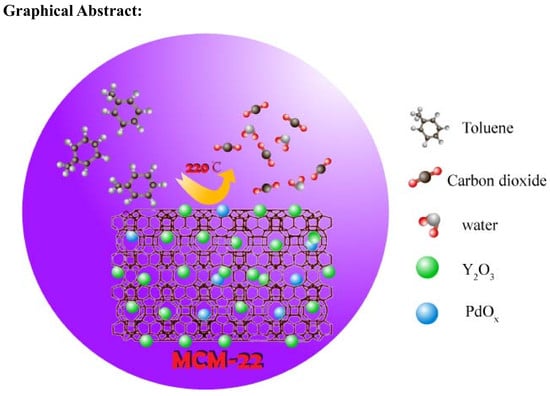

Y-Modified MCM-22 Supported PdOx Nanocrystal Catalysts for Catalytic Oxidation of Toluene

Abstract

:1. Introduction

2. Results and Discussion

2.1. Catalytic Activity and Durability Test

2.2. Characterization Section

2.2.1. XRD

2.2.2. N2 Adsorption/Desorption

2.2.3. SEM and HRTEM

2.2.4. ICP and CO Chemisorption

2.2.5. XPS

2.2.6. Toluene-TPSR

3. Experimental Section

3.1. Catalysts Preparation

3.2. Catalytic Activity Determination

3.3. Temperature-Programmed Reactions

3.4. Catalysts Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Hu, J.; Li, W.B.; Liu, R.F. Highly efficient copper-doped manganese oxide nanorod catalysts derived from CuMnO hierarchical nanowire for catalytic combustion of VOCs. Catal. Today 2018, 314, 147–153. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Chen, X.; Xu, W.J.; Xu, Z.; Jia, H.P.; Chen, J. Homogeneous introduction of CeOy into MnOx-based catalyst for oxidation of aromatic VOCs. Appl. Catal. B Environ. 2018, 224, 825–835. [Google Scholar] [CrossRef]

- Kamal, M.S.; Razzak, S.A.; Hossain, M.M. Catalytic oxidation of volatile organic compounds (VOCs)–A review. Atmos. Environ. 2016, 140, 117–134. [Google Scholar] [CrossRef]

- Zhu, A.M.; Zhou, Y.; Wang, Y.; Zhu, Q.L.; Liu, H.Y.; Zhang, Z.K.; Lu, H.F. Catalytic combustion of VOCs on Pt/CuMnCe and Pt/CeY honeycomb monolithic catalysts. J. Rare Earths 2018, 36, 1272–1277. [Google Scholar] [CrossRef]

- Tang, W.X.; Wu, X.F.; Liu, G.; Li, S.D.; Li, D.Y.; Li, W.H.; Chen, Y.F. Preparation of hierarchical layer-stacking Mn-Ce composite oxide for catalytic total oxidation of VOCs. J. Rare Earths 2015, 33, 62–69. [Google Scholar] [CrossRef]

- Gluhoi, A.C.; Nieuwenhuys, B.E. Catalytic oxidation of saturated hydrocarbons on multicomponent Au/Al2O3 catalysts: Effect of various promoters. Catal. Today 2007, 119, 305–310. [Google Scholar] [CrossRef]

- Kim, S.C. The catalytic oxidation of aromatic hydrocarbons over supported metal oxide. J. Hazard. Mater. 2002, 91, 285–299. [Google Scholar] [CrossRef]

- Lin, H.Q.; Chen, Y.W. Complete oxidation of toluene on Pd/modified-CeO2 catalysts. J. Taiwan Inst. Chem. Eng. 2016, 67, 69–73. [Google Scholar] [CrossRef]

- Yang, P.; Li, J.R.; Chen, Z.; Zuo, S.F. Promoting effects of Ce and Pt addition on the destructive performances of V2O5/γ-Al2O3 for catalytic combustion of benzene. Appl. Catal. A Gen. 2017, 542, 38–46. [Google Scholar] [CrossRef]

- Santos, V.P.; Carabineiro, S.A.C.; Tavares, P.B.; Pereira, M.F.R.; Órfão, J.J.M.; Figueiredo, J.L. Oxidation of CO, ethanol and toluene over TiO2 supported noble metal catalysts. Appl. Catal. B Environ. 2010, 99, 198–205. [Google Scholar] [CrossRef]

- Matějová, L.; Topka, P.; Jirátová, K.; Šolcová, O. Total oxidation of model volatile organic compounds over some commercial catalysts. Appl. Catal. A Gen. 2012, 443, 40–49. [Google Scholar] [CrossRef]

