Open-Cell Spray Polyurethane Foams Based on Biopolyols from Fruit Seed Oils

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Biopolyols

2.3. Preparation of Open-Cell PUR Foams on a Laboratory and an Industrial Scale

2.4. Methods of Biopolyol Characterization

2.5. Methods of PUR Foam Characterization

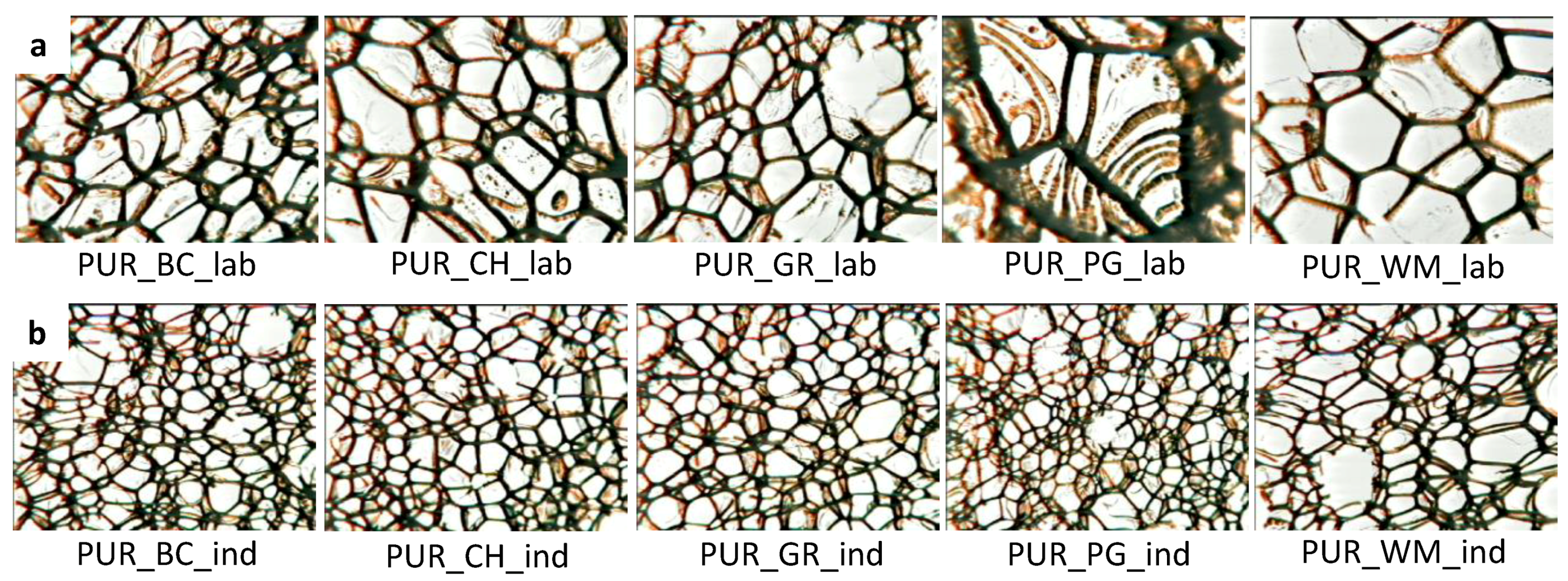

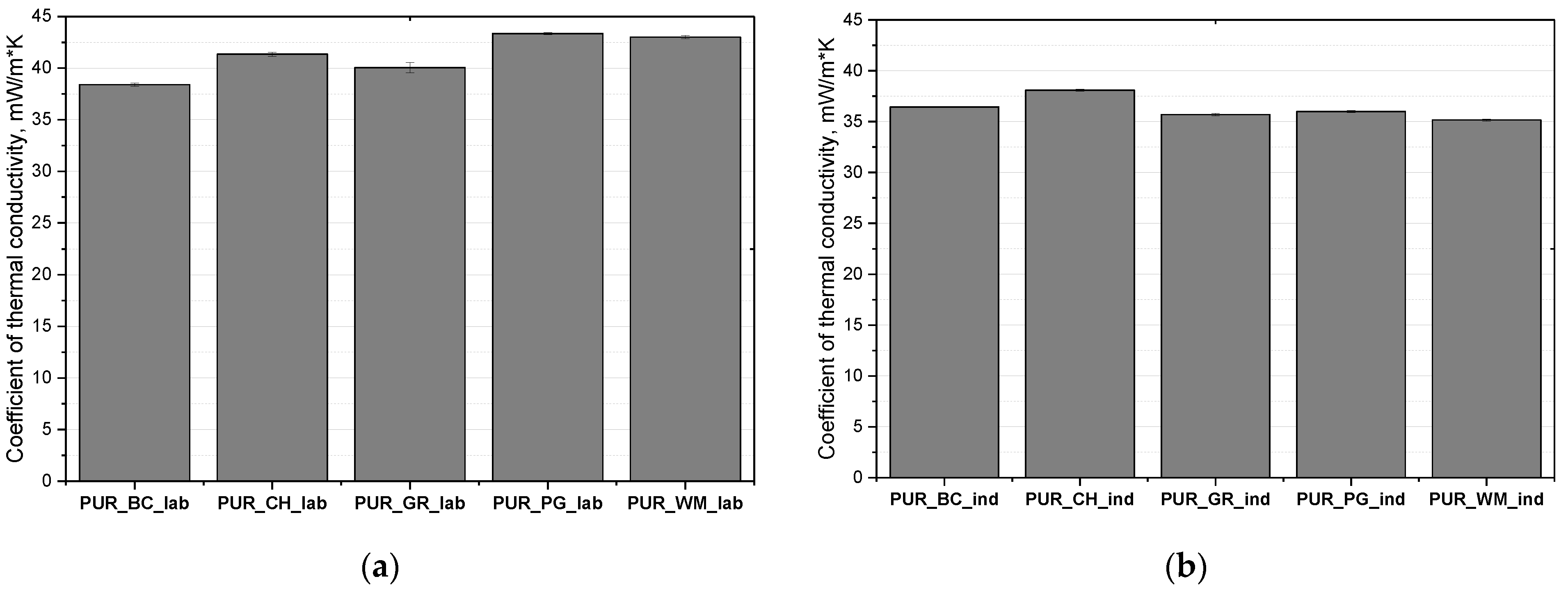

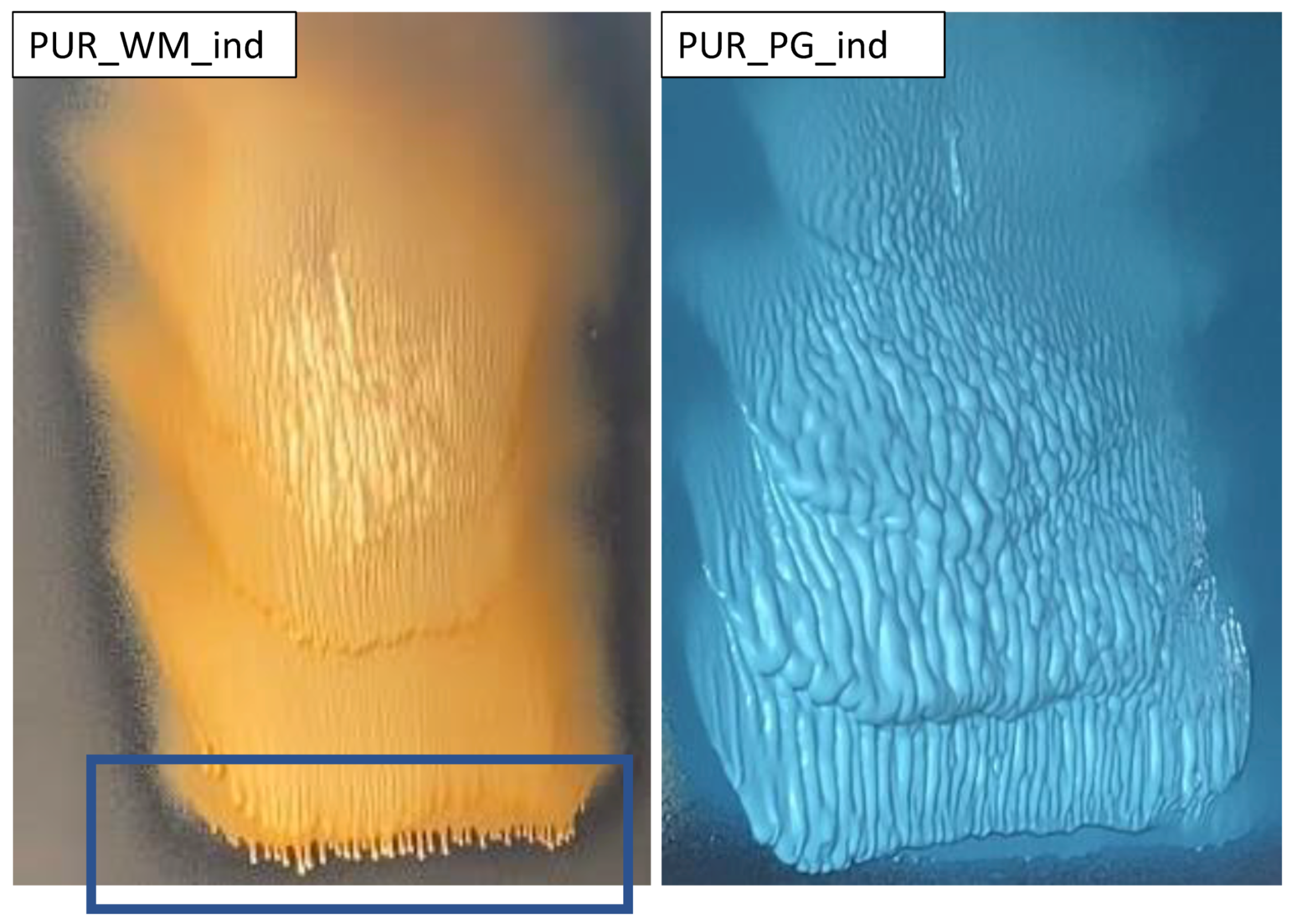

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, C.; Wu, H.; Cai, M.; Zhou, Y.; Guo, C.; Han, Y.; Zhang, L. Valorization of Biomass-Derived Polymers to Functional Biochar Materials for Supercapacitor Applications via Pyrolysis: Advances and Perspectives. Polymers 2023, 15, 2741. [Google Scholar] [CrossRef]

