Enhancing the Potential of Polymer Composites Using Biochar as a Filler: A Review

Abstract

:1. Introduction

2. Production, Properties, and Potential Applications of Biochar in Composites

3. Production of Polymer Composites through Extrusion and Casting

4. Types of Carbon-Based Filler Materials and Their Properties

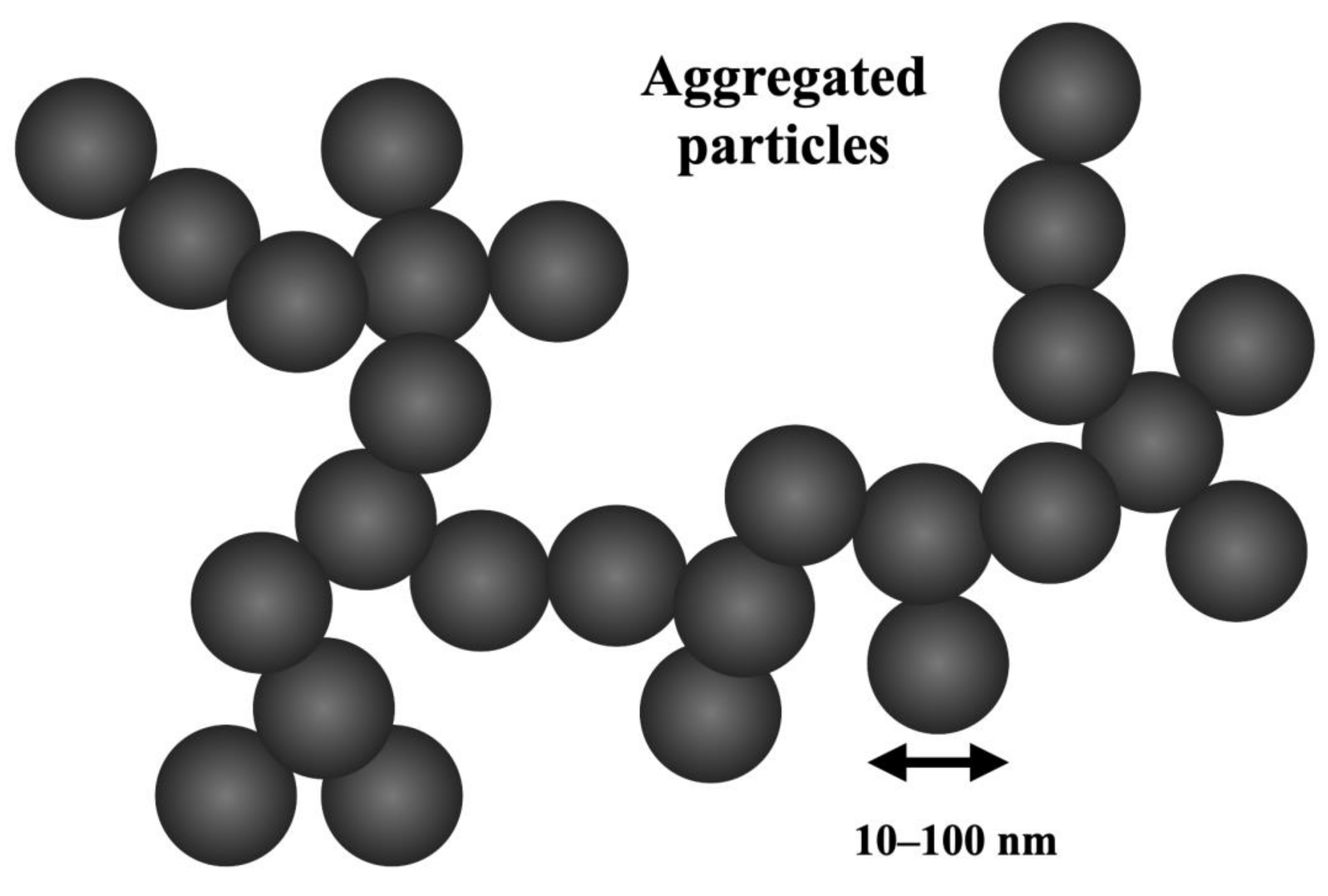

4.1. Carbon Black

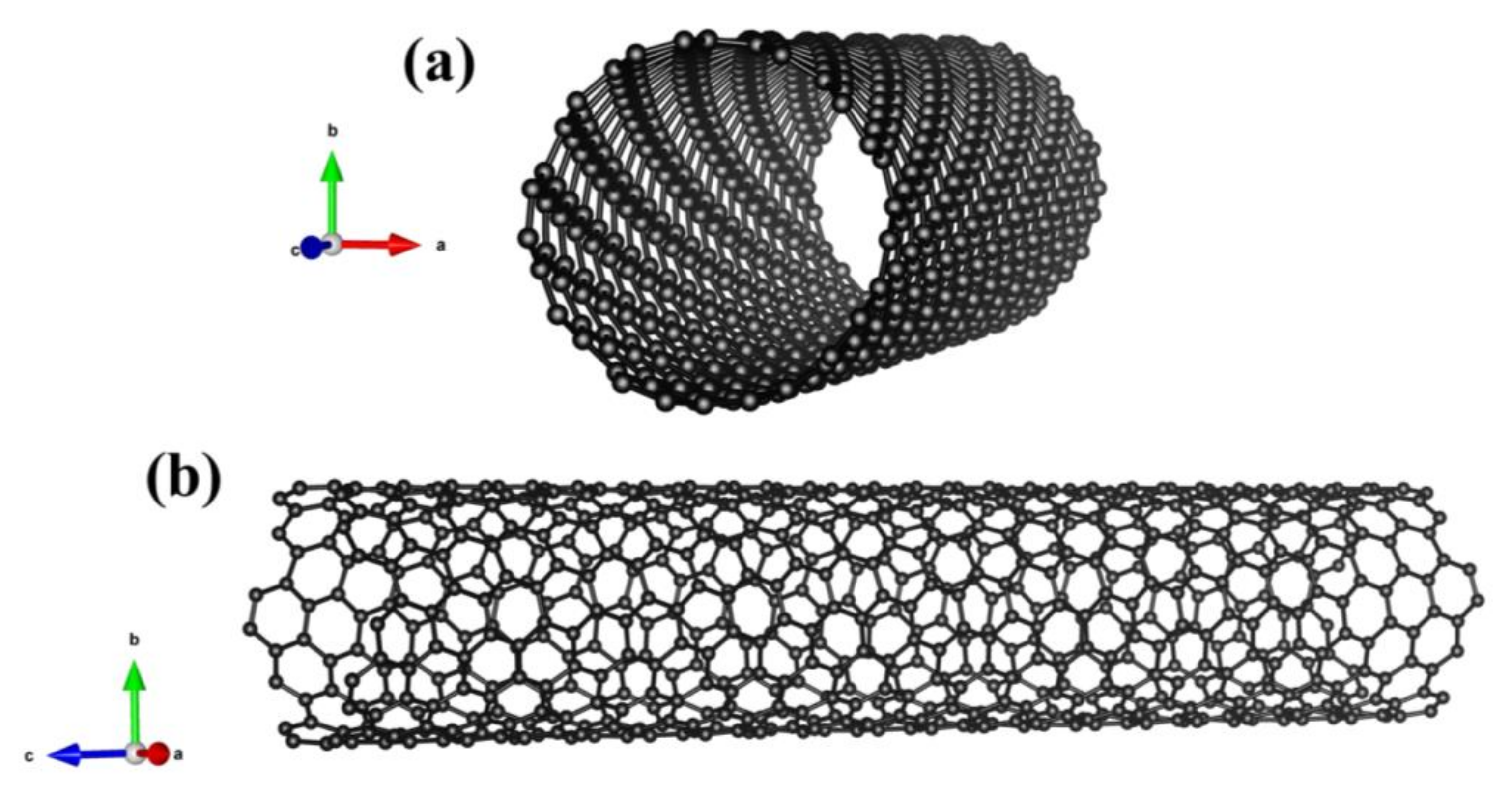

4.2. Carbon Nanotubes

4.3. Carbon Filaments and Fibers

4.4. Graphite and Graphene-Related Materials

4.5. Biochar

5. Use of Filler Materials in Polymer Composites: Effects and Limitations

5.1. Effects of Filler Addition on the Mechanical Performance of Polymer Composites

5.2. Thermal Conductivity in Polymer Composites

6. Biochar Properties and Biochar’s Impact as a Filler in Polymer Composites

6.1. Effects of Biochar Addition on the Thermal Stability of Polymer Composites

6.2. Effects of Biochar Addition on Flammability and Flame Retardancy

6.3. Electrical Conductivity of Polymers by Addition of Conductive Fillers

