Performance of Concentrically Loaded RC Wall-like Columns Upgraded with Innovative Hybrid NSM/CFRP System

Abstract

:1. Introduction

2. Experimental Program

2.1. Test Matrix

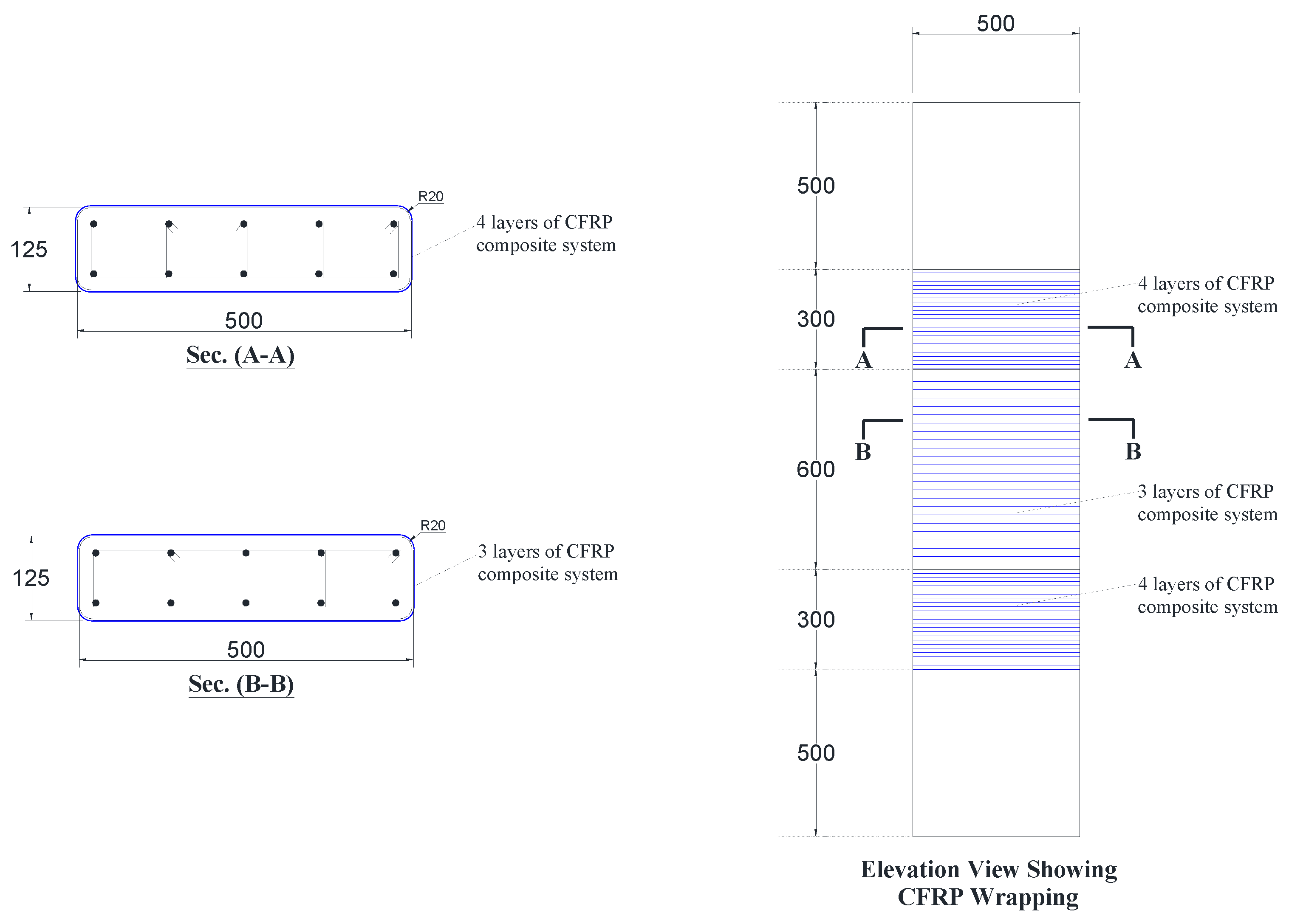

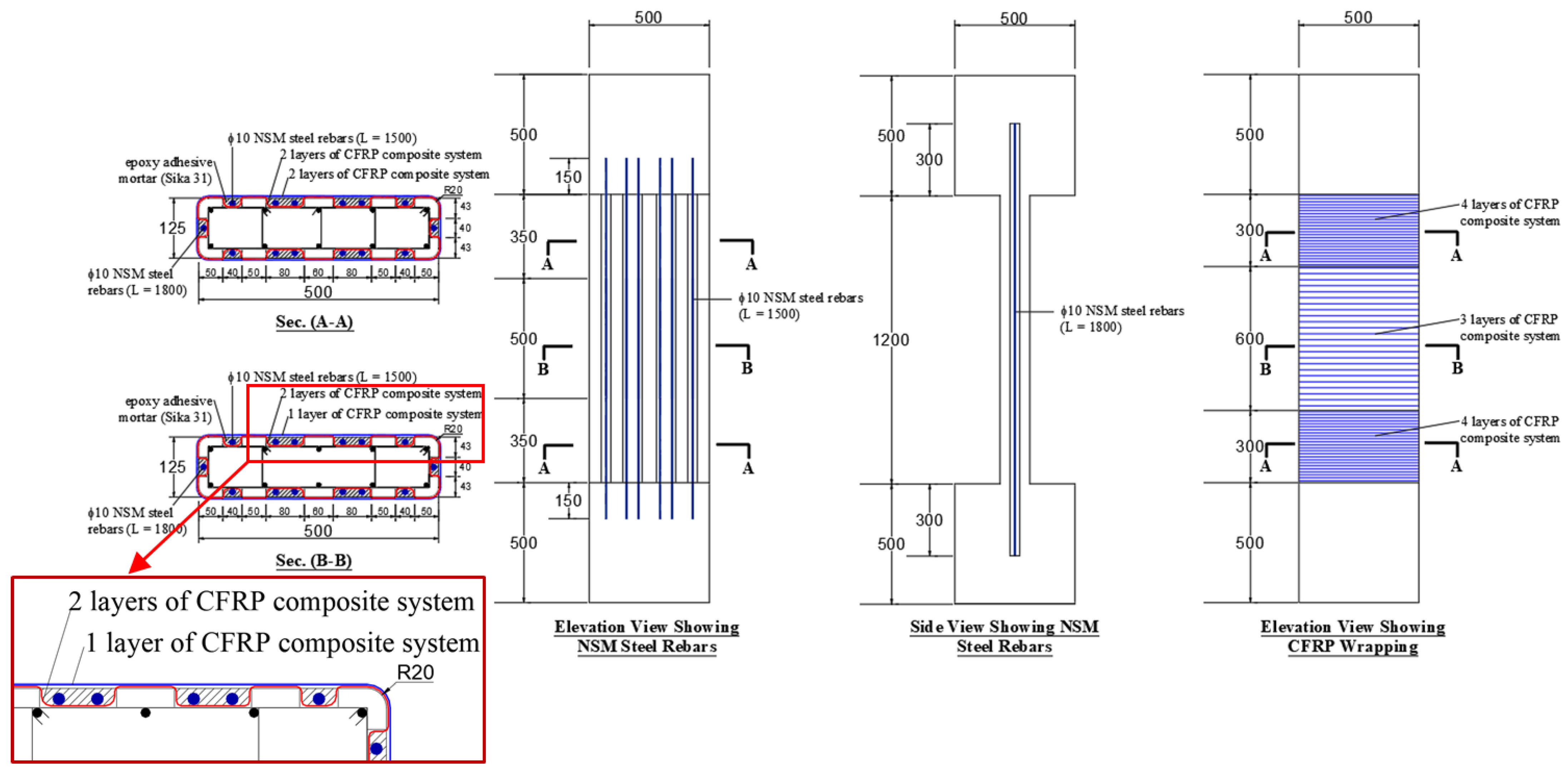

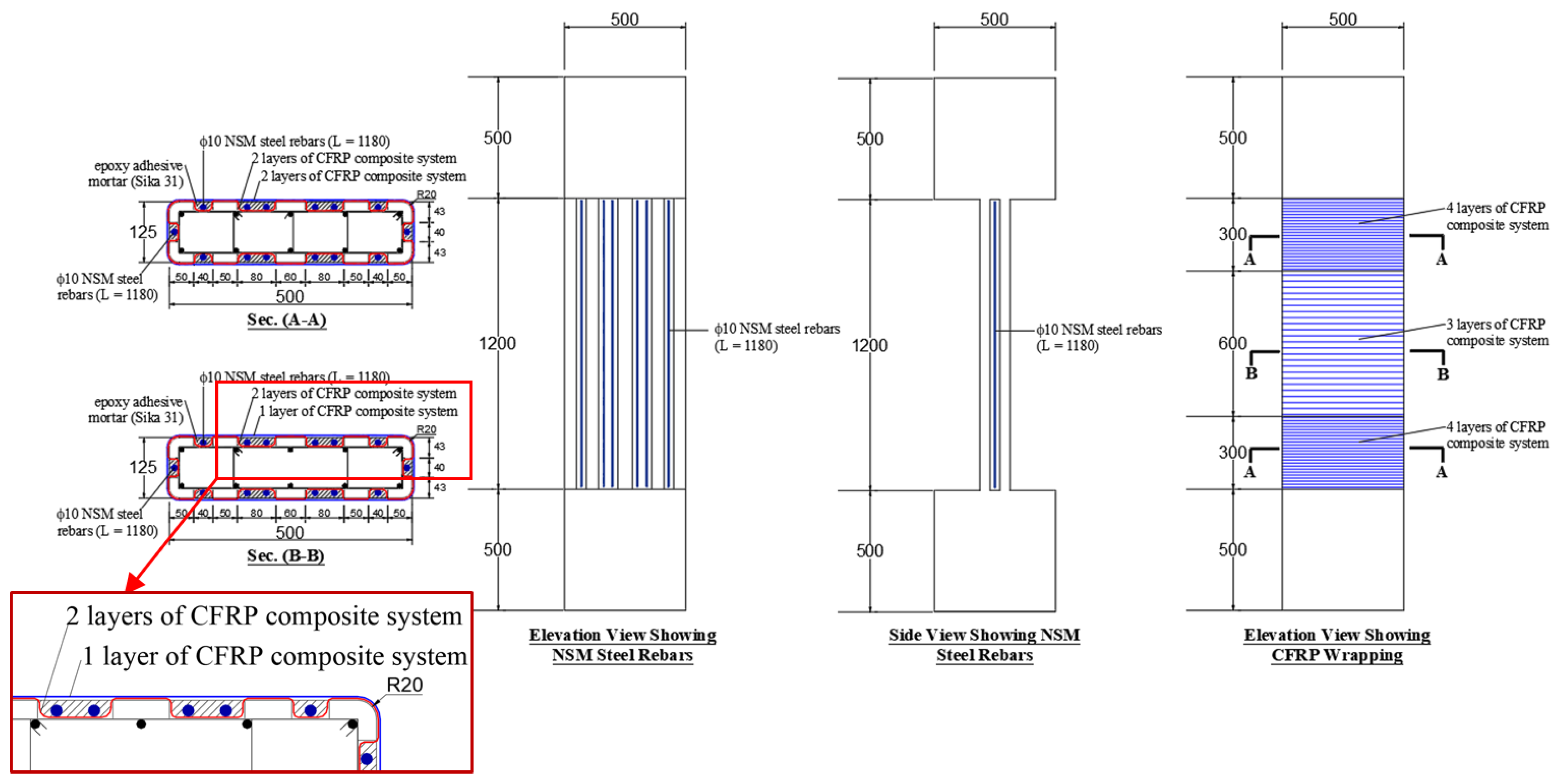

2.2. Strengthening Schemes

2.3. Properties of Material

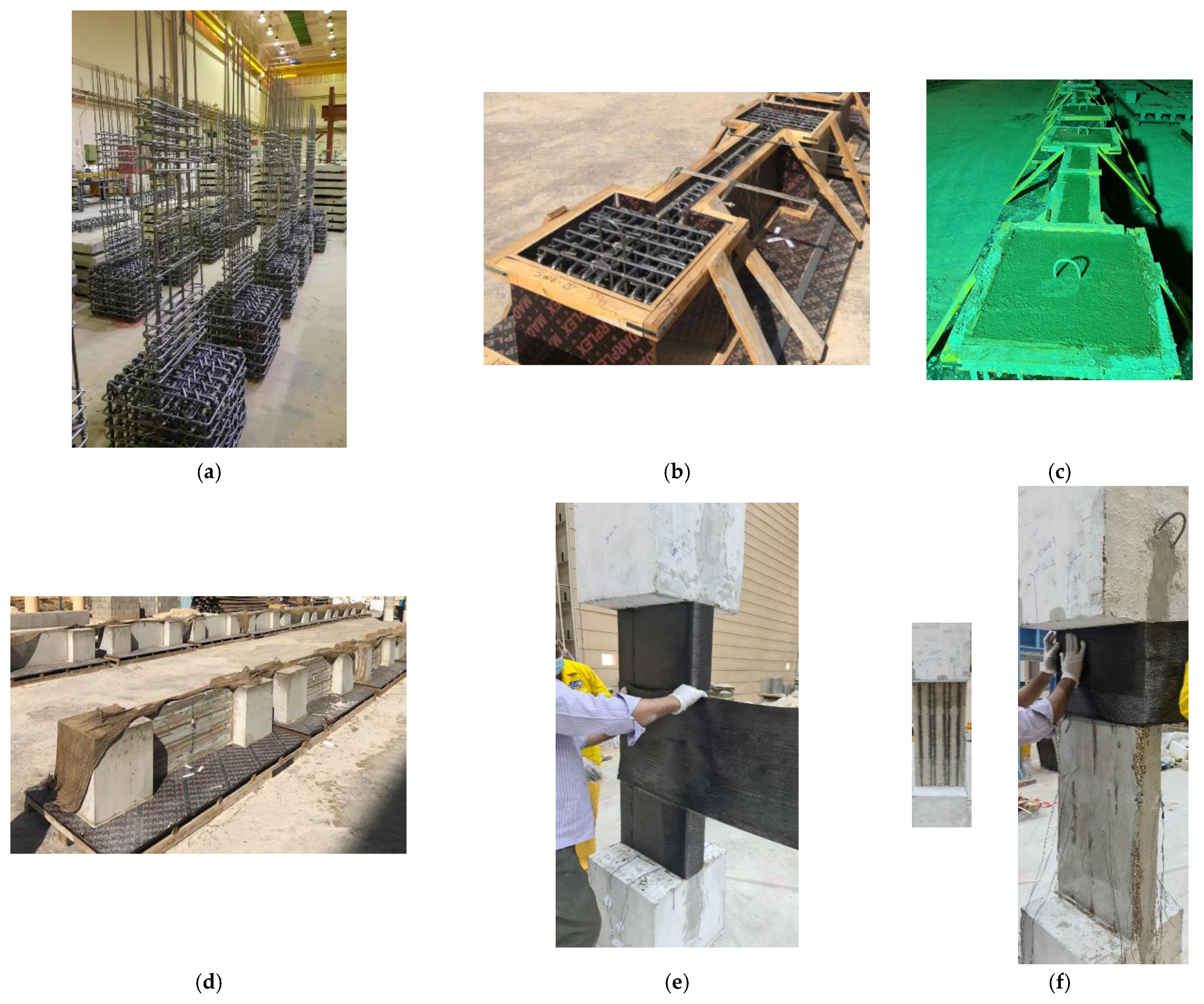

2.4. Preparation of Specimens

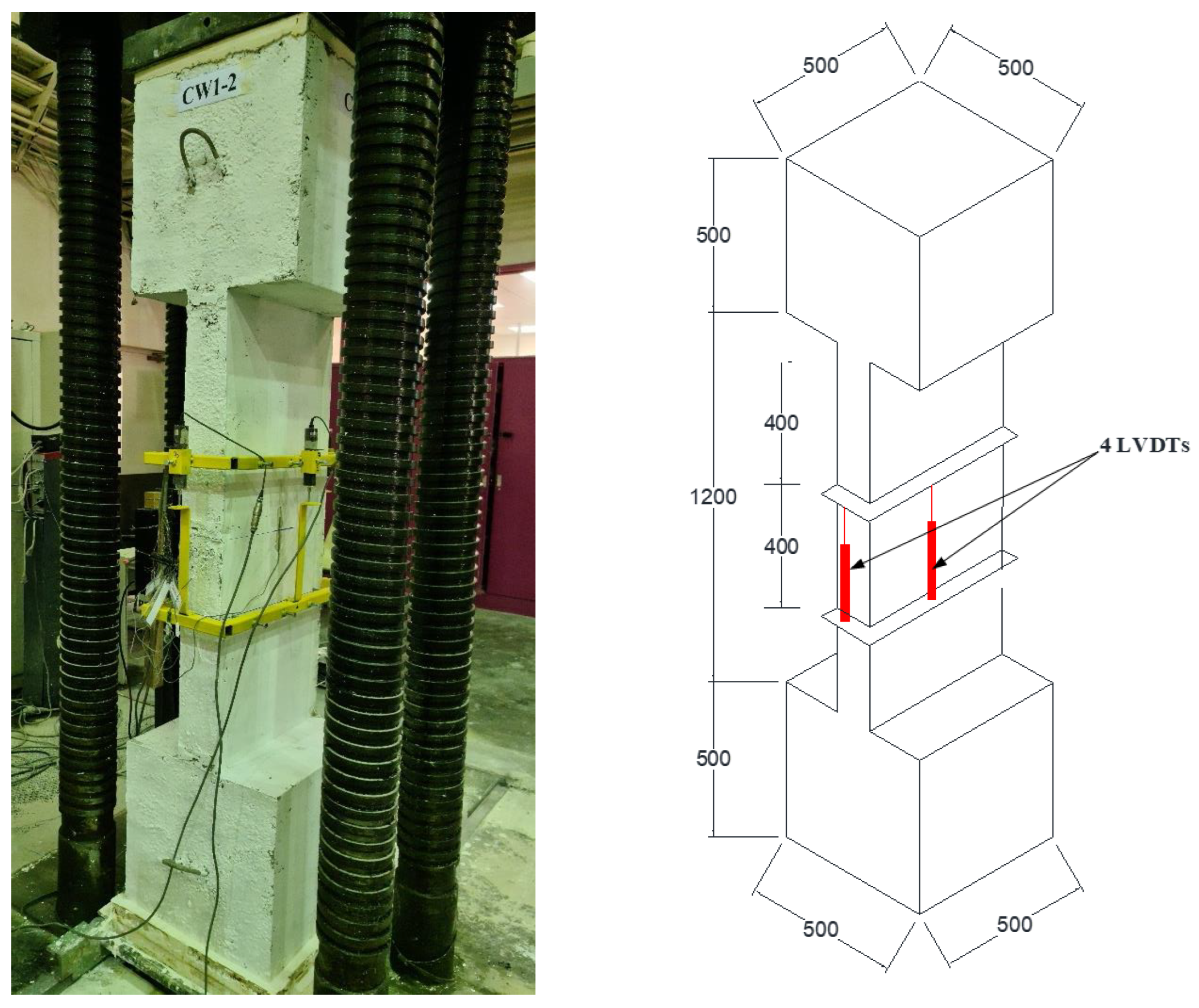

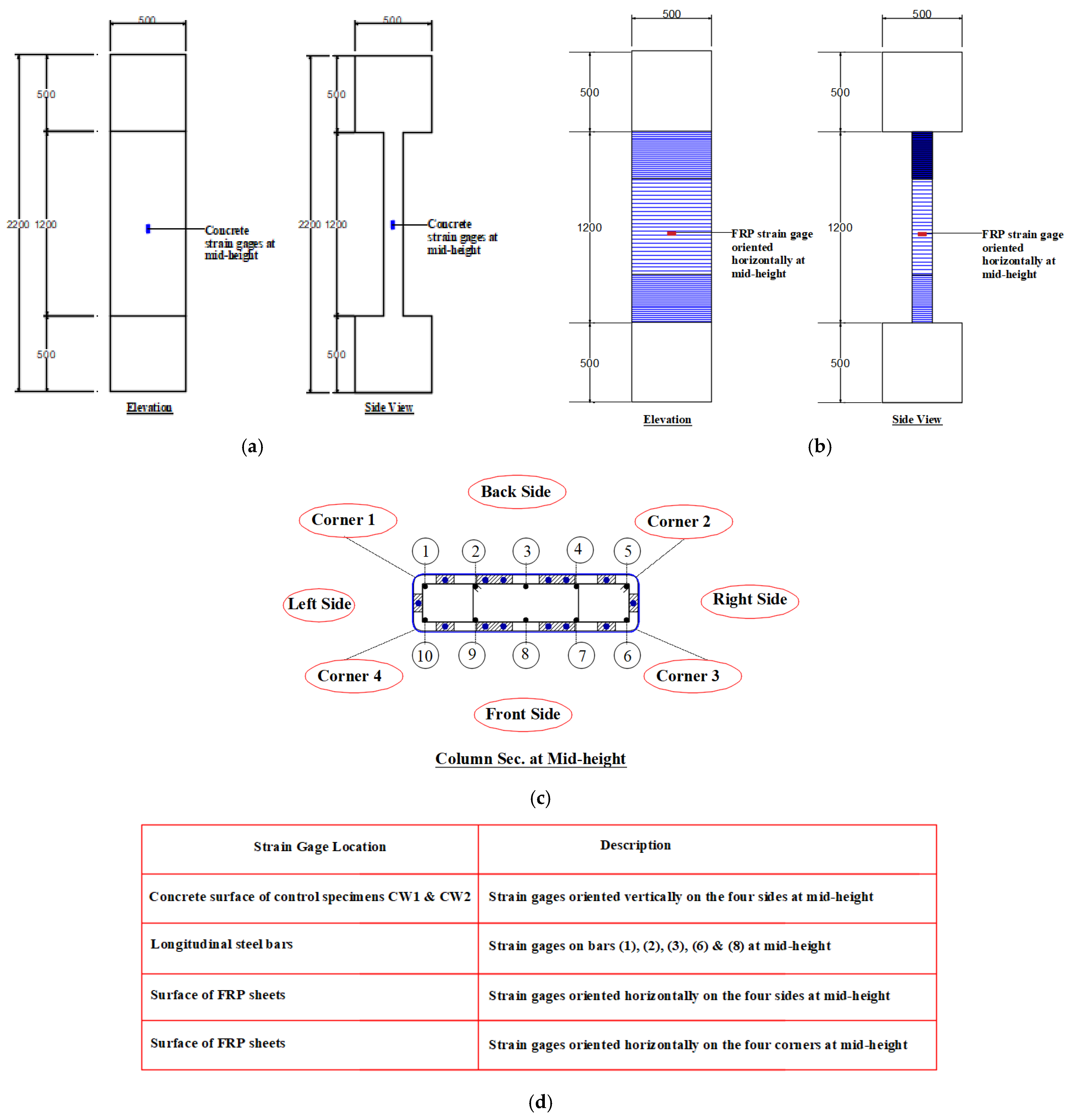

2.5. Testing Setup and Instrumentation Layout

3. Discussion of Experimental Results

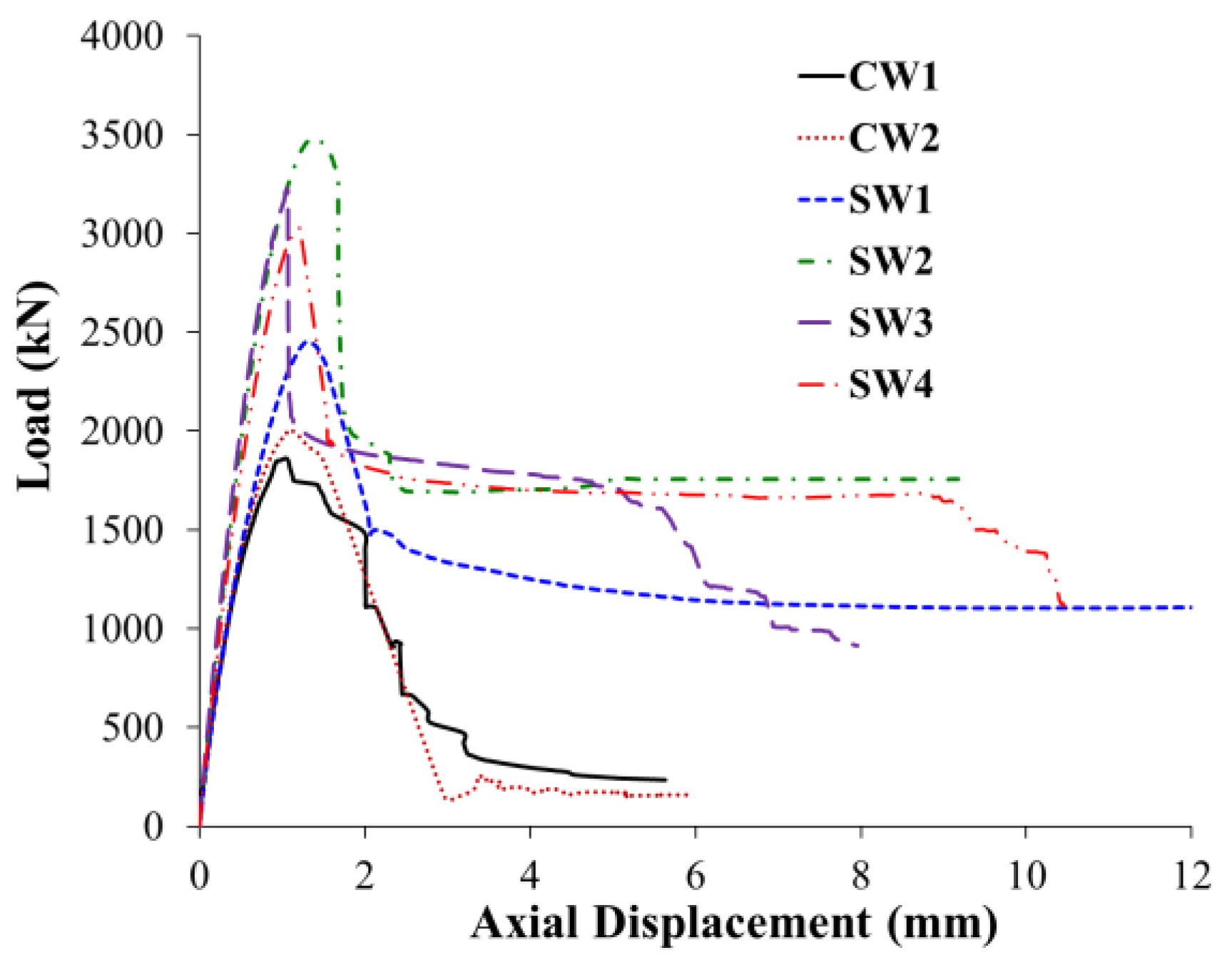

3.1. Unstrengthened Columns

3.2. Strengthened Columns

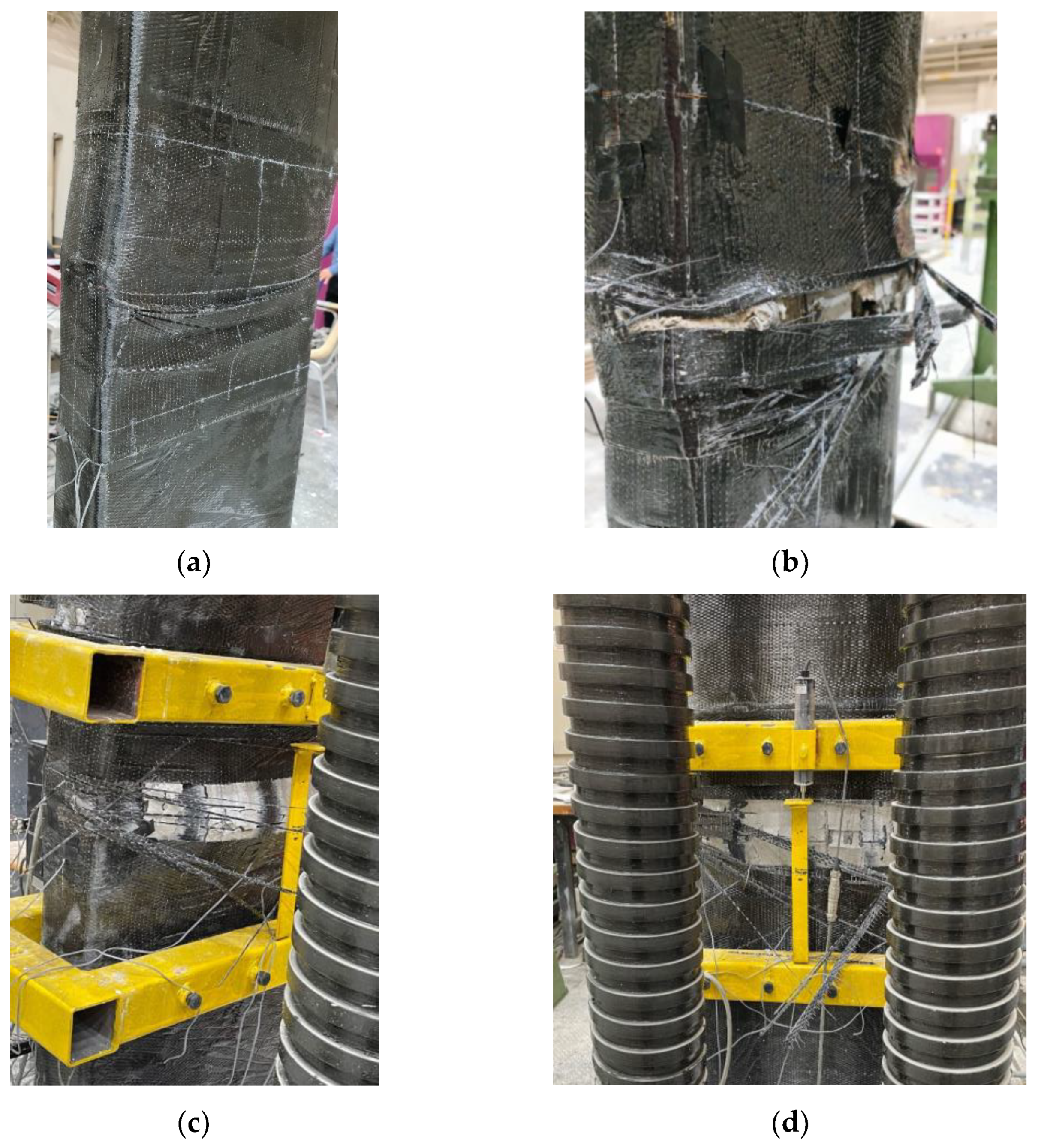

3.2.1. Column Strengthened with Scheme-1 (SW1)

3.2.2. Column Strengthened with Scheme-2 (SW2)

3.2.3. Column Strengthened with Scheme-3 (SW3)

3.2.4. Column Strengthened with Scheme-4 (SW4)

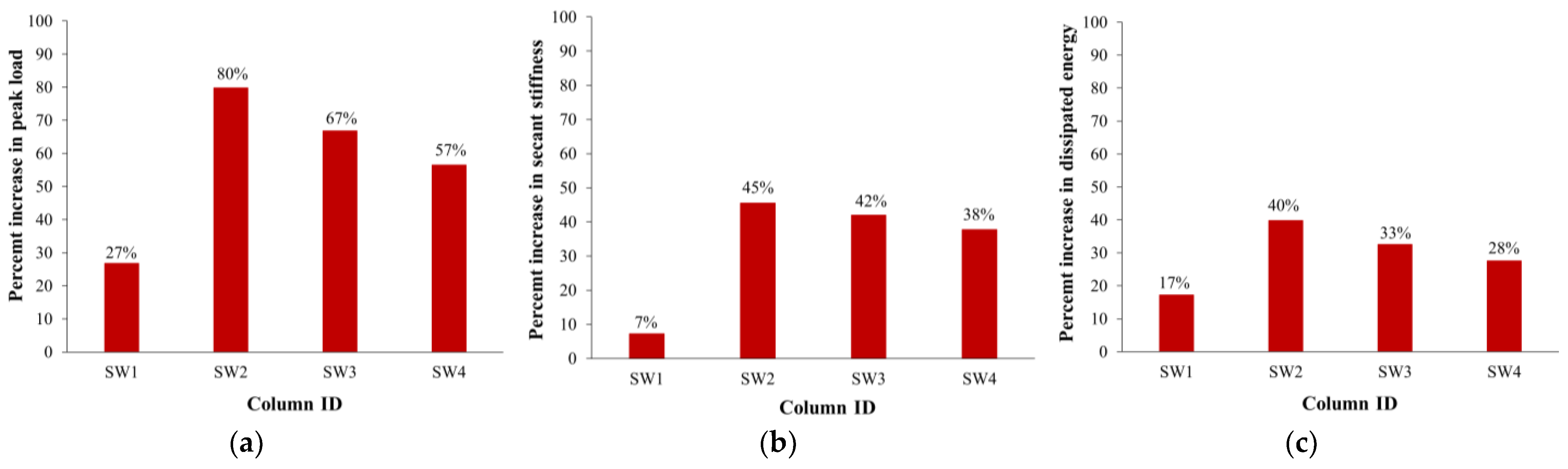

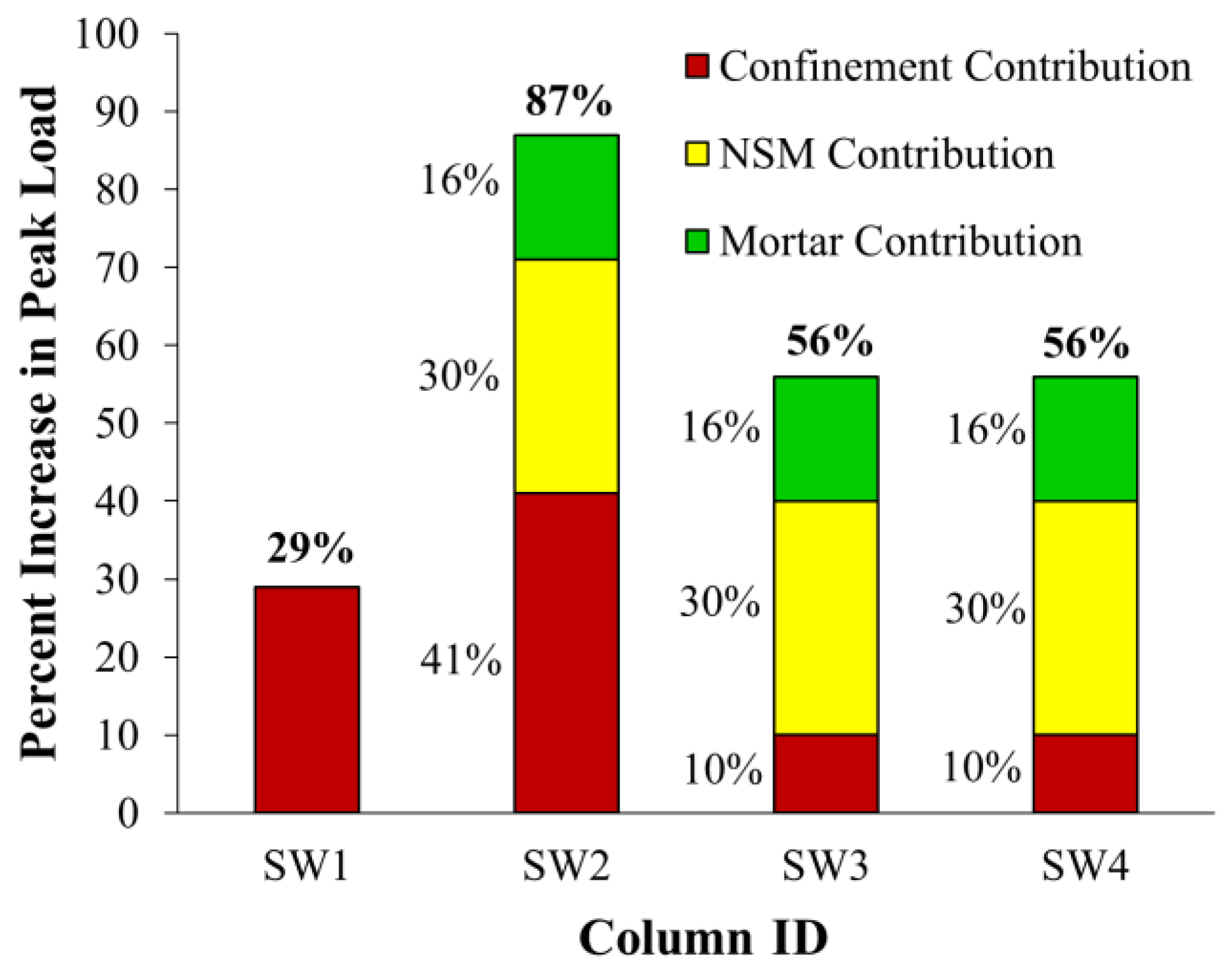

3.3. Comparison of Strengthening Schemes

4. Finite Element Analysis

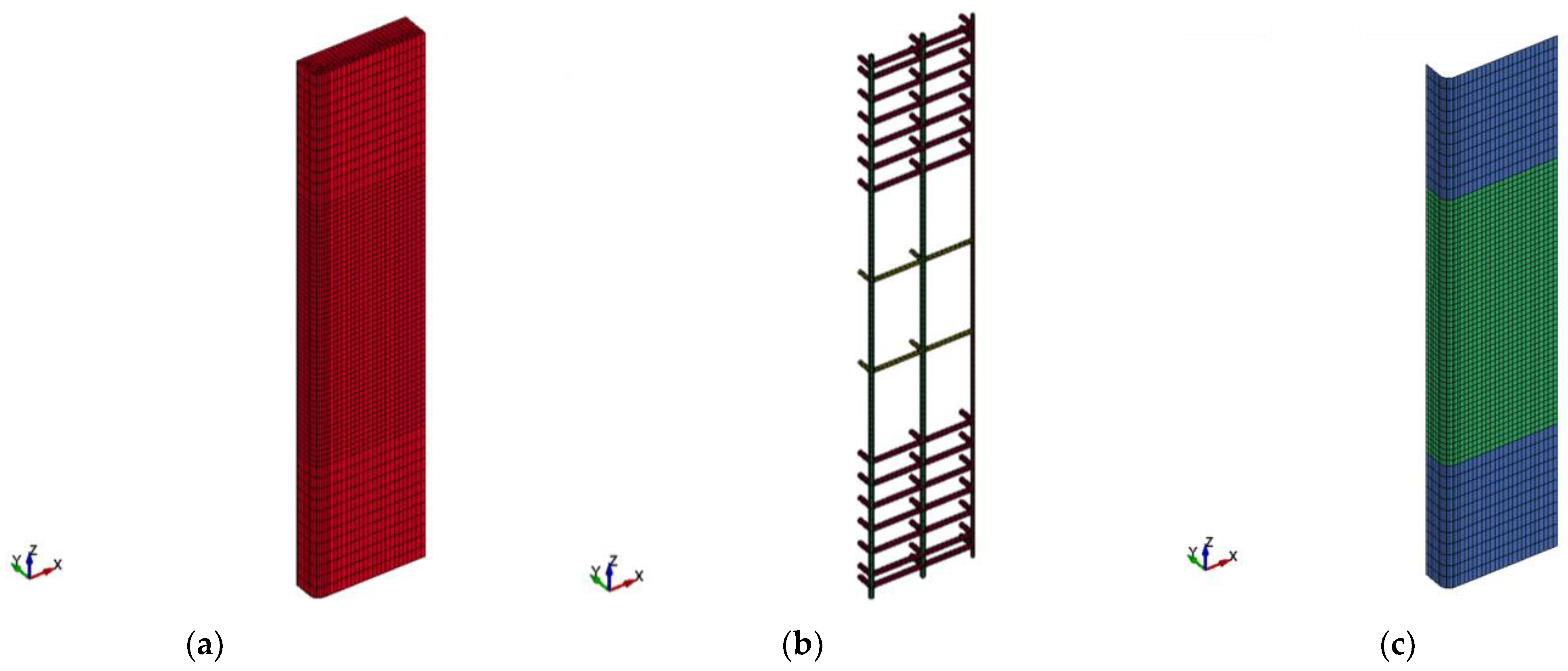

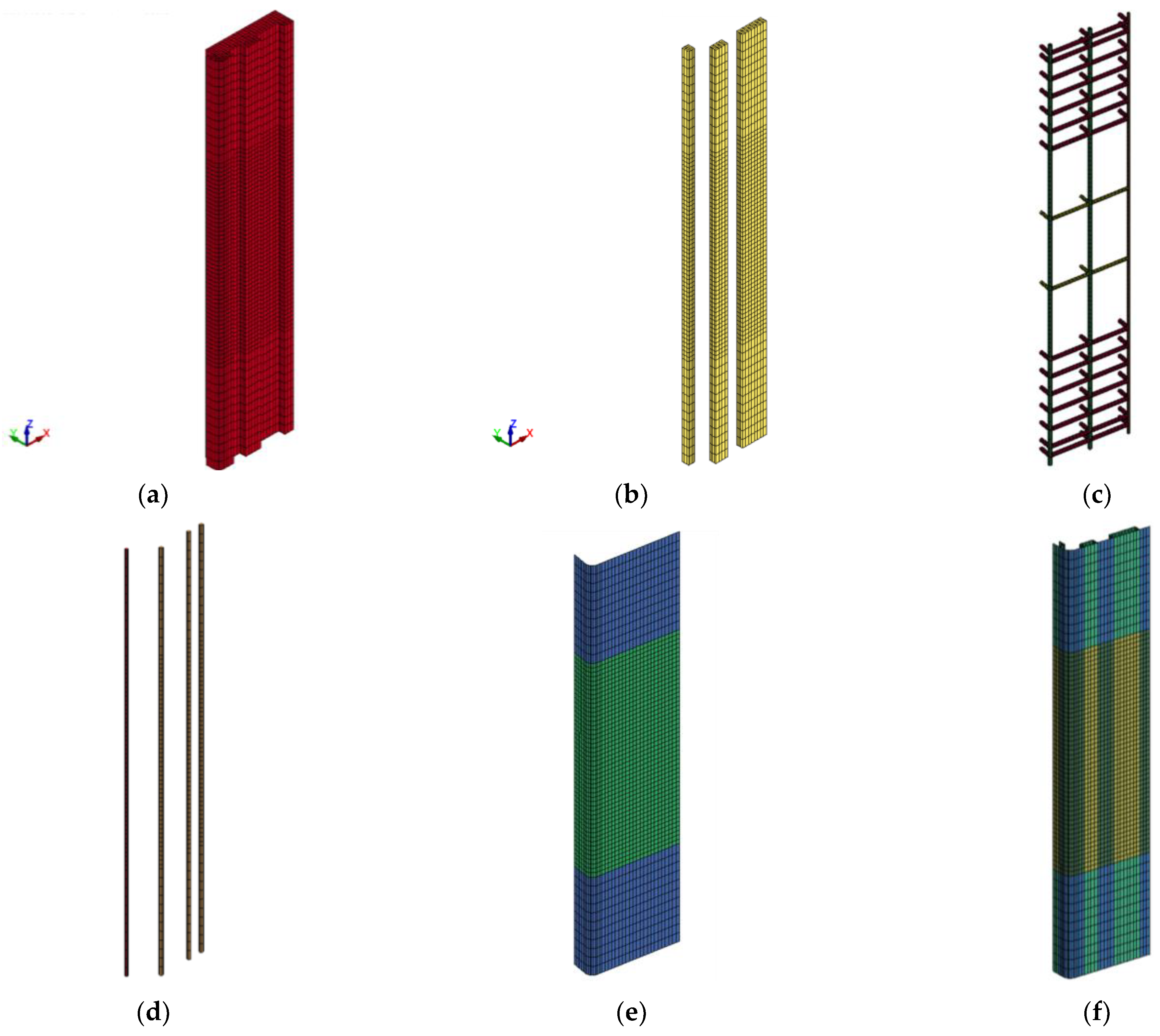

4.1. Model Geometry and Mesh Generation

4.2. Material Modeling

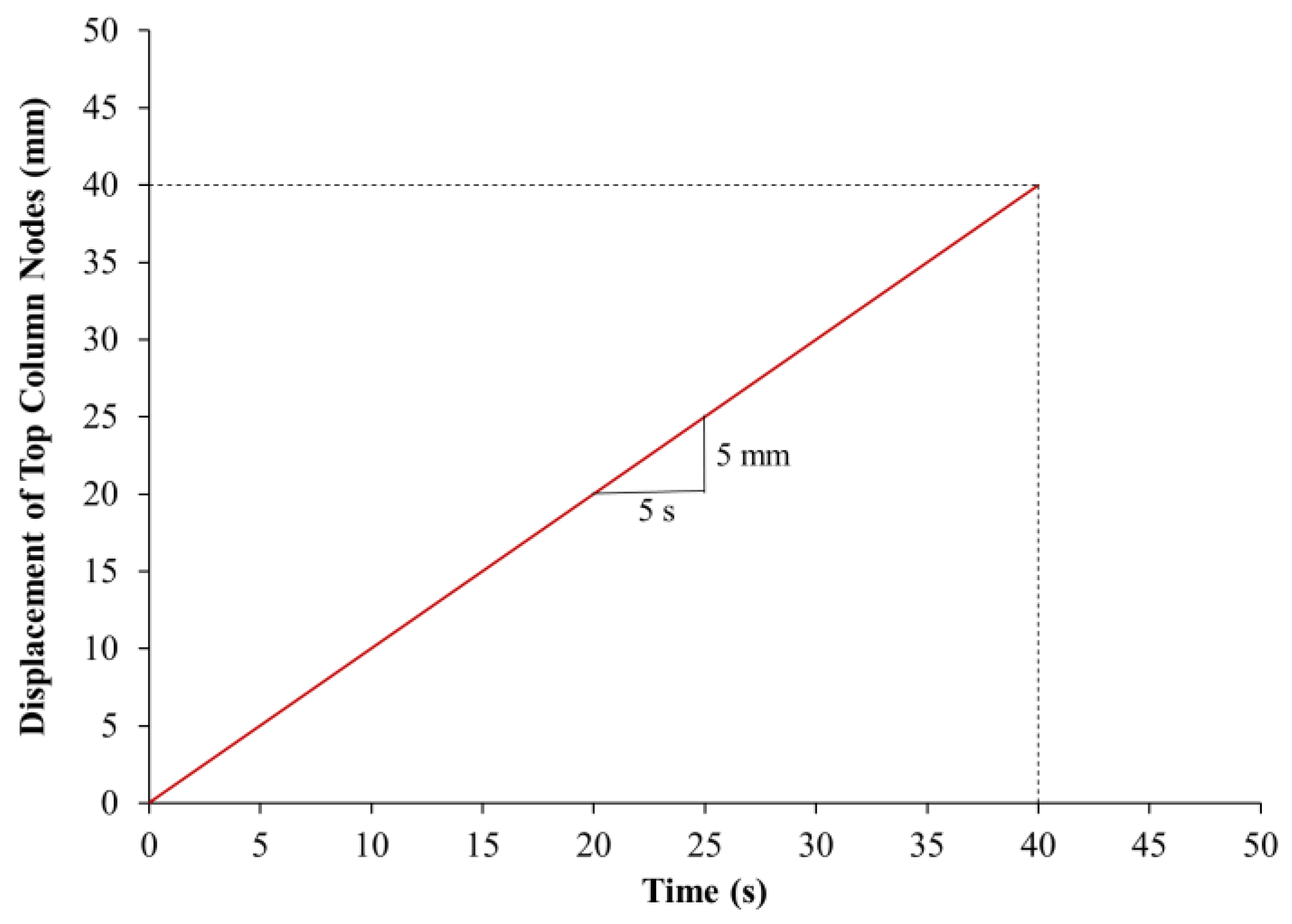

4.3. Loading Protocol and Boundary Conditions

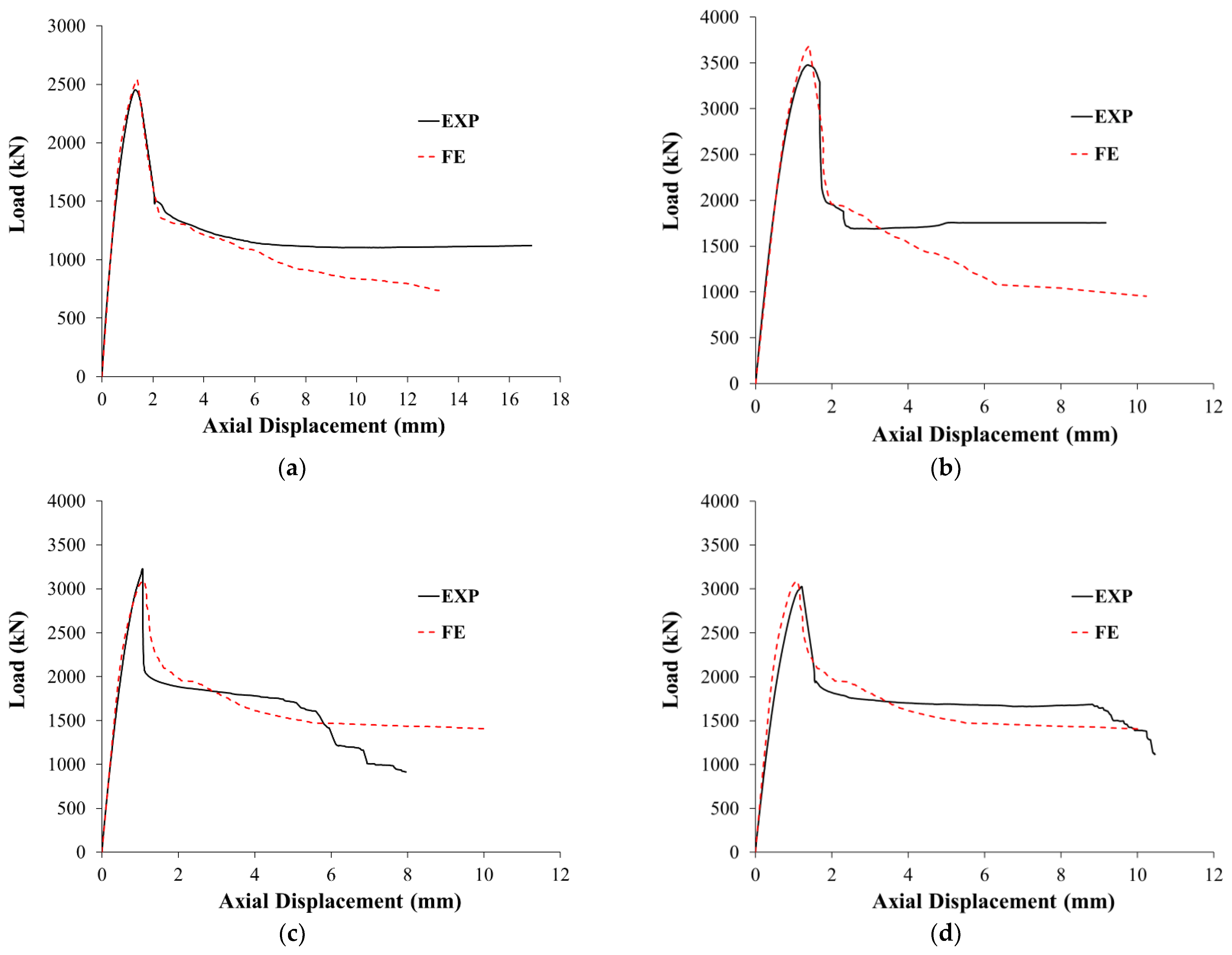

5. Discussion of FEA Results

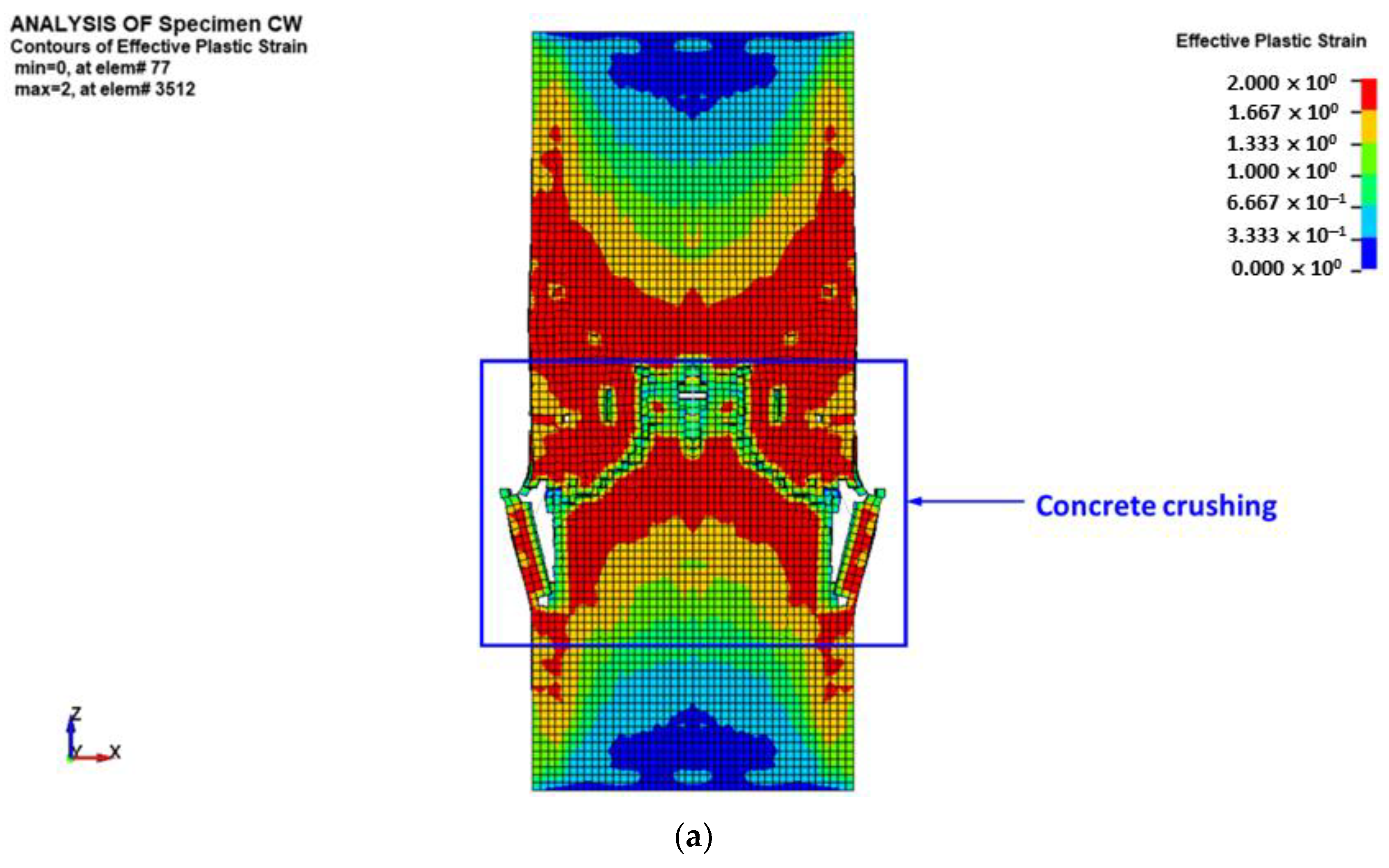

5.1. Unstrengthened Columns

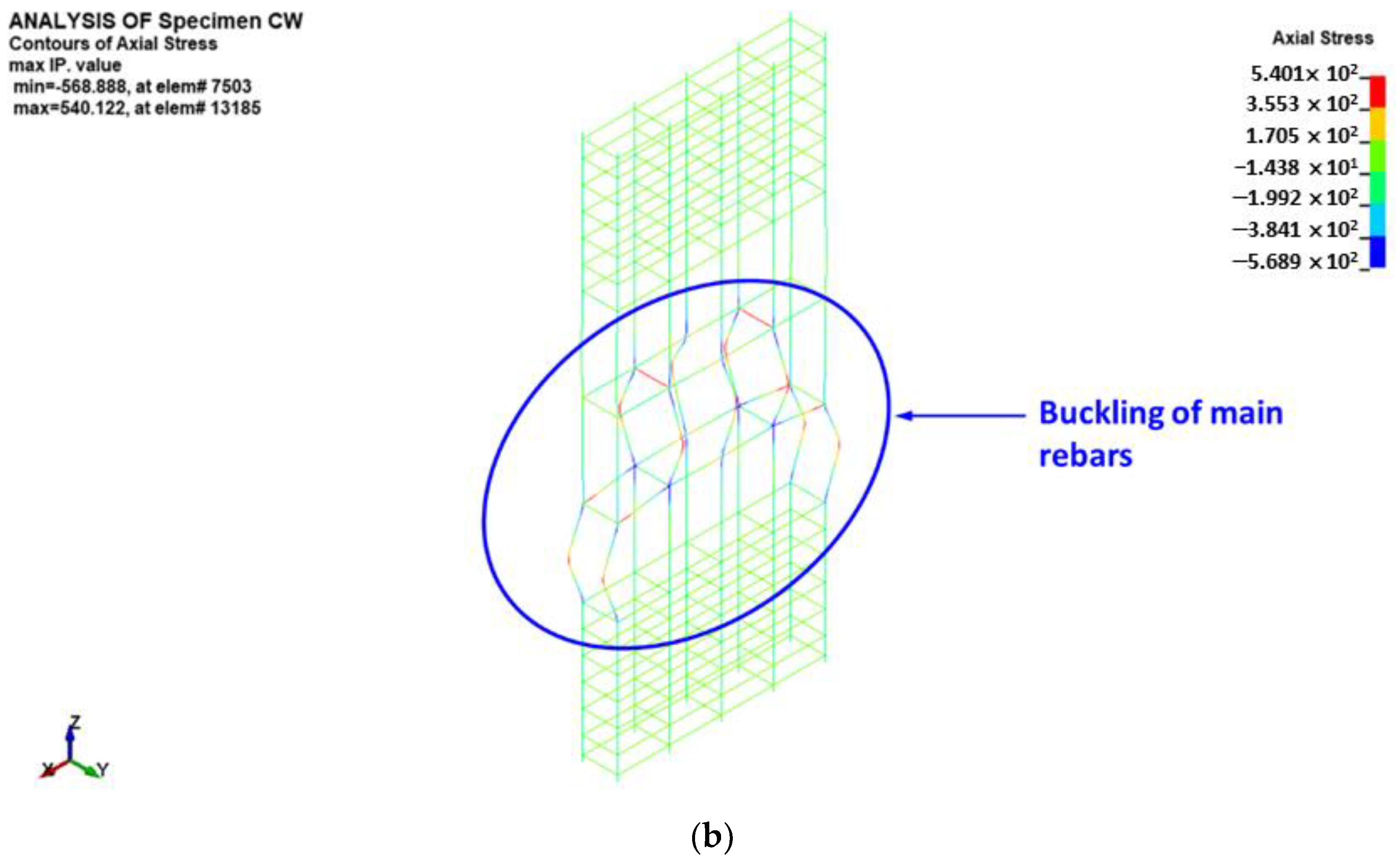

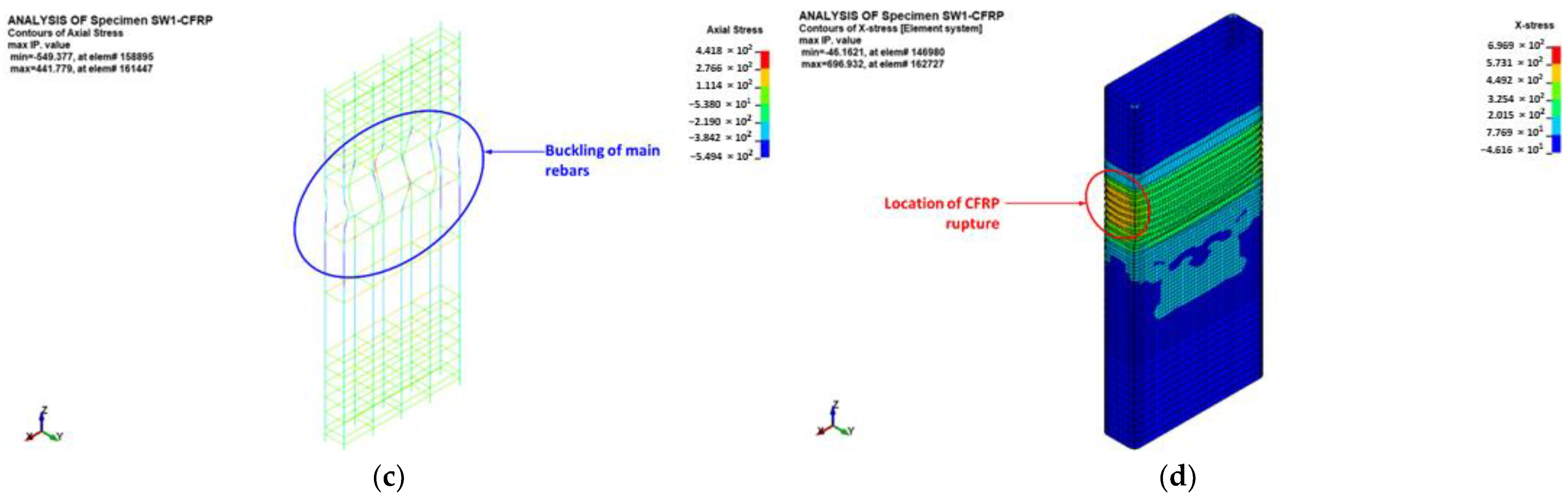

5.2. Strengthened Column SW1

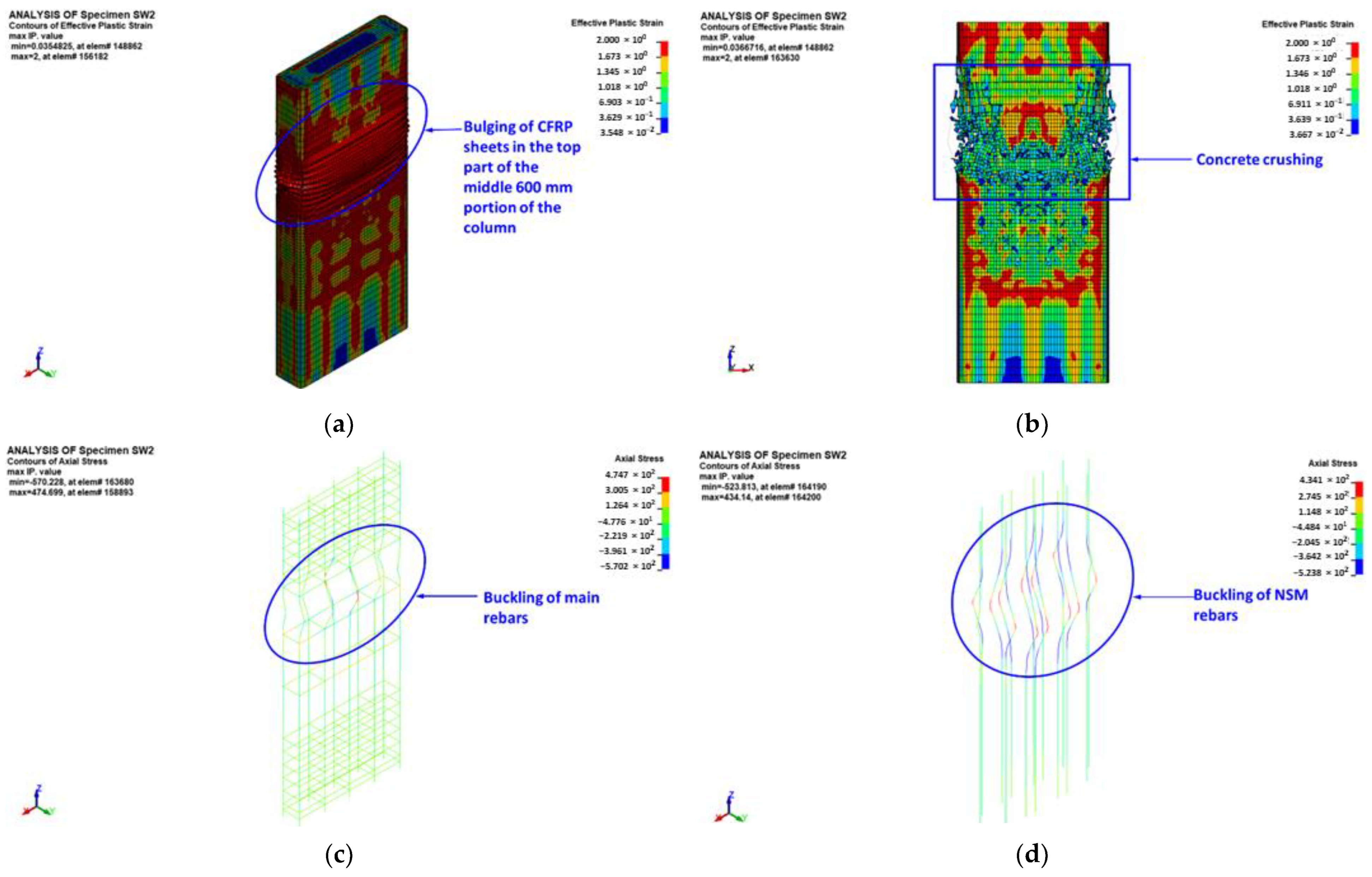

5.3. Strengthened Column SW2

