Geometry Design, Principles and Assembly of Micromotors

Abstract

:1. Introduction

1.1. Mechanical Machines: Simple, Complex, Chaotic, and Fluidic

1.2. Small Machines from Atoms to Nano-, Micro-, and Meso-Particles

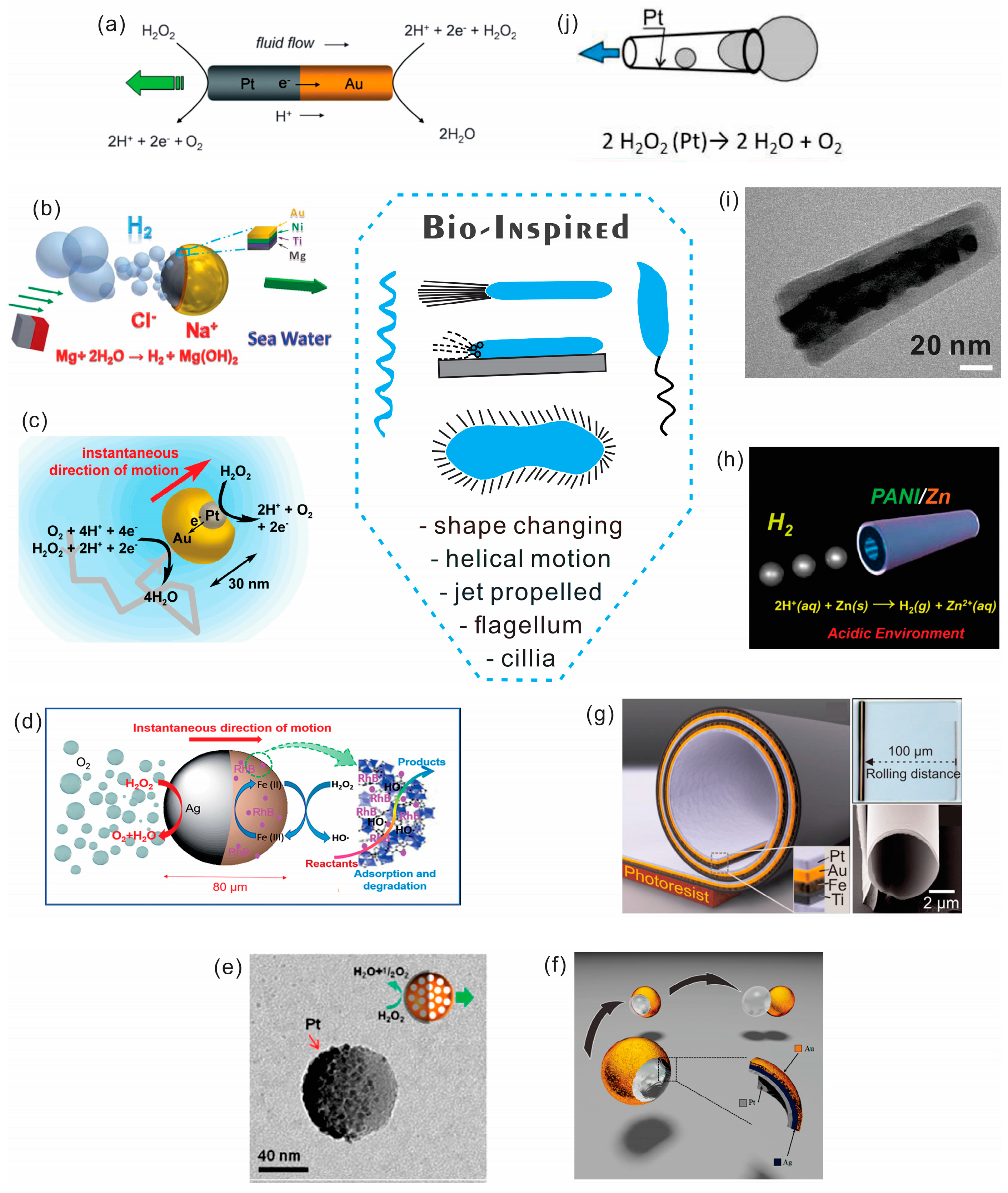

2. New Materials, Geometries and Fuels for Autonomous Motion

2.1. Improvement of Nano-/Micromotors’ Materials, Geometry, Surface and Motion

2.2. Improvements of Fabrication Methods

2.3. New Fuels

2.4. Efficiency

2.5. New Types of Motion and Trajectories

2.6. New Applications

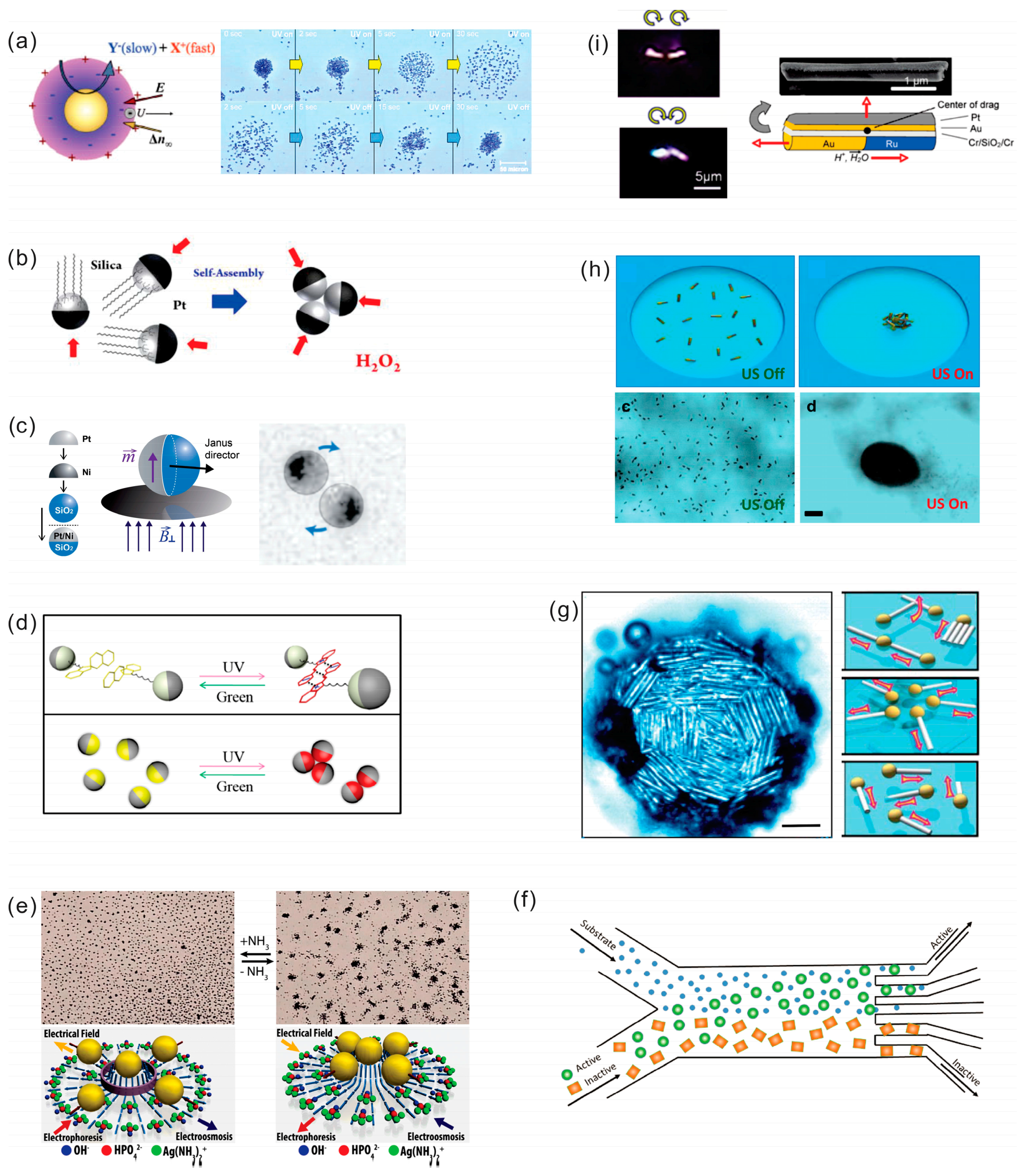

3. Motion Control and Externally Powered Micromotors

3.1. Magnetically Powered/Controlled Motion

3.2. Light Powered Motion

3.3. Acoustically Powered Motion

3.4. AC Field Powered Motion

3.5. Other Types of Motion Control

4. Interactive Micromotors: Swarming, Collective and Adaptive Behaviors

4.1. Dynamic Self-Assembly Induced by External Fields and Chemical Reactions

4.2. Dynamic Self-Assembly and Adaptive Systems

5. Towards Biomedical and Fluidic Micromachines

5.1. Biocompatible Fuels

5.2. Hybrid Bio-Micromotors for Drug-Delivery

5.3. Hybrid Bio-Motors for Biosensing

5.4. Towards an Assembly of “Synthetic Cells” Using Microfluidics

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ismagilov, R.F.; Schwartz, A.; Bowden, N.; Whitesides, G.M. Autonomous movement and self-assembly. Angew. Chem. Int. Ed. 2002, 41, 652–654. [Google Scholar] [CrossRef]

- Paxton, W.F.; Kistler, K.C.; Olmeda, C.C.; Sen, A.; Angelo, S.K.S.; Cao, Y.; Mallouk, T.E.; Lammert, P.E.; Crespi, V.H. Catalytic nanomotors: Autonomous movement of striped nanorods. J. Am. Chem. Soc. 2004, 126, 13424–13431. [Google Scholar] [CrossRef] [PubMed]

- Ozin, G.A.; Manners, I.; Fournier-Bidoz, S.; Arsenault, A. Dream nanomachines. Adv. Mater. 2005, 17, 3011–3018. [Google Scholar] [CrossRef]

- Xu, L.; Mou, F.; Gong, H.; Luo, M.; Guan, J. Light-driven micro/nanomotors: From fundamentals to applications. Chem. Soc. Rev. 2017, 46, 6905–6926. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Rozen, I.; Wang, J. Rocket science at the nanoscale. ACS Nano 2016, 10, 5619–5634. [Google Scholar] [CrossRef] [PubMed]

- Mei, Y.F.; Huang, G.S.; Solovev, A.A.; Ureña, E.B.; Mönch, I.; Ding, F.; Reindl, T.; Fu, R.K.; Chu, P.K.; Schmidt, O.G. Versatile approach for integrative and functionalized tubes by strain engineering of nanomembranes on polymers. Adv. Mater. 2008, 20, 4085–4090. [Google Scholar] [CrossRef]

- Solovev, A.A.; Mei, Y.F.; Ureña, U.B.; Huang, G.S.; Schmidt, O.G. Catalytic microtubular jet engines self-propelled by accumulated gas bubbles. Small 2009, 5, 1688–1692. [Google Scholar] [CrossRef] [PubMed]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nat. Lett. 2016, 536, 451–455. [Google Scholar] [CrossRef] [PubMed]

- Robert, S. Lecture: Chaos and Reductionism; Stanford University: Stanford, CA, USA, 2018; Available online: www.robertsapolskyrocks.com (accessed on 10 January 2018).

