Recent Progress in Rapid Sintering of Nanosilver for Electronics Applications

Abstract

:1. Introduction

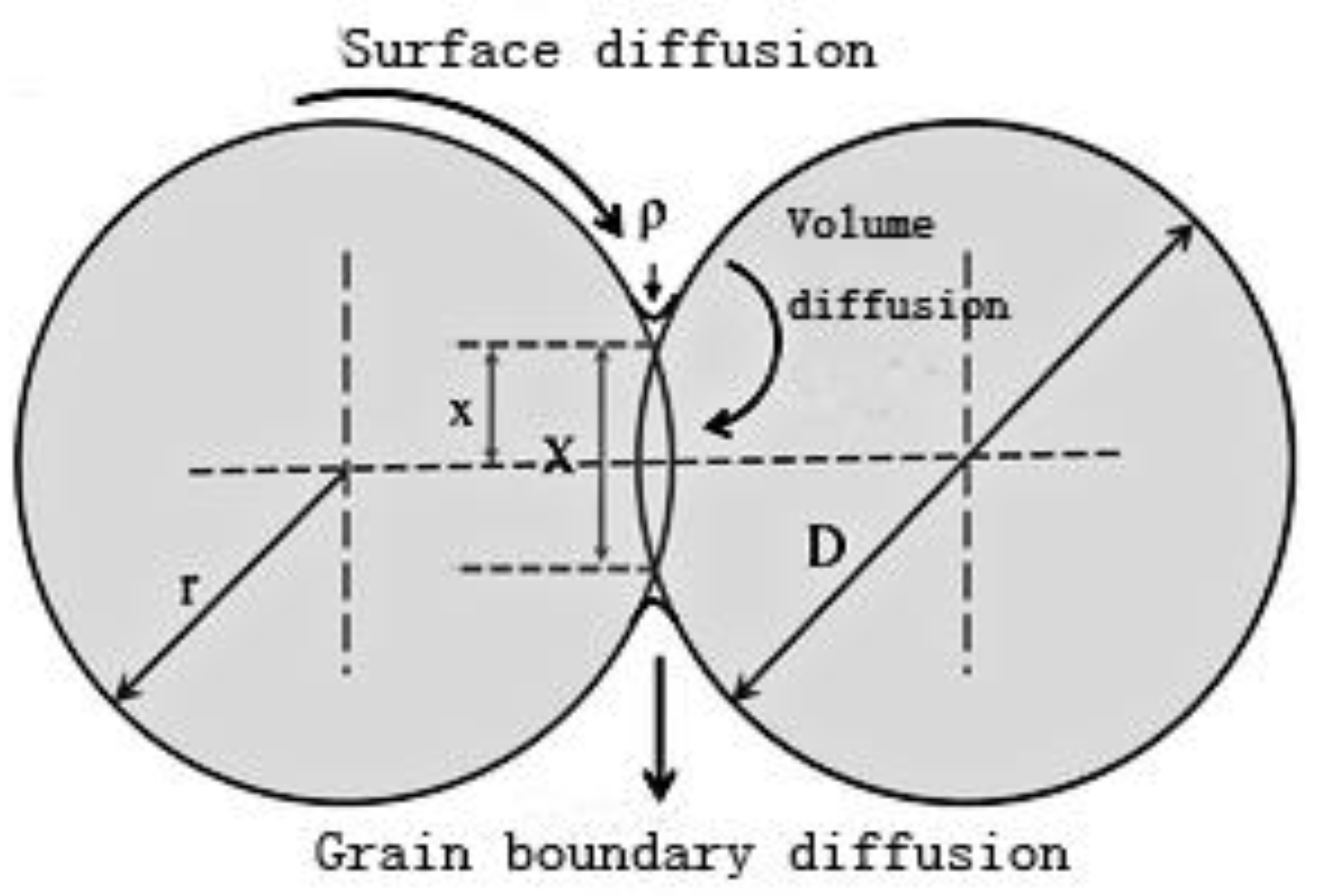

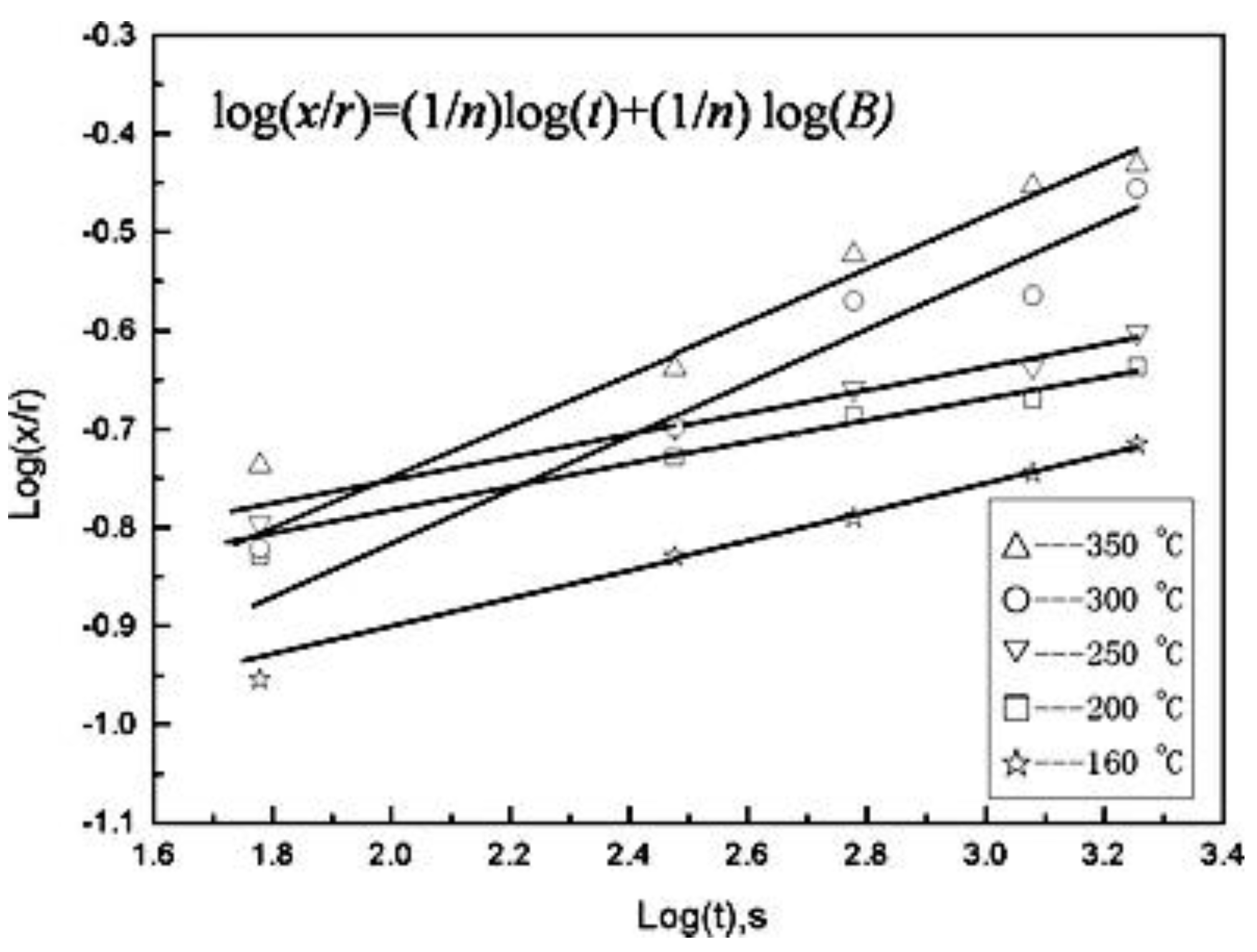

2. Sintering Mechanism of Nanosilver Particles

3. Preparation of Nanosilver Particles and Pastes

4. Rapid Sintering Processes of Nanoparticles

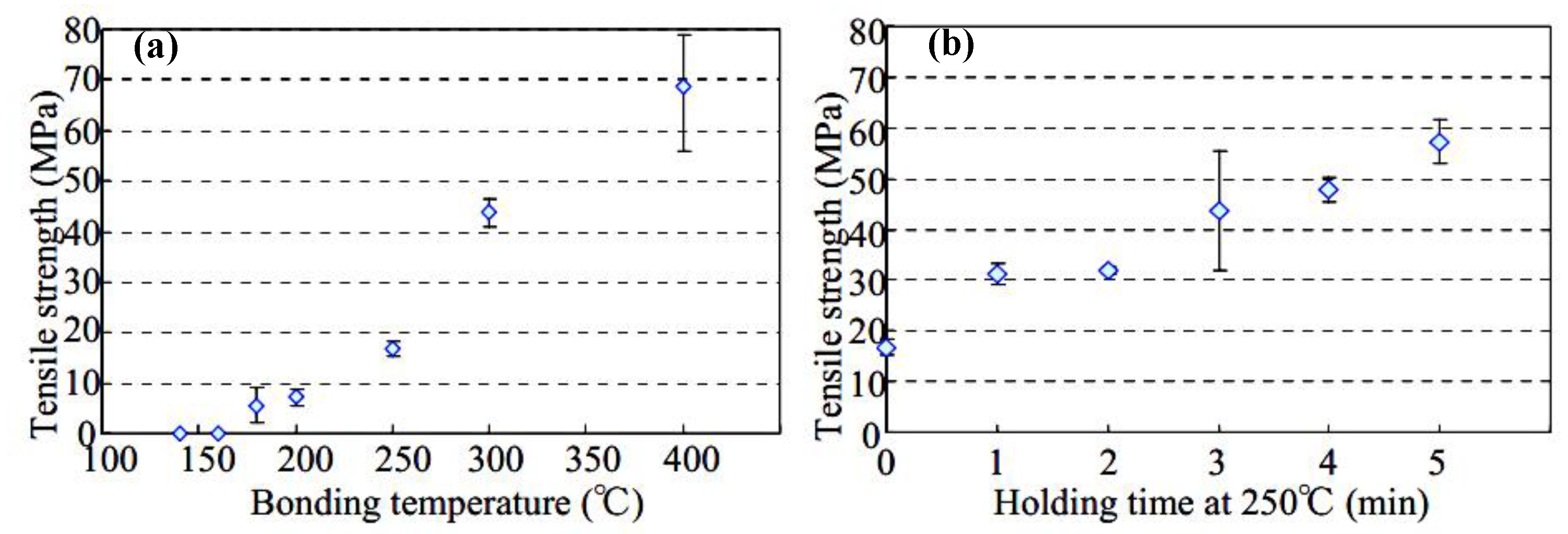

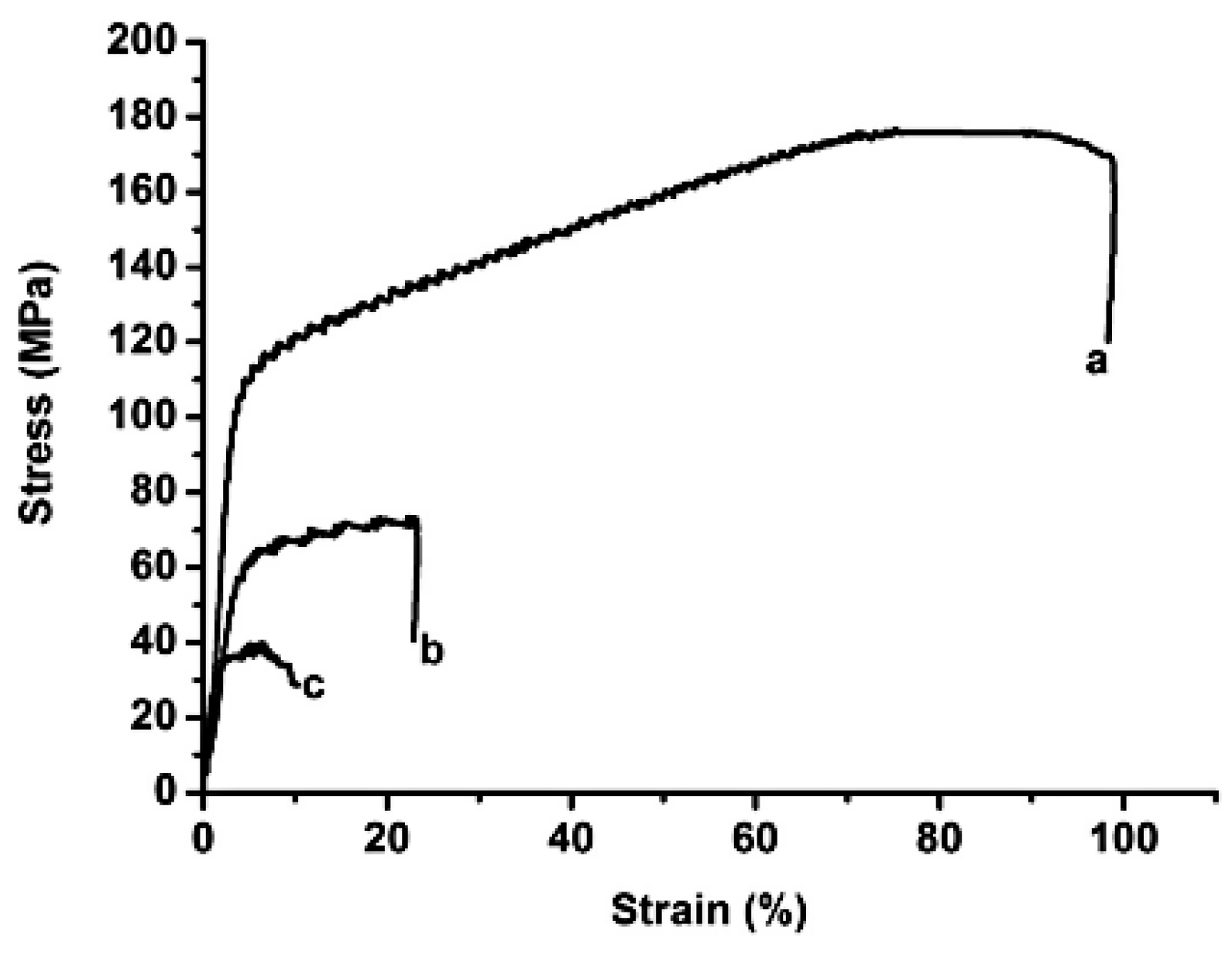

4.1. In-Situ Formation of Nanoparticles and Joints

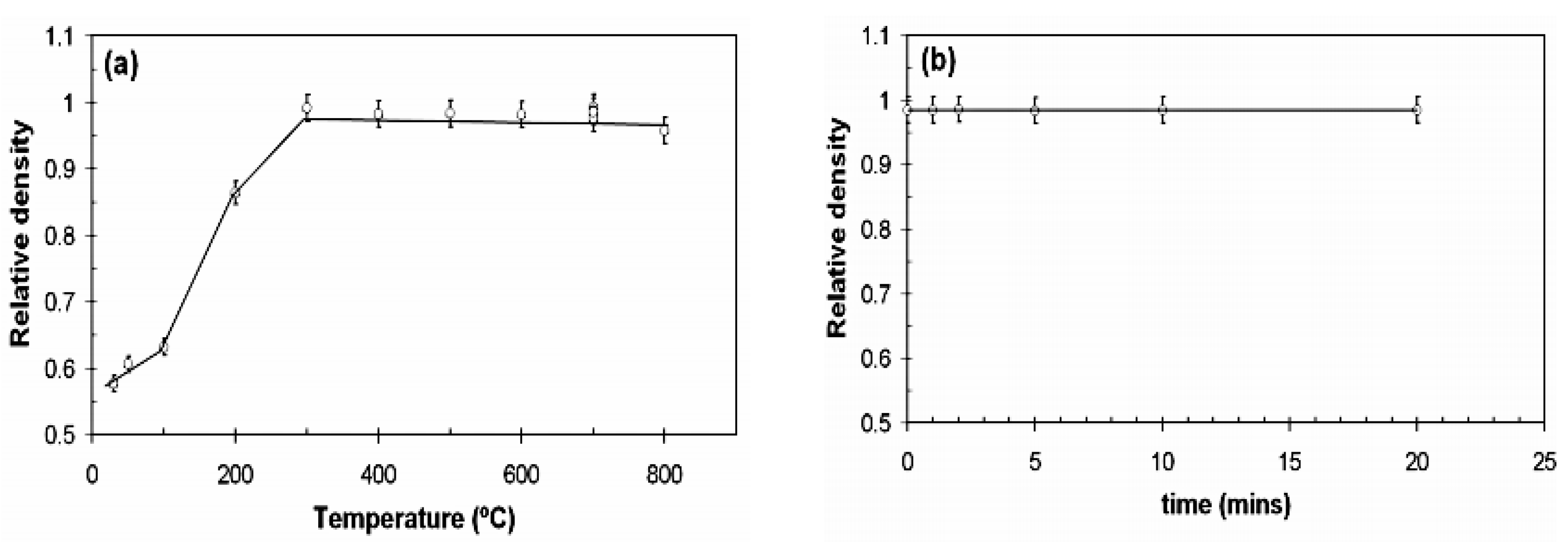

4.2. Spark Plasma Sintering

4.3. Laser Sintering

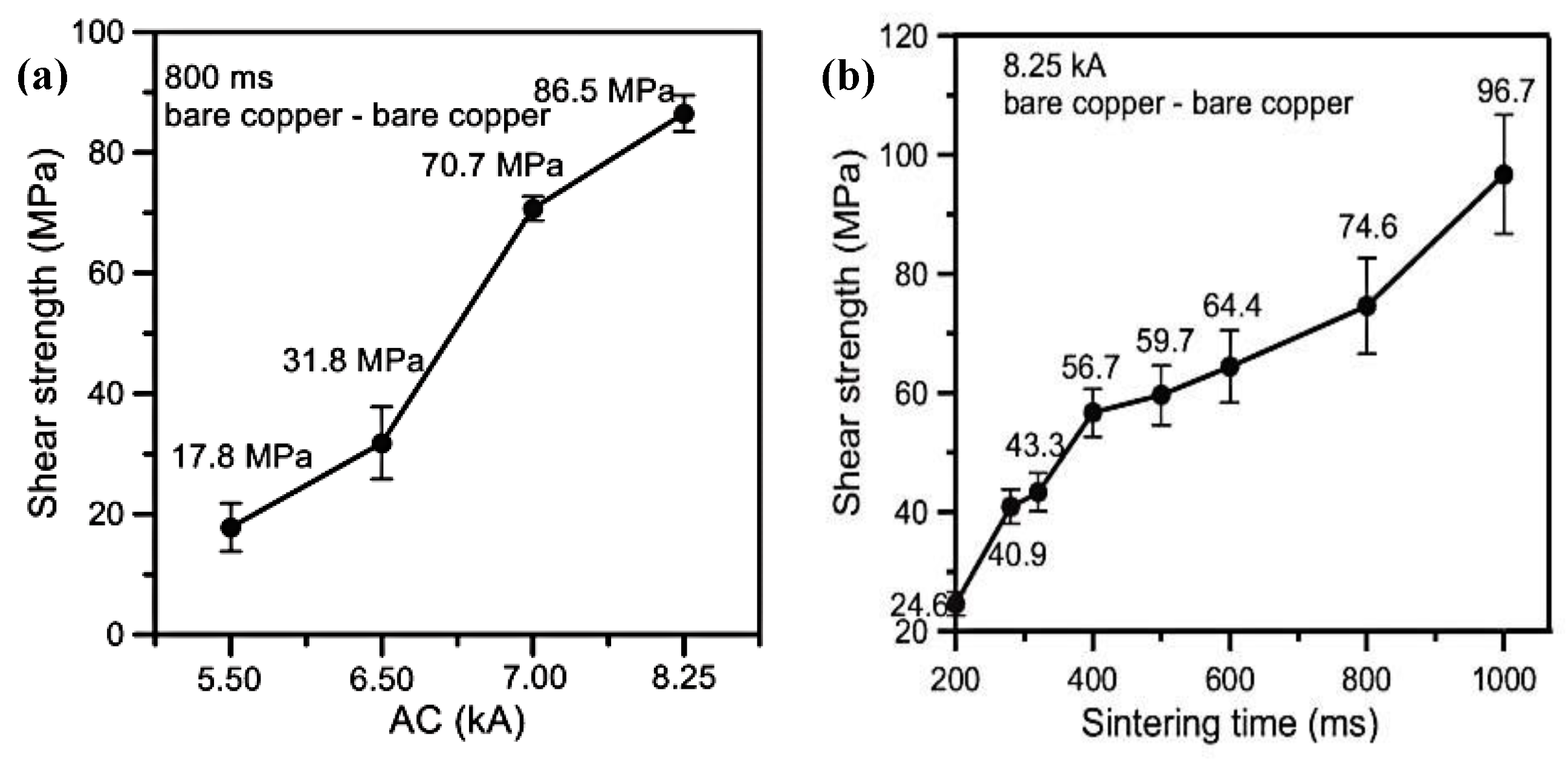

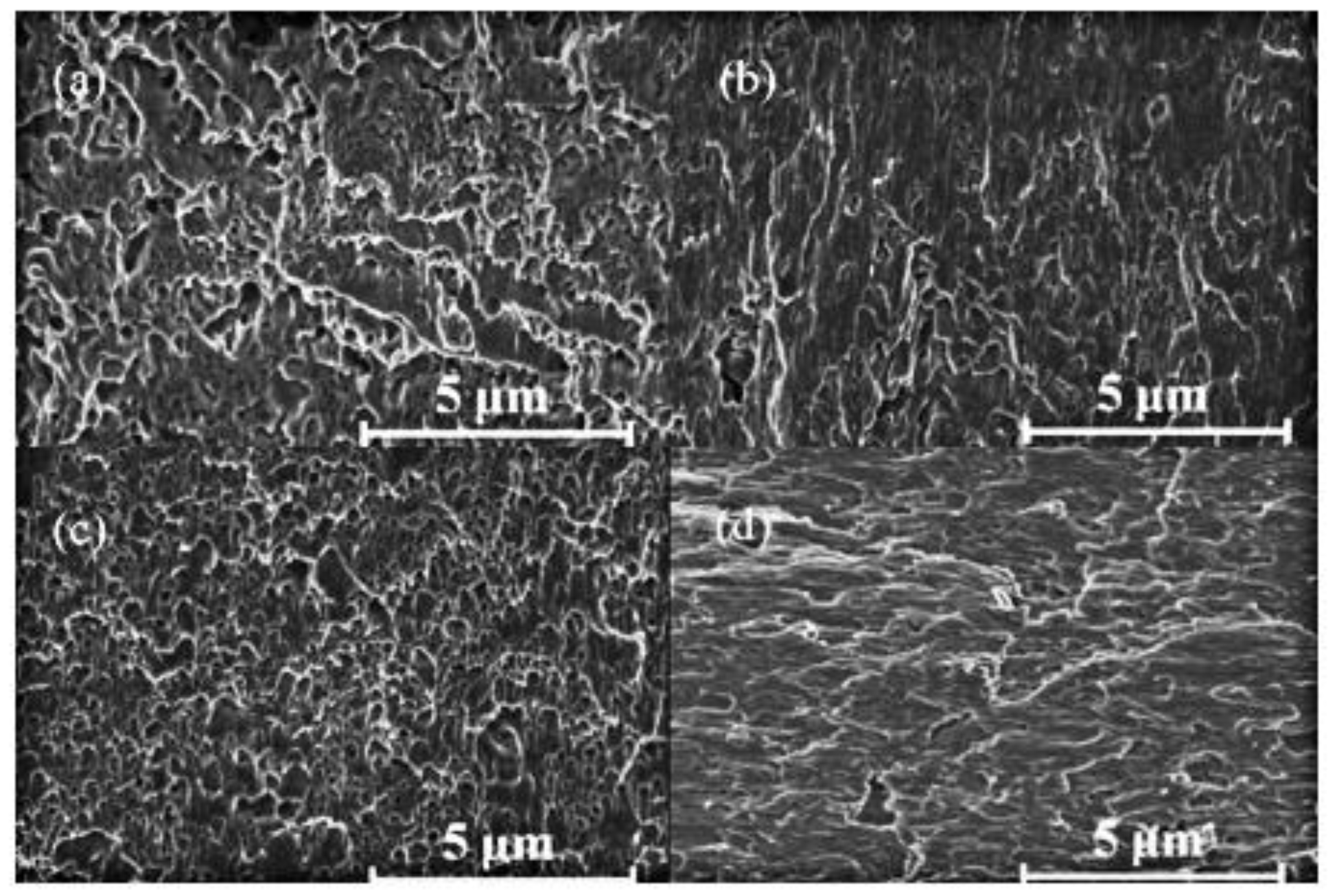

4.4. Current Assisted Sintering

5. Conclusions and Future Prospects

- (1)

- In some rapid sintering processes, the sintering time may be less than 1 s. The sintering mechanism of the processes may be different from that of traditional hot-pressing sintering. The sphere-to-sphere model may not