Customizing Starch Properties: A Review of Starch Modifications and Their Applications

Abstract

:1. Introduction

2. Native Starch Modification

3. In Planta Starch Modifications

4. Starch Modifications Outside the Plant System

4.1. Chemical Modifications of Isolated Starches

| Modification | Implications | Industrial Sectors | Example Applications | References |

|---|---|---|---|---|

| Cross-linking (Formation of inter and intramolecular bridges resulting from an interaction between reactive hydroxyl groups in starch and reagents.) | Higher stability of granules towards swelling, high temperature, and high shear and acidic conditions | Food | Viscosifiers and texturizers in dairy products | [40] |

| Pharmacy | Transport of molecules and excipients | [40] | ||

| Wastewater treatment | Chelation of pollutants | |||

| Packaging | Bioplastics | |||

| Esterification (Condensation of the carboxylic acids, fatty acids or phosphates with reactive hydroxyl groups of the starch) | Lower gelatinization temperature and retrogradation, lower tendency to form gels, and higher paste clarity | Food | Emulsion stabilizer in refrigerated and frozen foods | [50,59] |

| Textiles | Film-forming polymer | |||

| Paper production | For packaging | |||

| Etherification (Substitution of the reactive hydroxyl groups with anhydroglucose units using positively or negatively charged functional groups) | Improves the clarity of starch pastes, increases viscosity, reduces syneresis, and increases freeze-thaw stability | Pharmacy | Drug delivery | [60,61] |

| Wastewater treatment | Adsorbents of heavy metal ions | |||

| Oxidation (Involves oxidation of primary or secondary hydroxyl groups of the glucose units of starch with formation of carbonyl or carboxyl groups using various oxidizing agents) | Low viscosity, high clarity, and low-temperature stability | Food | In batter and bread for coating various foodstuffs and film formers, | [62,63] |

| Confection dairy | As binders and texturizers | |||

| Paper Textiles | Improved strength and printability | |||

| Grafting (Grafting of acrylic monomers onto the starch via free radicals generated through different free radical initiators) | High viscosity, thermal stability, biodegradability | Cosmetics | Moisturizer, skin-and hair products, perfumes | [58] |

| Pharmacy | Microparticle system for vaccine delivery | |||

| Agriculture | For mulching and controlling weeds, conserves soil moisture and heat | |||

| Electrical engineering | Cable sealing | |||

| Wastewater treatment | heavy metal ion removal | |||

| Bioplastic | biodegradable plastics and films | |||

| Acid hydrolysis (Hydrolysis of the glycosidic linkage because of attack of the hydronium ion on the oxygen atom in the glycosidic bond) | Low paste viscosity, high gel strength and water solubility | Food | Gelling agent in the production of gum and processed cheese loaves, fat replacers/fat mimetic | [64,65] |

4.2. Physical Modifications of Isolated Starches

| Modification Method | Implications | Industrial Sectors | Example Applications | References |

|---|---|---|---|---|

| Microwaves (Starch modification technique that involves usage of electromagnetic waves in the frequency range of 300–300,000 MHz to generate heat with the help of “molecular friction” in the presence of alternating electric field) | Change the morphology, crystallinity, the gelatinization mechanism, and the rheological properties of the starch | Pharmacy | Control of drug release | [80,81] |

| Ultrasonic (Involves utilization of frequencies above 20 kHz to modify starch by mechanical and cavitation effect) | Modifies the swelling of granules and pastes | Pharmacy | Reduction of pathogens; Preparation of nanoparticles | [82,83,84] |

| Energy | Pretreatment for production of biofuel | |||

| Wastewater treatment | Recycling industrial waste containing starch | |||

| Ultra-high pressure (A non-thermal technique capable of altering non-covalent chemical linkages by the application of ultra-high pressures (100–1000 MPa) | Reduces the swelling and viscosity of starch, lower gelatinization temperature | Food | Applied in the binding of aroma compounds; textural improvement, sterilizing of food | [85,86] |

| Extrusion (A thermomechanical procedure that can rupture the starch bonds leading to its degradation and gelatinization) | Breakdown of granules and destroying crystallinity, increase of water absorption | Engineered food | Meat analogous | [87] |

| Paper/packaging | Bioplastics | |||

| Heat moisture treatment (A hydrothermal treatment that involves heating starch granules for a fixed period of time under low moisture conditions and at temperatures above the glass transition temperature but below the gelatinization temperature) | Increase thermal transition temperatures (onset temperature (To), peak temperature (Tp), and conclusion temperature (Tc) | Food | Production of retort foods, dressings, noodles, baked foods, batter products, confections, dairy products, creams, fat mimetics, and resistant starches | [88] |

| Annealing (A hydrothermal modification method that involves heating of starch granules under high moisture conditions, between their glass transition and gelatinization temperatures for extended period) | Increase gelatinization transition temperature, crystallinity and heat stability | Food | Improve texture for bread making; canned and frozen food processing; improving noodles quality | [89] |

| Micronization (It involves utilization of infrared technology to heat and vibrate starch molecules resulting in increased gelatinization) | Destroying of granules and interrupting crystallinity, increase of solubility, decrease of swelling property, reduction of gelatinization transition temperature and enthalpy | Food | Fat substitute, noodles, convenience, and fried food | [89] |

| γ-irradiation (An ionizing and non-thermal physical method involving the use of a radioactive isotope that emits high-energy—γ-rays or photons capable of intruding in-depth into the starch) | Swelling power and viscosity decreased, reduction of viscosity and gelatinization enthalpy, high water solubility | Food | Preparation of water-soluble starch for food application, animal feed production | [90,91,92,93] |

| Plasma (Involves exposure of the starch granules to plasma (ionized gas) resulting in starch structure modification) | Crystallinity reduced, swelling ability and viscosity decreased, alteration of gelatinization temperature and molecular weight | Food | Desinfection/sterilization | [94,95] |

