Effects of Fiber Surface Grafting with Nano-Clay on the Hydrothermal Ageing Behaviors of Flax Fiber/Epoxy Composite Plates

Abstract

:1. Introduction

2. Experimental

2.1. Materials

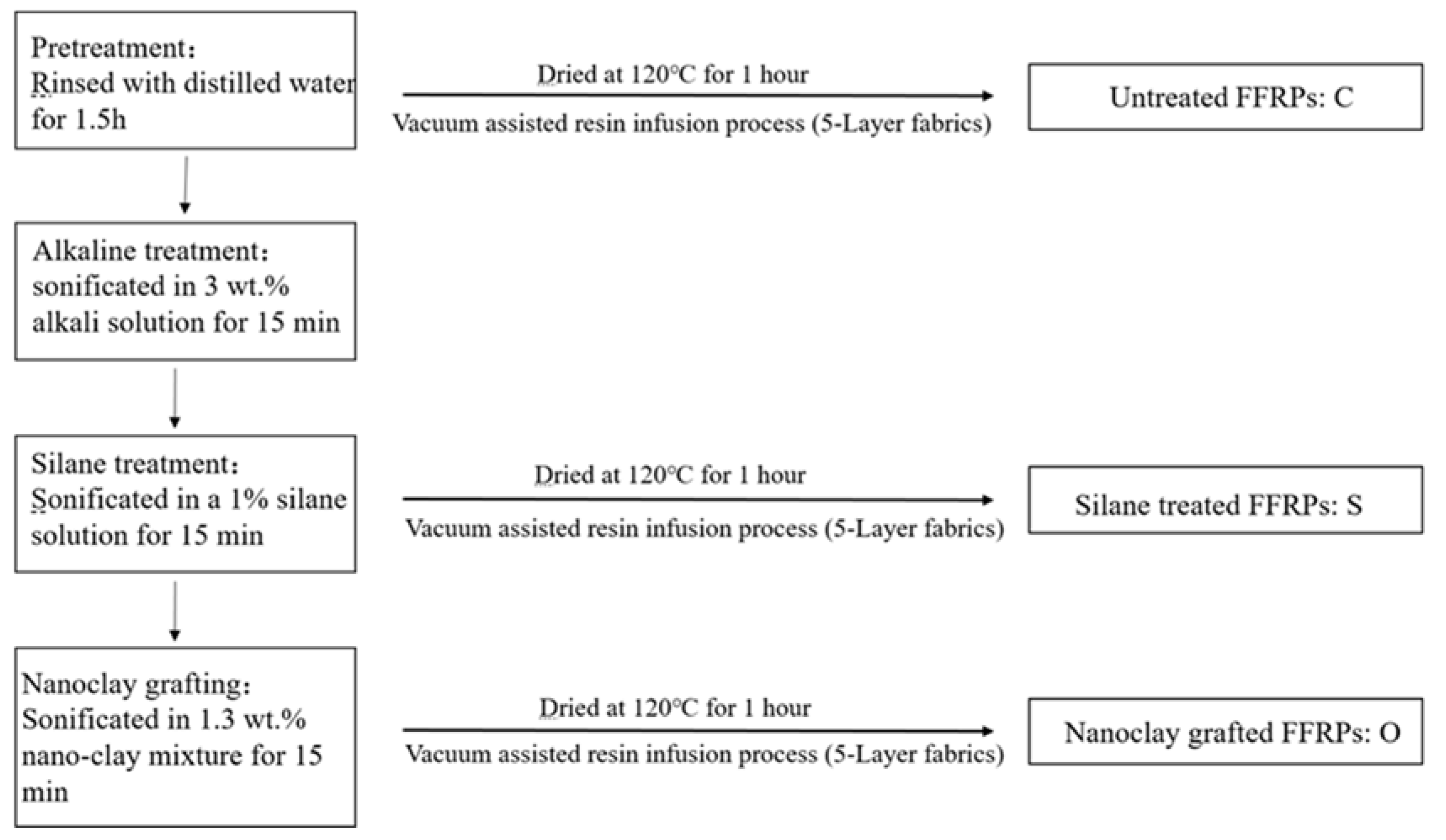

2.2. Surface Grafting of Flax Fabric

2.3. Hydrothermal Environment Conditions

2.4. Characterization

2.4.1. Moisture Uptake

2.4.2. Fourier Transform Infrared Test

2.4.3. FBG Monitoring

2.4.4. Mechanical Property Test

2.4.5. Scanning Electron Microscope (SEM) Test

3. Results and Discussion

3.1. Moisture Absorption of FFRPs

3.2. FTIR Observation