be proper to explain the sintering behavior in the rapid sintering processes. Therefore, more work needs to be done to explore the mechanism of rapid sintering.

- (2)

- In some rapid sintering processes, such as in-situ formation of nanoparticles and joints, high external pressure still needs to be applied on chips. The pressure may damage the chip during the sintering processes. Future work needs to focus on reducing the pressure applied on chips during the rapid sintering processes.

- (3)

- Generally, binder and dispersants in the nanosilver pastes can prevent the undesirable premature coalescence or agglomeration of nanosilver particles, and the metastable structure will be retained until the organic carriers have been burned out at relatively higher temperatures. It is necessary to study the burnout characteristics of the different organics systems and design nanosilver pastes with a proper processing temperature.

- (4)

- The bonding between different nanopaticles and metal films is a complicated process, which is related with physical, mechanical, electrostatic, diffusion, and chemical characters of the materials. Sintering parameters, such as sintering temperature, sintering time, pressure, and atmosphere will affect the bonding process and qualities of the interfaces of the materials. Future work needs to focus on the interfacial reactions and behaviors between nanoparticles and metal films during the rapid sintering processes.

- (5)

- Currently, studies on sintering mechanisms of nanosilver particles are usually based on the spherical particle models. However, beside nanoparticles with spherical morphology, nanomaterials with other morphologies such as wires, belts, disks, and flakes are also widely mixed in pastes. The sintering mechanism of nanomaterials with different morphologies during rapid sintering processes still needs great effort.