- Lorenz, E.N. Determenistic nonperiodic flow. J. Atmos. Sci. 1963, 20, 130–141. [Google Scholar] [CrossRef]

- Bensaude-Vincent, B.; Guchet, X. One word for three different paradigms. Tech. Res. Philos. Technol. 2007, 11, 71–89. [Google Scholar]

- Historical Motor Carriage (Year 1896). Available online: https://www.motorauthority.com/news/1110475_first-car-ever-caught-speeding-to-be-displayed-in-the-uk (accessed on 10 January 2018).

- Mechanical Clock. Available online: https://www.pinterest.co.uk/pin/420664421428587728 (accessed on 10 January 2018).

- Chaos Theory. Available online: http://universe-review.ca/R01-09-chaos.htm (accessed on 10 January 2018).

- Lorenz System. Available online: https://en.wikipedia.org/wiki/Lorenz_system (accessed on 10 February 2018).

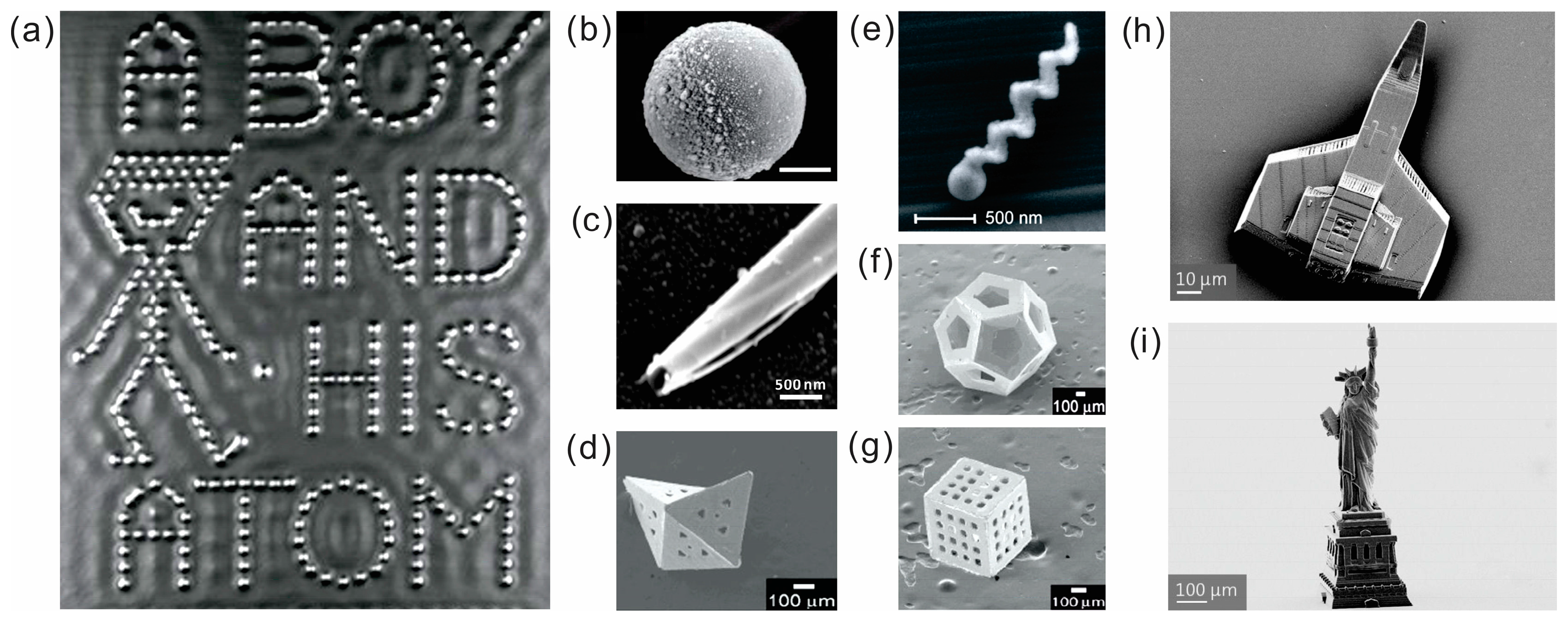

- A Boy and His Atom: The World’s Smallest Movie, IBM Company. Available online: http://www.research.ibm.com/articles/madewithatoms.shtml (accessed on 10 February 2018).

- Reigh, S.Y.; Huang, M.J.; Schofield, J.; Kapral, R. Microscopic and continuum descriptions of Janus motor fluid flow fields. Philos. Trans. A Math. Phys. Eng. Sci. 2016, 374. [Google Scholar] [CrossRef] [PubMed]

- Ozin, G.A.; Arsenault, A.; Cademartiri, L. Nanochemistry: A Chemical Approach to Nanomaterials, 1st ed.; Royal Society of Chemistry (RSC): London, UK, 2009; ISBN 9781847558954. [Google Scholar]

- Cademartiri, L.; Ozin, G.A. Concepts of Nanochemistry, 1st ed.; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2009; ISBN 978-3-527-32597-9. [Google Scholar]

- Wu, Y.F.; Dong, R.F.; Zhang, Q.L.; Ren, B.Y. Dye-enhanced self-electrophoretic propulsion of light-driven TiO2-Au Janus micromotors. Nano-Micro Lett. 2017, 9, 30. [Google Scholar] [CrossRef]

- The Creative Commons Attribution 4.0 International License. Available online: http://creativecommons.org/licenses/by/4.0/ (accessed on 10 January 2018).

- Leong, T.G.; Zarafshar, A.M.; Gracias, D.H. Three-dimensional fabrication at small size scales. Small 2010, 6, 792–806. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.; Fischer, P. Controlled propulsion of artificial magnetic nanostructured propellers. Nano Lett. 2009, 9, 2243–2245. [Google Scholar] [CrossRef] [PubMed]

- Rogers, B.; Adams, J.; Pennathur, S. Nanotechnology: Understanding Small Systems, 2nd ed.; Taylor & Francis Inc.: Bosa Roca, FL, USA, 2011; ISBN -13 978-1439849200. [Google Scholar]

- Alarcón-Correa, M.; Walker, D.; Qiu, T.; Fischer, P. Nanomotors. Eur. Phys. J. Spec. Top. 2016, 225, 2241–2254. [Google Scholar] [CrossRef]

- Wong, F.; Dey, K.K.; Sen, A. Synthetic micro/nanomotors and pumps: Fabrication and applications. Ann. Rev. Mater. Res. 2016, 46, 407–432. [Google Scholar] [CrossRef]

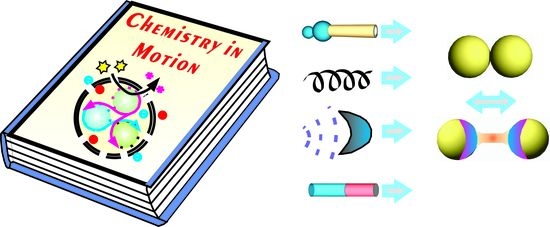

- Colberg, P.H.; Reigh, S.Y.; Robertson, B.; Kapral, R. Chemistry in motion: Tiny synthetic motors. Acc. Chem. Res. 2014, 47, 3504–3511. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Duan, W.; Ahmed, S.; Mallouk, T.E.; Sen, A. Small power: Autonomous nano- and micromotors propelled by self-generated gradients. Nano Today 2013, 8, 531–554. [Google Scholar] [CrossRef]

- Yadav, V.; Duan, W.; Butler, P.J.; Sen, A. Anatomy of nanoscale propulsion. Annu. Rev. Biophys. 2015, 44, 77–100. [Google Scholar] [CrossRef] [PubMed]

- Aubret, A.; Ramananarivo, S.; Palacci, J. Eppur si muove, and yet it moves: Patchy (phoretic) swimmers. Curr. Opin. Colloid Interface Sci. 2017, 30, 81–89. [Google Scholar] [CrossRef]

- Ebbens, S.J. Active colloids: Progress and challenges towards realising autonomous applications. Curr. Opin. Colloid Interface Sci. 2016, 21, 14–23. [Google Scholar] [CrossRef]

- Yamamoto, D.; Shioi, A. Self-propelled nano/micromotors with a chemical reaction: Underlying physics and strategies of motion control. KONA Powder Part. J. 2015, 32, 2–22. [Google Scholar] [CrossRef]

- Ebbens, S.J.; Howse, J.R. In pursuit of propulsion at the nanoscale. Soft Matter 2010, 6, 726–738. [Google Scholar] [CrossRef]

- Randhawa, J.S.; Lafl, K.E.; Seelam, N.; Gracias, D.H. Microchemomechanical systems. Adv. Funct. Mater. 2011, 21, 2395–2410. [Google Scholar] [CrossRef]

- Duan, W.; Wang, W.; Das, S.; Yadav, V.; Mallouk, T.E.; Sen, A. Synthetic nano- and micromachines in analytical chemistry: Sensing, migration, capture, delivery, and separation. Annu. Rev. Anal. Chem. 2015, 8, 311–333. [Google Scholar] [CrossRef] [PubMed]

- Qiu, T.; Lee, T.C.; Mark, A.G.; Morozov, K.I.; Munster, R.; Mierka, O.; Turek, S.; Leshansky, A.M.; Fischer, P. Swimming by reciprocal motion at low Reynolds number. Nat. Commun. 2014, 5, 5119. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liu, W.; Wang, J.; Rozen, I.; He, S.; Chen, C.; Kim, H.G.; Lee, H.-J.; Lee, H.-B.-R.; Kwon, S.-H.; et al. Nanoconfined atomic layer deposition of TiO2/Pt nanotubes: Toward ultrasmall highly efficient catalytic nanorockets. Adv. Funct. Mater. 2017, 27, 1700598. [Google Scholar] [CrossRef]

- Han, K.; Shields, C.W.; Velev, O.D. Engineering of self-propelling microbots and microdevices powered by magnetic and electric fields. Adv. Funct. Mater. 2018, 1705953. [Google Scholar] [CrossRef]

- Gánti, T. The Principles of Life, 1st ed.; Oxford University Press: Oxford, UK, 2003; ISBN 9780198507260. [Google Scholar]

- Sen, A.; Ibele, M.; Hong, Y.; Velegol, D. Chemo and phototactic nano/microbots. Faraday Discuss. 2009, 143, 15–27. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Feng, X.; Pei, A.; Gu, Y.; Li, J.; Wang, J. Seawater-driven magnesium based Janus micromotors for environmental remediation. Nanoscale 2013, 5, 4696–4700. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.C.; Alarcon-Correa, M.; Miksch, C.; Hahn, K.; Gibbs, J.G.; Fischer, P. Self-propelling nanomotors in the presence of strong Brownian forces. Nano Lett. 2014, 14, 2407–2412. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Guo, W.; Li, X.; Liu, Z.; Liu, H.; Ding, S. Highly efficient MOF-based self-propelled micromotors for water purification. RSC Adv. 2017, 7, 42462–42467. [Google Scholar] [CrossRef]