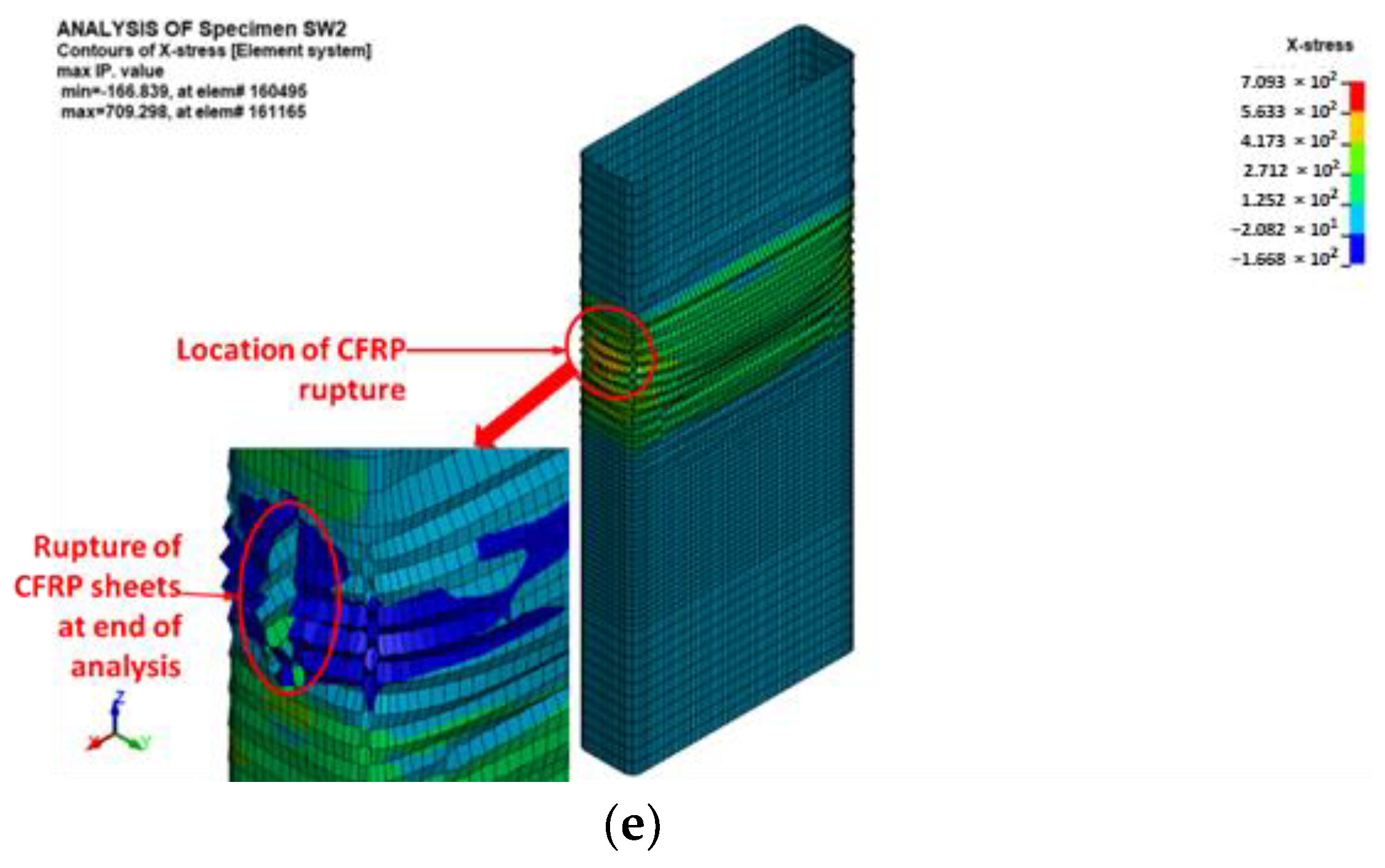

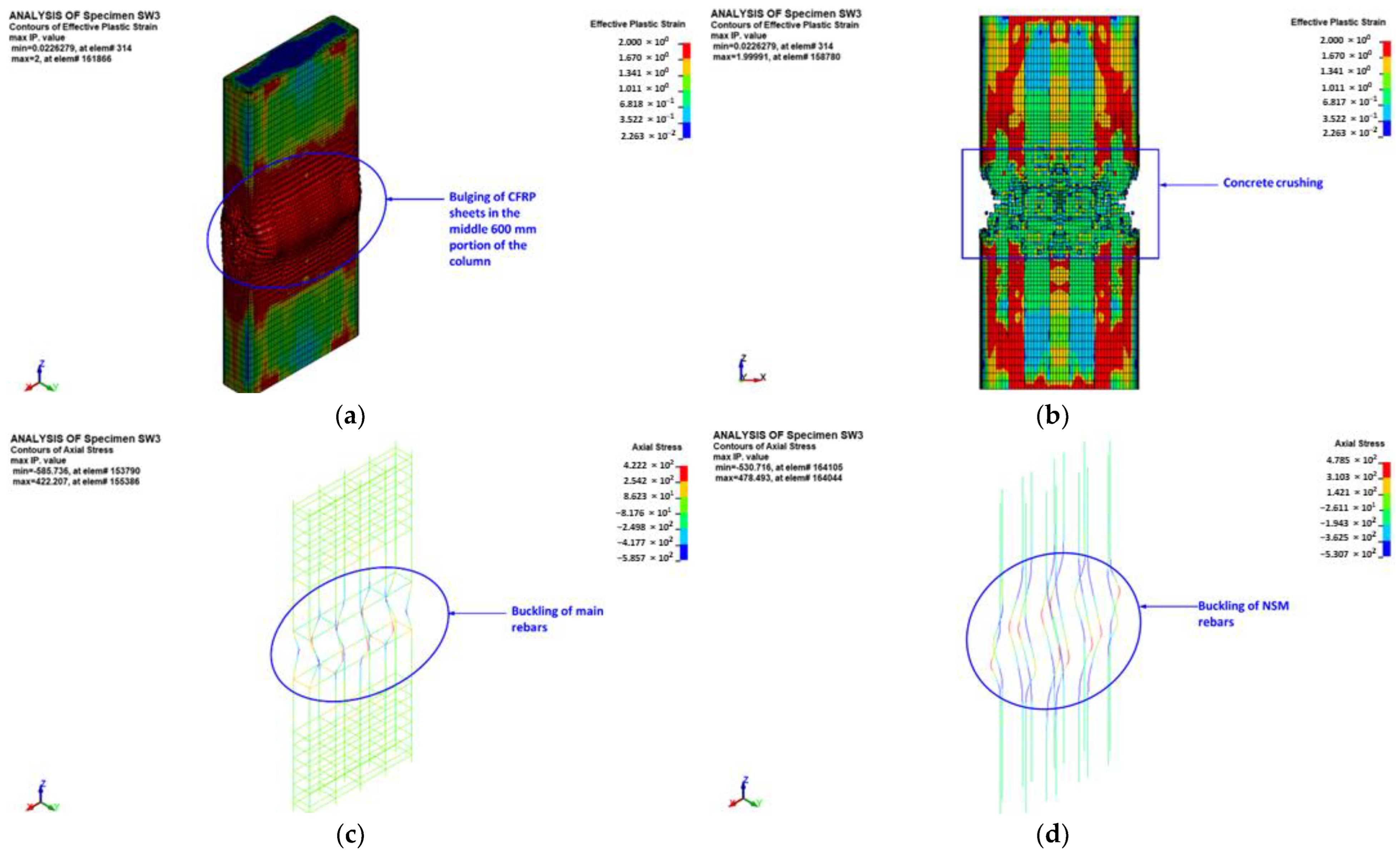

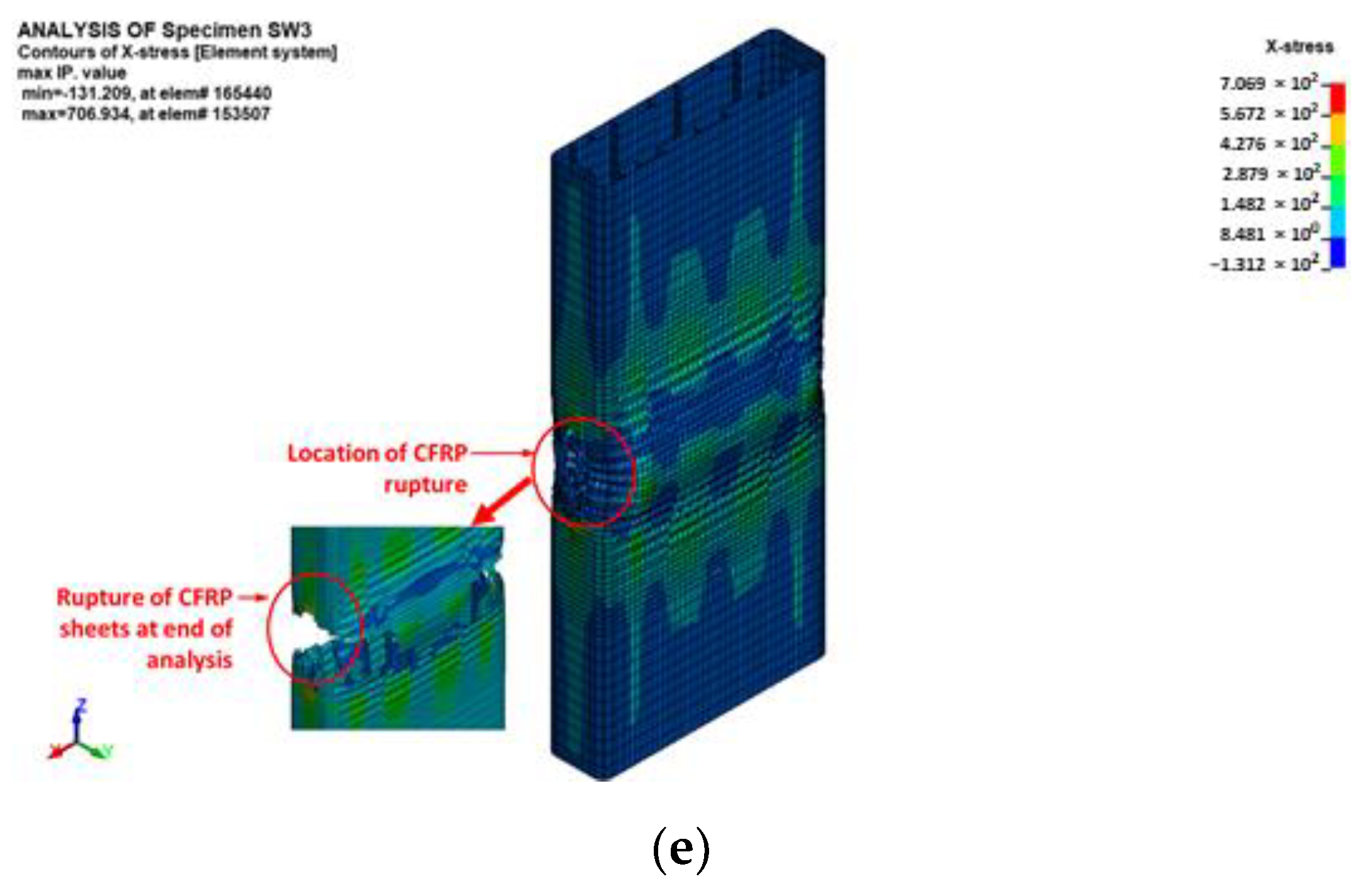

5.4. Strengthened Columns SW3 and SW4

5.5. Comparison of Strengthening Schemes

6. Conclusions

- The failure of unstrengthened columns was typical brittle failure caused by the spalling of concrete cover leading to the buckling of main column rebars and consequent total failure owing to concrete crushing.

- The failure of the strengthened wall-like columns in all the strengthening schemes started with the bulging of the CFRP sheets due to the bulging of the column section and buckling of NSM rebars (if present) and longitudinal column rebars. The ultimate failure of the upgraded columns was through the rupture of CFRP sheets.

- External wrapping of three CFRP layers in scheme-1 was not effective at enhancing the ultimate load of wall-like columns, as the increase was only moderate by about 27% and 29% for experimental and FE results, respectively. This scheme also had a minor effect on enhancing the secant stiffness of the wall-like column as the increase was limited to 7% and 11% for experimental and FE results, respectively.

- Using vertical continuous NSM rebars in combination with the wrapping of three CFRP layers onto the exterior column surface (scheme-2) was very efficient at enhancing the axial capacity of the wall-like columns by about 80% and 87% for experimental and numerical results, respectively. Scheme-2 was also very efficient at enhancing the secant stiffness of the wall-like columns by about 45% and 49% for experimental and FE results, respectively.