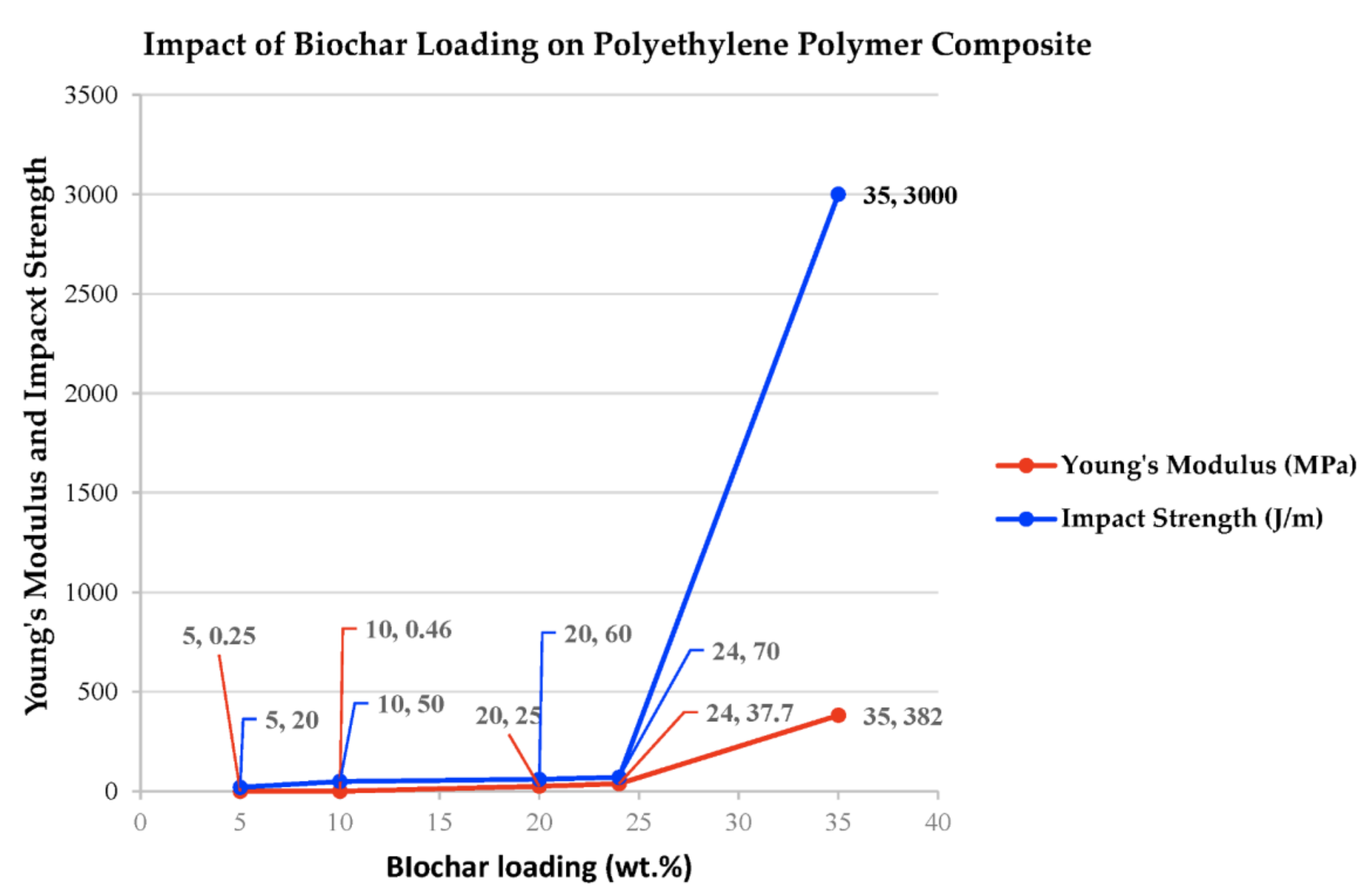

6.4. Impact of Biochar Filler Loading on Other Mechanical Properties

6.5. Effects of Biochar Particle Size and Loading on Polymer Composites

6.6. Effects of Biochar Surface Area

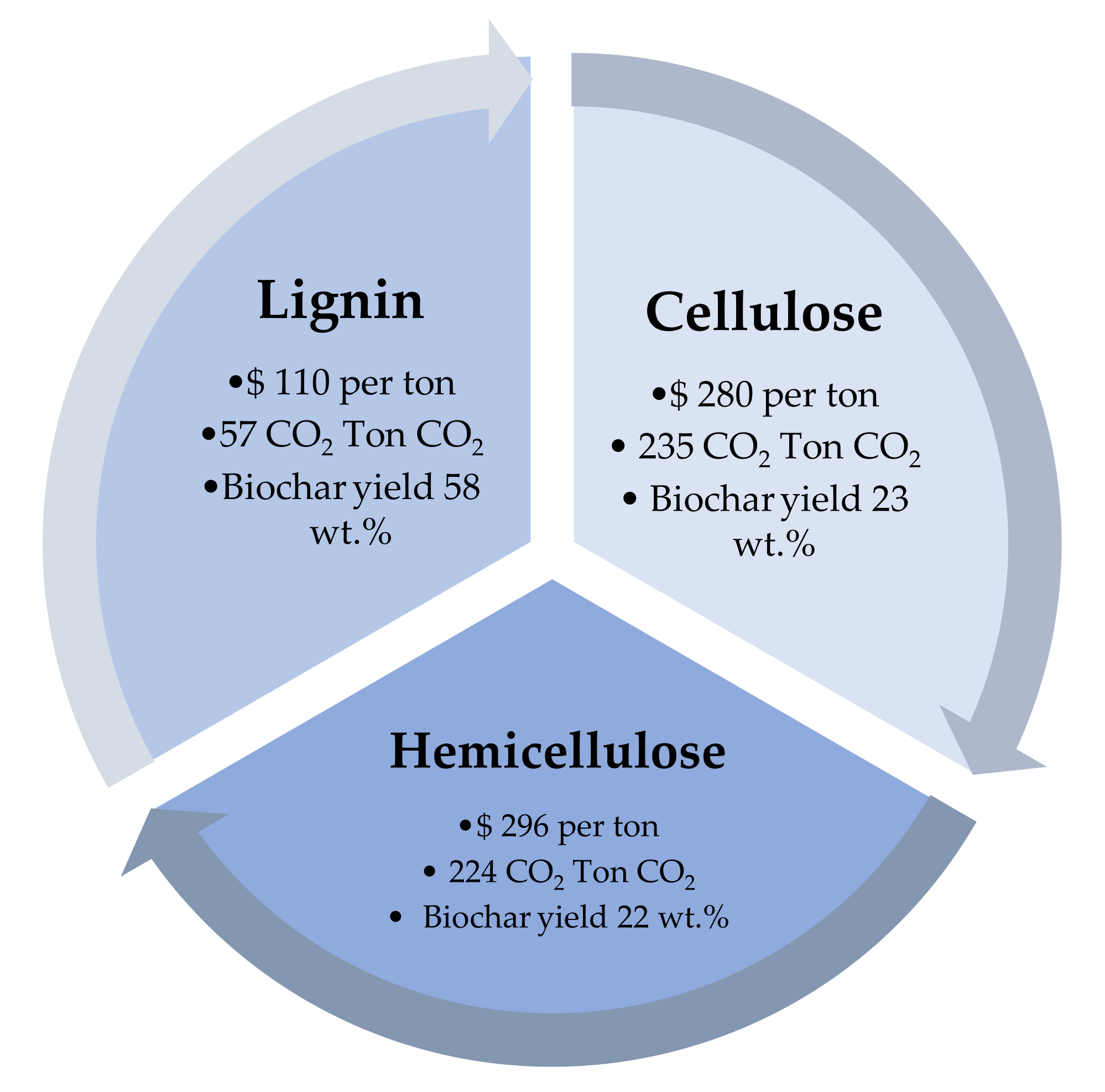

6.7. Effects of Biomass Feedstock Properties on the Quality of Biochar

6.8. Surface Interactions of Biochar Particles and Biochar Matrix in Polymer Composites

6.9. Economic Feasibility of Biochar in Polymer Composites

7. Research Gap and Future Prospective

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Glossary

| Symbols | |

| Sample melting enthalpy | |

| Pa-s | Pascal second (Pa-s) |

| S/cm | Siemens per centimeter |

| TPA | Tera pascal (elastic modulus) |

| Abbreviations | |

| CFRP | Carbon-fiber-reinforced polymer |

| MWCNTs | Multi-walled carbon nanotubes |

References

- Štefanko, A.U.; Leszczynska, D. Impact of Biomass Source and Pyrolysis Parameters on Physicochemical Properties of Biochar Manufactured for Innovative Applications. Front Energy Res. 2020, 8, 138. [Google Scholar] [CrossRef]

