Multi-axis Response of a Thermal Convection-based Accelerometer

Abstract

:1. Introduction

2. Materials and Methods

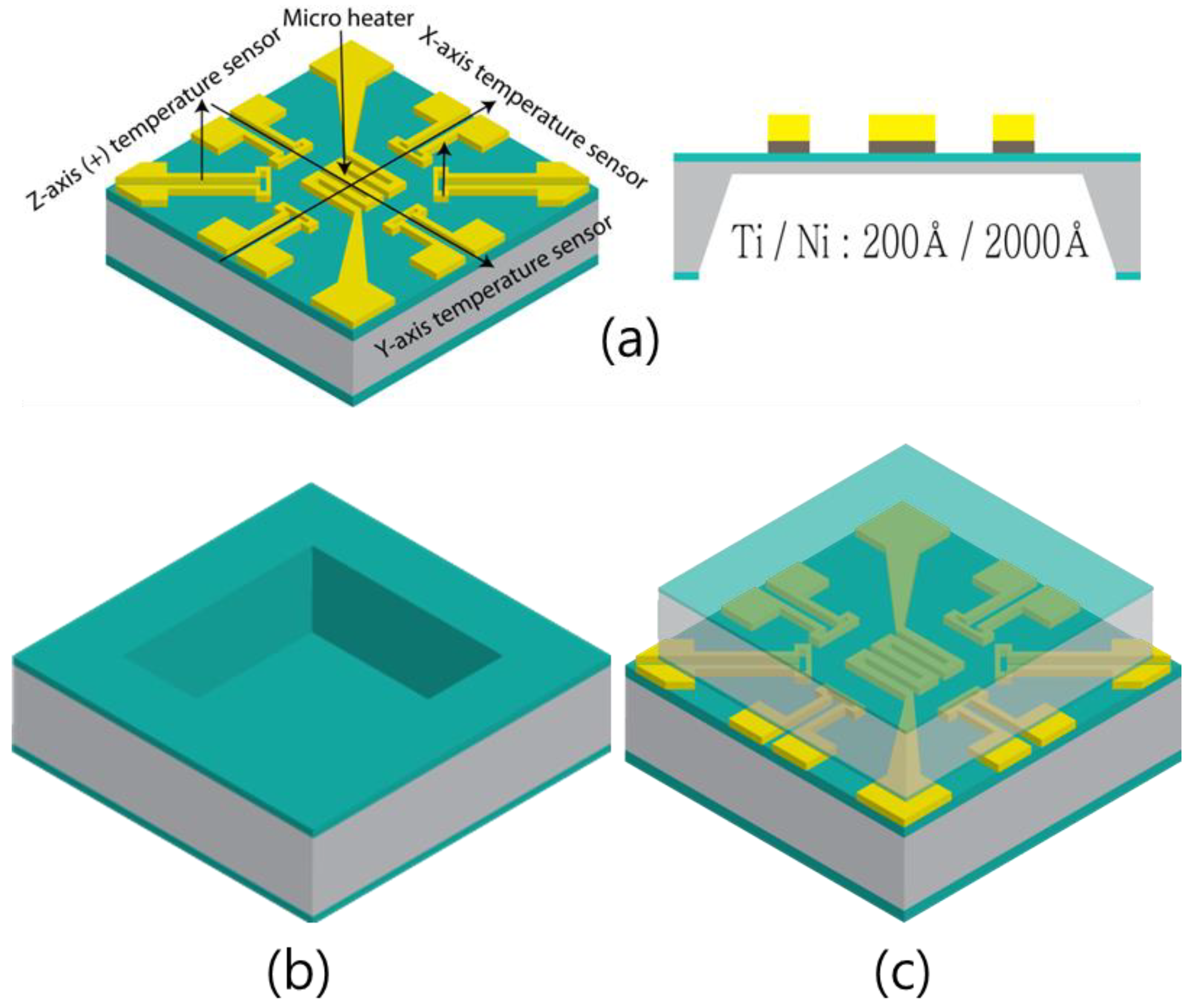

2.1. Device Structure and Working Principle