Funding

Conflicts of Interest

References

- Siow, K.S. Mechanical properties of nano-silver joints as die attach materials. J. Alloys Compd. 2012, 514, 6–19. [Google Scholar] [CrossRef]

- Navarro, L.A.; Perpiñà, X.; Godignon, P.; Montserrat, J.; Banu, V.; Vellvehi, M.; Jordà, X. Thermomechanical assessment of die-attach materials for wide bandgap semiconductor devices and harsh environment applications. IEEE Trans. Power Electron. 2014, 29, 2261–2271. [Google Scholar] [CrossRef]

- Kong, Y.F.; Li, X.; Mei, Y.H.; Lu, G.Q. Effects of die-attach material and ambient temperature on properties of high-power COB blue LED module. IEEE Trans. Electron. Devices 2015, 62, 2251–2256. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, K.; Zhang, M.; Yang, C.; Sun, H.; Gao, Z.; Yuen, M.M.; Yang, S. Highly conductive die attach adhesive from percolation control and its applications in light-emitting device thermal management. Appl. Phys. Lett. 2013, 102, 1274–1301. [Google Scholar] [CrossRef]

- Tan, K.S.; Wong, Y.H.; Cheong, K.Y. Thermal characteristic of sintered Ag-Cu nanopaste for high-temperature die-attach application. International J. Therm. Sci. 2015, 87, 169–177. [Google Scholar] [CrossRef]

- Zhang, G.; Feng, S.; Zhu, H.; Li, J.; Guo, C. Determination of thermal fatigue delamination of die attach materials for high-brightness LEDs. IEEE Photonics Technol. Lett. 2012, 24, 398–400. [Google Scholar] [CrossRef]

- Lin, Y.C.; Hesketh, P.J.; Schuster, J.P. Finite-element analysis of thermal stresses in a silicon pressure sensor for various die-mount materials. Sens. Actuators A Phys. 1994, 44, 145–149. [Google Scholar] [CrossRef]

- Meyyappan, K.; Mccluskey, P.; Chen, L.Y. Thermomechanical analysis of MEMS pressure sensor die-attach for high temperature applications. Curr. Opin. Environ. Sustain. 2004, 4, 2556–2561. [Google Scholar]

- Shen, W.; Zhang, X.; Huang, Q.; Xu, Q.; Song, W. Preparation of solid silver nanoparticles for inkjet printed flexible electronics with high conductivity. Nanoscale 2014, 6, 1622–1628. [Google Scholar] [CrossRef] [PubMed]

- Peng, P.; Hu, A.; Gerlich, A.P.; Zou, G.; Liu, L.; Zhou, Y.N. Joining of silver nanomaterials at low temperatures: processes, properties, and applications. ACS Appl. Mater. Interfaces 2015, 7, 12597–12618. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wong, C.P. Recent advances of conductive adhesives as a lead-free alternative in electronic packaging: Materials, processing, reliability and applications. Mater. Sci. Eng. R 2006, 51, 1–35. [Google Scholar] [CrossRef]

- Wu, H.P.; Wu, X.J.; Ge, M.Y.; Zhang, G.Q.; Wang, Y.W.; Jiang, J. Properties investigation on isotropical conductive adhesives filled with silver coated carbon nanotubes. Compos. Sci. Technol. 2007, 67, 1182–1186. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Zhang, J. Uniaxial ratchetting behavior of anisotropic conductive adhesive film under cyclic tension. Polym. Test. 2011, 30, 8–15. [Google Scholar] [CrossRef]

- Lin, W.; Xi, X.; Yu, C. Research of silver plating nano-graphite filled conductive adhesive. Synth. Met. 2009, 159, 619–624. [Google Scholar] [CrossRef]

- Lehman, L.P.; Xing, Y.; Bieler, T.R.; Cotts, E.J. Cyclic twin nucleation in tin-based solder alloys. Acta Mater. 2010, 58, 3546–3556. [Google Scholar] [CrossRef]

- Wong, E.H.; Selvanayagam, C.S.; Seah, S.K.W.; Van Driel, W.D.; Caers, J.F.J.M.; Zhao, X.J.; Owens, N.; Tan, L.C.; Frear, D.R.; Leoni, M. Stress-strain characteristics of tin-based solder alloys at medium strain rate. Mater. Lett. 2008, 62, 3031–3034. [Google Scholar] [CrossRef]

- Šebo, P.; Moser, Z.; Švec, P.; Janičkovič, D.; Dobročka, E.; Gasior, W.; Pstruś, J. Effect of indium on the microstructure of the interface between Sn3.13Ag0.74CuIn solder and Cu substrate. J. Alloys Compd. 2009, 480, 409–415. [Google Scholar] [CrossRef]

- Yu, D.Q.; Zhao, J.; Wang, L. Improvement on the microstructure stability, mechanical and wetting properties of Sn-Ag-Cu lead-free solder with the addition of rare earth elements. J. Alloys Compd. 2004, 376, 170–175. [Google Scholar] [CrossRef]

- Manikam, V.R.; Cheong, K.Y. Die attach materials for high temperature applications: A review. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 457–478. [Google Scholar] [CrossRef]

- Johnson, R.W.; Evans, J.L.; Jacobsen, P.; Thompson, J.R.; Christopher, M. The changing automotive environment: High-temperature electronics. IEEE Trans. Electron. Packag. Manuf. 2005, 27, 164–176. [Google Scholar] [CrossRef]

- Alarifi, H.; Hu, A.; Yavuz, M.; Zhou, Y.N. Silver Nanoparticle Paste for Low-Temperature Bonding of Copper. J. Electron. Mater. 2011, 40, 1394–1402. [Google Scholar] [CrossRef]

- Xiao, K.; Calata, J.N.; Zheng, H.; Ngo, K.D.; Lu, G.Q. Simplification of the nanosilver sintering process for large-area semiconductor chip bonding: reduction of hot-pressing temperature below 200/spl deg/C. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 1271–1278. [Google Scholar] [CrossRef]

- Liang, M.A.; Yin, L.M.; Xian, J.W. Research advancement of high temperature lead-free electronic packaging. Weld. Technol. 2009, 5, 003. [Google Scholar]

- Nah, J.; Gaynes, M.A.; Feger, C.; Katsurayama, S.; Suzuki, H. Development of wafer level underfill materials and assembly processes for fine pitch Pb-free solder flip chip packaging. In Proceedings of the 2011 IEEE 61st Electronic Components and Technology Conference (ECTC), Lake Buena Vista, FL, USA, 31 May–3 June 2011; pp. 1015–1022. [Google Scholar]

- Mustafa, M.; Suhling, J.C.; Lall, P. Experimental determination of fatigue behavior of lead free solder joints in microelectronic packaging subjected to isothermal aging. Microelectron. Reliab. 2016, 56, 136–147. [Google Scholar] [CrossRef]

- Kosmala, A.; Wright, R.; Zhang, Q.; Kirby, P. Synthesis of silver nano particles and fabrication of aqueous Ag inks for inkjet printing. Mater. Chem. Phys. 2011, 129, 1075–1080. [Google Scholar] [CrossRef] [Green Version]

- Decharat, A.; Wagle, S.; Jacobsen, S.; Melandsø, F. Using silver nano-particle ink in electrode fabrication of high frequency copolymer ultrasonic transducers: modeling and experimental investigation. Sensors 2015, 15, 9210–9227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bell, N.B.; Diantonio, C.B.; Dimos, D.B. Development of conductivity in low conversion temperature silver pastes via addition of nanoparticles. J. Mater. Res. 2002, 17, 2423–2432. [Google Scholar] [CrossRef]

- Huang, Q.; Shen, W.; Xu, Q.; Tan, R.; Song, W. Properties of polyacrylic acid-coated silver nanoparticle ink for inkjet printing conductive tracks on paper with high conductivity. Mater. Chem. Phys. 2014, 147, 550–556. [Google Scholar] [CrossRef]

- Tai, Y.L.; Wang, Y.X.; Yang, Z.G.; Chai, Z.Q. Green approach to prepare silver nanoink with potentially high conductivity for printed electronics. Surf. Interface Anal. 2011, 43, 1480–1485. [Google Scholar] [CrossRef]

- Wang, S.; Ji, H.J.; Li, M.Y.; Wang, C.Q. Pressureless low temperature sintering of Ag nanoparticles applied to electronic packaging. Electron. Process Technol. 2012, 8330, 1–4. [Google Scholar]

- Siow, K.S. Are Sintered Silver Joints Ready for Use as Interconnect Material in Microelectronic Packaging? J. Electron. Mater. 2014, 43, 947–961. [Google Scholar] [CrossRef] [Green Version]

- Zheng, H.; Berry, D.; Calata, J.N.; Ngo, K.D.; Luo, S.; Lu, G.Q. Low-pressure joining of large-area devices on copper using nanosilver paste. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 915–922. [Google Scholar] [CrossRef]

- Li, W.L. Processing and Mechanism of Electric Current Assisted Sintering Nanosilver Paste. Master’s Thesis, Tianjin University, Tianjin, China, 2014. [Google Scholar]

- Mu, F.W.; Zhao, Z.Y.; Zou, G.S.; Bai, H.; Wu, A.; Liu, L.; Zhang, D.; Zhou, Y.N. Mechanism of low temperature sintering-bonding through in-situ formation of silver nanoparticles using silver oxide microparticles. Mater. Trans. 2013, 54, 872–878. [Google Scholar] [CrossRef]

- Alayli, N.; Schoenstein, F.; Girard, A.; Tan, K.L.; Dahoo, P.R. Spark Plasma Sintering constrained process parameters of sintered silver paste for connection in power electronic modules: Microstructure, mechanical and thermal properties. Mater. Chem. Phys. 2014, 148, 125–133. [Google Scholar] [CrossRef]