- Bartoli, M.; Giorcelli, M.; Jagdale, P.; Rovere, M. Towards Traditional Carbon Fillers: Biochar-Based Reinforced Plastic. In Fillers; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Lin, Q.; Tan, X.; Almatrafi, E.; Yang, Y.; Wang, W.; Luo, H.; Qin, F.; Zhou, C.; Zeng, G.; Zhang, C. Effects of biochar-based materials on the bioavailability of soil organic pollutants and their biological impacts. Sci. Total Environ. 2022, 826, 153956. [Google Scholar] [CrossRef]

- Li, S.; Xu, Y.; Jing, X.; Yilmaz, G.; Li, D.; Turng, L.S. Effect of carbonization temperature on mechanical properties and biocompatibility of biochar/ultra-high molecular weight polyethylene composites. Compos. B Eng. 2020, 196, 108120. [Google Scholar] [CrossRef]

- Tan, R.R.; Aviso, K.B.; Bandyopadhyay, S. Pinch-based planning of terrestrial carbon management networks. Clean Eng. Technol. 2021, 4, 100141. [Google Scholar] [CrossRef]

- Zoghlami, A.; Paës, G. Lignocellulosic biomass: Understanding recalcitrance and predicting hydrolysis. Front. Chem. 2019, 7, 874. [Google Scholar] [CrossRef] [PubMed]

- Rothon, R. Fillers for Polymer Applications; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Harper, C.A. Handbook of Plastics, Elastomers, and Composites, Technology; McGraw-Hill Education: New York, NY, USA, 2002. [Google Scholar]

- Haeldermans, T.; Campion, L.; Kuppens, T.; Vanreppelen, K.; Cuypers, A.; Schreurs, S. A comparative techno-economic assessment of biochar production from different residue streams using conventional and microwave pyrolysis. Bioresour. Technol. 2020, 318, 124083. [Google Scholar] [CrossRef] [PubMed]

- Sobhan, A.; Muthukumarappan, K.; Wei, L.; Qiao, Q.; Rahman, M.T.; Ghimire, N. Development and characterization of a novel activated biochar-based polymer composite for biosensors. Int. J. Polym. Anal. Charact. 2021, 26, 544–560. [Google Scholar] [CrossRef]

- Frontini, P.M.; Pouzada, A.S. Trends in the multifunctional performance of polyolefin/clay nanocomposite injection moldings. In Multifunctionality of Polymer Composites: Challenges and New Solutions; William Andrew: Norwich, NY, USA, 2015. [Google Scholar] [CrossRef]

- Park, S.; Fu, K. Polymer-based filament feedstock for additive manufacturing. Compos. Sci. Technol. 2021, 213, 108876. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I. Reinforced Polymer Composites: Processing, Characterization and Post Life Cycle Assessment; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar] [CrossRef]

- DeArmitt, C.; Rothon, R.; Fillers, P. Selection, and Use in Polymer Composites. In Polymers and Polymeric Composites: A Reference Series; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Vivekanandhan, S. Biochar as Sustainable Reinforcement for Polymer Composites. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Poulose, A.M.; Elnour, A.Y.; Anis, A.; Shaikh, H.; Al-Zahrani, S.M.; George, J.; Al-Wabel, M.I.; Usman, A.R.; Ok, Y.S.; Tsang, D.C.W.; et al. Date palm biochar-polymer composites: An investigation of electrical, mechanical, thermal and rheological characteristics. Sci. Total Environ. 2017, 619, 311–318. [Google Scholar] [CrossRef]

- Gabhi, R.S.; Kirk, D.W.; Jia, C.Q. Preliminary investigation of electrical conductivity of monolithic biochar. Carbon 2017, 116, 435–442. [Google Scholar] [CrossRef]

- Kane, S.; Warnat, S.; Ryan, C. Improvements in methods for measuring the volume conductivity of electrically conductive carbon powders. Adv. Powder Technol. 2021, 32, 702–709. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C.Q. Low-cost carbon fillers to improve mechanical properties and conductivity of epoxy composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef]

- Das, C.; Tamrakar, S.; Mielewski, D.; Kiziltas, A.; Xie, X. Newly developed biocarbon to increase electrical conductivity in sustainable polyamide 12 composites. Polym. Compos. 2022, 43, 8084–8094. [Google Scholar] [CrossRef]

- Lepak-Kuc, S.; Kiciński, M.; Michalski, P.P.; Pavlov, K.; Giorcelli, M.; Bartoli, M.; Jakubowska, M. Innovative biochar-based composite fibres from recycled material. Materials 2021, 14, 5304. [Google Scholar] [CrossRef] [PubMed]

- Faga, M.G.; Duraccio, D.; Di Maro, M.; Pedraza, R.; Bartoli, M.; d’Ayala, G.G.; Torsello, D.; Ghigo, G.; Giulio, M.; Acetate, E.-V. Electrical, Thermal and Tribological Behavior. Polymers 2022, 14, 4171. [Google Scholar] [CrossRef]

- Kane, S.; Ulrich, R.; Harrington, A.; Stadie, N.P.; Ryan, C. Physical and chemical mechanisms that influence the electrical conductivity of lignin-derived biochar. Carbon Trends 2021, 5, 100088. [Google Scholar] [CrossRef]

- Dreyfuss, P.; Hansen, D.R.; Fetters, L.J. Elastomeric Block Polymers. Rubber Chem. Technol. 1980, 53, 728–771. [Google Scholar] [CrossRef]

- Sardar, M.; Arun, R.K.; Ige, E.O.; Singh, P.; Kumar, G.; Chanda, N.; Biswas, G. Sustainable Polymer-Based Microfluidic Fuel Cells for Low-Power Applications. In Advances in Sustainable Polymers: Processing and Applications; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Benkhelladi, A.; Laouici, H.; Bouchoucha, A. Tensile and flexural properties of polymer composites reinforced by flax, jute and sisal fibres. Int. J. Adv. Manuf. Technol. 2020, 108, 895–916. [Google Scholar] [CrossRef]

- Sun, F.; Tian, M.; Sun, X.; Xu, T.; Liu, X.; Zhu, S.; Zhang, X.; Qu, L. Stretchable Conductive Fibers of Ultrahigh Tensile Strain and Stable Conductance Enabled by a Worm-Shaped Graphene Microlayer. Nano Lett. 2019, 19, 6592–6599. [Google Scholar] [CrossRef]

- Singh, K.K.; Chaudhary, S.K.; Venugopal, R. Enhancement of flexural strength of glass fiber reinforced polymer laminates using multiwall carbon nanotubes. Polym. Eng. Sci. 2019, 59, E248–E261. [Google Scholar] [CrossRef]

- George, J.; Azad, L.B.; Poulose, A.M.; An, Y.; Sarmah, A.K. Nano-mechanical behaviour of biochar-starch polymer composite: Investigation through advanced dynamic atomic force microscopy. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105486. [Google Scholar] [CrossRef]

- Abeykoon, C.; Kelly, A.L.; Vera-Sorroche, J.; Brown, E.C.; Coates, P.D.; Deng, J.; Li, K.; Harkin-Jones, E.; Price, M. Process efficiency in polymer extrusion: Correlation between the energy demand and melt thermal stability. Appl. Energy 2014, 135, 560–571. [Google Scholar] [CrossRef]

- Abeykoon, C.; Kelly, A.L.; Brown, E.C.; Vera-Sorroche, J.; Coates, P.D.; Harkin-Jones, E.; Howell, K.B.; Deng, J.; Li, K.; Price, M. Investigation of the process energy demand in polymer extrusion: A brief review and an experimental study. Appl. Energy 2014, 136, 726–737. [Google Scholar] [CrossRef]

- Nastaj, A.; Wilczyński, K. Optimization and scale-up for polymer extrusion. Polymers 2021, 13, 1547. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.K.; Buziak, K. Fundamentals of global modeling for polymer extrusion. Polymers 2019, 11, 2106. [Google Scholar] [CrossRef]

- Vera-Sorroche, J.; Kelly, A.; Brown, E.; Coates, P.; Karnachi, N.; Harkin-Jones, E.; Li, K.; Deng, J. Thermal optimisation of polymer extrusion using in-process monitoring techniques. Appl. Therm. Eng. 2013, 53, 405–413. [Google Scholar] [CrossRef]

- Demay, Y.; Agassant, J.F. The Polymer Film Casting Process—An Overview. Int. Polym. Process. 2021, 36, 264–275. [Google Scholar] [CrossRef]

- Koomen, M. Using Polymer Solution Casting to Deliver High-Quality Films, Carestream Contract Manufacturing: Precision Custom Coating Services. Bachelor’s Thesis, Tampere University, Tampere, Finland, 2015. [Google Scholar]

- Xie, M.; Zhang, Y.; Kraśny, M.J.; Bowen, C.; Khanbareh, H.; Gathercole, N. Flexible and active self-powered pressure, shear sensors based on freeze casting ceramic-polymer composites. Energy Environ. Sci. 2018, 11, 2919–2927. [Google Scholar] [CrossRef]

