Multi-Modal Contractive Forces of Wools as Actuator

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

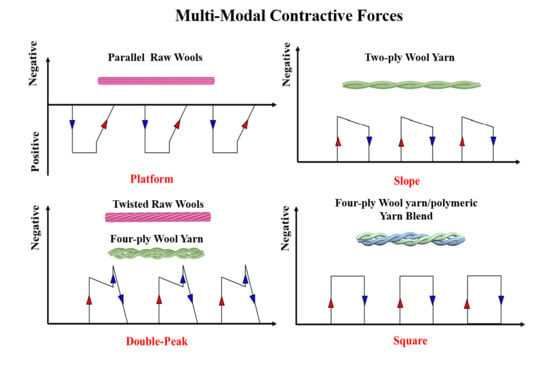

3.1. Platform-Like and Double-Peak Stress-Stroke Mode of Raw Wools

3.2. Slope-Like and Double-Peak Stress–Stroke Mode of Plied Wool Yarns

3.3. Stepwise and Square Stress–Stroke Mode

3.4. Tensile Hysteresis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shi, J.; Liu, S.; Zhang, L.; Yang, B.; Shu, L.; Yang, Y.; Ren, M.; Wang, Y.; Chen, J.; Chen, W. Smart textile-integrated microelectronic systems for wearable applications. Adv. Mater. 2020, 32, 1901958. [Google Scholar] [CrossRef]

- Di, J.; Zhang, X.; Yong, Z.; Zhang, Y.; Li, D.; Li, R.; Li, Q. Carbon-nanotube fibers for wearable devices and smart textiles. Adv. Mater. 2016, 28, 10529–10538. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S. Phase change materials for smart textiles—An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khattab, T.A.; Fouda, M.M.G.; Abdelrahman, M.S.; Othman, S.I.; Bin-Jumah, M.; Alqaraawi, M.A.; Al Fassam, H.; Allam, A.A. Development of illuminant glow-in-the-dark cotton fabric coated by luminescent composite with antimicrobial activity and ultraviolet protection. J. Fluoresc. 2019, 29, 703–710. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, A.; Van Langenhove, L.; Guermonprez, P.; Deguillemont, D. A roadmap on smart textiles. Text Prog. 2010, 42, 99–180. [Google Scholar] [CrossRef]

- Langereis, G.R.; Bouwstra, S.; Chen, W. 6-Sensors, actuators and computing systems for smart textiles for protection. In Smart Textiles for Protection; Chapman, R.A., Ed.; Woodhead Publishing: Sawston, Cambridge, UK, 2013; pp. 190–213. [Google Scholar]

- Khattab, T.A.; Fouda, M.M.G.; Abdelrahman, M.S.; Othman, S.I.; Bin-Jumah, M.; Alqaraawi, M.A.; Al Fassam, H.; Allam, A.A. Co-encapsulation of enzyme and tricyanofuran hydrazone into alginate microcapsules incorporated onto cotton fabric as a biosensor for colorimetric recognition of urea. React. Funct. Polym. 2019, 142, 199–206. [Google Scholar] [CrossRef]

- Cherenack, K.; Zysset, C.; Kinkeldei, T.; Münzenrieder, N.; Tröster, G. Woven electronic fibers with sensing and display functions for smart textiles. Adv. Mater. 2010, 22, 5178–5182. [Google Scholar] [CrossRef]

- Maziz, A.; Concas, A.; Khaldi, A.; Stalhand, J.; Persson, N.; Jager, E. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3, e1600327. [Google Scholar] [CrossRef] [Green Version]

- Mirvakili, S.M.; Hunter, I.W. Artificial muscles: Mechanisms, applications, and challenges. Adv. Mater. 2018, 30, 1704407. [Google Scholar] [CrossRef]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.; Kim, S.H.; Fang, S.; De Andrade, M.J.; Göktepe, F. Artificial muscles from fishing line and sewing thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Haines, C.S.; Li, N.; Spinks, G.M.; Aliev, A.E.; Di, J.; Baughman, R.H. New twist on artificial muscles. Proc. Natl. Acad. Sci. USA 2016, 113, 11709–11716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part. A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Xiao, X.; Hu, J. Animal hairs as water-stimulated shape memory materials: Mechanism and structural networks in molecular assemblies. Sci. Rep. 2016, 6, 26393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiao, X.; Zhou, H.; Qian, K. Mechanism study of biopolymer hair as a coupled thermo-water responsive smart material. Smart Mater. Struct. 2017, 26, 035023. [Google Scholar] [CrossRef]