3.3. FBG Monitoring

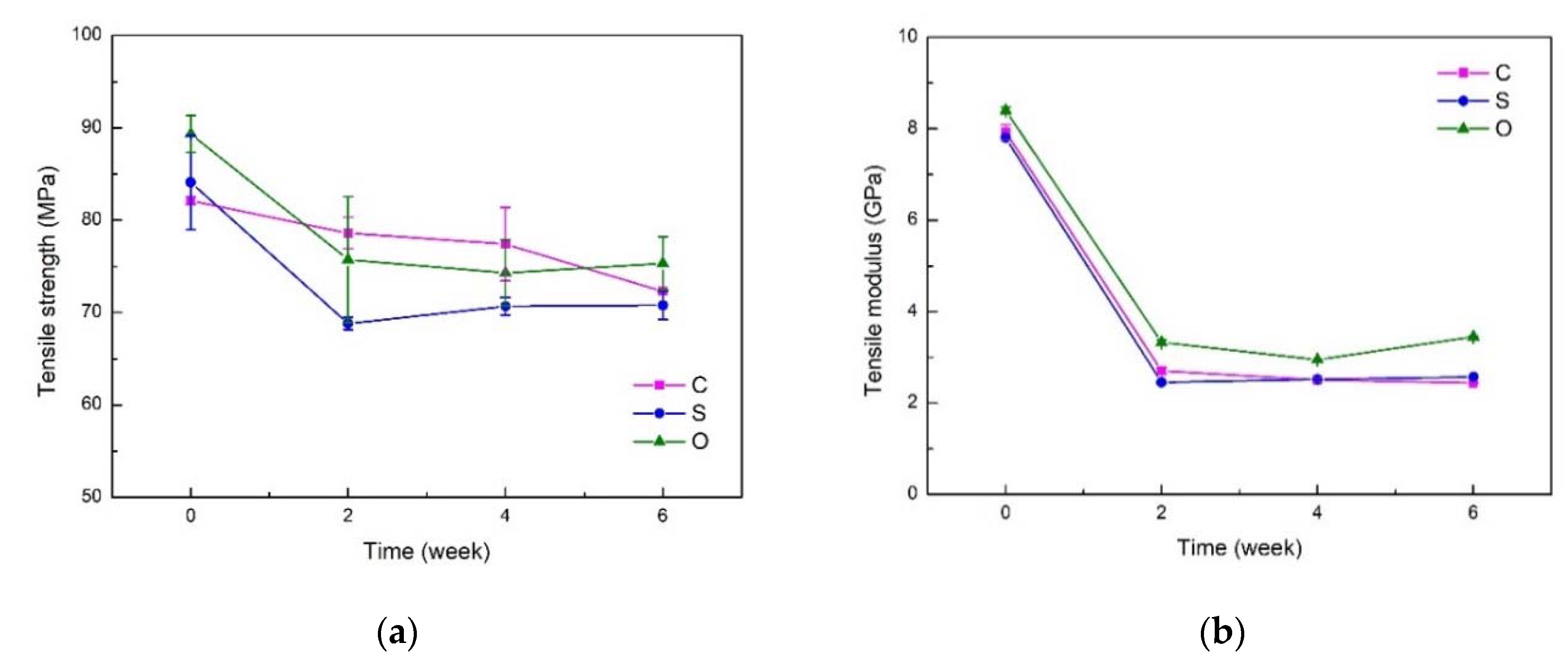

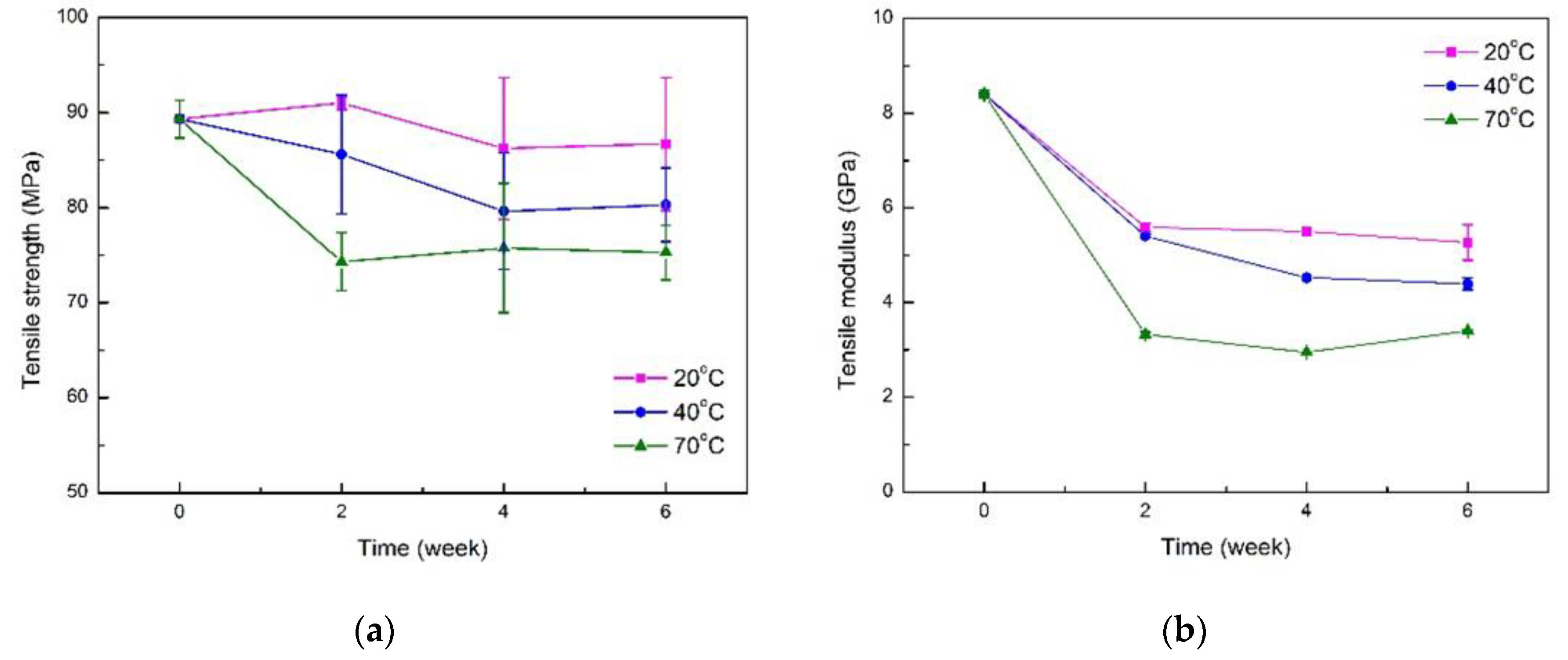

3.4. Tensile Properties

3.5. SEM Observation

4. Conclusions

- (1)

- The introduction of nano-clay onto the flax fiber reduced the saturated moisture uptake and the coefficient of diffusion by 38.4% and 13.2% of FFRP compared to the control samples. The introduction of lamellar nano-clay is expected to reduce the hydrophilicity of the fiber surface and increases the diffusion path of water molecules.

- (2)

- Nano-clay grafted FFRPs show better dimensional stability than the untreated ones. The linear moisture expansion coefficient of nano-clay grafted FFRP in radial and weft directions is smaller than that of untreated FFRP.

- (3)

- After exposure for six weeks, the retention rate of the tensile modulus of the nano-clay grafted flax fiber-based FFRP was increased by 33.8% compared with that of the control ones, while the retention rate of tensile strength has a little decrease by nano-clay grafting. On immersion in a hydrothermal environment, the degradation of tensile strength of FFRP is not obvious while the ultimate strain of FFRPs is increased.

