Simulation and Optimization Design of SiC-Based PN Betavoltaic Microbattery Using Tritium Source

Abstract

:1. Introduction

2. Monte Carlo Method and Simulation

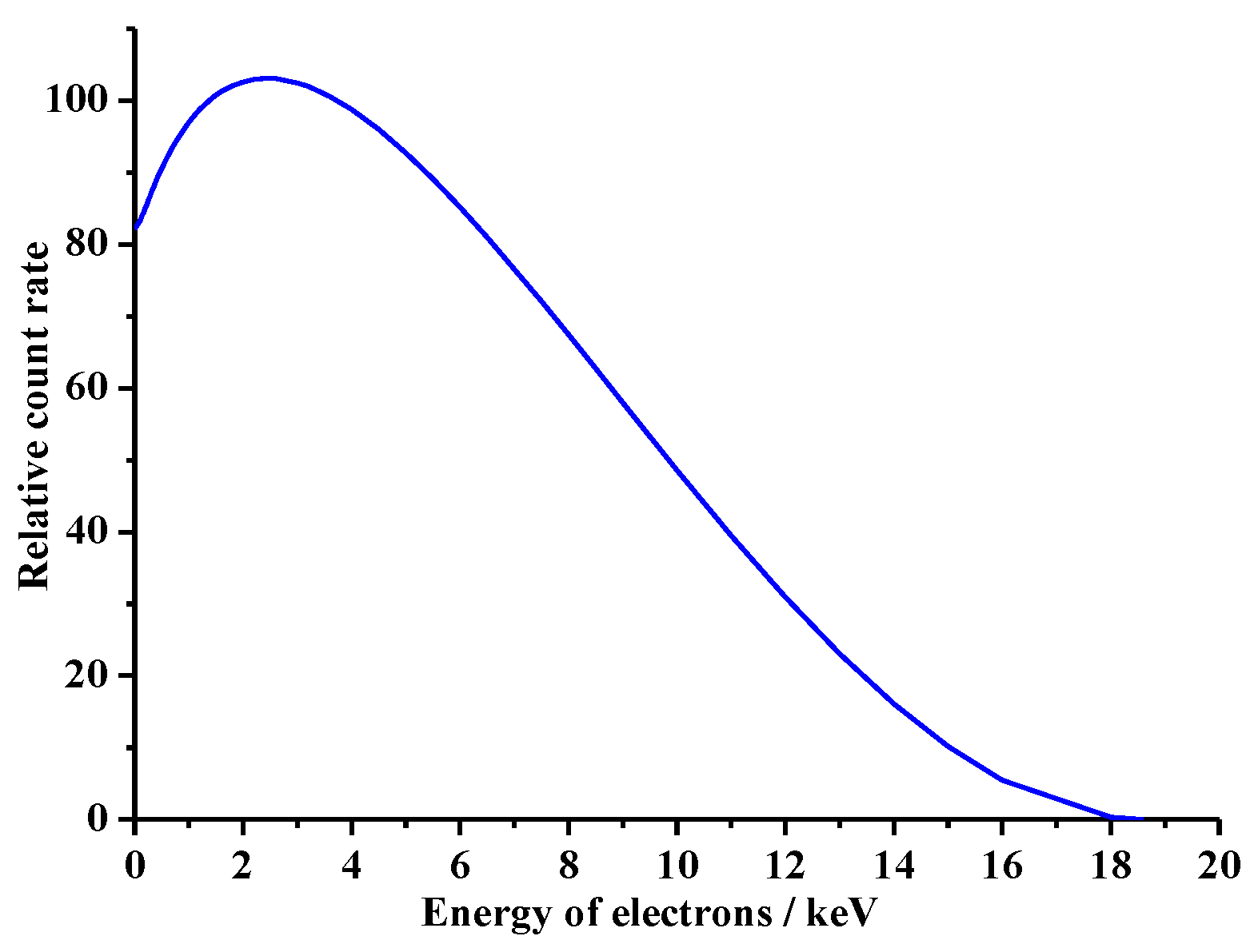

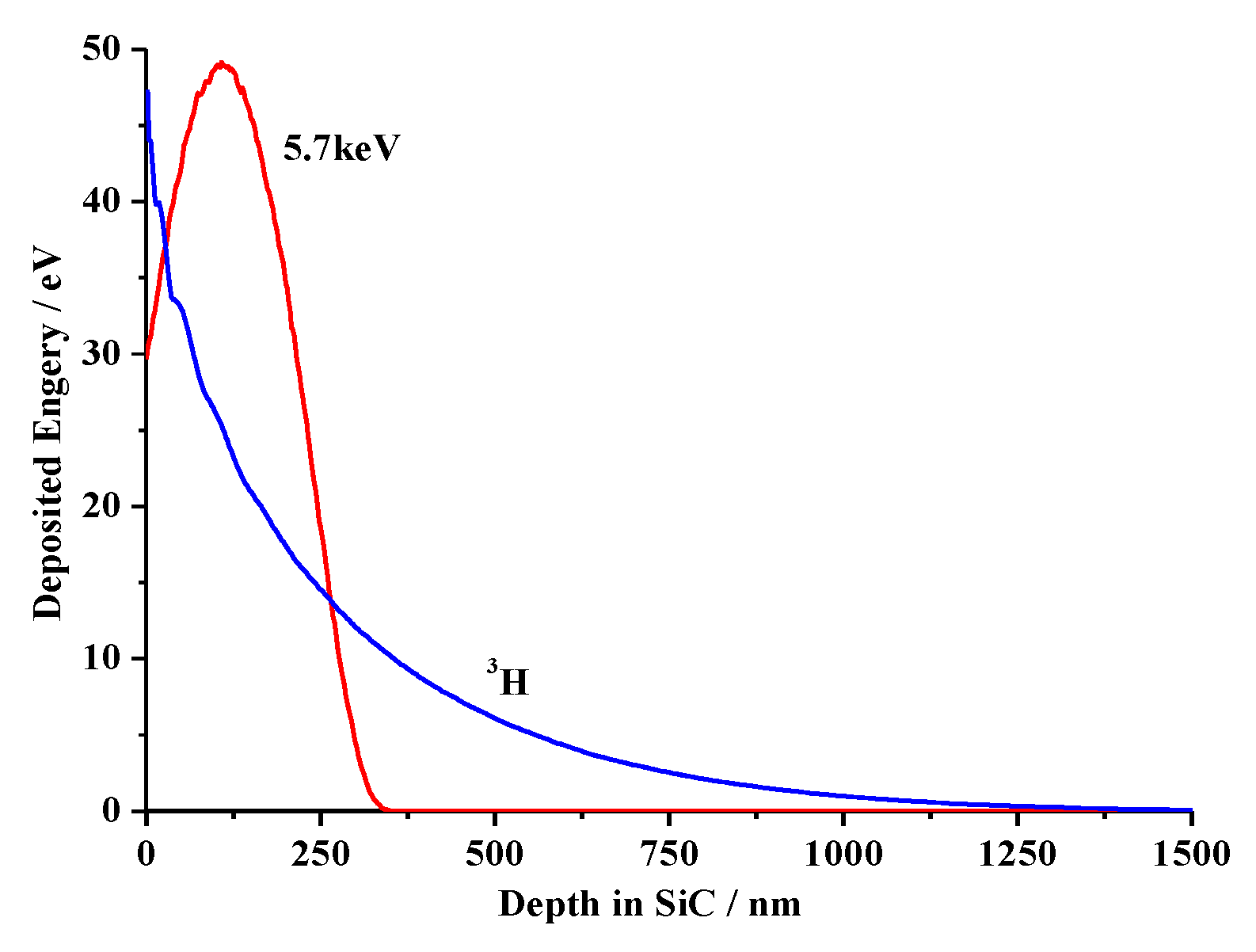

2.1. Ionization Energy Calculation of Incident Electron

2.2. Simulation Results and Analysis

3. Numerical Model and Simulation

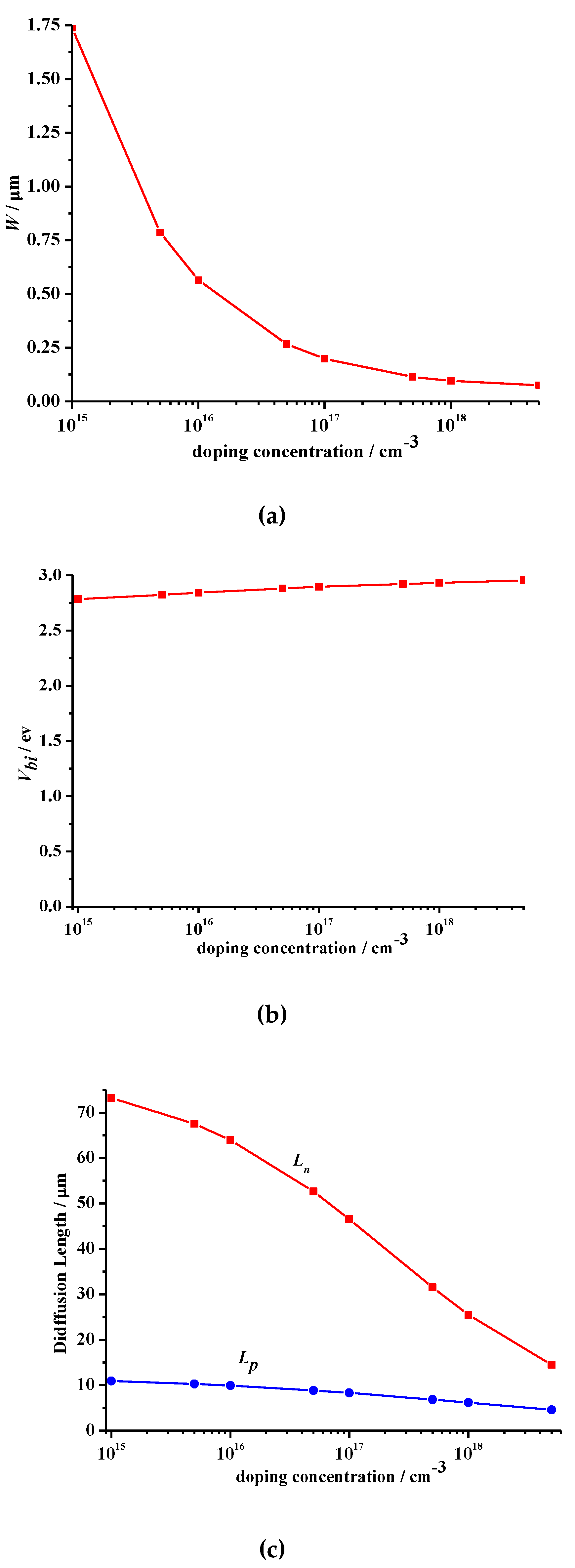