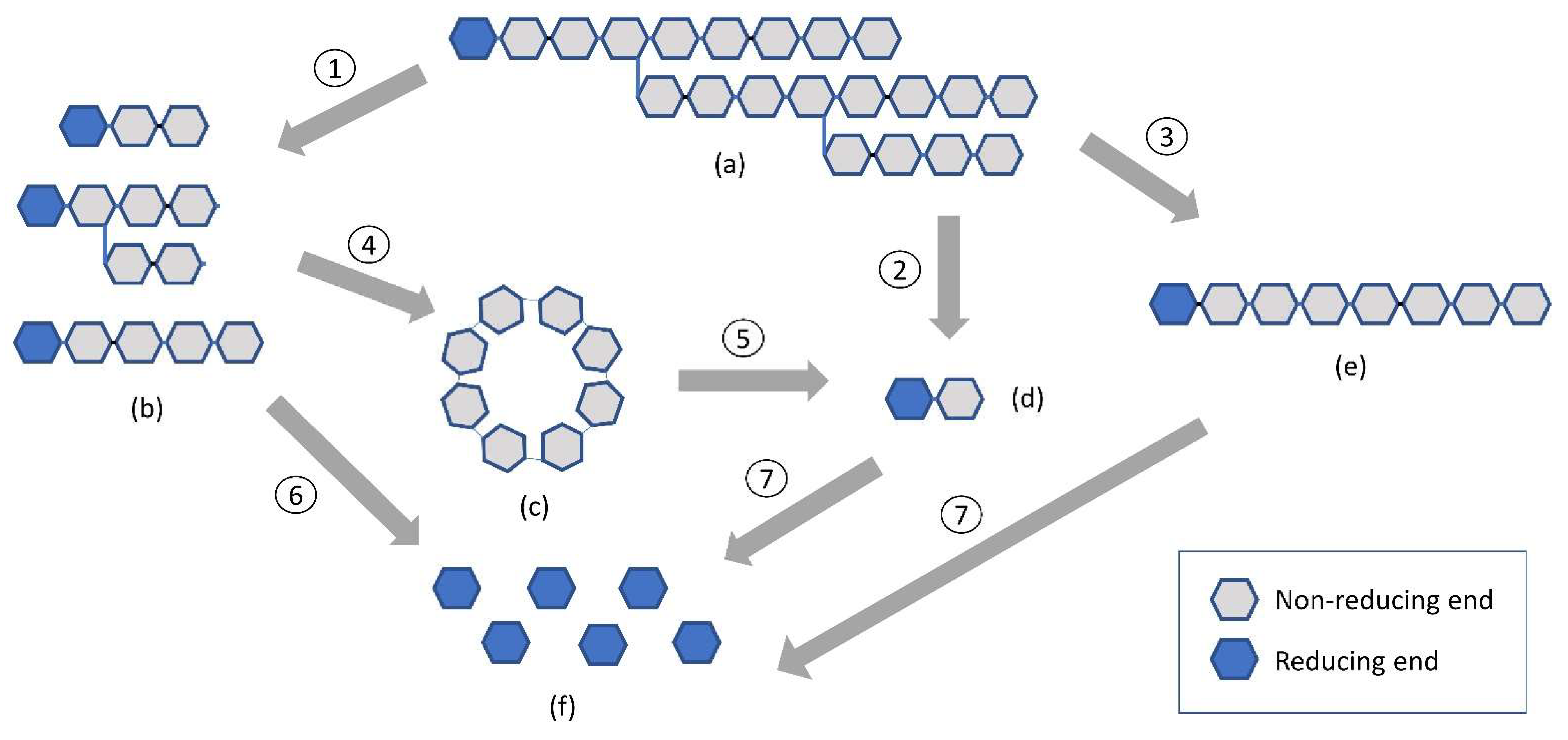

4.3. Enzymatic Modifications of Isolated Starches

| Modification | Mechanisms | Industrial Sectors | Example Applications | References |

|---|---|---|---|---|

| β-amylase [BAM; EC 3.2.1.2] | Cleave α-(1,4) glycosidic bonds from the nonreducing ends of the glucan chains | Food | Producing high-maltose syrups | [104,105] |

| Amyloglucosidase [AMG; EC 3.2.1.3] | Cleave both α-(1,4) and α-(1,6) glycosidic bonds from the nonreducing ends of the glucan chains | Food | Production of high-glucose syrups and high-fructose syrups | [106,107] |

| Energy | Biofuel production, produce fermentable sugars to produce ethanol | |||

| α-glucosidase [AGD; EC 3.2.1.20] | Hydrolysis of terminal, nonreducing (1,4) linked α-D-glucose residues with release of α-D-glucose from complex polymers with α-(1,4) bonds, such as malto-oligosaccharides, soluble starch, amylose and glycogen | Food | Production of isomalto- and malto-oligosaccharides with prebiotic activity; production of glucose from starchy sources | [102,108,109,110,111] |

| Energy | Biofuel production | |||

| Pharmacy | Medical biosensors | |||

| α-amylase [AMY; EC 3.2.1.1] | Endohydrolysis of α-(1,4) glycosidic linkage in polysacharides containing three or more α-(1,4) linked D-glucose units | Food | Saccharification or liquefaction of starch, the clarification of haze formed in beer or fruit juices, and the pretreatment of animal feed to improve digestibility | [39,112,113,114] |

| Textiles | Preparation of viscous and stable starch solutions for the sizing of textile fibers | |||

| Detergent | Improvement of detergency of laundry bleach composition and bleaching without color darkening | |||

| Energy | Biofuel production, produce fermentable sugars to produce ethanol | |||

| Maltogenic α-amylase [EC 3.2.1.133] | Hydrolysis of α-(1,4) glycosidic linkage in glucan chains to remove alpha-maltose from the non-reducing ends. Maltose production from amylose, amylopectin, and cyclodextrin in exo/or endo-like manner | Food | Prevention of staling of bakery products; non-digestible starch | [115,116] |

| Isoamylase [ISA; EC 3.2.1.68] | Hydrolyse the α-(1,6) glucosidic bond in amylopectin, glycogen and their β-limit dextrins. Inability to hydrolize pullulan. | Food | Saccharification or liquefaction of starch | [117] |

| Pullulanase [PULA; EC 3.2.1.41] | Hydrolyse the α-(1,6) glucosidic bond in pullulan, amylopectin, glycogen, also in alpha- and beta-limit dextrins of amylopectin and glycogen | Food | Saccharification or liquefaction of starch; production of high-glucose or high-maltose syrups; manufacturing of low-calorie beer; anti-stalling agent to improve texture, volume, and flavor of bakery products | [99,117,118] |

| Detergent | Additives in dishwashing and laundry detergents for the removal of starches | |||

| Paper | Used in adhesive products and in the production of corrugated board and paper | |||

| Amylomaltase [EC 2.4.1.25] | Transfers a segment of a (1,4)- α-D-glucan to a new position in an acceptor, which may be glucose or α (1,4)-α-D-glucan | Food | Fat replacer and enhancer of creaminess in yoghurt and mayonnaise; production of plant-based alternative to gelatin; prevention of staling of rice cake and bakery products; thermoreversible gel; lump-free cooked rice and porridge | [99,116,119,120,121,122,123] |

| Cyclodextrin glycosyltransferase [CDGT; EC 2.4.1.19] | Cyclizes part of a α-(1,4)-D-glucan chain by formation of α-(1,4) glycosidic linkage | Food | Production of cyclodextrins; glycosylation of the potent sweetener stevioside; retard of bread/rice cake retrogradation | [39,124,125,126,127] |

| Pharmaceutical | Drug delivery systems | |||

| Amylosucrase [AMYS; EC 2.4.1.4] | Sequential transglycosylation of glucosyl unit from sucrose onto acceptor molecule | Food | Resistant starch; slowly digestible starch | [128,129,130] |

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Apriyanto, A.; Compart, J.; Fettke, J. A review of starch, a unique biopolymer—Structure, metabolism and in planta modifications. Plant Sci. 2022, 318, 111223. [Google Scholar] [CrossRef] [PubMed]

- Compart, J.; Li, X.; Fettke, J. Starch—A complex and undeciphered biopolymer. J. Plant Physiol. 2021, 258–259, 153389. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Chao, C.; Cai, J.; Niu, B.; Copeland, L.; Wang, S. Starch-lipid and starch-lipid-protein complexes: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1056–1079. [Google Scholar] [CrossRef] [PubMed]

