A Comparison of the Mechanisms and Activation Barriers for Ammonia Synthesis on Metal Nitrides (Ta3N5, Mn6N5, Fe3Mo3N, Co3Mo3N)

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

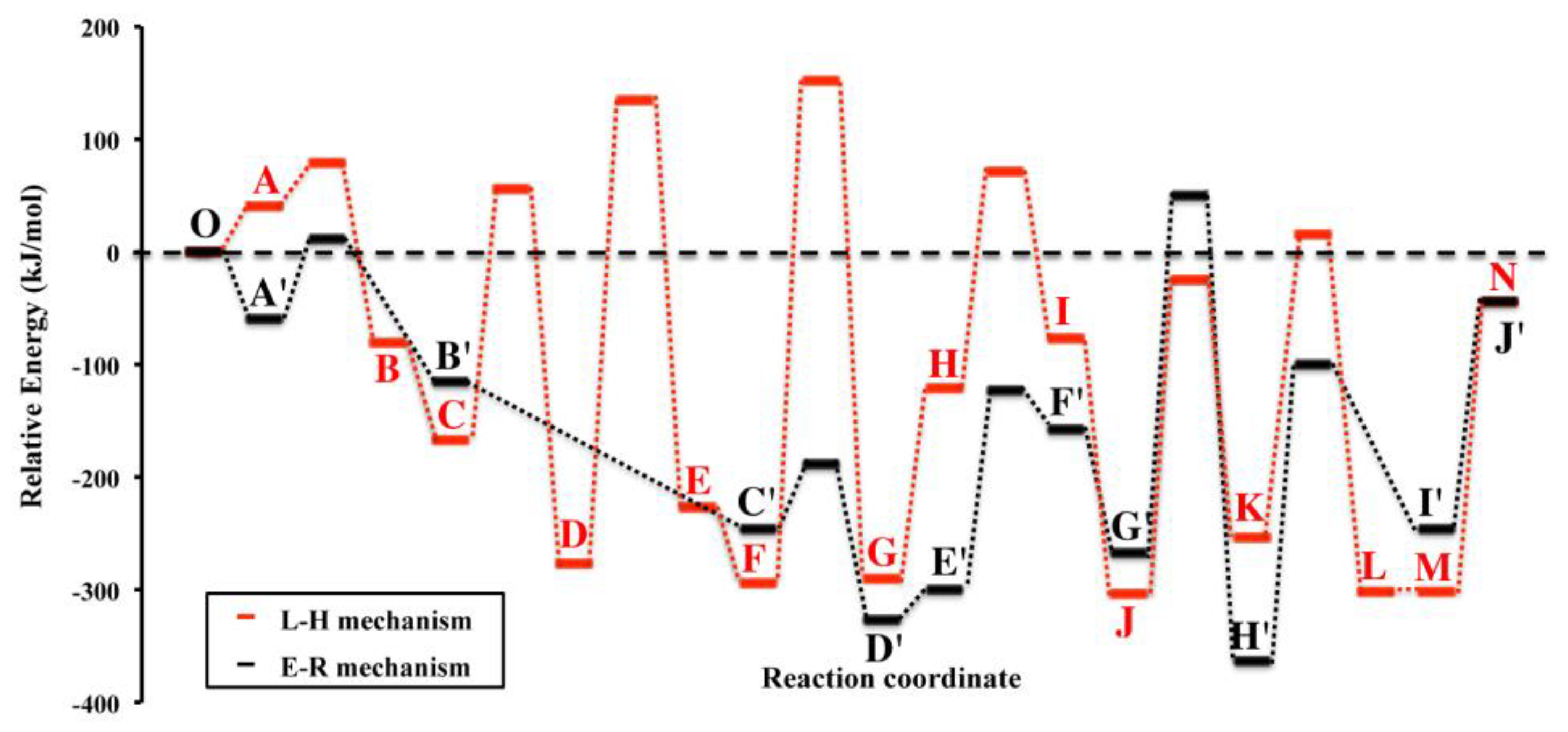

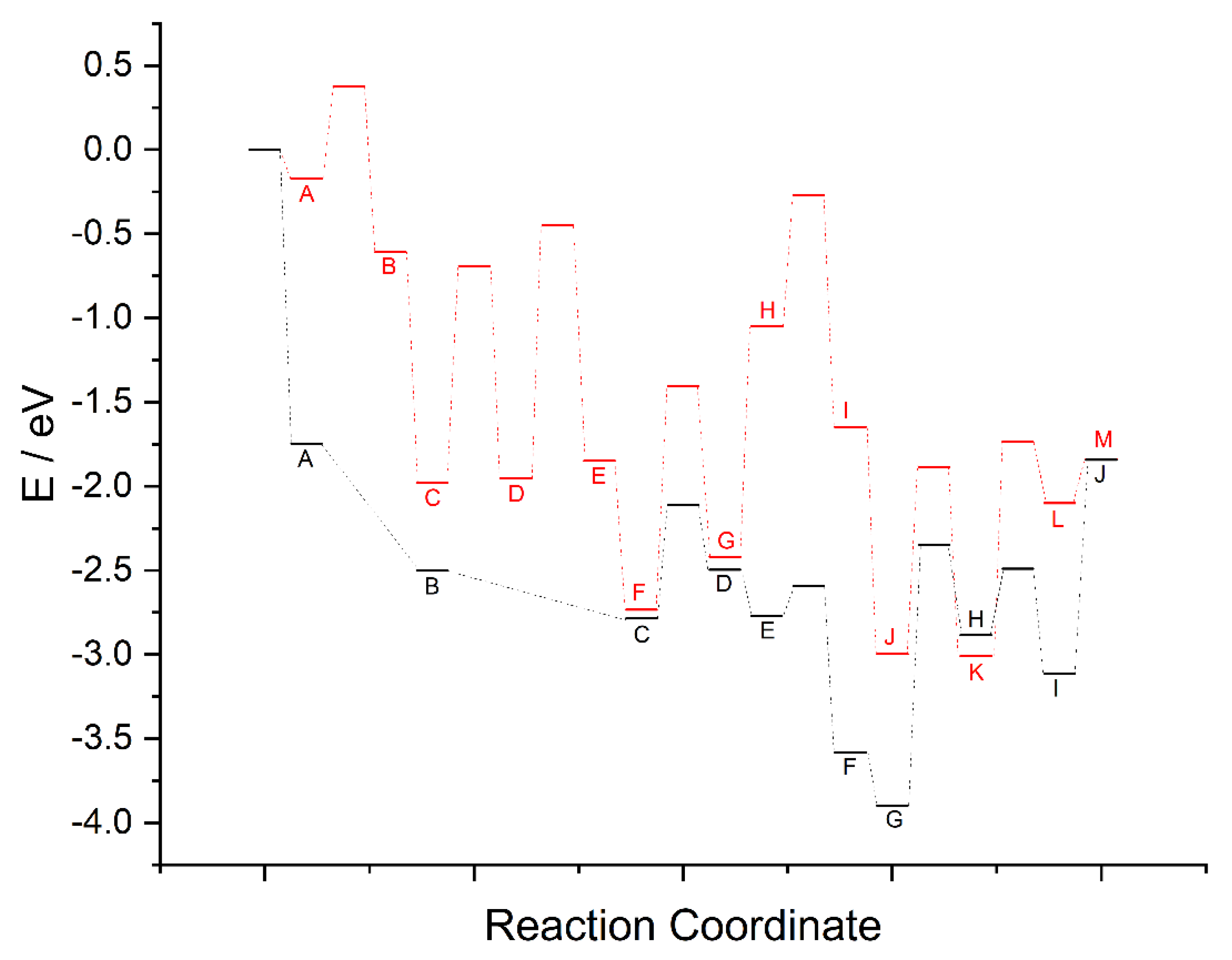

3.1. Cobalt Molybdenum Nitride (Co3Mo3N)