3.1. The Electrical Model of the Betavoltaic Microbattery

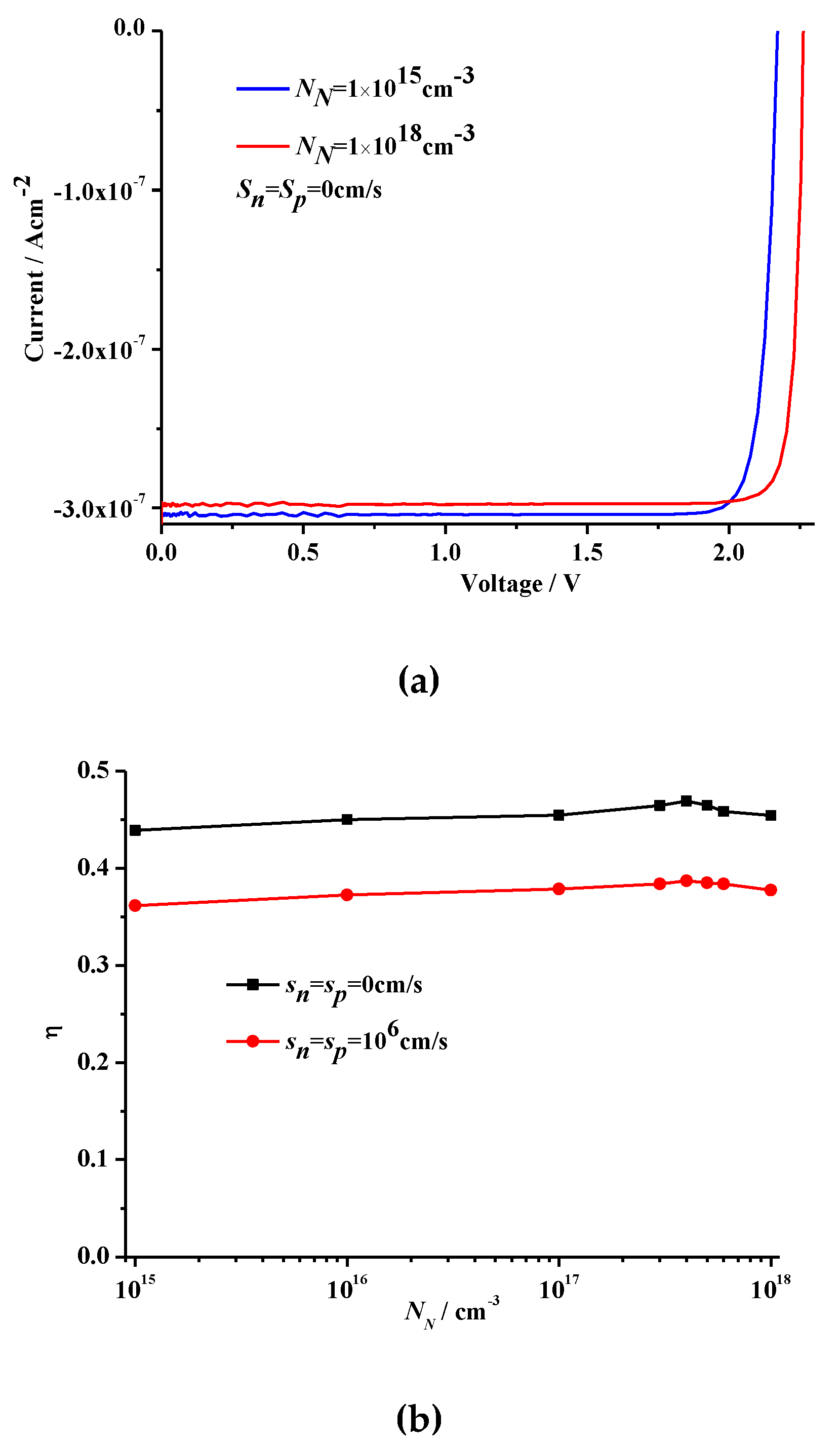

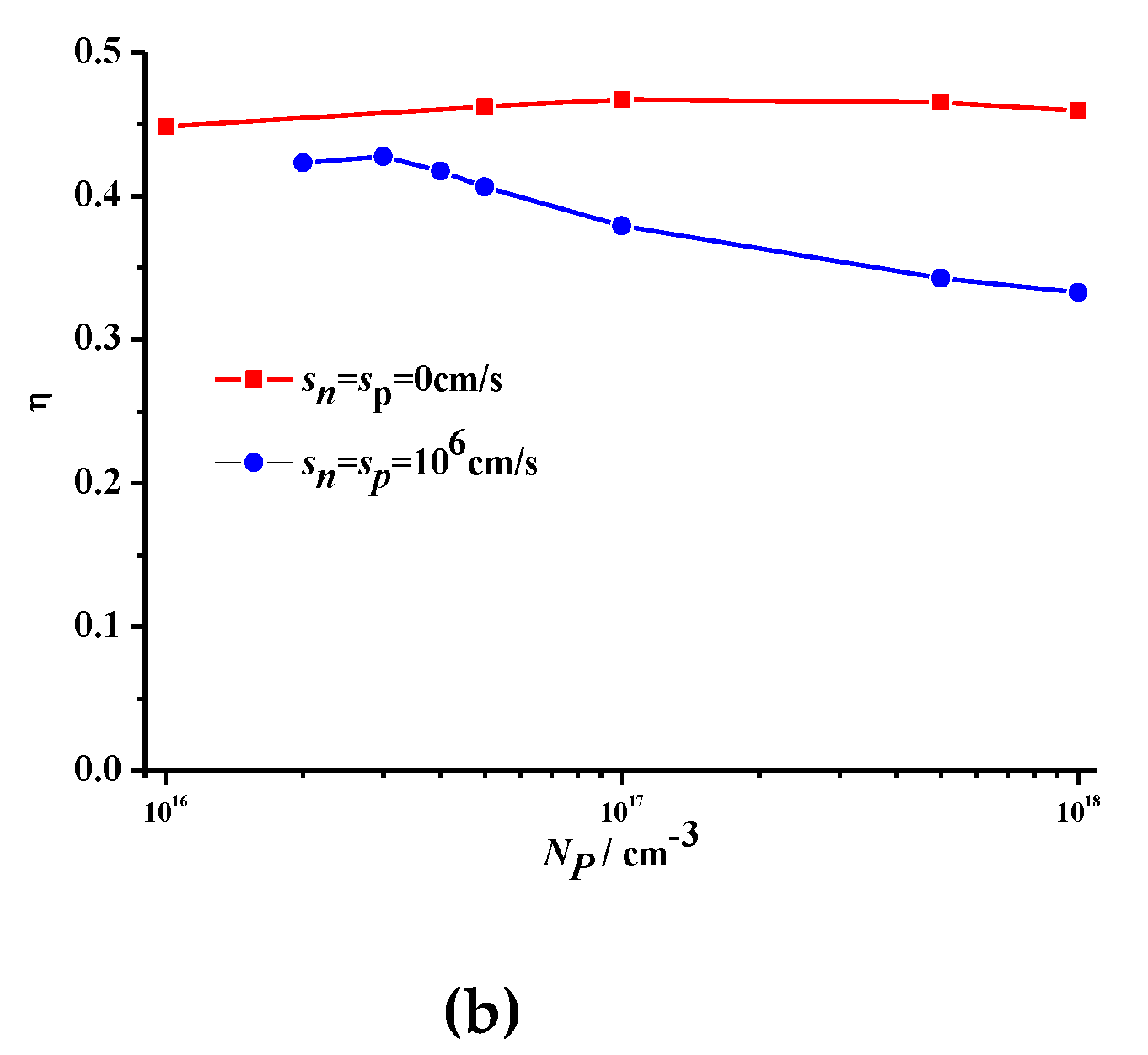

3.2. Simulation Results of the Battery Output Characteristics

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Thomas, C.; Portnoff, S.; Spencer, M.G. High efficiency 4H-SiC betavoltaic power sources using tritium radioisotopes. Appl. Phys. Lett. 2016, 108, 013505. [Google Scholar] [CrossRef]