- Close, R. Dynamic properties of mammalian skeletal muscles. Physiol. Rev. 1972, 52, 129–197. [Google Scholar] [CrossRef]

- Sjöblom, B.; Salmazo, A.; Djinović-Carugo, K. α-Actinin structure and regulation. Cell. Mol. Life Sci. 2008, 65, 2688. [Google Scholar] [CrossRef]

- Taylor, K.A.; Taylor, D.W. Projection image of smooth muscle α-actinin from two-dimensional crystals formed on positively charged lipid layers. J. Mol. Biol. 1993, 230, 196–205. [Google Scholar] [CrossRef]

- Ylänne, J.; Scheffzek, K.; Young, P.; Saraste, M. Crystal structure of the α-actinin rod reveals an extensive torsional twist. Structure 2001, 9, 597–604. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Yang, W.; Meyers, M.A. Viscoelastic properties of α-keratin fibers in hair. Acta Biomater. 2017, 64, 15–28. [Google Scholar] [CrossRef]

- Zhu, S.; Hu, J.; Zhang, Y. A single polymer artificial muscle having dual-mode contractibility, temperature sensibility, and trainability through enthalpy change. Adv. Mater. Technol. 2019, 4, 1900017. [Google Scholar] [CrossRef]

- Feughelman, M. A two-phase structure for keratin fibers. Text Res. J. 1959, 29, 223–228. [Google Scholar] [CrossRef]

- Weigmann, H.-D.; Rebenfield, L.; Dansizer, C. Kinetics and temperature dependence of the chemical stress relaxation of wool fibers. Text Res. J. 1966, 36, 535–542. [Google Scholar] [CrossRef]

- Rama Rao, D.; Gupta, V. Thermal characteristics of wool fibers. J. Macromol. Sci. Part B Phys. 1992, 31, 149–162. [Google Scholar] [CrossRef]

- Buckner, T.L.; Kramer-Bottiglio, R. Functional fibers for robotic fabrics. Multifunct. Mater. 2018, 1, 012001. [Google Scholar] [CrossRef]

- Cao, J.; Bhoyro, A.Y. Structural characterization of wool by thermal mechanical analysis of yarns. Text Res. J. 2001, 71, 63–66. [Google Scholar] [CrossRef]

- Cao, J.; Billows, C.A. Crystallinity determination of native and stretched wool by X-ray diffraction. Polym. Int. 1999, 48, 1027–1033. [Google Scholar] [CrossRef]

- Pelton, J.T.; McLean, L.R. Spectroscopic methods for analysis of protein secondary structure. Anal. Biochem 2000, 277, 167–176. [Google Scholar] [CrossRef]

- Lu, F.; Song, B.; He, P.; Wang, Z.; Wang, J. Electrochemical impedance spectroscopy (EIS) study on the degradation of acrylic polyurethane coatings. RSC Adv. 2017, 7, 13742–13748. [Google Scholar] [CrossRef] [Green Version]

- Yao, J.; Liu, Y.; Yang, S.; Liu, J. Characterization of secondary structure transformation of stretched and slenderized wool fibers with FTIR spectra. J. Eng. Fibers Fabr. 2008, 3, 155892500800300205. [Google Scholar] [CrossRef] [Green Version]

- Mason, P. Thermal transitions in keratin part I: Thermal expansion and structural transitions in alpha-keratin. Text Res. J. 1964, 34, 913–917. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, S.; Young, R.J.; Cai, Z.; Li, L.; Han, J.; Pan, N. Stress memory materials and their fundamental platform. J. Mater. Chem. A 2017, 5, 503–511. [Google Scholar] [CrossRef]

- Chung, T.; Romo-Uribe, A.; Mather, P.T. Two-way reversible shape memory in a semicrystalline network. Macromolecules 2008, 41, 184–192. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, S.; Hu, J. Multi-Modal Contractive Forces of Wools as Actuator. Polymers 2020, 12, 1464. https://doi.org/10.3390/polym12071464

Zhu S, Hu J. Multi-Modal Contractive Forces of Wools as Actuator. Polymers. 2020; 12(7):1464. https://doi.org/10.3390/polym12071464

Chicago/Turabian StyleZhu, Shanshan, and Jinlian Hu. 2020. "Multi-Modal Contractive Forces of Wools as Actuator" Polymers 12, no. 7: 1464. https://doi.org/10.3390/polym12071464