- Rokade, D.; Patil, P.; Nandimath, S.; Pol, H. A rheology and processing study on controlling material and process defects in polymer melt extrusion film casting using polymer blends. J. Plast. Film. Sheeting 2023, 39, 211–240. [Google Scholar] [CrossRef]

- Rosenblum, J.S.; Cappadona, A.J.; Lookian, P.P.; Chandrashekhar, V.; Bryant, J.P.; Chandrashekhar, V.; Zhao, D.Y.; Knutsen, R.H.; Donahue, D.R.; McGavern, D.B.; et al. Non-invasive in situ visualization of the murine cranial vasculature. Cell Rep. Methods 2022, 2, 100151. [Google Scholar] [CrossRef] [PubMed]

- Zajac, J.; Petruska, O.; Radchenko, S.; Duplakova, D.; Goldyniak, D. Hardness testing of polymer concrete castings by Schmidt hammer. Mater. Today Proc. 2020, 22, 293–299. [Google Scholar] [CrossRef]

- Mu, Y.; Hang, L.; Zhao, G.; Wang, X.; Zhou, Y.; Cheng, Z. Modeling and simulation for the investigation of polymer film casting process using finite element method. Math. Comput. Simul. 2019, 169, 88–102. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of interfacial properties between fibre and polymer matrix in composite materials—A critical review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Mohammed, M.; Rasidi, M.S.M.; Mohammed, A.M.; Rahman, R.; Osman, A.F.; Adam, T.; Betar, B.O.; Dahham, O.S. Interfacial Bonding Mechanisms of Natural Fibre-Matrix Composites: An Overview. Bioresources 2022, 17, 7031. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Lee, S.H. Importance of interfacial adhesion condition on characterization of plant-fiber-reinforced polymer composites: A review. Polymers 2021, 13, 438. [Google Scholar] [CrossRef]

- Babu, K.; Rendén, G.; Mensah, R.A.; Kim, N.K.; Jiang, L.; Xu, Q.; Restás, A.; Neisiany, R.E.; Hedenqvist, M.S.; Försth, M.; et al. A Review on the Flammability Properties of Carbon-Based Polymeric Composites: State-of-the-Art and Future Trends. Polymers 2020, 12, 1518. [Google Scholar] [CrossRef]

- Infurna, G.; Caruso, G.; Dintcheva, N.T. Sustainable Materials Containing Biochar Particles: A Review. Polymers 2023, 15, 343. [Google Scholar] [CrossRef]

- Danglad-Flores, J.; Eickelmann, S.; Riegler, H. Deposition of polymer films by spin casting: A quantitative analysis. Chem. Eng. Sci. 2018, 179, 257–264. [Google Scholar] [CrossRef]

- Zheng, W.; Hu, Y.; Zhang, X. Recent progress in synthesis of stereoblock copolymers. Kexue Tongbao/Chin. Sci. Bull. 2016, 61, 3651–3660. [Google Scholar] [CrossRef]

- Guggari, G.S.; Shivakumar, S.; Manjunath, G.A.; Nikhil, R.; Karthick, A.; Edacherian, A.; Saleel, C.A.; Afzal, A.; Prasath, S.; Saleh, B. Thermal and Mechanical Properties of Vinyl Ester Hybrid Composites with Carbon Black and Glass Reinforcement. Adv. Mater. Sci. Eng. 2021, 2021, 1–7. [Google Scholar] [CrossRef]

- Wolff, S.; Wang, M.-J. Carbon Black Filler Reinforcement of Elastomers. In Carbon Black: Science and Technology; Routledge: Oxfordshire, UK, 1993. [Google Scholar]

- Spahr, M.E.; Rothon, R. Carbon Black as a Polymer Filler. In Polymers and Polymeric Composites: A Reference Series; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Fan, Y.; Fowler, G.D.; Zhao, M. The past, present and future of carbon black as a rubber reinforcing filler—A review. J. Clean. Prod. 2019, 247, 119115. [Google Scholar] [CrossRef]

- Fukahori, Y. The mechanics and mechanism of the carbon black reinforcement of elastomers. Rubber Chem. Technol. 2003, 76, 548–566. [Google Scholar] [CrossRef]

- Branco-Vieira, M.; Mata, T.; Martins, A.; Freitas, M.; Caetano, N. Economic analysis of microalgae biodiesel production in a small-scale facility. Energy Rep. 2020, 6, 325–332. [Google Scholar] [CrossRef]

- Adohi, B.J.P.; Mdarhri, A.; Prunier, C.; Haidar, B.; Brosseau, C. A comparison between physical properties of carbon black-polymer and carbon nanotubes-polymer composites. J. Appl. Phys. 2010, 108, 074108. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F.; Ng, B.C. Directional alignment of carbon nanotubes in polymer matrices: Contemporary approaches and future advances. Compos. Part A Appl. Sci. Manuf. 2014, 56, 103–126. [Google Scholar] [CrossRef]

- Bokobza, L.; Pflock, T.; Lindemann, A.; Kwiryn, D.; Claro, P.D.S. Thermal conductivity and mechanical properties of composites based on multiwall carbon nanotubes and styrenebutadiene rubber. KGK Kautsch. Gummi Kunststoffe 2014, 67, 45–50. [Google Scholar]

- Wang, Y.; Cai, N.; Yang, H.; Wu, C. Application of Carbon Nanotubes from Waste Plastics as Filler to Epoxy Resin Composite. ACS Sustain. Chem. Eng. 2022, 10, 2204–2213. [Google Scholar] [CrossRef]

- Dhilipkumar, T.; Rajesh, M. Effect of manufacturing processes and multi-walled carbon nanotube loading on mechanical and dynamic properties of glass fiber reinforced composites. Polym. Compos. 2022, 43, 1772–1786. [Google Scholar] [CrossRef]

- Nuyang, P.; Wiriya-Amornchai, A.; Cheewawuttipong, W. The effects of a compatibilizer for improving mechanical properties on polymer matrix composites. Key Eng. Mater. 2021, 877, 3–8. [Google Scholar] [CrossRef]

- Zhang, M.; Zhai, Z.; Li, M.; Cheng, T.; Wang, C.; Jiang, D.; Chen, L.; Wu, Z.; Guo, Z. Epoxy nanocomposites with carbon nanotubes and montmorillonite: Mechanical properties and electrical insulation. J. Compos. Mater. 2016, 50, 3363–3372. [Google Scholar] [CrossRef]

- Ke, K.; McMaster, M.; Christopherson, W.; Singer, K.D.; Manas-Zloczower, I. Effects of branched carbon nanotubes and graphene nanoplatelets on dielectric properties of thermoplastic polyurethane at different temperatures. Compos. Part B Eng. 2019, 166, 673–680. [Google Scholar] [CrossRef]

- Savi, P.; Josè, S.P.; Khan, A.A.; Giorcelli, M.; Tagliaferro, A. Biochar and carbon nanotubes as fillers in polymers: A comparison. In Proceedings of the 2017 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications, IMWS-AMP 2017, Chengdu, China, 20–22 September 2018. [Google Scholar] [CrossRef]

- Kozlov, G.V.; Magomedov, G.M.; Magomedov, G.M.; Dolbin, I.V. The structure of carbon nanotubes in a polymer matrix. Kondens. Sredy I Mezhfaznye Granitsy = Condens. Matter Interphases 2021, 23, 223–228. [Google Scholar] [CrossRef]

- Horst, J.D.; De Andrade, P.P.; Duvoisin, C.A.; Vieira, R.D. Fabrication of Conductive Filaments for 3D-printing: Polymer Nanocomposites. Biointerface Res. Appl. Chem. 2020, 10, 6577–6586. [Google Scholar] [CrossRef]

- Hollaway, L.C. Key issues in the use of fibre reinforced polymer (FRP) composites in the rehabilitation and retrofitting of concrete structures. In Service Life Estimation and Extension of Civil Engineering Structures; Woodhead Publishing: Cambridge, UK, 2010. [Google Scholar]

- Chung, D. Comparison of submicron-diameter carbon filaments and conventional carbon fibers as fillers in composite materials. Carbon 2001, 39, 1119–1125. [Google Scholar] [CrossRef]

- Idrees, M.; Jeelani, S.; Rangari, V. Three-Dimensional-Printed Sustainable Biochar-Recycled PET Composites. ACS Sustain. Chem. Eng. 2018, 6, 13940–13948. [Google Scholar] [CrossRef]

- Noori, A.; Bartoli, M.; Frache, A.; Piatti, E.; Giorcelli, M.; Tagliaferro, A. Development of Pressure-Responsive PolyPropylene and Biochar-Based Materials. Micromachines 2020, 11, 339. [Google Scholar] [CrossRef]

