Optimized Subsurface Irrigation System: The Future of Sugarcane Irrigation

Abstract

:1. Introduction

2. Materials and Methods

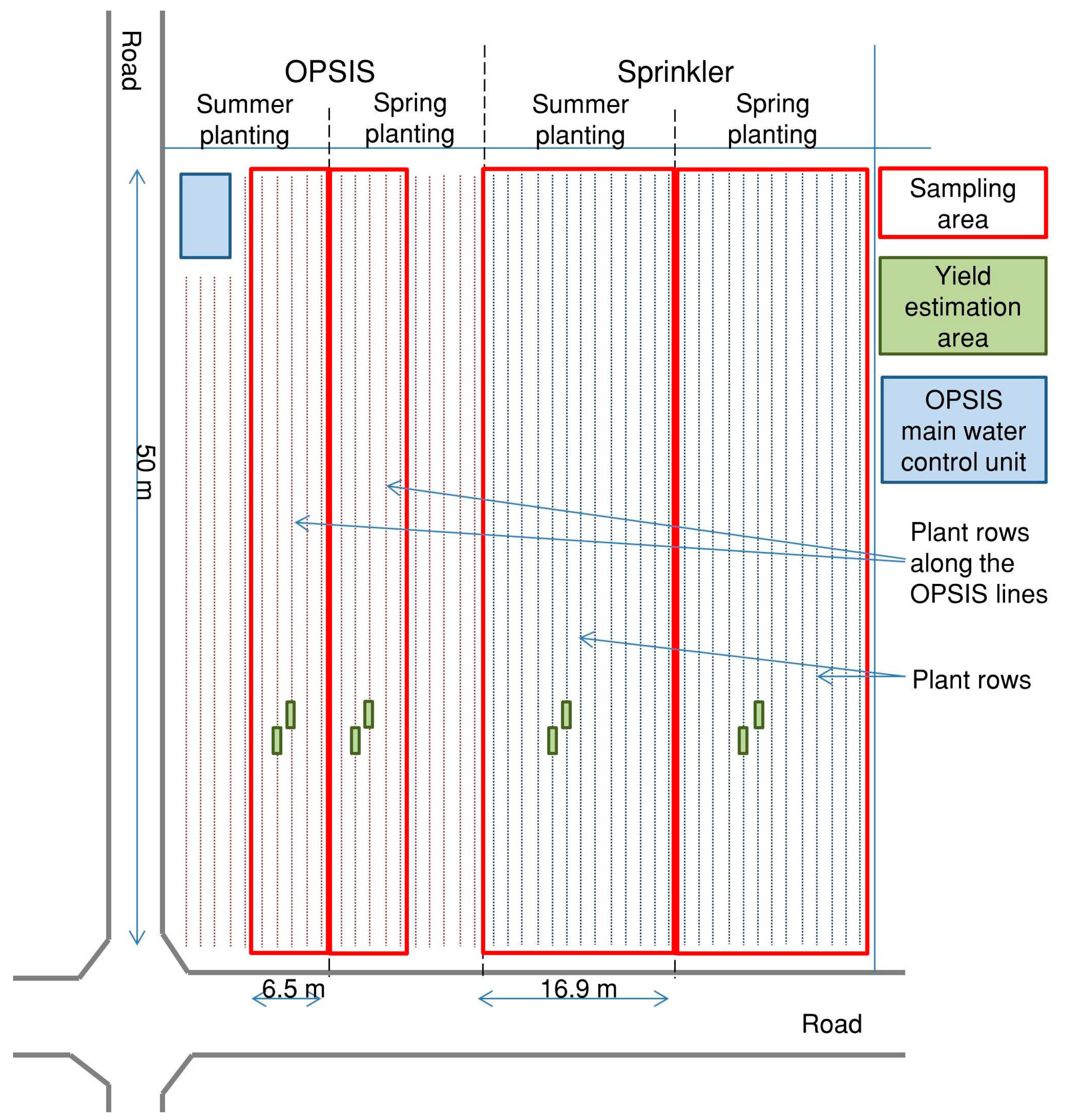

2.1. Field Experiment

2.2. Irrigation System Installation

2.3. Plant Growth and Yield Sampling

