Enhancing the Interfacial Shear Strength and Tensile Strength of Carbon Fibers through Chemical Grafting of Chitosan and Carbon Nanotubes

Abstract

:1. Introduction

2. Experimental

2.1. Materials

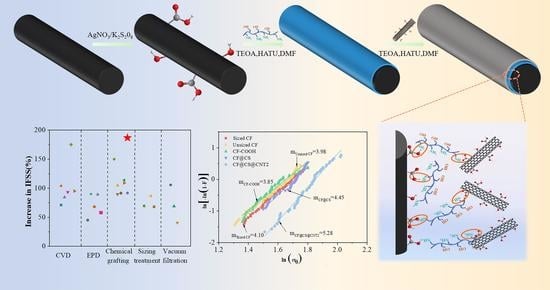

2.2. Surface Treatment of CNTs and CFs

2.3. Characterization

3. Results and Discussion

3.1. Microstructures of the CFs Surface

3.2. Characterization of the Chemical Composition of the CFs Surface

3.3. Interfacial Properties

3.4. Single-Fiber Tensile Strength

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Do, M.D.; Kim, M.; Nguyen, D.H.; Han, S.; Pham, V.H.; Choi, H.-J. Multistep Workpiece Localization with Automated Symmetry Identification for Aerospace Carbon Fiber Reinforced Plastic Components. Int. J. Precis. Eng. Manuf. Green Technol. 2022, 9, 1133–1150. [Google Scholar] [CrossRef]

- Ghosh, T.; Kim, H.C.; De Kleine, R.; Wallington, T.J.; Bakshi, B.R. Life cycle energy and greenhouse gas emissions implications of using carbon fiber reinforced polymers in automotive components: Front subframe case study. Sustain. Mater. Technol. 2021, 28, e00263. [Google Scholar] [CrossRef]

- Tiwari, S.; Bijwe, J. Surface Treatment of Carbon Fibers—A Review. Procedia Technol. 2014, 14, 505–512. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.; Mäder, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Z.; Xu, L.; Wang, H.; Peng, S.; Zheng, L.; Yang, Z.; Wu, L.; Miao, J.-T. Preparation of silver-plated carbon nanotubes/carbon fiber hybrid fibers by combining freeze-drying deposition with a sizing process to enhance the mechanical properties of carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2021, 146, 106421. [Google Scholar] [CrossRef]

- Ahmadi, M.; Zabihi, O.; Yadav, R.; Ferdowsi, M.R.G.; Naebe, M. The reinforcing role of 2D graphene analogue MoS2 nanosheets in multiscale carbon fibre composites: Improvement of interfacial adhesion. Compos. Sci. Technol. 2021, 207, 108717. [Google Scholar] [CrossRef]

- Park, S.-J.; Park, S.-J. Effect of ozone-treated single-walled carbon nanotubes on interfacial properties and fracture toughness of carbon fiber-reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105937. [Google Scholar] [CrossRef]

- Cuiqin, F.; Jinxian, W.; Julin, W.; Tao, Z. Modification of carbon fiber surfaces via grafting with Meldrum’s acid. Appl. Surf. Sci. 2015, 356, 9–17. [Google Scholar] [CrossRef]

- Stojcevski, F.; Hilditch, T.B.; Gengenbach, T.R.; Henderson, L.C. Effect of carbon fiber oxidization parameters and sizing deposition levels on the fiber-matrix interfacial shear strength. Compos. Part A Appl. Sci. Manuf. 2018, 114, 212–224. [Google Scholar] [CrossRef]

- Servinis, L.; Beggs, K.M.; Scheffler, C.; Wölfel, E.; Randall, J.D.; Gengenbach, T.R.; Demir, B.; Walsh, T.R.; Doeven, E.H.; Francis, P.S.; et al. Electrochemical surface modification of carbon fibres by grafting of amine, carboxylic and lipophilic amide groups. Carbon 2017, 118, 393–403. [Google Scholar] [CrossRef]