- Cheng, C.W.; Chen, J.K. Femtosecond laser sintering of copper nanoparticles. Appl. Phys. A 2016, 122, 289. [Google Scholar] [CrossRef]

- Yu, S.L.; Yun, C.; Kim, K.H.; Kim, W.H.; Jeon, S.W.; Lee, J.K.; Kim, J.P. Laser-sintered silver nanoparticles as a die adhesive layer for high-power light-emitting diodes. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1119–1124. [Google Scholar]

- Hu, A.; Guo, J.Y.; Alarifi, H.; Patane, G.; Zhou, Y.; Compagnini, G.; Xu, C.X. Low temperature sintering of Ag nanoparticles for flexible electronics packaging. Appl. Phys. Lett. 2010, 97, 153117. [Google Scholar] [CrossRef]

- Ide, E.; Angata, S.; Hirose, A.; Kobayashi, K.F. Metal-metal bonding process using Ag metallo-organic nanoparticles. Acta Mater. 2005, 53, 2385–2393. [Google Scholar] [CrossRef]

- Bai, J.G.; Zhang, Z.Z.; Calata, J.N.; Lu, G.Q. Low-temperature sintered nanoscale silver as a novel semiconductor device-metallized substrate interconnect material. IEEE Trans. Compon. Packag. Technol. 2006, 29, 589–593. [Google Scholar] [CrossRef]

- Yan, J.; Zou, G.; Wu, A.P.; Ren, J.; Yan, J.; Hu, A.; Zhou, Y. Pressureless bonding process using Ag nanoparticle paste for flexible electronics packaging. Scr. Mater. 2012, 66, 582–585. [Google Scholar] [CrossRef]

- Bakhishev, T.; Subramanian, V. Investigation of gold nanoparticle inks for low-temperature lead-free packaging technology. J. Electron. Mater. 2009, 38, 2720–2725. [Google Scholar] [CrossRef]

- Morita, T.; Ide, E.; Yasuda, Y.; Hirose, A.; Kobayashi, K. Study of bonding technology using silver nanoparticles. Jpn. J. Appl. Phys. 2014, 47, 6615–6622. [Google Scholar] [CrossRef]

- Frenkel, J. Viscous flow of crystalline bodies under the action of surface tension. J. Phys. USSR 1945, 9, 385. [Google Scholar]

- Shaler, A.J.; Wulff, J. Mechanism of Sintering. Acta Metall. 2002, 7, 222–223. [Google Scholar] [CrossRef]

- Kingery, W.D.; Woulbroun, J.M.; Charvat, F.R. Effects of Applied Pressure on Densification During Sintering in the Presence of Liquid Phase; Sintering Key Papers; Springer: Dordrecht, The Netherlands, 1990; pp. 405–415. [Google Scholar]

- Kang, S.J.L. Sintering: Densification, grain growth & microstructure. J. Phys. IV 2005, 7, 674–742. [Google Scholar]

- Coble, R.L. Sintering Crystalline Solids. I. Intermediate and Final State Diffusion Models. J. Appl. Phys. 1961, 32, 787–792. [Google Scholar] [CrossRef]

- Wu, M.; Chang, L.L.; Cui, Y.N.; Qu, X.H. Molecular dynamics simulation for the sintering process of Au nanoparticles. J. Univ. Sci. Technol. Beijing 2014, 36, 345–353. [Google Scholar]

- Yan, J.; Zou, G.; Liu, L.; Zhang, D.; Bai, H.; Wu, A.P.; Zhou, Y.N. Sintering mechanisms and mechanical properties of joints bonded using silver nanoparticles for electronic packaging applications. Weld. World 2015, 59, 427–432. [Google Scholar] [CrossRef]

- Wakuda, D.; Kim, K.S.; Suganuma, K. Time-dependent sintering properties of Ag nanoparticle paste for room temperature bonding. In Proceedings of the 9th IEEE Conference on Nanotechnology, Genoa, Italy, 26–30 July 2009; pp. 412–415. [Google Scholar]

- German, R.M. Manipulation of Strength During Sintering as a Basis for Obtaining Rapid Densification without Distortion. Mater. Trans. 2005, 42, 1400–1410. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Zeng, X. Silver nanoparticles prepared by chemical reduction-protection method, and their application in electrically conductive silver nanopaste. J. Alloys Compd. 2010, 494, 84–87. [Google Scholar] [CrossRef]

- Wang, C.X.; Li, Y.L.; Lei, X.U.; Zhou, S.B. Preparation of Nano-sized Silver Particles by Liquid Chemical Reduction Method. Technol. Dev. Chem. Ind. 2014, 64, 241–246. [Google Scholar]

- Kheybari, S.; Samadi, N.; Hosseini, S.V.; Fazeli, A.; Fazeli, M.R. Synthesis and antimicrobial effects of silver nanoparticles produced by chemical reduction method. DARU J. Pharm. Sci. 2010, 18, 168–172. [Google Scholar]

- Wang, X.Y.; Liu, J.G.; Cao, Y.; Cai, Z.X.; Li, X.Y.; Zeag, X.Y. Synthesis of Silver Nanoparticles by Chemical Reduction Method and Properties of Nano-silver Conductive Paste. Precious Met. 2011, 32, 14–19. [Google Scholar]

- Seop, G.; Sang, U.; Chae, K.G.; Kim, S.U.; Chae, G.; Han, G.S.; Hui, B.J.; Jeong, E.; Sik, B.D. Method for Preparing Silver Nano-Sized Powder of 5–10 nm in Size by Using Micro-Emulsion Process. KR Patent KR20040093911(A), 9 November 2004. [Google Scholar]

- Zhang, W.; Qiao, X.; Chen, J. Synthesis of nanosilver colloidal particles in water/oil microemulsion. Colloids Surf. A Physicochem. Eng. Asp. 2007, 299, 22–28. [Google Scholar] [CrossRef]

- Solanki, J.N.; Murthy, Z.V.P. Highly monodisperse and sub-nano silver particles synthesis via microemulsion technique. Colloids Surf. A Physicochem. Eng. Asp. 2010, 359, 31–38. [Google Scholar] [CrossRef]

- Yang, A.; Zhang, J.; Liang, S.H.; Ding, B.J. Monodisperse silver microspheres: A facile BSA template method. Sci. China Technol. Sci. 2013, 56, 2250–2258. [Google Scholar] [CrossRef]

- Peng, G.; Zhang, M.; Hou, H.; Xiao, Q. A simple template method for hierarchical dendrites of silver nanorods and their applications in catalysis. Mater. Res. Bull. 2008, 43, 531–538. [Google Scholar]

- Lu, Y.D.; Chen, X.X.; Chen, L.H. Synthesis of Silver Nanoparticles through the Soft Template Method and their Applications to Surface-Enhanced Raman Scattering. Appl. Mech. Mater. 2013, 395–396, 158–161. [Google Scholar] [CrossRef]

- Khaydarov, R.A.; Khaydarov, R.R.; Gapurova, O.; Estrin, Y.; Scheper, T. Electrochemical method for the synthesis of silver nanoparticles. J. Nanopart. Res. 2009, 11, 1193–1200. [Google Scholar] [CrossRef]

- Ma, H.; Yin, B.; Wang, S.; Jiao, Y.; Pan, W.; Huang, S.; Chen, S.; Meng, F. Synthesis of silver and gold nanoparticles by a novel electrochemical method. ChemPhysChem 2010, 5, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.J.; Liao, X.H.; Zhao, X.N.; Chen, H.Y. Preparation of silver nanorods by electrochemical methods. Mater. Lett. 2001, 49, 91–95. [Google Scholar] [CrossRef]

- Reicha, F.M.; Sarhan, A.; Abdelhamid, M.I.; El-Sherbiny, I.M. Preparation of silver nanoparticles in the presence of chitosan by electrochemical method. Carbohydr. Polym. 2012, 89, 236–244. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.P.; Jin, G.S.; Lee, T.G.; Park, H.M.; ong Song, J. One-step large-scale synthesis of micrometer-sized silver nanosheets by a template-free electrochemical method. Nanoscale Res. Lett. 2013, 8, 248. [Google Scholar] [Green Version]

- Krajczewski, J.; Joubert, V.; Kudelski, A. Light-induced transformation of citrate-stabilized silver nanoparticles: Photochemical method of increase of SERS activity of silver colloids. Colloids Surf. A Physicochem. Eng. Asp. 2014, 456, 41–48. [Google Scholar] [CrossRef]

- Krajczewski, J.; Kołątaj, K.; Kudelski, A. Light-induced growth of various silver seed nanoparticles: A simple method of synthesis of different silver colloidal SERS substrates. Chem. Phys. Lett. 2015, 625, 84–90. [Google Scholar] [CrossRef]

- Jia, H.; Xu, W.; An, J.; Li, D.; Zhao, B. A simple method to synthesize triangular silver nanoparticles by light irradiation. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2006, 64, 956–960. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Park, B.G.; Jung, K.H.; Kim, J.W.; Jeong, M.Y.; Jung, S.B. Microwave sintering of silver nanoink for radio frequency applications. J. Nanosc. Nanotechnol. 2015, 15, 2333–2337. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Song, Y.W. Microwave method for preparing nano silver sol. Guangzhou Chem. Ind. 2014, 42, 122–123. [Google Scholar]