- Blennow, A.; Bay-Smidt, A.M.; Olsen, C.E.; Møller, B.L. The distribution of covalently bound phosphate in the starch granule in relation to starch crystallinity. Int. J. Biol. Macromol. 2000, 27, 211–218. [Google Scholar] [CrossRef] [PubMed]

- Carpenter, M.A.; Joyce, N.I.; Genet, R.A.; Cooper, R.D.; Murray, S.R.; Noble, A.D.; Butler, R.C.; Timmerman-Vaughan, G.M. Starch phosphorylation in potato tubers is influenced by allelic variation in the genes encoding glucan water dikinase, starch branching enzymes I and II, and starch synthase III. Front. Plant Sci. 2015, 6, 143. [Google Scholar] [CrossRef]

- Mahlow, S.; Orzechowski, S.; Fettke, J. Starch phosphorylation: Insights and perspectives. Cell. Mol. Life Sci. 2016, 73, 2753–2764. [Google Scholar] [CrossRef] [PubMed]

- Helle, S.; Bray, F.; Putaux, J.-L.; Verbeke, J.; Flament, S.; Rolando, C.; D’Hulst, C.; Szydlowski, N. Intra-Sample Heterogeneity of Potato Starch Reveals Fluctuation of Starch-Binding Proteins According to Granule Morphology. Plants 2019, 8, 324. [Google Scholar] [CrossRef]

- Hebelstrup, K.H.; Sagnelli, D.; Blennow, A. The future of starch bioengineering: GM microorganisms or GM plants? Front. Plant Sci. 2015, 6, 247. [Google Scholar] [CrossRef] [PubMed]

- Samodien, E.; Jewell, J.F.; Loedolff, B.; Oberlander, K.; George, G.M.; Zeeman, S.C.; Damberger, F.F.; van der Vyver, C.; Kossmann, J.; Lloyd, J.R. Repression of Sex4 and Like Sex Four2 Orthologs in Potato Increases Tuber Starch Bound Phosphate With Concomitant Alterations in Starch Physical Properties. Front. Plant Sci. 2018, 9, 1044. [Google Scholar] [CrossRef]

- Wang, W.; Hostettler, C.E.; Damberger, F.F.; Kossmann, J.; Lloyd, J.R.; Zeeman, S.C. Modification of Cassava Root Starch Phosphorylation Enhances Starch Functional Properties. Front. Plant Sci. 2018, 9, 1562. [Google Scholar] [CrossRef]

- Liu, F.; Ahmed, Z.; Lee, E.A.; Donner, E.; Liu, Q.; Ahmed, R.; Morell, M.K.; Emes, M.J.; Tetlow, I.J. Allelic variants of the amylose extender mutation of maize demonstrate phenotypic variation in starch structure resulting from modified protein-protein interactions. J. Exp. Bot. 2012, 63, 1167–1183. [Google Scholar] [CrossRef]

- Chia, T.; Chirico, M.; King, R.; Ramirez-Gonzalez, R.; Saccomanno, B.; Seung, D.; Simmonds, J.; Trick, M.; Uauy, C.; Verhoeven, T.; et al. A carbohydrate-binding protein, B-GRANULE CONTENT 1, influences starch granule size distribution in a dose-dependent manner in polyploid wheat. J. Exp. Bot. 2020, 71, 105–115. [Google Scholar] [CrossRef]

- Saito, M.; Tanaka, T.; Sato, K.; Vrinten, P.; Nakamura, T. A single nucleotide polymorphism in the “Fra” gene results in fractured starch granules in barley. Theor. Appl. Genet. 2018, 131, 353–364. [Google Scholar] [CrossRef] [PubMed]

- Suh, D.S.; Verhoeven, T.; Denyer, K.; Jane, J.-L. Characterization of Nubet and Franubet barley starches. Carbohydr. Polym. 2004, 56, 85–93. [Google Scholar] [CrossRef]

- Peng, C.; Wang, Y.; Liu, F.; Ren, Y.; Zhou, K.; Lv, J.; Zheng, M.; Zhao, S.; Zhang, L.; Wang, C.; et al. FLOURY ENDOSPERM6 encodes a CBM48 domain-containing protein involved in compound granule formation and starch synthesis in rice endosperm. Plant J. 2014, 77, 917–930. [Google Scholar] [CrossRef]

- Matsushima, R.; Maekawa, M.; Kusano, M.; Kondo, H.; Fujita, N.; Kawagoe, Y.; Sakamoto, W. Amyloplast-localized SUBSTANDARD STARCH GRAIN4 protein influences the size of starch grains in rice endosperm. Plant Physiol. 2014, 164, 623–636. [Google Scholar] [CrossRef]

- Matsushima, R.; Maekawa, M.; Kusano, M.; Tomita, K.; Kondo, H.; Nishimura, H.; Crofts, N.; Fujita, N.; Sakamoto, W. Amyloplast Membrane Protein SUBSTANDARD STARCH GRAIN6 Controls Starch Grain Size in Rice Endosperm. Plant Physiol. 2016, 170, 1445–1459. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Zhang, H.; Zhai, H.; Liu, Q.; He, S. A soluble starch synthase I gene, IbSSI, alters the content, composition, granule size and structure of starch in transgenic sweet potato. Sci. Rep. 2017, 7, 2315. [Google Scholar] [CrossRef] [PubMed]

- Toyosawa, Y.; Kawagoe, Y.; Matsushima, R.; Crofts, N.; Ogawa, M.; Fukuda, M.; Kumamaru, T.; Okazaki, Y.; Kusano, M.; Saito, K.; et al. Deficiency of Starch Synthase IIIa and IVb Alters Starch Granule Morphology from Polyhedral to Spherical in Rice Endosperm. Plant Physiol. 2016, 170, 1255–1270. [Google Scholar] [CrossRef]

- Crumpton-Taylor, M.; Pike, M.; Lu, K.-J.; Hylton, C.M.; Feil, R.; Eicke, S.; Lunn, J.E.; Zeeman, S.C.; Smith, A.M. Starch synthase 4 is essential for coordination of starch granule formation with chloroplast division during Arabidopsis leaf expansion. New Phytol. 2013, 200, 1064–1075. [Google Scholar] [CrossRef]

- Malinova, I.; Alseekh, S.; Feil, R.; Fernie, A.R.; Baumann, O.; Schöttler, M.A.; Lunn, J.E.; Fettke, J. Starch Synthase 4 and Plastidal Phosphorylase Differentially Affect Starch Granule Number and Morphology. Plant Physiol. 2017, 174, 73–85. [Google Scholar] [CrossRef] [PubMed]

- Malinova, I.; Fettke, J. Reduced starch granule number per chloroplast in the dpe2/phs1 mutant is dependent on initiation of starch degradation. PLoS ONE 2017, 12, e0187985. [Google Scholar] [CrossRef]

- Miura, S.; Crofts, N.; Saito, Y.; Hosaka, Y.; Oitome, N.F.; Watanabe, T.; Kumamaru, T.; Fujita, N. Starch Synthase IIa-Deficient Mutant Rice Line Produces Endosperm Starch With Lower Gelatinization Temperature Than Japonica Rice Cultivars. Front. Plant Sci. 2018, 9, 645. [Google Scholar] [CrossRef]

