Thickness Study of Er-Doped Magnesium Zinc Oxide Diode by Spray Pyrolysis

Abstract

:1. Introduction

2. Experimental

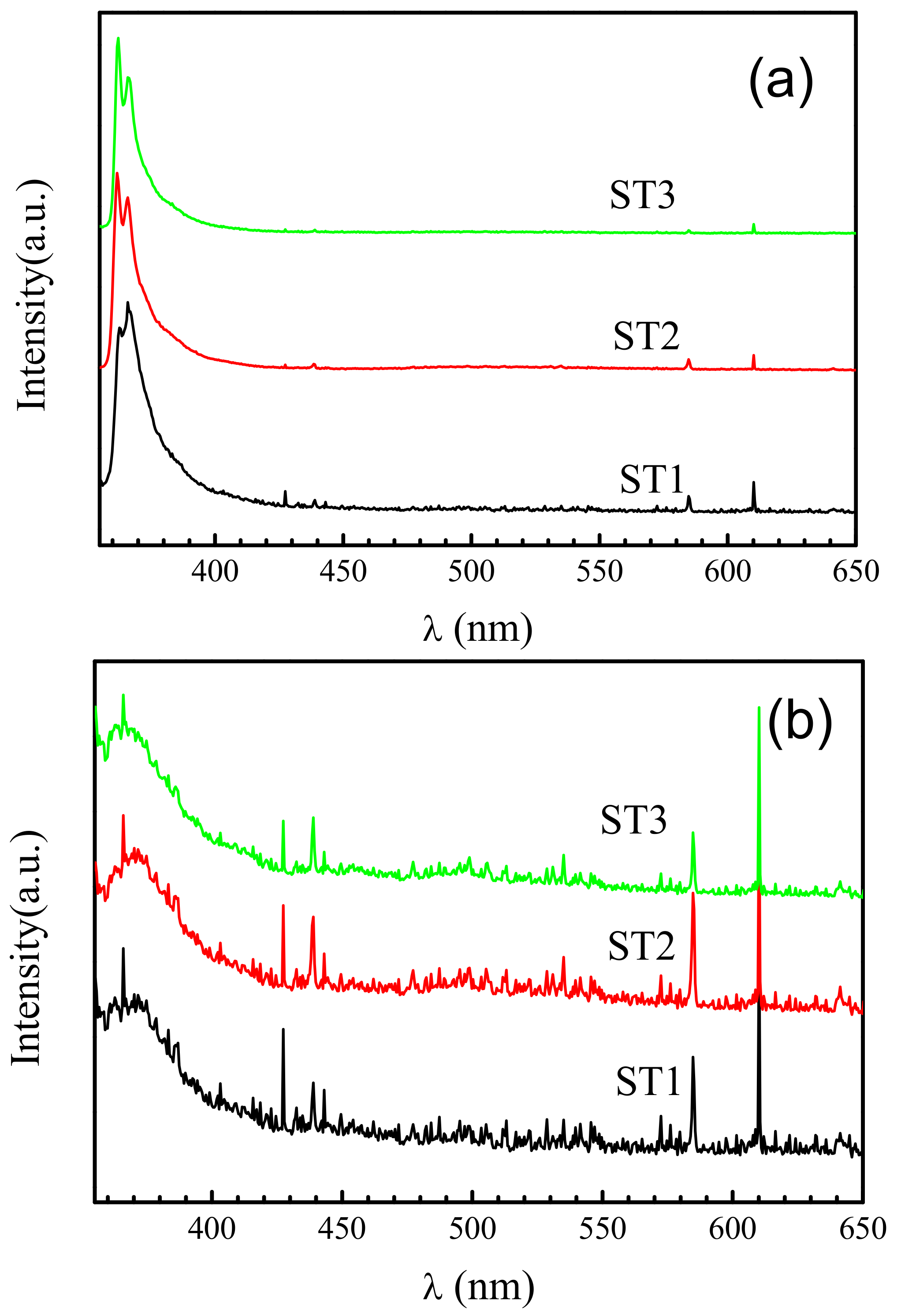

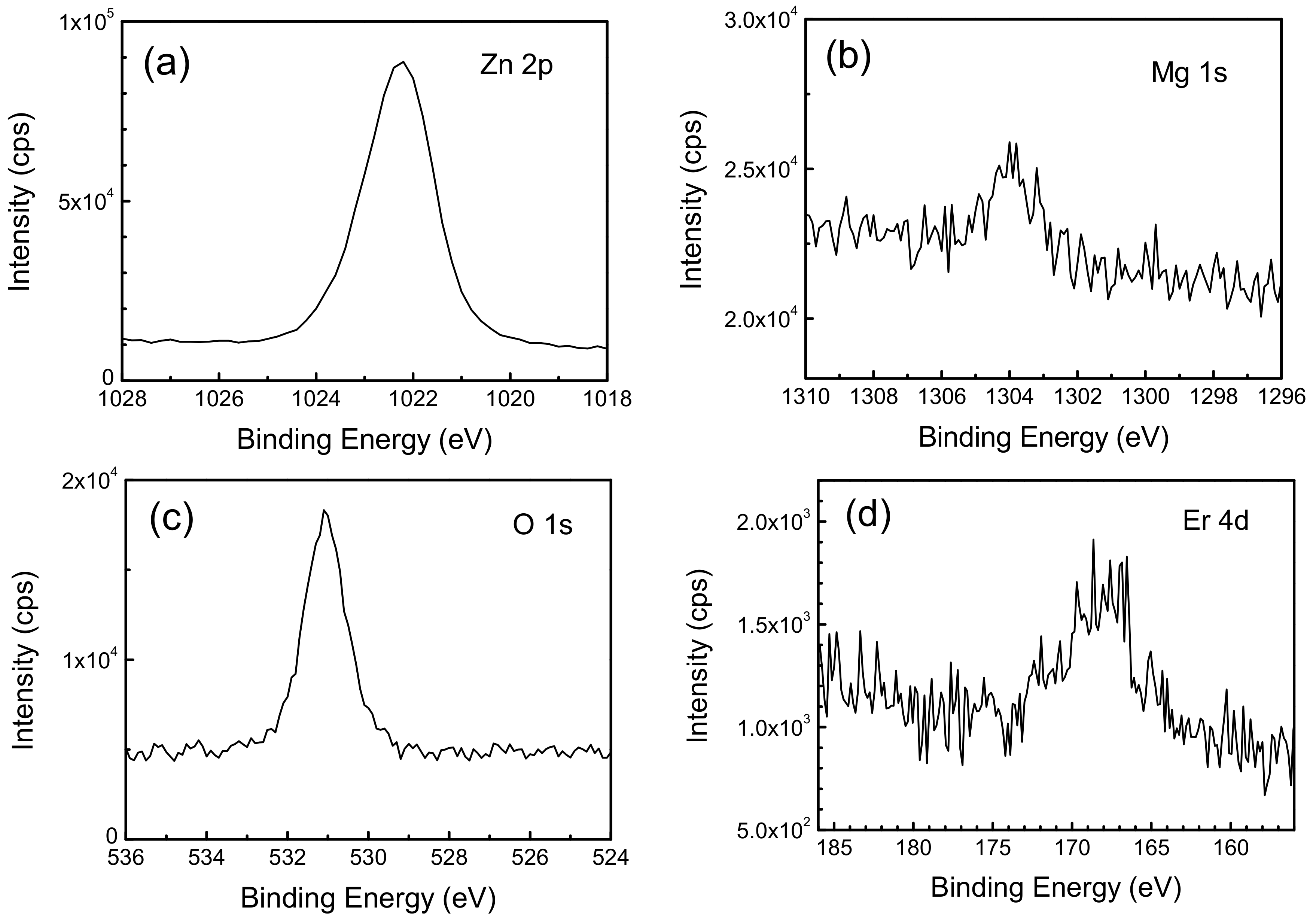

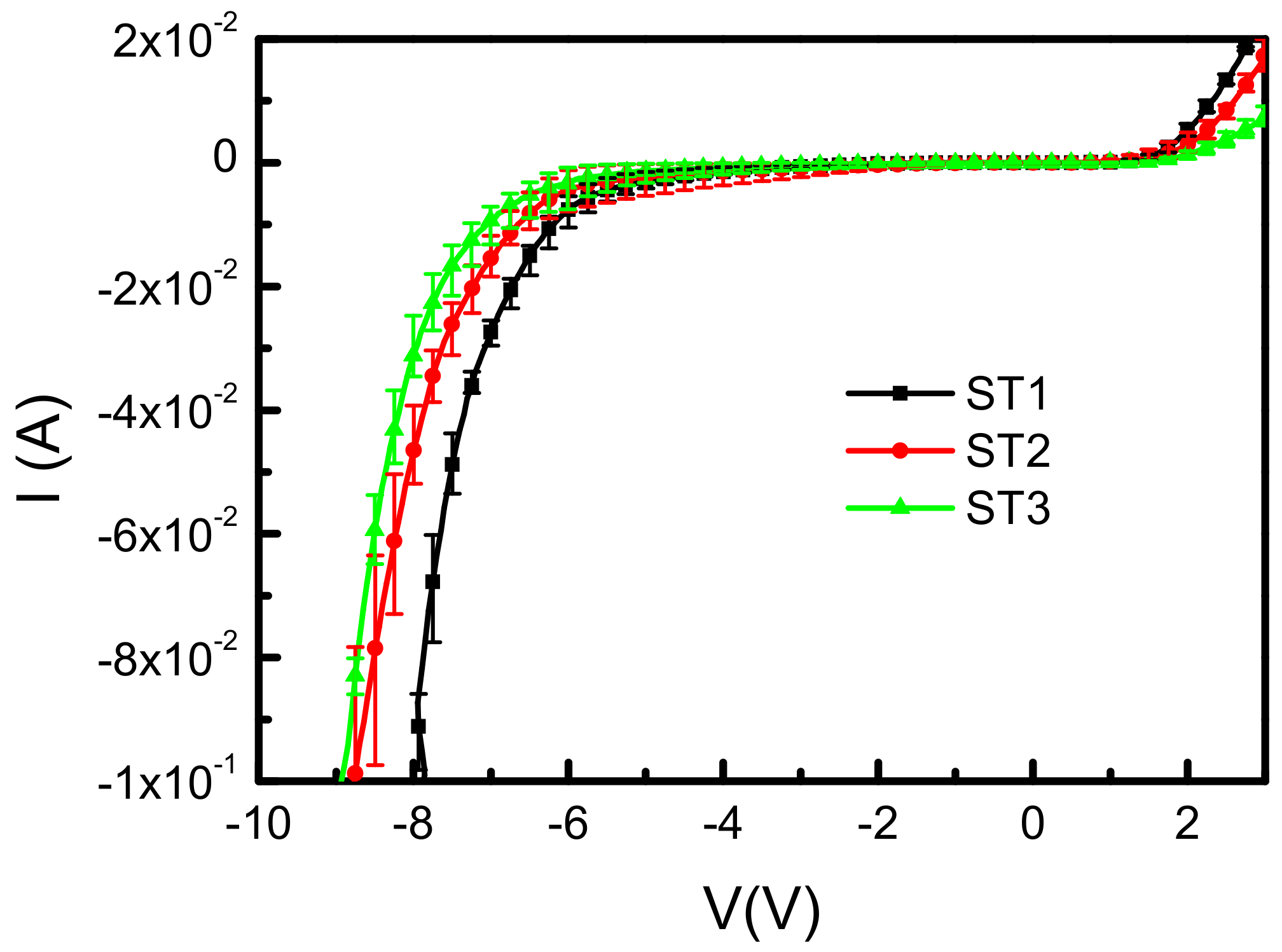

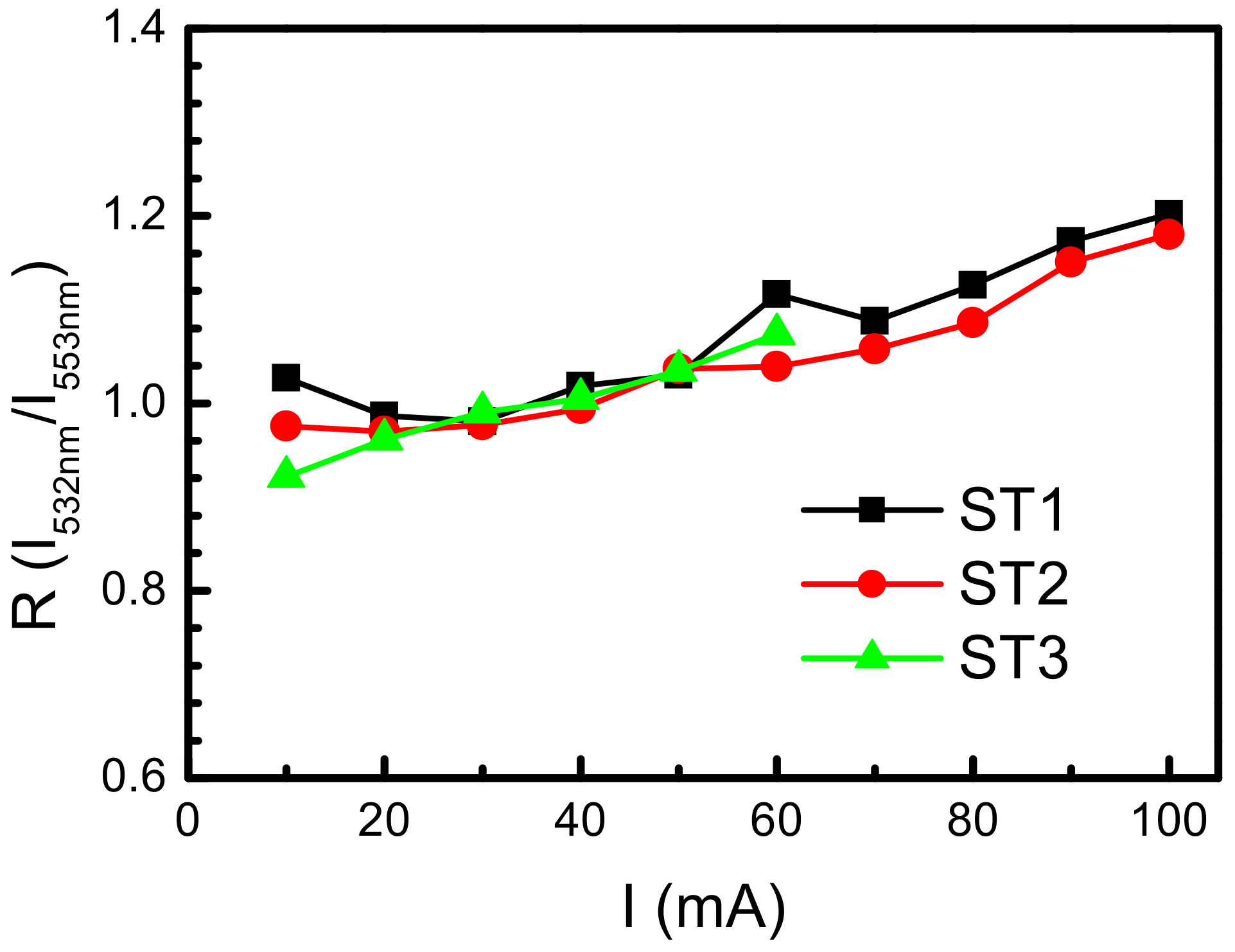

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gapontsev, V.P.; Matitsin, S.M.; Isineev, A.A.; Kravchenko, V.B. Erbium glass lasers and their applications. Opt. Laser Technol. 1982, 14, 189–196. [Google Scholar] [CrossRef]