- For scheme-3, which was the same as scheme-2, except that two of the three CFRP wrapping layers were bonded to the inside surface of the NSM grooves before the installation of the NSM rebars and the remaining CFRP layer was later attached to the outer surface of the column, the peak load enhancement was about 67% and 56% for experimental and FE results, respectively. However, for scheme-4, which was the same as scheme-3 except that the NSM steel rebars were disconnected from the top and bottom bases, the measured peak load increase was reduced to 57%. Nevertheless, the numerically predicted peak load enhancement for scheme-4 was the same as that for scheme-3 (= 56%). Both schemes were also efficient at increasing the secant stiffness of the unstrengthened column by about 38% to 49%.

- A good agreement was obtained between the measured and predicted results of tested columns with respect to modes of failure and characteristics of load versus axial displacement for both unstrengthened and strengthened specimens. This demonstrates the precision of the used material models for concrete, steel rebars, and CFRP sheets. Hence, the developed models can be confidently used in future research on upgrading wall-like columns with different parameters such as section aspect ratio, slenderness effect, and different strengthening schemes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bett, B.J.; Klingner, R.E.; Jisra, J.O. Lateral load response of strengthened and repaired reinforced concrete columns. ACI Struct. J. 1998, 85, 499–508. [Google Scholar]

- Rodriguey, M.; Park, R. Seismic load tests on reinforced concrete columns strengthened by jacketing. ACI Struct. J. 1994, 91, 150–159. [Google Scholar]