- Takahata, Y.; Tanaka, M.; Otani, M.; Katayama, K.; Kitahara, K.; Nakayachi, O.; Nakayama, H.; Yoshinaga, M. Inhibition of the expression of the starch synthase II gene leads to lower pasting temperature in sweetpotato starch. Plant Cell Rep. 2010, 29, 535–543. [Google Scholar] [CrossRef] [PubMed]

- Miao, H.; Sun, P.; Liu, Q.; Jia, C.; Liu, J.; Hu, W.; Jin, Z.; Xu, B. Soluble Starch Synthase III-1 in Amylopectin Metabolism of Banana Fruit: Characterization, Expression, Enzyme Activity, and Functional Analyses. Front. Plant Sci. 2017, 8, 454. [Google Scholar] [CrossRef] [PubMed]

- Brummell, D.A.; Watson, L.M.; Zhou, J.; McKenzie, M.J.; Hallett, I.C.; Simmons, L.; Carpenter, M.; Timmerman-Vaughan, G.M. Overexpression of STARCH BRANCHING ENZYME II increases short-chain branching of amylopectin and alters the physicochemical properties of starch from potato tuber. BMC Biotechnol. 2015, 15, 28. [Google Scholar] [CrossRef]

- Zeng, D.; Liu, T.; Ma, X.; Wang, B.; Zheng, Z.; Zhang, Y.; Xie, X.; Yang, B.; Zhao, Z.; Zhu, Q.; et al. Quantitative regulation of Waxy expression by CRISPR/Cas9-based promoter and 5′UTR-intron editing improves grain quality in rice. Plant Biotechnol. J. 2020, 18, 2385–2387. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, Q.; Li, X.; Wang, F.; Chen, Z.; Wang, J.; Li, W.; Fan, F.; Tao, Y.; Jiang, Y.; et al. Fine-tuning the amylose content of rice by precise base editing of the Wx gene. Plant Biotechnol. J. 2021, 19, 11–13. [Google Scholar] [CrossRef]

- Bull, S.E.; Seung, D.; Chanez, C.; Mehta, D.; Kuon, J.-E.; Truernit, E.; Hochmuth, A.; Zurkirchen, I.; Zeeman, S.C.; Gruissem, W.; et al. Accelerated ex situ breeding of GBSS- and PTST1-edited cassava for modified starch. Sci. Adv. 2018, 4, eaat6086. [Google Scholar] [CrossRef]

- Kitahara, K.; Hamasuna, K.; Nozuma, K.; Otani, M.; Hamada, T.; Shimada, T.; Fujita, K.; Suganuma, T. Physicochemical properties of amylose-free and high-amylose starches from transgenic sweetpotatoes modified by RNA interference. Carbohydr. Polym. 2007, 69, 233–240. [Google Scholar] [CrossRef]

- Kuipers, A.; Jacobsen, E.; Visser, R. Formation and Deposition of Amylose in the Potato Tuber Starch Granule Are Affected by the Reduction of Granule-Bound Starch Synthase Gene Expression. Plant Cell 1994, 6, 43–52. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Jiao, G.; Liu, Z.; Zhang, X.; Li, J.; Guo, X.; Du, W.; Du, J.; Francis, F.; Zhao, Y.; et al. Generation of High-Amylose Rice through CRISPR/Cas9-Mediated Targeted Mutagenesis of Starch Branching Enzymes. Front. Plant Sci. 2017, 8, 298. [Google Scholar] [CrossRef]

- Zhao, X.; Andersson, M.; Andersson, R. Resistant starch and other dietary fiber components in tubers from a high-amylose potato. Food Chem. 2018, 251, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Carciofi, M.; Shaik, S.S.; Jensen, S.L.; Blennow, A.; Svensson, J.T.; Vincze, É.; Hebelstrup, K.H. Hyperphosphorylation of cereal starch. J. Cereal Sci. 2011, 54, 339–346. [Google Scholar] [CrossRef]

- Kozlov, S.S.; Blennow, A.; Krivandin, A.V.; Yuryev, V.P. Structural and thermodynamic properties of starches extracted from GBSS and GWD suppressed potato lines. Int. J. Biol. Macromol. 2007, 40, 449–460. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Sun, X.; Zhou, X.; Hebelstrup, K.H.; Blennow, A.; Bao, J. Highly phosphorylated functionalized rice starch produced by transgenic rice expressing the potato GWD1 gene. Sci. Rep. 2017, 7, 3339. [Google Scholar] [CrossRef]

- Kringel, D.H.; El Halal, S.L.M.; Da Zavareze, E.R.; Dias, A.R.G. Methods for the Extraction of Roots, Tubers, Pulses, Pseudocereals, and Other Unconventional Starches Sources: A Review. Starch-Stärke 2020, 72, 1900234. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, L.; Qian, Y.; Wang, X.; Zhang, S.; Chang, J.; Ruan, Y.; Ma, B. Influences of Extraction Methods on Physicochemical and Functional Characteristics of Three New Bulbil Starches from Dioscorea opposita Thunb. cv. Tiegun. Molecules 2019, 24, 2232. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Liu, Y.; Liu, X. Starch Modification and Application. In Starch Structure, Functionality and Application in Foods; Wang, S., Ed.; Springer: Singapore, 2020; pp. 131–149. ISBN 978-981-15-0621-5. [Google Scholar]

- Ayoub, A.S.; Rizvi, S.S.H. An Overview on the Technology of Cross-Linking of Starch for Nonfood Applications. J. Plast. Film Sheeting 2009, 25, 25–45. [Google Scholar] [CrossRef]

- Wang, S. (Ed.) Starch Structure, Functionality and Application in Foods; Springer: Singapore, 2020; ISBN 978-981-15-0621-5. [Google Scholar]

- Koo, S.H.; Lee, K.Y.; Lee, H.G. Effect of cross-linking on the physicochemical and physiological properties of corn starch. Food Hydrocoll. 2010, 24, 619–625. [Google Scholar] [CrossRef]

- Chung, H.-J.; Woo, K.-S.; Lim, S.-T. Glass transition and enthalpy relaxation of cross-linked corn starches. Carbohydr. Polym. 2004, 55, 9–15. [Google Scholar] [CrossRef]

- Lehmann, A.; Volkert, B. Investigations on esterification reactions of starches in 1-N-butyl-3-methylimidazolium chloride and resulting substituent distribution. J. Appl. Polym. Sci. 2009, 114, 369–376. [Google Scholar] [CrossRef]

- Chen, Q.; Yu, H.; Wang, L.; ul Abdin, Z.; Chen, Y.; Wang, J.; Zhou, W.; Yang, X.; Khan, R.U.; Zhang, H.; et al. Recent progress in chemical modification of starch and its applications. RSC Adv. 2015, 5, 67459–67474. [Google Scholar] [CrossRef]

- Otache, M.A.; Duru, R.U.; Achugasim, O.; Abayeh, O.J. Advances in the Modification of Starch via Esterification for Enhanced Properties. J. Polym. Environ. 2021, 29, 1365–1379. [Google Scholar] [CrossRef]