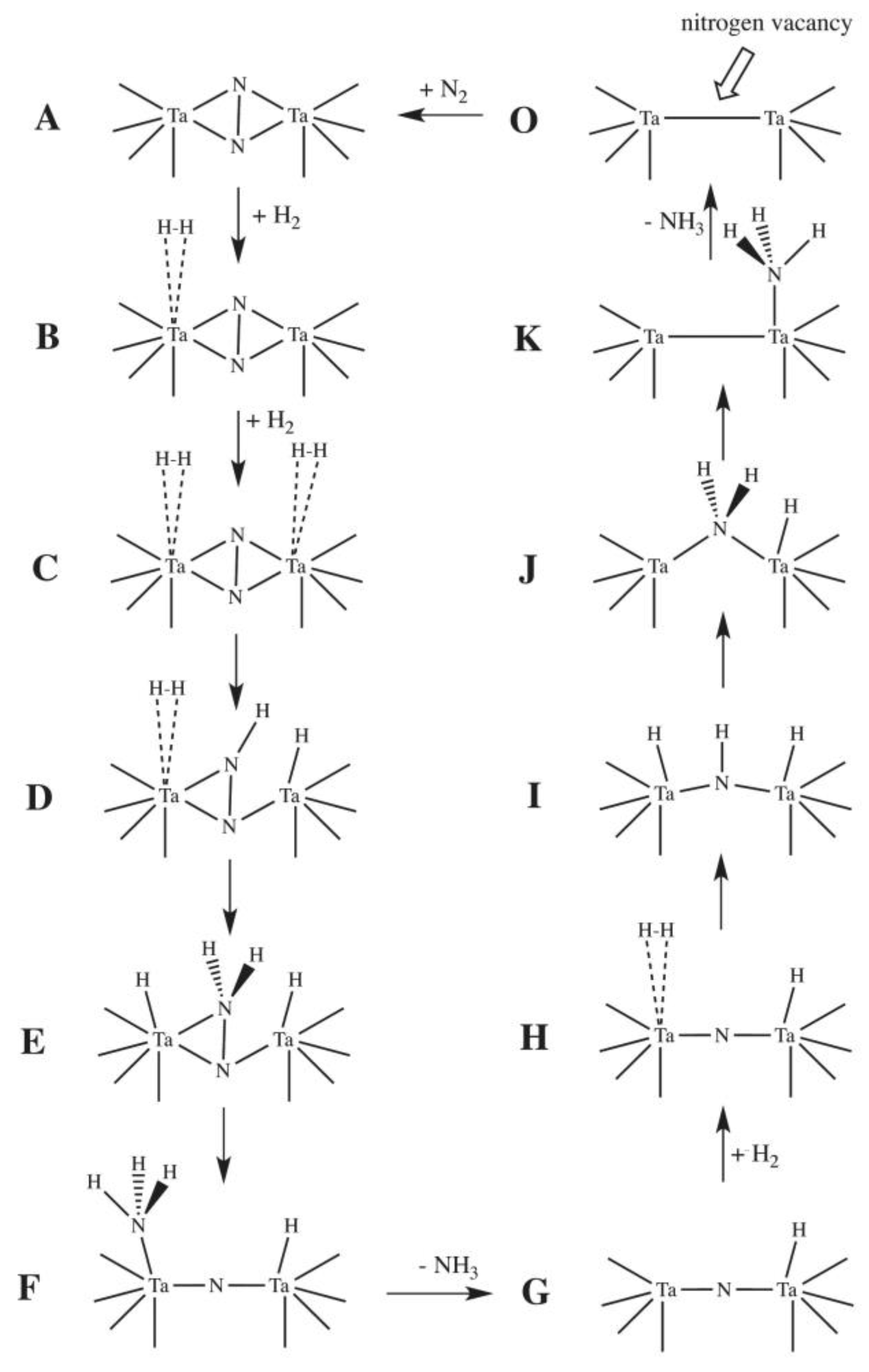

3.2. Tantalum Nitride (Ta3N5)

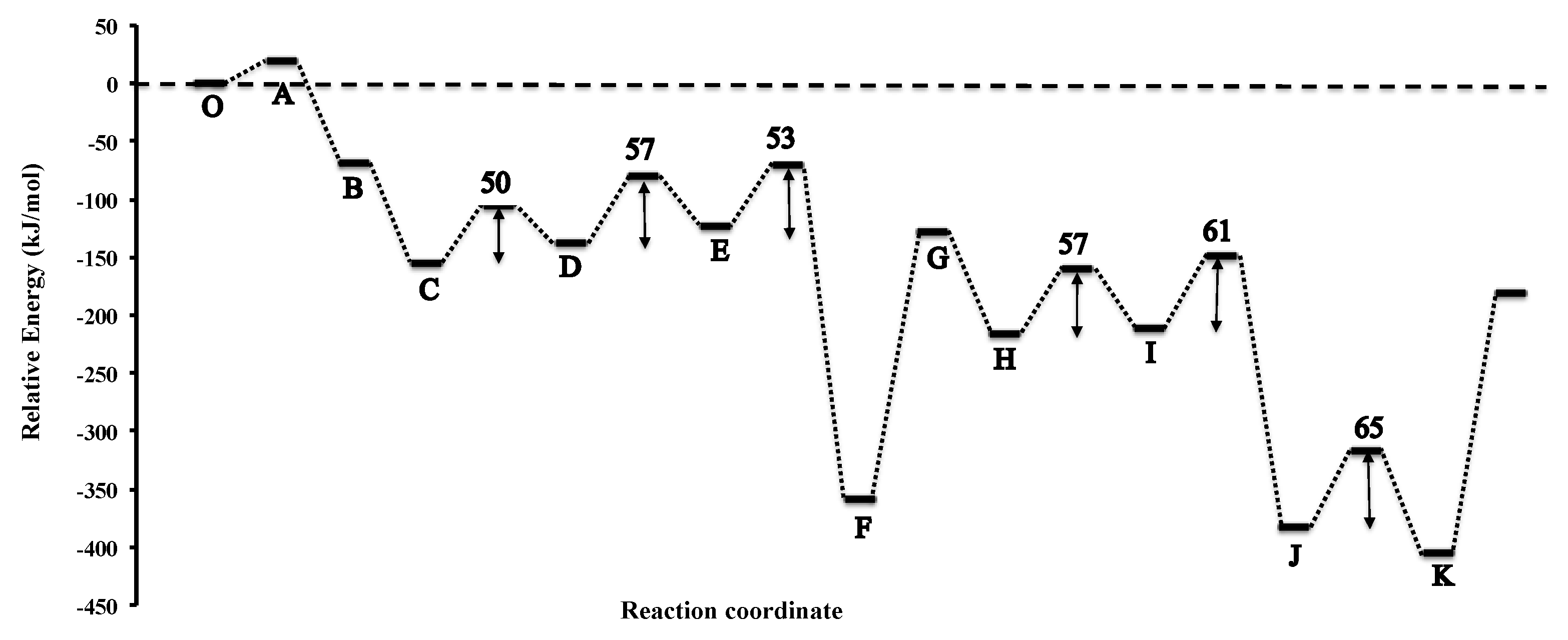