- Ledrappier, F. Research of nano-silver colloids prepared by microwave-assisted synthesis method and its fresh-keeping of strawberry. Sci. Technol. Food Ind. 2014, 35, 326–327. [Google Scholar]

- Li, Y.; Jing, H.; Han, Y.; Xu, L.; Lu, G. Microstructure and joint properties of nano-silver paste by ultrasonic-assisted pressureless sintering. J. Electron. Mater. 2016, 45, 3003–3012. [Google Scholar] [CrossRef]

- Wani, I.A.; Ganguly, A.; Ahmed, J.; Ahmad, T. Silver nanoparticles: Ultrasonic wave assisted synthesis, optical characterization and surface area studies. Mater. Lett. 2011, 65, 520–522. [Google Scholar] [CrossRef]

- Jiang, L.P.; Xu, S.; Zhu, J.M.; Zhang, J.R.; Zhu, J.J.; Chen, H.Y. Ultrasonic-assisted synthesis of monodisperse single-crystalline silver nanoplates and gold nanorings. Inorg. Chem. 2004, 43, 5877–5883. [Google Scholar] [CrossRef] [PubMed]

- Cui, G. Control of morphology and size of nano-silver particles in the liquid irradiation reduction process. J. Radiat. Res. Radiat. Process. 2010, 28, 29–36. [Google Scholar]

- Zhou, Y.; Zhao, Y.; Wang, L.; Xu, L.; Zhai, M.; Wei, S. Radiation synthesis and characterization of nanosilver/gelatin/ carboxymethyl chitosan hydrogel. Radiat. Phys. Chem. 2012, 81, 553–560. [Google Scholar] [CrossRef]

- Singh, R. Radiation synthesis of PVP/alginate hydrogel containing nanosilver as wound dressing. J. Mater. Sci. Mater. Med. 2012, 23, 2649–2658. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Qiao, X.; Qiu, X.; Chen, Q.; Cai, Y.; Chen, H. Controllable synthesis and ostwald ripening of silver nanoparticles. Curr. Nanosci. 2012, 9, 753–758. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, W.; Qiao, X.; Qiu, X.; Chen, Q.; Cai, Y. Controllable preparation of silver nanostructures and the effects of acidity-basicity of the reaction system. Sci. Adv. Mater. 2014, 6, 304–311. [Google Scholar] [CrossRef]

- Guan, Y.; Yu, P. The Synthesis of Nanosilver Using Gelatin as Additive. Sci. Technol. Gelatin 2015, 2, 34–39. [Google Scholar]

- Kang, B.K.; Son, D.M.; Kim, Y.H. Preparation and Characterization of Silver Nanoparticles Embedded in Silica Sol Particles. Bull. Korean Chem. Soc. 2011, 32, 3707–3711. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Liu, X.; Zhang, J.; Dai, Z.; Li, P.; Wei, J. One-pot synthesis of Ag nanoparticle/graphene composites using sodium citrate as reducing agent. J. Pure Appl. Microbiol. 2013, 7, 105–110. [Google Scholar]

- Wang, S.; Ji, H.; Li, M.; Wang, C. Fabrication of interconnects using pressureless low temperature sintered Ag nanoparticles. Mater. Lett. 2012, 85, 61–63. [Google Scholar] [CrossRef]

- He, H.; Zhou, J.; Dong, H.; Song, Y. Synthesis of flower-like silver nanoparticles by polyvinyl pyrrolidone (PVP) reduction. Gold 2013, 1, 8–12. [Google Scholar]

- Song, Y.; Zhou, J.; Lan, X. Microwave-assisted synthesis of size-controlled silver nanoparticles using polyvinyl pyrrolidone as a reducing agent. International J. Nanomanuf. 2014, 10, 33–41. [Google Scholar] [CrossRef]

- Wang, H.; Qiao, X.; Chen, J.; Wang, X.; Ding, S. Mechanisms of PVP in the preparation of silver nanoparticles. Mater. Chem. Phys. 2005, 94, 449–453. [Google Scholar] [CrossRef]

- Khan, M.S.; Chaudhari, V.R. Morphological Effect on Fluorescence Behavior of Silver Nanoparticles. J. Fluoresc. 2014, 24, 751–757. [Google Scholar] [CrossRef] [PubMed]

- Gill, R.; Tian, L.; Somerville, W.R.C.; Le Ru, E.C.; van Amerongen, H.; Subramaniam, V. Silver nanoparticle aggregates as highly efficient plasmonic antennas for fluorescence enhancement. J. Phys. Chem. C 2017, 116, 16687–16693. [Google Scholar] [CrossRef]

- Ortega, E.; Berk, D. Precipitation of Silver Powders in the Presence of Ethylenediamine Tetraacetic Acid. Ind. Eng. Chem. Res. 2006, 45, 1863–1868. [Google Scholar] [CrossRef]

- López-Miranda, A.; López-Valdivieso, A.; Viramontes-Gamboa, G. Silver nanoparticles synthesis in aqueous solutions using sulfite as reducing agent and sodium dodecyl sulfate as stabilizer. J. Nanopart. Res. 2012, 14, 1101. [Google Scholar] [CrossRef]

- Eltugral, N.; Simsir, H.; Karagoz, S. Preparation of nano-silver-supported activated carbon using different ligands. Res. Chem. Intermed. 2016, 42, 1663–1676. [Google Scholar] [CrossRef]

- Lengke, M.F.; Fleet, M.E.; Southam, G. Biosynthesis of silver nanoparticles by filamentous cyanobacteria from a silver(I) nitrate complex. Langmuir 2007, 23, 2694–2699. [Google Scholar] [CrossRef] [PubMed]

- Raut, R.W.; Mendhulkar, V.D.; Kashid, S.B. Photosensitized synthesis of silver nanoparticles using Withania somnifera, leaf powder and silver nitrate. J. Photochem. Photobiol. B 2014, 132, 45–55. [Google Scholar] [CrossRef] [PubMed]

- Khodashenas, B.; Ghorbani, H.R. Synthesis of silver nanoparticles with different shapes. Arabian J. Chem. 2015, 7, 1–16. [Google Scholar] [CrossRef]

- Soo, K.; Ji, H.K. One-Step Fabrication of Poly (ethylenimine)-Stabilized Silver Nanoparticles from Insoluble Silver Chloride Salt. Bull. Korean Chem. Soc. 2011, 32, 2469–2472. [Google Scholar]

- Dubas, S.T.; Pimpan, V. Green synthesis of silver nanoparticles for ammonia sensing. Talanta 2008, 76, 29–33. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.; Goswami, G.K.; Nanda, K.K. Green synthesis of biopolymer-silver nanoparticle nanocomposite: An optical sensor for ammonia detection. International J. Biol. Macromol. 2012, 51, 583–589. [Google Scholar] [CrossRef] [PubMed]

- And, L.M.; Ladotouriño, I. Reduction and Stabilization of Silver Nanoparticles in Ethanol by Nonionic Surfactants. Langmuir 1996, 12, 3585–3589. [Google Scholar]

- Pal, A.; Shah, S.; Devi, S. Microwave-assisted synthesis of silver nanoparticles using ethanol as a reducing agent. Mater. Chem. Phys. 2009, 114, 530–532. [Google Scholar] [CrossRef]

- Hong, S.I.; Duarte, A.; Gonzalez, G.A.; Kim, N.S. Synthesis of silver nanoparticles at the liquid-liquid using ultrasonic wave. J. Electron. Packag. 2013, 135, 011005. [Google Scholar] [CrossRef]

- Chitsazi, M.R.; Korbekandi, H.; Asghari, G.; Bahri Najafi, R.; Badii, A.; Iravani, S. Synthesis of silver nanoparticles using methanol and dichloromethane extracts of Pulicaria gnaphalodes (Vent.) Boiss. aerial parts. Artif. Cells Nanomed. Biotechnol. 2014, 44, 328–333. [Google Scholar] [CrossRef] [PubMed]

- Balan, L.; Malval, J.P.; Schneider, R.; Burget, D. Silver nanoparticles: New synthesis, characterization and photophysical properties. Mater. Chem. Phys. 2007, 104, 417–421. [Google Scholar] [CrossRef]

- Kim, M.; Byun, J.W.; Shin, D.S.; Lee, Y.S. Spontaneous formation of silver nanoparticles on polymeric supports. Mater. Res. Bull. 2009, 44, 334–338. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Chen, G.X.; Cui, Y.Y.; Chen, Q.F.; Tai, J.L.; Yang, Y. Morphology of nano silver synthesized in different solvent systems. Packag. Eng. 2015, 21, 44–47. [Google Scholar]

- Bai, G. Low-Temperature Sintering of Nanoscale Silver Paste for Semiconductor Device Interconnection. Ph.D. Thesis, Faculty of the Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2005. [Google Scholar]

- Ohashi, K.; Kosaka, Y.; Suzuki, S.; Kawakami, T. Resin Composition Containing Ultrafine Silver Particles. US Patent US8921452, 30 December 2014. [Google Scholar]