- Arnold, C.L.; Eyckens, D.J.; Servinis, L.; Nave, M.D.; Yin, H.; Marceau, R.K.W.; Pinson, J.; Demir, B.; Walsh, T.R.; Henderson, L.C. Simultaneously increasing the hydrophobicity and interfacial adhesion of carbon fibres: A simple pathway to install passive functionality into composites†. J. Mater. Chem. A 2019, 7, 13483–13494. [Google Scholar] [CrossRef]

- Karakassides, A.; Ganguly, A.; Kelly, J.; Sharma, P.K.; Papakonstantinou, P. Radially Grown Graphene Nanoflakes for Tough and Strong Carbon Fiber Epoxy Composites. ACS Appl. Nano Mater. 2021, 4, 9167–9180. [Google Scholar] [CrossRef]

- Lee, G.; Sung, M.; Youk, J.H.; Lee, J.; Yu, W.-R. Improved tensile strength of carbon nanotube-grafted carbon fiber reinforced composites. Compos. Struct. 2019, 220, 580–591. [Google Scholar] [CrossRef]

- Wu, D.; Yao, Z.; Sun, X.; Liu, X.; Liu, L.; Zhang, R.; Wang, C. Mussel-tailored carbon fiber/carbon nanotubes interface for elevated interfacial properties of carbon fiber/epoxy composites. Chem. Eng. J. 2022, 429, 132449. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. All-carbon multi-scale and hierarchical fibers and related structural composites: A review. Compos. Sci. Technol. 2020, 186, 107932. [Google Scholar] [CrossRef]

- Liu, L.; Wu, F.; Yao, H.; Shi, J.; Chen, L.; Xu, Z.; Deng, H. Investigation of surface properties of pristine and γ-irradiated PAN-based carbon fibers: Effects of fiber instinct structure and radiation medium. Appl. Surf. Sci. 2015, 337, 241–248. [Google Scholar] [CrossRef]

- Wang, B.; Duan, Y.; Zhang, J.; Zhao, X. Microwave radiation effects on carbon fibres interfacial performance. Compos. Part B Eng. 2016, 99, 398–406. [Google Scholar] [CrossRef]

- Lin, J.; Sun, C.; Min, J.; Wan, H.; Wang, S. Effect of atmospheric pressure plasma treatment on surface physicochemical properties of carbon fiber reinforced polymer and its interfacial bonding strength with adhesive. Compos. Part B Eng. 2020, 199, 108237. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, F.; Yao, Y.; Jin, Z.; Liu, X.; Huang, Y. High efficient and continuous surface modification of carbon fibers with improved tensile strength and interfacial adhesion. Appl. Surf. Sci. 2017, 412, 424–435. [Google Scholar] [CrossRef]

- Vautard, F.; Dentzer, J.; Nardin, M.; Schultz, J.; Defoort, B. Influence of surface defects on the tensile strength of carbon fibers. Appl. Surf. Sci. 2014, 322, 185–193. [Google Scholar] [CrossRef]

- Wu, Q.; Razzak, A.; Bai, H.; Deng, H.; Ye, Z.; Zhu, J. Dopamine concentration-dependent surface modification for gaining carbon fiber composites with enhanced interfacial adhesion. Compos. Commun. 2022, 29, 101047. [Google Scholar] [CrossRef]

- Szabó, L.; Imanishi, S.; Hirose, D.; Tsukegi, T.; Wada, N.; Takahashi, K. Mussel-Inspired Design of a Carbon Fiber-Cellulosic Polymer Interface toward Engineered Biobased Carbon Fiber-Reinforced Composites. ACS Omega 2020, 5, 27072–27082. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Wan, Q.; Yang, X.; Wang, F.; Zhu, J. Effects of chain length of polyether amine on interfacial adhesion of carbon fiber/epoxy composite in the absence or presence of polydopamine bridging platform. Appl. Surf. Sci. 2021, 547, 149162. [Google Scholar] [CrossRef]