- Campione, G. Load carrying capacity of RC compressed columns strengthened with steel angles and strips. Eng. Struct. 2012, 40, 457–465. [Google Scholar] [CrossRef]

- Khalifa, E.S.; Al-Tersawy, S.H. Experimental and analytical behavior of strengthened reinforced concrete columns with steel angles and strips. Int. J. Adv. Struct. Eng. 2014, 6, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Tarabia, A.M.; Albakry, H.F. Strengthening of RC columns by steel angles and strips. Alex. Eng. J. 2014, 53, 615–626. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Hay, A.S.; Fawzy, Y.A.G. Behavior of partially defected R.C columns strengthened using steel jackets. HBRC J. 2015, 11, 194–200. [Google Scholar] [CrossRef] [Green Version]

- Salah, A.; Elsanadedy, H.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Behavior of axially loaded L-shaped RC columns strengthened using steel jacketing. J. Build. Eng. 2022, 47, 103870. [Google Scholar] [CrossRef]

- Zeng, J.; Guo, Y.; Li, L.; Chen, W. Behavior and three-dimensional finite element modeling of circular concrete columns partially wrapped with FRP strips. Polymers 2018, 10, 253. [Google Scholar] [CrossRef] [Green Version]

- Anagnostou, E.; Rousakis, T. Performance of Steel Bar Lap Splices at the Base of Seismic Resistant Reinforced Concrete Columns Retrofitted with FRPs—3D Finite Element Analysis. Fibers 2022, 10, 107. [Google Scholar] [CrossRef]

- Elsanadedy, H.; Alaoud, L.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Externally bonded CFRP composites versus steel stirrups for the confinement of substandard lap spliced GFRP bars in RC beams. Compos. Struct. 2022, 306, 116602. [Google Scholar] [CrossRef]

