Recent Advances on p-Type III-Nitride Nanowires by Molecular Beam Epitaxy

Abstract

:1. Introduction

2. III-Nitride Nanowires by Molecular Beam Epitaxy: A General Discussion

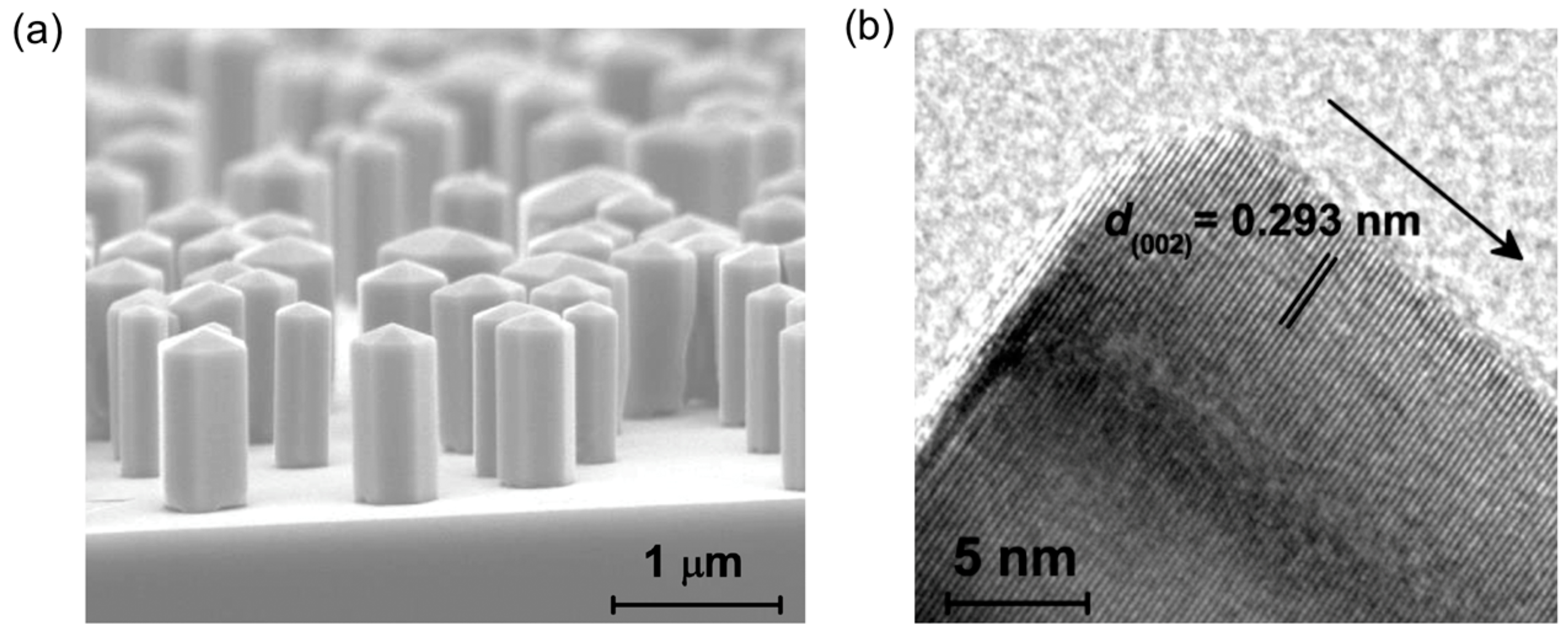

2.1. Spontaneous Formation of III-Nitride Nanowires

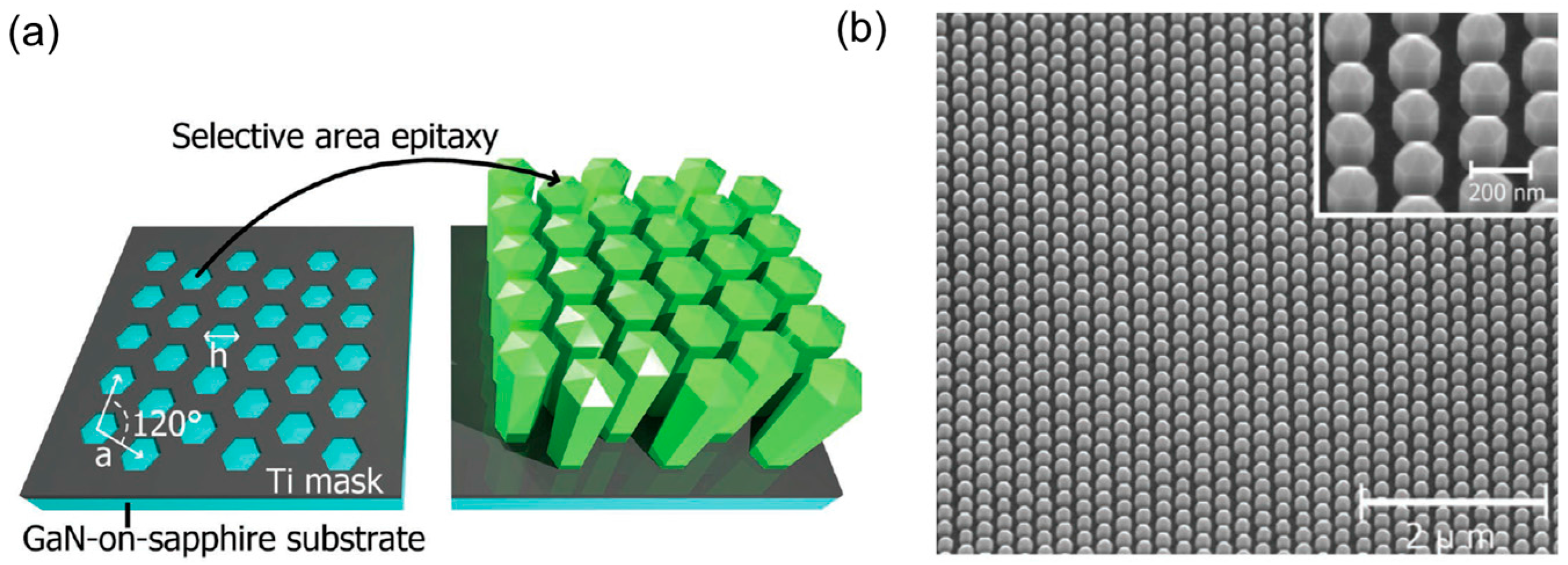

2.2. Selective Area Epitaxy

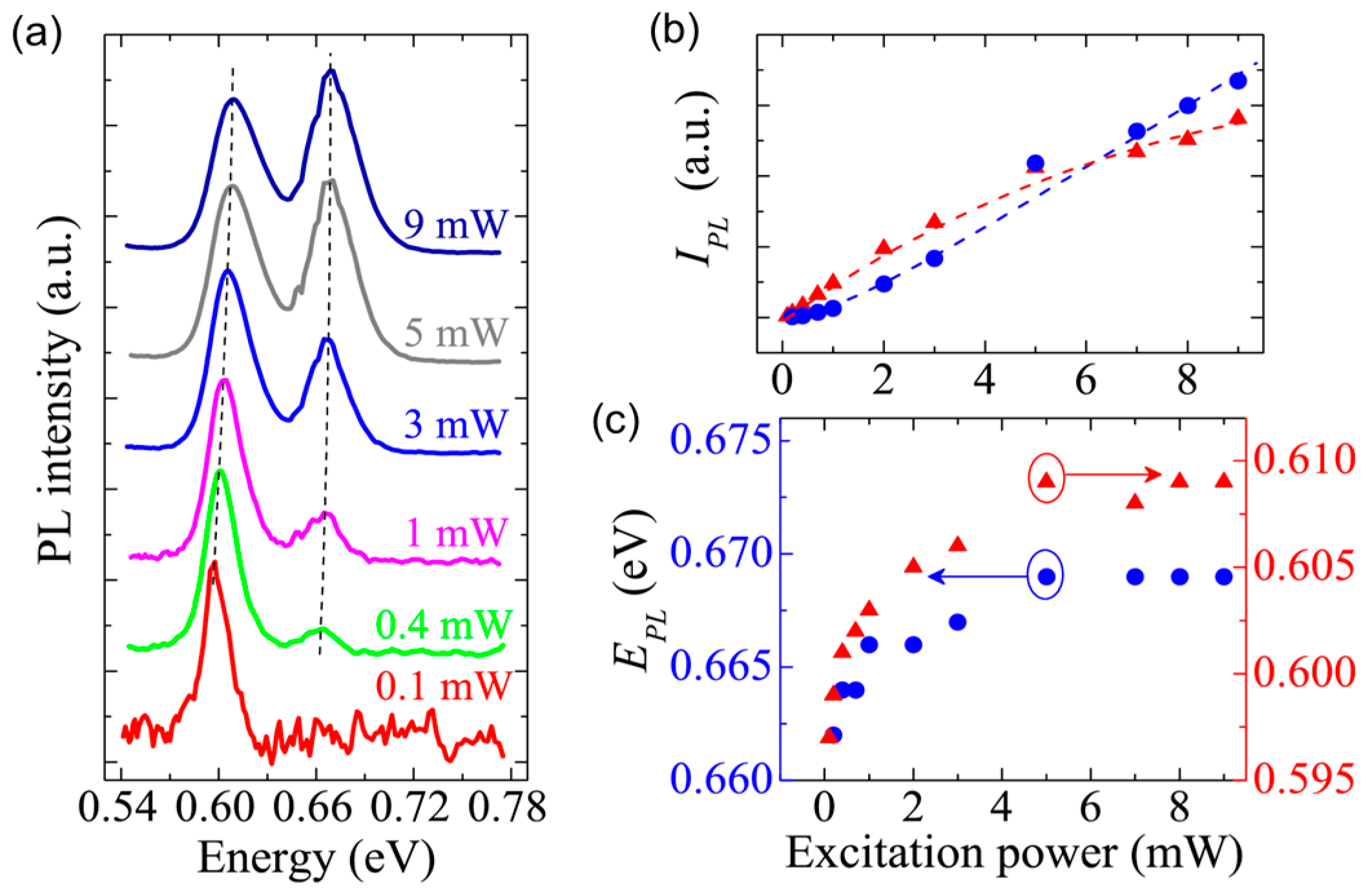

3. Mg-Doped InN Nanowires

3.1. Mg-Dopant Incorporation

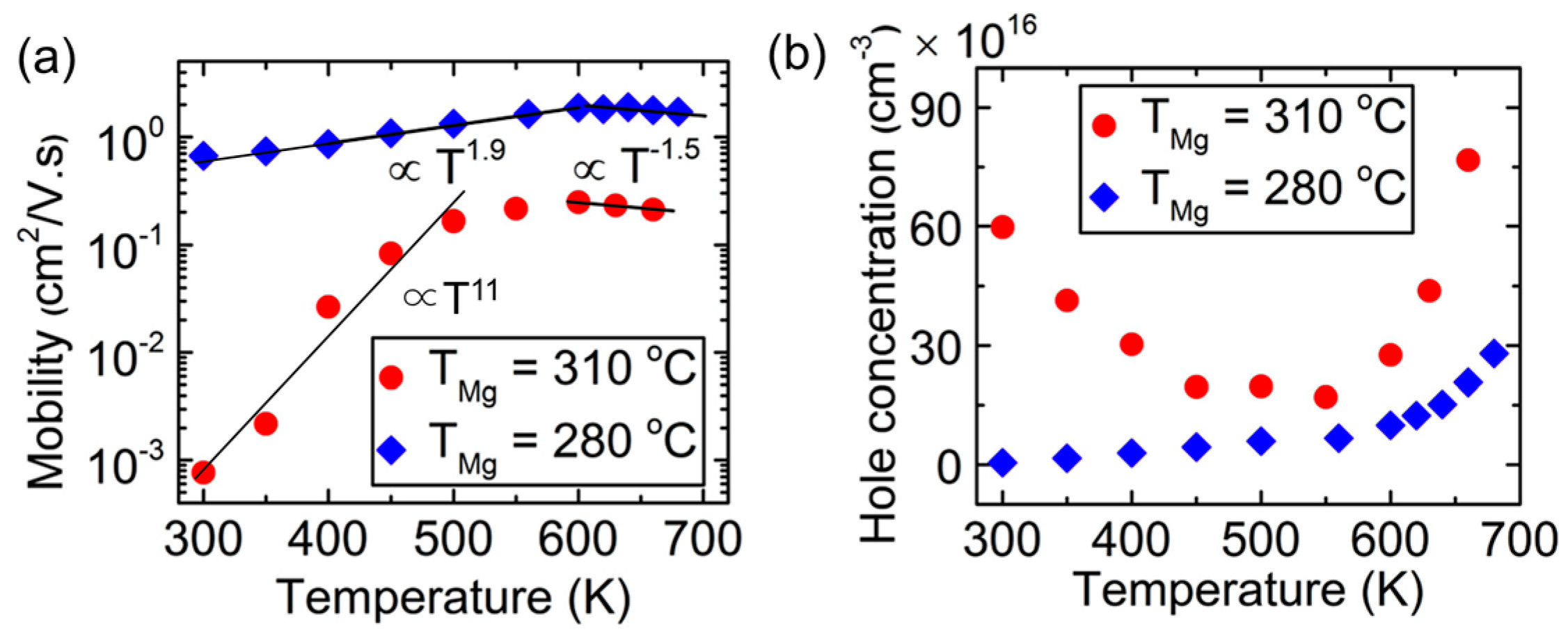

3.2. Direct Evidence for p-Type Doping

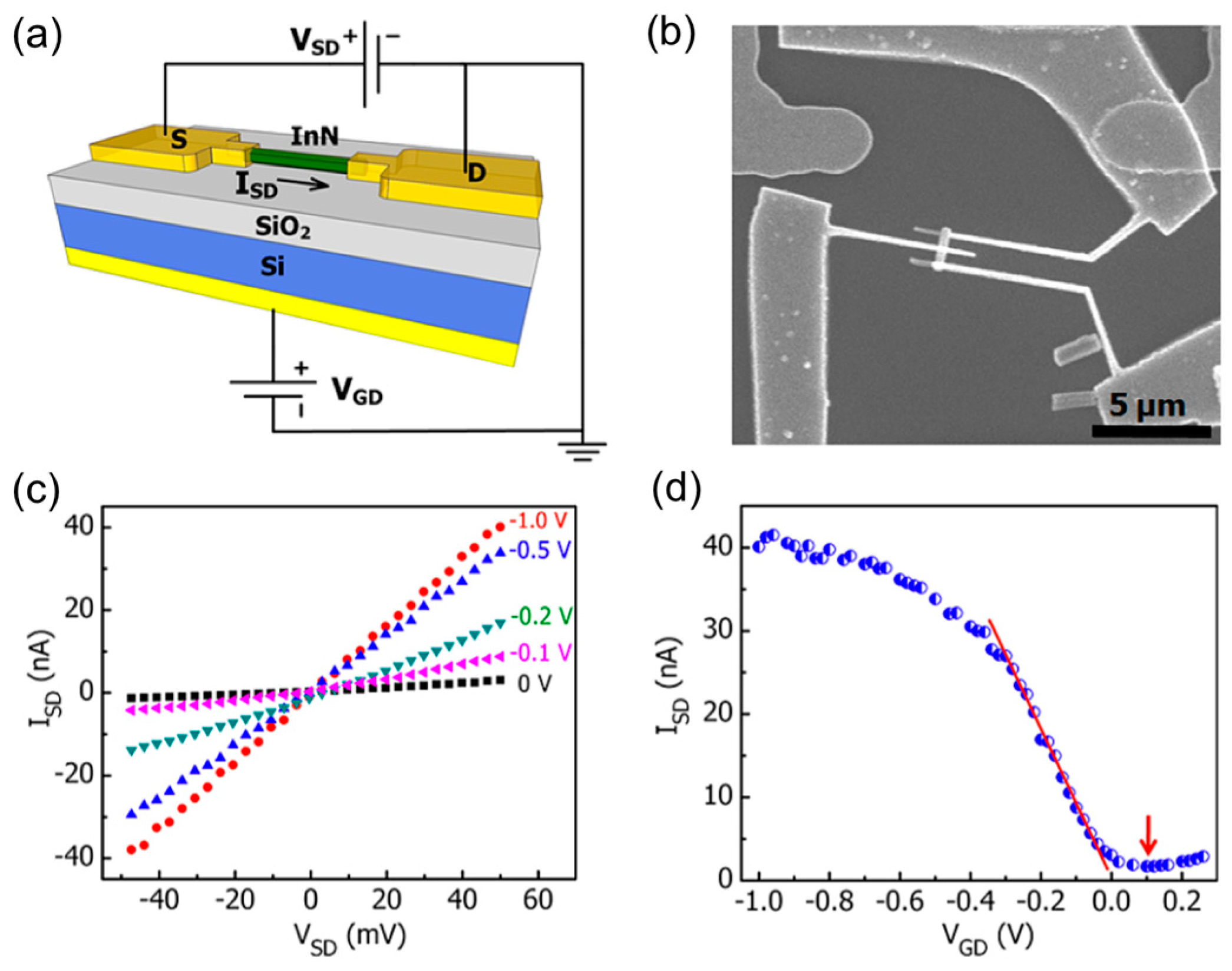

3.2.1. A Direct Measurement of p-Type Conduction

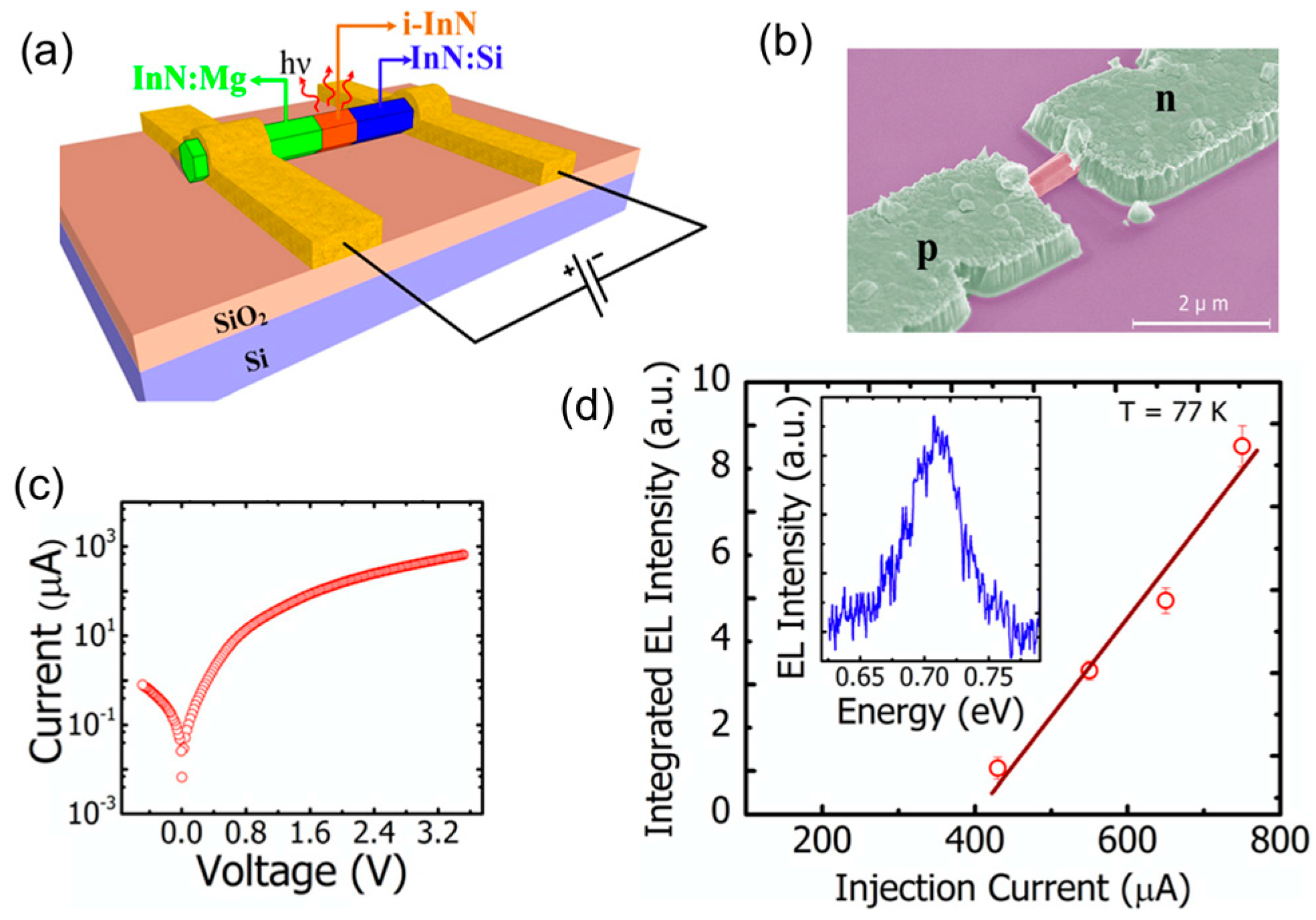

3.2.2. Electroluminescence from InN p-i-n Photodiode

- Due to efficient strain relaxation in nanowires, the density of defects (e.g., stacking faults, misfit dislocations) is drastically reduced. Moreover, the formation of nitrogen-vacancy related defect donors can be suppressed, due to the use of nitrogen-rich conditions.

- The In-substitutional Mg formation energy is reduced in InN nanowires, which can enhance Mg incorporation.

- Previous studies on the correlated surface charge properties and morphology of InN nanowires indicate that InN nanowires with tapered morphology tend to have high background electron concentration and surface electron accumulation, due to surface defects [44,76,77]. In this regard, maintaining excellent hexagonal-shaped morphology is another important factor to realize p-type InN nanowires.