- Singh, J.; Kaur, L.; McCarthy, O.J. Factors influencing the physico-chemical, morphological, thermal and rheological properties of some chemically modified starches for food applications—A review. Food Hydrocoll. 2007, 21, 1–22. [Google Scholar] [CrossRef]

- Ariyantoro, A.R.; Katsuno, N.; Nishizu, T. Effects of Dual Modification with Succinylation and Annealing on Physicochemical, Thermal and Morphological Properties of Corn Starch. Foods 2018, 7, 133. [Google Scholar] [CrossRef] [PubMed]

- Tharanathan, R.N. Starch--value addition by modification. Crit. Rev. Food Sci. Nutr. 2005, 45, 371–384. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.; Zeng, X.-A.; Brennan, C.S.; Brennan, M.; Han, Z. Recent Advances in Techniques for Starch Esters and the Applications: A Review. Foods 2016, 5, 50. [Google Scholar] [CrossRef]

- Spychaj, T.; Wilpiszewska, K.; Zdanowicz, M. Medium and high substituted carboxymethyl starch: Synthesis, characterization and application. Starch-Stärke 2013, 65, 22–33. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Manikantan, M.R.; Divya, V.; Ashokkumar, C.; Kaavya, R.; Kothakota, A.; Ramesh, S.V. Ozone: An Advanced Oxidation Technology for Starch Modification. Ozone Sci. Eng. 2019, 41, 491–507. [Google Scholar] [CrossRef]

- Djordjevic, S.; Nikolic, L.; Kovacevic, S.; Miljkovic, M.; Djordjevic, D. Graft copolymerization of acrylic acid onto hydrolyzed potato starch using various initiators. Period. Polytech. Chem. Eng. 2013, 57, 55. [Google Scholar] [CrossRef]

- Kurkuri, M.D.; Lee, J.-R.; Han, J.H.; Lee, I. Electroactive behavior of poly(acrylic acid) grafted poly(vinyl alcohol) samples, their synthesis using a Ce (IV) glucose redox system and their characterization. Smart Mater. Struct. 2006, 15, 417–423. [Google Scholar] [CrossRef]

- Athawale, V.D.; Rathi, S.C. Graft Polymerization: Starch as a Model Substrate. J. Macromol. Sci. Part C Polym. Rev. 1999, 39, 445–480. [Google Scholar] [CrossRef]

- Kumar, D.; Pandey, J.; Raj, V.; Kumar, P. A Review on the Modification of Polysaccharide Through Graft Copolymerization for Various Potential Applications. Open Med. Chem. J. 2017, 11, 109–126. [Google Scholar] [CrossRef] [PubMed]

- Noordergraaf, I.-W.; Fourie, T.; Raffa, P. Free-Radical Graft Polymerization onto Starch as a Tool to Tune Properties in Relation to Potential Applications. A Review. Processes 2018, 6, 31. [Google Scholar] [CrossRef]

- Jyothi, A.N. Starch Graft Copolymers: Novel Applications in Industry. Compos. Interfaces 2010, 17, 165–174. [Google Scholar] [CrossRef]

- Tian, S.; Chen, Y.; Chen, Z.; Yang, Y.; Wang, Y. Preparation and Characteristics of Starch Esters and Its Effects on Dough Physicochemical Properties. J. Food Qual. 2018, 2018, 1395978. [Google Scholar] [CrossRef]

- Pooresmaeil, M.; Namazi, H. Developments on carboxymethyl starch-based smart systems as promising drug carriers: A review. Carbohydr. Polym. 2021, 258, 117654. [Google Scholar] [CrossRef]

- Musarurwa, H.; Tavengwa, N.T. Application of carboxymethyl polysaccharides as bio-sorbents for the sequestration of heavy metals in aquatic environments. Carbohydr. Polym. 2020, 237, 116142. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Gonçalves, J.R.; El Halal, S.L.M.; Pinto, V.Z.; Dias, A.R.G.; Jacques, A.C.; Da Zavareze, E.R. Oxidation of potato starch with different sodium hypochlorite concentrations and its effect on biodegradable films. LWT-Food Sci. Technol. 2015, 60, 714–720. [Google Scholar] [CrossRef]

- Vanier, N.L.; El Halal, S.L.M.; Dias, A.R.G.; Da Rosa Zavareze, E. Molecular structure, functionality and applications of oxidized starches: A review. Food Chem. 2017, 221, 1546–1559. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Xie, F.; Zhao, L.; Qiao, Q.; Liu, X. Effect of acid hydrolysis on the multi-scale structure change of starch with different amylose content. Food Hydrocoll. 2017, 69, 359–368. [Google Scholar] [CrossRef]

- Silva, N.M.C.D.; de Lima, F.F.; Fialho, R.L.L.; Albuquerque, E.C.; Velasco, J.I.; Fakhouri, F.M. Production and Characterization of Starch Nanoparticles. In Applications of Modified Starches; Huicochea, E.F., Villalobos, R.R., Eds.; InTech: London, UK, 2018; ISBN 978-1-78923-372-8. [Google Scholar]

- Wang, S.; Copeland, L. Effect of acid hydrolysis on starch structure and functionality: A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1081–1097. [Google Scholar] [CrossRef]

- Pratiwi, M.; Faridah, D.N.; Lioe, H.N. Structural changes to starch after acid hydrolysis, debranching, autoclaving-cooling cycles, and heat moisture treatment (HMT): A review. Starch-Stärke 2018, 70, 1700028. [Google Scholar] [CrossRef]

- Dang, X.; Yang, M.; Shan, Z.; Mansouri, S.; May, B.K.; Chen, X.; Chen, H.; Woo, M.W. On spray drying of oxidized corn starch cross-linked gelatin microcapsules for drug release. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 74, 493–500. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Luo, S.; Li, C.; Ye, J.; Liu, C.; Gilbert, R.G. Physicochemical and structural properties of pregelatinized starch prepared by improved extrusion cooking technology. Carbohydr. Polym. 2017, 175, 265–272. [Google Scholar] [CrossRef]

- Moscicki, L.; Mitrus, M.; Wojtowicz, A.; Oniszczuk, T.; Rejak, A. Extrusion-Cooking of Starch. In Advances in Agrophysical Research; Grundas, S., Ed.; InTech: London, UK, 2013; ISBN 978-953-51-1184-9. [Google Scholar]

- Ye, J.; Hu, X.; Luo, S.; Liu, W.; Chen, J.; Zeng, Z.; Liu, C. Properties of Starch after Extrusion: A Review. Starch-Stärke 2018, 70, 1700110. [Google Scholar] [CrossRef]

- Da Zavareze, E.R.; Dias, A.R.G. Impact of heat-moisture treatment and annealing in starches: A review. Carbohydr. Polym. 2011, 83, 317–328. [Google Scholar] [CrossRef]

- Gunaratne, A. Heat-Moisture Treatment of Starch. In Physical Modifications of Starch; Sui, Z., Kong, X., Eds.; Springer: Singapore, 2018; pp. 15–36. ISBN 978-981-13-0724-9. [Google Scholar]

- Braşoveanu, M.; Nemţanu, M.R. Behaviour of starch exposed to microwave radiation treatment. Starch-Stärke 2014, 66, 3–14. [Google Scholar] [CrossRef]

