1. Introduction

The coating industry has always been searching for technological improvements, to achieve greater efficiency, productivity, and lower cost. There are significant contributions that have been made by the resin industry and its ancillaries, particularly, to improve the curing rates and film properties. A coating system without a solvent would be cheaper in cost and more environment-friendly. Thus, radiation curing techniques offer many advantages, such as an energy-saving, VOC (volatile organic compounds) free, and fast curing cycle. One pack UV-curable resin system is a rapidly growing technology within the coating, adhesive, and related industries. It has found a large variety of applications, due to its high efficiency, environment-friendliness, and energy-saving nature [

1,

2,

3]. The main components in the UV-curable formulation are the unsaturated oligomer, active diluents, and photoinitiator.

Most commercial UV-curable formulations are based on a combination of acrylic oligomers and monomers [

4,

5], urethane acrylate [

6,

7] polyester acrylate [

8], and epoxy acrylate [

9,

10]. Properties of the UV-curable coatings are determined by the type of oligomers employed in the formulation. Currently, most available resins are petroleum-based and lacking in natural materials and sustainability.

Depletion of petroleum reserves and increasing environmental concerns have stimulated the revolution to explore materials from readily-available, renewable, and inexpensive natural resources, such as carbohydrates, oils, fats, and proteins. These renewable materials are going to play noteworthy roles in the development of a sustainable green chemistry. Oils and fats of vegetable and animal origins have been the renewable materials for the coating and ink industry.

Elaeis guineensis is a palm plant that produces fruit with a high oil-yield in Malaysia. It is grown commercially and has been an important crop that contributes to the economy of the country. About 90% of the palm oil is used for food, and about 10% for non-edible products, such as soaps and detergents. Traditional vegetable oils like linseed, soybean, and castor oils have been commercially used for the synthesis of alkyds, epoxides, and polyesteramides [

11]. Less commonly, the cashew nut, karanja, annona squamosa, natural rubber seeds have also been investigated for producing polyurethane, polyesteramide, and alkyd resins [

12,

13]. Recently, there were several reports on palm oil-based resins. For example, an excellent baking enamel was produced from a water-reducible palm stearin alkyd, combined with melamine resin [

14,

15]. The problem of insufficient unsaturation could be overcome through the incorporation of maleic anhydride or fumaric acid into the alkyd structures, to make them UV-curable [

16,

17]. Further exploration of palm oil derivatives has produced many new coating resins that have various film properties [

18,

19,

20,

21]. In 2014, a US patent was granted for a palm oil-based polyurethane oligomer for use as a restorative dental material [

22].

Crude palm oil consists of about 94% triglycerides, 3–5% of free fatty acids, and about 1% of other minor constituents. The palm fatty acid distillate (PFAD) is a by-product of the crude palm oil refining process. It comprises mainly of free fatty acids, with around 45% palmitic and 33% oleic acid, as the major components, and it has been used in the making of soap and animal feed, and certain oleochemicals. Small amount of Vitamin E could be extracted from the PFAD [

23]. Gapor has developed a process for producing high purity (>90%) Squalene from the PFAD [

24]. This valuable compound is useful in heath supplements, cosmetics, and in the pharmaceutical industry. In a recent study, the PFAD has been explored as biodiesel feed stock [

25]. Many studies utilize various types of catalysts, such as SO

42−/TiO

2-SiO

2, and modified Zirconia compounds [

25,

26,

27]. Malaysian palm oil refineries produce more than 750,000 MT of PFAD, annually, as a by-product, which sold at a discounted price, as compared to the RBD (Refined, Bleached and Deodorized) palm oil, at USD200–250 per metric ton, for usage in animal feed [

28,

29]. There are yet no reports of its application in coating.

Similar to any other coating technologies, wood coating is one of the important segments in the coating industry that focuses on developing more environment-friendly resins, in comparison to traditional solvent-borne coating system. UV-curable resins offer less VOC, lower energy in the curing process, and shorter curing time. The worldwide market for Wood Coating is expected to grow at a compound annual growth rate of roughly 5.9%, over the next five years, and will reach 11,700 million US

$, in 2023, from 8740 million US

$, in 2017 [

30]. Malaysia, as one of the ten largest furniture exporters, has provided a very good economic base for the wood coating industry development. Modernization of architectural designs, including furniture, has driven the increasing need for improved aesthetic appeal of furniture and other wooden products, making wood coating a very important part of the woodworking industry. In addition, the material needs to be protected against mechanical, physical, and chemical attack. The available technologies include waterborne coatings, high-solids, and UV-cured coatings. There is a noticeable move from the solvent-borne coatings to solvent-free or solvent-reduced materials, driven by the environmental and regulatory demands. Other than conventional waterborne technologies where acrylate/vinyl emulsions are the main binder used, the solvent-borne technology has involved many types of alkyd resin as the main binder in the three, major coating systems, such as acid catalyzed, nitrocellulose, and polyurethane wood coating system. In a high-solid system, UV-curing is the current trend and the focus of development is to achieve 100% solidity, in a cured coating.

