Aligned P(VDF-TrFE) Nanofibers for Enhanced Piezoelectric Directional Strain Sensing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of the P(VDF-TrFE) Nanofibers

2.3. Analysis of Morphology and Crystallinity

2.4. Measurement of the Piezoelectricity

3. Results and Discussion

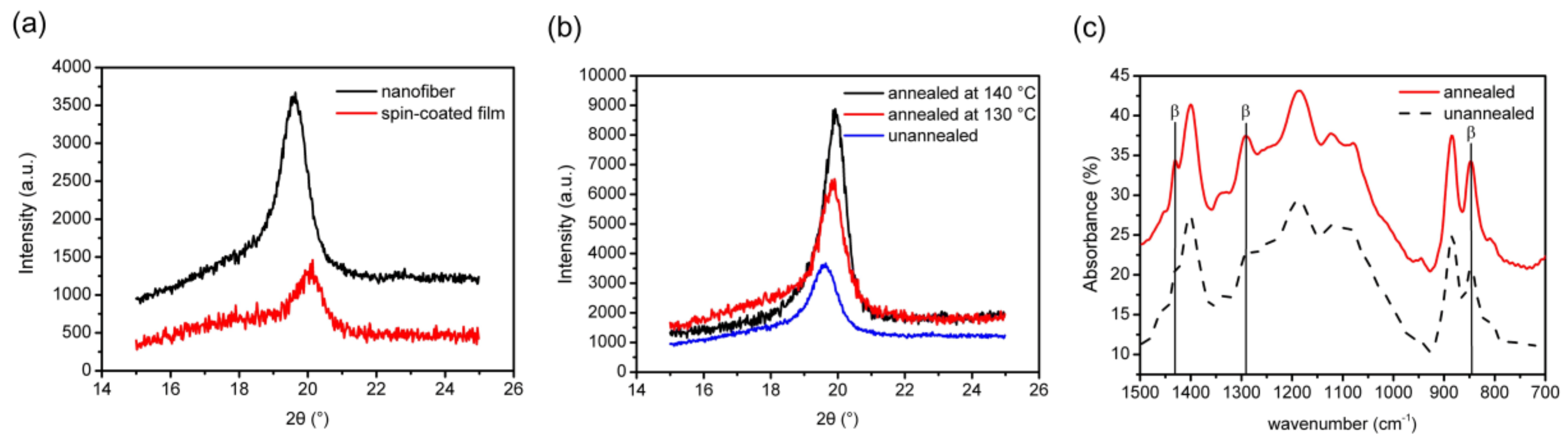

3.1. Morphologies and Crystallinities of P(VDF-TrFE) Nanofibers

3.2. PFM Characterization of the P(VDF-TrFE) Nanofiber

3.3. Piezoelectric Out in the Longitudinal Direction

3.4. Directional Strain Sensing by Aligned Nanofibers Mats

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Briscoe, J.; Dunn, S. Piezoelectric nanogenerators—A review of nanostructured piezoelectric energy harvesters. Nano Energy 2015, 14, 15–29. [Google Scholar] [CrossRef]

- Espinosa, H.D.; Bernal, R.A.; Minary-Jolandan, M. A review of mechanical and electromechanical properties of piezoelectric nanowires. Adv. Mater. 2012, 24, 4656–4675. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Zhu, G.; Yang, R.; Wang, A.C.; Wang, Z.L. Muscle-driven in vivo nanogenerator. Adv. Mater. 2010, 22, 2534–2537. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S.; Shin, K.Y.; Cheong, O.J.; Kim, J.H.; Jang, J. Highly sensitive and multifunctional tactile sensor using free-standing ZnO/PVDF thin film with graphene electrodes for pressure and temperature monitoring. Sci. Rep. 2015, 5, 7887. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.H.; Kahya, O.; Sharma, B.K.; Kwon, J.; Cho, H.J.; Özyilmaz, B.; Ahn, J.H. Graphene-P(VDF-TrFE) Multilayer Film for Flexible Applications. ACS Nano 2013, 7, 3130–3138. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Ma, Z.; Fu, J.; Zhang, D. Development of a Flexible Artificial Lateral Line Canal System for Hydrodynamic Pressure Detection. Sensors 2017, 17, 1220. [Google Scholar] [CrossRef] [PubMed]