- Elnour, A.Y.; Alghyamah, A.A.; Shaikh, H.M.; Poulose, A.M.; Al-Zahrani, S.M.; Anis, A.; Al-Wabel, M.I. Effect of Pyrolysis Temperature on Biochar Microstructural Evolution, Physicochemical Characteristics, and Its Influence on Biochar/Polypropylene Composites. Appl. Sci. 2019, 9, 1149. [Google Scholar] [CrossRef]

- Al Habis, N.; El Moumen, A.; Tarfaoui, M.; Lafdi, K. Mechanical properties of carbon black/poly (ε-caprolactone)-based tissue scaffolds. Arab. J. Chem. 2018, 13, 3210–3217. [Google Scholar] [CrossRef]

- Biron, M. Recycling Plastics: Advantages and Limitations of Use. In A Practical Guide to Plastics Sustainability; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Wallace, C.A.; Saha, G.C.; Afzal, M.T.; Lloyd, A. Experimental and computational modeling of effective flexural/tensile properties of microwave pyrolysis biochar reinforced GFRP biocomposites. Compos. Part B Eng. 2019, 175, 107180. [Google Scholar] [CrossRef]

- Ibrahim, A.; Klopocinska, A.; Horvat, K.; Hamid, Z.A. Graphene-Based Nanocomposites: Synthesis, Mechanical Properties, and Characterizations. Polymers 2021, 13, 2869. [Google Scholar] [CrossRef]

- Li, S.; Huang, A.; Chen, Y.-J.; Li, D.; Turng, L.-S. Highly filled biochar/ultra-high molecular weight polyethylene/linear low density polyethylene composites for high-performance electromagnetic interference shielding. Compos. Part B Eng. 2018, 153, 277–284. [Google Scholar] [CrossRef]

- Ji, X.; Xu, Y.; Zhang, W.; Cui, L.; Liu, J. Review of functionalization, structure and properties of graphene/polymer composite fibers. Compos. Part A Appl. Sci. Manuf. 2016, 87, 29–45. [Google Scholar] [CrossRef]

- Zhao, Y.; Qamar, S.A.; Qamar, M.; Bilal, M.; Iqbal, H.M. Sustainable remediation of hazardous environmental pollutants using biochar-based nanohybrid materials. J. Environ. Manag. 2021, 300, 113762. [Google Scholar] [CrossRef]

- Velusamy, K.; Devanand, J.; Kumar, P.S.; Soundarajan, K.; Sivasubramanian, V.; Sindhu, J.; Vo, D.-V.N. A review on nano-catalysts and biochar-based catalysts for biofuel production. Fuel 2021, 306, 121632. [Google Scholar] [CrossRef]

- Rjeily, M.A.; Gennequin, C.; Pron, H.; Abi-Aad, E.; Randrianalisoa, J.H. Pyrolysis-catalytic upgrading of bio-oil and pyrolysis-catalytic steam reforming of biogas: A review. Environ. Chem. Lett. 2021, 19, 2825–2872. [Google Scholar] [CrossRef]

- Aminu, I.; Nahil, M.A.; Williams, P.T. Hydrogen Production by Pyrolysis–Nonthermal Plasma/Catalytic Reforming of Waste Plastic over Different Catalyst Support Materials. Energy Fuels 2022, 36, 3788–3801. [Google Scholar] [CrossRef]

- Zhang, Q.; Khan, M.U.; Lin, X.; Cai, H.; Lei, H. Temperature varied biochar as a reinforcing filler for high-density polyethylene composites. Compos. Part B Eng. 2019, 175, 107151. [Google Scholar] [CrossRef]

- Cruz, G.; Crnkovic, P.M. Effects of High Temperature in the Combustion Chamber of a Drop Tube Furnace (DTF) for Different Thermochemical Processes. J. Energy Res. Rev. 2019, 2, 1–10. [Google Scholar] [CrossRef]

- Bartoli, M.; Arrigo, R.; Malucelli, G.; Tagliaferro, A.; Duraccio, D. Recent Advances in Biochar Polymer Composites. Polymers 2022, 14, 2506. [Google Scholar] [CrossRef]

- Kapoore, R.V.; Butler, T.O.; Pandhal, J.; Vaidyanathan, S. Microwave-Assisted Extraction for Microalgae: From Biofuels to Biorefinery. Biology 2018, 7, 18. [Google Scholar] [CrossRef] [PubMed]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.-T. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Wang, L.; Ruan, S.; Chen, J.; Li, H.; Yang, J.; Mechtcherine, V.; Tsang, D.C. Biochar-augmented carbon-negative concrete. Chem. Eng. J. 2021, 431, 133946. [Google Scholar] [CrossRef]

- Ayadi, R.; Koubaa, A.; Braghiroli, F.; Migneault, S.; Wang, H.; Bradai, C. Effect of the Pyro-Gasification Temperature of Wood on the Physical and Mechanical Properties of Biochar-Polymer Biocomposites. Materials 2020, 13, 1327. [Google Scholar] [CrossRef]

- Bartoli, M.; Troiano, M.; Giudicianni, P.; Amato, D.; Giorcelli, M.; Solimene, R.; Tagliaferro, A. Effect of heating rate and feedstock nature on electrical conductivity of biochar and biochar-based composites. Appl. Energy Combust. Sci. 2022, 12, 100089. [Google Scholar] [CrossRef]

- Das, C.; Tamrakar, S.; Kiziltas, A.; Xie, X. Incorporation of Biochar to Improve Mechanical, Thermal and Electrical Properties of Polymer Composites. Polymers 2021, 13, 2663. [Google Scholar] [CrossRef]

- Zhu, J.; Abeykoon, C.; Karim, N. Investigation into the effects of fillers in polymer processing. Int. J. Light. Mater. Manuf. 2021, 4, 370–382. [Google Scholar] [CrossRef]

- Praveenkumara, J.; Madhu, P.; Gowda, T.G.Y.; Sanjay, M.R.; Siengchin, S. A comprehensive review on the effect of synthetic filler materials on fiber-reinforced hybrid polymer composites. J. Text. Inst. 2021, 113, 1231–1239. [Google Scholar] [CrossRef]

- Chen, R.; Yu, R.; Pei, X.; Wang, W.; Li, D.; Xu, Z.; Luo, S.; Tang, Y.; Deng, H. Interface design of carbon filler/polymer composites for electromagnetic interference shielding. New J. Chem. 2021, 45, 8370–8385. [Google Scholar] [CrossRef]

- Kim, K.-H.; Ong, J.L.; Okuno, O. The effect of filler loading and morphology on the mechanical properties of contemporary composites. J. Prosthet. Dent. 2002, 87, 642–649. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Compatibilization of toughened polypropylene/biocarbon biocomposites: A full factorial design optimization of mechanical properties. Polym. Test. 2017, 61, 364–372. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Misra, M.; Mohanty, A.K. Impact of interfacial adhesion on the microstructure and property variations of biocarbons reinforced nylon 6 biocomposites. Compos. Part A Appl. Sci. Manuf. 2017, 98, 32–44. [Google Scholar] [CrossRef]

- Ouyang, Y.; Bai, L.; Tian, H.; Li, X.; Yuan, F. Recent progress of thermal conductive ploymer composites: Al2O3 fillers, properties and applications. Compos. Part A Appl. Sci. Manuf. 2021, 152, 106685. [Google Scholar] [CrossRef]

- Ronsse, F.; van Hecke, S.; Dickinson, D.; Prins, W. Production and characterization of slow pyrolysis biochar: Influence of feedstock type and pyrolysis conditions. GCB Bioenergy 2012, 5, 104–115. [Google Scholar] [CrossRef]

- Dhahak, A.; Grimmer, C.; Neumann, A.; Rüger, C.; Sklorz, M.; Streibel, T.; Zimmermann, R.; Mauviel, G.; Burkle-Vitzthum, V. Real time monitoring of slow pyrolysis of polyethylene terephthalate (PET) by different mass spectrometric techniques. Waste Manag. 2020, 106, 226–239. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Gholizadeh, M. Biomass pyrolysis: A review of the process development and challenges from initial researches up to the commercialisation stage. J. Energy Chem. 2019, 39, 109–143. [Google Scholar] [CrossRef]

- Ramanathan, A.; Begum, K.M.M.S.; Pereira, A.O.; Cohen, C. Pyrolysis of waste biomass: Toward sustainable development. In A Thermo-Economic Approach to Energy from Waste; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Leng, L.; Xiong, Q.; Yang, L.; Li, H.; Zhou, Y.; Zhang, W.; Jiang, S.; Li, H.; Huang, H. An overview on engineering the surface area and porosity of biochar. Sci. Total. Environ. 2020, 763, 144204. [Google Scholar] [CrossRef]

- Xu, Z.; He, M.; Xu, X.; Cao, X.; Tsang, D.C. Impacts of different activation processes on the carbon stability of biochar for oxidation resistance. Bioresour. Technol. 2021, 338, 125555. [Google Scholar] [CrossRef]