2.2. Determination of Materials

3. Results and Discussion

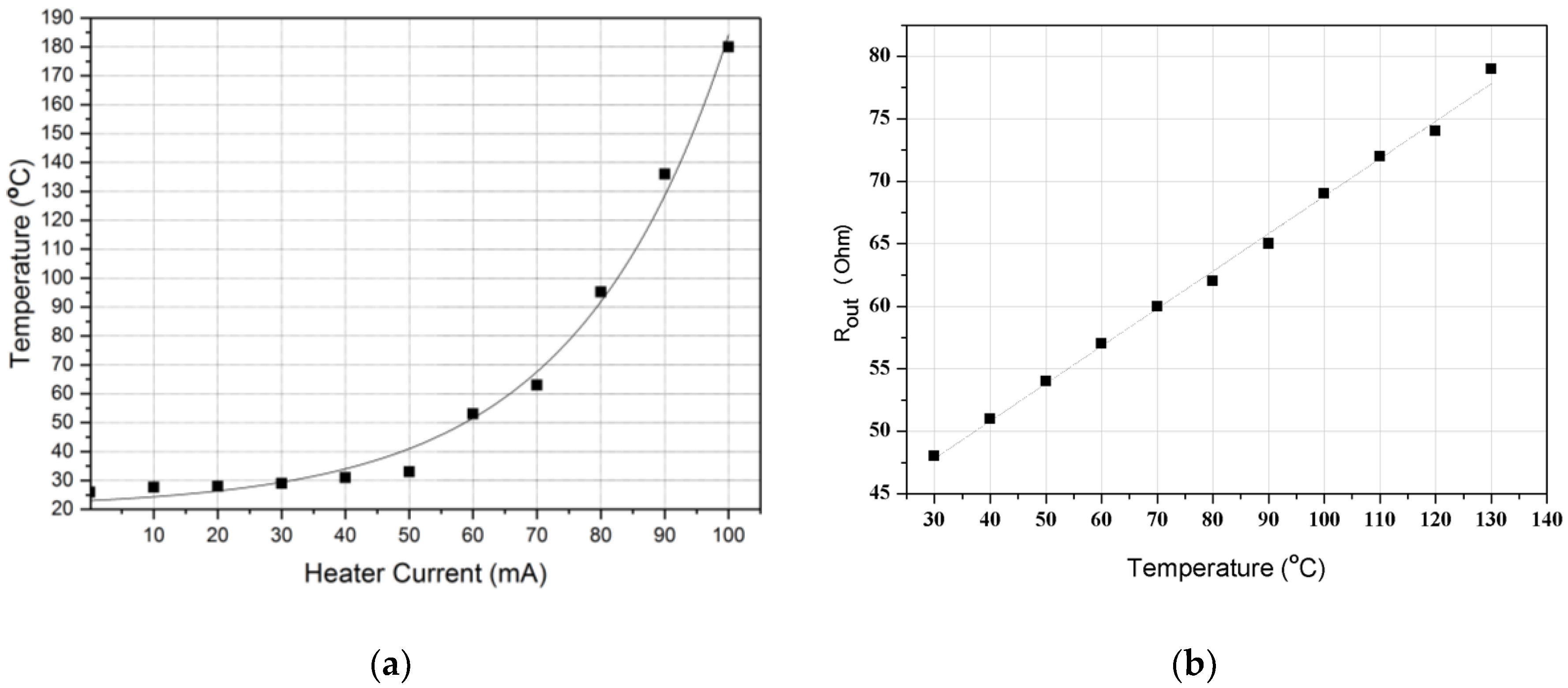

3.1. Characteristics of a Microheater and a Temperature Sensor