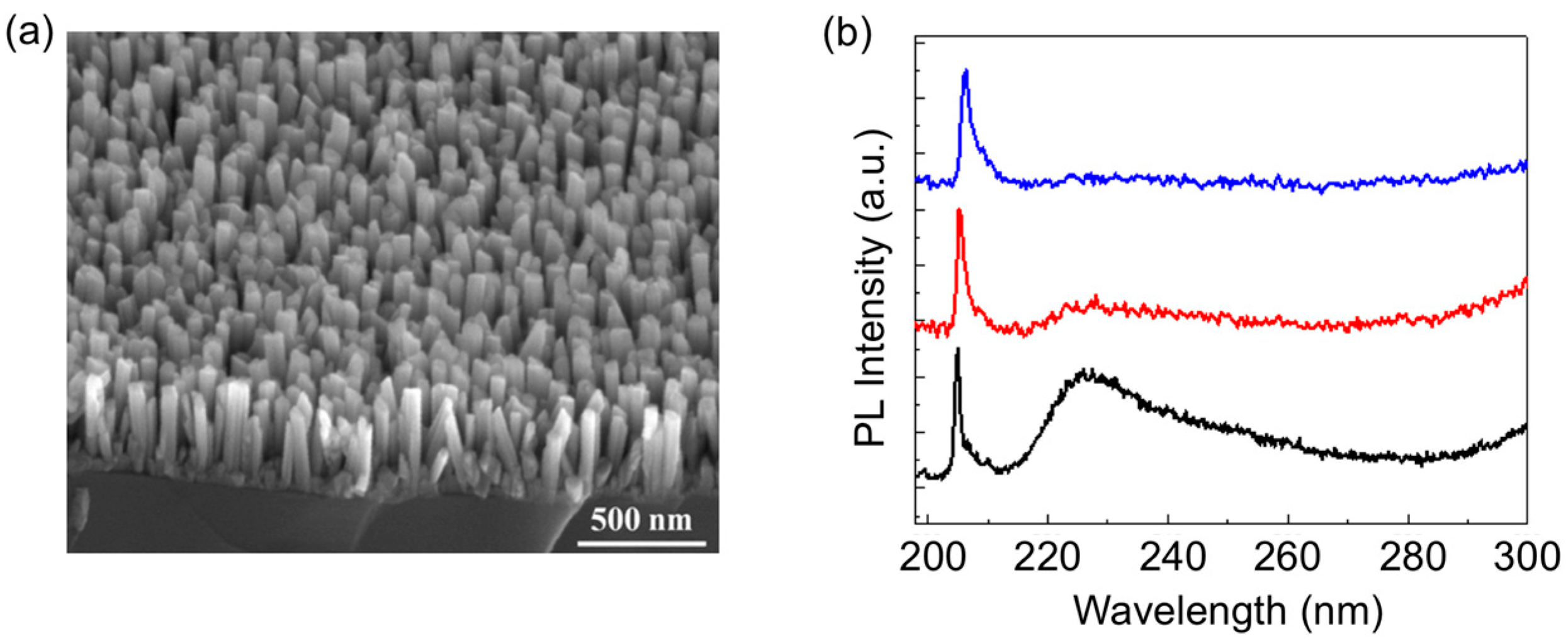

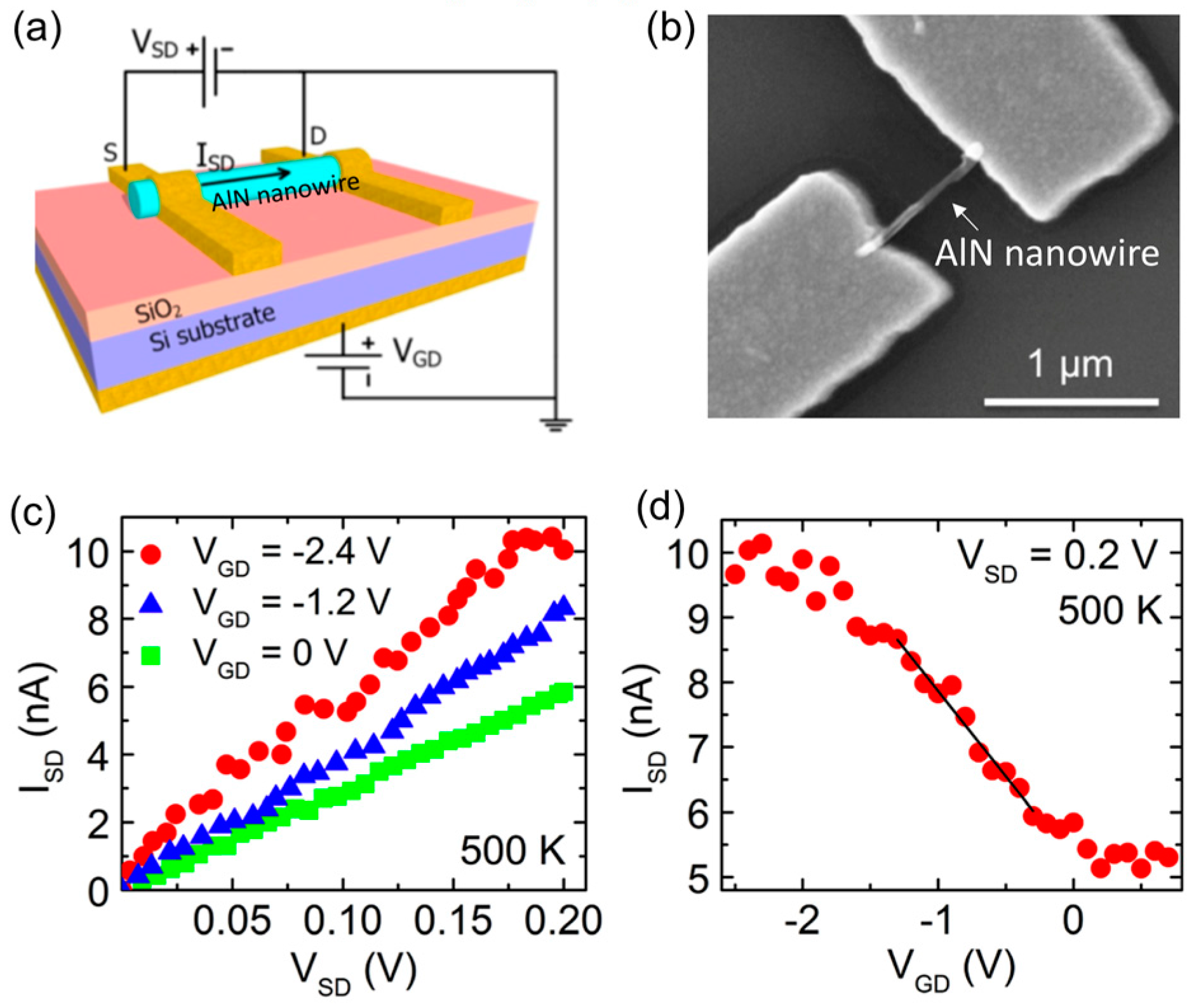

4. Mg-Doped AlN Nanowires and Their Applications in Deep UV Optoelectronics

4.1. Mg-Dopant Incorporation and p-Type Conduction

- AlN nanowires possess drastically reduced defect density. This is, first of all, due to efficient strain relaxation in nanowires. On top of this, other impurities, such as carbon, can be further minimized with the use of plasma-assisted MBE, compared to CVD or MOCVD. Additionally, such nanowires are formed under nitrogen-rich conditions, wherein nitrogen-vacancy related defects (donors) can be minimized.

- Similar to Mg doping in InN nanowires, the Al-substitutional Mg formation energy is also drastically reduced in AlN nanowires, thereby leading to significantly enhanced Mg-dopant incorporation [42]. This could lead to two mechanisms that enhance p-type conduction. Firstly, the formation of the Mg-impurity band enables the impurity band conduction, which requires much less activation energy for conduction compared to the energy needed to generate a valence band hole. Secondly, due to the band tailing effect and broadened Mg energy levels associated with the enhanced Mg-dopant incorporation, a portion of Mg dopants could have reduced activation energy, which further improves p-type conduction in the valence band.