- Su, B.; Cao, Z.-C.; Shi, Z.-J. Exploration of Earth-Abundant Transition Metals (Fe, Co, and Ni) as Catalysts in Unreactive Chemical Bond Activations. Accounts Chem. Res. 2015, 48, 886–896. [Google Scholar] [CrossRef]

- Alghyamah, A.A.; Elnour, A.Y.; Shaikh, H.; Haider, S.; Poulose, A.M.; Al-Zahrani, S.; Almasry, W.A.; Park, S.Y. Biochar/polypropylene composites: A study on the effect of pyrolysis temperature on crystallization kinetics, crystalline structure, and thermal stability. J. King Saud Univ. Sci. 2021, 33, 101409. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Bio/Technol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Khodaei, H.; Gonzalez, L.; Chapela, S.; Porteiro, J.; Nikrityuk, P.; Olson, C. CFD-based coupled multiphase modeling of biochar production using a large-scale pyrolysis plant. Energy 2021, 217, 119325. [Google Scholar] [CrossRef]

- Panchasara, H.; Ashwath, N. Effects of Pyrolysis Bio-Oils on Fuel Atomisation—A Review. Energies 2021, 14, 794. [Google Scholar] [CrossRef]

- Maljaee, H.; Madadi, R.; Paiva, H.; Tarelho, L.; Ferreira, V.M. Incorporation of biochar in cementitious materials: A roadmap of biochar selection. Constr. Build. Mater. 2021, 283, 122757. [Google Scholar] [CrossRef]

- An, X.; Yu, J.; Yu, J.; Tahmasebi, A.; Wu, Z.; Liu, X.; Yu, B. Incorporation of biochar into semi-interpenetrating polymer networks through graft co-polymerization for the synthesis of new slow-release fertilizers. J. Clean Prod. 2020, 272, 122731. [Google Scholar] [CrossRef]

- Minugu, O.P.; Gujjala, R.; Shakuntala, O.; Manoj, P.; Chowdary, M.S. Effect of biomass derived biochar materials on mechanical properties of biochar epoxy composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 5626–5638. [Google Scholar] [CrossRef]

- Arroyo, J.; Ryan, C. Incorporation of Carbon Nanofillers Tunes Mechanical and Electrical Percolation in PHBV:PLA Blends. Polymers 2018, 10, 1371. [Google Scholar] [CrossRef] [PubMed]

- Das, O.; Sarmah, A.K.; Zujovic, Z.; Bhattacharyya, D. Characterisation of waste derived biochar added biocomposites: Chemical and thermal modifications. Sci. Total. Environ. 2016, 550, 133–142. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Yee-Foong, L.N.; Lawal, A.A.; Farid, M.A.A.; Yusuf, M.Z.M.; Hassan, M.A.; Ariffin, H. Emerging application of biochar as a renewable and superior filler in polymer composites. RSC Adv. 2022, 12, 13938–13949. [Google Scholar] [CrossRef]

- Zouari, M.; Devallance, D.B.; Marrot, L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials 2022, 15, 2271. [Google Scholar] [CrossRef]

- Zhang, Q.; Cai, H.; Yang, K.; Yi, W. Effect of biochar on mechanical and flame retardant properties of wood—Plastic composites. Results Phys. 2017, 7, 2391–2395. [Google Scholar] [CrossRef]

- Wu, S.; Chen, Y.; Chen, Z.; Wang, J.; Cai, M.; Gao, J. Shape-stabilized phase change material with highly thermal conductive matrix developed by one-step pyrolysis method. Sci. Rep. 2021, 11, 822. [Google Scholar] [CrossRef]

- Atinafu, D.G.; Yun, B.Y.; Yang, S.; Kim, S. Encapsulation of dodecane in gasification biochar for its prolonged thermal/shape stability, reliability, and ambient enthalpy storage. Chem. Eng. J. 2022, 437, 135407. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Phase morphology, mechanical, and thermal properties of fiber-reinforced thermoplastic elastomer: Effects of blend composition and compatibilization. J. Reinf. Plast. Compos. 2021, 41, 267–283. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The effect of bio-carbon addition on the electrical, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. J. Compos. Mater. 2015, 50, 1161–1168. [Google Scholar] [CrossRef]

- Atta, M.; Henaish, A.; Elbasiony, A.; Taha, E.O.; Dorgham, A. Structural, optical, and thermal properties of PEO/PVP blend reinforced biochar. Opt. Mater. 2022, 127, 112268. [Google Scholar] [CrossRef]

- Huber, T.; Misra, M.; Mohanty, A.K. The effect of particle size on the rheological properties of polyamide 6/biochar composites. AIP Conf. Proc. 2015, 1664, 150004. [Google Scholar] [CrossRef]

- Abbasi, S.; Ladani, R.; Wang, C.; Mouritz, A. Boosting the electrical conductivity of polymer matrix composites using low resistivity Z-filaments. Mater. Des. 2020, 195, 109014. [Google Scholar] [CrossRef]

- Kumar, R.; Gunjal, J.; Chauhan, S. Effect of carbonization temperature on properties of natural fiber and charcoal filled hybrid polymer composite. Compos. Part B Eng. 2021, 217, 108846. [Google Scholar] [CrossRef]

- Nakayama, S.F.; Yoshikane, M.; Onoda, Y.; Nishihama, Y.; Iwai-Shimada, M.; Takagi, M.; Kobayashi, Y.; Isobe, T. Worldwide trends in tracing poly- and perfluoroalkyl substances (PFAS) in the environment. TrAC—Trends Anal. Chem. 2019, 121, 115410. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly(lactic Acid)–Biochar Biocomposites: Effect of Processing and Filler Content on Rheological, Thermal, and Mechanical Properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [PubMed]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Pudełko, A.; Postawa, P.; Stachowiak, T.; Malińska, K.; Dróżdż, D. Waste derived biochar as an alternative filler in biocomposites—Mechanical, thermal and morphological properties of biochar added biocomposites. J. Clean. Prod. 2020, 278, 123850. [Google Scholar] [CrossRef]

- Sundarakannan, R.; Arumugaprabu, V.; Manikandan, V.; Vigneshwaran, S. Mechanical property analysis of biochar derived from cashew nut shell waste reinforced polymer matrix. Mater. Res. Express 2019, 6, 125349. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, D.; Xu, H.; Lu, W.; Ren, X.; Cai, H.; Lei, H.; Huo, E.; Zhao, Y.; Qian, M.; et al. Biochar filled high-density polyethylene composites with excellent properties: Towards maximizing the utilization of agricultural wastes. Ind. Crop. Prod. 2020, 146, 112185. [Google Scholar] [CrossRef]

- Huang, C.-C.; Chang, C.-W.; Jahan, K.; Wu, T.-M.; Shih, Y.-F. Effects of the Grapevine Biochar on the Properties of PLA Composites. Materials 2023, 16, 816. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, K.; Fang, Y.; Guo, Z.; Wei, Y.; Sheng, K. Conversion from bamboo waste derived biochar to cleaner composites: Synergistic effects of aramid fiber and silica. J. Clean Prod. 2022, 347, 131336. [Google Scholar] [CrossRef]

- Dahal, R.K.; Acharya, B.; Saha, G.; Bissessur, R.; Dutta, A.; Farooque, A. Biochar as a filler in glassfiber reinforced composites: Experimental study of thermal and mechanical properties. Compos. Part B Eng. 2019, 175, 107169. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Sarmah, A.K.; Bhattacharyya, D. Development of waste based biochar/wool hybrid biocomposites: Flammability characteristics and mechanical properties. J. Clean. Prod. 2017, 144, 79–89. [Google Scholar] [CrossRef]

- Giorcelli, M.; Khan, A.; Pugno, N.M.; Rosso, C.; Tagliaferro, A. Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 2018, 120, 219–223. [Google Scholar] [CrossRef]

- Jayabalakrishnan, D.; Prabhu, P.; Iqbal, S.M.; Mugendiran, V.; Ravi, S.; Prakash, V.R.A. Mechanical; dielectric, and hydrophobicity behavior of coconut shell biochar toughened Caryota urens natural fiber reinforced epoxy composite. Polym. Compos. 2022, 43, 493–502. [Google Scholar] [CrossRef]

- Nam, N.H.; Anh, K.D.; Truc, L.G.T.; Ha, T.A.; Ha, V.T.T. Pyrolysis of cashew nut shell: A parametric study. Vietnam. J. Chem. 2020, 58, 506–511. [Google Scholar]

- Matta, S.; Bartoli, M.; Frache, A.; Malucelli, G. Investigation of Different Types of Biochar on the Thermal Stability and Fire Retardance of Ethylene-Vinyl Acetate Copolymers. Polymers 2021, 13, 1256. [Google Scholar] [CrossRef] [PubMed]

- Paul, D.; Robeson, L. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef]