Author Contributions

Funding

Conflicts of Interest

References

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part. B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Charlet, K.; Eve, S.; Jernot, J.P.; Gomina, M.; Breard, J. Tensile deformation of a flax fiber. Procedia Eng. 2009, 1, 233–236. [Google Scholar] [CrossRef] [Green Version]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part. A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Charlet, K.; Jernot, J.P.; Eve, S.; Gomina, M.; Bréard, J. Multi-scale morphological characterisation of flax: From the stem to the fibrils. Carbohydr. Polym. 2010, 82, 54–61. [Google Scholar] [CrossRef]

- Bourmaud, A.; Morvan, C.; Bouali, A.; Placet, V.; Perré, P.; Baley, C. Relationships between micro-fibrillar angle, mechanical properties and biochemical composition of flax fibers. Ind. Crop. Prod. 2013, 44, 343–351. [Google Scholar] [CrossRef] [Green Version]

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part. A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Duigou, A.L.; Bourmaud, A.; Kervoelen, A.; Morvan, C.; Baley, C. Analysis of the role of the main constitutive polysaccharides in the flax fibre mechanical behaviour. Ind. Crop. Prod. 2015, 76, 1039–1048. [Google Scholar] [CrossRef]

- Xian, Y.; Chen, F.; Li, H.; Wang, G.; Cheng, H.; Cao, S.J.F. The effect of moisture on the modulus of elasticity of several representative individual cellulosic fibers. Fiber Polym. 2015, 16, 1595–1599. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bourmaud, A.; Baley, C. In-situ evaluation of flax fibre degradation during water ageing. Ind. Crop. Prod. 2015, 70, 204–210. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; John, M.J. Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr. Polym. 2015, 131, 337–354. [Google Scholar] [CrossRef] [PubMed]

- Alamri, H.; Low, I.M. Mechanical properties and water absorption behaviour of recycled cellulose fibre reinforced epoxy composites. Polym. Test. 2012, 31, 620–628. [Google Scholar] [CrossRef]

- Scida, D.; Assarar, M.; Poilâne, C.; Ayad, R. Influence of hygrothermal ageing on the damage mechanisms of flax-fibre reinforced epoxy composite. Compos. Part. B Eng. 2013, 48, 51–58. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part. A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Wang, H.; Xian, G.; Li, H.; Sui, L.J.F. Durability study of a ramie-fiber reinforced phenolic composite subjected to water immersion. Fiber Polym. 2014, 15, 1029–1034. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Zadorozhnyy, M.; Tcherdyntsev, V.; Stepashkin, A.; Zherebtsov, D. Structure, mechanical and thermal properties of polyphenylene sulfide and polysulfone impregnated carbon fiber composites. Polymers 2019, 11, 684. [Google Scholar] [CrossRef]

- Chukov, D.I.; Stepashkin, A.A.; Gorshenkov, M.V.; Tcherdyntsev, V.V.; Kaloshkin, S.D. Surface modification of carbon fibers and its effect on the fiber–matrix interaction of uhmwpe based composites. J. Alloy. Compd. 2014, 586, S459–S463. [Google Scholar] [CrossRef]

- Stepashkin, A.A.; Chukov, D.I.; Cherdyntsev, V.V.; Kaloshkin, S.D. Surface treatment of carbon fibers-fillers for polymer matrixes. Inorg. Mater. Appl. Res. 2014, 5, 22–27. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Effect of water absorption on the mechanical properties of n-sic filled recycled cellulose fibre reinforced epoxy eco-nanocomposites. Polym. Test. 2012, 31, 810–818. [Google Scholar] [CrossRef]

- Dilfi KF, A.; Balan, A.; Hong, B.; Xian, G.; Thomas, S. Effect of surface modification of jute fiber on the mechanical properties and durability of jute fiber-reinforced epoxy composites. Polym. Compos. 2018, 39, E2519–E2528. [Google Scholar] [CrossRef]

- Ma, G.; Yan, L.; Shen, W.; Zhu, D.; Huang, L.; Kasal, B. Effects of water, alkali solution and temperature ageing on water absorption, morphology and mechanical properties of natural frp composites: Plant-based jute vs. Mineral-based basalt. Compos. Part. B Eng. 2018, 153, 398–412. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Mechanical and thermal properties of nanoclay-treated banana fibers. J. Nat. Fibers 2017, 14, 718–726. [Google Scholar] [CrossRef]