- Lee, H.S.; Yang, M.Y. The effect of negative pressure aging on the aggregation of Cu2O nanoparticles and its application to laser induced copper electrode fabrication. Phys. Chem. Chem. Phys. 2015, 17, 4360–4366. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.F.; Yu, S.J.; Yin, Y.G.; Chao, J.B. Methods for separation, identification, characterization and quantification of silver nanoparticles. TrAC Trends Anal. Chem. 2012, 33, 95–106. [Google Scholar] [CrossRef] [Green Version]

- Maheswari, P.; Prasannadevi, D.; Mohan, D. Preparation and performance of silver nanoparticle incorporated polyetherethersulfone nanofiltration membranes. High Perform. Polym. 2013, 25, 174–187. [Google Scholar] [CrossRef]

- Bai, J.G.; Lei, T.G.; Calata, J.N.; Lu, G.Q. Control of nanosilver sintering attained through organic binder burnout. J. Mater. Res. 2007, 22, 3494–3500. [Google Scholar] [CrossRef]

- Bai, J.G.; Lu, G.Q. Thermomechanical Reliability of Low-Temperature Sintered Silver Die Attached SiC Power Device Assembly. IEEE Trans. Device Mater. Reliab. 2006, 6, 436–441. [Google Scholar] [CrossRef]

- Mei, Y.; Cao, Y.; Chen, G.; Li, X.; Lu, G.Q.; Chen, X. Rapid sintering nanosilver joint by pulse current for power electronics packaging. IEEE Trans. Device Mater. Reliab. 2013, 13, 258–265. [Google Scholar] [CrossRef]

- Feng, S.T.; Mei, Y.H.; Chen, G.; Li, X.; Lu, G.Q. Characterizations of rapid sintered nanosilver joint for attaching power chips. Materials 2016, 9, 564. [Google Scholar] [CrossRef] [PubMed]

- Ermak, O.; Zenou, M.; Toker, G.B.; Ankri, J.; Shacham-Diamand, Y.; Kotler, Z. Rapid laser sintering of metal nano-particles inks. Nanotechnology 2016, 27, 385201. [Google Scholar] [CrossRef] [PubMed]

- Hirose, A.; Tatsumi, H.; Takeda, N.; Akada, Y.; Ogura, T.; Ide, E.; Morita, T. A novel metal-to-metal bonding process through in-situ formation of Ag nanoparticles using Ag2O microparticles. J. Phys. Conf. Ser. 2009, 165, 012074. [Google Scholar] [CrossRef]

- Morita, T.; Yasuda, Y.; Ide, E.; Akada, Y.; Hirose, A. Bonding technique using micro-scaled silver-oxide particles for in-situ formation of silver nanoparticles. Mater. Trans. 2008, 49, 2875–2880. [Google Scholar] [CrossRef]

- Ogura, T.; Nishimura, M.; Tatsumi, H.; Takeda, N.; Takahara, W.; Hirose, A. Evaluation of interfacial bonding utilizing Ag2O-derived silver nanoparticles using TEM observation and molecular dynamics simulation. Open Surf. Sci. J. 2011, 3, 55–59. [Google Scholar] [CrossRef]

- Takeda, N.; Tatsumi, H.; Akada, Y.; Ogura, T.; Ide, E.; Morita, T.; Hirose, A. Low-temperature bonding process via in-situ formation of Ag nanoparticles using Ag2O microparticles. Prep. Nat. Meet. JWS 2009, 103. [Google Scholar]

- Jianfeng, Y.; Guisheng, Z.; Anming, H.; Zhou, Y.N. Preparation of PVP coated Cu NPs and the application for low-temperature bonding. J. Mater. Chem. 2011, 21, 15981–15986. [Google Scholar] [CrossRef]

- Yasuda, Y.; Ide, E.; Morita, T. Evaluation of copper oxide-based interconnecting materials. Open Surf. Sci. J. 2011, 3, 123–130. [Google Scholar] [CrossRef]

- Morisada, Y.; Nagaoka, T.; Fukusumi, M.; Kashiwagi, Y.; Yamamoto, M.; Nakamoto, M. A Low-temperature bonding process using mixed Cu-Ag nanoparticles. J. Electron. Mater. 2010, 39, 1283–1288. [Google Scholar] [CrossRef]

- Yan, J.; Wu, A.; Ren, J.; Hu, A.; Zhou, Y.N. Polymer-protected Cu-Ag mixed NPs for low-temperature bonding application. J. Electron. Mater. 2012, 41, 1886–1892. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, Z.F.; Lu, J.F.; Shen, X.B.; Wang, F.C.; Wang, Y.D. The sintering mechanism in spark plasma sintering—Proof of the occurrence of spark discharge. Scr. Mater. 2014, 81, 56–59. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Wang, F.C.; Lee, S.K.; Liu, Y.; Cheng, J.W.; Liang, Y. Microstructure characteristic, mechanical properties and sintering mechanism of nanocrystalline copper obtained by SPS process. Mater. Sci. Eng. A 2009, 523, 134–138. [Google Scholar] [CrossRef]

- Zhang, L.; Elwazri, A.M.; Zimmerly, T.; Brochu, M. Fabrication of bulk nanostructured silver material from nanopowders using shockwave consolidation technique. Mater. Sci. Eng. A 2008, 487, 219–227. [Google Scholar] [CrossRef]

- Liu, Z.F.; Zhang, Z.H.; Korznikov, A.V.; Lu, J.F.; Korznikova, G.; Wang, F.C. A novel and rapid route for synthesizing nanocrystalline aluminum. Mater. Sci. Eng. A 2014, 615, 320–323. [Google Scholar] [CrossRef]

- Sweet, G.A.; Brochu, M., Jr.; Hexemer, R.L.; Donaldson, I.W.; Bishop, D.P. Consolidation of aluminum-based metal matrix composites via spark plasma sintering. Mater. Sci. Eng. A 2015, 648, 123–133. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Sweet, G.A.; Brochu, M.; Hexemer, R.L., Jr.; Donaldson, I.W.; Bishop, D.P. Microstructure and mechanical properties of air atomized aluminum powder consolidated via spark plasma sintering. Mater. Sci. Eng. A 2014, 608, 273–282. [Google Scholar] [CrossRef]

- Anselmi-Tamburini, U.; Garay, J.E.; Munir, Z.A.; Tacca, A.; Maglia, F.; Spinolo, G. Spark plasma sintering and characterization of bulk nanostructured fully stabilized zirconia: Part I. Densification studies. J. Mater. Res. 2004, 19, 3255–3262. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-assisted sintering technology/spark plasma sintering: mechanisms, materials, and technology developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef] [Green Version]

- Ye, M.; Qiang, W.; Jia, C. Status quo of spark plasma sintering in Japan. Powder Metall. Technol. 2014, 32, 296–305. [Google Scholar]

- Santanach, J.G.; Weibel, A.; Estournès, C.; Yang, Q.; Laurent, C.; Peigney, A. Spark plasma sintering of alumina: Study of parameters, formal sintering analysis and hypotheses on the mechanism(s) involved in densification and grain growth. Acta Mater. 2011, 59, 1400–1408. [Google Scholar] [CrossRef] [Green Version]

- Ng, H.B.; Shearwood, C.; Khor, K.A. Spark plasma sintering of silver nanopowder. In Proceedings of the SPIE Microelectronics, MEMS, and Nanotechnology, Canberra, Australia, 27 December 2007. [Google Scholar]

- Niittynen, J.; Sowade, E.; Kang, H.; Baumann, R.R.; Mäntysalo, M. Comparison of laser and intense pulsed light sintering (IPL) for inkjet-printed copper nanoparticle layers. Sci. Rep. 2015, 5, 8832. [Google Scholar] [CrossRef] [PubMed]

- Zenou, M.; Ermak, O.; Saar, A.; Kotler, Z. Laser sintering of copper nanoparticles. J. Phys. D Appl. Phys. 2013, 47, 025501. [Google Scholar] [CrossRef]

- Niittynen, J.; Abbel, R.; Mäntysalo, M.; Perelaer, J.; Schubert, U.S.; Lupo, D. Alternative sintering methods compared to conventional thermal sintering for inkjet printed silver nanoparticle ink. Thin Solid Films 2014, 556, 452–459. [Google Scholar] [CrossRef]

- Liu, W.; Wang, C.; Wang, C.; Jiang, X.; Huang, X. Laser Sintering of Nano-Ag Particle Paste for High-Temperature Electronics Assembly. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 1050–1057. [Google Scholar] [CrossRef]

- Qin, G.; Watanabe, A. Conductive network structure formed by laser sintering of silver nanoparticles. J. Nanopart. Res. 2014, 16, 2684. [Google Scholar] [CrossRef]

- Liu, Y.K.; Lee, M.T. Laser direct synthesis and patterning of silver nano/microstructures on a polymer substrate. ACS Appl. Mater. Interfaces 2014, 6, 14576–14582. [Google Scholar] [CrossRef] [PubMed]