- Qiao, D.Y.; Chen, X.J.; Ren, Y.; Zang, B.; Yuan, W.Z. A nuclear micro-battery based on silicon PIN diode. Acta Phys. Sin. 2011, 60, 020701. [Google Scholar]

- Wang, G.Q.; Li, H.; Lei, Y.S.; Zhao, W.B.; Yang, Y.Q.; Luo, S.Z. Demonstration of Pm-147 GaN betavoltaic cells. Nucl. Sci. Tech. 2014, 25, 20403. [Google Scholar]

- Eiting, C.J.; Krishnamoorthy, V.; Rodgers, S.; George, T.; Robertson, J.D.; Brockman, J. Demonstration of a radiation resistant, high efficiency SiC betavoltaic. Appl. Phys. Lett. 2006, 88, 064101. [Google Scholar] [CrossRef]

- Munson, C.E., IV; Arif, M.; Streque, J.; Belahsene, S.; Martinez, A.; Ramdane, A.; el Gmili, Y.; Salvestrini, J.; Voss, P.L.; Ougazzaden, A. Model of Ni-63 battery with realistic PIN structure. J. Appl. Phys. 2015, 118, 105101. [Google Scholar] [CrossRef]

- Sachenko, A.V.; Shkrebtii, A.I.; Korkishko, R.M.; Kostylyov, V.P.; Kulish, M.R.; Sokolovskyi, I.O. Efficiency analysis of betavoltaic elements. Solid State Electron. 2015, 111, 147–152. [Google Scholar] [CrossRef] [Green Version]

- Bao, R.; Brand, P.J.; Chrisey, D.B. Betavoltaic Performance of Radiation-Hardened High-Efficiency Si Space Solar Cells. IEEE Trans. Electron Devices 2012, 59, 1286–1294. [Google Scholar] [CrossRef]