- Tzounis, L.; Debnath, S.; Rooj, S.; Fischer, D.; Mäder, E.; Das, A.; Stamm, M.; Heinrich, G. High performance natural rubber composites with a hierarchical reinforcement structure of carbon nanotube modified natural fibers. Mater. Des. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Tan, B.; Thomas, N.L. A review of the water barrier properties of polymer/clay and polymer/graphene nanocomposites. J. Membr. Sci. 2016, 514, 595–612. [Google Scholar] [CrossRef] [Green Version]

- Malik, N.; Shrivastava, S.; Ghosh, S.B. Moisture absorption behaviour of biopolymer polycapralactone (pcl)/organo modified montmorillonite clay (ommt) biocomposite films. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 346. [Google Scholar]

- Wang, A.; Xia, D.; Xian, G.; Li, H. Effect of nanoclay grafting onto flax fibers on the interfacial shear strength and mechanical properties of flax/epoxy composites. Polym. Compos. 2019. [Google Scholar] [CrossRef]

- Shih, Y.-F.; Jeng, R.-J. Ipns based on unsaturated polyester/epoxy: Iv. Investigation on hydrogen bonding, compatability and interaction behavior. Polym. Int. 2004, 53, 1892–1898. [Google Scholar] [CrossRef]

- Wu, H.-D.; Chu, P.P.; Ma, C.-C.M.; Chang, F.-C. Effects of molecular structure of modifiers on the thermodynamics of phenolic blends: An entropic factor complementing pcam. Macromolecules 1999, 32, 3097–3105. [Google Scholar] [CrossRef]

- Cui, Y.-H.; Lee, S.; Tao, J. Effects of alkaline and silane treatments on the water-resistance properties of wood-fiber-reinforced recycled plastic composites. J. Vinyl Addit. Techn. 2008, 14, 211–220. [Google Scholar] [CrossRef]

- Gonon, P.; Sylvestre, A.; Teysseyre, J.; Prior, C. Combined effects of humidity and thermal stress on the dielectric properties of epoxy-silica composites. Mater. Sci. Eng. B 2001, 83, 158–164. [Google Scholar] [CrossRef]

- Ramezani-Dana, H.; Casari, P.; Perronnet, A.; Fréour, S.; Jacquemin, F.; Lupi, C. Hygroscopic strain measurement by fibre bragg gratings sensors in organic matrix composites—Application to monitoring of a composite structure. Compos. Part. B Eng. 2014, 58, 76–82. [Google Scholar] [CrossRef]

- Le Duigou, A.; Merotte, J.; Bourmaud, A.; Davies, P.; Belhouli, K.; Baley, C. Hygroscopic expansion: A key point to describe natural fibre/polymer matrix interface bond strength. Compos. Sci. Technol. 2017, 151, 228–233. [Google Scholar] [CrossRef] [Green Version]

- Reddy, N.; Yang, Y. Biofibers from agricultural byproducts for industrial applications. Trends Biotechnol. 2005, 23, 22–27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hearle, J.W.S. The fine structure of fibers and crystalline polymers. Iii. Interpretation of the mechanical properties of fibers. J. Appl. Polym. Sci. 1963, 7, 1207–1223. [Google Scholar] [CrossRef]

- Joseph, P.V.; Rabello, M.S.; Mattoso, L.H.C.; Joseph, K.; Thomas, S. Environmental effects on the degradation behaviour of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2002, 62, 1357–1372. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part. A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Pavlidou, S.; Papaspyrides, C.D. The effect of hygrothermal history on water sorption and interlaminar shear strength of glass/polyester composites with different interfacial strength. Compos. Part. A Appl. Sci. Manuf. 2003, 34, 1117–1124. [Google Scholar] [CrossRef]

- Apolinario, G.; Ienny, P.; Corn, S.; Léger, R.; Bergeret, A.; Haudin, J.-M. Effects of Water Ageing on the Mechanical Properties of Flax and Glass Fibre Composites: Degradation and Reversibility; Springer Netherlands: Dordrecht, The Netherlands, 2016; pp. 183–196. [Google Scholar]