- An, K.; Hong, S.; Han, S.; Lee, H.; Yeo, J.; Ko, S.H. Selective sintering of metal nanoparticle ink for maskless fabrication of an electrode micropattern using a spatially modulated laser beam by a digital micromirror device. ACS Appl. Mater. Interfaces 2014, 6, 2786–2790. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Kwon, J.; Shin, W.S.; Kim, HR.; Shin, J.; Cho, H.; Han, S. Large-Area Compatible Laser Sintering Schemes with a Spatially Extended Focused Beam. Micromachines 2017, 8, 153. [Google Scholar] [CrossRef]

- Yu, J.H.; Kang, K.T.; Hwang, J.Y.; Lee, S.H.; Kang, H. Rapid sintering of copper nano ink using a laser in air. International J. Precis. Eng. Manuf. 2014, 15, 1051–1054. [Google Scholar] [CrossRef]

- Paeng, D.; Yeo, J.; Lee, D.; Moon, S.J.; Grigoropoulos, C.P. Laser wavelength effect on laser-induced photo-thermal sintering of silver nanoparticles. Appl. Phys. A 2015, 120, 1229–1240. [Google Scholar] [CrossRef]

- Theodorakos, I.; Zacharatos, F.; Geremia, R.; Karnakis, D.; Zergioti, I. Selective laser sintering of Ag nanoparticles ink for applications in flexible electronics. Appl. Surf. Sci. 2015, 336, 157–162. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Araga, S.; Mita, M.; Yamasaki, K.; Maekawa, K. On-demand infrared laser sintering of gold nanoparticle paste for electrical contacts. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 1160–1168. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, Y.; Chen, J.K. Modeling of Ultrafast Phase Change Processes in a Thin Metal Film Irradiated by Femtosecond Laser Pulse Trains. J. Heat Transf. 2011, 133, 031003. [Google Scholar] [CrossRef]

- Choi, J.H.; Ryu, K.; Park, K.; Moon, S.J. Thermal conductivity estimation of inkjet-printed silver nanoparticle ink during continuous wave laser sintering. International J. Heat Mass Transf. 2015, 85, 904–909. [Google Scholar] [CrossRef]

- Munir, Z.A.; Quach, D.V.; Ohyanagi, M. Electric current activation of sintering: A review of the pulsed electric current sintering process. J. Am. Ceram. Soc. 2011, 94, 1–19. [Google Scholar] [CrossRef]

- Gubicza, J.; Bui, H.; Fellah, F.; Dirras, G.F. Microstructure and mechanical behavior of ultrafine-grained Ni processed by different powder metallurgy methods. J. Mater. Res. 2009, 24, 217–226. [Google Scholar] [CrossRef] [Green Version]

- Ritasalo, R.; Cura, M.E.; Liu, X.W.; Söderberg, O.; Ritvonen, T.; Hannula, S.P. Spark plasma sintering of submicron-sized Cu-powder-Influence of processing parameters and powder oxidization on microstructure and mechanical properties. Mater. Sci. Eng. A 2010, 527, 2733–2737. [Google Scholar] [CrossRef]

- Kanamori, K.; Kineri, T.; Fukuda, R.; Nishio, K.; Hashimoto, M.; Mae, H. Spark plasma sintering of sol-gel derived amorphous ZrW2O8 nanopowder. J. Am. Ceram. Soc. 2010, 92, 32–35. [Google Scholar] [CrossRef]

- Guo, S.Q.; Nishimura, T.; Kagawa, Y.; Yang, J.M. Spark plasma sintering of zirconium diborides. J. Am. Ceram. Soc. 2008, 91, 2848–2855. [Google Scholar] [CrossRef]

- Musa, C.; Licheri, R.; Locci, A.M.; Orrù, R.; Cao, G.; Rodriguez, M.A.; Jaworska, L. Energy efficiency during conventional and novel sintering processes: The case of Ti–Al2O3–TiC composites. J. Clean. Prod. 2009, 17, 877–882. [Google Scholar] [CrossRef]

- Grasso, S.; Sakka, Y.; Maizza, G. Electric current activated/assisted sintering (ECAS): A review of patents 1906–2008. Sci. Technol. Adv. Mater. 2009, 10, 053001. [Google Scholar] [CrossRef] [PubMed]

- Mei, Y.; Chen, G.; Cao, Y.; Li, X.; Han, D.; Chen, X. Simplification of low-temperature sintering nanosilverfor power electronics packaging. J. Electron. Mater. 2013, 42, 1209–1218. [Google Scholar] [CrossRef]

- Mei, Y.H.; Cao, Y.; Chen, G.; Li, X.; Lu, G.Q.; Chen, X. Characterization and reliability of sintered nanosilver joints by a rapid current-assisted method for power electronics packaging. IEEE Trans. Device Mater. Reliab. 2014, 14, 262–267. [Google Scholar] [CrossRef]

- Lu, G.Q.; Li, W.; Mei, Y.; Li, X. Measurements of electrical resistance and temperature distribution during current assisted sintering of nanosilver die-attach material. In Proceedings of the 2014 International Conference on Electronics Packaging (ICEP), Toyama, Japan, 23–25 April 2014; pp. 538–543. [Google Scholar]

- Xie, Y.; Wang, Y.; Mei, Y.; Xie, H.; Zhang, K.; Feng, S.; Siow, K.S.; Li, X.; Lu, G.Q. Rapid sintering of nano-Ag paste at low current to bond large area (>100 mm2) power chips for electronics packaging. J. Mater. Process. Technol. 2018, 255, 644–649. [Google Scholar] [CrossRef]

- Mei, Y.; Li, L.; Li, X.; Li, W.; Yan, H.; Xie, Y. Electric-current-assisted sintering of nanosilver paste for copper bonding. J. Mater. Sci. Mater. Electron. 2017, 28, 9155–9166. [Google Scholar] [CrossRef]

- Urbański, K.J.; Fałat, T.; Felba, J.; Mościcki, A.; Smolarek, A.; Bonfert, D.; Bock, K. Experimental method for low-temperature sintering of nano-Ag inks using electrical excitation. In Proceedings of the 2012 12th IEEE International Conference on Nanotechnology (IEEE-NANO), Birmingham, UK, 20–23 August 2012; pp. 1–4. [Google Scholar]

- Khazaka, R.; Mendizabal, L.; Henry, D. Review on Joint Shear Strength of Nano-Silver Paste and Its Long-Term High Temperature Reliability. J. Electron. Mater. 2014, 43, 2459–2466. [Google Scholar] [CrossRef]

- Pešina, Z.; Vykoukal, V.; Palcut, M.; Sopoušek, J. Shear strength of copper joints prepared by low temperature sintering of silver nanoparticles. Electron. Mater. Lett. 2014, 10, 293–298. [Google Scholar] [CrossRef] [Green Version]

- Zou, G.; Yan, J.; Mu, F.; Wu, A.; Ren, J.; Hu, A.; Zhou, Y. Low temperature bonding of Cu metal through sintering of Ag nanoparticles for high temperature electronic application. Open Surf. Sci. J. 2011, 3, 70–75. [Google Scholar] [CrossRef]

- Maekawa, K.; Yamasaki, K.; Niizeki, T.; Mita, M.; Matsuba, Y.; Terada, N.; Saito, H. Drop-on-demand laser sintering with silver nanoparticles for electronics packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 868–877. [Google Scholar] [CrossRef]

- Maekawa, K.; Yamasaki, K.; Niizeki, T.; Mita, M.; Matsuba, Y.; Terada, N.; Saito, H. Laser sintering of silver nanoparticles for electronic use. Mater. Sci. Forum 2010, 638–642, 2085–2090. [Google Scholar] [CrossRef]

- Niizeki, T.; Maekawa, K.; Mita, M.; Yamasaki, K.; Matsuba, Y.; Terada, N.; Saito, H. Laser sintering of Ag nanopaste film and its application to bond-pad formation. In Proceedings of the 2008 58th Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 27–30 May 2008; pp. 1745–1750. [Google Scholar]

| Sintering Method | Sintering Time | Shear Strength | Cost | Ref. |

|---|---|---|---|---|

| Hot-pressing | 30–90 min | 30–84 MPa | Low | [22,165,166,167] |

| In-situ formation | 3–5 min | 50–70 MPa | Low | [35,118,120,121] |

| Spark Plasma | 30–300 s | 30–100 MPa | Medium | [36,129,130,131,132] |

| Laser | 1–15 s | 8–10 MPa | High | [38,168,169,170] |

| Current | 0.1–1 s | 40–97 MPa | Medium | [34,115,159,160,161] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; An, R.; Wang, C.; Zheng, Z.; Tian, Y.; Xu, R.; Wang, Z. Recent Progress in Rapid Sintering of Nanosilver for Electronics Applications. Micromachines 2018, 9, 346. https://doi.org/10.3390/mi9070346

Liu W, An R, Wang C, Zheng Z, Tian Y, Xu R, Wang Z. Recent Progress in Rapid Sintering of Nanosilver for Electronics Applications. Micromachines. 2018; 9(7):346. https://doi.org/10.3390/mi9070346

Chicago/Turabian StyleLiu, Wei, Rong An, Chunqing Wang, Zhen Zheng, Yanhong Tian, Ronglin Xu, and Zhongtao Wang. 2018. "Recent Progress in Rapid Sintering of Nanosilver for Electronics Applications" Micromachines 9, no. 7: 346. https://doi.org/10.3390/mi9070346