3.3. Manganese Nitride (Mn6N5)

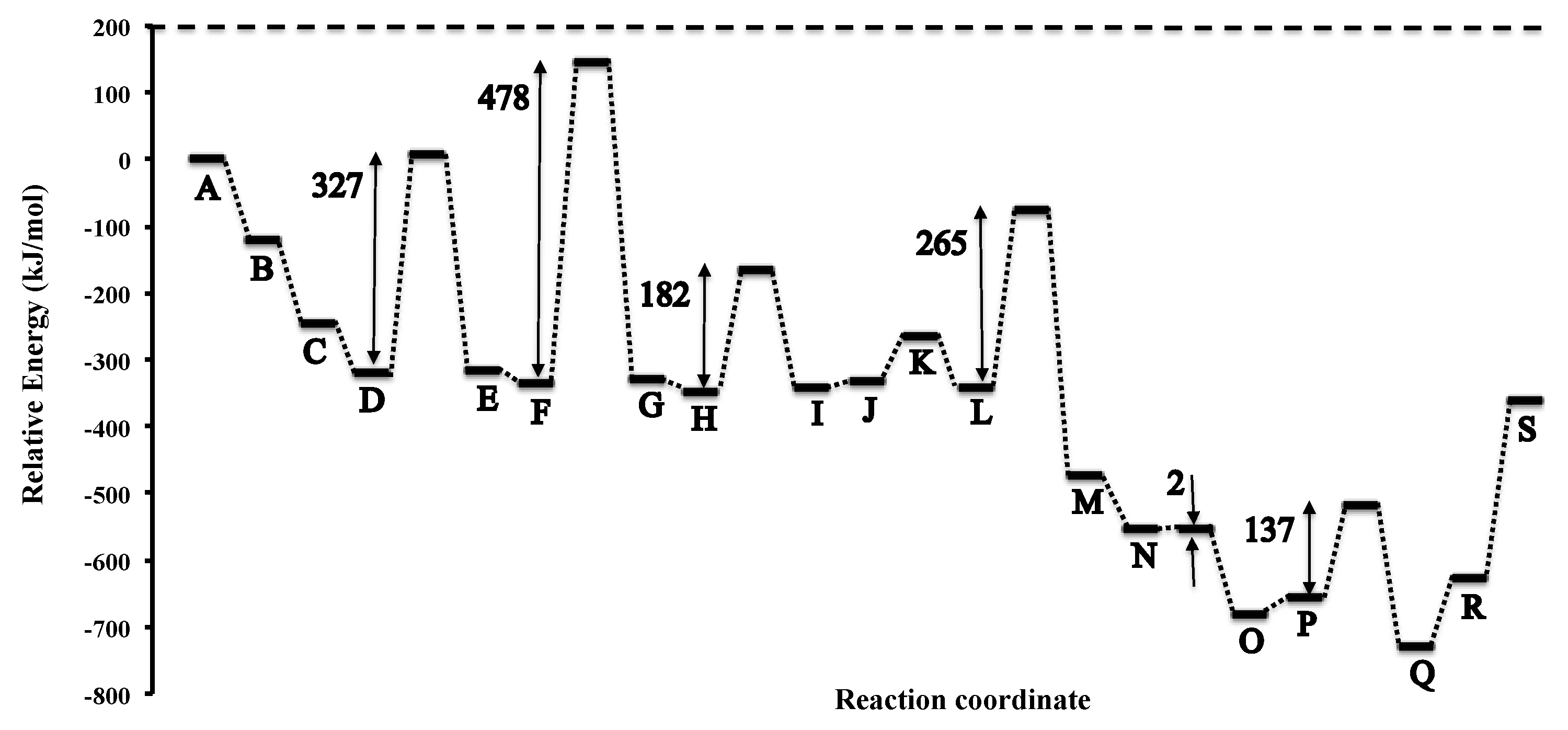

3.4. Iron Molybdenum Nitride (Fe3Mo3N)

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ertl, G.; Knözinger, H.; Weitkamp, J. Handbook of Heterogeneous Catalysis; VCH: Weinheim, Germany, 1997; Volume 2. [Google Scholar]