- Han, P.; Ma, L.; Song, G.; Shi, L.; Gu, Z.; Li, X.; Yang, C.; Wang, G. Strengthening and Modulating Interphases in Carbon Fiber/Epoxy Composites by Grafting Dendritic Polyetheramine With Different Molecular Weights Onto Carbon Fiber. Polym. Compos. 2019, 40, E1525–E1536. [Google Scholar] [CrossRef]

- Gao, B.; Zhang, R.; Gao, F.; He, M.; Wang, C.; Liu, L.; Zhao, L.; Cui, H. Interfacial Microstructure and Enhanced Mechanical Properties of Carbon Fiber Composites Caused by Growing Generation 1–4 Dendritic Poly(amidoamine) on a Fiber Surface. Langmuir 2016, 32, 8339–8349. [Google Scholar] [CrossRef]

- Gao, B.; Zhang, R.; Wang, C. Enhanced mechanical properties of carbon fiber composites by grafting different structural poly(amido amine) onto fiber surface. Polym. Test. 2016, 56, 192–199. [Google Scholar] [CrossRef]

- Patnaik, S.; Gangineni, P.K.; Prusty, R.K. Influence of cryogenic temperature on mechanical behavior of graphene carboxyl grafted carbon fiber reinforced polymer composites: An emphasis on concentration of nanofillers. Compos. Commun. 2020, 20, 100369. [Google Scholar] [CrossRef]

- Sharma, H.; Kumar, A.; Rana, S.; Guadagno, L. An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance. Polymers 2022, 14, 1548. [Google Scholar] [CrossRef]

- Gangineni, P.K.; Yandrapu, S.; Ghosh, S.K.; Anand, A.; Prusty, R.K.; Ray, B.C. Mechanical behavior of Graphene decorated carbon fiber reinforced polymer composites: An assessment of the influence of functional groups. Compos. Part A Appl. Sci. Manuf. 2019, 122, 36–44. [Google Scholar] [CrossRef]

- Jäger, M.; Zabihi, O.; Ahmadi, M.; Li, Q.; Depalmeanar, A.; Naebe, M. Nano-enhanced interface in carbon fibre polymer composite using halloysite nanotubes. Compos. Part A Appl. Sci. Manuf. 2018, 109, 115–123. [Google Scholar] [CrossRef]

- Moaseri, E.; Karimi, M.; Maghrebi, M.; Baniadam, M. Fabrication of multi-walled carbon nanotube–carbon fiber hybrid material via electrophoretic deposition followed by pyrolysis process. Compos. Part A Appl. Sci. Manuf. 2014, 60, 8–14. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, C.; Wang, Y.; Qin, J.; Ma, Z.; Cui, X.; Wang, Q.; Wei, H. Effect of CNTs deposition on carbon fiber followed by amination on the interfacial properties of epoxy composites. Compos. Struct. 2022, 292, 115665. [Google Scholar] [CrossRef]

- Wu, Q.; Bai, H.; Deng, H.; Ye, Z.; Wang, Q.; Zhu, J. Intermittent carbon nanotube encapsulation of carbon fiber: A facile and efficient strategy to simultaneously strengthen and toughen interphase of composites. Compos. Part B Eng. 2022, 235, 109785. [Google Scholar] [CrossRef]

- Baghdadi, Y.N.; Sinno, J.; Bouhadir, K.; Harb, M.; Mustapha, S.; Patra, D.; Tehrani-Bagha, A.R. The mechanical and thermal properties of graphitic carbon nitride (g-C3N4)-based epoxy composites. J. Appl. Polym. Sci. 2021, 138, 51324. [Google Scholar] [CrossRef]