- Ma, X.; Hahn, K.; Sanchez, S. Catalytic mesoporous Janus nanomotors for active cargo delivery. J. Am. Chem. Soc. 2015, 137, 4976–4979. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Manjare, M.; Zhao, Y. Catalytic nanoshell micromotors. J. Phys. Chem. C 2013, 117, 21590–21596. [Google Scholar] [CrossRef]

- Gao, W.; Uygun, A.; Wang, J. Hydrogen-bubble-propelled zinc-based microrockets in strongly acidic media. J. Am. Chem. Soc. 2012, 134, 897–900. [Google Scholar] [CrossRef] [PubMed]

- Niemeyer, C.M.; Mirkin, C.A. Nanobiotechnology, Concepts, Applications and Perspectives, 1st ed.; Wiley-VCH: Weinheim, Germany, 2005; ISBN 978-3-527-30658-9. [Google Scholar]

- Purcell, E.M. The efficiency of propulsion by a rotating flagellum. Proc. Natl. Acad. Sci. USA 1997, 94, 11307. [Google Scholar] [CrossRef] [PubMed]

- Yao, K.; Manjare, M.; Barrett, C.A.; Yang, B.; Salguero, T.T.; Zhao, Y. Nanostructured Scrolls from Graphene Oxide for Microjet Engines. J. Phys. Chem. Lett. 2012, 3, 2204–2208. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Singh, A.K.; Dasmahapatra, A.K.; Mandal, T.K.; Bandyopadhyay, D. Graphene based multifunctional superbots. Carbon 2015, 89, 31–40. [Google Scholar] [CrossRef]

- Gao, W.; Sattayasamitsathit, S.; Uygun, A.; Pei, A.; Ponedal, A.; Wang, J. Polymer-based tubular microbots: Role of composition and preparation. Nanoscale 2012, 4, 2447–2453. [Google Scholar] [CrossRef] [PubMed]

- Yoshizumi, Y.; Suzuki, H. Self-propelled metal-polymer hybrid micromachines with bending and rotational motions. ACS Appl. Mater. Interfaces 2017, 9, 21355–21361. [Google Scholar] [CrossRef] [PubMed]

- Jang, B.; Wang, W.; Wiget, S.; Petruska, A.J.; Chen, X.; Hu, C.; Hong, A.; Folio, D.; Ferreira, A.; Pane, S.; et al. Catalytic locomotion of core-shell nanowire motors. ACS Nano 2016, 10, 9983–9991. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Miao, J.; Grüber, G. Disk-like nanojets with steerable trajectory using platinum nozzle nanoengines. RSC Adv. 2016, 6, 3399–3405. [Google Scholar] [CrossRef]

- Manjare, M.; Yang, B.; Zhao, Y.P. Bubble-propelled microjets: Model and experiment. J. Phys. Chem. C 2013, 117, 4657–4665. [Google Scholar] [CrossRef]

- Huang, G.S.; Wang, J.; Mei, Y.F. Material considerations and locomotive capability in catalytic tubular microengines. J. Mater. Chem. 2012, 22, 6519–6525. [Google Scholar] [CrossRef]

- Wang, L.; Li, L.; Li, T.; Zhang, G.; Sun, Q. Locomotion of chemically powered autonomous nanowire motors. Appl. Phys. Lett. 2015, 107, 063102. [Google Scholar] [CrossRef]

- Chang, X.; Li, L.; Li, T.; Zhou, D.; Zhang, G. Accelerated microrockets with a biomimetic hydrophobic surface. RSC Adv. 2016, 6, 87213–87220. [Google Scholar] [CrossRef]

- Wang, Y.S.; Xia, H.; Lv, C.; Wang, L.; Dong, W.F.; Feng, J.; Sun, H.B. Self-propelled micromotors based on Au-mesoporous silica nanorods. Nanoscale 2015, 7, 11951–11955. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Feng, H.; Liang, C.; Liu, X.; Zeng, F.; Wang, Y. Mesoporous silica as micro/nano-carrier: From passive to active cargo delivery, a mini review. J. Mater. Sci. Technol. 2017, 33, 1067–1074. [Google Scholar] [CrossRef]

- Claussen, J.C.; Daniele, M.A.; Geder, J.; Pruessner, M.; Makinen, A.J.; Melde, B.J.; Twigg, M.; Verbarg, J.M.; Medintz, I.L. Platinum-paper micromotors: An urchin-like nanohybrid catalyst for green monopropellant bubble-thrusters. ACS Appl. Mater. Interfaces 2014, 6, 17837–17847. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yu, X.; Xu, M.; Liu, W.; Sandraz, E.; Lan, H.; Wang, J.; Cohen, S.M. Metal-organic frameworks as micromotors with tunable engines and brakes. J. Am. Chem. Soc. 2017, 139, 611–614. [Google Scholar] [CrossRef] [PubMed]

- Safdar, M.; Itkonen, T.; Jänis, J. Bubble-propelled trimetallic microcaps as functional catalytic micromotors. RSC Adv. 2015, 5, 13171–13174. [Google Scholar] [CrossRef]

- Safdar, M.; Wani, O.M.; Janis, J. Manganese oxide-based chemically powered micromotors. ACS Appl. Mater. Interfaces 2015, 7, 25580–25585. [Google Scholar] [CrossRef] [PubMed]

- Maria-Hormigos, R.; Jurado-Sanchez, B.; Vazquez, L.; Escarpa, A. Carbon allotrope nanomaterials based catalytic micromotors. Chem. Mater. 2016, 28, 8962–8970. [Google Scholar] [CrossRef]

- Liu, R.; Sen, A. Autonomous nanomotor based on copper-platinum segmented nanobattery. J. Am. Chem. Soc. 2011, 133, 20064–20067. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Liu, L.; Gao, W.; Su, M.; Ge, Y.; Shi, L.; Zhang, H.; Dong, B.; Li, C.Y. Nanoparticle mediated micromotor motion. Nanoscale 2015, 7, 4949–4955. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Xiao, Q.; Jiang, J.-Z.; Chen, G.-N.; Sun, J.-J. Au–Fe/Ni alloy hybrid nanowire motors with dramatic speed. RSC Adv. 2014, 4, 27522–27525. [Google Scholar] [CrossRef]

- Wang, H.; Pumera, M. Fabrication of micro/nanoscale motors. Chem. Rev. 2015, 115, 8704–8735. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Pumera, M. Emerging materials for the fabrication of micro/nanomotors. Nanoscale 2017, 9, 2109–2116. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Liu, M.; Liu, L.; Zhang, H.; Dong, B.; Li, C.Y. One-step fabrication of multifunctional micromotors. Nanoscale 2015, 7, 13918–13923. [Google Scholar] [CrossRef] [PubMed]

- Tabrizi, M.A.; Shamsipur, M. A simple method for the fabrication of nanomotors based on a gold nanosheet decorated with CoPt nanoparticles. RSC Adv. 2015, 5, 51508–51511. [Google Scholar] [CrossRef]

- Su, M.; Liu, M.; Liu, L.; Sun, Y.; Li, M.; Wang, D.; Zhang, H.; Dong, B. Shape-controlled fabrication of the polymer-based micromotor based on the polydimethylsiloxane template. Langmuir 2015, 31, 11914–11920. [Google Scholar] [CrossRef] [PubMed]

- Martin, A.; Jurado-Sanchez, B.; Escarpa, A.; Wang, J. Template electrosynthesis of high-performance graphene microengines. Small 2015, 11, 3568–3574. [Google Scholar] [CrossRef] [PubMed]

- Gai, M.; Frueh, J.; Hu, N.; Si, T.; Sukhorukov, G.B.; He, Q. Self-propelled two dimensional polymer multilayer plate micromotors. Phys. Chem. Chem. Phys. 2016, 18, 3397–3401. [Google Scholar] [CrossRef] [PubMed]

- He, T.; Wu, H.; Wang, X.; Zang, Q.; Xue, P.; Shen, R.; Dang, L.; Zhang, Y.; Xiang, J. Shape-controlled synthesis of organometallic microcrystal-based hollow hexagonal micromotors through evaporation-induced supramolecular self-assembly. Cryst. Growth Des. 2016, 16, 6239–6249. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Xie, Y.; Ju, H. An efficient polymeric micromotor doped with Pt nanoparticle@carbon nanotubes for complex bio-media. Chem. Commun. 2015, 51, 6325–6328. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; D’Agostino, M.; Garcia-Gradilla, V.; Orozco, J.; Wang, J. Multi-fuel driven Janus micromotors. Small 2013, 9, 467–471. [Google Scholar] [CrossRef] [PubMed]

- Mallick, A.; Lai, D.; Roy, S. Autonomous movement induced in chemically powered active soft-oxometalates using dithionite as fuel. New J. Chem. 2016, 40, 1057–1062. [Google Scholar] [CrossRef]

- Mou, F.; Chen, C.; Ma, H.; Yin, Y.; Wu, Q.; Guan, J. Self-propelled micromotors driven by the magnesium-water reaction and their hemolytic properties. Angew. Chem. Int. Ed. 2013, 52, 7208–7212. [Google Scholar] [CrossRef] [PubMed]

- Akhavan, O.; Saadati, M.; Jannesari, M. Graphene jet nanomotors in remote controllable self-propulsion swimmers in pure water. Nano Lett. 2016, 16, 5619–5630. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Li, J.; Rozen, I.; Ezhilan, B.; Xu, T.; Christianson, C.; Gao, W.; Saintillan, D.; Ren, B.; Wang, J. Vapor-driven propulsion of catalytic micromotors. Sci. Rep. 2015, 5, 13226. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Hu, Y.; Zhao, F.; Dong, Z.; Wang, Y.; Chen, N.; Zhang, Z.; Qu, L. Moisture-activated torsional graphene-fiber motor. Adv. Mater. 2014, 26, 2909–2913. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Li, J.; de Ávila, B.E.-F.; Li, T.; Gao, W.; He, Q.; Zhang, L.; Wang, J. Water-powered cell-mimicking Janus micromotor. Adv. Funct. Mater. 2015, 25, 7497–7501. [Google Scholar] [CrossRef]

- Guix, M.; Meyer, A.K.; Koch, B.; Schmidt, O.G. Carbonate-based Janus micromotors moving in ultra-light acidic environment generated by HeLa cells in situ. Sci. Rep. 2016, 6, 21701. [Google Scholar] [CrossRef] [PubMed]

- Brown, A.T.; Poon, W.C.; Holm, C.; de Graaf, J. Ionic screening and dissociation are crucial for understanding chemical self-propulsion in polar solvents. Soft Matter 2017, 13, 1200–1222. [Google Scholar] [CrossRef] [PubMed]

- Simmchen, J.; Magdanz, V.; Sanchez, S.; Chokmaviroj, S.; Ruiz-Molina, D.; Baeza, A.; Schmidt, O.G. Effect of surfactants on the performance of tubular and spherical micromotors—A comparative study. RSC Adv. 2014, 4, 20334–20340. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhao, G.; Pumera, M. Crucial role of surfactants in bubble-propelled microengines. J. Phys. Chem. C 2014, 118, 5268–5274. [Google Scholar] [CrossRef]

