Complex Effects of Hemp Fibers and Impact Modifiers in Multiphase Polypropylene Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites and Specimens

2.3. Characterization

3. Results and Discussion

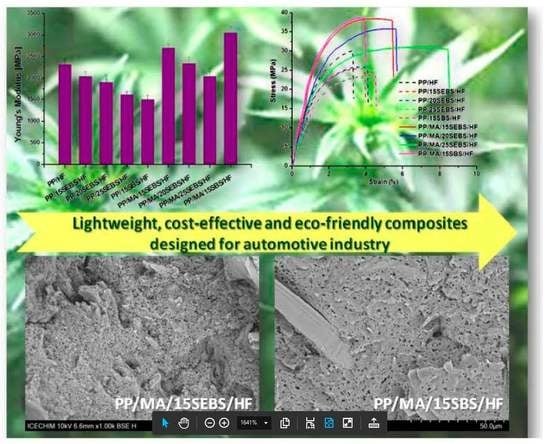

3.1. Mechanical Properties

3.1.1. Influence of Block-Copolymer Elastomers on PP Properties

3.1.2. Influence of HF and Compatibilizer in the Multiphase Systems

3.2. Dynamic Mechanical Analysis

3.3. Morphological Characterization

3.4. Melting and Crystallization Behaviors of Blends and Composites

3.5. Thermogravimetric Analysis of Blends and Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amasawa, E.; Hasegawa, M.; Yokokawa, N.; Sugiyama, H.; Hirao, M. Environmental performance of an electric vehicle composed of 47% polymers and polymer composites. Sustain. Mater. Technol. 2020, 25, e00189. [Google Scholar] [CrossRef]

- Selwyn, T.S. Formation, characterization and suitability analysis of polymer matrix composite materials for automotive bumper. Mater. Today Proc. 2021, 43, 1197–1203. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Balaji, K.V.; Yadav, R.; Zabihi, O.; Ahmadi, M.; Adetunji, P.; Naebe, M. Balancing the toughness and strength in polypropylene composites. Compos. Part B Eng. 2021, 223, 109121. [Google Scholar] [CrossRef]

- Mihalic, M.; Sobczak, L.; Pretschuh, C.; Unterweger, C. Increasing the Impact Toughness of Cellulose Fiber Reinforced Polypropylene Composites—Influence of Different Impact Modifiers and Production Scales. J. Compos. Sci. 2019, 3, 82. [Google Scholar] [CrossRef] [Green Version]

- Xiong, J.; Chen, J.; Lee, P.S. Functional Fibers and Fabrics for Soft Robotics, Wearables, and Human–Robot Interface. Adv. Mater. 2021, 33, e2002640. [Google Scholar] [CrossRef] [PubMed]

- Rana, A.K.; Scarpa, F.; Thakur, V.K. Cellulose/polyaniline hybrid nanocomposites: Design, fabrication, and emerging multidimensional applications. Ind. Crop. Prod. 2022, 187, 115356. [Google Scholar] [CrossRef]

- Rana, A.K.; Gupta, V.K.; Newbold, J.; Roberts, D.; Rees, R.M.; Krishnamurthy, S.; Thakur, V.K. Sugar beet pulp: Resurgence and trailblazing journey towards a circular bioeconomy. Fuel 2022, 312, 122953. [Google Scholar] [CrossRef]

- Patil, A.; Patel, A.; Purohit, R. An overview of polymeric materials for automotive applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Gopi, J.A.; Radoor, S.; Dominic, M.; Krishnasamy, S.; Deshmukh, K.; Hameed, N.; Salim, N.V.; Sienkiewicz, N. Turning waste plant fibers into advanced plant fiber reinforced polymer composites: A comprehensive review. Compos. Part C Open Access 2022, 3, 10. [Google Scholar] [CrossRef]

- Rana, A.K.; Guleria, S.; Gupta, V.K.; Thakur, V.K. Cellulosic pine needles-based biorefinery for a circular bioeconomy. Bioresour. Technol. 2023, 367, 128255. [Google Scholar] [CrossRef]

- Ali, B.A.A.; Sapuan, S.M.; Zainudin, E.S.; Othman, M. Implementation of the expert decision system for environmental assessment in composite materials selection for automotive components. J. Clean. Prod. 2015, 107, 557–567. [Google Scholar] [CrossRef]