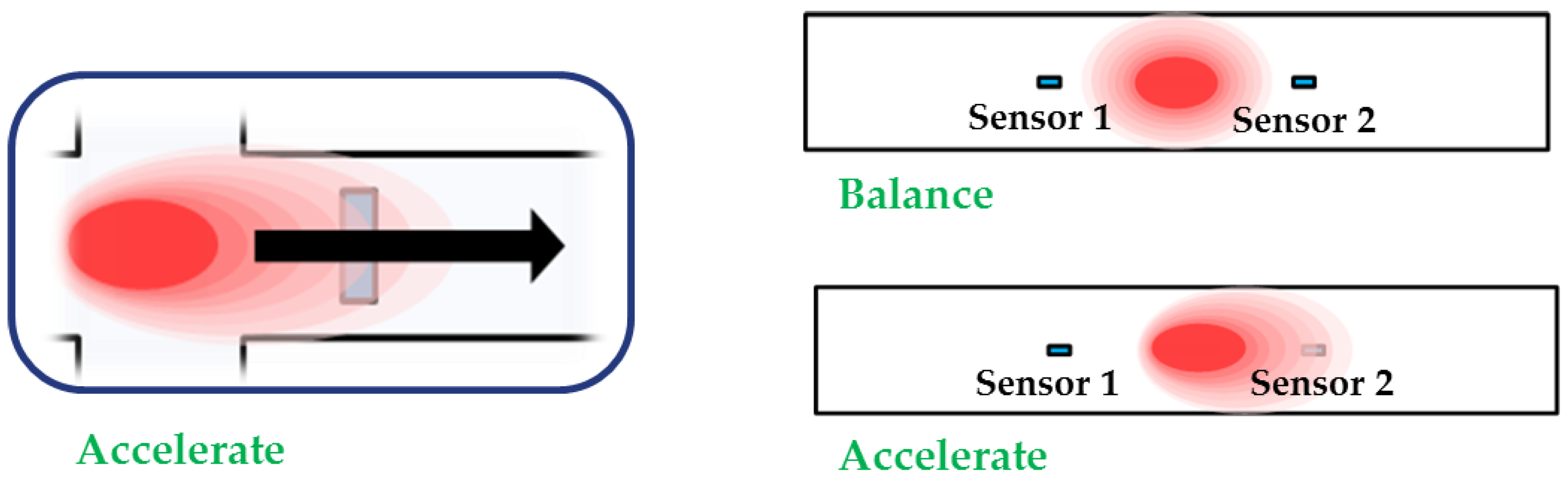

3.2. Operating Principle

3.3. Characteristics of the Accelerometer

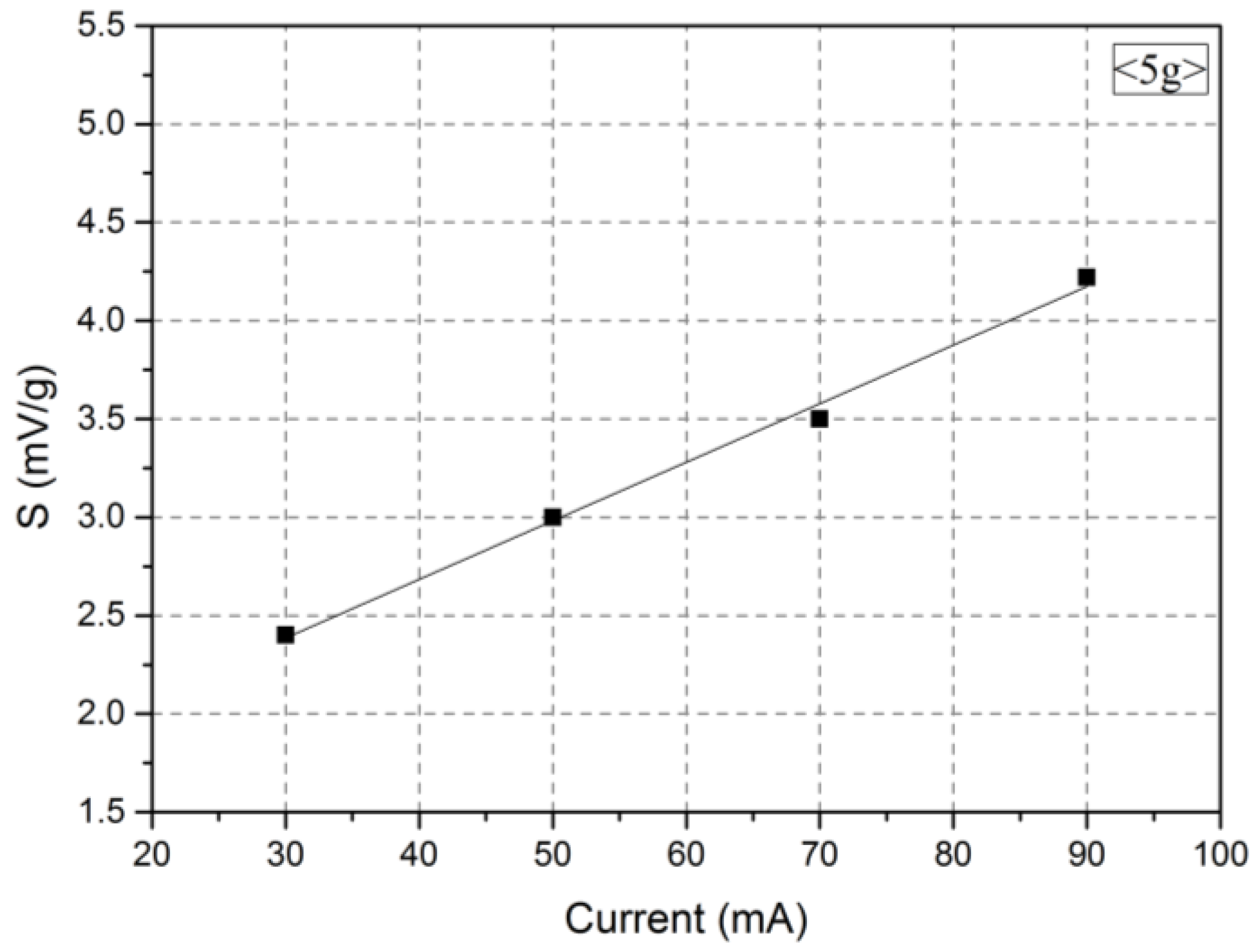

3.3.1. Effects of the Heating Power