- Rousakis, T.; Anagnostou, E.; Fanaradelli, T. Advanced Composite Retrofit of RC Columns and Frames with Prior Damages—Pseudodynamic Finite Element Analyses and Design Approaches. Fibers 2021, 9, 56. [Google Scholar] [CrossRef]

- Fanaradelli, T.D.; Rousakis, T.C. 3D finite element pseudodynamic analysis of deficient RC rectangular columns confined with fiber reinforced polymers under axial compression. Polymers 2020, 12, 2546. [Google Scholar] [CrossRef] [PubMed]

- Fanaradelli, T.D.; Rousakis, T.C. Prediction of ultimate strain for rectangular reinforced concrete columns confined with fiber reinforced polymers under cyclic axial compression. Polymers 2020, 12, 2691. [Google Scholar] [CrossRef] [PubMed]

- Yu, T.T.J.G.; Teng, J.G.; Wong, Y.L.; Dong, S.L. Finite element modeling of confined concrete-I: Drucker–Prager type plasticity model. Eng. Struct. 2010, 32, 665–679. [Google Scholar] [CrossRef]

- Ahmed, D.; Baluch, M.H.; Rahman, M.K.; Ilki, A. Finite element modeling of seismic performance of low strength concrete exterior beam-column joints. In Seismic Evaluation and Rehabilitation of Structures; Springer: Cham, Switzerland, 2014; pp. 221–242. [Google Scholar]

- Sirajudeen, R.S.; Sekar, R. Buckling analysis of pultruded glass fiber reinforced polymer (GFRP) angle sections. Polymers 2020, 12, 2532. [Google Scholar] [CrossRef] [PubMed]

- Bedirhanoglu, I.; Ilki, A.; Kumbasar, N. Precast fiber reinforced cementitious composites for seismic retrofit of deficient RC joints–a pilot study. Eng. Struct. 2013, 52, 192–206. [Google Scholar] [CrossRef]