- Kamik, S.A.; Chandrappan, J.; Murray, M.; Steenson, P.; Krauss, T.F.; Jose, G. Ultrafast laser plasma doping of Er3+ ions in silica-on-silicon for optical waveguiding applications. Opt. Lett. 2016, 41, 4684–4687. [Google Scholar]

- Irrera, A.; Miritello, M.; Pacifici, D.; Franzo, G.; Priolo, F.; Iacona, F.; Sanfilippo, D.; di Stefano, G.; Fallica, P.G. Electroluminescence properties of SiOx layers implanted with rare earth ions. Nucl. Instrum. Methods Phys. Res. B 2004, 216, 222–227. [Google Scholar] [CrossRef]

- Nakamura, K.; Takemoto, S.; Terai, Y.; Suzuki, M.; Koizumi, A.; Takeda, Y.; Tonouchi, M.; Fujiwara, Y. Direct observation of trapping of photo-excited carriers in Er, O-codoped GaAs. Phys. B 2006, 376–377, 556–559. [Google Scholar] [CrossRef]

- Fujiwara, Y.; Koizumi, A.; Urakami, A.; Yoshikane, T.; Inoue, K.; Takeda, Y. Room temperature 1.5 μm electroluminescnence from GaInP/Er,O-codoped GaAs/GaInP double heterostructure injection-type light emitting diodes grown by organometallic vapor phase epitaxy. Mater. Sci. Eng. B 2003, 105, 57–60. [Google Scholar] [CrossRef]

- Dahal, R.; Lin, J.Y.; Jiang, H.X.; Zavada, J.M. Room temperature 1.5 μm electroluminescnence from GaInP/Er,O-codoped GaAs/GaInP double heterostructure injection-type light emitting diodes grown by organometallic vapor phase epitaxy. Opt. Mater. 2011, 33, 1066–1070. [Google Scholar] [CrossRef]