- Liu, L.; Bai, T.; Chi, Q.; Wang, Z.; Xu, S.; Liu, Q.; Wang, Q. How to make a fast, efficient bubble-driven micromotor: A mechanical view. Micromachines 2017, 8, 267. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, H.; Li, Z.; Wang, W. Chemistry pumps: A review of chemically powered micropumps. Lab Chip 2016, 16, 1797–1811. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Chiang, T.Y.; Velegol, D.; Mallouk, T.E. Understanding the efficiency of autonomous nano- and microscale motors. J. Am. Chem. Soc. 2013, 135, 10557–10565. [Google Scholar] [CrossRef] [PubMed]

- Solovev, A.A.; Sanchez, S.; Mei, Y.F.; Schmidt, O.G. Tunable catalytic tubular micro-pumps operating at low concentrations of hydrogen peroxide. Phys. Chem. Chem. Phys. 2011, 13, 10131–10135. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Sattayasamitsathit, S.; Orozco, J.; Wang, J. Highly efficient catalytic microengines: Template electrosynthesis of polyaniline/platinum microtubes. J. Am. Chem. Soc. 2011, 133, 11862–11864. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Pei, A.; Dong, R.; Wang, J. Catalytic iridium-based Janus micromotors powered by ultralow levels of chemical fuels. J. Am. Chem. Soc. 2014, 136, 2276–2279. [Google Scholar] [CrossRef] [PubMed]

- Esplandiu, M.J.; Afshar Farniya, A.; Reguera, D. Key parameters controlling the performance of catalytic motors. J. Chem. Phys. 2016, 144, 124702. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Sofer, Z.; Eng, A.Y.; Pumera, M. Iridium-catalyst-based autonomous bubble-propelled graphene micromotors with ultralow catalyst loading. Chemistry 2014, 20, 14946–14950. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Huang, G.S.; Ding, S.J.; Dong, H.L.; Men, C.L.; Mei, Y.F. Atomic layer deposition of Pt nanoparticles for microengine with promoted catalytic motion. Nanoscale Res. Lett. 2016, 11. [Google Scholar] [CrossRef] [PubMed]

- Li, J.X.; Liu, Z.Q.; Huang, G.S.; Mei, Y.F. Hierarchical nanoporous microtubes for high-speed catalytic microengines. NPG Asia Mater. 2014, 6, e94. [Google Scholar] [CrossRef]

- Manjare, M.; Ting Wu, Y.; Yang, B.; Zhao, Y.P. Hydrophobic catalytic Janus motors: Slip boundary condition and enhanced catalytic reaction rate. Appl. Phys. Lett. 2014, 104, 054102. [Google Scholar] [CrossRef]

- Kim, K.; Guo, J.; Liang, Z.X.; Zhu, F.Q.; Fan, D.L. Man-made rotary nanomotors: A review of recent developments. Nanoscale 2016, 8, 10471–10490. [Google Scholar] [CrossRef] [PubMed]

- Fournier-Bidoz, S.; Arsenault, A.C.; Manners, I.; Ozin, G.A. Synthetic self-propelled nanorotors. Chem. Commun. 2005, 28, 441–443. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Ripoll, M.; Chen, K. Catalytic microrotor driven by geometrical asymmetry. J. Chem. Phys. 2015, 142, 054902. [Google Scholar] [CrossRef] [PubMed]

- Hayakawa, M.; Onoe, H.; Nagai, K.; Takinoue, M. Influence of asymmetry and driving forces on the propulsion of bubble-propelled catalytic micromotors. Micromachines 2016, 7, 229. [Google Scholar] [CrossRef]

- Gregory, D.A.; Campbell, A.I.; Ebbens, S.J. Effect of catalyst distribution on spherical bubble swimmer trajectories. J. Phys. Chem. C 2015, 119, 15339–15348. [Google Scholar] [CrossRef]

- Campbell, A.I.; Wittkowski, R.; Ten Hagen, B.; Lowen, H.; Ebbens, S.J. Helical paths, gravitaxis, and separation phenomena for mass-anisotropic self-propelling colloids: Experiment versus theory. J. Chem. Phys. 2017, 147, 084905. [Google Scholar] [CrossRef] [PubMed]

- Nakata, S.; Nomura, M.; Yamamoto, H.; Izumi, S.; Suematsu, N.J.; Ikura, Y.; Amemiya, T. Periodic oscillatory motion of a self-propelled motor driven by decomposition of H2O2 by catalase. Angew. Chem. Int. Ed. 2017, 56, 861–864. [Google Scholar] [CrossRef] [PubMed]

- Klingner, A.; Khalil, I.S.M.; Magdanz, V.; Fomin, V.M.; Schmidt, O.G.; Misra, S. Modeling of unidirectional-overloaded transition in catalytic tubular microjets. J. Phys. Chem. C 2017, 121, 14854–14863. [Google Scholar] [CrossRef]

- Colberg, P.H.; Kapral, R. Nanoconfined catalytic Angstrom-size motors. J. Chem. Phys. 2015, 143, 184906. [Google Scholar] [CrossRef] [PubMed]

- Colberg, P.H.; Kapral, R. Ångström-scale chemically powered motors. Europhys. Lett. 2014, 106, 30004. [Google Scholar] [CrossRef]

- Moo, J.G.; Pumera, M. Chemical energy powered nano/micro/macromotors and the environment. Chemistry 2015, 21, 58–72. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Gu, X.; Wang, C. Self-propelling hydrogel/emulsion-hydrogel soft motors for water purification. ACS Appl. Mater. Interfaces 2016, 8, 9413–9422. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Jiang, Z.; Ouyang, S.; Dai, Z.; Wang, T. Internally/externally bubble-propelled photocatalytic tubular nanomotors for efficient water cleaning. ACS Appl. Mater. Interfaces 2017, 9, 23974–23982. [Google Scholar] [CrossRef] [PubMed]

- Eskandarloo, H.; Kierulf, A.; Abbaspourrad, A. Nano- and micromotors for cleaning polluted waters: Focused review on pollutant removal mechanisms. Nanoscale 2017, 9, 13850–13863. [Google Scholar] [CrossRef] [PubMed]

- Soler, L.; Sanchez, S. Catalytic nanomotors for environmental monitoring and water remediation. Nanoscale 2014, 6, 7175–7182. [Google Scholar] [CrossRef] [PubMed]

- Jurado-Sanchez, B.; Sattayasamitsathit, S.; Gao, W.; Santos, L.; Fedorak, Y.; Singh, V.V.; Orozco, J.; Galarnyk, M.; Wang, J. Self-propelled activated carbon Janus micromotors for efficient water purification. Small 2015, 11, 499–506. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Wu, Z.; Lin, X.; He, Q. Catalytic polymer multilayer shell motors for separation of organics. Chemistry 2016, 22, 1587–1591. [Google Scholar] [CrossRef] [PubMed]

- Xuan, M.; Lin, X.; Shao, J.; Dai, L.; He, Q. Motion-based, high-yielding, and fast separation of different charged organics in water. Chem. Phys. Chem. 2015, 16, 147–151. [Google Scholar] [CrossRef] [PubMed]

- Wani, O.M.; Safdar, M.; Kinnunen, N.; Janis, J. Dual effect of manganese oxide micromotors: Catalytic degradation and adsorptive bubble separation of organic pollutants. Chemistry 2016, 22, 1244–1247. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Shklyaev, O.E.; Li, T.; Liu, W.; Shum, H.; Rozen, I.; Balazs, A.C.; Wang, J. Self-propelled nanomotors autonomously seek and repair cracks. Nano Lett. 2015, 15, 7077–7085. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liu, W.; Li, T.; Rozen, I.; Zhao, J.; Bahari, B.; Kante, B.; Wang, J. Swimming microrobot optical nanoscopy. Nano Lett. 2016, 16, 6604–6609. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Ge, Y.; Liu, L.; Zhang, L.; Liu, M.; Sun, Y.; Zhang, H.; Dong, B. Motion-based pH sensing based on the cartridge-case-like micromotor. ACS Appl. Mater. Interfaces 2016, 8, 4250–4257. [Google Scholar] [CrossRef] [PubMed]

- Jurado-Sanchez, B.; Escarpa, A.; Wang, J. Lighting up micromotors with quantum dots for smart chemical sensing. Chem. Commun. 2015, 51, 14088–14091. [Google Scholar] [CrossRef] [PubMed]

- Ezhilan, B.; Gao, W.; Pei, A.; Rozen, I.; Dong, R.; Jurado-Sanchez, B.; Wang, J.; Saintillan, D. Motion-based threat detection using microrods: Experiments and numerical simulations. Nanoscale 2015, 7, 7833–7840. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Sun, Y.; Wang, T.; Ye, Z.; Zhang, H.; Dong, B.; Li, C.Y. A biodegradable, all-polymer micromotor for gas sensing applications. J. Mater. Chem. C 2016, 4, 5945–5952. [Google Scholar] [CrossRef]

- Li, Y.; Mou, F.; Chen, C.; You, M.; Yin, Y.; Xu, L.; Guan, J. Light-controlled bubble propulsion of amorphous TiO2/Au Janus micromotors. RSC Adv. 2016, 6, 10697–10703. [Google Scholar] [CrossRef]

- Schematic Image of Photocatalytic Micromotor. Available online: http://research.chem.psu.edu/axsgroup/Ran/research/energyconversion.html (accessed on 15 January 2018).

- Solovev, A.A.; Smith, E.J.; Bof Bufon, C.C.; Sanchez, S.; Schmidt, O.G. Light-controlled propulsion of catalytic microengines. Angew. Chem. 2011, 50, 10875–10878. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Soto, F.; Gao, W.; Garcia-Gradilla, V.; Li, J.; Zhang, X.; Wang, J. Ultrasound-modulated bubble propulsion of chemically powered microengines. J. Am. Chem. Soc. 2014, 136, 8552–8555. [Google Scholar] [CrossRef] [PubMed]

- Kline, T.R.; Paxton, W.F.; Mallouk, T.E.; Sen, A. Catalytic nanomotors: Remote-controlled autonomous movement of striped metallic nanorods. Angew. Chem. 2005, 117, 754–756. [Google Scholar] [CrossRef]

- Dynabeads, Commercial Product. Available online: www.thermofisher.com (accessed on 10 February 2018).

- Dynamic Biosensors, Commercial Product. Available online: www.dynamic-biosensors.com (accessed on 10 February 2018).