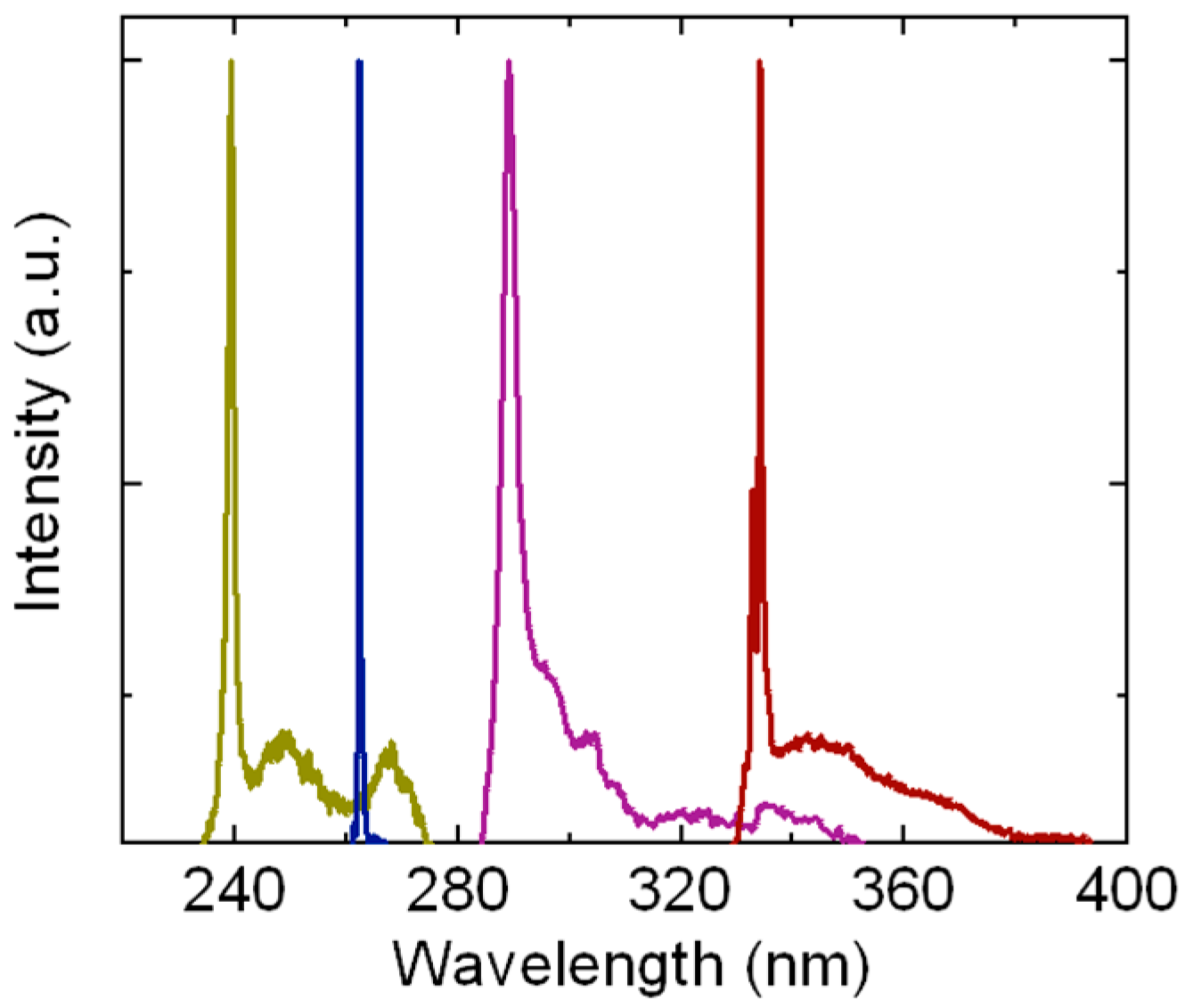

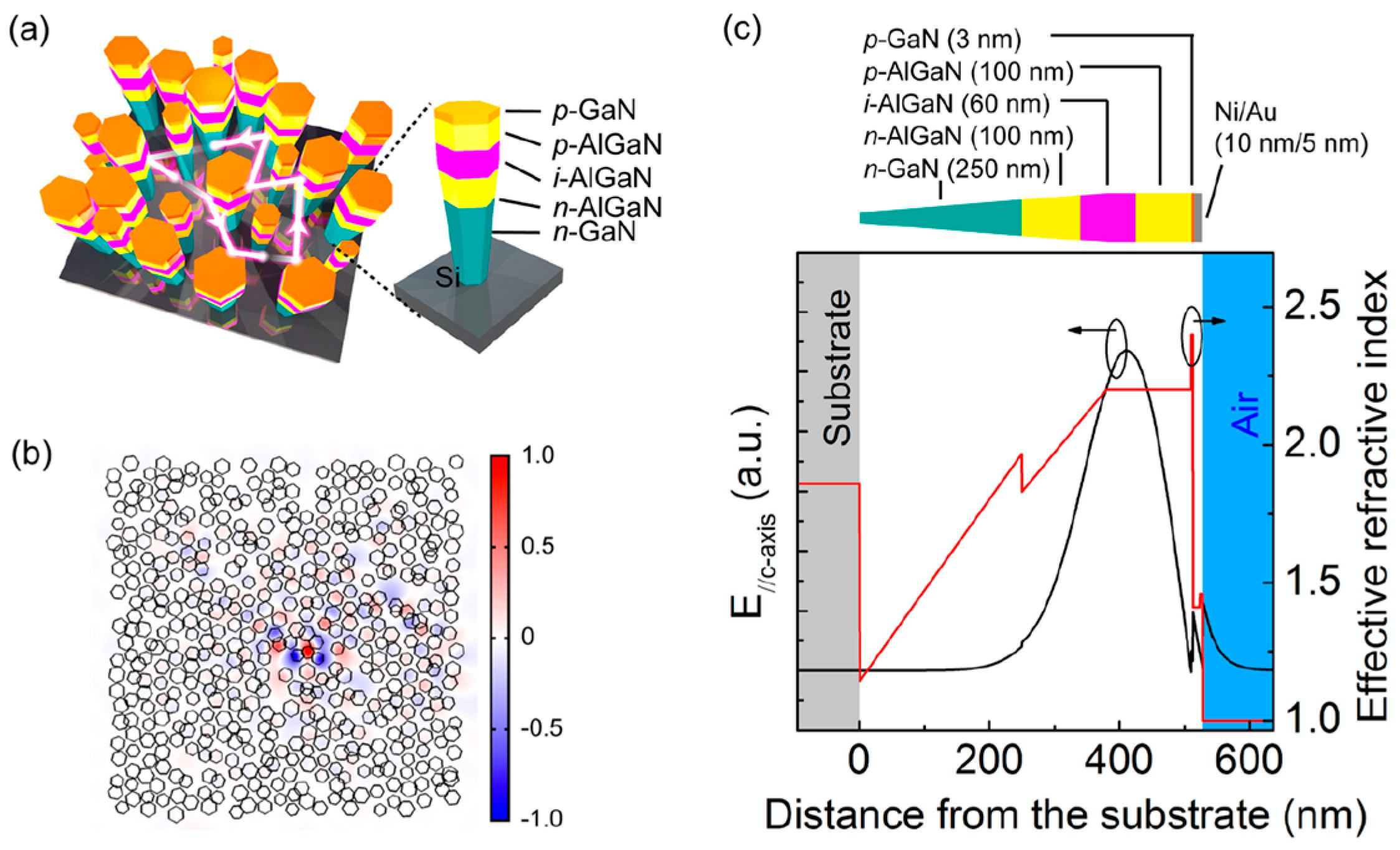

4.2. AlN Nanowire-Based Deep UV Optoelectronic Devices

4.2.1. AlN Nanowire LEDs

4.2.2. Electrically-Injected Deep UV Lasers

5. Conclusions and Future Prospects

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wu, J. When group-III nitrides go infrared: New properties and perspectives. J. Appl. Phys. 2009, 106, 011101. [Google Scholar] [CrossRef]

- Nakamura, S.; Pearton, S.; Fasol, G. The blue laser diode: The complete story. In Science & Business Media; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Akasaki, I. Key inventions in the history of nitride-based blue LED and LD. J. Cryst. Growth 2007, 300, 2–10. [Google Scholar] [CrossRef]

- Yoshikawa, A.; Wang, X.; Ishitani, Y.; Uedono, A. Recent advances and challenges for successful p-type control of InN films with Mg acceptor doping by molecular beam epitaxy. Phys. Status Solidi A 2010, 207, 1011–1023. [Google Scholar] [CrossRef]

- Khan, A.; Balakrishnan, K.; Katona, T. Ultraviolet light-emitting diodes based on group three nitrides. Nat. Photonics 2008, 2, 77–84. [Google Scholar] [CrossRef]

- Yoshida, H.; Kuwabara, M.; Yamashita, Y.; Uchiyama, K.; Kan, H. The current status of ultraviolet laser diodes. Phys. Status Solidi A 2011, 208, 1586–1589. [Google Scholar] [CrossRef]

- Kneissl, M.; Kolbe, T.; Chua, C.; Kueller, V.; Lobo, N.; Stellmach, J.; Knauer, A.; Rodriguez, H.; Einfeldt, S.; Yang, Z.; et al. Advances in group III-nitride-based deep UV light-emitting diode technology. Semicond. Sci. Technol. 2011, 26, 014036. [Google Scholar] [CrossRef]

- Yamamoto, A.; Islam, M.R.; Kang, T.-T.; Hashimoto, A. Recent advances in InN-based solar cells: Status and challenges in InGaN and InGaN solar cells. Phys. Status Solidi C 2010, 7, 1309–1316. [Google Scholar] [CrossRef]

- Bhuiyan, A.G.; Sugita, K.; Hashimoto, A.; Yamamoto, A. InGaN solar cells: Present state of the art and important challenges. IEEE J. Photovotaics 2012, 2, 276–293. [Google Scholar] [CrossRef]

- Hirayama, H.; Maeda, N.; Fujikawa, S.; Toyoda, S.; Kamata, N. Recent progress and future prospects of AlGaN-based high-efficiency deep-ultraviolet light-emitting diodes. Jpn. J. Appl. Phys. 2014, 53, 100209. [Google Scholar] [CrossRef]