- Pi, Z.; Zhang, J.; Wen, C.; Zhang, Z.; Wu, D. Flexible piezoelectric nanogenerator made of poly (vinylidenefluoride-co-trifluoroethylene) (PVDF-TrFE) thin film. Nano Energy 2014, 7, 33–41. [Google Scholar] [CrossRef]

- Cho, Y.; Park, J.B.; Kim, B.S.; Lee, J.; Hong, W.K.; Park, I.K.; Jang, J.E.; Sohn, J.I.; Cha, S.N.; Kim, J.M. Enhanced energy harvesting based on surface morphology engineering of P(VDF-TrFE) film. Nano Energy 2015, 16, 524–532. [Google Scholar] [CrossRef]

- Bhavanasi, V.; Kumar, V.; Parida, K.; Wang, J.; Lee, P.S. Enhanced Piezoelectric Energy Harvesting Performance of Flexible PVDF-TrFE Bilayer Films with Graphene Oxide. ACS Appl. Mater. Interfaces 2016, 8, 521–529. [Google Scholar] [CrossRef] [PubMed]

- Zabek, D.; Taylor, J.; Boulbar, E.L.; Bowen, C.R. Micropatterning of Flexible and Free Standing Polyvinylidene Difl uoride (PVDF) Films for Enhanced Pyroelectric Energy Transformation. Adv. Energy Mater. 2015, 5, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Asadnia, M.; Kottapalli, A.G.P.; Karavitaki, K.D.; Warkiani, M.E.; Miao, J.; Corey, D.P. From Biological Cilia to Artificial Flow Sensors: Biomimetic Soft Polymer Nanosensors with High Sensing Performance. Sci. Rep. 2016, 6, 32955. [Google Scholar] [CrossRef] [PubMed]

- Lang, C.; Fang, J.; Shao, H.; Ding, X.; Lin, T. High-sensitivity acoustic sensors from 311 nanofibre webs. Nat. Commun. 2016, 7, 11108. [Google Scholar] [CrossRef] [PubMed]

- Fuh, Y.K.; Ye, J.C.; Chen, P.C.; Huang, Z.M. A highly flexible and substrate-independent self- powered deformation sensor based on massively aligned piezoelectric nano-microfibers. J. Mater. Chem. A 2014, 2, 16101–16106. [Google Scholar] [CrossRef]

- Huang, T.; Wang, C.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. Human walking-driven wearable all-fiber triboelectric nanogenerator containing electrospun polyvinylidene fluoride piezoelectric nanofiber. Nano Energy 2015, 14, 226–235. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Ho, H.C. Highly flexible self-powered sensors based on printed circuit board technology for human motion detection and gesture recognition. Nanotechnology 2016, 27, 95401. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Tian, H.; Li, X.; Shao, J.; Ding, Y.; An, N.; Zhou, Y. A high performance P(VDF-TrFE) nanogenerator with self-connected and vertically integrated fibers by patterned EHD pulling. Nanoscale 2015, 7, 11536–11544. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Han, M.; Chen, H.; Cheng, X.; Song, Y.; Su, Z.; Jiang, Y.; Zhang, H. A wave-shaped hybrid piezoelectric and triboelectric nanogenerator based on P(VDF-TrFE) nanofiber. Nanoscale 2017, 9, 1263–1270. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Song, Y.; Su, Z.; Chen, H.; Cheng, X.; Zhang, J.; Han, M.; Zhang, H. Flexible fiber-based hybrid nanogenerator for biomechanical energy harvesting and physiological monitoring. Nano Energy 2017, 38, 43–50. [Google Scholar] [CrossRef]

- Cui, N.; Gu, L.; Liu, J.; Bai, S.; Qiu, J.; Fu, J.; Kou, X.; Liu, H.; Qin, Y.; Wang, Z.L. High performance sound driven triboelectric nanogenerator for harvesting noise energy. Nano Energy 2015, 15, 321–328. [Google Scholar] [CrossRef]