- Wang, J.; Manesh, K.M. Motion control at the nanoscale. Small 2010, 6, 338–345. [Google Scholar] [CrossRef] [PubMed]

- Haeufle, D.F.; Bauerle, T.; Steiner, J.; Bremicker, L.; Schmitt, S.; Bechinger, C. External control strategies for self-propelled particles: Optimizing navigational efficiency in the presence of limited resources. Phys. Rev. E 2016, 94, 012617. [Google Scholar] [CrossRef] [PubMed]

- Teo, W.Z.; Pumera, M. Motion control of micro-/nanomotors. Chemistry 2016, 22, 14796–14804. [Google Scholar] [CrossRef] [PubMed]

- Tu, Y.; Peng, F.; Wilson, D.A. Motion manipulation of micro- and nanomotors. Adv. Mater. 2017, 1701970. [Google Scholar] [CrossRef] [PubMed]

- Ariga, K.; Mori, T.; Ishihara, S.; Kawakami, K.; Hill, J.P. Bridging the difference to the billionth-of-a-meter length scale: How to operate nanoscopic machines and nanomaterials by using macroscopic actions. Chem. Mater. 2013, 26, 519–532. [Google Scholar] [CrossRef]

- Solovev, A.A.; Sanchez, S.; Pumera, M.; Mei, Y.F.; Schmidt, O.G. Magnetic control of tubular catalytic microbots for the transport, assembly, and delivery of micro-objects. Adv. Funct. Mater. 2010, 20, 2430–2435. [Google Scholar] [CrossRef]

- Karshalev, E.; Chen, C.; Marolt, G.; Martin, A.; Campos, I.; Castillo, R.; Wu, T.; Wang, J. Utilizing iron’s attractive chemical and magnetic properties in microrocket design, extended motion, and unique performance. Small 2017, 13. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Pumera, M. Magnetotactic artificial self-propelled nanojets. Langmuir 2013, 29, 7411–7415. [Google Scholar] [CrossRef] [PubMed]

- Li, J.-X.; Lu, B.-R.; Shen, Z.; Xu, Z.; Li, H.; Wen, J.; Li, Z.; Qu, X.-P.; Chen, Y.-F.; Mei, Y.; et al. Magnetic and meniscus-effect control of catalytic rolled-up micromotors. Microelectron. Eng. 2011, 88, 1792–1794. [Google Scholar] [CrossRef]

- Liu, M.; Wu, F.; Piao, H.; Huang, X.; Cong, J.; Luo, Z.; Pan, L.; Liu, Y. Rod-shaped nanomotor powered by magnetic field gradients and its application to surface-enhanced Raman-scattering-based detection. Appl. Phys. Express 2017, 10, 045202. [Google Scholar] [CrossRef]

- Schattling, P.S.; Ramos-Docampo, M.A.; Salgueirino, V.; Stadler, B. Double-fueled Janus swimmers with magnetotactic behavior. ACS Nano 2017, 11, 3973–3983. [Google Scholar] [CrossRef] [PubMed]

- Baraban, L.; Makarov, D.; Schmidt, O.G.; Cuniberti, G.; Leiderer, P.; Erbe, A. Control over Janus micromotors by the strength of a magnetic field. Nanoscale 2013, 5, 1332–1336. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Mandal, T.K.; Bandyopadhyay, D. Magnetically guided chemical locomotion of self-propelling paperbots. RSC Adv. 2015, 5, 64444–64449. [Google Scholar] [CrossRef]

- Kumar, S.; Ali Faridi, M.R.; Dasmahapatra, A.K.; Bandyopadhyay, D. Magnetic field induced push–pull motility of liquibots. RSC Adv. 2016, 6, 107049–107056. [Google Scholar] [CrossRef]

- Li, T.; Li, J.; Morozov, K.I.; Wu, Z.; Xu, T.; Rozen, I.; Leshansky, A.M.; Li, L.; Wang, J. Highly efficient freestyle magnetic nanoswimmer. Nano Lett. 2017, 17, 5092–5098. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Li, J.; Zhang, H.; Chang, X.; Song, W.; Hu, Y.; Shao, G.; Sandraz, E.; Zhang, G.; Li, L.; et al. Magnetically propelled fish-like nanoswimmers. Small 2016, 12, 6098–6105. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.-C.; Gui, H.; Yuan, B.; Liu, J. Magnetic trap effect to restrict motion of self-powered tiny liquid metal motors. Appl. Phys. Lett. 2015, 107, 071904. [Google Scholar] [CrossRef]

- Yang, T.; Tasci, T.O.; Neeves, K.B.; Wu, N.; Marr, D.W.M. Magnetic microlassos for reversible cargo capture, transport, and release. Langmuir 2017, 33, 5932–5937. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Dey, K.K.; Chattopadhyay, A.; Mandal, T.K.; Bandyopadhyay, D. Multimodal chemo-magnetic control of self-propelling microbots. Nanoscale 2014, 6, 1398–1405. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.-Z.; Shamsudhin, N.; Hoop, M.; Pieters, R.; Siringil, E.; Sakar, M.S.; Nelson, B.J.; Pané, S. Magnetoelectric micromachines with wirelessly controlled navigation and functionality. Mater. Horiz. 2016, 3, 113–118. [Google Scholar] [CrossRef]

- Li, J.; Li, T.; Xu, T.; Kiristi, M.; Liu, W.; Wu, Z.; Wang, J. Magneto-acoustic hybrid nanomotor. Nano Lett. 2015, 15, 4814–4821. [Google Scholar] [CrossRef] [PubMed]

- Eslami, S.; Gibbs, J.G.; Rechkemmer, Y.; Van Slageren, J.; Alarcón-Correa, M.; Lee, T.-C.; Mark, A.G.; Rikken, G.L.J.A.; Fischer, P. Chiral nanomagnets. ACS Photonics 2014, 1, 1231–1236. [Google Scholar] [CrossRef]

- Xu, T.; Gao, W.; Xu, L.P.; Zhang, X.; Wang, S. Fuel-free synthetic micro-/nanomachines. Adv. Mater. 2017, 29, 1603250. [Google Scholar] [CrossRef] [PubMed]

- Mou, F.; Pan, D.; Chen, C.; Gao, Y.; Xu, L.; Guan, J. Magnetically modulated pot-like MnFe2O4 micromotors: Nanoparticle assembly fabrication and their capability for direct oil removal. Adv. Funct. Mater. 2015, 25, 6173–6181. [Google Scholar] [CrossRef]

- Sattayasamitsathit, S.; Kou, H.; Gao, W.; Thavarajah, W.; Kaufmann, K.; Zhang, L.; Wang, J. Fully loaded micromotors for combinatorial delivery and autonomous release of cargoes. Small 2014, 10, 2830–2833. [Google Scholar] [CrossRef] [PubMed]

- Maria-Hormigos, R.; Jurado-Sanchez, B.; Escarpa, A. Labs-on-a-chip meet self-propelled micromotors. Lab Chip 2016, 16, 2397–2407. [Google Scholar] [CrossRef] [PubMed]

- Maria-Hormigos, R.; Jurado-Sanchez, B.; Escarpa, A. Tailored magnetic carbon allotrope catalytic micromotors for ‘on-chip’ operations. Nanoscale 2017, 9, 6286–6290. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Torres, J.; Serra, A.; Tierno, P.; Alcobe, X.; Valles, E. Magnetic propulsion of recyclable catalytic nanocleaners for pollutant degradation. ACS Appl. Mater. Interfaces 2017, 9, 23859–23868. [Google Scholar] [CrossRef] [PubMed]

- Eskandarloo, H.; Kierulf, A.; Abbaspourrad, A. Light-harvesting synthetic nano- and micromotors: A review. Nanoscale 2017, 9, 12218–12230. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Zhang, Q.; Gao, W.; Pei, A.; Ren, B. Highly efficient light-driven TiO2-Au Janus micromotors. ACS Nano 2016, 10, 839–844. [Google Scholar] [CrossRef] [PubMed]

- Enachi, M.; Guix, M.; Postolache, V.; Ciobanu, V.; Fomin, V.M.; Schmidt, O.G.; Tiginyanu, I. Light-induced motion of microengines based on microarrays of TiO2 nanotubes. Small 2016, 12, 5497–5505. [Google Scholar] [CrossRef] [PubMed]

- Mou, F.; Li, Y.; Chen, C.; Li, W.; Yin, Y.; Ma, H.; Guan, J. Single-component TiO2 tubular microengines with motion controlled by light-induced bubbles. Small 2015, 11, 2564–2570. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Si, T.; Wu, Z.; Gao, C.; Lin, X.; He, Q. Light-activated active colloid ribbons. Angew. Chem. Int. Ed. 2017, 56, 13517–13520. [Google Scholar] [CrossRef] [PubMed]

- Palacci, J.; Sacanna, S.; Vatchinsky, A.; Chaikin, P.M.; Pine, D.J. Photoactivated colloidal dockers for cargo transportation. J. Am. Chem. Soc. 2013, 135, 15978–15981. [Google Scholar] [CrossRef] [PubMed]

- Palacci, J.; Sacanna, S.; Kim, S.H.; Yi, G.R.; Pine, D.J.; Chaikin, P.M. Light-activated self-propelled colloids. Philos. Trans. Soc. A 2014, 372, 20130372. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Wang, C.; Wang, Q.; Pei, A.; She, X.; Zhang, Y.; Cai, Y. ZnO-based microrockets with light-enhanced propulsion. Nanoscale 2017, 9, 15027–15032. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Hao, W.; Yu, S.; Feng, R.; Liu, Y.; Yu, F.; Tao, P.; Shang, W.; Wu, J.; Song, C.; et al. Vapor-enabled propulsion for plasmonic photothermal motor at the liquid/air interface. J. Am. Chem. Soc. 2017, 139, 12362–12365. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.H.; Mark, A.G.; Lee, T.C.; Alarcon-Correa, M.; Eslami, S.; Qiu, T.; Gibbs, J.G.; Fischer, P. Active nanorheology with plasmonics. Nano Lett. 2016, 16, 4887–4894. [Google Scholar] [CrossRef] [PubMed]

- Dai, B.; Wang, J.; Xiong, Z.; Zhan, X.; Dai, W.; Li, C.C.; Feng, S.P.; Tang, J. Programmable artificial phototactic microswimmer. Nat. Nanotechnol. 2016, 11, 1087–1092. [Google Scholar] [CrossRef] [PubMed]

- Grant, A. Micromotors swim toward and away from the light. Phys. Today 2016, 69, 25. [Google Scholar] [CrossRef]

- Dong, R.; Hu, Y.; Wu, Y.; Gao, W.; Ren, B.; Wang, Q.; Cai, Y. Visible-light-driven BiOI-based Janus micromotor in pure water. J. Am. Chem. Soc. 2017, 139, 1722–1725. [Google Scholar] [CrossRef] [PubMed]

- Jang, B.; Hong, A.; Kang, H.E.; Alcantara, C.; Charreyron, S.; Mushtaq, F.; Pellicer, E.; Buchel, R.; Sort, J.; Lee, S.S.; et al. Multiwavelength light-responsive Au/B-TiO2 Janus micromotors. ACS Nano 2017, 11, 6146–6154. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Ren, L.; Li, Y.C.; Xu, P.; Gao, Y.; Zhang, G.; Wang, W.; Mallouk, T.E.; Li, L. Visible light-driven, magnetically steerable gold/iron oxide nanomotors. Chem. Commun. 2017, 53, 11465–11468. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Li, Y.C.; Xu, P.; Ren, L.; Zhang, G.; Mallouk, T.E.; Li, L. Visible-light driven Si-Au micromotors in water and organic solvents. Nanoscale 2017, 9, 11434–11438. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Li, Y.C.; Xu, P.; McCool, N.S.; Li, L.; Wang, W.; Mallouk, T.E. Visible-light controlled catalytic Cu2O-Au micromotors. Nanoscale 2017, 9, 75–78. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.; Sun, Y.; Zhang, H.; Song, B.; Dong, B. A phototactic micromotor based on platinum nanoparticle decorated carbon nitride. Nanoscale 2017, 9, 18516–18522. [Google Scholar] [CrossRef] [PubMed]