3.3.2. Effects of the Frequency

3.3.3. Effects of the Medium Type

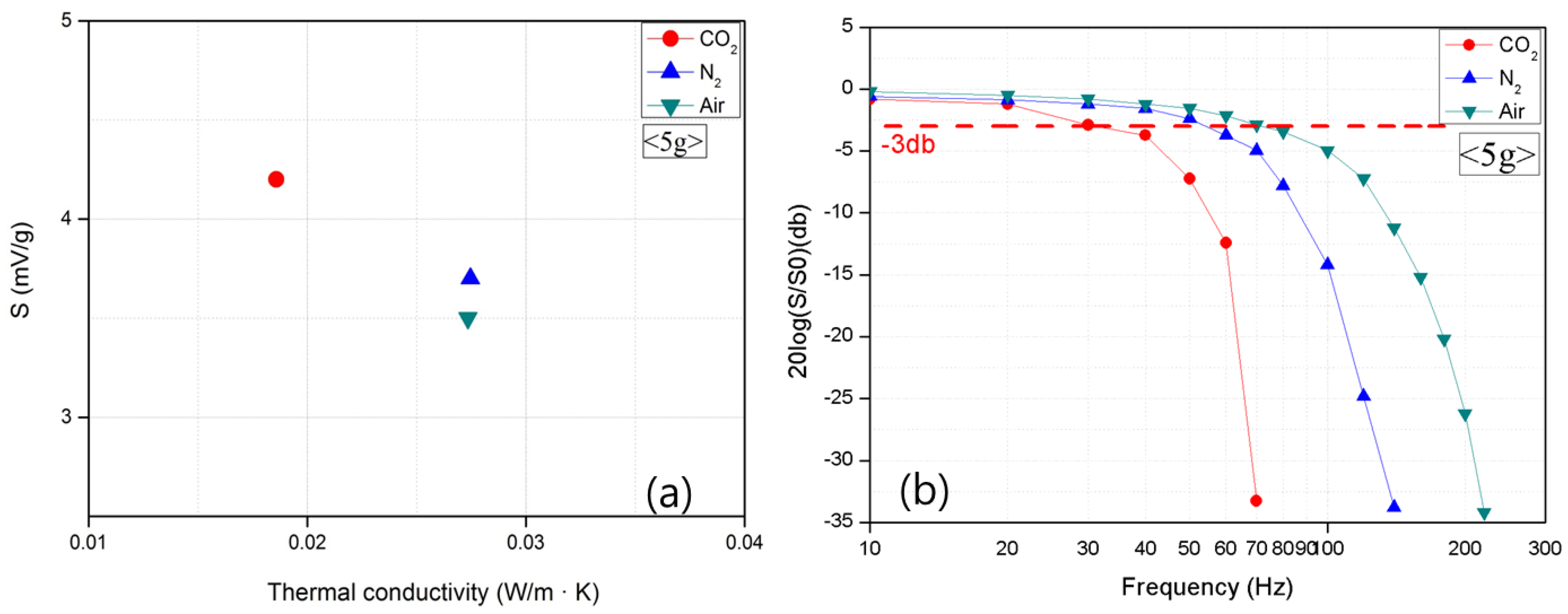

3.3.4. Effects of the Gas Pressure

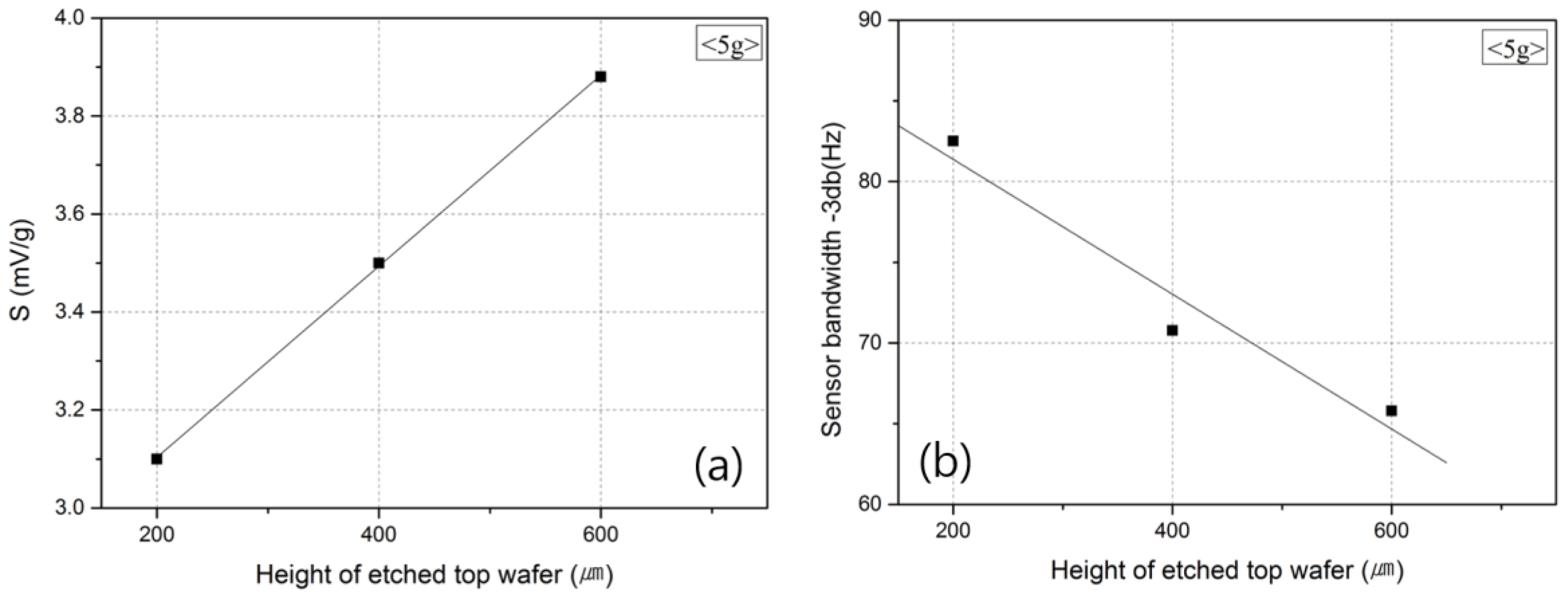