- Hansen, B.J.; Liu, Y.; Yang, R.; Wang, Z.L. Hybrid nanogenerator for concurrently harvesting biomechanical and biochemical energy. ACS Nano 2010, 4, 3647–3652. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Cheng, L.; Yuan, M.; Wang, Z.; Zhang, L.; Qin, Y.; Jing, T. An electrospun nanowire-based triboelectric nanogenerator and its application in a fully self-powered UV detector. Nanoscale 2014, 6, 7842–7846. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.; Wang, X.; Lin, T. Electrical power generator from randomly oriented electrospun poly(vinylidene fluoride) nanofibre membrane. J. Mater. Chem. 2011, 21, 11088–11091. [Google Scholar] [CrossRef]

- Sun, D.; Chang, C.; Li, S.; Lin, L. Near-field electrospinning. Nano Lett. 2006, 6, 839–842. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.; Tran, V.H.; Wang, J.; Fuh, Y.K.; Lin, L. Direct-Write Piezoelectric Polymeric Nanogenerator with High Energy Conversion Efficienc. Nano Lett. 2010, 10, 726–731. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.T.; Yen, C.K.; Wang, S.Y.; Lai, Y.C.; Lin, L.; Huang, J.C.; Kuo, S.W. Near-field electrospinning enhances the energy harvesting of hollow PVDF piezoelectric fibers. RSC Adv. 2015, 5, 85073–85081. [Google Scholar] [CrossRef]

- Pan, C.T.; Yen, C.K.; Wu, H.C.; Lin, L.; Lu, Y.S.; Huang, J.C.; Kuo, S.W. Significant piezoelectric and energy harvesting enhancement of poly(vinylidene fluoride)/polypeptide fiber composites prepared through near-field electrospinning. J. Mater. Chem. A 2015, 3, 6835–6843. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Chen, S.Y.; Ye, J.C. Massively parallel aligned microfibers-based harvester deposited via in situ, oriented poled near-field electrospinning. Appl. Phys. Lett. 2013, 103, 033114. [Google Scholar] [CrossRef]

- Pan, C.T.; Yen, C.K.; Lin, L.; Lu, Y.S.; Li, H.W.; Huang, J.C.C.; Kuo, S.W. Energy harvesting with piezoelectric poly(g- benzyl-L-glutamate) fibers prepared through cylindrical near-field electrospinning. RSC Adv. 2014, 4, 21563–21570. [Google Scholar] [CrossRef]

- Persano, L.; Dagdeviren, C.; Su, Y.; Zhang, Y.; Girardo, S.; Pisignano, D.; Huang, Y.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 2013, 4, 1633. [Google Scholar] [CrossRef] [PubMed]

- Baniasadi, M.; Huang, J.; Xu, Z.; Moreno, S.; Yang, X.; Chang, J.; Quevedo-Lopez, M.A.; Naraghi, M.; Minary-Jolandan, M. High-performance coils and yarns of polymeric piezoelectric nanofibers. ACS Appl. Mater. Interfaces 2015, 7, 5358–5366. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Lee, K.Y.; Kumar, B.; Tien, N.T.; Lee, N.E.; Kim, S.W. Highly sensitive stretchable transparent piezoelectric nanogenerators. Energy Environ. Sci. 2013, 6, 169–175. [Google Scholar] [CrossRef]

- Mandal, D.; Yoon, S.; Kim, K.J. Origin of Piezoelectricity in an Electrospun Poly(vinylidene fluoride-trifluoroethylene) Nanofiber Web-Based Nanogenerator and Nano-Pressure Sensor. Macromol. Rapid Commun. 2011, 32, 831–837. [Google Scholar] [CrossRef] [PubMed]

- Baniasadi, M.; Xu, Z.; Hong, S.; Naraghi, M.; Minary-Jolandan, M. Thermo-electromechanical Behavior of Piezoelectric Nanofiber. ACS Appl. Mater. Interfaces 2016, 8, 2540–2551. [Google Scholar] [CrossRef] [PubMed]

- Rault, J. Crystallization Process of Polymers: Adsorption and Annealing. Cryst. Polym. 1993, 405, 313–322. [Google Scholar]

- Ryan, T.G.; Calvert, P.D. Diffusion and annealing in crystallizing polymers. Polymer 1982, 23, 877–883. [Google Scholar] [CrossRef]