- Eyckens, D.J.; Randall, J.D.; Stojcevski, F.; Sarlin, E.; Palola, S.; Kakkonen, M.; Scheffler, C.; Henderson, L.C. Examining interfacial interactions in a range of polymers using poly(ethylene oxide) functionalized carbon fibers. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106053. [Google Scholar] [CrossRef]

- Fang, Q.; Yao, J.; Niu, K.; Tang, J.; Wei, Y.; Guo, Q.; Yang, C. Effect of Molecular Weight of Self-Emulsifying Amphiphilic Epoxy Sizing Emulsions on the Carbon Fibres and Interfacial Properties of Their Composites. Polymers 2020, 12, 2439. [Google Scholar] [CrossRef]

- Qiu, B.; Qiu, B.; Sun, T.; Zou, Q.; Yuan, M.; Zhou, S.; Chen, Y.; Xia, S.; Heng, Z.; Zou, H.; et al. Constructing a multiscale rigid-flexible interfacial structure at the interphase by hydrogen bonding to improve the interfacial performance of high modulus carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2022, 229, 109672. [Google Scholar] [CrossRef]

- Feng, P.; Song, G.; Li, X.; Xu, H.; Xu, L.; Lv, D.; Zhu, X.; Huang, Y.; Ma, L. Effects of different “rigid-flexible” structures of carbon fibers surface on the interfacial microstructure and mechanical properties of carbon fiber/epoxy resin composites. J. Colloid Interface Sci. 2021, 583, 13–23. [Google Scholar] [CrossRef]

- Wu, Q.; Bai, H.; Zhao, R.; Ye, Z.; Deng, H.; Xiao, B.; Zhu, J. Amine-caged ZrO2@GO multilayer core-shell hybrids in epoxy matrix for enhancing interfacial adhesion of carbon fiber composites. Compos. Part B Eng. 2022, 245, 110207. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, X.; Qiu, B.; Zhang, H.; Yan, L.; Liang, M.; Zou, H. Electrochemical construction of amino-functionalized GO/carbon fiber multiscale structure to improve the interfacial properties of epoxy composites. Mater. Chem. Phys. 2022, 286, 126197. [Google Scholar] [CrossRef]

- Zhang, S.; Han, P.; Yang, L.; Hu, S.; Wang, J.; Gu, Z. Constructing a Double Alternant “Rigid-Flexible” Structure for Simultaneously Strengthening and Toughening the Interface of Carbon Fiber/Epoxy Composites. Nanomaterials 2022, 12, 3056. [Google Scholar] [CrossRef] [PubMed]

- Peng, Q.; He, X.; Li, Y.; Wang, C.; Wang, R.; Hu, P.; Yan, Y.; Sritharan, T. Chemically and uniformly grafting carbon nanotubes onto carbon fibers by poly(amidoamine) for enhancing interfacial strength in carbon fiber composites. J. Mater. Chem. 2012, 22, 5928–5931. [Google Scholar] [CrossRef]

- Feng, P.; Song, G.; Zhu, X.; Lv, D.; Zhao, Y.; Yang, X.; Li, N.; Zhang, L.; Ma, L. Enhanced interfacial adhesion of carbon fiber/epoxy composites by synergistic reinforcement with multiscale “rigid-flexible” structure at interphase. Compos. Part B Eng. 2021, 225, 109315. [Google Scholar] [CrossRef]

- Wu, Q.; Yang, X.; Wan, Q.; Zhao, R.; He, J.; Zhu, J. Layer-by-layer assembled nacre-like polyether amine/GO hierarchical structure on carbon fiber surface toward composites with excellent interfacial strength and toughness. Compos. Sci. Technol. 2020, 198, 108296. [Google Scholar] [CrossRef]

- Zheng, H.; Song, G.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, Y.; Ma, R.; Zhu, S.; Yang, X.; et al. Enhancing the interfacial strength of carbon fiber/epoxy composites by introducing “rigid-flexible” structure onto carbon fiber surface via π–π interaction. Surf. Interfaces 2022, 30, 101899. [Google Scholar] [CrossRef]