3.3.5. Effects of the Cavity Volume

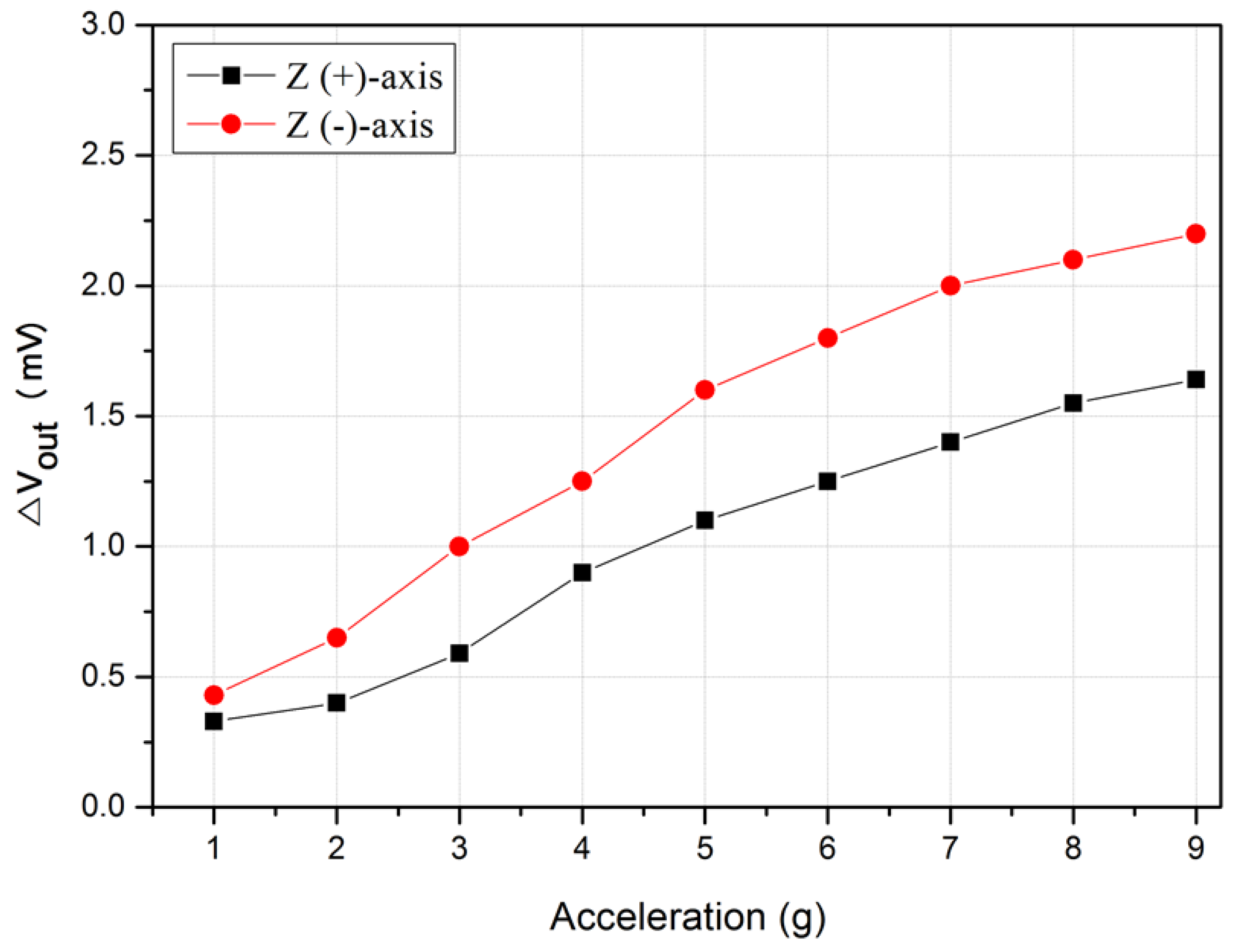

3.3.6. Z-axis Characteristics of the Accelerometer

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- He, J.; Xie, J.; He, X.; Du, L.; Zhou, W. Analytical study and compensation for temperature drift of a bulk silicon MEMS capacitive accelerometer. Sens. Actuators A 2016, 239, 174–184. [Google Scholar] [CrossRef]

