Application of the Products from the Maillard Reaction of Polyglutamic Acid and Glucose to Prepare Colored and Bioactive Silk

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Maillard Reaction of PGA and Glc

2.3. Dyeing of Silk with the PGA/Glc Reaction Products

2.4. Measurements

3. Results and Discussion

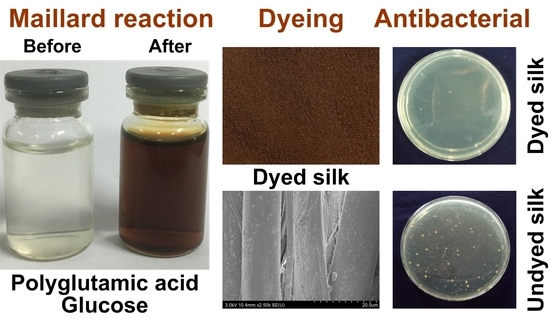

3.1. Maillard Reaction of PGA and Glc

3.2. Characterization of the Maillard Reaction Products

3.3. Dyeing of Silk with the PGA/Glc Reaction Products

3.4. Color Characteristics and Color Fastness of the Dyed Silk

3.5. Morphological Structure of the Dyed Silk

3.6. Antibacterial and Antioxidant Activity of the Dyed Silk

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ames, J.M. Applications of the Maillardreaction in the food industry. Food Chem. 1998, 62, 431–439. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Qian, H.; Yao, W.-R. Melanoidins produced by the Maillard reaction: Structure and biological activity. Food Chem. 2011, 128, 573–584. [Google Scholar] [CrossRef]

- Chandra, R.; Bharagava, R.N.; Rai, V. Melanoidins as major colourant in sugarcane molasses based distillery effluent and its degradation. Bioresour. Technol. 2008, 99, 4648–4660. [Google Scholar] [CrossRef] [PubMed]

- Trézl, L.; Horváth, V.; Lanczki, M.; Vida, C.; Rusznák, I.; Tóke, L.; Bakó, P. Increase in dye pick-up of wool caused by the Maillard reaction. J. Soc. Dyers Color. 1997, 111, 293–297. [Google Scholar] [CrossRef]

- Haroun, A.A.; Mansour, H.F. New approaches for the reactive dyeing of the retanned carbohydrate crust leather. Dyes Pigments 2008, 76, 213–219. [Google Scholar] [CrossRef]

- Ohe, T.; Yoshimura, Y. Coloration of polyamide fibers in an aqueous solution by Maillard reaction. Text. Res. J. 2014, 84, 539–545. [Google Scholar] [CrossRef]

- Ohe, T.; Moriyoshi, K.; Ohmoto, T.; Yoshimura, Y.; Shimada, Y. Anti-bacterial activity of polyamide fibers colored by Maillard reaction. Sen’iGakkaishi 2015, 71, 151–156. [Google Scholar] [CrossRef]

- Ohe, T.; Nakai, T.; Yoshimura, Y. Coloration of different textile fibers using glycerol oxides. Text. Res. J. 2016, 86, 2216–2224. [Google Scholar] [CrossRef]

- Bajaj, I.; Singhal, R. Poly(glutamic acid)—An emerging biopolymer of commercial interest. Bioresour. Technol. 2011, 102, 5551–5561. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, N.A.; Khalil, H.M.; Eid, B.M. A cleaner production of ultra-violet shielding wool prints. J. Clean. Prod. 2015, 92, 187–195. [Google Scholar] [CrossRef]

- Zhou, Y.; Tang, R.-C. Modification of curcumin with a reactive UV absorber and its dyeing and functional properties for silk. Dyes Pigments 2016, 134, 203–211. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, J.; Tang, R.-C.; Zhang, J. Simultaneous dyeing and functionalization of silk with three natural yellow dyes. Ind. Crops Prod. 2015, 64, 224–232. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Z.-Y.; Tang, R.-C. Bioactive and UV protective silk materials containing baicalin—The multifunctional plant extract from Scutellariabaicalensis Georgi. Mater. Sci. Eng. C 2016, 67, 336–344. [Google Scholar] [CrossRef] [PubMed]

- Ajandouz, E.H.; Tchiakpe, L.S.; Dalle Ore, F.; Benajiba, A.; Puigserver, A. Effects of pH on caramelization and Maillard reaction kinetics in fructose-lysine model systems. J. Food Sci. 2001, 66, 926–931. [Google Scholar] [CrossRef]