- Barczewski, M.; Kurańska, M.; Sałasińska, K.; Michałowski, S.; Prociak, A.; Uram, K.; Lewandowski, K. Rigid polyurethane foams modified with thermoset polyester-glass fiber composite waste. Polym. Test. 2020, 81, 106190. [Google Scholar] [CrossRef]

- Barczewski, M.; Aniśko, J.; Hejna, A.; Mysiukiewicz, O.; Kosmela, P.; Sałasińska, K.; Boczkowska, A.; Przybylska-Balcerek, A.; Stuper-Szablewska, K. Ground lemon and stevia leaves as renewable functional fillers with antioxidant activity for high-density polyethylene composites. Clean Technol. Environ. Policy 2023, 25, 3345–3361. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Barczewski, M.; Czarnecka-Komorowska, D.; Rydzkowski, T.; Gawdzińska, K.; Thakur, V.K. Manufacturing and characterization of sustainable and recyclable wood-polypropylene biocomposites: Multiprocessing-properties-structure relationships. Ind. Crops Prod. 2024, 207, 117710. [Google Scholar] [CrossRef]

- Kairytė, A.; Makowska, S.; Rybiński, P.; Strzelec, K.; Kremensas, A.; Šeputytė-Jucikė, J.; Vaitkus, S. Effect of Liquid Glass-Modified Lignin Waste on the Flammability Properties of Biopolyurethane Foam Composites. Polymers 2024, 16, 205. [Google Scholar] [CrossRef]

- Polaczek, K.; Kurańska, M.; Malewska, E.; Czerwicka-Pach, M.; Prociak, A. From Bioresources to Thermal Insulation Materials: Synthesis and Properties of Two-Component Open-Cell Spray Polyurethane Foams Based on Bio-Polyols from Used Cooking Oil. Materials 2023, 16, 6139. [Google Scholar] [CrossRef]