- Kasgoz, A.; Akın, D.; Ayten, A.I.; Durmus, A. Effect of different types of carbon fillers on mechanical and rheological properties of cyclic olefin copolymer (COC) composites. Compos B Eng. 2014, 66, 126–135. [Google Scholar] [CrossRef]

- Lee, J.H.; Jang, Y.K.; Hong, C.E.; Kim, N.H.; Li, P.; Lee, H.K. Effect of carbon fillers on properties of polymer composite bipolar plates of fuel cells. J. Power Sources 2009, 193, 523–529. [Google Scholar] [CrossRef]

- Ray, J.R.; Shabtai, I.A.; Teixidó, M.; Mishael, Y.G.; Sedlak, D.L. Polymer-clay composite geomedia for sorptive removal of trace organic compounds and metals in urban stormwater. Water Res. 2019, 157, 454–462. [Google Scholar] [CrossRef]

- Korey, M.; Rencheck, M.L.; Tekinalp, H.; Wasti, S.; Wang, P.; Bhagia, S.; Walker, R.; Smith, T.; Zhao, X.; Lamm, M.E.; et al. Recycling polymer composite granulate/regrind using big area additive manufacturing. Compos. B Eng. 2023, 256, 110652. [Google Scholar] [CrossRef]

- Antunes, P.; Ramalho, A.; Carrilho, E. Mechanical and wear behaviours of nano and microfilled polymeric composite: Effect of filler fraction and size. Mater. Des. 2014, 61, 50–60. [Google Scholar] [CrossRef]

- Hardinnawirda, K.; Aisha, I.S. Effect of Rice Husks as Filler in Polymer Matrix Composites. J. Mech. Eng. Sci. 2012, 2, 181–186. [Google Scholar] [CrossRef]

- Sudheer, M.; Prabhu, R.; Raju, K.; Bhat, T. Effect of Filler Content on the Performance of Epoxy/PTW Composites. Adv. Mater. Sci. Eng. 2014, 2014, 970468. [Google Scholar] [CrossRef]

- Guermazi, N.; Haddar, N.; Elleuch, K.; Ayedi, H.F. Effect of filler addition and weathering conditions on the performance of PVC/CaCO3composites. Polym. Compos. 2015, 37, 2171–2183. [Google Scholar] [CrossRef]

- Huang, H.-X.; Zhang, J.-J. Effects of filler-filler and polymer-filler interactions on rheological and mechanical properties of HDPE-wood composites. J. Appl. Polym. Sci. 2009, 111, 2806–2812. [Google Scholar] [CrossRef]

- Gupta, N.; Brar, B.S.; Woldesenbet, E. Effect of filler addition on the compressive and impact properties of glass fibre reinforced epoxy. Bull. Mater. Sci. 2001, 24, 219–223. [Google Scholar] [CrossRef]

- Munde, Y.S.; Ingle, R.B.; Siva, I. Effect of sisal fiber loading on mechanical, morphological and thermal properties of extruded polypropylene composites. Mater. Res. Express 2019, 6, 085307. [Google Scholar] [CrossRef]

- Yang, L.; Han, P.; Gu, Z. Grafting of a novel hyperbranched polymer onto carbon fiber for interfacial enhancement of carbon fiber reinforced epoxy composites. Mater. Des. 2021, 200, 109456. [Google Scholar] [CrossRef]

- Cappello, M.; Rossi, D.; Filippi, S.; Cinelli, P.; Seggiani, M. Wood Residue-Derived Biochar as a Low-Cost, Lubricating Filler in Poly(butylene succinate-co-adipate) Biocomposites. Materials 2023, 16, 570. [Google Scholar] [CrossRef] [PubMed]

- Awad, S. Swelling, Thermal and Mechanical Characterizations of High-Density Polyethylene/ Recycled Biochar Composites. J. Turk. Chem. Soc. Sect. A Chem. 2021, 8, 1137–1144. [Google Scholar] [CrossRef]

- Giorcelli, M.; Savi, P.; Khan, A.; Padovano, E.; Tagliaferro, A. Thermal treatments for biochar and their electrical characterization in epoxy resin composites. AIP Conf. Proc. 2018, 1981, 020022. [Google Scholar] [CrossRef]

- Wystalska, K.; Kwarciak-Kozłowska, A. The Effect of Biodegradable Waste Pyrolysis Temperatures on Selected Biochar Properties. Materials 2021, 14, 1644. [Google Scholar] [CrossRef]

- Akpasi, S.O.; Anekwe, I.M.S.; Adedeji, J.; Kiambi, S.L.; Akpasi, S.O.; Anekwe, I.M.S.; Adedeji, J.; Kiambi, S.L. Biochar Development as a Catalyst and Its Application, Biochar—Productive Technologies, Properties and Applications; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Ibrahim, I.; Tsubota, T.; Hassan, M.A.; Andou, Y. Surface Functionalization of Biochar from Oil Palm Empty Fruit Bunch through Hydrothermal Process. Processes 2021, 9, 149. [Google Scholar] [CrossRef]

- Jeffery, S.; Meinders, M.B.J.; Stoof, C.; Bezemer, T.M.; Voorde, T.F.J.V.; Mommer, L.; Van Groenigen, J.W.; Jeffery, S.; Meinders, M.B.J.; Stoof, C.; et al. Why biochar application did not improve the soil water retention of a sandy soil: An investigation into the underlying mechanisms. EGUGA 2015, 17, 10226. [Google Scholar]

- Huang, Y.; Anderson, M.; Lyons, G.; McRoberts, W.; Wang, Y.; McIlveen-Wright, D.; Roskilly, A.; Hewitt, N. Techno-economic Analysis of BioChar Production and Energy Generation from Poultry Litter Waste. Energy Procedia 2014, 61, 714–717. [Google Scholar] [CrossRef]

- Xiao, L.; Feng, L.; Yuan, G.; Wei, J. Low-cost field production of biochars and their properties. Environ. Geochem. Heal. 2019, 42, 1569–1578. [Google Scholar] [CrossRef]

| Carbon Fiber | Fiber Mechanical Strength | Elasticity Modulus (GPa) | Tensile Strength (MPa) | Ultimate Strain (%) | References |

|---|---|---|---|---|---|

| Pan-based fiber | High modulus | 300 | 5000 | 1.73 | [67,72] |

| Hysol Grafil Apollo | Ultra-high modulus material | 450 | 3500 | 0.77 | |

| Pitch-based fiber | High-quality fiber | 227 | 2758 | 1.76 | |

| Hysol Union Carbide | High modulus | 240 | 3440 | 1.75 |

| Filler Material | Biochar | CNT | Carbon Filaments | References |

|---|---|---|---|---|

| Raw material and its production method | Synthesized by pyrolysis above 500 °C. | Produced by either catalytic chemical disposition, laser ablation, or arc discharge. | Carbon fibers are converted to long strands and heated to very high temperatures without contact with oxygen. | [11,43,67,68,73] |

| Advantage of filler material | Improves thermal stability. Addition of biochar between 20 wt.% and 30 wt.% increases the glass transition temperature of the polymer composite by 7–20 wt.%. | CNT possess excellent adsorption ability due to strong interaction with heavy metal ions. | Film and rigid mechanical structure; high tensile strength and stiffness; high chemical and heat resistance. | |

| Disadvantage of filler material | The properties of biochar depend upon properties of biomass and thermal conditions during pyrolysis. Different biochar yields different mechanical properties. | Homogenous dispersion of CNTs is difficult especially at high loadings. Molecular modification is needed to enhance dispersion and reduce aggregation. Also, they have a very high cost compared to alternative fillers. | High production cost; negative temperature coefficient of resistance. |

| Pyrolysis | Vapor Residence Time (s) | Heating Rate (°C) | Process Temperature (°C) | Solid Yield (wt.%) | Liquid Yield (wt.%) | Gaseous Yield (wt.%) | References |

|---|---|---|---|---|---|---|---|

| Slow | 450–500 | 0.1–1 | 300–700 | ~35 | ~30 | ~35 | [21,89,108] |

| Fast | 1–10 | 10–200 | 400–800 | ~20 | ~50 | ~30 | [45,46,108] |

| Flash | <1 | ~1000 | 800–1000 | ~12 | ~12 | ~75 | [20,21,108] |

| Polymer | Biochar Source | Filler Loading Rate | Carbonization Temperature (°C) | Fabrication Method | References |

|---|---|---|---|---|---|

| High molecular polyethylene | Bamboo tree | 5 to 9 wt.% | 1000 | Compression molding | [12,13] |

| Polyethylene | Biochar synthesized from wood (50 to 100 µm) (MAPP) Biochar (1000 µm and 50 µm)wood | 24 to 30 wt.% | 900 | Extrusion and injection molding | |

| Polypropylene | Miscanthus grass (106–125 and <20 µm) | NR | 630 | Melt processing | [24,25,125] |

| Nylon 6 | Miscanthus fiber | 20 wt.% | 500 and 900 | Melt compounding and injection molding | |