- Tan, K.H. Strength enhancement of rectangular RC columns using FRP. J. Compos. Constr. 2002, 6, 175–183. [Google Scholar] [CrossRef]

- Hosny, A.; Shaheen, H.; Abdelrahman, A.; Elafandy, T. Uniaxial tests on rectangular columns strengthened with CFRP. In Proceedings of the Third Middle East Symposium on Structural Composites for Infrastructure Applications, Aswan, Egypt, 17–20 December 2002. [Google Scholar]

- Tanwongsval, S.; Maalej, M.; Paramasivam, P. Strengthening of RC wall-like columns with FRP under sustained loading. RILEM Mater Struct 2003, 36, 282–290. [Google Scholar] [CrossRef]

- Maalej, M.; Tanwongsval, S.; Paramasivam, P. Modelling of rectangular RC columns strengthened with FRP. Cem. Concr. Compos. 2003, 25, 263–276. [Google Scholar] [CrossRef]

- Prota, A.; Manfredi, G.; Cosenza, E. Ultimate behavior of axially loaded RC wall-like columns confined with GFRP. Compos. Part B 2006, 37, 670–678. [Google Scholar] [CrossRef]

- De Luca, A.; Nardone, F.; Lignola, G.P.; Prota, A.; Nanni, A. Wall-like reinforced concrete columns externally confined by means of glass FRP laminates. Adv. Struct. Eng. 2013, 16, 593–603. [Google Scholar] [CrossRef] [Green Version]

- Alsayed, S.H.; Almusallam, T.H.; Ibrahim, S.M.; Al-Hazmi, N.M.; Al-Salloum, Y.A.; Abbas, H. Experimental and numerical investigation for compression response of CFRP strengthened shape modified wall-like RC column. Constr. Build. Mater. 2014, 63, 72–80. [Google Scholar] [CrossRef]