- Stirna, U.; Fridrihsone, A.; Lazdin, B. Biobased Polyurethanes from Rapeseed Oil Polyols: Structure, Mechanical and Thermal Properties. J. Polym. Environ. 2013, 21, 952–962. [Google Scholar] [CrossRef]

- Miao, S.; Wang, P.; Su, Z.; Zhang, S. Acta Biomaterialia Vegetable-oil-based polymers as future polymeric biomaterials q. Acta Biomater. 2014, 10, 1692–1704. [Google Scholar] [CrossRef]

- Kurańska, M.; Pinto, J.A.; Salach, K.; Barreiro, M.F.; Prociak, A. Industrial Crops & Products Synthesis of thermal insulating polyurethane foams from lignin and rapeseed based polyols: A comparative study. Ind. Crop. Prod. 2020, 143, 111882. [Google Scholar] [CrossRef]

- Gosz, K.; Kosmela, P.; Hejna, A.; Gajowiec, G.; Piszczyk, Ł. Biopolyols obtained via microwave-assisted liquefaction of lignin: Structure, rheological, physical and thermal properties. Wood Sci. Technol. 2018, 52, 599–617. [Google Scholar] [CrossRef]

- Vieira, F.R.; Magina, S.; Evtiguin, D.V.; Barros-Timmons, A. Lignin as a Renewable Building Block for Sustainable Polyurethanes. Materials 2022, 15, 6182. [Google Scholar] [CrossRef]

- Borowicz, M.; Paciorek-Sadowska, J.; Isbrandt, M.; Grzybowski, Ł.; Czupryński, B. Glycerolysis of poly(lactic acid) as away to extend the “life cycle” of this material. Polymers 2019, 11, 1963. [Google Scholar] [CrossRef]

- Borowicz, M.; Isbrandt, M.; Paciorek-Sadowska, J. Effect of new eco-polyols based on pla waste on the basic properties of rigid polyurethane and polyurethane/polyisocyanurate foams. Int. J. Mol. Sci. 2021, 22, 8981. [Google Scholar] [CrossRef]

- Ji, D.; Fang, Z.; He, W.; Luo, Z.; Jiang, X.; Wang, T.; Guo, K. Polyurethane rigid foams formed from different soy-based polyols by the ring opening of epoxidised soybean oil with methanol, phenol, and cyclohexanol. Ind. Crops Prod. 2015, 74, 76–82. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Czupryński, B.; Tomaszewska, E.; Liszkowska, J. Oenothera biennis seed oil as an alternative raw material for production of bio-polyol for rigid polyurethane-polyisocyanurate foams. Ind. Crops Prod. 2018, 126, 208–217. [Google Scholar] [CrossRef]

- Paciorek-sadowska, J.; Borowicz, M.; Isbrandt, M. Effect of evening primrose (Oenothera biennis) oil cake on the properties of polyurethane/polyisocyanurate bio-composites. Int. J. Mol. Sci. 2021, 22, 8950. [Google Scholar] [CrossRef]

- Ribeiro, V.; Mosiewicki, M.A.; Irene, M.; Coelho, M.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modi fi ed tung oil and reinforced with rice husk ash I: Synthesis and physical chemical characterization. Polym. Test. 2013, 32, 438–445. [Google Scholar] [CrossRef]

- Zhou, W.; Bo, C.; Jia, P.; Zhou, Y.; Zhang, M. Effects of Tung Oil-Based Polyols on the Thermal Stability, Flame Retardancy, and Mechanical Properties of Rigid Polyurethane Foam. Polymers 2018, 11, 45. [Google Scholar] [CrossRef]

- Vanags, E.; Kirpluks, M.; Cabulis, U.; Walterova, Z. Highly functional polyol synthesis from epoxidized tall oil fatty acids. J. Renew. Mater. 2018, 6, 764–771. [Google Scholar] [CrossRef]

- Kairytė, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vaitkus, S.; Pundienė, I. Cleaner production of polyurethane foam: Replacement of conventional raw materials, assessment of fire resistance and environmental impact. J. Clean. Prod. 2018, 183, 760–771. [Google Scholar] [CrossRef]

