Bearing Capacity and Mechanism of the H–V Geogrid-Reinforced Foundation

Abstract

:1. Introduction

2. Materials and Methods

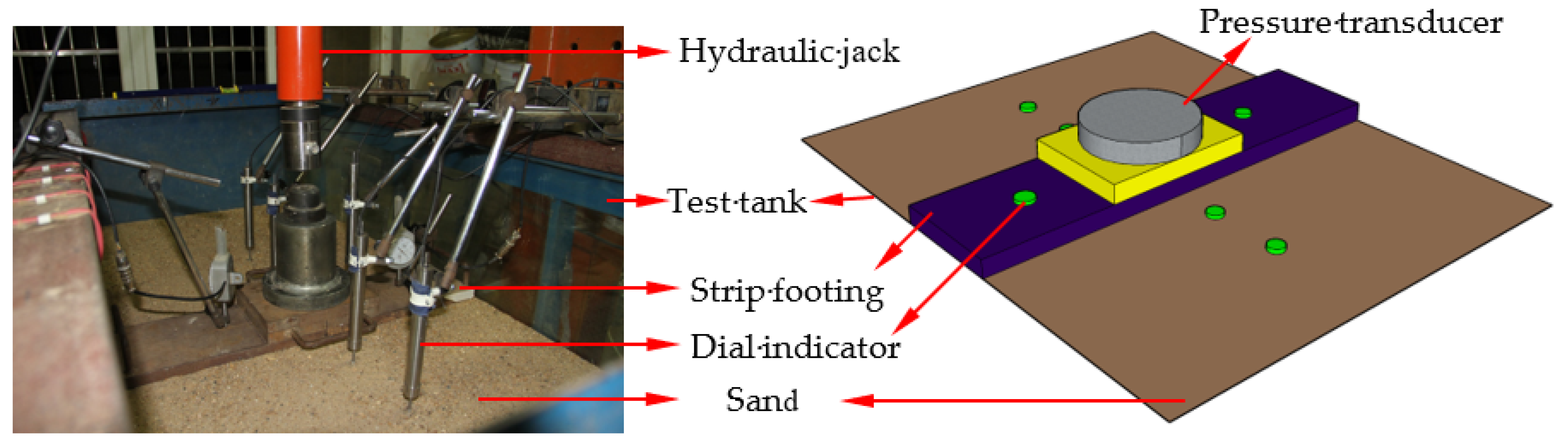

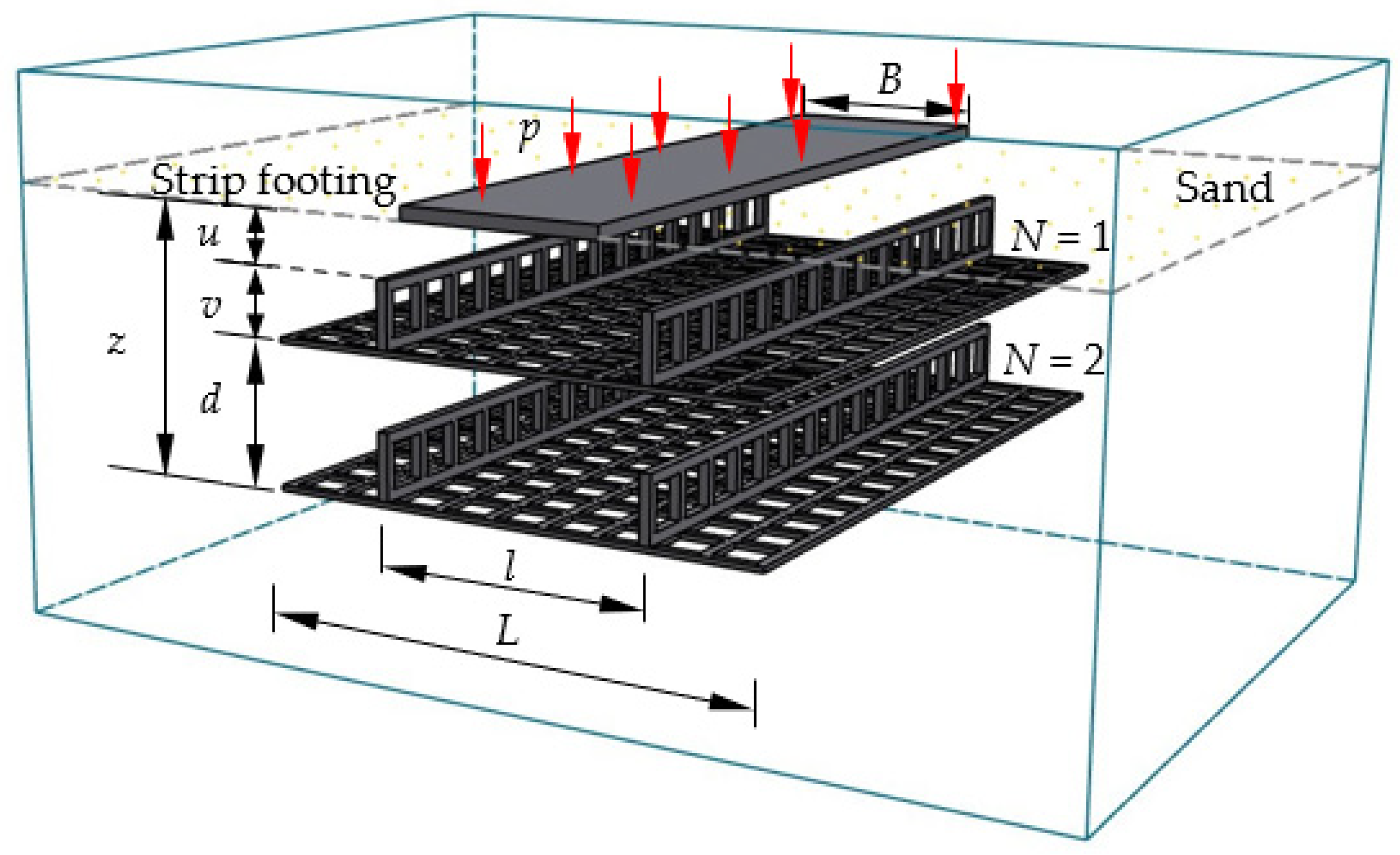

2.1. Test Setup

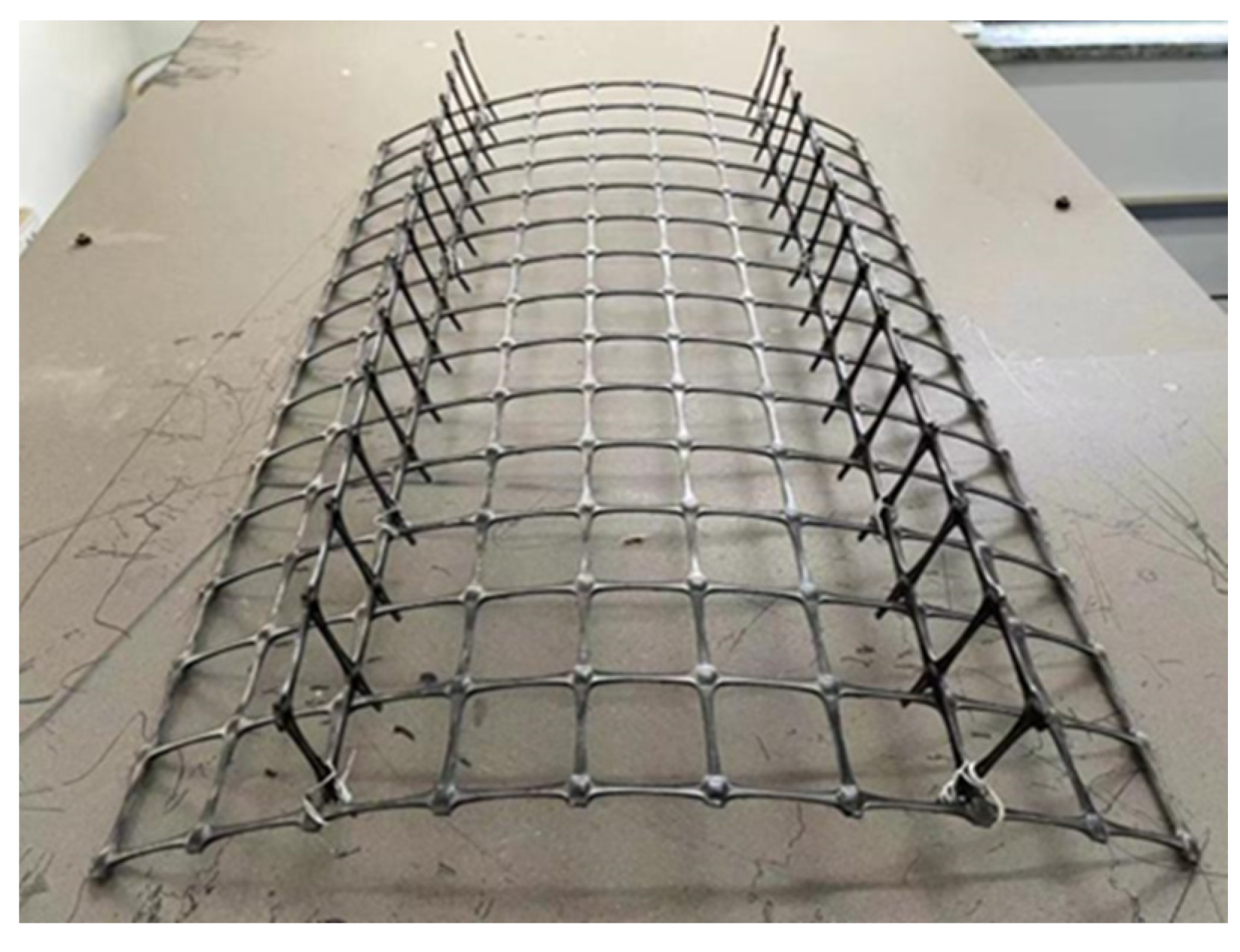

2.2. Test Materials

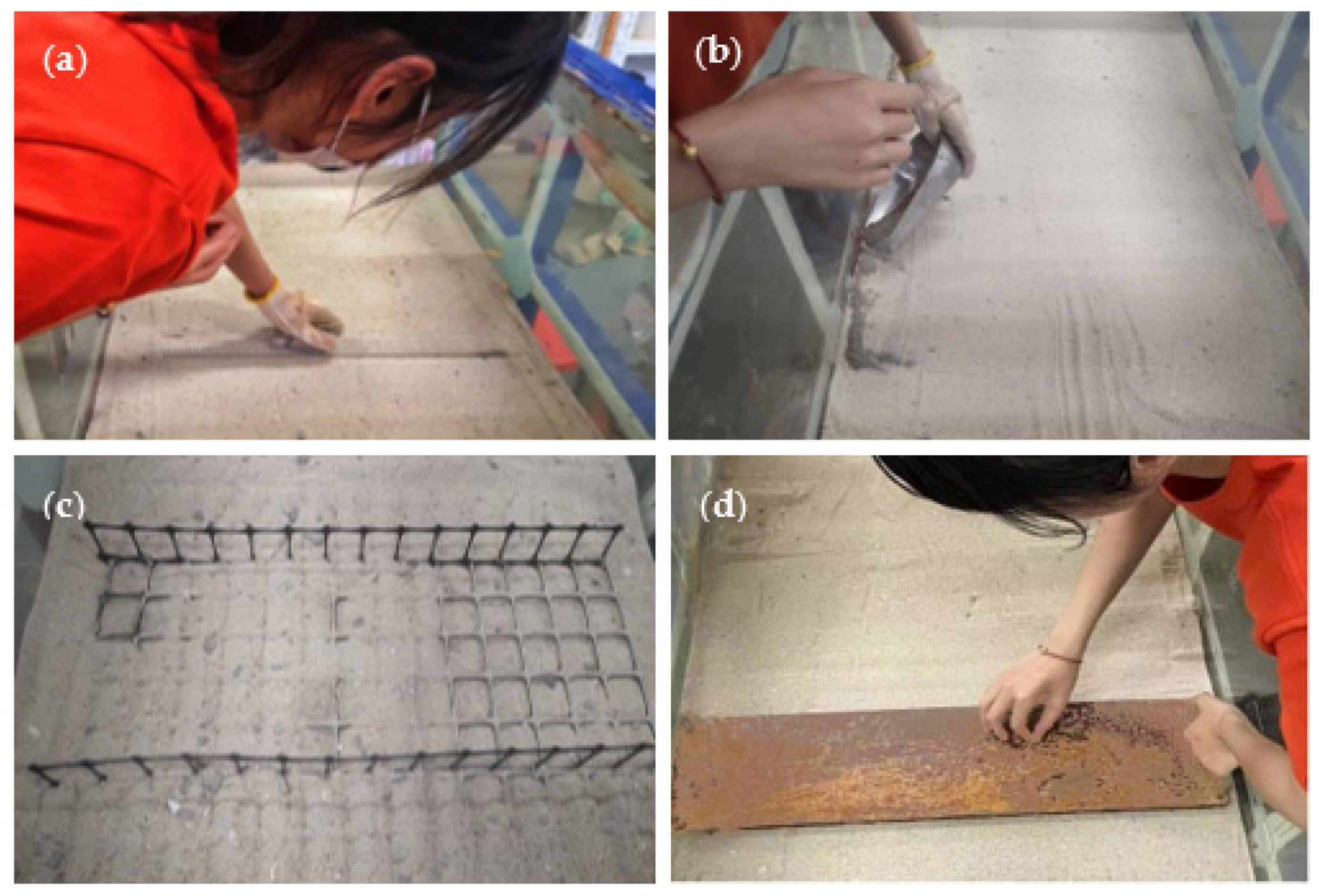

2.3. Test Procedure

3. Results and Discussion

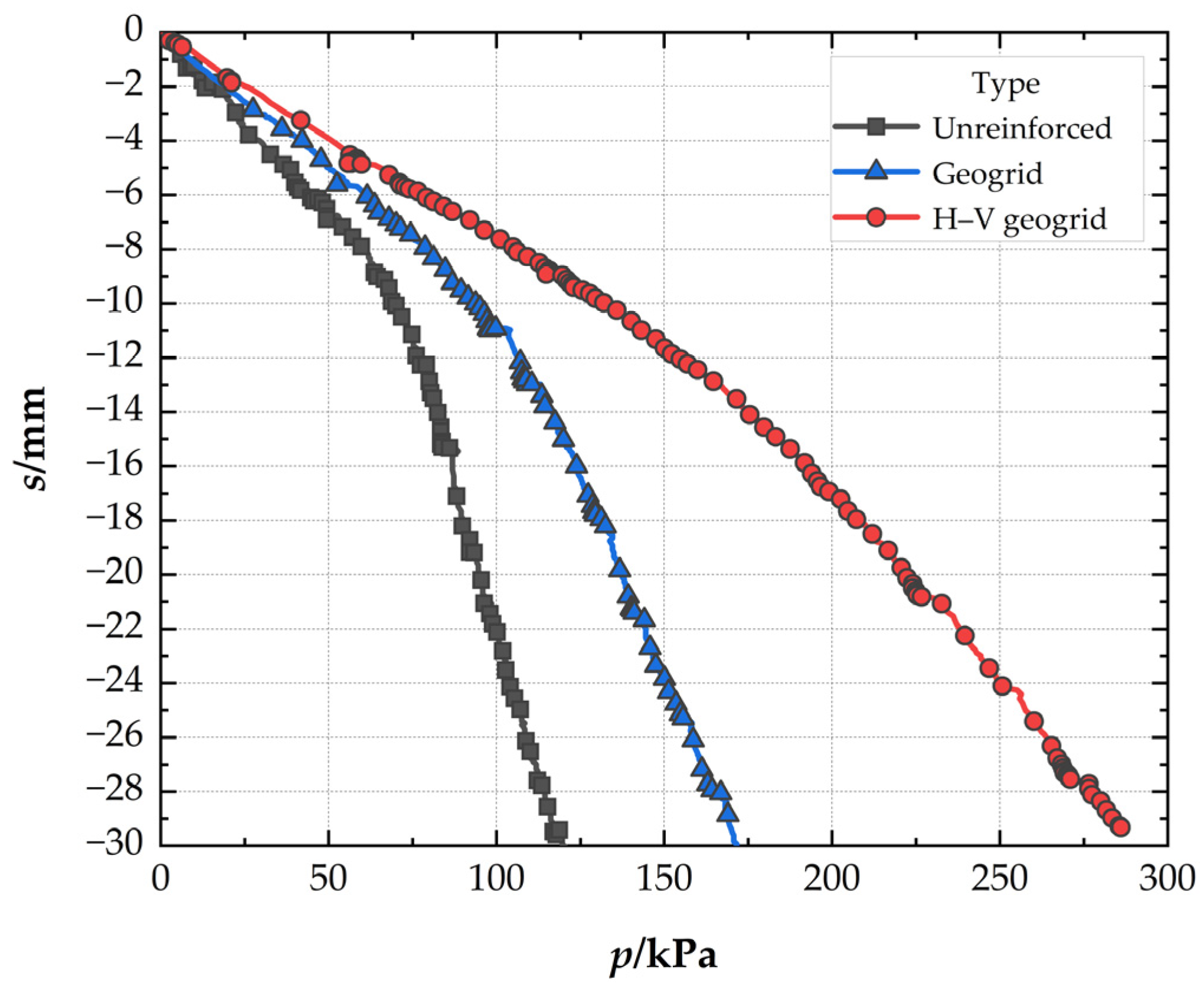

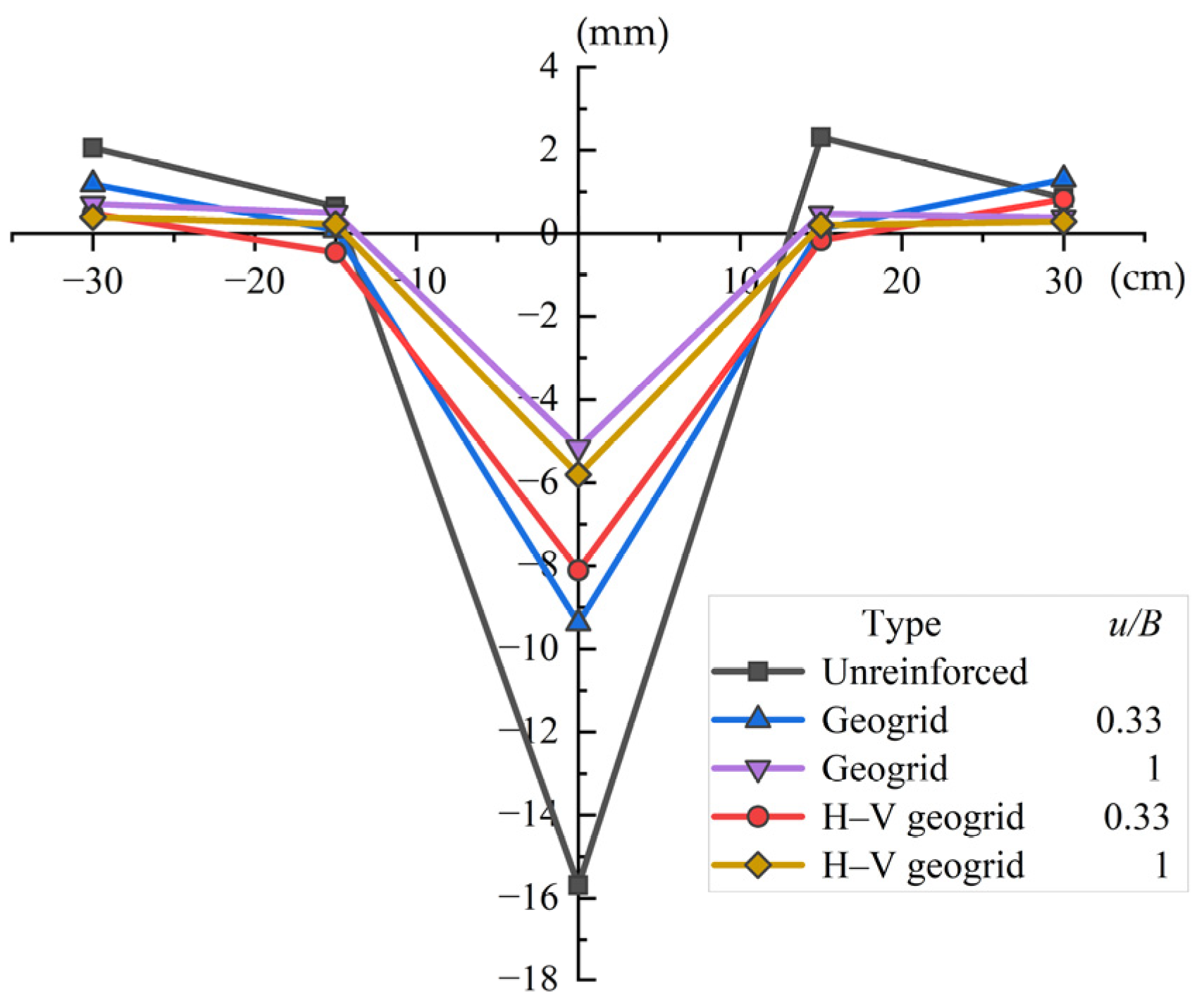

3.1. Comparison of the Different Reinforced Foundation

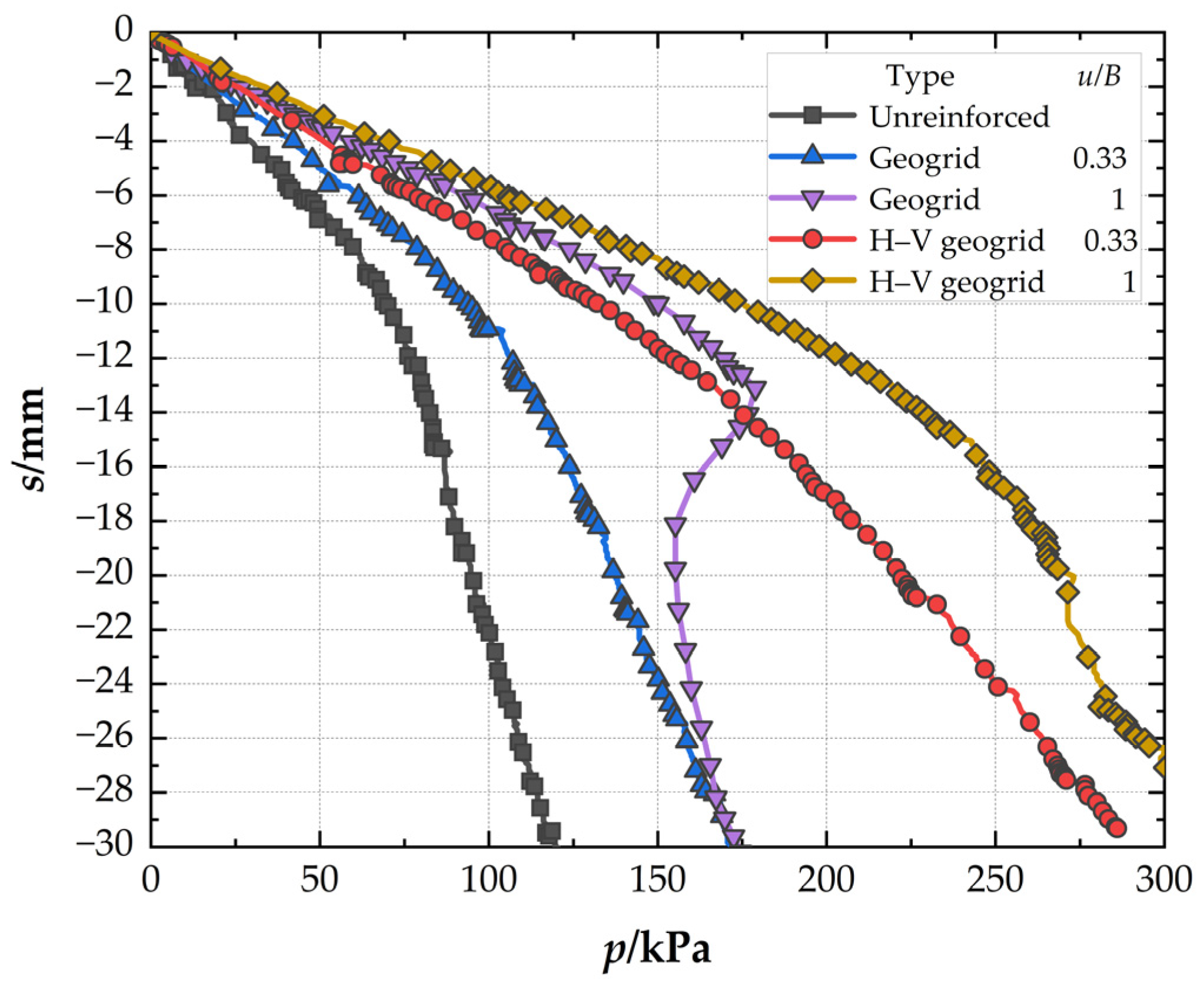

3.2. Effect of the Depth of the Top Layer

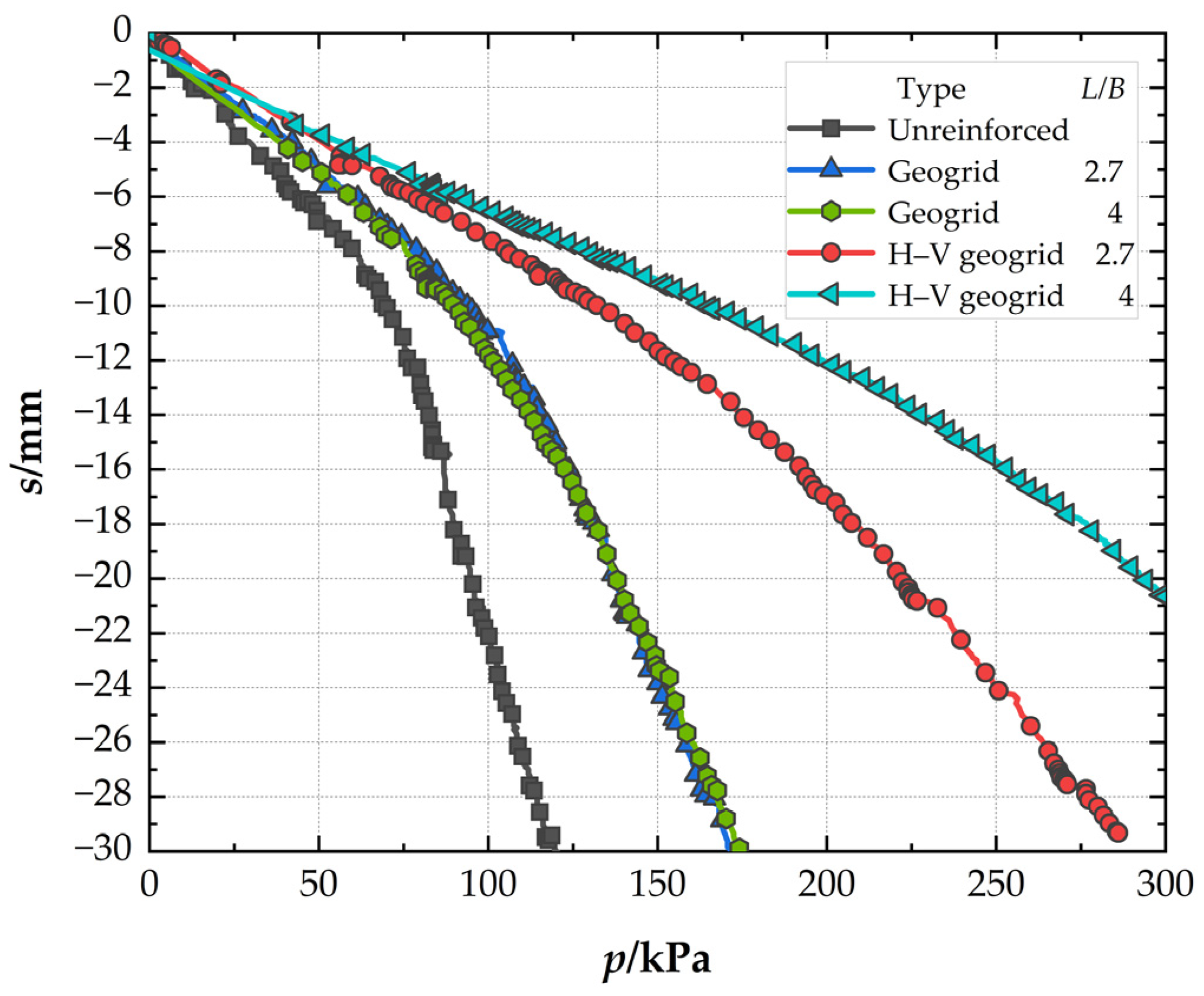