- Rao, Q.; Si, T.; Wu, Z.; Xuan, M.; He, Q. A light-activated explosive micropropeller. Sci. Rep. 2017, 7, 4621. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Si, T.; Gao, W.; Lin, X.; Wang, J.; He, Q. Superfast near-infrared light-driven polymer multilayer rockets. Small 2016, 12, 577–582. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Si, T.; Shao, J.; Wu, Z.; He, Q. Near-infrared light-driven Janus capsule motors: Fabrication, propulsion, and simulation. Nano Res. 2016, 9, 3747–3756. [Google Scholar] [CrossRef]

- Maggi, C.; Saglimbeni, F.; Dipalo, M.; De Angelis, F.; Di Leonardo, R. Micromotors with asymmetric shape that efficiently convert light into work by thermocapillary effects. Nat. Commun. 2015, 6, 7855. [Google Scholar] [CrossRef] [PubMed]

- Foy, J.T.; Li, Q.; Goujon, A.; Colard-Itte, J.R.; Fuks, G.; Moulin, E.; Schiffmann, O.; Dattler, D.; Funeriu, D.P.; Giuseppone, N. Dual-light control of nanomachines that integrate motor and modulator subunits. Nat. Nanotechnol. 2017, 12, 540–545. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xiong, Z.; Zhan, X.; Dai, B.; Zheng, J.; Liu, J.; Tang, J. A silicon nanowire as a spectrally tunable light-driven nanomotor. Adv. Mater. 2017, 29, 1701451. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Dai, B.; Wang, J.; Xiong, Z.; Yang, Y.; Liu, J.; Zhan, X.; Wan, Z.; Tang, J. Orthogonal navigation of multiple visible-light-driven artificial microswimmers. Nat. Commun. 2017. [Google Scholar] [CrossRef] [PubMed]

- Palagi, S.; Mark, A.G.; Reigh, S.Y.; Melde, K.; Qiu, T.; Zeng, H.; Parmeggiani, C.; Martella, D.; Sanchez-Castillo, A.; Kapernaum, N.; et al. Structured light enables biomimetic swimming and versatile locomotion of photoresponsive soft microrobots. Nat. Mater. 2016, 15, 647–653. [Google Scholar] [CrossRef] [PubMed]

- Schamel, D.; Pfeifer, M.; Gibbs, J.G.; Miksch, B.; Mark, A.G.; Fischer, P. Chiral colloidal molecules and observation of the propeller effect. J. Am. Chem. Soc. 2013, 135, 12353–12359. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Tang, S.-Y.; Sivan, V.; Zhang, W.; Mitchell, A.; Kalantar-zadeh, K.; Khoshmanesh, K. Photochemically induced motion of liquid metal marbles. Appl. Phys. Lett. 2013, 103, 174104. [Google Scholar] [CrossRef]

- Wong, F.; Sen, A. Progress toward light-harvesting self-electrophoretic motors: Highly efficient bimetallic nanomotors and micropumps in halogen media. ACS Nano 2016, 10, 7172–7179. [Google Scholar] [CrossRef] [PubMed]

- Safdar, M.; Simmchen, J.; Jänis, J. Light-driven micro- and nanomotors for environmental remediation. Environ. Sci. Nano 2017, 4, 1602–1616. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, A.; Wang, F.; Ren, J.; Qu, X. Design of a plasmonic micromotor for enhanced photo-remediation of polluted anaerobic stagnant waters. Chem. Commun. 2016, 52, 5550–5553. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Dong, R.; Wu, Y.; Gao, W.; He, Z.; Ren, B. Light-driven Au-WO3@C Janus micromotors for rapid photodegradation of dye pollutants. ACS Appl. Mater. Interfaces 2017, 9, 4674–4683. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Pedrero, F.; Massana-Cid, H.; Tierno, P. Assembly and transport of microscopic cargos via reconfigurable photoactivated magnetic microdockers. Small 2017, 13. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, D.; Baasch, T.; Jang, B.; Pane, S.; Dual, J.; Nelson, B.J. Artificial swimmers propelled by acoustically activated flagella. Nano Lett. 2016, 16, 4968–4974. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, D.; Dillinger, C.; Hong, A.; Nelson, B.J. Artificial acousto-magnetic soft microswimmers. Adv. Mater. Technol. 2017, 2, 1700050. [Google Scholar] [CrossRef]

- Chen, M.; Cai, F.; Wang, C.; Wang, Z.; Meng, L.; Li, F.; Zhang, P.; Liu, X.; Zheng, H. Observation of metal nanoparticles for acoustic manipulation. Adv. Sci. 2017, 4, 1600447. [Google Scholar] [CrossRef] [PubMed]

- Collis, J.F.; Chakraborty, D.; Sader, J.E. Autonomous propulsion of nanorods trapped in an acoustic field. J. Fluid Mech. 2017, 825, 29–48. [Google Scholar] [CrossRef]

- Feng, J.; Yuan, J.; Cho, S.K. Micropropulsion by an acoustic bubble for navigating microfluidic spaces. Lab Chip 2015, 15, 1554–1562. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Yuan, J.; Cho, S.K. 2-D steering and propelling of acoustic bubble-powered microswimmers. Lab Chip 2016, 16, 2317–2325. [Google Scholar] [CrossRef] [PubMed]

- Soto, F.; Martin, A.; Ibsen, S.; Vaidyanathan, M.; Garcia-Gradilla, V.; Levin, Y.; Escarpa, A.; Esener, S.C.; Wang, J. Acoustic microcannons: Toward advanced microballistics. ACS Nano 2016, 10, 1522–1528. [Google Scholar] [CrossRef] [PubMed]

- Soto, F.; Wagner, G.L.; Garcia-Gradilla, V.; Gillespie, K.T.; Lakshmipathy, D.R.; Karshalev, E.; Angell, C.; Chen, Y.; Wang, J. Acoustically propelled nanoshells. Nanoscale 2016, 8, 17788–17793. [Google Scholar] [CrossRef] [PubMed]

- Esteban-Fernandez de Avila, B.; Angell, C.; Soto, F.; Lopez-Ramirez, M.A.; Baez, D.F.; Xie, S.; Wang, J.; Chen, Y. Acoustically propelled nanomotors for intracellular siRNA delivery. ACS Nano 2016, 10, 4997–5005. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Frueh, J.; Hu, N.; Liu, L.; Gai, M.; He, Q. Guidable thermophoretic Janus micromotors containing gold nanocolorifiers for infrared laser assisted tissue welding. Adv. Sci. 2016, 3, 1600206. [Google Scholar] [CrossRef] [PubMed]

- Melde, K.; Mark, A.G.; Qiu, T.; Fischer, P. Holograms for acoustics. Nature 2016, 537, 518–522. [Google Scholar] [CrossRef] [PubMed]

- Rao, K.J.; Li, F.; Meng, L.; Zheng, H.; Cai, F.; Wang, W. A force to be reckoned with: A review of synthetic microswimmers powered by ultrasound. Small 2015, 11, 2836–2846. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Duan, W.; Zhang, Z.; Sun, M.; Sen, A.; Mallouk, T.E. A tale of two forces: Simultaneous chemical and acoustic propulsion of bimetallic micromotors. Chem. Commun. 2015, 51, 1020–1023. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.T.; Paunov, V.N.; Petsev, D.N.; Velev, O.D. Remotely powered self-propelling particles and micropumps based on miniature diodes. Nat. Mater. 2007, 6, 235–240. [Google Scholar] [CrossRef] [PubMed]

- Essmann, V.; Voci, S.; Loget, G.; Sojic, N.; Schuhmann, W.; Kuhn, A. Wireless light-emitting electrochemical rotors. J. Phys. Chem. Lett. 2017, 8, 4930–4934. [Google Scholar] [CrossRef] [PubMed]

- Calvo-Marzal, P.; Sattayasamitsathit, S.; Balasubramanian, S.; Windmiller, J.R.; Dao, C.; Wang, J. Propulsion of nanowire diodes. Chem. Commun. 2010, 46, 1623–1624. [Google Scholar] [CrossRef] [PubMed]

- Yoshizumi, Y.; Honegger, T.; Berton, K.; Suzuki, H.; Peyrade, D. Trajectory control of self-propelled micromotors using AC electrokinetics. Small 2015, 11, 5630–5635. [Google Scholar] [CrossRef] [PubMed]

- Moo, J.G.S.; Pumera, M. Self-propelled micromotors monitored by particle-electrode impact voltammetry. ACS Sens. 2016, 1, 949–957. [Google Scholar] [CrossRef]

- Tan, S.-C.; Yuan, B.; Liu, J. Electrical method to control the running direction and speed of self-powered tiny liquid metal motors. Proc. R. Soc. A 2015, 471, 20150297. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Kagan, D.; Manesh, K.M.; Calvo-Marzal, P.; Flechsig, G.U.; Wang, J. Thermal modulation of nanomotor movement. Small 2009, 5, 1569–1574. [Google Scholar] [CrossRef] [PubMed]

- Cai, K.; Yu, J.; Liu, L.; Shi, J.; Qin, Q.H. Rotation measurements of a thermally driven rotary nanomotor with a spring wing. Phys. Chem. Chem. Phys. 2016, 18, 22478–22486. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Liang, T.; Ye, W. Knudsen torque: A rotational mechanism driven by thermal force. Phys. Rev. E Stat. Nonlin. Soft Matter Phys. 2014, 90, 033009. [Google Scholar] [CrossRef] [PubMed]

- Valdez, L.; Shum, H.; Ortiz-Rivera, I.; Balazs, A.C.; Sen, A. Solutal and thermal buoyancy effects in self-powered phosphatase micropumps. Soft Matter 2017, 13, 2800–2807. [Google Scholar] [CrossRef] [PubMed]

- Moo, J.G.; Presolski, S.; Pumera, M. Photochromic spatiotemporal control of bubble-propelled micromotors by a spiropyran molecular switch. ACS Nano 2016, 10, 3543–3552. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.S.; Wang, J.Y.; Liu, Z.Q.; Zhou, D.K.; Tian, Z.A.; Xu, B.R.; Li, L.Q.; Mei, Y.F. Rocket-inspired tubular catalytic microjets with grating-structured walls as guiding empennages. Nanoscale 2017, 47, 18590–18596. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Zhou, C.; Wang, W.; Zhang, H.P. Bimetallic microswimmers speed up in confining channels. Phys. Rev. Lett. 2016, 117, 198001. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Qian, S.; Zhao, Y.; Qiao, R. Self-diffusiophoresis of Janus catalytic micromotors in confined geometries. Langmuir 2016, 32, 5580–5592. [Google Scholar] [CrossRef] [PubMed]