- Ertl, G.; Lee, S.B.; Weiss, M. Kinetics of nitrogen adsorption on Fe(111). Surf. Sci. 1982, 114, 515–526. [Google Scholar] [CrossRef]

- Erisman, J.W.; Sutton, M.A.; Galloway, J.; Klimont, Z.; Winiwarter, W. How a century of ammonia synthesis changed the world. Nat. Geosci. 2008, 1, 636. [Google Scholar] [CrossRef]

- Ertl, G. Surface Science and Catalysis—Studies on the Mechanism of Ammonia Synthesis: The P. H. Emmett Award Address. Catal. Rev. 1980, 21, 201–223. [Google Scholar] [CrossRef]

- Bowker, M. Modelling of ammonia synthesis kinetics. Catal. Today 1992, 12, 153–163. [Google Scholar] [CrossRef]

- Fuller, J.; Fortunelli, A.; Goddard, W.A., III; An, Q. Reaction mechanism and kinetics for ammonia synthesis on the Fe(211) reconstructed surface. Phys. Chem. Chem. Phys. 2019, 21, 11444–11454. [Google Scholar] [CrossRef]

- Liu, J.-C.; Ma, X.-L.; Li, Y.; Wang, Y.-G.; Xiao, H.; Li, J. Heterogeneous Fe3 single-cluster catalyst for ammonia synthesis via an associative mechanism. Nat. Commun. 2018, 9, 1610. [Google Scholar] [CrossRef]

- Saadatjou, N.; Jafari, A.; Sahebdelfar, S. Ruthenium Nanocatalysts for Ammonia Synthesis: A Review. Chem. Eng. Commun. 2015, 202, 420–448. [Google Scholar] [CrossRef]

- Garden, A.L.; Skúlason, E. The Mechanism of Industrial Ammonia Synthesis Revisited: Calculations of the Role of the Associative Mechanism. J. Phys. Chem. C 2015, 119, 26554–26559. [Google Scholar] [CrossRef]

- Boisen, A.; Dahl, S.; Jacobsen, C.J.H. Promotion of Binary Nitride Catalysts: Isothermal N2 Adsorption, Microkinetic Model, and Catalytic Ammonia Synthesis Activity. J. Catal. 2002, 208, 180–186. [Google Scholar] [CrossRef]

- Jacobsen, C.J.H.; Dahl, S.; Clausen, B.S.; Bahn, S.; Logadottir, A.; Nørskov, J.K. Catalyst Design by Interpolation in the Periodic Table: Bimetallic Ammonia Synthesis Catalysts. J. Am. Chem. Soc. 2001, 123, 8404–8405. [Google Scholar] [CrossRef]

- Nørskov, J.; Bligaard, T.; Logadóttir, A.; Bahn, S.; Hansen, L.; Bollinger, M.; Bengaard, H.; Hammer, B.; Sljivancanin, Z.; Mavrikakis, M.; et al. Universality in Heterogeneous Catalysis. J. Catal. 2002, 209, 275–278. [Google Scholar] [CrossRef]

- Kojima, R.; Aika, K.-I. Cobalt Molybdenum Bimetallic Nitride Catalysts for Ammonia Synthesis. Chem. Lett. 2000, 5, 514–515. [Google Scholar] [CrossRef]

- Kojima, R.; Aika, K.-I. Cobalt molybdenum bimetallic nitride catalysts for ammonia synthesis: Part 1. Preparation and characterization. Appl. Catal. A Gen. 2001, 215, 149–160. [Google Scholar] [CrossRef]

- Rai, R.K.; Maligal-Ganesh, R.; Maksoud, W.A.; Kim, S.-J.; Vaishnav, Y.; Yavuz, C.T.; Kobayashi, Y. Enhancing Ammonia Synthesis on Co3Mo3N via Metal Support Interactions on a Single-crystalline MgO Support. ChemCatChem 2024, e202301579. [Google Scholar] [CrossRef]