- Van de Walle, C.G.; Neugebauer, J. Universal alignment of hydrogen levels in semiconductors, insulators and solutions. Nature 2003, 423, 626. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, S.; Ma, N.; Feng, L.; Chen, G.; Xu, F.; Tang, N.; Huang, S.; Chen, K.J.; Zhou, S.; et al. High-electron-mobility InN layers grown by boundary-temperature-controlled epitaxy. Appl. Phys. Express 2012, 5, 015502. [Google Scholar] [CrossRef]

- Fehlberg, T.B.; Umana-Membreno, G.A.; Gallinat, C.S.; Koblmüller, G.; Bernardis, S.; Nener, B.D.; Parish, G.; Speck, J.S. Characterisation of multiple carrier transport in indium nitride grown by molecular beam epitaxy. Phys. Status Solidi C 2007, 4, 2423–2427. [Google Scholar] [CrossRef]

- Wang, K.; Araki, T.; Yu, K.M.; Katsuki, T.; Mayer, M.A.; Alarcon-Llado, E.; Ager, J.W.; Walukiewicz, W.; Nanishi, Y. P-type InGaN across the entire alloy composition range. Appl. Phys. Lett. 2013, 102, 102111. [Google Scholar] [CrossRef]

- Ruffenach, S.; Moret, M.; Briot, O.; Gil, B. Recent advances in the MOVPE growth of indium nitride. Phys. Status Solidi A 2010, 207, 9–18. [Google Scholar] [CrossRef]

- Zhao, S.; Mi, Z. Chapter Eight-InN Nanowires: Epitaxial Growth, Characterization, and Device Applications. Semicond. Semimet. 2017, 96, 267–304. [Google Scholar]

- Calarco, R. InN nanowires: Growth and optoelectronic properties. Materials 2012, 5, 2137. [Google Scholar] [CrossRef]

- Van de Walle, C.G.; Lyons, J.L.; Janotti, A. Controlling the conductivity of InN. Phys. Status Solidi A 2010, 207, 1024–1036. [Google Scholar] [CrossRef]

- Anderson, P.A.; Swartz, C.H.; Carder, D.; Reeves, R.J.; Durbin, S.M.; Chandril, S.; Myers, T.H. Buried p-type layers in Mg-doped InN. Appl. Phys. Lett. 2006, 89, 184104. [Google Scholar] [CrossRef]

- Mayer, M.A.; Choi, S.; Bierwagen, O.; Smith, H.M.; Haller, E.E.; Speck, J.S.; Walukiewicz, W. Electrical and optical properties of p-type InN. J. Appl. Phys. 2011, 110, 123707. [Google Scholar] [CrossRef]

- Wang, X.; Che, S.-B.; Ishitani, Y.; Yoshikawa, A. Growth and properties of Mg-doped In-polar InN films. Appl. Phys. Lett. 2007, 90, 201913. [Google Scholar] [CrossRef]

- Khan, N.; Nepal, N.; Sedhain, A.; Lin, J.Y.; Jiang, H.X. Mg acceptor level in InN epilayers probed by photoluminescence. Appl. Phys. Lett. 2007, 91, 012101. [Google Scholar] [CrossRef]