3.3. Effect of the Length of Reinforcement

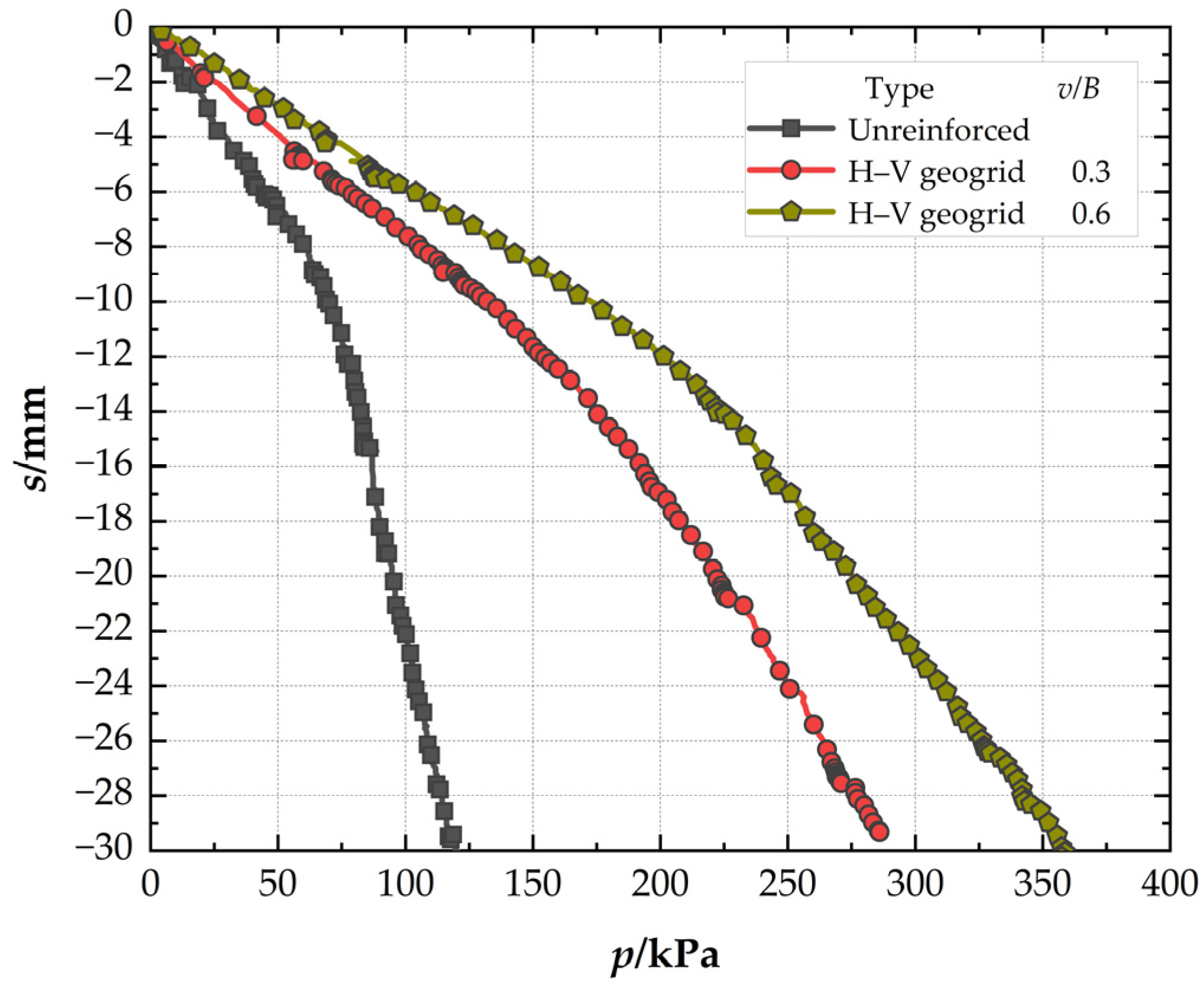

3.4. Effect of the Vertical Geogrid Height

3.5. Effect of Number of H–V Geogrid Layers

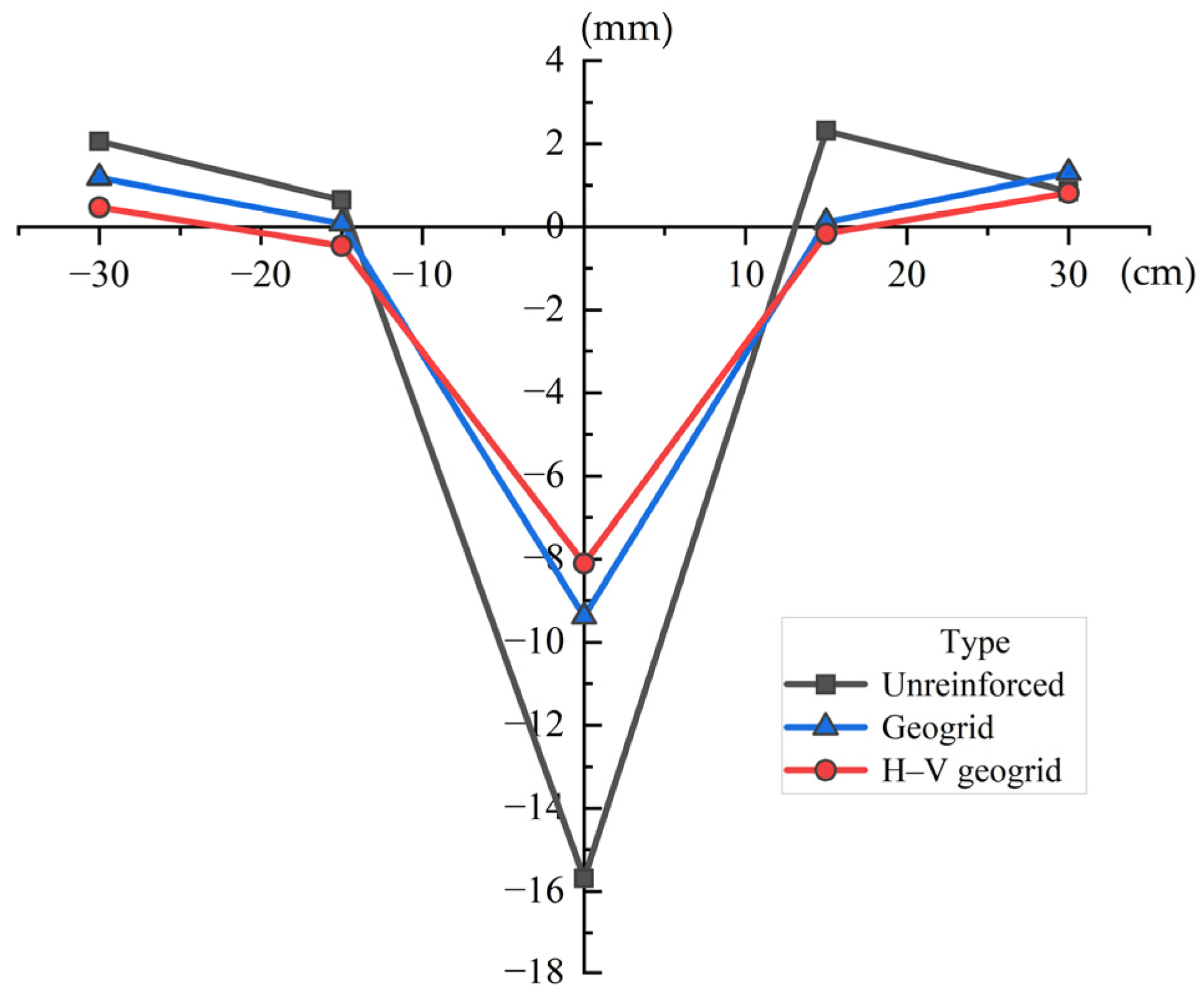

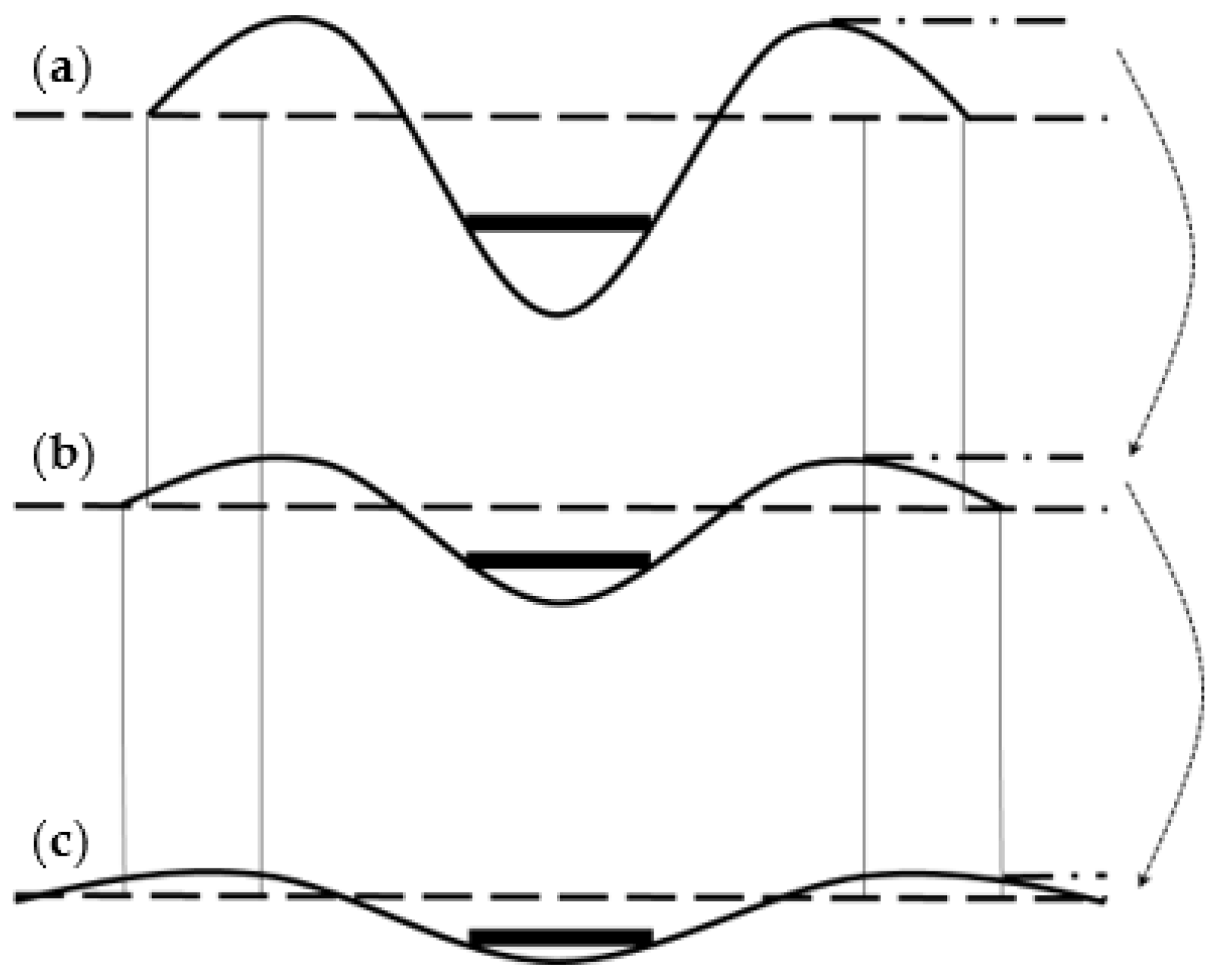

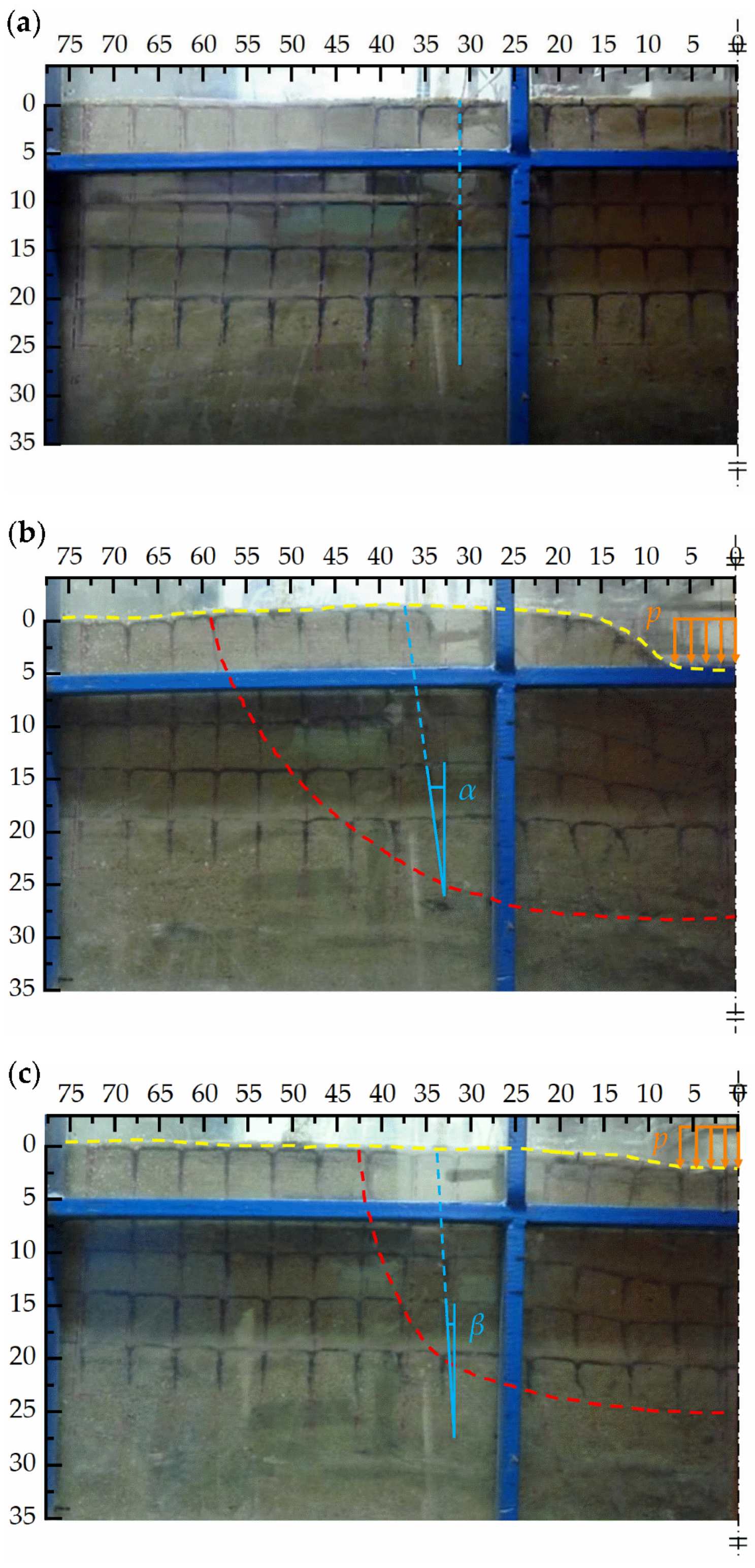

3.6. Failure Mode and Possible Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- King, K.H.; Das, B.M.; Puri, V.K.; Cook, E.E.; Yen, S.C. The bearing capacity of a strip foundation on geogrid-reinforced sand. Geotext. Geomembr. 1993, 12, 351–361. [Google Scholar] [CrossRef]

- Das, B.M.; Omar, M.T. The effects of foundation width on model tests for the bearing capacity of sand with geogrid reinforcement. Geotech. Geol. Eng. 1994, 12, 133–141. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Hou, J. Bearing capacity of rigid shallow footing on geogrid-reinforced fine sand-experimental modeling. Arab. J. Geosci. 2018, 11, 774. [Google Scholar] [CrossRef]

- El-Soud, S.A.; Belal, A.M. An analytical model of the strip footing reinforced with geogrid. Arab. J. Geosci. 2018, 11, 247. [Google Scholar]

- Mandal, J.N.; Manjunath, V.R. Bearing capacity of strip footing resting on reinforced sand subgrades. Constr. Build. Mater. 1995, 9, 35–38. [Google Scholar] [CrossRef]

- Wang, J.Q.; Zhang, L.L.; Tang, Y.; Huang, S.B. Influence of reinforcement-arrangements on dynamic response of geogrid reinforced foundation under repeated loading. Constr. Build. Mater. 2021, 274, 122093. [Google Scholar] [CrossRef]

- Phanikumar, B.R.; Prasad, R.; Singh, A. Compressive load response of geogrid-reinforced fine, medium and coarse sands. Geotext. Geomembr. 2009, 27, 183–186. [Google Scholar] [CrossRef]

- Roy, S.S.; Deb, K. Effects of aspect ratio of footings on bearing capacity for geogrid-reinforced sand over soft soil. Geosynth. Int. 2017, 24, 362–382. [Google Scholar]

- Binquet, J.; Lee, K.L. Bearing capacity tests on reinforced earth slabs. J. Geotech. Eng. Div. 1975, 101, 1241–1255. [Google Scholar] [CrossRef]