- Aslan, M.Y.; Hargreaves, J.S.J.; Uner, D. The effect of H2:N2 ratio on the NH3 synthesis rate and on process economics over the Co3Mo3N catalyst. Faraday Discuss. 2021, 229, 475–488. [Google Scholar] [CrossRef] [PubMed]

- Zeinalipour-Yazdi, C.D.; Hargreaves, J.S.J.; Catlow, C.R.A. Nitrogen Activation in a Mars–van Krevelen Mechanism for Ammonia Synthesis on Co3Mo3N. J. Phys. Chem. C 2015, 119, 28368–28376. [Google Scholar] [CrossRef]

- Zeinalipour-Yazdi, C.D.; Hargreaves, J.S.J.; Catlow, C.R.A. Low-T Mechanisms of Ammonia Synthesis on Co3Mo3N. J. Phys. Chem. C 2018, 122, 6078–6082. [Google Scholar] [CrossRef]

- Zeinalipour-Yazdi, C.D.; Hargreaves, J.S.J.; Laassiri, S.; Catlow, C.R.A. DFT-D3 study of H2 and N2 chemisorption over cobalt promoted Ta3N5-(100), (010) and (001) surfaces. Phys. Chem. Chem. Phys. 2017, 19, 11968–11974. [Google Scholar] [CrossRef]

- Zeinalipour-Yazdi, C.D. On the possibility of an Eley–Rideal mechanism for ammonia synthesis on Mn6N5+x (x = 1)-(111) surfaces. Phys. Chem. Chem. Phys. 2018, 20, 18729–18736. [Google Scholar] [CrossRef] [PubMed]

- Higham, M.D.; Zeinalipour-Yazdi, C.D.; Hargreaves, J.S.J.; Catlow, C.R.A. Mechanism of ammonia synthesis on Fe3Mo3N. Faraday Discuss. 2023, 243, 77–96. [Google Scholar] [CrossRef] [PubMed]

- Abghoui, Y.; Garden, A.L.; Hlynsson, V.F.; Bjorgvinsdottir, S.; Olafsdottir, H.; Skulason, E. Enabling electrochemical reduction of nitrogen to ammonia at ambient conditions through rational catalyst design. Phys. Chem. Chem. Phys. 2015, 17, 4909–4918. [Google Scholar] [CrossRef] [PubMed]

- Abghoui, Y.; Garden, A.; Howat, J.; Vegge, T.; Skulason, E. Electroreduction of N2 to Ammonia at Ambient Conditions on Mononitrides of Zr, Nb, Cr, and V: A DFT Guide for Experiments. ACS Catal. 2016, 6, 635–646. [Google Scholar] [CrossRef]

- Michalsky, R.; Pfromm, P.; Steinfeld, A. Rational Design of Metal Nitride Redox Materials for Solar-Driven Ammonia Synthesis. Interface Focus 2015, 5, 20140084. [Google Scholar] [CrossRef] [PubMed]

- Michalsky, R.; Avram, A.; Peterson, B.; Pfromm, P.; Peterson, A. Chemical Looping of Metal Nitride Catalysts: Low-Pressure Ammonia Synthesis for Energy Storage. Chem. Sci. 2015, 6, 3965–3974. [Google Scholar] [CrossRef] [PubMed]

- Abghoui, Y.; Skúlason, E. Electrochemical synthesis of ammonia via Mars-van Krevelen mechanism on the (111) facets of group III–VII transition metal mononitrides. Catal. Today 2017, 286, 78–84. [Google Scholar] [CrossRef]

- Srifa, A.; Okura, K.; Okanishi, T.; Muroyama, H.; Matsui, T.; Eguchi, K. Hydrogen production by ammonia decomposition over Cs-modified Co3Mo3N catalysts. Appl. Catal. B Environ. 2017, 218, 1–8. [Google Scholar] [CrossRef]