- Molaba, T.P.; Chapple, S.; John, M.J. Aging studies on flame retardant treated lignocellulosic fibers. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Bennett, N.; Lopez-Arraiza, A.; Vallejo, F. Effects of water immersion ageing on the mechanical properties of flax and jute fibre biocomposites evaluated by nanoindentation and flexural testing. J. Compos. Mater. 2014, 48, 1399–1406. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bourmaud, A.; Davies, P.; Baley, C. Long term immersion in natural seawater of flax/pla biocomposite. Ocean Eng. 2014, 90, 140–148. [Google Scholar] [CrossRef]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D.T. Properties and potential application of the selected natural fibers as limited life geotextiles. Carbohydr. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Chilali, A.; Zouari, W.; Assarar, M.; Kebir, H.; Ayad, R. Effect of water ageing on the load-unload cyclic behaviour of flax fibre-reinforced thermoplastic and thermosetting composites. Compos. Struct. 2018, 183, 309–319. [Google Scholar] [CrossRef]

| Temperatures | 20 °C | 40 °C | 70 °C |

|---|---|---|---|

| Saturated salt solvent for 80% RH | Potassium bromide (KBr) | Potassium bromide (KBr) | Potassium chloride (KCl) |

| Samples | M∞ (%) | |

|---|---|---|

| Untreated FFRPs | 5.41 | 3.03 |

| Silane treated FFRPs | 4.53 | 6.04 |

| Nano-clay grafted FFRPs | 3.91 | 2.62 |

| Hydrothermal Environments | M∞ (%) | |

|---|---|---|

| 20 °C, 80% RH | 3.20 | 0.22 |

| 40 °C, 80% RH | 4.11 | 0.43 |

| 70 °C, 80% RH | 3.91 | 2.62 |

| Maximum Strain (Radial) | Radial Expansion Coefficient | Maximum Strain (Weft) | Weft Expansion Coefficient | |

|---|---|---|---|---|

| Untreated FFRPs | 0.0042 | 0.0777 | 0.007 | 0.1296 |

| Nano-clay grafted FFRPs | 0.0028 | 0.0717 | 0.005 | 0.1282 |

| Hydrothermal Environments | Properties | Untreated FFRPs | Silane Treated FFRPs | Nano-Clay Grafted FFRPs | |||

|---|---|---|---|---|---|---|---|

| 0W | 6W | 0W | 6W | 0W | 6W | ||

| 20 °C, 80% RH | Elongation at break | _ | _ | _ | _ | 0.88% | 1.38% |

| Strength (MPa) | 82.1 | _ | 84.1 | _ | 89.3 | 86.7 | |

| Modulus (GPa) | 7.9 | _ | 7.8 | _ | 8.4 | 5.3 | |

| 40 °C, 80% RH | Elongation at break | _ | _ | _ | _ | 0.88% | 1.85% |

| Strength (MPa) | 82.1 | _ | 84.1 | _ | 89.3 | 80.3 | |

| Modulus (GPa) | 7.9 | _ | 7.8 | _ | 8.4 | 4.4 | |

| 70 °C, 80% RH | Elongation at break | 0.84% | 2.36% | 0.86% | 3.51% | 0.88% | 1.96% |

| Strength (MPa) | 82.1 | 72.3 | 84.1 | 70.7 | 89.3 | 75.3 | |

| Modulus (GPa) | 7.9 | 2.4 | 7.8 | 2.6 | 8.4 | 3.4 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, A.; Xian, G.; Li, H. Effects of Fiber Surface Grafting with Nano-Clay on the Hydrothermal Ageing Behaviors of Flax Fiber/Epoxy Composite Plates. Polymers 2019, 11, 1278. https://doi.org/10.3390/polym11081278

Wang A, Xian G, Li H. Effects of Fiber Surface Grafting with Nano-Clay on the Hydrothermal Ageing Behaviors of Flax Fiber/Epoxy Composite Plates. Polymers. 2019; 11(8):1278. https://doi.org/10.3390/polym11081278

Chicago/Turabian StyleWang, Anni, Guijun Xian, and Hui Li. 2019. "Effects of Fiber Surface Grafting with Nano-Clay on the Hydrothermal Ageing Behaviors of Flax Fiber/Epoxy Composite Plates" Polymers 11, no. 8: 1278. https://doi.org/10.3390/polym11081278