- Emami, S.; Meda, V.; Pickard, M.D.; Tyler, R.T. Impact of micronization on rapidly digestible, slowly digestible, and resistant starch concentrations in normal, high-amylose, and waxy barley. J. Agric. Food Chem. 2010, 58, 9793–9799. [Google Scholar] [CrossRef]

- Li, E.; Dhital, S.; Hasjim, J. Effects of grain milling on starch structures and flour/starch properties. Starch-Stärke 2014, 66, 15–27. [Google Scholar] [CrossRef]

- Punia, S. Barley starch modifications: Physical, chemical and enzymatic—A review. Int. J. Biol. Macromol. 2020, 144, 578–585. [Google Scholar] [CrossRef]

- Castro, L.M.; Alexandre, E.M.; Saraiva, J.A.; Pintado, M. Impact of high pressure on starch properties: A review. Food Hydrocoll. 2020, 106, 105877. [Google Scholar] [CrossRef]

- Bonto, A.P.; Tiozon, R.N.; Sreenivasulu, N.; Camacho, D.H. Impact of ultrasonic treatment on rice starch and grain functional properties: A review. Ultrason. Sonochem. 2021, 71, 105383. [Google Scholar] [CrossRef]

- Luu, T.D.; Phan, N.H.; Tran, T.T.-D.; van Vo, T.; Tran, P.H.-L. Use of Microwave Method for Controlling Drug Release of Modified Sprouted Rice Starch. In 5th International Conference on Biomedical Engineering in Vietnam; van Toi, V., Lien Phuong, T.H., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 314–316. ISBN 978-3-319-11775-1. [Google Scholar]

- Lewicka, K.; Siemion, P.; Kurcok, P. Chemical Modifications of Starch: Microwave Effect. Int. J. Polym. Sci. 2015, 2015, 867697. [Google Scholar] [CrossRef]

- Konwarh, R.; Karak, N.; Sawian, C.E.; Baruah, S.; Mandal, M. Effect of sonication and aging on the templating attribute of starch for “green” silver nanoparticles and their interactions at bio-interface. Carbohydr. Polym. 2011, 83, 1245–1252. [Google Scholar] [CrossRef]

- Pejin, D.J.; Mojović, L.V.; Pejin, J.D.; Grujić, O.S.; Markov, S.L.; Nikolić, S.B.; Marković, M.N. Increase in bioethanol production yield from triticale by simultaneous saccharification and fermentation with application of ultrasound. J. Chem. Technol. Biotechnol. 2012, 87, 170–176. [Google Scholar] [CrossRef]

- Hernoux, A.; Lévêque, J.-M.; Lassi, U.; Molina-Boisseau, S.; Marais, M.-F. Conversion of a non-water soluble potato starch waste into reducing sugars under non-conventional technologies. Carbohydr. Polym. 2013, 92, 2065–2074. [Google Scholar] [CrossRef] [PubMed]

- Błaszczak, W.; Fornal, J.; Kiseleva, V.I.; Yuryev, V.P.; Sergeev, A.I.; Sadowska, J. Effect of high pressure on thermal, structural and osmotic properties of waxy maize and Hylon VII starch blends. Carbohydr. Polym. 2007, 68, 387–396. [Google Scholar] [CrossRef]

- Zhang, L.; Ji, H.; Yang, M.; Ma, H. Effects of High Hydrostatic Pressure Treated Mung Bean Starch on Characteristics of Batters and Crusts from Deep-Fried Pork Nuggets. Int. J. Food Eng. 2014, 10, 261–268. [Google Scholar] [CrossRef]

- Jia, F.; Wang, J.; Wang, Q.; Zhang, X.; Chen, D.; Chen, Y.; Zhang, C. Effect of extrusion on the polymerization of wheat glutenin and changes in the gluten network. J. Food Sci. Technol. 2020, 57, 3814–3822. [Google Scholar] [CrossRef] [PubMed]

- Kurahashi, Y.; Yoshino, Z. Heat-Moisture-Treated Starch; Its Production, Properties, and Uses. J. Appl. Glycosci. 2000, 47, 125–132. [Google Scholar] [CrossRef]

- Yao, T.; Sui, Z.; Janaswamy, S. Annealing. In Physical Modifications of Starch; Sui, Z., Kong, X., Eds.; Springer: Singapore, 2018; pp. 37–49. ISBN 978-981-13-0724-9. [Google Scholar]

- Roushdi, M.; Harras, A.; El-Meligi, A.; Bassim, M. Effect of High Doses of Gamma Rays on Corn Grains. Part II. Influence on Some Physical and Chemical Properties of Starch and Its Fractions. Starch-Stärke 1983, 35, 15–18. [Google Scholar] [CrossRef]

- Polesi, L.F.; Da Junior, M.D.M.; Sarmento, S.B.S.; Canniatti-Brazaca, S.G. Starch Digestibility and Physicochemical and Cooking Properties of Irradiated Rice Grains. Rice Sci. 2017, 24, 48–55. [Google Scholar] [CrossRef]

- Gul, K.; Singh, A.K.; Sonkawade, R.G. Physicochemical, thermal and pasting characteristics of gamma irradiated rice starches. Int. J. Biol. Macromol. 2016, 85, 460–466. [Google Scholar] [CrossRef]

- Tomasik, P.; Zaranyika, M.F. Nonconventional methods of modification of starch. Adv. Carbohydr. Chem. Biochem. 1995, 51, 243–320. [Google Scholar] [CrossRef]

- Thirumdas, R.; Trimukhe, A.; Deshmukh, R.R.; Annapure, U.S. Functional and rheological properties of cold plasma treated rice starch. Carbohydr. Polym. 2017, 157, 1723–1731. [Google Scholar] [CrossRef]

- Zhu, F. Plasma modification of starch. Food Chem. 2017, 232, 476–486. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.; Sun, D.-W.; Zhu, Z. Enhancing Food Processing by Pulsed and High Voltage Electric Fields: Principles and Applications. Crit. Rev. Food Sci. Nutr. 2018, 58, 2285–2298. [Google Scholar] [CrossRef]

- Han, Z.; Zeng, X.-A.; Zhang, B.; Yu, S. Effects of pulsed electric fields (PEF) treatment on the properties of corn starch. J. Food Eng. 2009, 93, 318–323. [Google Scholar] [CrossRef]

- Li, L.; Chen, J.; Wang, H.; Guo, H.; Li, D.; Li, J.; Liu, J.; Shao, H.; Zong, J. Cold plasma treatment improves seed germination and accelerates the establishment of centipedegrass. Crop Sci. 2021, 61, 2827–2836. [Google Scholar] [CrossRef]

- van der Maarel, M.J.E.C.; van der Veen, B.; Uitdehaag, J.C.M.; Leemhuis, H.; Dijkhuizen, L. Properties and applications of starch-converting enzymes of the alpha-amylase family. J. Biotechnol. 2002, 94, 137–155. [Google Scholar] [CrossRef] [PubMed]

- Hyun, H.H.; Zeikus, J.G. Regulation and genetic enhancement of beta-amylase production in Clostridium thermosulfurogenes. J. Bacteriol. 1985, 164, 1162–1170. [Google Scholar] [CrossRef] [PubMed]