- Abbas, H.; Ibrahim, S.M.; Al-Hazmi, N.; Elsanadedy, H.; Almusallam, T.; Al-Salloum, Y. Axial Compression Behavior of Wall-like Reinforced Concrete Columns Retrofitted Using Different FRP Schemes. Buildings 2022, 13, 26. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Choutopoulou, E.; Fotaki, E.; Skorda, M.; Stathopoulou, M.; Karlos, K. FRP confinement of wall-like reinforced concrete columns. Mater. Struct. Mater. Constr. 2016, 49, 651–664. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.C.; Resrepo, J.I. Investigations of concentrically loaded reinforced concrete columns confined with glass fiber-reinforced polymer jackets. ACI Struct J. 2001, 98, 377–385. [Google Scholar]

- Saatcioglu, M.; Razvi, S.R. Strength and ductility of confined concrete. J. Struct Eng. 1992, 118, 590–607. [Google Scholar] [CrossRef]

- Yalcim, C.; Saatcioglu, M. Inelastic analysis of reinforced concrete columns. Comput. Struct. 2000, 77, 539–555. [Google Scholar] [CrossRef]

- ACI Committee 440. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; ACI 440.2R-17 2000; American Concrete Institute: Detroit, MI, USA, 2017. [Google Scholar]

- National Cooperative Highway Research Program (NCHRP). Recommended Guide Specification for the Design of Externally Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements; NCHRP Report 655; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2010. [Google Scholar]

- ISIS. Design Manual No. 4—FRP Rehabilitation of Reinforced Concrete Structures; The Canadian Network of Centers of Excellence on Intelligent Sensing for Innovative Structures (ISIS Canada): Winnipeg, MB, Canada, 2008. [Google Scholar]

- EN 1998-3; Eurocode 8—Design of Structures for Earthquake Resistance—Part 3: Assessment and Retrofitting of Buildings. European Committee for Standardization: Brussels, Belgium, 2005.