- Pietrzak, K.; Kirpluks, M.; Cabulis, U.; Ryszkowska, J. Effect of the addition of tall oil-based polyols on the thermal and mechanical properties of ureaurethane elastomers. Polym. Degrad. Stab. 2014, 108, 201–211. [Google Scholar] [CrossRef]

- Abolins, A.; Pomilovskis, R.; Vanags, E.; Mierina, I.; Michalowski, S. Impact of Different Epoxidation Approaches of Tall Oil Fatty Acids on Rigid Polyurethane Foam Thermal Insulation. Materials 2021, 14, 894. [Google Scholar] [CrossRef]

- Kirpluks, M.; Vanags, E.; Abolins, A.; Fridrihsone, A.; Cabulis, U. Chemo-enzymatic oxidation of tall oil fatty acids as a precursor for further polyol production. J. Clean. Prod. 2019, 215, 390–398. [Google Scholar] [CrossRef]

- Stuhr, R.; Bayer, P.; Stark, C.B.W.; Jacobi, A.; Wangelin, V. Light-Driven Waste-To-Value Upcycling: Bio-Based Polyols and Polyurethanes from the Photo-Oxygenation of Cardanols. ChemSusChem 2021, 14, 3325–3332. [Google Scholar] [CrossRef]

- Suresh, K.I. Rigid Polyurethane Foams from Cardanol: Synthesis, Structural Characterization, and Evaluation of Polyol and Foam Properties. ACS Sustain. Chem. Eng. 2013, 1, 232–242. [Google Scholar]

- Kosmela, P.; Hejna, A.; Formela, K.; Haponiuk, J.T.; Piszczyk, Ł. Biopolyols obtained via crude glycerol-based liquefaction of cellulose: Their structural, rheological and thermal characterization. Cellulose 2016, 23, 2929–2942. [Google Scholar] [CrossRef]

- Zhang, J.; Hori, N.; Takemura, A. In fl uence of NCO/OH ratio on preparation of four agricultural wastes lique fi ed polyols based polyurethane foams. Polym. Degrad. Stab. 2020, 179, 109256. [Google Scholar] [CrossRef]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer 2020, 190, 122164. [Google Scholar] [CrossRef]

- Polaczek, K.; Kurańska, M. Hemp Seed Oil and Oilseed Radish Oil as New Sources of Raw Materials for the Synthesis of Bio-Polyols for Open-Cell Polyurethane Foams. Materials 2022, 15, 8891. [Google Scholar] [CrossRef]

- Polish Standards: PN-81/C-04959; Determining the Water Content by the Karl Fischer Method in Organic and Inorganic Products. Polish Committee for Standardization: Warsaw, Poland, 1981.

- ISO 845; Cellular Plastics and Rubbers—Determination of Apparent Density. ISO (International Organization for Standardization): Geneva, Switzerland, 2006.

- ISO 4590; Rigid Cellular Plastics—Determination of the Volume Percentage of Open Cells and of Closed Cells. ISO (InternationalOrganization for Standardization): Geneva, Switzerland, 2016.

- ISO 844; Rigid Cellular Plastics—Determination of Compression Properties. ISO (International Organization for Standardization): Geneva, Switzerland, 2014.

- ISO 2796-1986; Cellular Plastics, Rigid–Test for Dimensional Stability. ISO (International Organization for Standardization): Geneva, Switzerland, 2014.

- ISO 4589-2; Plastics—Determination of Burning Behaviour by Oxygen Index—Part 2: Ambient-Temperature Test. ISO (Interna-tional Organization for Standardization): Geneva, Switzerland, 2017.