| Polypropylene | Landfill pine wood | 24 wt.% | 900 | Extrusion and injection molding | [40,41,42,43] |

| Polylactic acid | Mixed hardwood (<250 μm) | 2, 6 and 10 wt.% | 800 | Solvent casting | |

| HDPE | Rice husk | 30–70 wt.% | 500 | Twin-screw extrusion | [90] |

| PLA | Waste brewed coffee powder | 1, 2.5, 5, and 7.5 wt.% | 700 | Solvent casting | [123] |

| Polypropylene | Date palm waste | 0–15 wt.% | 700 and 900 | Micro injection molding | [124] |

| Polypropylene | Pine wood | 6, 12, 18, 24, and 30 wt.% | 450 | Twin-screw extrusion and melt blending | [126] |

| Polylactic acid and BIOPLAST GS2189 | Wood residue and sewage sludge | 0, 10, 20 wt.% | 550 | Injection molding | [127] |

| Polyester | Cashew nutshell waste | 5, 10, 15 wt.% | 500 | Resin casting | [128] |

| Polypropylene | Landfill pinewood waste | 0, 15, 25, 30, 35 wt.% | Pyrolyzed at 500 followed by activation at 900 | Extrusion and injection molding | [129] |

| HDPE | Rice husk | 10–70 wt.% | 600 | Micro twin-screw extruder | [130] |

| Polylactic acid | Grapevine (120 mesh) | 1–10 wt.% | 500 | Compression molding | [131] |

| Polylactic acid | Bamboo waste biochar, aramid fiber, and silica | 0–40, 0–20, and 0–20 wt.%, respectively | 500 | Micro-injection molding | [132] |

| Fiber glass reinforced epoxy resin | Spruce wood pellets | 0, 5, and 10 wt.% | 150 °C for 30 min followed by 450 °C for 30 min | Resin casting | [133] |

| Epoxy | Arhar stalks and Bael shell | 2, 4, and 6 wt.% | 800 | Hand lay-up technique | [111] |

| Polypropylene | Landfill pine sawdust biochar and wool | 0–25, and 0–10 wt.%, respectively | 500 followed by activation at 900 | Twin-screw extrusion | [134] |

| Low viscosity epoxy resin | Maple tree (10 μm) | 0, 1, 2, 4, and 20 wt.% | 600 and 1000 | Resin molding | [135] |

| Diglycidyl ether of bisphenol A based epoxy resin | Coconut shell biochar and C. urens fibers | 1–7, and 30 vol.%, respectively | RT-200 followed by 200–500 followed by 500–800 | Hand lay-up technique | [136] |

| Polymer Type | Polymer Blend | Plasticizer/Hardener/ Stabilizer/Compatibilizer | Preparation Method | Change in Properties | References |

|---|---|---|---|---|---|

| Polystyrene | Single-wall carbon nanotubes | Dimethyl; dibutyl | Catalytic chemical vapor deposition for CNTs; copolymerization for composite | Glass temperature (Tg) increase by 3 °C | [139] |

| Poly(propylene carbonate) | Nanoclay at 4 wt.% | Glass fiber; talc or calcium carbonate | Co-polymerization | Glass temperature (Tg) increase by 13 °C | [25,26,139] |

| Polylactide | Naoclay at 3 wt.% | Co-polymerization of CO2 and chemicals called epoxides | Glass temperature decreases by 4 °C | [55,67,68,69,70,71,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,140,141] | |

| Rubber | Nanoclay at 5 wt.% | Adipates and Sebacates | Triethyl citrate or tributyl citrate | Glass temperature increases by 3 °C | [94,95,96,97,98,99,100,101,102,103,104] |

| Glass-fiber-reinforced composites | Biochar at 5 wt.% to 10 wt.% | Organic esters | Pyrolysis and carbonization for biochar; extrusion for polymer composite | Higher glass temperature; higher stiffness and fire retardancy | [12,13,14,84,142,143] |

| Poly(dimethyl siloxane) | Silica pore size between 2 nm and 3 nm | Trimethylsiloxy-terminated | Replica molding or casting | Higher glass temperature at 10 °C | [12,13,14,84,142,143] |

| Unsaturated polyester resin | High-purity silica at 30% (average particle size = 3, 6, 16, and 22 µm), 10% (average particle size = 0.1, 1, 2, 3, 6, 16, and 22 µm), 12%, 16%, 24%, 37%, and 46% filler volume | methyl-ethyl-ketone-peroxide (MEKPO) | Molding or casting | Present good homogeneous and effective bond between matrix and particles; hardness and elastic modulus increases linearly with filler content | [144] |

| Unsaturated polyester | Rice husks at 10, 15, 20, and 25 wt.% | methyl-ethyl-ketone-peroxide (MEKPO) | Room-temperature molding | Tensile strength of the composite decreases with increased filler loading; Young’s modulus increased remarkably for 15 wt.%; the composite showed higher water absorption | [145] |

| Semi-crystalline LDPE, and two amorphous (polystyrene and polymethyl methacrylate) | Graphene-based flakes (average flake size = 1.45 μm); fumed silica (average particle size = 0.2–0.3 μm) | Graphene-based flakes are prepared using micro-fluidization; polymer composite using extrusion melt-mixing followed by injection molding | Lower filler content increases the viscosity; glass transition temperature showed mixed behavior, e.g., increasing/decreasing nature | [91] | |

| Epoxy belong to diglycidyl ether of bisphenol A (DGEBA) family | Potassium titanate whisker (PTW) with aspect ratio 20–40 | Amino based | Mechanical stirring and vacuum-assisted casting method | 15 wt.% composite showed improved wear resistance and highest friction coefficient; positive effect on hardness, density, and stiffness. But the strength and ductility decreases | [146] |

| Polyvinyl chloride (PVC) of density 1.41 g/cm3 | Calcium Carbonate (CaCO3) in 1–2 μm particle size | Arkopan | Melt-blended in twin-screw extruder | Increases glass transition temperature, storage, and elastic modulus; however, reduces tensile strength and elongation at break and no significant effect on water absorption | [147] |

| High-density polyethylene (HDPE) of different grades | Poplar wood flour sieved through 60 mesh | Maleic anhydride-modified polyethylene with melt index 6 g/10 min, and a graft ratio of 1.1% | Twin-screw extrusion | Increased filler content improves filler–filler interaction; agglomeration of wood particles which increases storage modulus and viscosity of the composite with decreased tensile strength; elongation at break; notched impact strength due to stress concentration | [148] |

| Glass fibers reinforced low-temperature curing epoxy | Flyash (Class-F) with density 2 g/cc and total silica and alumina content > 70% | Hardener HY951 | Resin molding | Steep increase in impact strength is noted for small filler content; compressive strength found to be decreasing | [149] |

| Visible-light-activated polyphenylene polymethacrylate resin | Silanated barium borosilicate with particle size 2 µm (at 20, 40, 45, 50, and 53 vol% loading) and 15 µm (at 20, 40, 50, 60, and 65 vol% loading) | Increased filler level enhances compressive strength, hardness, stiffness with reduced water absorption; all the resins showed significant improvement in resistance to wear by hydroxyapatite than unfilled resins; however, particle sizes of filler have moderate impact on the resin properties | [43] |

| Influential Factor | Description | Biochar Product Yield | References |

|---|---|---|---|

| Lignin weight content of biomass feedstock | Lignin content has an impact on biochar yield and fixed carbon content | High biochar yield based on lignin content with low surface area; high surface PH and functional groups; high ion exchange capacity. | [2,22,71,76,78,86] |

| Influence of inorganic content | Inorganic content weight percentage has an impact on biochar properties | The inorganic content increases, biochar yield through bond dissociation energy between organic and inorganic carbon increases; higher electrical conductivity and loss of volatile matter. | |

| Higher operating temperature in thermochemical reactions | Low product yield of biochar; high fixed carbon and lower volatile matter | Higher surface area of biochar and higher pore volume with stronger mechanical properties; higher PH and electrical conductivity; high crushing and impact strengths of biochar. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aboughaly, M.; Babaei-Ghazvini, A.; Dhar, P.; Patel, R.; Acharya, B. Enhancing the Potential of Polymer Composites Using Biochar as a Filler: A Review. Polymers 2023, 15, 3981. https://doi.org/10.3390/polym15193981

Aboughaly M, Babaei-Ghazvini A, Dhar P, Patel R, Acharya B. Enhancing the Potential of Polymer Composites Using Biochar as a Filler: A Review. Polymers. 2023; 15(19):3981. https://doi.org/10.3390/polym15193981

Chicago/Turabian StyleAboughaly, Mohamed, Amin Babaei-Ghazvini, Piyali Dhar, Ravi Patel, and Bishnu Acharya. 2023. "Enhancing the Potential of Polymer Composites Using Biochar as a Filler: A Review" Polymers 15, no. 19: 3981. https://doi.org/10.3390/polym15193981