- Wang, X.; Che, S.-B.; Ishitani, Y.; Yoshikawa, A. Hole mobility in Mg-doped p-type InN films. Appl. Phys. Lett. 2008, 92, 132108. [Google Scholar] [CrossRef]

- Wang, K.; Miller, N.; Iwamoto, R.; Yamaguchi, T.; Mayer, M.A.; Araki, T.; Nanishi, Y.; Yu, K.M.; Haller, E.E.; Walukiewicz, W.; et al. Mg doped InN and confirmation of free holes in InN. Appl. Phys. Lett. 2011, 98, 042104. [Google Scholar] [CrossRef]

- Ager, J.W.; Miller, N.; Jones, R.E.; Yu, K.M.; Wu, J.; Schaff, W.J.; Walukiewicz, W. Mg-doped InN and InGaN—Photoluminescence, capacitance–voltage and thermopower measurements. Phys. Status Solidi B 2008, 245, 873–877. [Google Scholar] [CrossRef]

- Wang, X.; Che, S.-B.; Ishitani, Y.; Yoshikawa, A. Systematic study on p-type doping control of InN with different Mg concentrations in both In and N polarities. Appl. Phys. Lett. 2007, 91, 242111. [Google Scholar] [CrossRef]

- Dmowski, L.H.; Baj, M.; Suski, T.; Przybytek, J.; Czernecki, R.; Wang, X.; Yoshikawa, A.; Lu, H.; Schaff, W.J.; Muto, D.; et al. Search for free holes in InN:Mg-interplay between surface layer and Mg-acceptor doped interior. J. Appl. Phys. 2009, 105, 123713. [Google Scholar] [CrossRef]

- Dmowski, L.H.; Baj, M.; Konczewicz, L.; Suski, T.; Maude, D.K.; Grzanka, S.; Wang, X.Q.; Yoshikawa, A. Coexistence of free holes and electrons in InN:Mg with In- and N-growth polarities. J. Appl. Phys. 2012, 111, 093719. [Google Scholar] [CrossRef]

- Li, S.; Zhang, T.; Wu, J.; Yang, Y.; Wang, Z.; Wu, Z.; Chen, Z.; Jiang, Y. Polarization induced hole doping in graded AlxGa1−xN (x = 0.7~1) layer grown by molecular beam epitaxy. Appl. Phys. Lett. 2013, 102, 062108. [Google Scholar] [CrossRef]

- Kinoshita, T.; Obata, T.; Yanagi, H.; Inoue, S.-I. High p-type conduction in high-Al content Mg-doped AlGaN. Appl. Phys. Lett. 2013, 102, 012105. [Google Scholar] [CrossRef]

- Nakarmi, M.L.; Nepal, N.; Ugolini, C.; Altahtamouni, T.M.; Lin, J.Y.; Jiang, H.X. Correlation between optical and electrical properties of Mg-doped AlGaN epilayers. Appl. Phys. Lett. 2006, 89, 152120. [Google Scholar] [CrossRef]

- Allerman, A.A.; Crawford, M.H.; Miller, M.A.; Lee, S.R. Growth and characterization of Mg-doped AlGaN–AlN short-period superlattices for deep-UV optoelectronic devices. J. Cryst. Growth 2010, 312, 756–761. [Google Scholar] [CrossRef]

- Waldron, E.L.; Graff, J.W.; Schubert, E.F. Improved mobilities and resistivities in modulation-doped p-type AlGaN/GaN superlattices. Appl. Phys. Lett. 2001, 79, 2737. [Google Scholar] [CrossRef]

- Liao, Y.; Kao, C.-K.; Thomidis, C.; Moldawer, A.; Woodward, J.; Bhattarai, D.; Moustakas, T.D. Recent progress of efficient deep UV-LEDs by plasma-assisted molecular beam epitaxy. Phys. Status Solidi C 2012, 9, 798–801. [Google Scholar] [CrossRef]

- Zhang, Y.; Krishnamoorthy, S.; Johnson, J.M.; Akyol, F.; Allerman, A.; Moseley, M.W.; Armstrong, A.; Hwang, J.; Rajan, S. Interband tunneling for hole injection in III-nitride ultraviolet emitters. Appl. Phys. Lett. 2015, 106, 141103. [Google Scholar] [CrossRef]

- Zhao, S.; Mi, Z. Al (Ga) N Nanowire Deep Ultraviolet Optoelectronics. Semicond. Semimet. 2017, 96, 167–199. [Google Scholar]

- Nakarmi, M.L.; Kim, K.H.; Khizar, M.; Fan, Z.Y.; Lin, J.Y.; Jiang, H.X. Electrical and optical properties of Mg-doped Al0.7Ga0.3N alloys. Appl. Phys. Lett. 2005, 86, 092108. [Google Scholar] [CrossRef]

- Gunning, B.P.; Fabien, C.A.M.; Merola, J.J.; Clinton, E.A.; Doolittle, W.A.; Wang, S.; Fischer, A.M.; Ponce, F.A. Comprehensive study of the electronic and optical behavior of highly degenerate p-type Mg-doped GaN and AlGaN. J. Appl. Phys. 2015, 117, 045710. [Google Scholar] [CrossRef]

- Taniyasu, Y.; Kasu, M.; Makimoto, T. An aluminium nitride light-emitting diode with a wavelength of 210 nanometres. Nature 2006, 441, 325–328. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Nguyen, H.P.T.; Kibria, M.G.; Mi, Z. III-nitride nanowire optoelectronics. Prog. Quantum Electron. 2015, 44, 14–68. [Google Scholar] [CrossRef]

- Glas, F. Critical dimensions for the plastic relaxation of strained axial heterostructures in free-standing nanowires. Phys. Rev. B 2006, 74, 121302. [Google Scholar] [CrossRef]

- Zhao, S.; Connie, A.T.; Dastjerdi, M.H.; Kong, X.H.; Wang, Q.; Djavid, M.; Sadaf, S.; Liu, X.D.; Shih, I.; Guo, H.; et al. Aluminum nitride nanowire light emitting diodes: Breaking the fundamental bottleneck of deep ultraviolet light sources. Sci. Rep. 2015, 5, 8332. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Le, B.H.; Liu, D.P.; Liu, X.D.; Kibria, M.G.; Szkopek, T.; Guo, H.; Mi, Z. p-Type InN nanowires. Nano Lett. 2013, 13, 5509–5513. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Fathololoumi, S.; Bevan, K.H.; Liu, D.P.; Kibria, M.G.; Li, Q.; Wang, G.T.; Guo, H.; Mi, Z. Tuning the surface charge properties of epitaxial InN nanowires. Nano Lett. 2012, 12, 2877–2882. [Google Scholar] [CrossRef] [PubMed]

- Perea, D.E.; Hemesath, E.R.; Schwalbach, E.J.; Lensch-Falk, J.L.; Voorhees, P.W.; Lauhon, L.J. Direct measurement of dopant distribution in an individual vapour-liquid-solid nanowire. Nat. Nanotechnol. 2009, 4, 315–319. [Google Scholar] [CrossRef] [PubMed]

- Allen, J.E.; Perea, D.E.; Hemesath, E.R.; Lauhon, L.J. Nonuniform nanowire doping profiles revealed by quantitative scanning photocurrent microscopy. Adv. Mater. 2009, 21, 3067–3072. [Google Scholar] [CrossRef]

- Xie, P.; Hu, Y.; Fang, Y.; Huang, J.; Lieber, C.M. Diameter-dependent dopant location in silicon and germanium nanowires. Proc. Natl. Acad. Sci. USA 2009, 106, 15254–15258. [Google Scholar] [CrossRef] [PubMed]

- Bertness, K.; Roshko, A.; Mansfield, L.; Harvey, T.; Sanford, N. Mechanism for spontaneous growth of GaN nanowires with molecular beam epitaxy. J. Cryst. Growth 2008, 310, 3154–3158. [Google Scholar] [CrossRef]

- Plante, M.C.; LaPierre, R.R. Growth mechanisms of GaAs nanowires by gas source molecular beam epitaxy. J. Cryst. Growth 2006, 286, 394–399. [Google Scholar] [CrossRef]

- Zhao, S.; Woo, S.Y.; Bugnet, M.; Liu, X.; Kang, J.; Botton, G.A.; Mi, Z. Three-dimensional quantum confinement of charge carriers in self-organized AlGaN nanowires: A viable route to electrically injected deep ultraviolet lasers. Nano Lett. 2015, 15, 7801–7807. [Google Scholar] [CrossRef] [PubMed]

- Belloeil, M.; Gayral, B.; Daudin, B. Quantum dot-like behavior of compositional fluctuations in AlGaN nanowires. Nano Lett. 2016, 16, 960–966. [Google Scholar] [CrossRef] [PubMed]