- Sfeir, A.; Teles, C.A.; Ciotonea, C.; Reddy, G.N.M.; Marinova, M.; Dhainaut, J.; Löfberg, A.; Dacquin, J.-P.; Royer, S.; Laassiri, S. Enhancing ammonia catalytic production over spatially confined cobalt molybdenum nitride nanoparticles in SBA-15. Appl. Catal. B Environ. 2023, 325, 122319. [Google Scholar] [CrossRef]

- Ferree, M.; Gunduz, S.; Kim, J.; LaRosa, R.; Khalifa, Y.; Co, A.C.; Ozkan, U.S. Enhanced N2 Activation on a Composite Co3Mo3N Nitride and La0.6Sr0.4Co0.2Fe0.8O3 Perovskite Cathode for High-Temperature Electrochemical Ammonia Synthesis. ACS Sustain. Chem. Eng. 2023, 11, 5007–5013. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169–11186. [Google Scholar] [CrossRef] [PubMed]

- Kresse, G.; Hafner, J. Ab initio Molecular Dynamics for Liquid Metals. Phys. Rev. B 1993, 47, 558. [Google Scholar] [CrossRef] [PubMed]

- Monkhorst, H.; Pack, J. Special points for Brillouin-zone integrations. Phys. Rev. B 1976, 13, 5188. [Google Scholar] [CrossRef]

- Perdew, J.; Burke, K.; Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996, 77, 3865. [Google Scholar] [CrossRef] [PubMed]

- Blöchl, P. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953. [Google Scholar] [CrossRef] [PubMed]

- Kresse, G.; Jouber, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1999, 59, 1758–1775. [Google Scholar] [CrossRef]

- Grimme, S.; Antony, J.; Ehrlich, S.; Krieg, H.A. Consistent and Accurate ab initio Parametrization of Density Functional Dispersion Correction (DFT-D) for the 94 Elements H-Pu. J. Chem. Phys. 2010, 132, 154104. [Google Scholar] [CrossRef] [PubMed]

- Mills, G.; Jónsson, H.; Schenter, G. Reversible Work Transition State Theory: Application to Dissociative Adsorption of Hydrogen. Surf. Sci. 1995, 324, 305–337. [Google Scholar] [CrossRef]

- Zeinalipour-Yazdi, C.D. Mechanistic aspects of ammonia synthesis on Ta3N5 surfaces in the presence of intrinsic nitrogen vacancies. Phys. Chem. Chem. Phys. 2021, 23, 6959–6963. [Google Scholar] [CrossRef] [PubMed]

- Hunter, S.M.; McKay, D.; Smith, R.I.; Hargreaves, J.S.J.; Gregory, D.H. Topotactic Nitrogen Transfer: Structural Transformation in Cobalt Molybdenum Nitrides. Chem. Mater. 2010, 22, 2898–2907. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeinalipour-Yazdi, C.D. A Comparison of the Mechanisms and Activation Barriers for Ammonia Synthesis on Metal Nitrides (Ta3N5, Mn6N5, Fe3Mo3N, Co3Mo3N). Crystals 2024, 14, 392. https://doi.org/10.3390/cryst14050392

Zeinalipour-Yazdi CD. A Comparison of the Mechanisms and Activation Barriers for Ammonia Synthesis on Metal Nitrides (Ta3N5, Mn6N5, Fe3Mo3N, Co3Mo3N). Crystals. 2024; 14(5):392. https://doi.org/10.3390/cryst14050392

Chicago/Turabian StyleZeinalipour-Yazdi, Constantinos D. 2024. "A Comparison of the Mechanisms and Activation Barriers for Ammonia Synthesis on Metal Nitrides (Ta3N5, Mn6N5, Fe3Mo3N, Co3Mo3N)" Crystals 14, no. 5: 392. https://doi.org/10.3390/cryst14050392