- Dura, A.; Błaszczak, W.; Rosell, C.M. Functionality of porous starch obtained by amylase or amyloglucosidase treatments. Carbohydr. Polym. 2014, 101, 837–845. [Google Scholar] [CrossRef]

- Del Moral, S.; Barradas-Dermitz, D.M.; Aguilar-Uscanga, M.G. Production and biochemical characterization of α-glucosidase from Aspergillus niger ITV-01 isolated from sugar cane bagasse. 3 Biotech 2018, 8, 7. [Google Scholar] [CrossRef]

- Ashok, P.; Soccol, C.R.; Soccol, V.T. Biopotential of immobilized amylases. Indian J. Microbiol. 2000, 40, 1–14. [Google Scholar]

- Gaouar, O.; Zakhia, N.; Aymard, C.; Rios, G.M. Production of maltose syrup by bioconversion of cassava starch in an ultrafiltration reactor. Ind. Crops Prod. 1998, 7, 159–167. [Google Scholar] [CrossRef]

- Teotia, S.; Khare, S.K.; Gupta, M.N. An efficient purification process for sweet potato beta-amylase by affinity precipitation with alginate. Enzym. Microb. Technol. 2001, 28, 792–795. [Google Scholar] [CrossRef]

- Abraham, T.E.; Jamuna, R.; Bansilal, C.V.; Ramakrishna, S.V. Continuous Synthesis of Glucoamylase by Immobilized Fungal Mycelium of Aspergillus niger. Starch-Stärke 1991, 43, 113–116. [Google Scholar] [CrossRef]

- Berghofer, E.; Sarhaddar, S. Production of glucose and high fructose syrup by enzymatic direct hydrolysis of cassava roots. Process Biochem. 1988, 23, 188–194. [Google Scholar]

- Kirk, O.; Borchert, T.V.; Fuglsang, C.C. Industrial enzyme applications. Curr. Opin. Biotechnol. 2002, 13, 345–351. [Google Scholar] [CrossRef] [PubMed]

- Chiba, S. Molecular mechanism in alpha-glucosidase and glucoamylase. Biosci. Biotechnol. Biochem. 1997, 61, 1233–1239. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.-L.; Tong, X.; Chen, S.-W.; Chen, S.; Wu, D.; Fang, S.-G.; Wu, J.; Chen, J. Heterologous expression and biochemical characterization of alpha-glucosidase from Aspergillus niger by Pichia pastroris. J. Agric. Food Chem. 2010, 58, 4819–4824. [Google Scholar] [CrossRef]

- Mohiuddin, M.; Arbain, D.; Islam, A.K.M.S.; Ahmad, M.S.; Ahmad, M.N. Alpha-Glucosidase Enzyme Biosensor for the Electrochemical Measurement of Antidiabetic Potential of Medicinal Plants. Nanoscale Res. Lett. 2016, 11, 95. [Google Scholar] [CrossRef]

- Borchert, T.V.; Lassen, S.F.; Svendsen, A.; Frantzen, H.B. Oxidation stable amylases for detergents. Prog. Biotechnol. 1995, 10, 175–179. [Google Scholar]

- Beier, L.; Svendsen, A.; Andersen, C.; Frandsen, T.P.; Borchert, T.V.; Cherry, J.R. Conversion of the maltogenic alpha-amylase Novamyl into a CGTase. Protein Eng. 2000, 13, 509–513. [Google Scholar] [CrossRef] [PubMed]

- Kelly, R.M.; Dijkhuizen, L.; Leemhuis, H. Starch and alpha-glucan acting enzymes, modulating their properties by directed evolution. J. Biotechnol. 2009, 140, 184–193. [Google Scholar] [CrossRef]

- Ao, Z.; Simsek, S.; Zhang, G.; Venkatachalam, M.; Reuhs, B.L.; Hamaker, B.R. Starch with a slow digestion property produced by altering its chain length, branch density, and crystalline structure. J. Agric. Food Chem. 2007, 55, 4540–4547. [Google Scholar] [CrossRef]

- LEE, K.; KIM, Y.; PARK, K.; LEE, H. Effects of α-glucanotransferase treatment on the thermo-reversibility and freeze-thaw stability of a rice starch gel. Carbohydr. Polym. 2006, 63, 347–354. [Google Scholar] [CrossRef]

- Hii, S.L.; Tan, J.S.; Ling, T.C.; Ariff, A.B. Pullulanase: Role in starch hydrolysis and potential industrial applications. Enzym. Res. 2012, 2012, 921362. [Google Scholar] [CrossRef]

- Jobling, S. Improving starch for food and industrial applications. Curr. Opin. Plant Biol. 2004, 7, 210–218. [Google Scholar] [CrossRef]

- Alting, A.C.; van de Velde, F.; Kanning, M.W.; Burgering, M.; Mulleners, L.; Sein, A.; Buwalda, P. Improved creaminess of low-fat yoghurt: The impact of amylomaltase-treated starch domains. Food Hydrocoll. 2009, 23, 980–987. [Google Scholar] [CrossRef]

- Park, J.-H.; Kim, H.-J.; Kim, Y.-H.; Cha, H.; Kim, Y.-W.; Kim, T.-J.; Kim, Y.-R.; Park, K.-H. The action mode of Thermus aquaticus YT-1 4-α-glucanotransferase and its chimeric enzymes introduced with starch-binding domain on amylose and amylopectin. Carbohydr. Polym. 2007, 67, 164–173. [Google Scholar] [CrossRef]

- Kim, Y.-L.; Mun, S.; Park, K.-H.; Shim, J.-Y.; Kim, Y.-R. Physicochemical functionality of 4-α-glucanotransferase-treated rice flour in food application. Int. J. Biol. Macromol. 2013, 60, 422–426. [Google Scholar] [CrossRef] [PubMed]

- Mun, S.; Kim, Y.-L.; Kang, C.-G.; Park, K.-H.; Shim, J.-Y.; Kim, Y.-R. Development of reduced-fat mayonnaise using 4alphaGTase-modified rice starch and xanthan gum. Int. J. Biol. Macromol. 2009, 44, 400–407. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.H.D.; Tran, P.L.; Li, D.; Han, J.-A.; Hwang, J.-Y.; Hong, W.-S.; Lee, J.-S.; Kim, Y.-R.; Yoo, S.-H.; Park, J.-T.; et al. Modification of rice grain starch for lump-free cooked rice using thermostable disproportionating enzymes. Food Res. Int. 2014, 63, 55–61. [Google Scholar] [CrossRef]

- PEDERSEN, S. A better enzyme for cyclodextrins. Chemtech 1995, 25, 19–25. [Google Scholar]

- Shim, J.-H.; Seo, N.-S.; Roh, S.-A.; Kim, J.-W.; Cha, H.; Park, K.-H. Improved bread-baking process using Saccharomyces cerevisiae displayed with engineered cyclodextrin glucanotransferase. J. Agric. Food Chem. 2007, 55, 4735–4740. [Google Scholar] [CrossRef]