- Pierret, A.; Bougerol, C.; Murcia-Mascaros, S.; Cros, A.; Renevier, H.; Gayral, B.; Daudin, B. Growth, structural and optical properties of AlGaN nanowires in the whole composition range. Nanotechnology 2013, 24, 115704. [Google Scholar] [CrossRef] [PubMed]

- Mi, Z.; Zhao, S.; Woo, S.Y.; Bugnet, M.; Djavid, M.; Liu, X.; Kang, J.; Kong, X.; Ji, W.; Guo, H.; et al. Molecular beam epitaxial growth and characterization of Al(Ga)N nanowire deep ultraviolet light emitting diodes and lasers. J. Phys. D Appl. Phys. 2016, 49, 364006. [Google Scholar] [CrossRef]

- Djavid, M.; Mi, Z. Enhancing the light extraction efficiency of AlGaN deep ultraviolet light emitting diodes by using nanowire structures. Appl. Phys. Lett. 2016, 108, 051102. [Google Scholar] [CrossRef]

- Le, B.H.; Zhao, S.; Liu, X.; Woo, S.Y.; Botton, G.A.; Mi, Z. Controlled coalescence of AlGaN nanowire arrays: An architecture for nearly dislocation-free planar ultraviolet photonic device applications. Adv. Mater. 2016, 28, 8446–8454. [Google Scholar] [CrossRef] [PubMed]

- Kishino, K.; Hoshino, T.; Ishizawa, S.; Kikuchi, A. Selective-area growth of GaN nanocolumns on titanium-mask-patterned silicon (111) substrates by RF-plasma-assisted molecular-beam epitaxy. Electron. Lett. 2008, 44, 819–821. [Google Scholar] [CrossRef]

- Kametani, T.; Kamimura, J.; Inose, Y.; Kunugita, H.; Kikuchi, A.; Kishino, K.; Ema, K. Fundamental optical properties of InN grown by epitaxial lateral overgrowth method. AIP Conf. Proc. 2013, 1566, 107–108. [Google Scholar]

- Ishizawa, S.; Kishino, K.; Araki, R.; Kikuchi, A.; Sugimoto, S. Optically pumped green (530–560 nm) stimulated emissions from InGaN/GaN multiple-quantum-well triangular-lattice nanocolumn arrays. Appl. Phys. Express 2011, 4, 055001. [Google Scholar] [CrossRef]

- Bertness, K.A.; Sanders, A.W.; Rourke, D.M.; Harvey, T.E.; Roshko, A.; Schlager, J.B.; Sanford, N.A. Controlled nucleation of GaN nanowires grown with molecular beam epitaxy. Adv. Funct. Mater. 2010, 20, 2911–2915. [Google Scholar] [CrossRef]

- Gacevic, Z.; Gomez Sanchez, D.; Calleja, E. Formation mechanisms of GaN nanowires grown by selective area growth homoepitaxy. Nano Lett. 2015, 15, 1117–1121. [Google Scholar] [CrossRef] [PubMed]

- Albert, S.; Bengoechea-Encabo, A.; Sánchez-García, M.A.; Kong, X.; Trampert, A.; Calleja, E. Selective area growth of In(Ga)N/GaN nanocolumns by molecular beam epitaxy on GaN-buffered Si(111): From ultraviolet to infrared emission. Nanotechnology 2013, 24, 175303. [Google Scholar] [CrossRef] [PubMed]

- Bengoechea-Encabo, A.; Barbagini, F.; Fernandez-Garrido, S.; Grandal, J.; Ristic, J.; Sanchez-Garcia, M.A.; Calleja, E.; Jahn, U.; Luna, E.; Trampert, A. Understanding the selective area growth of GaN nanocolumns by MBE using Ti nanomasks. J. Cryst. Growth 2011, 325, 89–92. [Google Scholar] [CrossRef] [Green Version]

- Kamimura, J.; Kishino, K.; Kikuchi, A. Dislocation reduction via selective-area growth of InN accompanied by lateral growth by RF-plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett. 2010, 97, 141913. [Google Scholar]

- Kamimura, J.; Kishino, K.; Kikuchi, A. Photoluminescence properties of selectively grown inn microcrystals. Phys. Status Solidi (RRL)-Rapid Res. Lett. 2012, 6, 157–159. [Google Scholar] [CrossRef]

- Schumann, T.; Gotschke, T.; Limbach, F.; Stoica, T.; Calarco, R. Selective-area catalyst-free MBE growth of GaN nanowires using a patterned oxide layer. Nanotechnology 2011, 22, 095603. [Google Scholar] [CrossRef] [PubMed]

- Kishino, K.; Sekiguchi, H.; Kikuchi, A. Improved ti-mask selective-area growth (SAG) by RF-plasma-assisted molecular beam epitaxy demonstrating extremely uniform GaN nanocolumn arrays. J. Cryst. Growth 2009, 311, 2063–2068. [Google Scholar] [CrossRef]

- Yamano, K.; Kishino, K.; Sekiguchi, H.; Oto, T.; Wakahara, A.; Kawakami, Y. Novel selective area growth (SAG) method for regularly arranged AlGaN nanocolumns using nanotemplates. J. Cryst. Growth 2015, 425, 316–321. [Google Scholar] [CrossRef]

- Schafer-Nolte, E.O.; Stoica, T.; Gotschke, T.; Limbach, F.A.; Sutter, E.; Sutter, P.; Grutzmacher, D.; Calarco, R. Enhanced light scattering of the forbidden longitudinal optical phonon mode studied by micro-raman spectroscopy on single InN nanowires. Nanotechnology 2010, 21, 315702. [Google Scholar] [CrossRef] [PubMed]

- Cuscó, R.; Domènech-Amador, N.; Artús, L.; Gotschke, T.; Jeganathan, K.; Stoica, T.; Calarco, R. Probing the electron density in undoped, Si-doped, and Mg-doped InN nanowires by means of raman scattering. Appl. Phys. Lett. 2010, 97, 221906. [Google Scholar] [CrossRef]

- Le, B.H.; Zhao, S.; Tran, N.H.; Mi, Z. Electrically injected near-infrared light emission from single InN nanowire p-i-n diode. Appl. Phys. Lett. 2014, 105, 231124. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, X.; Mi, Z. Photoluminescence properties of Mg-doped InN nanowires. Appl. Phys. Lett. 2013, 103, 203113. [Google Scholar] [CrossRef]

- Klochikhin, A.; Davydov, V.; Emtsev, V.; Sakharov, A.; Kapitonov, V.; Andreev, B.; Lu, H.; Schaff, W. Acceptor states in the photoluminescence spectra of n-InN. Phys. Rev. B 2005, 71, 195207. [Google Scholar] [CrossRef]

- Fang, Z.; Robin, E.; Rozas-Jimenez, E.; Cros, A.; Donatini, F.; Mollard, N.; Pernot, J.; Daudin, B. Si donor incorporation in GaN nanowires. Nano Lett. 2015, 15, 6794–6801. [Google Scholar] [CrossRef] [PubMed]

- Le, B.H.; Zhao, S.; Tran, N.H.; Szkopek, T.; Mi, Z. On the fermi-level pinning of InN grown surfaces. Appl. Phys. Express 2015, 8, 061001. [Google Scholar] [CrossRef]

- Ma, N.; Wang, X.Q.; Liu, S.T.; Chen, G.; Pan, J.H.; Feng, L.; Xu, F.J.; Tang, N.; Shen, B. Hole mobility in wurtzite InN. Appl. Phys. Lett. 2011, 98, 192114. [Google Scholar] [CrossRef]

- Stoica, T.; Meijers, R.J.; Calarco, R.; Richter, T.; Sutter, E.; Lueth, H. Photoluminescence and intrinsic properties of MBE-grown InN nanowires. Nano Lett. 2006, 6, 1541–1547. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Calleja, E.; Grandal, J.; Sánchez-García, M.A.; Niebelschütz, M.; Cimalla, V.; Ambacher, O. Evidence of electron accumulation at nonpolar surfaces of InN nanocolumns. Appl. Phys. Lett. 2007, 90, 262110. [Google Scholar] [CrossRef]

- Hu, H.; Wu, Z.; Zhang, W.; Li, H.; Zhuo, R.; Yan, D.; Wang, J.; Yan, P. Effect of Mg doping on growth and photoluminescence of AlN hexagonal nanorods. J. Alloys Compd. 2015, 624, 241–246. [Google Scholar] [CrossRef]

- Hui, Y.Y.; Ye, J.; Lortz, R.; Teng, K.S.; Lau, S.P. Magnetic properties of Mg-doped AlN zigzag nanowires. Phys. Status Solidi A 2012, 209, 1988–1992. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, N.; Zhang, Y.; Qian, W.; Wang, X.; Hu, Z. Tuning the field emission properties of AlN nanocones by doping. J. Mater. Chem. C 2015, 3, 1113–1117. [Google Scholar] [CrossRef]