- Nyk, M.; Kuzmin, A.; Prasad, P.N.; Strek, W.; de Araújo, C. Red up-conversion emission from nanocrystalline GaN powders co-doped with Er3+ and Yb3+. Opt. Mater. 2009, 31, 800–804. [Google Scholar] [CrossRef]

- Li, S.; Ye, S.; Liu, T.; Wang, H.; Wang, D. Enhanced up-conversion emissions in ZnO-LiYbO2: RE3+ (RE= Er or Ho) hybrid phosphors through surface modification. J. Alloy. Compd. 2016, 658, 85–90. [Google Scholar] [CrossRef]

- Iwan, S.; Bambang, S.; Zhao, J.L.; Tan, S.T.; Fan, H.M.; Sun, L.; Zhang, S.; Ryu, H.H.; Sun, X.W. Green electroluminescence from an n-ZnO: Er/p-Si heterostructured light-emitting diode. Phys. B 2012, 407, 2721–2724. [Google Scholar] [CrossRef]

- Saito, S.; Hashimoto, R.; Hwang, J.; Nunoue, S. InGaN Light-Emitting Diodes on c-Face Sapphire Substrates in Green Gap Spectral Range. Appl. Phys. Express 2003, 6, 111004. [Google Scholar] [CrossRef]

- Zubia, J.; Arrue, J. Plastic Optical Fibers: An Introduction to Their Technological Processes and Applications. Opt. Fiber Technol. 2001, 7, 101–140. [Google Scholar] [CrossRef]

- Jambois, O.; Berencen, Y.; Hijazi, K.; Wojdak, M.; Kenyon, A.J.; Gourbilleau, F.; Rizk, R.; Garrido, B. Current transport and electroluminesc ence mechanisms in thin SiO2 films containing Si nanocluster-sensitized erbium ions. J. Appl. Phys. 2009, 106, 063526. [Google Scholar] [CrossRef] [Green Version]

- Breitenstein, O.; Bauer, J.; Wagner, J.M.; Zakharov, N.; Blumtritt, H.; Lotnyk, A.; Kasemann, M.; Kwapil, W.; Warta, W. Defect-Induced Breakdown in Multicrystalline Silicon Solar Cells. IEEE Trans. Elec. Dev. 2010, 57, 2227–2234. [Google Scholar] [CrossRef]

- Kizilyalli, I.C.; Edwards, A.P.; Nie, H.; Disney, D.; Bour, D. High Voltage Vertical GaN p-n Diodes with Avalanche Capability. IEEE Trans. Elec. Dev. 2013, 60, 3067–3070. [Google Scholar] [CrossRef]

- Shan, F.K.; Kim, B.I.; Liu, G.X.; Liu, Z.F.; Sohn, J.Y.; Lee, W.J.; Shin, B.C.; Yu, Y.S. Blueshift of near band edge emission in Mg doped ZnO thin films and aging. J. Appl. Phys. 2004, 95, 4772–4776. [Google Scholar] [CrossRef]

- Chi, C.T.; Cheng, I.C.; Chen, J.Z. Bandgap tuning of MgZnO in flexible transparent n+-ZnO:Al/n-MgZnO/p-CuAlOx:Ca diodes on polyethylene terephthalate substrates. J. Alloy. Compd. 2012, 544, 111–114. [Google Scholar] [CrossRef]

- Perez-Casero, R.; Gutiérrez-Llorente, A.; Pons-Y-Moll, O.; Seiler, W.; Defourneau, R.M.; Millon, E.; Perriere, J.; Goldner, P.; Viana, B. Er-doped ZnO thin films grown by pulsed-laser deposition. J. Appl. Phys. 2005, 97, 054905. [Google Scholar] [CrossRef]

- Lautenschlaeger, S.; Eisermann, S.; Meyer, B.K.; Callison, G.; Wagner, M.R.; Hoffmann, A. Nitrogen incorporation in homoepitaxial ZnO CVD epilayers. Phys. Status Solidi RRL 2009, 3, 16–18. [Google Scholar] [CrossRef]

- Ogata, K.; Sakurai, K.; Fujita, S.; Matsushige, K. Effects of thermal annealing of ZnO layers grown by MBE. J. Cryst. Growth 2000, 214–215, 312–315. [Google Scholar] [CrossRef]