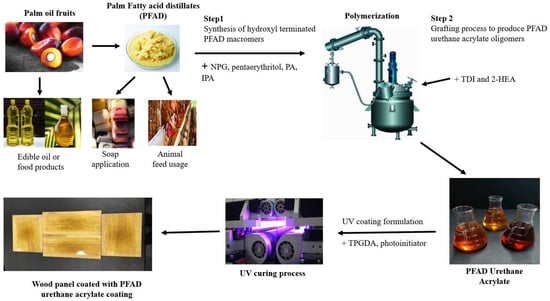

We have investigated the use of PFAD in wood-coating resins. To fulfil the current technology trend of low VOC or no VOC, PFAD-based resins should be extended into high solid or UV-curable resins for wood-coating applications. This project has aimed to synthesize PFAD-based urethane acrylates with different PFAD contents. The urethane acrylates (UA) were investigated as UV-curable resins for wood coating applications.

2. The Experimental Method

2.1. Materials

The PFAD was a kind gift from (Sime Darby Group, Kuala Lumpur, Malaysia). This commercial PFAD was used without further treatment. 2,2-dimethyl-1,3-propanediol (neopentaglycol, NPG) was purchased from (LG Chemicals, Yeosu, Korea), 2,2-bis(hydroxylmethyl)1,3-propanediol (Pentaerythritol) from (Perstop AB, Malmo, Sweden), phthalic anhydride from (Nanya Plastic, Kaohsiung, Taiwan), purified isophthalic acid from (MGC Chemicals, Tokyo, Japan), mono-butyl tin oxide from (Arkema, Colombes, France), toluene diisocyanate (80/20 TDI) from (Covestro AG, Leverkusen, Germany), 2-hydroxy ethyl acrylate (2-HEA) from (BASF, Shah Alam, Malaysia), xylene from (Exxonmobil, Leatherhead, UK), Tripropylene glycol diacarylate (TPGDA), triphenyl phosphine (TPP) and 4-methoxy phenol from (Sigma Aldric Chemicals, Saint Louis, MS, USA), Speedcure 73 (2-hydroxy-2-methylpropiophenone) from (Lambson, Wetherby, UK). Tetrahydrofuran (THF) from (Thermo Fisher Scientific, Waltham, MA, USA). All Chemicals were used as received.

2.2. Synthesis

2.2.1. Synthesis of the PFAD Hydroxyl-Terminated Macromer

A hydroxyl-terminated macromer was first synthesized by one batch reaction of PFAD, isophthalic acid, phthalic anhydride, neopentagylcol, and pentaerythritol. The procedure is a modified process that had been described elsewhere [

30].

PEAD and Neopentaglycol were charged into a 2 L round-bottom flask, fitted with a decanter, and stirrer. The mixture was heated slowly to 100 °C, until all of the material melted, and subsequently pentaerythritol, isophthalic acid, phthalic anhydride, and mono-butyl tin oxide were added. Maintaining stirring at 250 rpm, the temperature was raised, gradually, and water from the condensation reactions that evolved above 180 °C, was trapped and removed from the decanter. Temperature was raised and maintained at 235–240 °C. Progress of the reaction was monitored by measuring the acid value and viscosity of a small sample taken from the reactor, at different reaction intervals. The sample was diluted with xylene to an 80% solid content, before its viscosity was measured by the Brookefield viscometer (model DVI). Acid value was determined by titrating a known weight of the sample with a standardized NaOH solution, according to the ASTM (American Society for Testing and Materials) D4662-93 Method. When the acid value had fallen below 10 mgKOH/g, heating was turned off and allowed to cool down to 100 °C, before the PFAD macromer was transferred to a storage container and diluted with TPGDA, to a 70% solid content and kept for further use. Five macromers were synthesized with a PFAD content of 15%, 25%, 45%, 55%, and 70%, respectively, the recipes of the reactions are as shown in

Table 1.