- Ashori, A. Wood–plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Vuluga, Z.; Ghiurea, M.; Iorga, M.; Nicolae, C.; Gabor, R. Influence of compatibilizing system on morphology, thermal and mechanical properties of high flow polypropylene reinforced with short hemp fibers. Compos. Part B Eng. 2015, 69, 286–295. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Ismadi; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties characterization of chemically modified hemp hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.K.; Verma, N.; Zafar, S. Conventional Processing of Polymer Matrix Composites. In Lightweight Polymer Composite Structures—Design and Manufacturing Techniques; Rangappa, S.M., Parameswaranpillai, J., Siengchin, S., Kroll, L., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 21–66. [Google Scholar]

- Kumar, S.; Bharj, R.S. Emerging composite material use in current electric vehicle: A review. Mater. Today Proc. 2018, 5, 27946–27954. [Google Scholar] [CrossRef]

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of natural fiber composites: Challenges and opportunities. Resour. Conserv. Recycl. 2022, 177, 105962. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Ismadi; Amin, Y.; Damayanti, R.; Lubis, M.A.R.; Wulandari, A.P.; Nurindah; Iswanto, A.H.; et al. A Comprehensive review on natural fibers: Technological and socio-economical aspects. Polymers 2021, 13, 4280. [Google Scholar] [CrossRef]

- Mihai, M.; Chapleau, N.; Denault, J. Processing-formulation-performance relationships of polypropylene/short flax fiber composites. J. Appl. Polym. Sci. 2015, 132, 41528. [Google Scholar] [CrossRef]

- Bourmaud, A.; Baley, C. Investigations on the recycling of hemp and sisal fibre reinforced polypropylene composites. Polym. Degrad. Stab. 2007, 92, 1034–1045. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite material recycling technology—State-of-the-art and sustainable development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Li, F.; Gao, Y.; Jiang, W. Design of high impact thermal plastic polymer composites with balanced toughness and rigidity: Toughening with one phase modifier. Polymer 2019, 170, 101–106. [Google Scholar] [CrossRef]

- Yi, S.; Xu, S.; Li, Y.; Gan, W.; Yi, X.; Liu, W.; Wang, Q.; Wang, H.; Ou, R. Synergistic toughening effects of grafting modification and elastomer-olefin block copolymer addition on the fracture resistance of wood particle/polypropylene/elastomer composites. Mater. Des. 2019, 181, 107918. [Google Scholar] [CrossRef]

- Sudár, A.; Renner, K.; Móczó, J.; Lummerstorfer, T.; Burgstaller, C.; Jerabek, M.; Gahleitner, M.; Doshev, P.; Pukánszky, B. Fracture resistance of hybrid PP/elastomer/wood composites. Compos. Struct. 2016, 141, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Guo, C.-G.; Wang, Q.-W. Effect of maleic anhydride grafted styrene-ethylene-butylene-styrene (MA-SEBS) on impact fracture behavior of polypropylene/wood fiber composites. J. For. Res. 2007, 18, 203–207. [Google Scholar] [CrossRef]

- Sharma, R.; Maiti, S.N. Effects of crystallinity of polypropylene (PP) on the mechanical properties of PP/styrene-ethylenebutylene-styrene-g-maleic anhydride (SEBS-g-MA)/teak wood flour (TWF) composites. Polym. Bull. 2015, 72, 627–643. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Vuluga, Z.; Sanporean, C.G.; Nicolae, C.A.; Gabor, A.R.; Trusca, R. High flow polypropylene/SEBS composites reinforced with differently treated hemp fibers for injection molded parts. Compos. Part B Eng. 2019, 174, 107062. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Fierascu, R.C.; Gabor, A.R.; Nicolae, C.A. Effect of hemp fiber length on the mechanical and thermal properties of polypropylene/SEBS/hemp fiber composites. J. Mater. Res. Technol. 2020, 9, 10768–10781. [Google Scholar] [CrossRef]

- Girones, J.; Vo, L.T.T.; Haudin, J.-M.; Freire, L.; Navard, P. Crystallization of polypropylene in the presence of biomass-based fillers of different compositions. Polymer 2017, 127, 220–231. [Google Scholar] [CrossRef]

- Bu, H.-S.; Cheng, S.Z.D.; Wunderlich, B. Addendum to the thermal properties of polypropylene. Die Makromol. Chem. Rapid Commun. 1988, 9, 75–77. [Google Scholar] [CrossRef]