- Kim, J.-S.; Lee, Y.-S. Effect of reaction pH on enolization and racemization reactions of glucose and fructose on heating with amino acid enantiomers and formation of melanoidins as result of the Maillard reaction. Food Chem. 2008, 108, 582–592. [Google Scholar] [CrossRef] [PubMed]

- Bekedam, E.K.; Schols, H.A.; van Boekel, M.A.; Smit, G. High molecular weight melanoidins from coffee brew. J. Agric. Food Chem. 2006, 54, 7658–7666. [Google Scholar] [CrossRef] [PubMed]

- Kareb, O.; Gomaa, A.; Champagne, C.P.; Jean, J.; Aïder, M. Electro-activation of sweet defatted whey: Impact on the induced Maillard reaction products and bioactive peptides. Food Chem. 2017, 221, 590–598. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Shi, X.; Wang, M.; Du, Y. Xylan chitosan conjugate—A potential food preservative. Food Chem. 2011, 126, 520–525. [Google Scholar] [CrossRef]

- Mohsin, G.F.; Schmitt, F.J.; Kanzler, C.; Epping, J.D.; Flemig, S.; Hornemann, A. Structural characterization of melanoidin formed from d-glucose and l-alanineat different temperatures applying FTIR, NMR, EPR, and MALDI-ToF-MS. Food Chem. 2018, 245, 761–767. [Google Scholar] [CrossRef] [PubMed]

- Tang, R.-C.; Yao, F. The sorption of a syntan on nylon and its resist effectiveness towards reactive dyes. Dyes Pigments 2008, 77, 665–672. [Google Scholar] [CrossRef]

- Zhao, Y.; Cai, Z.; Zhou, Z.; Fu, X. Adsorption behavior of monomers and formation of conducting polymers on polyester fibers. J. Appl.Polym. Sci. 2011, 119, 662–669. [Google Scholar] [CrossRef]

- National general safety technical code for textile products, GB 18401; Standardization Administration of China (SAC): Beijing, China, 2010.

- Lee, N.-R.; Go, T.-H.; Lee, S.-M.; Jeong, S.-Y.; Park, G.-T.; Hong, C.-O.; Son, H.-J. In vitro evaluation of new functional properties of poly-γ-glutamic acid produced by Bacillussubtilis D7. Saudi J. Biol. Sci. 2014, 21, 153–158. [Google Scholar] [CrossRef] [PubMed]

| Variable | Levels | Other p-arameters |

|---|---|---|

| Time | 2.5 to 120 min | PGA/Glc weight ratio 1:1, pH 12, 90 °C |

| PGA/Glc weight ratio | 7:1 to 1:7 | pH 12, 90 °C, 60 min |

| pH | 9 to 13 | PGA/Glc weight ratio 1:1, 90 °C, 60 min |

| Temperature | 60 to90°C | PGA/Glc weight ratio 1:1, pH 12, 60 min |

| Variable | Levels | Other parameters |

|---|---|---|

| pH | 2–6 | PGA 2 g/100mL, 90 °C, 120 min |

| Temperature | 60–90°C | PGA 2 g/100mL, pH 3, 120 min |

| Time | 20–120 min | PGA 2 g/100 mL, pH 3, 90 °C |

| PGA concentration | 1–6 g/100 mL | pH 3, 90 °C, 120 min |

| Reactionproducts | Washing (rating) | Rubbing (rating) | Light (rating) | |||

|---|---|---|---|---|---|---|

| Color change | Stain | Dry | Wet | |||

| Silk | Cotton | |||||

| No UV-Sun Cel | 5 | 4–5 | 4–5 | 5 | 4–5 | 2 |

| UV-Sun Cel | 5 | 4–5 | 4–5 | 5 | 4–5 | 3–4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Tang, R.-C. Application of the Products from the Maillard Reaction of Polyglutamic Acid and Glucose to Prepare Colored and Bioactive Silk. Polymers 2018, 10, 648. https://doi.org/10.3390/polym10060648

Zhang W, Tang R-C. Application of the Products from the Maillard Reaction of Polyglutamic Acid and Glucose to Prepare Colored and Bioactive Silk. Polymers. 2018; 10(6):648. https://doi.org/10.3390/polym10060648

Chicago/Turabian StyleZhang, Wen, and Ren-Cheng Tang. 2018. "Application of the Products from the Maillard Reaction of Polyglutamic Acid and Glucose to Prepare Colored and Bioactive Silk" Polymers 10, no. 6: 648. https://doi.org/10.3390/polym10060648