- Inamdar, S.I.; Rajpure, K.Y. High-performance metal–semiconductor–metal UV photodetector based on spray deposited ZnO thin films. J. Alloy. Compd. 2014, 595, 55–59. [Google Scholar] [CrossRef]

- Allah, F.K.; Abe, S.Y.; Nunez, C.M.; Khelil, A.; Cattin, L.; Morsli, M.; Bernede, J.C.; Bougrine, A.; del Valle, M.A.; Diaz, F.R. Characterisation of porous doped ZnO thin films deposited by spray pyrolysis technique. Appl. Surf. Sci. 2007, 253, 9241–9247. [Google Scholar] [CrossRef]

- Lin, T.H.; Lan, W.H.; Shih, M.C.; Wang, M.C.; Chang, K.J.; Lin, J.C.; Lee, S.Y.; Lin, W.J.; Huang, C.J. Resistance Study of Er-doped Zinc Oxide Diode by Spray Pyrolysis. Sens. Mater. 2018, 30, 939–946. [Google Scholar]

- Zhao, J.L.; Li, X.M.; Zhang, S.; Yang, C.; Gao, X.D.; Yu, W.D. Highly (002)-oriented ZnO film grown by ultrasonic spray pyrolysis on ZnO-seeded Si (100) substrate. J. Mater. Res. 2006, 21, 2185–2190. [Google Scholar] [CrossRef]

- Morrison, J.L.; Huso, J.; Hoeck, H.; Casey, E.; Mitchell, J.; Bergman, L.; Norton, M.G. Optical properties of ZnO and MgZnO nanocrystals below and at the phase separation Range. J. Appl. Phys. 2008, 104, 123519. [Google Scholar] [CrossRef]

- Jayachandraiah, C.; Krishnaiah, G. Erbium induced raman studies and dielectric properties of Er-doped ZnO nanoparticles. Adv. Mater. Lett. 2015, 6, 743–748. [Google Scholar] [CrossRef]

- Shiau, J.S.; Brahma, S.; Liu, C.P.; Huang, J.L. Ultraviolet photodetectors based on MgZnO thin film grown by RF magnetron sputtering. Thin Solid Films 2016, 620, 170–174. [Google Scholar] [CrossRef]

- Chen, F.H.; Her, J.L.; Shao, Y.H.; Matsuda, Y.H.; Pan, T.M. Structural and electrical characteristics of high-k Er2O3 and Er2TiO5 gate dielectrics for a-IGZO thin-film transistors. Nanoscale Res. Lett. 2013, 8, 1–5. [Google Scholar] [CrossRef]

- Shelke, V.; Bhole, M.P.; Patil, D.S. Open air annealing effect on the electrical and optical properties of tin doped ZnO nanostructure. Solid State Sci. 2012, 14, 705–710. [Google Scholar] [CrossRef]

- Wang, X.; Saito, K.; Tanaka, T.; Nishio, M.; Guo, Q. Lower temperature growth of single phase MgZnO films in all Mg content range. J. Alloy. Compd. 2015, 627, 383–387. [Google Scholar] [CrossRef]

- Teke, A.; Ozgur, U.; Dogan, S.; Gu, X.; Morkoc, H.; Nemeth, B.; Nause, J.; Everitt, H.O. Excitonic fine structure and recombination dynamics in single-crystalline ZnO. Phys. Rev. B 2004, 70, 195207. [Google Scholar] [CrossRef]

- Meyer, B.K.; Alves, H.; Hofmann, D.M.; Kriegseis, W.; Forster, D.; Bertram, F.; Christen, J.; Hoffmann, A.; Strabburg, M.; Dworzak, M.; et al. Bound exciton and donor–acceptor pair recombinations in ZnO. Phys. Stat. Sol. (B) 2004, 241, 231–260. [Google Scholar] [CrossRef]

- Yan, W.; Tan, J.; Zhang, W.; Liang, Y.; Feng, S.; Lei, X.; Wang, H. Spray pyrolysis derived ZnMgO:In thin films: Investigation of the structural, optical and electrical properties. Superlattices Microstruct. 2013, 60, 407–413. [Google Scholar] [CrossRef]

- Pal, S.; Rakshit, T.; Singha, S.S.; Asokan, K.; Dutta, S.; Jana, D.; Sarkar, A. Shallow acceptor state in ZnO realized by ion irradiation and annealing route. J. Alloy. Compd. 2017, 703, 26–33. [Google Scholar] [CrossRef]