- Mau, A.; Dietlin, C.; Dumur, F.; Lalevée, J. Concomitant initiation of radical and cationic polymerisations using new copper complexes as photoinitiators: Synthesis and characterisation of acrylate/epoxy interpenetrated polymer networks. Eur. Polym. J. 2021, 152, 110457. [Google Scholar] [CrossRef]

- Ibrahim, H.; Farag, M.; Megahed, H.; Mehanny, S. Characteristics of starch-based biodegradable composites reinforced with date palm and flax fibers. Carbohydr. Polym. 2014, 101, 11–19. [Google Scholar] [CrossRef]

- Thygesen, A.; Madsen, B.; Bjerre, A.B.; Lilholt, H. Cellulosic Fibers: Effect of Processing on Fiber Bundle Strength. J. Nat. Fibers 2011, 8, 161–175. [Google Scholar] [CrossRef]

- Abreu, F.O.M.S.; Forte, M.M.C.; Liberman, S.A. SBS and SEBS block copolymers as impact modifiers for polypropylene compounds. J. Appl. Polym. Sci. 2005, 95, 254–263. [Google Scholar] [CrossRef]

- Denac, M.; Musil, V.; Šmit, I. Polypropylene/talc/SEBS (SEBS-g-MA) composites. Part 2. Mechanical properties. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1282–1290. [Google Scholar] [CrossRef]

- Vuluga, Z.; Panaitescu, D.M.; Radovici, C.; Nicolae, C.; Iorga, M.D. Effect of SEBS on morphology, thermal, and mechanical properties of PP/organoclay nanocomposites. Polym. Bull. 2012, 69, 1073–1091. [Google Scholar] [CrossRef]

- Pang, A.L.; Ismail, H. Influence of Kenaf Form and Loading on the Properties of Kenaf-Filled Polypropylene/Waste Tire Dust Composites: A Comparison Study. J. Appl. Polym. Sci. 2014, 131, 40877. [Google Scholar] [CrossRef]

- Borysiak, S. Fundamental Studies on Lignocellulose/Polypropylene Composites: Effects of Wood Treatment on the Transcrystalline Morphology and Mechanical Properties. J. Appl. Polym. Sci. 2013, 127, 1309–1322. [Google Scholar] [CrossRef]

- Demir, H.; Atikler, U.; Balköse, D.; Tıhmınlıoğlu, F. The effect of fiber surface treatments on the tensile and water sorption properties of polypropylene–luffa fiber composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 447–456. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.R.; Gupta, A.; Rivai, M.; Beg, M.D.H.; Mina, M.F. Effects of fiber-surface treatment on the properties of hybrid composites prepared from oil palm empty fruit bunch fibers, glass fibers, and recycled polypropylene. J. Appl. Polym. Sci. 2016, 133, 43049. [Google Scholar] [CrossRef]

- Ashir, M.; Nocke, A.; Bulavinov, A.; Pinchuk, R.; Cherif, C. Influence of defined amount of voids on the mechanical properties of carbon fiber-reinforced plastics. Polym. Compos. 2019, 40, E1049–E1056. [Google Scholar] [CrossRef]

- Stricker, F.; Thomann, Y.; Mulhaupt, R. Influence of Rubber Particle Size on Mechanical Properties of Polypropylene—SEBS Blends. J. Appl. Polym. Sci. 1998, 68, 1891–1901. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. PartB Eng. 2017, 114, 15–22. [Google Scholar] [CrossRef] [Green Version]

- Etaati, A.; Wang, H.; Pather, S.; Yan, Z.; Mehdizadeh, S.A. 3D X-ray microtomography study on fibre breakage in noil hemp fibre reinforced polypropylene composites. Compos. Part B Eng. 2013, 50, 239–246. [Google Scholar] [CrossRef]

- Saroop, M.; Mathur, G.N. Studies on dynamically vulcanized polypropylene (PP)/butadiene styrene block copolymer (SBS) blends: Crystallization and thermal behavior. J. Appl. Polym. Sci. 1999, 71, 151–161. [Google Scholar] [CrossRef]

- Chen, J.-Q.; Wang, X.; Sun, W.-F.; Zhao, H. Improved Water-Tree Resistances of SEBS/PP Semi-Crystalline Composites under Crystallization Modifications. Molecules 2020, 25, 3669. [Google Scholar] [CrossRef]