- Kim, T.; Lee, N.; Jung, H.K.; Kim, J.H. Enhancement of energy performance in betavoltaic cells by optimizing self-absorption of beta particles. Int. J. Energy Res. 2016, 40, 522–528. [Google Scholar] [CrossRef]

- Gui, G.; Zhang, K.; Blanchard, J.P.; Ma, Z. Prediction of 4H–SiC betavoltaic microbattery characteristics based on practical Ni-63 sources. Appl. Radiat. Isot. 2016, 107, 272–277. [Google Scholar] [CrossRef]

- Zhang, K.; Gui, G.; Pathak, P.; Seo, J.; Blanchard, J.P.; Ma, Z. Quantitative modeling of betavoltaic microbattery performance. Sens. Actuators A 2016, 240, 131–137. [Google Scholar] [CrossRef]

- Zhang, L.; Cheng, H.-L.; Hu, X.-C.; Xu, X.B. Model and optimal design of 147Pm SiC-based betavoltaic cell. Superlattices Microstruct. 2018, 123, 60–70. [Google Scholar] [CrossRef]

- Love, G.; Cox, M.G.C.; Scott, V.D. A simple Monte Carlo method for simulating electron-solid interactions and its application to electron probe microanalysis. J. Phys. D Appl. Phys. 1997, 10, 7–23. [Google Scholar] [CrossRef]

- San, H.; Yao, S.; Wang, X.; Cheng, Z.; Chen, X. Design and simulation of GaN based Schottky betavoltaic nuclear micro-battery. Appl. Radiat. Isot. 2013, 80, 17–22. [Google Scholar] [CrossRef]

- Da, K.; Dai, C.-H.; Guo, H. Study of GaN betavoltaic microbattery using Monte Carlo method. Energy Convert. Microsyst. Technol. 2013, 32, 11–17. [Google Scholar]

- Tang, X.B.; Ding, D.; Liu, Y.P.; Chen, D. Optimization design and analysis of Si-63Ni betavoltaic battery. Sci. China Tech. Sci. 2012, 55, 990–996. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, F.; Xiao, J.; Gu, W.P.; Qiu, Y.Z. Power characteristics of SiC bipolar-mode JFET. Acta Phys. Sin. 2011, 60, 107304. [Google Scholar]

- Galeckas, A.; Linnros, J.; Frischholz, M.; Grivickas, V. Optical characterization of excess carrier lifetime and surface recombination in 4H/6H–SiC. Appl. Phys. Lett. 2001, 79, 365–367. [Google Scholar] [CrossRef]

- Galeckas, A.; Linnros, J.; Frischholz, M.; Rottner, K.; Nordell, N.; Karlsson, S.; Grivickas, V. Investigation of surface recombination and carrier lifetime in 4H/6H-SiC. Mater. Sci. Eng. B 1999, 61, 239–243. [Google Scholar] [CrossRef]

- Mori, Y.; Kato, M.; Ichimura, M. Estimation of Surface Recombination Velocities for n-Type 4H-SiC Surfaces Treated by Various Processes. Mater. Sci. Forum 2014, 778, 432–435. [Google Scholar] [CrossRef]

- King, R.R.; Sinton, R.A.; Swanson, R.M. Studies of diffused phosphorus emitters: Saturation current, surface recombination velocity, and quantum efficiency. IEEE Trans. Electron Devices 1990, 37, 365–371. [Google Scholar] [CrossRef]

- King, R.R.; Swanson, R.M. Studies of Diffused Boron Emitters: Saturation Current, Bandgap Narrowing, and Surface Recombination Velocity. IEEE Trans. Electron Devices 1991, 38, 1399–1409. [Google Scholar] [CrossRef]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Z. Simulation and Optimization Design of SiC-Based PN Betavoltaic Microbattery Using Tritium Source. Crystals 2020, 10, 105. https://doi.org/10.3390/cryst10020105

Lin Z. Simulation and Optimization Design of SiC-Based PN Betavoltaic Microbattery Using Tritium Source. Crystals. 2020; 10(2):105. https://doi.org/10.3390/cryst10020105

Chicago/Turabian StyleLin, Zhang. 2020. "Simulation and Optimization Design of SiC-Based PN Betavoltaic Microbattery Using Tritium Source" Crystals 10, no. 2: 105. https://doi.org/10.3390/cryst10020105