- RWahyuono, A.; Hermann-Westendorf, F.; Dellith, A.; Schmidt, C.; Dellith, J.; Plentz, J.; Schulz, M.; Presselt, M.; Seyring, M.; Rettenmeyer, M.; et al. Effect of annealing on the sub-bandgap, defects and trapping states of ZnO nanostructures. Chem. Phys. 2017, 483–484, 112–121. [Google Scholar] [CrossRef]

- Varshni, Y.P. Temperature Dependence of the Energy Gap in Semiconductor. Physica 1967, 34, 149–154. [Google Scholar] [CrossRef]

- Wang, L.; Giles, N.C. Temperature dependence of the free-exciton transition energy in zinc oxide by photoluminescence excitation spectroscopy. J. Appl. Phys. 2003, 94, 973–975. [Google Scholar] [CrossRef]

- Zeng, H.; Duan, G.; Li, Y.; Yang, S.; Xu, X.; Cai, W. Blue luminescence of ZnO nanoparticles based on non-equilibrium processes: Defect origins and emission controls. Adv. Funct. Mater. 2010, 20, 561–572. [Google Scholar] [CrossRef]

- Ellmer, K.; Mientus, R. Carrier transport in polycrystalline transparent conductive oxides: A comparative study of zinc oxide and indium oxide. Thin Solid Films 2008, 516, 4620–4627. [Google Scholar] [CrossRef] [Green Version]

- Yu, C.C.; Lan, W.H.; Huang, K.F. Indium-nitrogen co-doped zinc oxide thin film deposited by ultrasonic spray pyrolysis on n-(111) Si substrate: The effect of film thickness. J. Nanomater. 2014, 2014, 861234. [Google Scholar] [CrossRef]

- Elleuch, R.; Salhi, R.; Maalej, N.; Deschanvres, J.L.; Maalej, R. Structural and luminescence correlation of annealed Er-ZnO/Si thin films deposited by AACVD process. Mater. Sci. Eng. B 2013, 178, 1124–1129. [Google Scholar] [CrossRef]

- Lee, C.; Chen, C.A.; Lai, C.Y.; Lin, W.J.; Chang, K.J.; Feng, D.J.Y.; Shih, M.C.; Wang, M.C.; Lan, W.H. Photoluminescence Study of Annealed MgZnO:Er Diode. In Proceedings of the Optics & Photonics Taiwan, International Conference (OPTIC) 2018, Tainan, Taiwan, 6–8 December 2018. [Google Scholar]

- Kumar, P.; Sharma, V.; Sarwa, A.; Kumar, A.; Surbhi; Goyal, R.; Sachdev, K.; Annapoorni, S.; Asokan, K.; Kanjilal, D. Understanding the origin of ferromagnetism in Erdoped ZnO system. RSC Adv. 2016, 6, 89242–89249. [Google Scholar] [CrossRef]

- Harako, S.; Yokoyama, S.; Ide, K.; Zhao, X.; Komoro, S. Visible and infrared electroluminescence from an Er-doped n-ZnO/p-Si light emitting diode. Phys. Stat. Sol. (A) 2008, 205, 19–22. [Google Scholar] [CrossRef]

- Wei, X.Q.; Man, B.Y.; Liu, M.; Xue, C.S.; Zhuang, H.Z.; Yang, C. Blue luminescent centers and microstructural evaluation by XPS and Raman in ZnO thin films annealed in vacuum, N2 and O2. Phys. B 2007, 388, 145–152. [Google Scholar] [CrossRef]

- Wang, M.; Jiang, L.; Kim, E.J.; Hahn, S.H. Electronic structure and optical properties of Zn(OH)2: LDA+U calculations and intense yellow Luminescence. RSC Adv. 2015, 5, 87496–87503. [Google Scholar] [CrossRef]

- Corneille, J.S.; He, J.W.; Goodmanm, D.W. XPS characterization of ultra-thin MgO films on a Mo(100) surface. Surf. Sci. 1994, 306, 269–278. [Google Scholar] [CrossRef]

- Coppa, B.J.; Davis, R.F.; Nemanich, R.J. Gold Schottky contacts on oxygen plasma-treated, n-type ZnO(0001-). Appl. Phys. Lett. 2003, 82, 400–403. [Google Scholar] [CrossRef]