- Malekmotiei, L.; Voyiadjis, G.Z.; Samadi-Dooki, A. Effect of Annealing Temperature on Interrelation Between the Microstructural Evolution and Plastic Deformation in Polymers. J. Polym. Sci. B Polym. Phys. 2017, 55, 1286–1297. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Pospori, A.; Demirci, G. Fast Bragg Grating Inscription in PMMA Polymer Optical Fibres: Impact of Thermal Pre-Treatment of Preforms. Sensors 2017, 17, 891. [Google Scholar] [CrossRef] [PubMed]

- Acheroy, S.; Merken, P.; Ottevaere, H. Thermal effects on the photoelastic coefficient of polymer optical fibers. Optics Lett. 2016, 41, 2517–2520. [Google Scholar]

- Liu, X.; Ma, J.; Wu, X.M.; Lin, L.W.; Wang, X.H. Polymeric Nanofibers with Ultrahigh Piezoelectricity via Self-Orientation of Nanocrystals. ACS Nano 2017, 11, 1901–1910. [Google Scholar] [CrossRef] [PubMed]

- Ahn, Y.J.; Lim, J.Y.; Hong, S.M.; Lee, J.; Ha, J.; Choi, H.J.; Seo, Y. Enhanced piezoelectric properties of electrospun poly(vinylidene fluoride)/multiwalled carbon nanotube composites due to high β-phase formation in poly(vinylidene fluoride). J. Phys. Chem. C 2013, 117, 11791–11799. [Google Scholar] [CrossRef]

- Kaur, S.; Kumar, A.; Sharma, A.L.; Singh, D.P. Influence of Annealing on Dielectric and Polarization Behavior of PVDF Thick Films. J. Mater. Sci. Mater. Electron. 2017, 28, 8391–8396. [Google Scholar] [CrossRef]

- Jiang, Y.; Shiono, S.; Hamada, H.; Takayuki, F.; Zhang, D.; Maenaka, K. Reactive ion etching of poly(vinylidene fluoride-trifluoroethylene) copolymer for flexible piezoelectric devices. Chin. Sci. Bull. 2013, 58, 2091–2094. [Google Scholar] [CrossRef]

- Noyori, M.; Neo, Y.; Mimura, H. Single-crystalline poly(vinylidene fluoride–trifluoroethylene) nanofiber webs fabricated by electrospinning. Jpn. J. Appl. Phys. 2015, 54, 021601. [Google Scholar] [CrossRef]

- Jiang, Y.; Fu, J.; Zhang, D.; Zhao, Y. Investigation on the lateral line systems of two cavefish: Sinocyclocheilus macrophthalmus and S. microphthalmus (Cypriniformes: Cyprinidae). J. Bionic Eng. 2016, 13, 108–114. [Google Scholar] [CrossRef]

- Van Netten, S.M. Hydrodynamics of the excitation of the cupula in the fish canal lateral line. J. Acoust. Soc. Am. 1991, 89, 310–319. [Google Scholar] [CrossRef]

- Bathellier, B.; Steinmann, T.; Barth, F.G.; Casas, J. Air motion sensing hairs of arthropods detect high frequencies at near-maximal mechanical efficiency. J. R. Soc. Interface 2012, 9, 1131–1143. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Gong, L.; Hu, X.; Zhao, Y.; Chen, H.; Feng, L.; Zhang, D. Aligned P(VDF-TrFE) Nanofibers for Enhanced Piezoelectric Directional Strain Sensing. Polymers 2018, 10, 364. https://doi.org/10.3390/polym10040364

Jiang Y, Gong L, Hu X, Zhao Y, Chen H, Feng L, Zhang D. Aligned P(VDF-TrFE) Nanofibers for Enhanced Piezoelectric Directional Strain Sensing. Polymers. 2018; 10(4):364. https://doi.org/10.3390/polym10040364

Chicago/Turabian StyleJiang, Yonggang, Longlong Gong, Xiaohe Hu, Yong Zhao, Huawei Chen, Lin Feng, and Deyuan Zhang. 2018. "Aligned P(VDF-TrFE) Nanofibers for Enhanced Piezoelectric Directional Strain Sensing" Polymers 10, no. 4: 364. https://doi.org/10.3390/polym10040364