- Ciuprina, F.; Panaitescu, D.M.; Enache, L.; Damian, C.M.; Grigorescu, R.M.; Gabor, A.R.; Nicolae, C.A.; Nistor, C.L.; Trusca, R. Control of Dielectric and Mechanical Properties of Styrenic Block Copolymer by Graphite Incorporation. Materials 2022, 15, 7577. [Google Scholar] [CrossRef]

- Lu, L.; Yu, H.; Wang, S.; Zhang, Y. Thermal degradation behavior of styrene-butadiene-styrene tri-block copolymer/multiwalled carbon nanotubes composites. J. Appl. Polym. Sci. 2009, 112, 524–531. [Google Scholar] [CrossRef]

| Samples | PP (wt%) | SEBS (wt%) | SBS (wt%) | MAPP (wt%) | HF (wt%) |

|---|---|---|---|---|---|

| PP | 100 | - | - | - | - |

| PP/15SEBS | 85 | 15 | - | - | - |

| PP/20SEBS | 80 | 20 | - | - | - |

| PP/25SEBS | 75 | 25 | - | - | - |

| PP/15SBS | 85 | - | 15 | - | - |

| PP/HF | 70 | - | - | - | 30 |

| PP/15SEBS/HF | 55 | 15 | - | - | 30 |

| PP/20SEBS/HF | 50 | 20 | - | - | 30 |

| PP/25SEBS/HF | 45 | 25 | - | - | 30 |

| PP/15SBS/HF | 55 | - | 15 | - | 30 |

| PP/MA/15SEBS/HF | 50 | 15 | - | 5 | 30 |

| PP/MA/20SEBS/HF | 45 | 20 | - | 5 | 30 |

| PP/MA/25SEBS/HF | 40 | 25 | - | 5 | 30 |

| PP/MA/15SBS/HF | 50 | - | 15 | 5 | 30 |

| Samples | E′−75 GPa | E′0 GPa | E′30 GPa | E′90 GPa | TgSEBS °C | TgSBS °C | T′g °C | TgPP °C | TαPP °C | C90°C |