- Garcia, M.A.V.T.; Garcia, C.F.; Faraco, A.A.G. Pharmaceutical and Biomedical Applications of Native and Modified Starch: A Review. Starch-Stärke 2020, 72, 1900270. [Google Scholar] [CrossRef]

- Shin, H.J.; Choi, S.J.; Park, C.S.; Moon, T.W. Preparation of starches with low glycaemic response using amylosucrase and their physicochemical properties. Carbohydr. Polym. 2010, 82, 489–497. [Google Scholar] [CrossRef]

- Kim, H.R.; Choi, S.J.; Park, C.-S.; Moon, T.W. Kinetic studies of in vitro digestion of amylosucrase-modified waxy corn starches based on branch chain length distributions. Food Hydrocoll. 2017, 65, 46–56. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, X.; He, J.; Wang, T.; Luo, X.; Wang, L.; Wang, R.; Chen, Z. Impact of amylosucrase modification on the structural and physicochemical properties of native and acid-thinned waxy corn starch. Food Chem. 2017, 220, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Ryu, J.-H.; Lee, B.-H.; Seo, D.-H.; Baik, M.-Y.; Park, C.-S.; Wang, R.; Yoo, S.-H. Production and characterization of digestion-resistant starch by the reaction of Neisseria polysaccharea amylosucrase. Starch-Stärke 2010, 62, 221–228. [Google Scholar] [CrossRef]

- Bender, H.; Lehmann, J.; Wallenfels, K. Pullulan, an extracellular glucan from Pullularia pullulans. Biochim. Biophys. Acta 1959, 36, 309–316. [Google Scholar] [CrossRef] [PubMed]

- Barnett, C.; Smith, A.; Scanlon, B.; Israilides, C.J. Pullulan production by Aureobasidium pullulans growing on hydrolysed potato starch waste. Carbohydr. Polym. 1999, 38, 203–209. [Google Scholar] [CrossRef]

- Kaur, B.; Ariffin, F.; Bhat, R.; Karim, A.A. Progress in starch modification in the last decade. Food Hydrocoll. 2012, 26, 398–404. [Google Scholar] [CrossRef]

- Seo, D.-H.; Yoo, S.-H.; Choi, S.-J.; Kim, Y.-R.; Park, C.-S. Versatile biotechnological applications of amylosucrase, a novel glucosyltransferase. Food Sci. Biotechnol. 2020, 29, 1–16. [Google Scholar] [CrossRef]

- Pfister, B.; Zeeman, S.C.; Rugen, M.D.; Field, R.A.; Ebenhöh, O.; Raguin, A. Theoretical and experimental approaches to understand the biosynthesis of starch granules in a physiological context. Photosynth. Res. 2020, 145, 55–70. [Google Scholar] [CrossRef]

- Adak, S.; Banerjee, R. A green approach for starch modification: Esterification by lipase and novel imidazolium surfactant. Carbohydr. Polym. 2016, 150, 359–368. [Google Scholar] [CrossRef]

| Starch Parameter | Gene Target | Organism Species (Gene Changes) | Structural Changes | Reference |

|---|---|---|---|---|

| Granule size | B-Granule Content 1 (BGC1) | Wheat Triticum aestivum (mutation) | Reduced B-type granules | [12] |

| Floury Endosperm 6 (FLO6) | Barley Hordeum vulgare (mutation) | Fractured granules | [13,14] | |

| Floury Endosperm 6 (FLO6) | Rice Oryza sativa (mutation) | Formation of compound granule was defective—smaller irregular granules | [15] | |

| Substandard Starch Grain 4/6 (SSG4 or SSG6) | Rice Oryza sativa (mutation) | Higher compound granule size | [16,17] | |

| Starch Synthase 1 (SS1) | Sweet potato Ipomoea batatas (overexpression) | Higher granule size Bimodal granule size distribution | [18] | |

| Granule morphology | Starch Synthase 3a/4b (SS3a/SS4b) | Rice Oryza sativa (mutation) | Change granules from polyhedral to spherical | [19] |

| Starch Synthase 4 (SS4) | Arabidopsis Arabidopsis thaliana (mutation) | Change granules from discoid to spherical | [20,21] | |

| Cytosolic disproportionating enzyme 2 (DPE2) and plastidial phosphorylase (PHS1) | Arabidopsis Arabidopsis thaliana (mutation) | Change granules from discoid to spherical | [22] | |

| Amylopectin content | Starch Synthase 2 (SS2) | Rice Oryza sativa (mutation) | Higher in amylopectin short chains | [23] |

| Sweet potato Ipomoea batatas (suppression) | Higher in amylopectin short chains | [24] | ||

| Starch Synthase 3 (SS3) | Tomato Solanum lycopersicum (overexpression) | Higher amylopectin content | [25] | |

| Starch Branching Enzyme 2 (SBE2) | Potato Solanum tuberosum (overexpression) | Higher in amylopectin short chains, more branches | [26] | |

| Amylose content | Granule-Bound Starch Synthase (GBSS) | Rice Oryza sativa (mutation) | Lower amylose content | [27,28] |

| Cassava Manihot esculenta (mutation) | Lower amylose content | [29] | ||

| Sweet potato Ipomoea batatas (suppression) | Lower amylose content Absence of long amylopectin chains | [30] | ||

| Potato Solanum tuberosum (suppression) | Lower amylose content | [31] | ||

| Starch Branching Enzyme (SBEIIb) | Rice Oryza sativa (mutation) | Higher amylose content Higher in amylopectin long chains Change of granule morphology | [32] | |

| Maize Zea mays (mutation) | Amylose extender starch Higher amylose content Higher in amylopectin long chains Change of granule morphology | [11] | ||

| Starch Branching Enzyme (SBEI/SBEII) | Potato Solanum tuberosum (suppression) | Higher amylose content Higher in amylopectin long chains Change of granule morphology | [33] | |

| Phosphate content | Glucan, Water Dikinase (GWD) | Barley Hordeum vulgare (overexpression) | Higher phosphate content Change of granule morphology | [34] |

| Cassava Manihot esculenta (overexpression) | Higher phosphate content | [10] | ||

| Potato Solanum tuberosum (suppression) | Lower phosphate content Higher amylose content | [35] | ||

| Rice Oryza sativa (overexpression) | Higher phosphate content | [36] | ||

| Starch Excess 4 or Like Sex Four 2 (SEX4 or LSF2) | Potato Solanum tuberosum (suppression) | Higher phosphate content Altered amylopectin structure. Reduced granule size | [9] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Compart, J.; Singh, A.; Fettke, J.; Apriyanto, A. Customizing Starch Properties: A Review of Starch Modifications and Their Applications. Polymers 2023, 15, 3491. https://doi.org/10.3390/polym15163491

Compart J, Singh A, Fettke J, Apriyanto A. Customizing Starch Properties: A Review of Starch Modifications and Their Applications. Polymers. 2023; 15(16):3491. https://doi.org/10.3390/polym15163491

Chicago/Turabian StyleCompart, Julia, Aakanksha Singh, Joerg Fettke, and Ardha Apriyanto. 2023. "Customizing Starch Properties: A Review of Starch Modifications and Their Applications" Polymers 15, no. 16: 3491. https://doi.org/10.3390/polym15163491