- International Federation for Structural Concrete. Fib Bulletin 14. In Externally Bonded FRP Reinforcement for RC Structures; Technical Report Prepared by the Working Party EBR of Task Group 9.3; International Federation for Structural Concrete: Lausanne, Switzerland, 2001. [Google Scholar]

- The Concrete Society (CS). TR55 Design Guidance for Strengthening Concrete Structures using Fibre Composite Materials; The Concrete Society: Camberley, UK, 2012. [Google Scholar]

- Italian National Research Council (CNR). CNR-DT 200 R1/2013: Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures: Materials, RC and PC Structures, Masonry Structures; Italian National Research Council: Rome, Italy, 2013. [Google Scholar]

- Japan Society of Civil Engineers (JSCE). Recommendations for Upgrading of Concrete Structures with Use of Continuous Fiber Sheet; Concrete Engineering Series 41; Japan Society of Civil Engineers: Tokyo, Japan, 2001. [Google Scholar]

- China Association for Engineering Construction Standards (CECS). Technical Specifications for Strengthening Structures with Carbon Fiber Reinforced Polymer Laminates; CECS 146-2003; China Planning Press: Beijing, China, 2003. [Google Scholar]

- Egyptian Code of Practice (ECP). The Use of Fiber Reinforced Polymer (FRP) in the Construction Fields; Code no. ECP 208-2005; Egyptian Code of Practice: Cairo, Egypt, 2005. [Google Scholar]

- CSA S806-12; Design and Construction of Building Structures with Fibre Reinforced Polymers. Canadian Standards Association: Toronto, ON, Canada, 2012.

- D’Antino, T.; Pisani, M.A. General Analytical Model for the Bond Capacity of NSM FRP-Concrete Joints. J. Compos. Constr. 2020, 24, 04020065. [Google Scholar] [CrossRef]

- Ameli, Z.; D’Antino, T.; Carloni, C. A new predictive model for FRCM-confined columns: A reflection on the composite behavior at peak stress. Constr. Build. Mater. 2022, 337, 127534. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Alsayed, S.H.; Iqbal, R.A. Experimental and numerical investigation of size effects in FRP-wrapped concrete columns. Constr. Build. Mater. 2012, 29, 56–72. [Google Scholar] [CrossRef]

- ACI 318R-19; Building Code Requirements for Structural Concrete (ACI 318-19)—An ACI standard: Commentary on Building Code Requirements for Structural Concrete (), an ACI Report. ACI Committee 318. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Saudi Building Code National Committee (SBCNC). Concrete Structures Requirements—SBC 304; Saudi Building Code National Committee: Riyadh, Saudi Arabia, 2019. [Google Scholar]

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018.

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2016.

- ASTM D3039/D3039M; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2014.

- Al-Salloum, Y.A.; Almusallam, T.H.; Elsanadedy, H.M.; Iqbal, R.A. Effect of elevated temperature environments on the residual axial capacity of RC columns strengthened with different techniques. Constr. Build. Mater. 2016, 115, 345–361. [Google Scholar] [CrossRef]

- Elsanadedy, H.; Almusallam, T.; Al-Salloum, Y.; Iqbal, R. Effect of high temperature on structural response of reinforced concrete circular columns strengthened with fiber reinforced polymer composites. J. Compos. Mater. 2017, 51, 333–355. [Google Scholar] [CrossRef]

- Livermore Software Technology Corporation (LSTC). LS-DYNA Keyword User’s Manual—Vol. 1–3; Version R11; LSTC: Livermore, CA, USA, 2018. [Google Scholar]

- Belytschko, T.B.; Tsay, C.S. Explicit algorithms for non-linear dynamics of shells. J. Appl. Mech. Appl. Mech. Div. ASME 1981, 48, 209–231. [Google Scholar]

- Malvar, L.J.; Crawford, J.E.; Wesevich, J.W.; Simons, D. A plasticity concrete material model for DYNA 3D. Int. J. Impact Eng. 1997, 19, 847–873. [Google Scholar] [CrossRef]

- Malvar, L.J.; Crawford, J.E.; Morrill, K.B. K&C Concrete Material Model Release III—Automated Generation of Material Input; Technical Report TR-99-24.3; Karagozian and Case Structural Engineers Inc.: Los Angeles, CA, USA, 2000. [Google Scholar]

- Magallanes, J.M.; Wu, Y.; Malvar, L.J.; Crawford, J.E. Recent improvements to release III of the K&C concrete model 2000. In Proceedings of the 11th International LS-DYNA Users Conference, Dearborn, MI, USA, 6–8 June 2010. [Google Scholar]

- Chang, F.K.; Chang, K.Y. A progressive damage model for laminated composites containing stress concentration. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

| Column ID | Strengthening Scheme | No. of Columns |

|---|---|---|

| CW | Control specimen (see Figure 1) | 2 |

| SW1 | This specimen is strengthened using scheme-1 (wrapping of CFRP laminates around the outer column surface) (see Figure 2) | 1 |

| SW2 | This specimen is strengthened using scheme-2 (wrapping of CFRP laminates around the outer column surface + connected NSM steel rebars) (see Figure 3) | 1 |

| SW3 | This specimen is strengthened using scheme-3 (bending of two CFRP layers inside the NSM grooves before the installation of NSM rebars and wrapping of the remaining CFRP layers around the outer column surface + connected NSM steel rebars) (see Figure 4) | 1 |

| SW4 | This specimen is strengthened using scheme-4 (bending of two CFRP layers inside the NSM grooves before the installation of NSM rebars and wrapping of the remaining CFRP layers around the outer column surface + disconnected NSM steel rebars) (see Figure 5) | 1 |

| Total No. of columns = | 6 |

| Concrete-Like Materials | Concrete | Epoxy Mortar |

|---|---|---|

| Constitutive model | Control specimen | 2 |

| Density (kg/m3) | 2170 | 2170 |

| Uni-axial compressive strength (MPa) | 29.15 | 65 |

| Poisson’s ratio | 0.2 | 0.2 |

| Maximum size of aggregate (mm) | 10 | 5 |

| Steel rebars | ф8 | ф10 |

| Constitutive model | Type 24 (piecewise linear plasticity model) | |

| Density (kg/m3) | 7850 | |

| Elastic modulus (GPa) | 200 | |

| Poisson’s ratio | 0.3 | |

| Yield stress (MPa) | 548 | 531 |

| Tangent modulus (MPa) | 86.37 | 133.75 |

| Plastic strain to failure (%) | 9.72 | 9.73 |

| CFRP material | ||

| Constitutive model | Type 54–55 (enhanced comp. damage model) | |

| Density (kg/m3) | 1740 | |

| Thickness of single layer (mm) | 1.3 | |

| Tensile modulus in long. dir. (GPa) | 71.46 | |

| Tensile modulus in transverse dir. (GPa) | 3.59 | |

| Longitudinal tensile strength (MPa) | 710 | |

| Transverse tensile strength (MPa) | 71 | |

| Column ID | Results | Py (kN) | Pu (kN) | Δs (mm) | Δy (mm) | Δpu (mm) | Δu (mm) | Ks (kN/mm) | Eu (kN.mm) |

|---|---|---|---|---|---|---|---|---|---|

| Control specimens | |||||||||

| CW1 | EXP | 1846 | 1862 | 0.27 | 0.93 | 1.05 | 2.01 | 2810 | 2866 |

| FE | 1969 | 1974 | 0.29 | 1.04 | 1.09 | 2.15 | 2693 | 3220 | |

| EXP/FE | 0.94 | 0.94 | 0.90 | 0.89 | 0.96 | 0.93 | 1.04 | 0.89 | |

| CW2 | EXP | 1919 | 2006 | 0.29 | 0.93 | 1.11 | 1.97 | 2815 | 3157 |

| FE | 1969 | 1974 | 0.29 | 1.04 | 1.09 | 2.15 | 2693 | 3220 | |

| EXP/FE | 0.97 | 1.02 | 0.97 | 0.89 | 1.02 | 0.92 | 1.05 | 0.98 | |

| Strengthened specimens | |||||||||

| SW1 | EXP | 2241 | 2451 | 0.33 | 1.02 | 1.31 | 2.02 | 3017 | 3531 |

| FE | 2439 | 2540 | 0.34 | 1.18 | 1.39 | 1.99 | 2991 | 3424 | |

| EXP/FE | 0.92 | 0.96 | 0.96 | 0.86 | 0.94 | 1.01 | 1.01 | 1.03 | |

| SW2 | EXP | 3223 | 3478 | 0.34 | 1.06 | 1.37 | 1.72 | 4092 | 4212 |

| FE | 3491 | 3686 | 0.37 | 1.18 | 1.40 | 1.75 | 4020 | 4343 | |

| EXP/FE | 0.92 | 0.94 | 0.93 | 0.89 | 0.98 | 0.98 | 1.02 | 0.97 | |

| SW3 | EXP | 3027 | 3225 | 0.32 | 0.92 | 1.06 | 1.11 | 3993 | 3992 |

| FE | 2971 | 3088 | 0.31 | 0.91 | 1.10 | 1.26 | 4004 | 3849 | |

| EXP/FE | 1.02 | 1.04 | 1.05 | 1.01 | 0.97 | 0.88 | 1.00 | 1.04 | |

| SW4 | EXP | 2859 | 3027 | 0.31 | 1.00 | 1.20 | 1.22 | 3875 | 3842 |

| FE | 2971 | 3088 | 0.31 | 0.91 | 1.10 | 1.26 | 4004 | 3849 | |

| EXP/FE | 0.96 | 0.98 | 1.01 | 1.10 | 1.10 | 0.97 | 0.97 | 1.00 | |

| Column ID | Results | (MPa) | (MPa) | |||||

|---|---|---|---|---|---|---|---|---|

| Control specimens | ||||||||

| CW1 | EXP | 29.79 | 23.41 | 0.0026 | 0.0050 | 0.0034 | - | - |

| FE | 31.59 | 25.23 | 0.0027 | 0.0054 | 0.0033 | - | - | |

| EXP/FE | 0.94 | 0.93 | 0.96 | 0.93 | 1.04 | - | - | |

| CW2 | EXP | 32.09 | 25.74 | 0.0028 | 0.0049 | 0.0031 | - | - |

| FE | 31.59 | 25.23 | 0.0027 | 0.0054 | 0.0033 | - | - | |

| EXP/FE | 1.02 | 1.02 | 1.02 | 0.92 | 0.95 | - | - | |

| Strengthened specimens | ||||||||

| SW1 | EXP | 39.43 | 33.15 | 0.0033 | 0.0050 | 0.0049 | - | −0.0092 |

| FE | 40.65 | 34.60 | 0.0035 | 0.0050 | 0.0041 | - | −0.0098 | |

| EXP/FE | 0.97 | 0.96 | 0.94 | 1.01 | 1.19 | - | 0.94 | |

| SW2 | EXP | 55.96 | 41.11 | 0.0034 | 0.0043 | 0.0038 | NA | NA |

| FE | 58.98 | 44.56 | 0.0035 | 0.0044 | 0.0038 | 0.0033 | −0.0099 | |

| EXP/FE | 0.95 | 0.92 | 0.98 | 0.98 | 1.00 | - | - | |

| SW3 | EXP | 51.89 | 36.92 | 0.0027 | 0.0028 | 0.0034 | NA | −0.0099 |

| FE | 49.41 | 34.63 | 0.0027 | 0.0031 | 0.0039 | 0.0038 | −0.0099 | |

| EXP/FE | 1.05 | 1.07 | 0.97 | 0.88 | 0.87 | - | 0.99 | |

| SW4 | EXP | 48.70 | 33.62 | 0.0030 | 0.0031 | 0.0043 | NA | −0.0081 |

| FE | 49.41 | 34.63 | 0.0027 | 0.0031 | 0.0039 | 0.0038 | −0.0099 | |

| EXP/FE | 0.99 | 0.97 | 1.10 | 0.97 | 1.08 | - | 0.81 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsanadedy, H.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Performance of Concentrically Loaded RC Wall-like Columns Upgraded with Innovative Hybrid NSM/CFRP System. Polymers 2023, 15, 378. https://doi.org/10.3390/polym15020378

Elsanadedy H, Abbas H, Almusallam T, Al-Salloum Y. Performance of Concentrically Loaded RC Wall-like Columns Upgraded with Innovative Hybrid NSM/CFRP System. Polymers. 2023; 15(2):378. https://doi.org/10.3390/polym15020378

Chicago/Turabian StyleElsanadedy, Hussein, Husain Abbas, Tarek Almusallam, and Yousef Al-Salloum. 2023. "Performance of Concentrically Loaded RC Wall-like Columns Upgraded with Innovative Hybrid NSM/CFRP System" Polymers 15, no. 2: 378. https://doi.org/10.3390/polym15020378