing; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Mahorowala, A.P.; Sawin, H.H. Etching of polysilicon in inductively coupled Cl2 and HBr discharges. II. Simulation of profile evolution using cellular representation of feature composition and Monte Carlo computation of flux and surface kinetics. J. Vac. Sci. Technol. B 2002, 20, 1064–1076. [Google Scholar] [CrossRef]

- Strasser, E.; Selberherr, S. Algorithms and models for cellular based topography simulation. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 1995, 14, 1104–1114. [Google Scholar] [CrossRef]

- Jewett, R. A String Model Etching Algorithm; California University Berkeley Electronics Research Lab: Berkeley, CA, USA, 1979. [Google Scholar]

- Ertl, O.; Selberherr, S. A fast level set framework for large three-dimensional topography simulations. Comput. Phys. Commun. 2009, 180, 1242–1250. [Google Scholar] [CrossRef]

- Sethian, J.A.; Adalsteinsson, D. An overview of level set methods for etching, deposition, and lithography development. IEEE Trans. Semicond. Manuf. 1997, 10, 167–184. [Google Scholar] [CrossRef]

- Malladi, R.; Sethian, J.A.; Vemuri, B.C. Shape modeling with front propagation: A level set approach. IEEE Trans. Pattern Anal. Mach. Intell. 1995, 17, 158–175. [Google Scholar] [CrossRef]

- Singh, S.S.; Li, Y.; Xing, Y.; Pal, P. The application of level set method for simulation of PECVD/LPCVD processes. In Proceedings of the Physics of Semiconductor Devices: 17th International Workshop on the Physics of Semiconductor Devices, Noida, India, 10–14 December 2013; Springer Science + Business Media: Berlin, Germany, 2013; p. 239. [Google Scholar]

- Wald, I.; Boulos, S.; Shirley, P. Ray tracing deformable scenes using dynamic bounding volume hierarchies. ACM Trans. Graph. (TOG) 2007, 26, 6. [Google Scholar] [CrossRef]

- Havran, V. Heuristic Ray Shooting Algorithms. Ph.D. Thesis, Department of Computer Science and Engineering, Faculty of Electrical Engineering, Czech Technical University in Prague, Prague, Czech Republic, 2000. [Google Scholar]

- Glassner, A.S. An Introduction to Ray Tracing; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Lorensen, W.E.; Cline, H.E. Marching Cubes: A High Resolution 3D Surface Construction Algorithm; ACM: New York, NY, USA, 1987; pp. 163–169. [Google Scholar]

- Gosalvez, M.A.; Zhou, Y.; Zhang, Y.; Zhang, G.; Li, Y.; Xing, Y. Simulation of microloading and arde in drie. In Proceedings of the Transducers—2015 International Conference on Solid-State Sensors, Actuators and Microsystems, Anchorage, AK, USA, 21–25 June 2015; pp. 1255–1258. [Google Scholar]

- Isamoto, K.; Kato, K.; Morosawa, A.; Chong, C.; Fujita, H.; Toshiyoshi, H. A 5-V operated MEMS variable optical attenuator by SOI bulk micromachining. IEEE J. Sel. Top. Quantum Electron. 2004, 10, 570–578. [Google Scholar] [CrossRef]

- Haobing, L.; Chollet, F. Layout controlled one-step dry etch and release of MEMS using deep RIE on SOI wafer. J. Microelectromech. Syst. 2006, 15, 541–547. [Google Scholar] [CrossRef]

| R. Zhou | X. Li | O. Ertl and S. Selberherr | This Simulator | |

|---|---|---|---|---|

| Dimension | 2D | 3D | 3D | 3D |

| Meshing | - | 100 × 100 | 500 × 140 | 300 × 300 |

| Methods | String-cell hybrid | Narrow band level set | Sparse field level set and ray tracing with disks | Narrow band level set and ray tracing with spheres |

| Runtime | Not Presented | Half a hour | About two days | 19.6 h |

| Locations and Items | Sizes in Experiments | Sizes in Simulation | Errors (%) |

|---|---|---|---|

| Location 1 | 33.505 μm | 35.608 μm | 6.277% |

| Location 2 | 7.1160 μm | 7.0000 μm | 1.630% |

| Location 3 | 7.2160 μm | 7.2511 μm | 0.4864% |

| Location 4 | 6.3230 μm | 6.2049 μm | 1.868% |

| Aspect Ratio | 4.7084 | 5.0869 | 8.050% |

| Locations and Items | Sizes in Experiments | Sizes in Simulation | Errors (%) |

|---|---|---|---|

| Location 1 | 19.114 μm | 18.504 μm | 3.191% |

| Location 2 | 19.132 μm | 19.200 μm | 0.355% |

| Location 3 | 19.132 μm | 18.527 μm | 3.162% |

| Location 4 | 52.844 μm | 52.026 μm | 1.548% |

| Location 5 | 8.056 μm | 8.000 μm | 0.695% |

| Location 6 | 8.254 μm | 8.287 μm | 0.400% |

| Location 7 | 8.452 μm | 7.926 μm | 6.223% |

| Location 8 | 51.495 μm | 49.548 μm | 3.781% |

| Aspect Ratio | 6.392 | 6.194 | 3.098% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.-C.; Zhou, Z.-F.; Su, J.-L.; Xia, C.-F.; Zhang, X.-W.; Wu, Z.-Z.; Huang, Q.-A. Three-Dimensional Simulation of DRIE Process Based on the Narrow Band Level Set and Monte Carlo Method. Micromachines 2018, 9, 74. https://doi.org/10.3390/mi9020074

Yu J-C, Zhou Z-F, Su J-L, Xia C-F, Zhang X-W, Wu Z-Z, Huang Q-A. Three-Dimensional Simulation of DRIE Process Based on the Narrow Band Level Set and Monte Carlo Method. Micromachines. 2018; 9(2):74. https://doi.org/10.3390/mi9020074

Chicago/Turabian StyleYu, Jia-Cheng, Zai-Fa Zhou, Jia-Le Su, Chang-Feng Xia, Xin-Wei Zhang, Zong-Ze Wu, and Qing-An Huang. 2018. "Three-Dimensional Simulation of DRIE Process Based on the Narrow Band Level Set and Monte Carlo Method" Micromachines 9, no. 2: 74. https://doi.org/10.3390/mi9020074