2.2.2. PFAD Urethane Acrylate Oligomer (UA)

The PFAD urethane acrylate oligomer was synthesized via the reactions of the PFAD macromers (M1–M5) with 2HEA and TDI. The procedure is as follows. The TDI (95.9 g) was charged into a four-necked flask equipped with a mechanical stirrer, dropping funnel, thermometer, and a nitrogen inlet. The flask was thermostated to 35 °C in a water bath. The 2HEA (63.4 g) and 0.1 g of the 4-methoxyphenol were mixed in a separate flask and the mixture dosed into the flask, dropwise, over a period of 2 h. The progress of the reaction could be checked by both the FTIR spectrum and by determining the isocyanate value through titration. When the isocyanate content had reduced to half of the initial value, the –OH peak in the FTIR spectrum would have disappeared, and the specified amount of the PFAD macromer was charged into the reaction mixture. The temperature was raised to 97 °C to accelerate the reaction, which was stopped when the residual isocyanate content had dropped to less than 0.05%. Then 64.0 g of the TPGDA was added and the final resin was ready for further evaluation.

Table 2 summarizes the compositions of the urethane acrylic oligomers UA1, UA2, UA3, UA4, and UA5 prepared from the PFAD macromers M1, M2, M3, M4, and M5, respectively.

2.2.3. UV-Curable Formulation

The UV curable formulations were prepared by mixing the urethane acrylic oligomer (UA) at 80.00% (w/w), Speedcure 73 at 3.00% (w/w), and 17.00% (w/w) TPGDA.

2.3. Characterization

2.3.1. Molecular Weight Measurement

Molecular weights of the samples were measured by a Gel permeation chromatography (GPC) (Shimadzu, Kyoto, Japan) with tetrahydrofuran as the mobile phase (set at 1.0 mL min−1). Monodisperse polystyrene standards were used for the calibration of the column.

2.3.2. FTIR Analysis

FTIR spectra were recorded by using the ATR technique on a Perkim Elmer Spectrum Two FTIR spectrometer (Perkin Elmer, Waltham, MA, UAS). The polymer was coated directly onto the ATR diamond plate and the spectrum was recorded.

2.3.3. Viscosity Measurement

A Brookefield viscometer (model DVI) was used to measure the sample dynamic viscosity at a temperature of 25 °C. A sample of macromer was diluted to 70% of the oligomer content, with TPGDA, before viscosity measurement.

2.3.4. Glass Transition Temperature

To determine the Tg of the resin and the cured film, samples were encapsulated in a 40 μL aluminum pan and analyzed using the Shimadzu DSC (model DSC-60), at a heating rate of 20 °C min−1.

2.3.5. Pendulum Hardness

The hardness of the UV-cured film was measured with the Sheen Konig pendulum hardness tester (TQCSHEEN, Capelle aan den IJssel, Netherlands), according to ATSM 4366.

2.3.6. Acid Value, Isocyanate Value, and Hydroxyl Value

The resin acidity (acid value), isocyanate value, and hydroxyl value were determined by the standard titration method, according to the ASTM D4662-93, ISO 14896/3, and ASTM D1957-86 (2001), respectively.

2.3.7. Gloss Measurement

The gloss of the cured film was measured with the BYK tri-gloss meter, according to the ASTM D523, for non-metallic substrate. The gloss level was reported as the gloss unit (GU).

2.3.8. Adhesion

The film adhesion was performed according to the ASTM D3359-09 test method B. The adhesion performance was rated as shown in

Table 3.

2.3.9. Pencil Hardness

The hardness of the cured film was measured by the pencil hardness, according to ASTM D3363. The pencil hardness scale is as follow, where 6B denotes the softest and 6H being the hardest: Pencil Hardness Scale: 6B-5B-4B-3B-2B-B-HB-F-H-2H-3H-4H-5H-6H.

2.4. Monitoring of the UV Curing

UV curing was carried out by casting the formulated UA resin, using a bar coater of 20 µm, onto a glass panel. The film was then irradiated with UV light at a distance of 10 cm, from the source, for the specified exposure time, for 5 to 60 s. The UV light was provided by a mercury vapor lamp with an intensity of 225 mW/cm2, at a UV wavelength of 254–365 nm. The extent of cure at each instant, was correlated to the hardness and the Tg of the film.

2.5. Chemical Resistance of the Cured Film

The cured films were subject to the wood-coating standards of the chemical resistance test. The coating was applied on a rubber wood panel and cured by irradiation, with a UV light, for 60 s. The cured panel was conditioned at room temperature, for 1 h, before carrying out the chemical resistance test. Ten milliliter of chemical reagent was dropped onto the film surface and allowed to stand for 24 h; to minimize the evaporation of the reagent, it was covered with a plastic cap. The reagent was then wiped off with a dry clean cloth, and the surface was then dried for 15 min, before making observations and reporting. The reagents commonly applied by the Industrial Wood-Coating Standard include coffee, tea, dish washing solution, acetone, cooking oil, 1% ethanol aqueous solution (wt/wt), vinegar (8% acetic acid, v/v), 10% ammonia solution, 5% sodium hydroxide (NaOH) solution (wt/v), and 5% hydrochloric (HCl) solution (w/v).