- Wu, Q.; Bai, H.; Ye, Z.; Deng, H.; Xiao, B.; Yi, D.; Zhu, J. Design of an alternating distributed large and small amounts of CNT/polyether amine coating on carbon fiber to derive enhancement in interfacial adhesion. Compos. Sci. Technol. 2023, 232, 109855. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, X.; Wu, G. Facile Strategy of Improving Interfacial Strength of Silicone Resin Composites Through Self-Polymerized Polydopamine Followed via the Sol-Gel Growing of Silica Nanoparticles onto Carbon Fiber. Polymers 2019, 11, 1639. [Google Scholar] [CrossRef]

- Cui, X.; Ma, L.; Wu, G. Mussel-Inspired Co-Deposition of Polydopamine/Silica Nanoparticles onto Carbon Fiber for Improved Interfacial Strength and Hydrothermal Aging Resistance of Composites. Polymers 2020, 12, 712. [Google Scholar] [CrossRef]

- Wu, D.; Hao, Z.; Sheng, Y.; Zhao, Q.; Dong, Q.; Han, Y.; Liu, L.; Zhang, R.; Wang, M. Construction of an Orderly Carbon Fiber/Carbon Nanotubes Hybrid Composites by a Mild, Effective, and Green Method for Highly Interface Reinforcement. Adv. Mater. Interfaces 2022, 9, 2201360. [Google Scholar] [CrossRef]

- Pu, Y.; Ma, Z.; Liu, L.; Bai, Y.; Huang, Y. Improvement on strength and toughness for CFRPs by construction of novel “soft-rigid” interface layer. Compos. Part B Eng. 2022, 236, 109846. [Google Scholar] [CrossRef]

- Park, M.; Park, J.H.; Yang, B.J.; Cho, J.; Kim, S.Y.; Jung, I. Enhanced interfacial, electrical, and flexural properties of polyphenylene sulfide composites filled with carbon fibers modified by electrophoretic surface deposition of multi-walled carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2018, 109, 124–130. [Google Scholar] [CrossRef]

- Yu, J.; Meng, L.; Fan, D.; Zhang, C.; Yu, F.; Huang, Y. The oxidation of carbon fibers through K2S2O8/AgNO3 system that preserves fiber tensile strength. Compos. Part B Eng. 2014, 60, 261–267. [Google Scholar] [CrossRef]

- Liu, J.; Rinzler, A.G.; Dai, H.; Hafner, J.H.; Bradley, R.K.; Boul, P.J.; Lu, A.; Iverson, T.; Shelimov, K.; Huffman, C.B.; et al. Fullerene Pipes. Science 1998, 280, 1253–1256. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Tian, Y.; Chen, Y.; Liang, J. Interfacial and mechanical properties of carbon fibers modified by electrochemical oxidation in (NH4HCO3)/(NH4)2C2O4·H2O aqueous compound solution. Appl. Surf. Sci. 2010, 256, 6199–6204. [Google Scholar] [CrossRef]

- Sugimoto, Y.; Imai, Y.; Hojo, M.; Shimamoto, D.; Hotta, Y. Determination of Carbon Fiber Strength Distribution Using Bundle Fiber Tensile Test: Correction of Measurement System Elongation and Kinetic Friction Between Fibers in the Fiber Bundle. J. Mater. Res. 2021, 36, 961–969. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, X.; Luo, Y.; Liang, M.; Zou, H. Green and Nondestructive Method for Constructing Multiscale Carbon Fiber Reinforcement via Encapsulating Chitosan and Grafting Carbon Nanotubes. ACS Appl. Nano Mater. 2021, 4, 13388–13397. [Google Scholar] [CrossRef]