- Guido, V.A.; Chang, D.K.; Sweeny, M.A. Comparison of geogrid and geotextile reinforced earth slabs. Can. Geotech. J. 1986, 23, 435–440. [Google Scholar] [CrossRef]

- Patra, C.R.; Das, B.M.; Atalar, C. Bearing capacity of embedded strip foundation on geogrid-reinforced sand. Geotext. Geomembr. 2005, 23, 454–462. [Google Scholar] [CrossRef]

- Sawwaf, M.A.E. Behavior of strip footing on geogrid-reinforced sand over a soft clay slope. Geotext. Geomembr. 2007, 25, 50–60. [Google Scholar] [CrossRef]

- Omar, M.T.; Das, B.M.; Puri, V.K.; Yen, S.C. Ultimate bearing capacity of shallow foundations on sand with geogrid reinforced. Can. Geotech. J. 1993, 30, 545–549. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Shi, L. Deformation patterns of reinforced foundation sand at failure. J. Geotech. Geoenviron. Eng. 2003, 129, 439–449. [Google Scholar] [CrossRef]

- Bai, X.H.; Huang, X.Z.; Wei, Z. Bearing capacity of square footing supported by a geobelt-reinforced crushed stone cushion on soft soil. Geotext. Geomembr. 2013, 38, 37–42. [Google Scholar] [CrossRef]

- Vinod, P.; Bhaskar, A.B.; Sreehari, S. Behaviour of a square model footing on loose sand reinforced with braided coir rope. Geotext. Geomembr. 2009, 27, 464–474. [Google Scholar] [CrossRef]

- Laman, M.; Yildiz, A. Numerical studies of ring foundations on geogrid-reinforced sand. Geosynth. Int. 2007, 14, 52–64. [Google Scholar] [CrossRef]

- Basudhar, P.K.; Saha, S.; Deb, K. Circular footings resting on geotextile-reinforced sand bed. Geotext. Geomembr. 2007, 25, 377–384. [Google Scholar] [CrossRef]

- Biabani, M.M.; Indraratna, B.; Ngo, T.N. Modelling of geocell-reinforced subballast subjected to cyclic loading. Geotext. Geomembr. 2016, 44, 489–503. [Google Scholar] [CrossRef] [Green Version]

- Tafreshi, S.N.M.; Dawson, A.R. Comparison of bearing capacity of a strip footing on sand with geocell and with planar forms of geotextile reinforcement. Geotext. Geomembr. 2010, 28, 72–84. [Google Scholar] [CrossRef]