- Khder, A.E.R.S.; Altass, H.M.; Orif, M.I.; Ashour, S.S.; Almazroai, L.S. Preparation and characterization of highly active Pd nanoparticles supported Mn3O4 catalyst for low-temperature CO oxidation. Mater. Res. Bull. 2019, 113, 215–222. [Google Scholar] [CrossRef]

- Xiong, H.F.; Wiebenga, M.H.; Carrillo, C.; Gaudet, J.R.; Pham, H.N.; Kunwar, D.; Oh, S.H.; Qi, G.; Kim, C.H.; Datye, A.K. Design considerations for low-temperature hydrocarbon oxidation reactions on Pd based catalysts. Appl. Catal. B Environ. 2018, 236, 436–444. [Google Scholar] [CrossRef]

- Ye, N.; Li, Y.; Yang, Z.; Zheng, J.; Zuo, S.F. Rare earth modified kaolin-based Cr2O3 catalysts for catalytic combustion of chlorobenzene. Appl. Catal. A Gen. 2019, 579, 44–51. [Google Scholar] [CrossRef]

- Abbasi, Z.; Haghighi, M.; Fatehifar, E.; Saedy, S. Synthesis and physicochemical characterizations of nanostructured Pt/Al2O3-CeO2 catalysts for total oxidation of VOCs. J. Hazard. Mater. 2011, 186, 1445–1454. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.L.; Gao, Y.J.; Li, X.; Zhuang, G.L.; Wang, K.C.; Zheng, Y.; Sun, D.H.; Huang, J.L.; Li, Q.B. Catalytic benzene oxidation by biogenic Pd nanoparticles over 3D-ordered mesoporous CeO2. Chem. Eng. J. 2019, 362, 41–52. [Google Scholar] [CrossRef]

- Fu, X.R.; Liu, Y.; Yao, W.Y.; Wu, Z.B. One-step synthesis of bimetallic Pt-Pd/MCM-41 mesoporous materials with superior catalytic performance for toluene oxidation. Catal. Commun. 2016, 83, 22–26. [Google Scholar] [CrossRef]

- Feio, L.S.; Escritori, J.C.; Noronha, F.B.; Hori, C.E. Combustion of butyl carbitol using supported palladium catalysts. Catal. Lett. 2008, 120, 229–235. [Google Scholar] [CrossRef]

- Garcia, T.; Solsona, B.; Murphy, D.M.; Antcliff, K.L.; Taylor, S.H. Deep oxidation of light alkanes over titania-supported palladium/vanadium catalysts. J. Catal. 2005, 229, 1–11. [Google Scholar] [CrossRef]

- Mitsui, T.; Matsui, T.; Kikuchi, R.; Eguchi, K. Low-temperature complete oxidation of ethyl acetate over CeO2-supported precious metal catalysts. Top. Catal. 2009, 52, 464–469. [Google Scholar] [CrossRef]

- Lim, T.H.; Nam, K.; Song, I.K.; Lee, K.Y.; Kim, D.H. Effect of Si/Al2 ratios in Mo/H-MCM-22 on methane dehydroaromatization. Appl. Catal. A Gen. 2018, 552, 11–20. [Google Scholar] [CrossRef]

- Martins, A.; Silva, J.M.; Henriques, C.; Ribeiro, F.R.; Ribeiro, M.F. Influence of rare earth elements La, Nd and Yb on the acidity of H-MCM-22 and H-Beta zeolites. Catal. Today 2005, 107, 663–670. [Google Scholar] [CrossRef]

- Wang, Y.A.; Gao, Y.; Xie, S.J.; Liu, S.L.; Chen, F.C.; Xin, W.J.; Zhu, X.X.; Li, X.J.; Jiang, N.; Xu, L.Y. Adjustment of the Al siting in MCM-22 zeolite and its effect on alkylation performance of ethylene with benzene. Catal. Today 2018, 316, 71–77. [Google Scholar] [CrossRef]

- Fan, X.; Wang, F.; Zhu, T.L.; He, H. Effects of Ce on catalytic combustion of methane over Pd-Pt/Al2O3 catalyst. J. Environ. Sci. 2012, 24, 507–511. [Google Scholar] [CrossRef]

- Kotolevich, Y.; Kolobova, E.; Khramov, E.; Farías, M.H.; Zubavichus, Y.; Tiznado, H.; Martínez-González, S.; Corberán, V.C.; Mota-Morales, J.D.; Pestryakov, A.; et al. n-Octanol oxidation on Au/TiO2 catalysts promoted with La and Ce oxides. Mol. Catal. 2017, 427, 1–10. [Google Scholar] [CrossRef]