- Fred Schubert, E. Light-Emitting Diodes, 2nd ed.; Cambridge University Press: New York, NY, USA, 2006; pp. 64–65. [Google Scholar]

- Shah, J.M.; Li, Y.L.; Gessmann, T.; Schubert, E.F. Experimental analysis and theoretical model for anomalously high ideality factors (n>>2.0) in AlGaN/GaN pn junction diodes. J. Appl. Phys. 2003, 94, 2627–2629. [Google Scholar] [CrossRef]

- Sah, C.T.; Noyce, R.N.; Shockley, W. Carrier generation and recombination in pn junctions and pn junction characteristics. Proc. IRE 1957, 45, 1228–1243. [Google Scholar] [CrossRef]

- Zebbar, N.; Kheireddine, Y.; Mokeddem, K.; Hafdallah, A.; Kechouane, M.; Aida, M.S. Structural, optical and electrical properties of n-ZnO/p-Si heterojunction prepared by ultrasonic spray. Mater. Sci. Semicond. Process. 2011, 14, 229–234. [Google Scholar] [CrossRef]

- Zhu, D.; Xu, J.; Noemaun, A.N.; Kim, J.K.; Schubert, E.F.; Crawford, M.H.; Koleske, D.D. The origin of the high diode-ideality factors in GaInN/GaN multiple quantum well light-emitting diodes. Appl. Phys. Lett. 2009, 94, 081113. [Google Scholar] [CrossRef] [Green Version]

- Langer, J.M.; Lemanska-Bajorek, A.; Suchocki, A. A method of excitation profiling in high-field electroluminescence. Appl. Phys. Lett. 1981, 39, 386–388. [Google Scholar] [CrossRef]

- Franzo, G.; Coffa, S.; Priolo, F.; Spinella, C. Mechanism and performance of forward and reverse bias electroluminescence at 1.54 μm from Er-doped Si diodes. J. Appl. Phys. 1997, 81, 2784–2793. [Google Scholar] [CrossRef]

- Prucnal, S.; Rebohle, L.; Skorupa, W. Electroluminescence from Er and Yb co-doped silicon dioxide layers: The excitation mechanism. J. Non-Cryst. Solids 2011, 357, 915–918. [Google Scholar] [CrossRef]

- Polman, A. Erbium as a probe of everything? Phys. B 2001, 300, 78–90. [Google Scholar] [CrossRef]

- Kim, H.; Yang, H.; Huh, C.; Kim, S.W.; Park, S.J.; Hwang, H. Electromigration-induced failure of GaN multi-quantum well light emitting diode. Electron. Lett. 2000, 36, 908–910. [Google Scholar] [CrossRef]

- Figge, S.; Bottcher, T.; Hommel, D.; Zellweger, C.; Ilegems, M. Heat generation and dissipation in GaN-based light emitting devices. Phys. Stat. Sol. (A) 2003, 200, 83–86. [Google Scholar] [CrossRef]

| Sample | n | Rs (Ω) |

|---|---|---|

| ST1 | 6.4 ± 0.9 | 38 ± 8 |

| ST2 | 6.1 ± 0.8 | 33 ± 6 |

| ST3 | 7.2 ± 0.6 | 107 ± 6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, Y.-T.; Lee, C.-C.; Lan, W.-H.; Huang, K.-F.; Chang, K.-J.; Lin, J.-C.; Lee, S.-Y.; Lin, W.-J.; Wang, M.-C.; Huang, C.-J. Thickness Study of Er-Doped Magnesium Zinc Oxide Diode by Spray Pyrolysis. Crystals 2018, 8, 454. https://doi.org/10.3390/cryst8120454

Hsu Y-T, Lee C-C, Lan W-H, Huang K-F, Chang K-J, Lin J-C, Lee S-Y, Lin W-J, Wang M-C, Huang C-J. Thickness Study of Er-Doped Magnesium Zinc Oxide Diode by Spray Pyrolysis. Crystals. 2018; 8(12):454. https://doi.org/10.3390/cryst8120454

Chicago/Turabian StyleHsu, Yu-Ting, Che-Chi Lee, Wen-How Lan, Kai-Feng Huang, Kuo-Jen Chang, Jia-Ching Lin, Shao-Yi Lee, Wen-Jen Lin, Mu-Chun Wang, and Chien-Jung Huang. 2018. "Thickness Study of Er-Doped Magnesium Zinc Oxide Diode by Spray Pyrolysis" Crystals 8, no. 12: 454. https://doi.org/10.3390/cryst8120454