- Davies Wykes, M.S.; Zhong, X.; Tong, J.; Adachi, T.; Liu, Y.; Ristroph, L.; Ward, M.D.; Shelley, M.J.; Zhang, J. Guiding microscale swimmers using teardrop-shaped posts. Soft Matter 2017, 13, 4681–4688. [Google Scholar] [CrossRef] [PubMed]

- Illien, P.; Golestanian, R.; Sen, A. ‘Fuelled’ motion: Phoretic motility and collective behaviour of active colloids. Chem. Soc. Rev. 2017, 46, 5508–5518. [Google Scholar] [CrossRef] [PubMed]

- Maggi, C.; Simmchen, J.; Saglimbeni, F.; Katuri, J.; Dipalo, M.; De Angelis, F.; Sanchez, S.; Di Leonardo, R. Self-assembly of micromachining systems powered by Janus micromotors. Small 2016, 12, 446–451. [Google Scholar] [CrossRef] [PubMed]

- Ben-Jacob, E.; Cohen, I.; Levine, H. Cooperative self-organization of microorganisms. Adv. Phys. 2000, 49, 395–554. [Google Scholar] [CrossRef]

- Kei Cheang, U.; Lee, K.; Julius, A.A.; Kim, M.J. Multiple-robot drug delivery strategy through coordinated teams of microswimmers. Appl. Phys. Lett. 2014, 105, 083705. [Google Scholar] [CrossRef]

- Huang, M.J.; Kapral, R. Collective dynamics of diffusiophoretic motors on a filament. Eur. Phys. J. E Soft Matter 2016, 39, 36. [Google Scholar] [CrossRef] [PubMed]

- Kolmakov, G.V.; Yashin, V.V.; Levitan, S.P.; Balazs, A.C. Designing communicating colonies of biomimetic microcapsules. Proc. Natl. Acad. Sci. USA 2010, 107, 12417–12422. [Google Scholar] [CrossRef] [PubMed]

- Bishop, K.J.M.; Wilmer, C.E.; Soh, S.; Grzybowski, B.A. Nanoscale forces and their uses in self-assembly. Small 2009, 5, 1600–1630. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Mou, F.; Feng, Y.; Che, S.; Li, W.; Xu, L.; Guan, J. Dynamic colloidal molecules maneuvered by light-controlled Janus micromotors. ACS Appl. Mater. Interfaces 2017, 9, 22704–22712. [Google Scholar] [CrossRef] [PubMed]

- Mou, F.; Kong, L.; Chen, C.; Chen, Z.; Xu, L.; Guan, J. Light-controlled propulsion, aggregation and separation of water-fuelled TiO2/Pt Janus submicromotors and their “on-the-fly” photocatalytic activities. Nanoscale 2016, 8, 4976–4983. [Google Scholar] [CrossRef] [PubMed]

- Singh, D.P.; Choudhury, U.; Fischer, P.; Mark, A.G. Non-equilibrium assembly of light-activated colloidal mixtures. Adv. Mater. 2017, 1701328. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Diaz, M.; Córdova-Figueroa, U.M.; Sen, A. Light-driven titanium-dioxide-based reversible microfireworks and micromotor/micropump systems. Adv. Funct. Mater. 2010, 20, 1568–1576. [Google Scholar] [CrossRef]

- Duan, W.; Ibele, M.; Liu, R.; Sen, A. Motion analysis of light-powered autonomous silver chloride nanomotors. Eur. Phys. J. E Soft Matter 2012, 35, 77. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Bashirzadeh, Y.; Bernadowski, T.; Zhang, X. UV light–induced aggregation of Titania submicron particles. Micromachines 2016, 7, 203. [Google Scholar] [CrossRef]

- Zhang, Q.; Dong, R.; Chang, X.; Ren, B.; Tong, Z. Spiropyran-decorated SiO2-Pt Janus micromotor: Preparation and light-induced dynamic self-assembly and disassembly. ACS Appl. Mater. Interfaces 2015, 7, 24585–24591. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Pei, A.; Feng, X.; Hennessy, C.; Wang, J. Organized self-assembly of Janus micromotors with hydrophobic hemispheres. J. Am. Chem. Soc. 2013, 135, 998–1001. [Google Scholar] [CrossRef] [PubMed]

- Nourhani, A.; Brown, D.; Pletzer, N.; Gibbs, J.G. Engineering contactless particle-particle interactions in active microswimmers. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef] [PubMed]

- Bayati, P.; Najafi, A. Dynamics of two interacting active Janus particles. J. Chem. Phys. 2016, 144, 134901. [Google Scholar] [CrossRef] [PubMed]

- Afshar Farniya, A.; Esplandiu, M.J.; Bachtold, A. Sequential tasks performed by catalytic pumps for colloidal crystallization. Langmuir 2014, 30, 11841–11845. [Google Scholar] [CrossRef] [PubMed]

- Manjare, M.; Yang, F.; Qiao, R.; Zhao, Y. Marangoni flow induced collective motion of catalytic micromotors. J. Phys. Chem. C 2015, 119, 28361–28367. [Google Scholar] [CrossRef]

- Kokot, G.; Kolmakov, G.V.; Aranson, I.S.; Snezhko, A. Dynamic self-assembly and self-organized transport of magnetic micro-swimmers. Sci. Rep. 2017, 7, 14726. [Google Scholar] [CrossRef] [PubMed]

- Vach, P.J.; Walker, D.; Fischer, P.; Fratzl, P.; Faivre, D. Pattern formation and collective effects in populations of magnetic microswimmers. J. Phys. D 2017, 50, 11LT03. [Google Scholar] [CrossRef]

- Xu, T.; Soto, F.; Gao, W.; Dong, R.; Garcia-Gradilla, V.; Magana, E.; Zhang, X.; Wang, J. Reversible swarming and separation of self-propelled chemically powered nanomotors under acoustic fields. J. Am. Chem. Soc. 2015, 137, 2163–2166. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Duan, W.; Ahmed, S.; Sen, A.; Mallouk, T.E. From one to many: Dynamic assembly and collective behavior of self-propelled colloidal motors. Acc. Chem. Res. 2015, 48, 1938–1946. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Velegol, D.; Chaturvedi, N.; Sen, A. Biomimetic behavior of synthetic particles: From microscopic randomness to macroscopic control. Phys. Chem. Chem. Phys. 2010, 12, 1423–1430. [Google Scholar] [CrossRef] [PubMed]

- Purcell, E.M. Life at low Reynolds number. Am. J. Phys. 1977, 45, 3–11. [Google Scholar] [CrossRef]

- Altemose, A.; Sanchez-Farran, M.A.; Duan, W.; Schulz, S.; Borhan, A.; Crespi, V.H.; Sen, A. Chemically controlled spatiotemporal oscillations of colloidal assemblies. Angew. Chem. Int. Ed. Engl. 2017, 56, 7817–7821. [Google Scholar] [CrossRef] [PubMed]

- Duan, W.; Liu, R.; Sen, A. Transition between collective behaviors of micromotors in response to different stimuli. J. Am. Chem. Soc. 2013, 135, 1280–1283. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhang, H.; Liu, M.; Dong, B. Reprogrammable logic gate and logic circuit based on multistimuli-responsive raspberry-like micromotors. ACS Appl. Mater. Interfaces 2016, 8, 15654–15660. [Google Scholar] [CrossRef] [PubMed]

- Dey, K.K.; Wong, F.; Altemose, A.; Sen, A. Catalytic motors—Quo vadimus? Curr. Opin. Colloid Interface Sci. 2016, 21, 4–13. [Google Scholar] [CrossRef]

- Dey, K.K.; Sen, A. Chemically propelled molecules and machines. J. Am. Chem. Soc. 2017, 139, 7666–7676. [Google Scholar] [CrossRef] [PubMed]

- Grzybowski, B.A.; Fitzner, K.; Paczesny, J.; Granick, S. From dynamic self-assembly to networked chemical systems. Chem. Soc. Rev. 2017, 46, 5647–5678. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Luijten, E.; Grzybowski, B.A.; Granick, S. Active colloids with collective mobility status and research opportunities. Chem. Soc. Rev. 2017, 46, 5551–5569. [Google Scholar] [CrossRef] [PubMed]

- Dey, K.K.; Das, S.; Poython, M.F.; Sengupta, S.; Butler, P.J.; Cremer, P.S; Sen, A. Chemotactic separation of enzymes. ACS Nano 2014, 8, 11941–11949. [Google Scholar] [CrossRef] [PubMed]

- Solovev, A.A.; Mei, Y.; Schmidt, O.G. Catalytic microstrider at the air-liquid interface. Adv. Mater. 2010, 22, 4340–4344. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Fei, S.; Byun, W.M.; Lammert, P.E.; Crespi, V.H.; Sen, A.; Mallouk, T.E. Dynamic interactions between fast microscale rotors. J. Am. Chem. Soc. 2009, 131, 9926–9927. [Google Scholar] [CrossRef] [PubMed]

- Solovev, A.A.; Sanchez, S.; Schmidt, O.G. Collective behaviour of self-propelled catalytic micromotors. Nanoscale 2013, 5, 1284–1293. [Google Scholar] [CrossRef] [PubMed]

- Fialkowski, M.; Bishop, K.J.M.; Klajn, R.; Smoukov, S.K.; Campbell, C.J.; Grzybowski, B.A. Principles and implementations of dissipative (dynamic) self-assembly. J. Phys. Chem. B 2006, 110, 2482–2496. [Google Scholar] [CrossRef] [PubMed]

- Turing, A.M. The chemical basis of morphogenesis. Philos. Trans. R. Soc. B Biol. Sci. 1952, 237, 37–72. [Google Scholar] [CrossRef]

- Howard, J.; Grill, S.W.; Bois, J.S. Turing’s next steps: The mechanochemical basis of morphogenesis. Nat. Rev. Mol. Cell Biol. 2011, 12, 392–398. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.V.; Soto, F.; Kaufmann, K.; Wang, J. Micromotor-based energy generation. Angew. Chem. Int. Ed. 2015, 54, 6896–6899. [Google Scholar] [CrossRef] [PubMed]

- Morikawa, M.; Ogura, Y.; Ahmed, N.; Kawamura, S.; Mikami, G.; Okamotoband, S.; Izumi, Y. Photocatalytic conversion of carbon dioxide intomethanol in reverse fuel cells with tungsten oxide and layered double hydroxide photocatalysts forsolar fuel generation. Catal. Sci. Technol. 2014, 4, 1644–1651. [Google Scholar] [CrossRef]

- Peng, F.; Tu, Y.; Wilson, D.A. Micro/nanomotors towards in vivo application: Cell, tissue and biofluid. Chem. Soc. Rev. 2017, 46, 5289–5310. [Google Scholar] [CrossRef] [PubMed]

- Abdelmohsen, L.K.E.A.; Nijemeisland, M.; Pawar, G.M.; Janssen, G.-J.A.; Nolte, R.J.M.; van Hest, J.C.M.; Wilson, D.A. Dynamic loading and unloading of proteins in polymeric stomatocytes: Formation of an enzyme-loaded supramolecular nanomotor. ACS Nano 2016, 10, 2652–2660. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Medina-Sanchez, M.; Schwarz, L.; Meyer, A.K.; Hebenstreit, F.; Schmidt, O.G. Cellular cargo delivery: Toward assisted fertilization by sperm-carrying micromotors. Nano Lett. 2016, 16, 555–561. [Google Scholar] [CrossRef] [PubMed]