- Zhao, M.; Meng, L.; Ma, L.; Ma, L.; Yang, X.; Huang, Y.; Ryu, J.E.; Shankar, A.; Li, T.; Yan, C.; et al. Layer-by-layer grafting CNTs onto carbon fibers surface for enhancing the interfacial properties of epoxy resin composites. Compos. Sci. Technol. 2018, 154, 28–36. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Tong, L.; Song, Q.; Li, K.; Li, J.; Peng, Q.; He, X.; Wang, R.; Jiao, W.; et al. The role of grafting force and surface wettability in interfacial enhancement of carbon nanotube/carbon fiber hierarchical composites. Carbon 2014, 69, 239–246. [Google Scholar] [CrossRef]

- Qin, W.; Lei, K.; Yan, M.; Li, Z.; Yan, Y.; Hu, Y.; Wu, Z.; He, J.; Chen, L. Carbon fiber-reinforced epoxy composite properties improvement by incorporation of polydopamine sizing at fiber–matrix interface. Polym. Compos. 2023, 44, 2441–2448. [Google Scholar] [CrossRef]

- Xu, N.; Li, Y.; Zheng, T.; Xiao, L.; Liu, Y.; Chen, S.; Zhang, D. A mussel-inspired strategy for CNT/carbon fiber reinforced epoxy composite by hierarchical surface modification. Colloids Surf. A Physicochem. Eng. Asp. 2022, 635, 128085. [Google Scholar] [CrossRef]

- Griffith, A.A.; Taylor, G.I., VI. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. London. Ser. A Contain. Pap. Math. Phys. Character 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Sun, T.; Li, M.; Zhou, S.; Liang, M.; Chen, Y.; Zou, H. Multi-scale structure construction of carbon fiber surface by electrophoretic deposition and electropolymerization to enhance the interfacial strength of epoxy resin composites. Appl. Surf. Sci. 2020, 499, 143929. [Google Scholar] [CrossRef]

- Hu, Y.; Pang, S.; Yang, G.; Yao, X.; Li, C.; Jiang, J.; Li, Y. MXene modified carbon fiber composites with improved mechanical properties based on electrophoretic deposition. Mater. Res. Bull. 2022, 150, 111761. [Google Scholar] [CrossRef]

| Samples | C/N/O (%) | C1s (%) | |||

|---|---|---|---|---|---|

| C-C | C-O | O-C=O | N-C=O | ||

| desized CF | 85.5/2.5/12.0 | 64.1 | 26.4 | 9.5 | — |

| CF-COOH | 83.7/3.2/13.1 | 58.8 | 21.3 | 19.9 | — |

| CF@CS | 82.3/3.3/14.4 | 52.9 | 31.3 | 6.9 | 8.9 |

| CF@CS@CNT2 | 69.2/6.6/24.2 | 45.3 | 41.5 | 9.7 | 3.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, J.; Li, H.; Lu, M.; Wang, Y.; Jiang, J.; Yang, W.; Qu, S.; Lu, W. Enhancing the Interfacial Shear Strength and Tensile Strength of Carbon Fibers through Chemical Grafting of Chitosan and Carbon Nanotubes. Polymers 2023, 15, 2147. https://doi.org/10.3390/polym15092147

Xiao J, Li H, Lu M, Wang Y, Jiang J, Yang W, Qu S, Lu W. Enhancing the Interfacial Shear Strength and Tensile Strength of Carbon Fibers through Chemical Grafting of Chitosan and Carbon Nanotubes. Polymers. 2023; 15(9):2147. https://doi.org/10.3390/polym15092147

Chicago/Turabian StyleXiao, Jingyue, Huigai Li, Munan Lu, Yuqiong Wang, Jin Jiang, Wengang Yang, Shuxuan Qu, and Weibang Lu. 2023. "Enhancing the Interfacial Shear Strength and Tensile Strength of Carbon Fibers through Chemical Grafting of Chitosan and Carbon Nanotubes" Polymers 15, no. 9: 2147. https://doi.org/10.3390/polym15092147