- Oliaei, M.; Kouzegaran, S. Efficiency of cellular geosynthetics for foundation reinforcement. Geotext. Geomembr. 2017, 45, 11–22. [Google Scholar] [CrossRef]

- Shadmand, A.; Ghazavi, M.; Ganjian, N. Load-settlement characteristics of large-scale square footing on sand reinforced with opening geocell reinforcement. Geotext. Geomembr. 2018, 46, 319–326. [Google Scholar] [CrossRef]

- Sireesh, S.; Sitharam, T.G.; Dash, S.K. Bearing capacity of circular footing on geocell-sand mattress overlying clay bed with void. Geotext. Geomembr. 2008, 27, 89–98. [Google Scholar] [CrossRef]

- Thallak, S.G.; Saride, S.; Dash, S.K. Performance of surface footing on geocell-reinforced soft clay beds. Geotech. Geol. Eng. 2007, 25, 509–524. [Google Scholar] [CrossRef]

- Wesseloo, J.; Visser, A.T.; Rust, E. The stress-strain behavior of multiple cell geocell packs. Geotext. Geomembr. 2009, 27, 31–38. [Google Scholar] [CrossRef]

- Dash, S.K.; Sireesh, S.; Sitharam, T.G. Model studies on circular footing supported on geocell reinforced sand underlain by soft clay. Geotext. Geomembr. 2003, 21, 197–219. [Google Scholar] [CrossRef]

- Alamshahi, S.; Hataf, N. Bearing capacity of strip footings on sand slopes reinforced with geogrid and grid-anchor. Geotext. Geomembr. 2009, 27, 217–226. [Google Scholar] [CrossRef]

- Mosallanezhad, M.; Hataf, N.; Ghahramani, A. Experimental study of bearing capacity of granular soils. Geotech. Geol. Eng. 2008, 26, 299–312. [Google Scholar] [CrossRef]

- Makkar, F.M.; Chandrakaran, S.; Sankar, N. Behaviour of model square footing resting on sand reinforced with three-dimensional geogrid. Int. J. Geosynth. Ground Eng. 2017, 3, 3. [Google Scholar] [CrossRef]

- Zhang, M.X. Behaviour of Model Square Footing Resting on Sand Reinforced with Three-Dimensional Geogrid. China Patent No. zl 2005100028241.8, 28 July 2005. [Google Scholar]

- Zhang, M.X.; Javadi, A.A.; Min, X. Triaxial tests of sand reinforced with 3D inclusions. Geotext. Geomembr. 2006, 24, 201–209. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, M.X.; Dai, Z.H.; Li, J.Z.; Zeng, F.F. Bearing capacity of strip foundations in horizontal-vertical reinforced soils. Geotext. Geomembr. 2017, 45, 29–34. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, M.X.; Javadi, A.A.; Peng, M.Y. Experiment and analysis of strength behavior of soil reinforced with horizontal-vertical inclusions. Geosynth. Int. 2011, 18, 150–158. [Google Scholar] [CrossRef]

- Zhang, M.X.; Zhao, F.; Hou, J. Model tests of H–V reinforced sand bed subjected to strip loading. J. Civ. Eng. China 2008, 41, 94–99. [Google Scholar]

- Hou, J.; Zhang, M.X.; Zhang, T.T.; Wang, X. Reinforcement Arrangement Tool in the Soil Model Test. China Patent No. 201020126231, 9 March 2010. [Google Scholar]

- Abu-Farsakh, M.; Chen, Q.M.; Sharma, R. An experimental evaluation of the behavior of footings on geosynthetic-reinforced sand. Soils Found. 2013, 53, 335–348. [Google Scholar] [CrossRef] [Green Version]

- Hou, J.; Zhang, M.X.; Zhang, T.T.; Chen, T. Experimental research on effect of horizontal-vertical reinforcement configurations on foundations. Rock Soil Mech. China 2011, 32, 2365–2370. [Google Scholar]

- Schmertmann, J.H.; Hartmann, J.P.; Brown, P.R. Improved strain influence factor diagrams. J. Geotech. Eng. 1978, 104, 1131–1135. [Google Scholar] [CrossRef]

- Sharma, R.; Chen, Q.M.; Abu-Farsakh, M.; Yoon, S. Analytical modeling of geogrid reinforced soil foundation. Geotext. Geomembr. 2009, 27, 63–72. [Google Scholar] [CrossRef]

- Guo, Y.X.; Zhu, H.H.; Ni, Y.F.; Wei, C.; Shi, B. Experimental study on uplift behavior of shallow anchor plates in geogrid-reinforced soil. Geotext. Geomembr. 2022, 50, 994–1003. [Google Scholar] [CrossRef]

- Mukherjee, S.; Sivakumar Babu, G.L. Three-dimensional numerical modeling of geogrid reinforced foundations. Comput. Geotech. 2023, 158, 105397. [Google Scholar] [CrossRef]

| The Angle of Internal Friction φ/° | Moisture Content ω/% | Relative Density of Particle ds | Unit Weight γ/kN/m3 |

|---|---|---|---|

| 35.2 | 0.15 | 2.63 | 16.74 |

| Polymer Type | Aperture Size | Thickness | Peak Tensile Strength | Strain at Break |

|---|---|---|---|---|

| HDPE | 45 mm × 40 mm | 2 mm | 12.5 kN/m | 2.5% |

| No. | Type | N | u/B | z/B | L/B | l/B | v/B | d/B |

|---|---|---|---|---|---|---|---|---|

| A-1 | Unreinforced | |||||||

| B-1 | Conventional geogrid | 1 | 0.33 | 0.33 | 2.7 | |||

| B-2 | 1 | 1 | 2.7 | |||||

| B-3 | 0.33 | 0.66 | 4 | |||||

| C-1 | H–V geogrid | 1 | 0.33 | 0.33 | 2.7 | 1.5 | 0.3 | |

| C-2 | 1 | 1 | 2.7 | 1.5 | 0.3 | |||

| C-3 | 0.33 | 0.33 | 4 | 1.5 | 0.3 | |||

| C-4 | 0.33 | 0.33 | 2.7 | 1.5 | 0.6 | |||

| C-5 | 2 | 0.33 | 0.66 | 2.7 | 1.5 | 0.3 | 0.33 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.; Liu, S.; Nam, B.; Ma, Y. Bearing Capacity and Mechanism of the H–V Geogrid-Reinforced Foundation. Polymers 2023, 15, 2606. https://doi.org/10.3390/polym15122606

Hou J, Liu S, Nam B, Ma Y. Bearing Capacity and Mechanism of the H–V Geogrid-Reinforced Foundation. Polymers. 2023; 15(12):2606. https://doi.org/10.3390/polym15122606

Chicago/Turabian StyleHou, Juan, Sitong Liu, Boohyun Nam, and Yanxia Ma. 2023. "Bearing Capacity and Mechanism of the H–V Geogrid-Reinforced Foundation" Polymers 15, no. 12: 2606. https://doi.org/10.3390/polym15122606