- Yue, B.H.; Zhou, R.X.; Zheng, X.M.; Lu, W.C. Remarkable improvement of yttrium on the activity and thermal stability of methane combustion over Pd/Ce-Zr/Al2O3 catalyst. Mater. Chem. Phys. 2009, 114, 722–727. [Google Scholar] [CrossRef]

- He, H.; Dai, H.X.; Ng, L.H.; Wong, K.W.; Au, C.T. Pd-, Pt-, and Rh-loaded Ce0.6Zr0.35Y0.05O2 three-way catalysts: An investigation on performance and redox properties. J. Catal. 2002, 206, 1–13. [Google Scholar] [CrossRef]

- Li, J.F.; Xia, C.; Au, C.T.; Liu, B.S. Y2O3-promoted NiO/SBA-15 catalysts highly active for CO2/CH4 reforming. Int. J. Hydrogen Energy 2014, 39, 10927–10940. [Google Scholar] [CrossRef]

- Li, L.Y.; Han, W.L.; Dong, F.; Zong, L.Y.; Tang, Z.C.; Zhang, J.Y. Controlled pore size of ordered mesoporous Al2O3-supported Mn/Cu catalysts for CO oxidation. Micropor. Mesopor. Mater. 2017, 249, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Zeng, H.; Jia, B.; Wang, Z.H.; Liu, Z.M. Selective catalytic reduction of NOx by H2 over Pd/TiO2 catalyst. Chin. J. Catal. 2019, 40, 849–855. [Google Scholar] [CrossRef]

- Oemar, U.; Hidajat, K.; Kawi, S. High catalytic stability of Pd-Ni/Y2O3 formed by interfacial Cl for oxy-CO2 reforming of CH4. Catal. Today 2017, 281, 276–294. [Google Scholar] [CrossRef]

- Baldwin, T.R.; Burch, R. Catalytic combustion of methane over supported palladium catalysts: II. Support and possible morphological effects. Appl. Catal. 1990, 66, 359–381. [Google Scholar] [CrossRef]

- Marques, A.L.S.; Monteiro, J.L.F.; Pastore, H.O. Static crystallization of zeolites MCM-22 and MCM-49. Micropor. Mesopor. Mater. 1999, 32, 131–145. [Google Scholar] [CrossRef]

| Samples | SBETa (m2/g) | Ames (Amic)b (m2/g) | VPc (cm3/g) | Vmicd (cm3/g) |

|---|---|---|---|---|

| MCM-22 | 466.4 | 161.1 (305.3) | 0.55 | 0.14 |

| 0.2%Pd/MCM-22 | 391.6 | 144.4 (247.2) | 0.55 | 0.11 |

| 0.2%Pd/7.5%Y/MCM-22 | 264.1 | 89.4 (174.7) | 0.34 | 0.081 |

| Catalysts | Pd Species | 3d5/2 BE/ev | 3d3/2 BE/eV | Conc. a (%) | Pd Content b (wt. %) | Pd Dispersion c (%) | |

|---|---|---|---|---|---|---|---|

| Pd2+ | Pd0 | ||||||

| 0.2%Pd/MCM-22 | Pd0 | 335.3 | 339.8 | 71.1 | 28.9 | 0.19 | 22 |

| Pd2+ | 336.6 | 342.1 | |||||

| 0.2%Pd/7.5%Y/MCM-22 | Pd0 | 335.3 | 340.5 | 73.3 | 26.7 | 0.18 | 43 |

| Pd2+ | 336.3 | 341.8 | |||||

| 0.2%Pd/7.5%Y/MCM-22-used | Pd0 | 335.3 | 340.5 | 47.8 | 52.2 | 0.18 | 41 |

| Pd2+ | 336.5 | 342.1 | |||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Situ, D.; Zheng, J.; Cheng, Z.; Wang, Z.; Zuo, S. Y-Modified MCM-22 Supported PdOx Nanocrystal Catalysts for Catalytic Oxidation of Toluene. Catalysts 2019, 9, 902. https://doi.org/10.3390/catal9110902

Chen Z, Situ D, Zheng J, Cheng Z, Wang Z, Zuo S. Y-Modified MCM-22 Supported PdOx Nanocrystal Catalysts for Catalytic Oxidation of Toluene. Catalysts. 2019; 9(11):902. https://doi.org/10.3390/catal9110902

Chicago/Turabian StyleChen, Zhu, Danna Situ, Jie Zheng, Zhen Cheng, Zhuo Wang, and Shufeng Zuo. 2019. "Y-Modified MCM-22 Supported PdOx Nanocrystal Catalysts for Catalytic Oxidation of Toluene" Catalysts 9, no. 11: 902. https://doi.org/10.3390/catal9110902