- Yu, H.; Guo, B.; Haridas, K.; Lin, T.-H.; Cheong, J.H.; Tsai, M.L.; Yee, T.B. Capacitive micromachined ultrasonic transducer based tilt sensing. Appl. Phys. Lett. 2012, 101, 153502. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, J.; Kurashima, Y.; Takagi, H.; Maeda, R. Gase studies of a planar piezoresistive vibration sensor: Measuring transient time history signal waves. Microelectron. Eng. 2016, 165, 27–31. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, Q.; Hu, Y.; Young, J. Micromachined piezoresistive accelerometers based on an asymmetrically gapped cantilever. IEEE/ASME J. Microelectromech. Syst. 2011, 20, 83–94. [Google Scholar] [CrossRef]

- Zhu, R.; Ding, H.; Su, Y.; Zhou, Z. Micromachined gas inertial sensor based on convection heat transfer. Sens. Actuators A 2006, 130–131, 68–74. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, R. Mcromachined fluid inertial sensors. Sensors 2017, 17, 367. [Google Scholar] [CrossRef] [PubMed]

- Dinh, T.; Phan, H.P.; Qamar, A.; Woodfield, P.; Nguyen, N.T.; Dao, D.V. Thermoresistive effect for advanced thermal sensor: Fundamentals, design consideration, and applications. J. Microelectromech. Syst. 2017, 26, 966–986. [Google Scholar] [CrossRef]

- Mailly, F.; Martinez, A.; Giani, A.; Pascal-Delannoy, F.; Boyer, A. Design of a micromachined thermal accelerometer: Thermal simulation and experimental results. Microelectron. J. 2003, 34, 275–280. [Google Scholar] [CrossRef]

- Mezghani, B.; Tounsi, F.; Masmoudi, M. Development of an accurate heat conduction model for micromachined convective accelerometers. Microsyst. Technol. 2015, 21, 345–353. [Google Scholar] [CrossRef]

- Goustouridis, D.; Kaltsas, G.; Nassiopoulou, A.G. A silicon thermal accelerometer without solid proof mass using porous silicon thermal isolation. IEEE Sensors J. 2007, 7, 983–989. [Google Scholar] [CrossRef]

- Luo, X.B.; Li, Z.X.; Guo, Z.Y.; Yang, Y.Z. Theraml optimization on micromachined convective accelerometer. Heat Mass Transfer 2001, 38, 705–712. [Google Scholar] [CrossRef]

- Luo, X.B.; Yang, Y.J.; Zheng, F.; Li, Z.X.; Guo, Z.Y. An optimized micromachined convective accelerometer with no proof mass. J. Micromech. Microeng. 2001, 11, 504–508. [Google Scholar] [CrossRef]

- Han, M.; Kim, J.K.; Park, J.H.; Kim, W.; Kang, S.W.; Kong, S.H.; Jung, D. Sensitivity and frequency response improvement of a thermal convection-based accelerometer. Sensors 2017, 17, 1765. [Google Scholar] [CrossRef] [PubMed]

- Courteaud, J.; Crespy, N.; Combette, P.; Sorli, B.; Giani, A. Studies and optimization of the frequency response of a micromachined thermal accelerometer. Sens. Actuators A 2008, 147, 75–82. [Google Scholar] [CrossRef]

- Hodnett, P. Natural convection between horizontal heat concentric circular cylinders. J. Appl. Math. Phys. 1973, 24, 507–516. [Google Scholar] [CrossRef]

- Chaehoi, A.; Mailly, F.; Latorre, L.; Nouet, P. Experimental and finite-element study of convective accelerometer on CMOS. Sens. Actuators A 2006, 132, 78–84. [Google Scholar] [CrossRef]

- Mukherjee, R.; Basu, J.; Mandal, P.; Guha, P.K. A revew of micromachined thermal accelerometers. J. Micromech. Microeng. 2017, 27, 123002. [Google Scholar] [CrossRef]

- Garraud, A.; Giani, A.; Combette, P.; Charlot, B.; Richard, M. A dual axis CMOS micromachined convective thermal accelerometer. Sens. Actuators A 2011, 170, 44–50. [Google Scholar] [CrossRef]