- Xu, Y.; Yao, B.; Liu, D.; Lei, W.; Zhu, P.; Cui, Q.; Zou, G. Room temperature ferromagnetism in new diluted magnetic semiconductor AlN:Mg nanowires. CrystEngComm 2013, 15, 3271–3274. [Google Scholar] [CrossRef]

- Tang, Y.B.; Bo, X.H.; Xu, J.; Cao, Y.L.; Chen, Z.H.; Song, H.S.; Liu, C.P.; Hung, T.F.; Zhang, W.J.; Cheng, H.-M.; et al. Tunable p-type conductivity and transport properties of AlN nanowires via Mg doping. ACS Nano 2011, 5, 3591–3598. [Google Scholar] [CrossRef] [PubMed]

- Landré, O.; Fellmann, V.; Jaffrennou, P.; Bougerol, C.; Renevier, H.; Cros, A.; Daudin, B. Molecular beam epitaxy growth and optical properties of AlN nanowires. Appl. Phys. Lett. 2010, 96, 061912. [Google Scholar] [CrossRef]

- Zhao, S.; Djavid, M.; Mi, Z. A surface emitting, high efficiency near-vacuum ultraviolet light source with aluminum nitride nanowires monolithically grown on silicon. Nano Lett. 2015, 15, 7006–7009. [Google Scholar] [CrossRef] [PubMed]

- Connie, A.T.; Zhao, S.; Sadaf, S.M.; Shih, I.; Mi, Z.; Du, X.; Lin, J.; Jiang, H. Optical and electrical properties of Mg-doped AlN nanowires grown by molecular beam epitaxy. Appl. Phys. Lett. 2015, 106, 213105. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, S.; Connie, A.T.; Shih, I.; Mi, Z.; Gonzalez, T.; Andrews, M.P.; Du, X.Z.; Lin, J.Y.; Jiang, H.X. Optical properties of strain-free AlN nanowires grown by molecular beam epitaxy on Si substrates. Appl. Phys. Lett. 2014, 104, 223107. [Google Scholar] [CrossRef]

- Tran, N.H.; Le, B.H.; Zhao, S.; Mi, Z. On the mechanism of highly efficient p-type conduction of Mg-doped ultra-wide-bandgap AlN nanostructures. Appl. Phys. Lett. 2017, 110, 032102. [Google Scholar] [CrossRef]

- Molnar, R.J.; Lei, T.; Moustakas, T.D. Electron transport mechanism in gallium nitride. Appl. Phys. Lett. 1993, 62, 72–74. [Google Scholar] [CrossRef]

- Sadaf, S.M.; Zhao, S.; Wu, Y.; Ra, Y.H.; Liu, X.; Vanka, S.; Mi, Z. An AlGaN core-shell tunnel junction nanowire light-emitting diode operating in the ultraviolet-C band. Nano Lett. 2017, 17, 1212–1218. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Woo, S.Y.; Sadaf, S.M.; Wu, Y.; Pofelski, A.; Laleyan, D.A.; Rashid, R.T.; Wang, Y.; Botton, G.A.; Mi, Z. Molecular beam epitaxy growth of Al-rich AlGaN nanowires for deep ultraviolet optoelectronics. APL Mater. 2016, 4, 086115. [Google Scholar] [CrossRef]

- Zhao, S.; Sadaf, S.M.; Vanka, S.; Wang, Y.; Rashid, R.; Mi, Z. Sub-milliwatt AlGaN nanowire tunnel junction deep ultraviolet light emitting diodes on silicon operating at 242 nm. Appl. Phys. Lett. 2016, 109, 201106. [Google Scholar] [CrossRef]

- Li, K.H.; Liu, X.; Wang, Q.; Zhao, S.; Mi, Z. Ultralow-threshold electrically injected AlGaN nanowire ultraviolet lasers on Si operating at low temperature. Nat. Nanotechnol. 2015, 10, 140–144. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Liu, X.; Woo, S.Y.; Kang, J.; Botton, G.A.; Mi, Z. An electrically injected AlGaN nanowire laser operating in the ultraviolet-C band. Appl. Phys. Lett. 2015, 107, 043101. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, X.; Wu, Y.; Mi, Z. An electrically pumped 239 nm AlGaN nanowire laser operating at room temperature. Appl. Phys. Lett. 2016, 109, 191106. [Google Scholar] [CrossRef]

- Stoica, T.; Sutter, E.; Meijers, R.J.; Debnath, R.K.; Calarco, R.; Luth, H.; Grutzmacher, D. Interface and wetting layer effect on the catalyst-free nucleation and growth of GaN nanowires. Small 2008, 4, 751–754. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.L.; Li, F.; Fatehi, A.; Mi, Z. Molecular beam epitaxial growth and characterization of non-tapered InN nanowires on Si(111). Nanotechnology 2009, 20, 345203. [Google Scholar] [CrossRef] [PubMed]

- Knelangen, M.; Consonni, V.; Trampert, A.; Riechert, H. In situ analysis of strain relaxation during catalyst-free nucleation and growth of GaN nanowires. Nanotechnology 2010, 21, 245705. [Google Scholar] [CrossRef] [PubMed]

- Landre, O.; Bougerol, C.; Renevier, H.; Daudin, B. Nucleation mechanism of GaN nanowires grown on (111) Si by molecular beam epitaxy. Nanotechnology 2009, 20, 415602. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Kibria, M.G.; Wang, Q.; Nguyen, H.P.T.; Mi, Z. Growth of large-scale vertically aligned GaN nanowires and their heterostructures with high uniformity on SiOx by catalyst-free molecular beam epitaxy. Nanoscale 2013, 5, 5283–5287. [Google Scholar] [CrossRef] [PubMed]

- Ristić, J.; Calleja, E.; Fernández-Garrido, S.; Cerutti, L.; Trampert, A.; Jahn, U.; Ploog, K.H. On the mechanisms of spontaneous growth of III-nitride nanocolumns by plasma-assisted molecular beam epitaxy. J. Cryst. Growth 2008, 310, 4035–4045. [Google Scholar] [CrossRef] [Green Version]

- Consonni, V.; Hanke, M.; Knelangen, M.; Geelhaar, L.; Trampert, A.; Riechert, H. Nucleation mechanisms of self-induced GaN nanowires grown on an amorphous interlayer. Phys. Rev. B 2011, 83, 035310. [Google Scholar] [CrossRef]

- May, B.J.; Sarwar, A.T.M.G.; Myers, R.C. Nanowire LEDs grown directly on flexible metal foil. Appl. Phys. Lett. 2016, 108, 141103. [Google Scholar] [CrossRef]

- Sarwar, A.T.; Carnevale, S.D.; Yang, F.; Kent, T.F.; Jamison, J.J.; McComb, D.W.; Myers, R.C. Semiconductor nanowire light-emitting diodes grown on metal: A direction toward large-scale fabrication of nanowire devices. Small 2015, 11, 5402–5408. [Google Scholar] [CrossRef] [PubMed]

- Janjua, B.; Sun, H.; Zhao, C.; Anjum, D.H.; Priante, D.; Alhamoud, A.A.; Wu, F.; Li, X.; Albadri, A.M.; Alyamani, A.Y.; et al. Droop-free AlxGaN1-xN/AlyGaN1-yN quantum-disks-in-nanowires ultraviolet LED emitting at 337 nm on metal/silicon substrates. Opt. Express 2017, 25, 1381–1390. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Ng, T.K.; Wei, N.; Prabaswara, A.; Alias, M.S.; Janjua, B.; Shen, C.; Ooi, B.S. Facile formation of high-quality InGaN/GaN quantum-disks-in-nanowires on bulk-metal substrates for high-power light-emitters. Nano Lett. 2016, 16, 1056–1063. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Ng, T.K.; ElAfandy, R.T.; Prabaswara, A.; Consiglio, G.B.; Ajia, I.A.; Roqan, I.S.; Janjua, B.; Shen, C.; Eid, J.; et al. Droop-free, reliable, and high-power InGaN/GaN nanowire light-emitting diodes for monolithic metal-optoelectronics. Nano Lett. 2016, 16, 4616–4623. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, S.; Mi, Z. Recent Advances on p-Type III-Nitride Nanowires by Molecular Beam Epitaxy. Crystals 2017, 7, 268. https://doi.org/10.3390/cryst7090268

Zhao S, Mi Z. Recent Advances on p-Type III-Nitride Nanowires by Molecular Beam Epitaxy. Crystals. 2017; 7(9):268. https://doi.org/10.3390/cryst7090268

Chicago/Turabian StyleZhao, Songrui, and Zetian Mi. 2017. "Recent Advances on p-Type III-Nitride Nanowires by Molecular Beam Epitaxy" Crystals 7, no. 9: 268. https://doi.org/10.3390/cryst7090268