- Kurańska, M.; Cabulis, U.; Prociak, A.; Polaczek, K.; Uram, K.; Kirpluks, M. Scale-Up and Testing of Polyurethane Bio-Foams as Potential Cryogenic Insulation Materials. Materials 2022, 15, 3469. [Google Scholar] [CrossRef]

- Carriço, C.S.; Fraga, T.; Pasa, V.M.D. Production and characterization of polyurethane foams from a simple mixture of castor oil, crude glycerol and untreated lignin as bio-based polyols. Eur. Polym. J. 2016, 85, 53–61. [Google Scholar] [CrossRef]

| Symbol | PUR_BR_lab PUR_BR_ind, g | PUR_CH_lab PUR_CH_ind, g | PUR_GR_lab PUR_GR_ind, g | PUR_PG_lab PUR_PG_ind, g | PUR_WM_lab PUR_WM_ind, g |

|---|---|---|---|---|---|

| Biopolyol BR | 100 | ||||

| Biopolyol CH | 100 | ||||

| Biopolyol GR | 100 | ||||

| Biopolyol PG | 100 | ||||

| Biopolyol WM | 100 | ||||

| Polycat 142 | 4 | 4 | 4 | 4 | 4 |

| Tegostab 8870 | 2 | 2 | 2 | 2 | 2 |

| Tegostab 8523 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Ortegol 500 | 1 | 1 | 1 | 1 | 1 |

| TCPP | 20 | 20 | 20 | 20 | 20 |

| Water | 20 | 20 | 20 | 20 | 20 |

| Isocyanate index | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Symbol | Dimensional Stability at −25 °C, % | Dimensional Stability at +70 °C, % | Oxygen Index, % | ||||

|---|---|---|---|---|---|---|---|

| DSl | DSw | DSt | DSl | DSw | DSt | ||

| PUR_BC_lab | 0.10 | −0.02 | −0.36 | −0.09 | −0.25 | −0.17 | 21.0 ± 0.1 |

| PUR_CH_lab | 0.09 | 0.02 | 0.61 | −0.50 | −0.47 | 0.11 | 21.0 ± 0.1 |

| PUR_GR_lab | 0.24 | 0.24 | 0.53 | −0.04 | −0.08 | 0.09 | 20.6 ± 0.1 |

| PUR_PG_lab | −0.76 | −0.24 | −0.06 | −0.24 | −0.63 | 0.74 | 20.9 ± 0.1 |

| PUR_WM_lab | −0.10 | −0.03 | −0.72 | −0.47 | −0.35 | −0.09 | 20.7 ± 0.1 |

| PUR_BC_ind | −0.59 | 0.04 | 0.34 | −0.19 | −0.16 | 0.22 | 21.4 ± 0.1 |

| PUR_CH_ind | 0.64 | 0.06 | −0.31 | −0.20 | −0.12 | −0.21 | 21.3 ± 0.1 |

| PUR_GR_ind | 0.80 | 0.32 | 0.05 | −0.19 | 0.06 | 0.28 | 21.4 ± 0.1 |

| PUR_PG_ind | −0.17 | −0.05 | −0.45 | −0.38 | −0.41 | −0.14 | 21.2 ± 0.1 |

| PUR_WM_ind | −0.03 | −0.09 | −0.19 | −0.07 | −0.26 | −0.03 | 21.3 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurańska, M.; Malewska, E.; Ożóg, H.; Sędzimir, J.; Put, A.; Kowalik, N.; Michałowski, S.; Zemła, M.; Kucała, M.; Prociak, A. Open-Cell Spray Polyurethane Foams Based on Biopolyols from Fruit Seed Oils. Polymers 2024, 16, 1145. https://doi.org/10.3390/polym16081145

Kurańska M, Malewska E, Ożóg H, Sędzimir J, Put A, Kowalik N, Michałowski S, Zemła M, Kucała M, Prociak A. Open-Cell Spray Polyurethane Foams Based on Biopolyols from Fruit Seed Oils. Polymers. 2024; 16(8):1145. https://doi.org/10.3390/polym16081145

Chicago/Turabian StyleKurańska, Maria, Elżbieta Malewska, Hubert Ożóg, Julia Sędzimir, Aleksandra Put, Natalia Kowalik, Sławomir Michałowski, Marcin Zemła, Michał Kucała, and Aleksander Prociak. 2024. "Open-Cell Spray Polyurethane Foams Based on Biopolyols from Fruit Seed Oils" Polymers 16, no. 8: 1145. https://doi.org/10.3390/polym16081145