- Sanders, C.J.; Holman, J.P. Franz Grashof and the Grashof number. Int. J. Heat Mass Transfer. 1972, 15, 562–563. [Google Scholar] [CrossRef]

- Singal, R.K. Refrigeration and psychrometric charts with property tables (S.I. units), Appendix 1 Property tables and charts (SI units); S.K.KATARIA & SONS: Delhi, India, 2006. [Google Scholar]

- Kaltsas, G.; Goustouridis, D.; Nassiopoulou, A.G. A thermal convective accelerometer system based on a silicon sensor-study and packaging. Sens. Actuators A 2006, 132, 147–153. [Google Scholar] [CrossRef]

- Bahari, J.; Jones, J.D.; Leung, A.M. Sensitivity improvement of micromachined convective accelerometers. J. Microelectromech. Syst. 2012, 21, 646–655. [Google Scholar] [CrossRef]

- Courteaud, J.; Combette, P.; Crespy, N.; Cathebras, G.; Giani, A. Thermal simulation and experimental results of a micromachined thermal inclinometer. Sens. Actuators A 2008, 141, 307–313. [Google Scholar] [CrossRef]

- Zhao, K.; Dalton, P.; Yang, G.C.; Scherer, P.W. Numerical modeling of turbulent and laminar airflow and odorant transport during sniffing in the human and rat nose. Chem. Senses. 2006, 31, 107–118. [Google Scholar] [CrossRef] [PubMed]

- Garraud, A.; Combette, P.; Courteaud, J.; Giani, A. Effect of the detector width and gas pressure on the frequency response of a micromachined thermal accelerometer. Micromachines 2011, 2, 167–178. [Google Scholar] [CrossRef]

- Garraud, A.; Combette, P.; Pichot, F.; Courteaud, J.; Charlot, B.; Giani, A. Frequency response analysis of an accelerometer based on thermal convection. J. Micromech. Microeng. 2011, 21, 035017. [Google Scholar] [CrossRef]

- Mailly, F.; Martinez, A.; Giani, A.; Pascal-Delannoy, F.; Boyer, A. Effect of gas pressure on the sensitivity of a micromachined thermal accelerometer. Sens. Actuators A 2003, 109, 88–94. [Google Scholar] [CrossRef]

- Van, T.; Dzung, V.D.; Susumu, S. A 2–DOF convective micro accelerometer with a low thermal stress sensing element. Smart Mater. Struct. 2007, 16, 2308–2314. [Google Scholar]

| Density (kg/m3) | Specific Heat (kJ/kg·K) | Kinematic Viscosity (×10−6) (m2/s) | Thermal Diffusivity (×10−4) (m2/s) | Thermal Conductivity (W/m·K) | |

|---|---|---|---|---|---|

| Air | 1.092 | 1.007 | 19.6 | 0.248 | 0.02735 |

| N2 | 1.0564 | 1.042 | 17.74 | 0.249 | 0.02746 |

| CO2 | 1.6597 | 0.8666 | 9.71 | 0.129 | 0.01858 |

| Air | N2 | CO2 | |

|---|---|---|---|

| Gr | 7.44 × 10−3 | 8.07 × 10−3 | 4.24 × 10−2 |

| Pr | 7.16 × 10−4 | 6.46 × 10−4 | 5.22 × 10−4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.K.; Han, M.; Kang, S.-W.; Kong, S.H.; Jung, D. Multi-axis Response of a Thermal Convection-based Accelerometer. Micromachines 2018, 9, 329. https://doi.org/10.3390/mi9070329

Kim JK, Han M, Kang S-W, Kong SH, Jung D. Multi-axis Response of a Thermal Convection-based Accelerometer. Micromachines. 2018; 9(7):329. https://doi.org/10.3390/mi9070329

Chicago/Turabian StyleKim, Jae Keon, Maeum Han, Shin-Won Kang, Seong Ho Kong, and Daewoong Jung. 2018. "Multi-axis Response of a Thermal Convection-based Accelerometer" Micromachines 9, no. 7: 329. https://doi.org/10.3390/mi9070329