|---|---|---|---|---|---|---|---|---|---|---|

| PP | 2.71 | 1.86 | 1.28 | 0.41 | - | - | −46.8 | 13.9 | 84.8 | |

| PP/15SEBS | 2.64 | 1.68 | 1.14 | 0.34 | −46.2 | - | - | 13.2 | 82.9 | |

| PP/25SEBS | 2.18 | 1.23 | 0.82 | 0.25 | −44.6 | - | - | 14.3 | 82.7 | |

| PP/15SBS | 2.38 | 1.65 | 1.09 | 0.33 | - | −87.0 | −46.0 | 13.3 | 84.2 | |

| PP/HF | 4.13 | 2.80 | 2.17 | 0.93 | - | - | −46.3 | 11.5 | 85.3 | 0.667 |

| PP/15SEBS/HF | 3.72 | 2.40 | 1.80 | 0.71 | −47.5 | - | - | 11.9 | 82.0 | 0.742 |

| PP/25SEBS/HF | 3.26 | 1.83 | 1.35 | 0.54 | −44.6 | - | - | 10.9 | 81.2 | 0.773 |

| PP/15SBS/HF | 3.40 | 2.27 | 1.69 | 0.63 | - | −84.4 | −46.2 | 10.9 | 80.0 | 0.789 |

| PP/MA/15SEBS/HF | 4.22 | 2.54 | 1.95 | 0.86 | −45.9 | - | - | 11.4 | 87.5 | 0.660 |

| PP/MA/25SEBS/HF | 3.44 | 1.94 | 1.44 | 0.60 | −44.0 | - | - | 11.9 | 82.2 | 0.733 |

| PP/MA/15SBS/HF | 4.31 | 3.19 | 2.44 | 1.08 | - | −86.4 | −45.3 | 12.5 | 83.4 | 0.632 |

| Blends/Composites | TgEB °C | TmEB °C | TcPP °C | TmPP °C | ∆HmPP J/g | XC % |

|---|---|---|---|---|---|---|

| PP | (−56) | - | 130.6 | 165.3 | 94.9 | 45.8 |

| PP/15SEBS | −54.8 | 18.0 | 129.8 | 164.9 | 75.2 | 42.7 |

| PP/20SEBS | −56.0 | 18.2 | 129.4 | 165.1 | 71.3 | 43.1 |

| PP/25SEBS | −55.6 | 18.5 | 129.2 | 165.0 | 66.3 | 42.7 |

| PP/15SBS | (−52) | - | 128.4 | 164.6 | 75.4 | 42.8 |

| PP/HF | (−52) | - | 129.3 | 165.3 | 67.3 | 46.5 |

| PP/15SEBS/HF | −56.4 | 13.2 | 129.2 | 165.1 | 54.1 | 47.5 |

| PP/20SEBS/HF | −56.1 | 12.6 | 129.3 | 165.0 | 45.9 | 44.3 |

| PP/25SEBS/HF | −57.9 | 13.7 | 128.9 | 164.9 | 40.9 | 43.9 |

| PP/15SBS/HF | (−52) | - | 128.0 | 164.8 | 52.1 | 45.8 |

| PP/MA/15SEBS/HF | −55.6 | 14.0 | 129.7 | 164.9 | 48.9 | 47.2 |

| PP/MA/20SEBS/HF | −58.2 | 14.1 | 129.6 | 165.2 | 44.7 | 48.0 |

| PP/MA/25SEBS/HF | −57.3 | 13.0 | 129.3 | 165.0 | 40.6 | 49.0 |

| PP/MA/15SBS/HF | (−52) | - | 128.3 | 164.3 | 53.7 | 51.9 |

| Blends/Composites | Ton °C | T5% °C | Tmax1 °C | Tmax2 °C | WL200°C % | R700°C % |

|---|---|---|---|---|---|---|

| PP | 383.7 | 345.6 | 426.7 | - | 0.14 | 0.6 |

| PP/15SEBS | 387.6 | 350.3 | 427.8 | - | 0.15 | 0.5 |

| PP/20SEBS | 389.2 | 357.6 | 426.3 | - | 0.11 | 0.4 |

| PP/25SEBS | 393.3 | 356.0 | 428.2 | - | 0.10 | 0.4 |

| PP/15SBS | 412.4 | 385.6 | 451.1 | - | 0.14 | 0.4 |

| PP/HF | 279.8 | 268.1 | 451.0 | 319.6 | 1.76 | 1.8 |

| PP/15SEBS/HF | 279.9 | 270.9 | 445.3 | 318.2 | 1.60 | 2.2 |

| PP/20SEBS/HF | 278.7 | 270.4 | 445.8 | 318.3 | 1.57 | 3.0 |

| PP/25SEBS/HF | 277.4 | 270.0 | 445.7 | 317.2 | 1.56 | 2.7 |

| PP/15SBS/HF | 280.0 | 273.1 | 458.6 | 319.2 | 1.51 | 2.9 |

| PP/MA/15SEBS/HF | 282.1 | 269.0 | 447.9 | 318.6 | 1.66 | 3.3 |

| PP/MA/20SEBS/HF | 280.2 | 268.9 | 447.5 | 317.7 | 1.56 | 3.1 |

| PP/MA/25SEBS/HF | 281.9 | 271.8 | 446.4 | 318.0 | 1.49 | 3.1 |

| PP/MA/15SBS/HF | 280.1 | 273.9 | 459.0 | 319.0 | 1.46 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panaitescu, D.M.; Vuluga, Z.; Frone, A.N.; Gabor, A.R.; Nicolae, C.-A.; Uşurelu, C.-D. Complex Effects of Hemp Fibers and Impact Modifiers in Multiphase Polypropylene Systems. Polymers 2023, 15, 409. https://doi.org/10.3390/polym15020409

Panaitescu DM, Vuluga Z, Frone AN, Gabor AR, Nicolae C-A, Uşurelu C-D. Complex Effects of Hemp Fibers and Impact Modifiers in Multiphase Polypropylene Systems. Polymers. 2023; 15(2):409. https://doi.org/10.3390/polym15020409

Chicago/Turabian StylePanaitescu, Denis Mihaela, Zina Vuluga, Adriana Nicoleta Frone, Augusta Raluca Gabor, Cristian-Andi Nicolae, and Cătălina-Diana Uşurelu. 2023. "Complex Effects of Hemp Fibers and Impact Modifiers in Multiphase Polypropylene Systems" Polymers 15, no. 2: 409. https://doi.org/10.3390/polym15020409

APA StylePanaitescu, D. M., Vuluga, Z., Frone, A. N., Gabor, A. R., Nicolae, C.-A., & Uşurelu, C.-D. (2023). Complex Effects of Hemp Fibers and Impact Modifiers in Multiphase Polypropylene Systems. Polymers, 15(2), 409. https://doi.org/10.3390/polym15020409