- Shah, R.K.; Shum, H.C.; Rowat, A.C.; Lee, D.; Agresti, J.J.; Utada, A.S. Designer emulsions using microfluidics. Mater. Today 2008, 11, 18–27. [Google Scholar] [CrossRef]

- Gaspar, S. Enzymatically induced motion at nano- and micro-scales. Nanoscale 2014, 6, 7757–7763. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Hortelao, A.C.; Patiño, T.; Sanchez, S. Enzyme catalysis to power micro/nanomachines. ACS Nano 2016, 10, 9111–9122. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Wu, Z.; Wu, Y.; Xuan, M.; He, Q. Self-propelled micro-/nanomotors based on controlled assembled architectures. Adv. Mater. 2016, 28, 1060–1072. [Google Scholar] [CrossRef] [PubMed]

- Mano, N.; Heller, A. Bioelectrochemical propulsion. J. Am. Chem. Soc. 2005, 127, 11574–11575. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Jannasch, A.; Albrecht, U.R.; Hahn, K.; Lopez, A.M.; Schaffer, E.; Sanchez, S. Enzyme-powered hollow mesoporous Janus nanomotors. Nano Lett. 2015, 15, 7043–7050. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Hortelao, A.C.; Lopez, A.M.; Sanchez, S. Bubble-free propulsion of ultrasmall tubular nanojets powered by biocatalytic reactions. J. Am. Chem. Soc. 2016, 138, 13782–13785. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Dong, R.; Thamphiwatana, S.; Li, J.X.; Gao, W.W.; Zhang, L.F.; Wang, J. Artificial micromotors in the mouse’s stomach: A step toward in vivo use of synthetic motors. ACS Nano 2015, 9, 117–123. [Google Scholar] [CrossRef] [PubMed]

- Gregory, D.A.; Zhang, Y.; Smith, P.J.; Zhao, X.; Ebbens, S.J. Reactive inkjet printing of biocompatible enzyme powered silk micro-rockets. Small 2016, 12, 4048–4055. [Google Scholar] [CrossRef] [PubMed]

- Pavlick, R.A.; Sengupta, S.; McFadden, T.; Zhang, H.; Sen, A. A polymerization-powered motor. Angew. Chem. Int. Ed. 2011, 50, 9374–9397. [Google Scholar] [CrossRef] [PubMed]

- Yoshizumi, Y.; Okubo, K.; Yokokawa, M.; Suzuki, H. Programmed transport and release of cells by self-propelled micromotors. Langmuir 2016, 32, 9381–9388. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Yin, J.; Wu, C.; Du, L.; Wang, Y. Efficient target capture and transport by fuel-free micromotors in a multichannel microchip. Soft Matter 2017, 13, 8064–8069. [Google Scholar] [CrossRef] [PubMed]

- Esteban-Fernandez de Avila, B.; Ramirez-Herrera, D.E.; Campuzano, S.; Angsantikul, P.; Zhang, L.; Wang, J. Nanomotor-enabled pH-responsive intracellular delivery of caspase-3: Toward rapid cell apoptosis. ACS Nano 2017, 11, 5367–5374. [Google Scholar] [CrossRef] [PubMed]

- Mou, F.; Chen, C.; Zhong, Q.; Yin, Y.; Ma, H.; Guan, J. Autonomous motion and temperature-controlled drug delivery of Mg/Pt-poly(N-isopropylacrylamide) Janus micromotors driven by simulated body fluid and blood plasma. ACS Appl. Mater. Interfaces 2014, 6, 9897–9903. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Chen, J.; Feng, X.; Zeng, W.; Liu, R.; Lin, X.; Ma, Y.; Wang, L. Self-propelled manganese oxide-based catalytic micromotors for drug delivery. RSC Adv. 2016, 6, 65624–65630. [Google Scholar] [CrossRef]

- Orozco, J.; Cortes, A.; Cheng, G.; Sattayasamitsathit, S.; Gao, W.; Feng, X.; Shen, Y.; Wang, J. Molecularly imprinted polymer-based catalytic micromotors for selective protein transport. J. Am. Chem. Soc. 2013, 135, 5336–5339. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Wang, J. Synthetic micro/nanomotors in drug delivery. Nanoscale 2014, 6, 10486–10494. [Google Scholar] [CrossRef] [PubMed]

- Patra, D.; Sengupta, S.; Duan, W.; Zhang, H.; Pavlick, R.; Sen, A. Intelligent, self-powered, drug delivery systems. Nanoscale 2013, 5, 1273–1283. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.; Ge, X.-H.; Chen, J.; Zhang, L.; Xu, J.-H. Multi-functional micromotor: Microfluidic fabrication and water treatment application. Lab Chip 2017, 17, 4220–4224. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.P.; Zhai, Y.G.; Qi, G.B.; Lin, Y.X.; Luo, Q.; Yang, Y.; Xu, A.P.; Yang, C.; Li, Y.S.; Wang, L.; et al. NIR light propulsive Janus-like nanohybrids for enhanced photothermal tumor therapy. Small 2016, 12, 5423–5430. [Google Scholar] [CrossRef] [PubMed]

- Bhuyan, T.; Kumar Singh, A.; Dutta, D.; Unal, A.; Sankar Ghosh, S.; Bandyopadhyay, D. Magnetic field guided chemotaxis of imushbots for targeted anticancer therapeutics. ACS Biomater. Sci. Eng. 2017, 3, 1627–1640. [Google Scholar] [CrossRef]

- Chen, F.; Hong, H.; Zhang, Y.; Valdovinos, H.F.; Shi, S.; Kwon, G.S.; Theuer, C.P.; Barnhart, T.E.; Cai, W. In vivo tumor targeting and image-guided drug delivery with antibody-conjugated, radiolabeled mesoporous silica nanoparticles. ACS Nano 2013, 7, 9027–9039. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Angsantikul, P.; Liu, W.; Esteban-Fernández de Ávila, B.; Thamphiwatana, S.; Xu, M.; Sandraz, E.; Wang, X.; Delezuk, J.; Gao, W.; et al. Micromotors spontaneously neutralize gastric acid for pH-responsive payload release. Angew. Chem. Int. Ed. 2017, 56, 2156–2161. [Google Scholar] [CrossRef] [PubMed]

- De Ávila, B.E.; Angsantikul, P.; Li, J.; Angel Lopez-Ramirez, M.; Ramírez-Herrera, D.E.; Thamphiwatana, S.; Chen, C.; Delezuk, J.; Samakapiruk, R.; Ramez, V.; et al. Micromotor-enabled active drug delivery for in vivo treatment of stomach infection. Nat. Commun. 2017, 8, 272. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Lin, X.; Zou, X.; Sun, J.; He, Q. Biodegradable protein-based rockets for drug transportation and light-triggered release. ACS Appl. Mater. Interfaces 2015, 7, 250–255. [Google Scholar] [CrossRef] [PubMed]

- Tu, Y.; Peng, F.; White, P.B.; Wilson, D.A. Redox-sensitive stomatocyte nanomotors: Destruction and drug release in the presence of glutathione. Angew. Chem. Int. Ed. 2017, 56, 7620–7624. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, Y.; He, J.; Hourwitz, M.J.; Yang, Y.; Fourkas, J.T.; Han, X.; Nie, Z. Continuous microfluidic self-assembly of hybrid Janus-like vesicular motors: Autonomous propulsion and controlled release. Small 2015, 11, 3762–3767. [Google Scholar] [CrossRef] [PubMed]

- Solovev, A.A.; Xi, W.; Gracias, D.H.; Harazim, S.M.; Deneke, C.; Sanchez, S.; Schmidt, O.G. Self-propelled nanotools. Acs Nano 2012, 6, 1751–1756. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Khezri, B.; Pumera, M. Catalytic DNA-functionalized self-propelled micromachines for environmental remediation. Chem 2016, 1, 473–481. [Google Scholar] [CrossRef]

- Fu, S.; Zhang, X.; Xie, Y.; Wu, J.; Ju, H. An efficient enzyme-powered micromotor device fabricated by cyclic alternate hybridization assembly for DNA detection. Nanoscale 2017, 9, 9026–9033. [Google Scholar] [CrossRef] [PubMed]

- Van Nguyen, K.; Minteer, S.D. DNA-functionalized Pt nanoparticles as catalysts for chemically powered micromotors: Toward signal-on motion-based DNA biosensor. Chem. Commun. 2015, 51, 4782–4784. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Balasubramanian, S.; Kagan, D.; Manesh, K.M.; Campuzano, S.; Wang, J. Motion-based DNA detection using catalytic nanomotors. Nat. Commun. 2010, 1, 36. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.V.; Kaufmann, K.; Esteban-Fernández de Ávila, B.; Uygun, M.; Wang, J. Nanomotors responsive to nerve-agent vapor plumes. Chem. Commun. 2016, 52, 3360–3363. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhang, H.; Liu, M.; Dong, B. Motion-based glucose sensing based on a fish-like enzymeless motor. J. Mater. Chem. C 2017, 5, 4400–4407. [Google Scholar] [CrossRef]

- Esteban-Fernández de Ávila, B.; Zhao, M.; Campuzano, S.; Ricci, F.; Pingarrónc, J.M.; Mascinia, M.; Wang, J. Rapid micromotor-based naked-eye immunoassay. Talanta 2017, 167, 651–657. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Gao, W. Nano/microscale motors: Biomedical opportunities and challenges. ACS Nano 2012, 6, 5745–5751. [Google Scholar] [CrossRef] [PubMed]

- Weaver, R. Molecular Biology, 5th ed.; McGraw-Hill Education—Europe: New York, NY, USA, 2011; ISBN 9789813150508. [Google Scholar]

- Adams, L.L.A.; Kodger, T.E.; Kim, S.-H.; Shum, H.C.; Franke, T.; Weitz, D.A. Single step emulsification for the generation of multi-component double emulsions. Soft Matter 2012, 8, 10719–10724. [Google Scholar] [CrossRef]

- Epstein, I.R.; Showalter, K. Nonlinear chemical dynamics: Oscillations, patterns, and chaos. J. Phys. Chem. 1996, 100, 13132–13147. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, H.; Zhang, Y.; Zhu, H.; Ingham, A.; Huang, G.; Mei, Y.; Solovev, A.A. Geometry Design, Principles and Assembly of Micromotors. Micromachines 2018, 9, 75. https://doi.org/10.3390/mi9020075

Ning H, Zhang Y, Zhu H, Ingham A, Huang G, Mei Y, Solovev AA. Geometry Design, Principles and Assembly of Micromotors. Micromachines. 2018; 9(2):75. https://doi.org/10.3390/mi9020075

Chicago/Turabian StyleNing, Huanpo, Yan Zhang, Hong Zhu, Andreas Ingham, Gaoshan Huang, Yongfeng Mei, and Alexander A. Solovev. 2018. "Geometry Design, Principles and Assembly of Micromotors" Micromachines 9, no. 2: 75. https://doi.org/10.3390/mi9020075