2.4. Measurement of Irrigation Water Use

2.5. Water Use Efficiency

3. Results

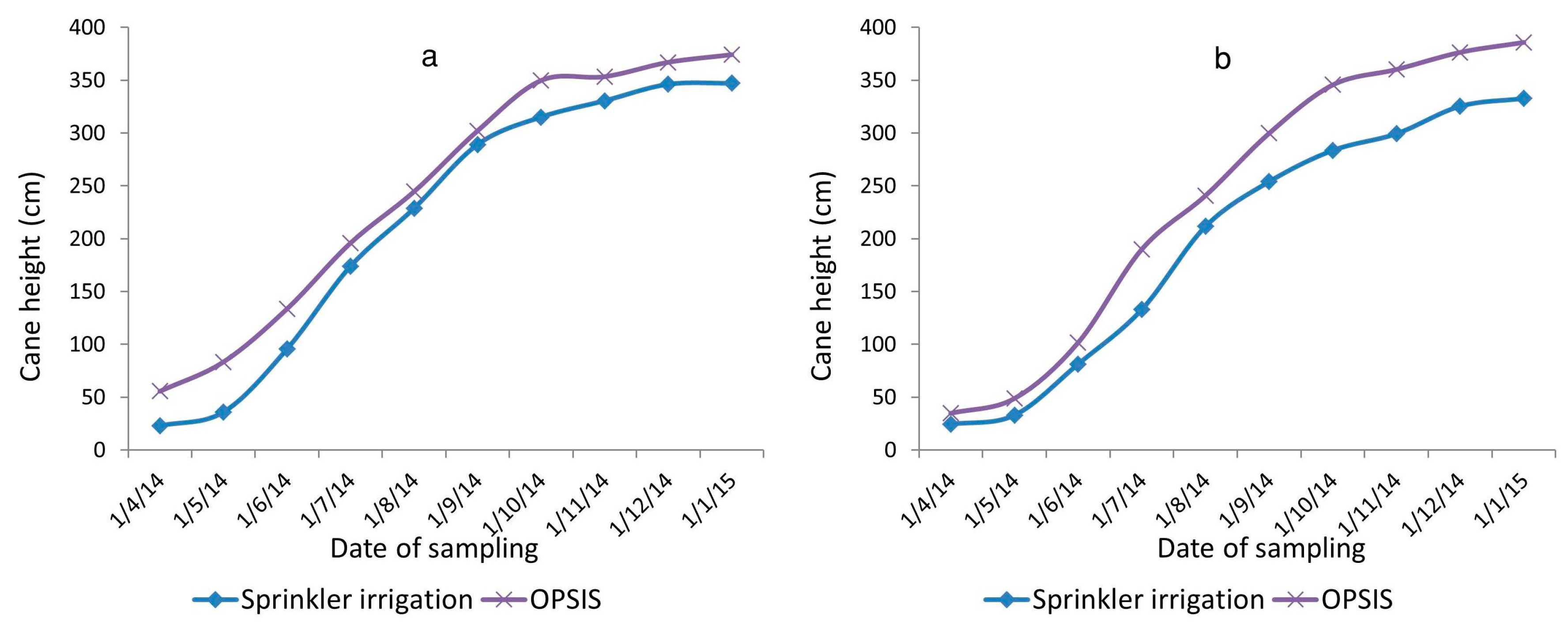

3.1. Plant Height during Crop Growth

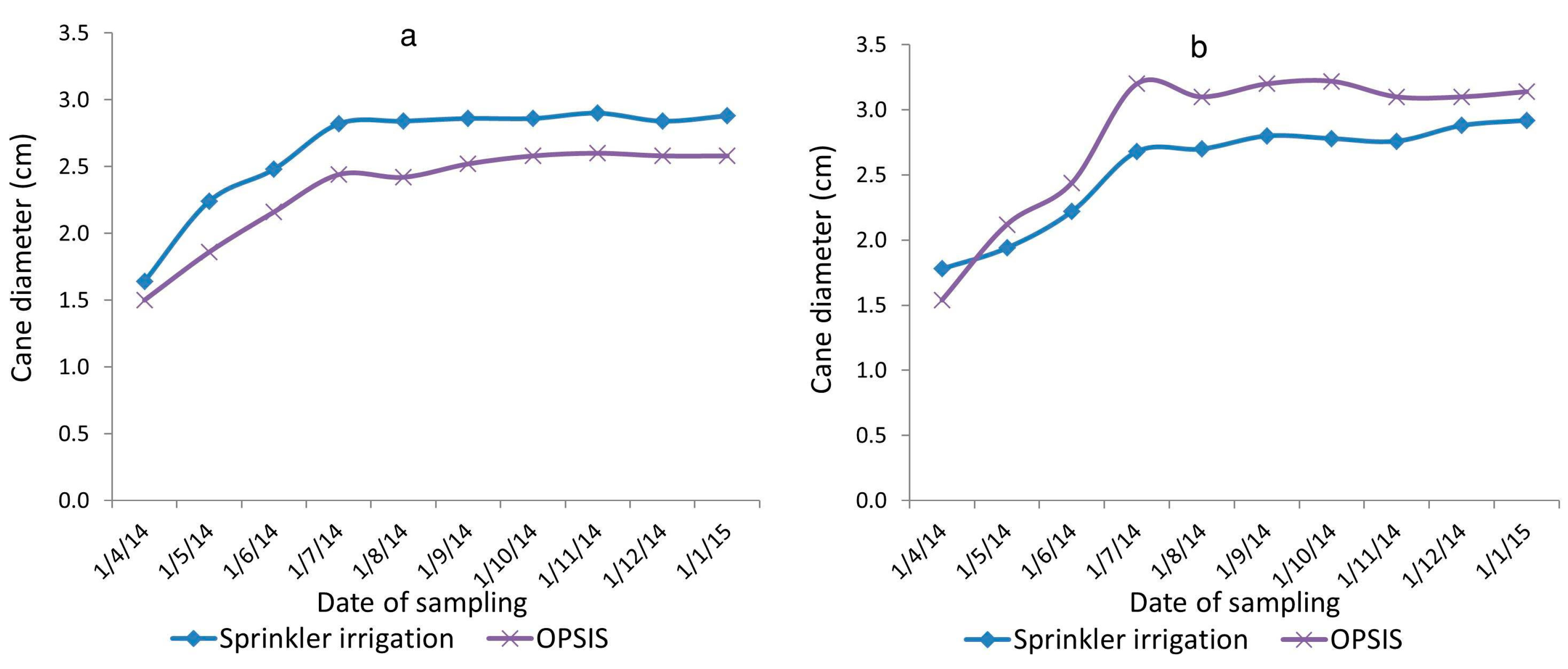

3.2. Cane Diameter during Crop Growth

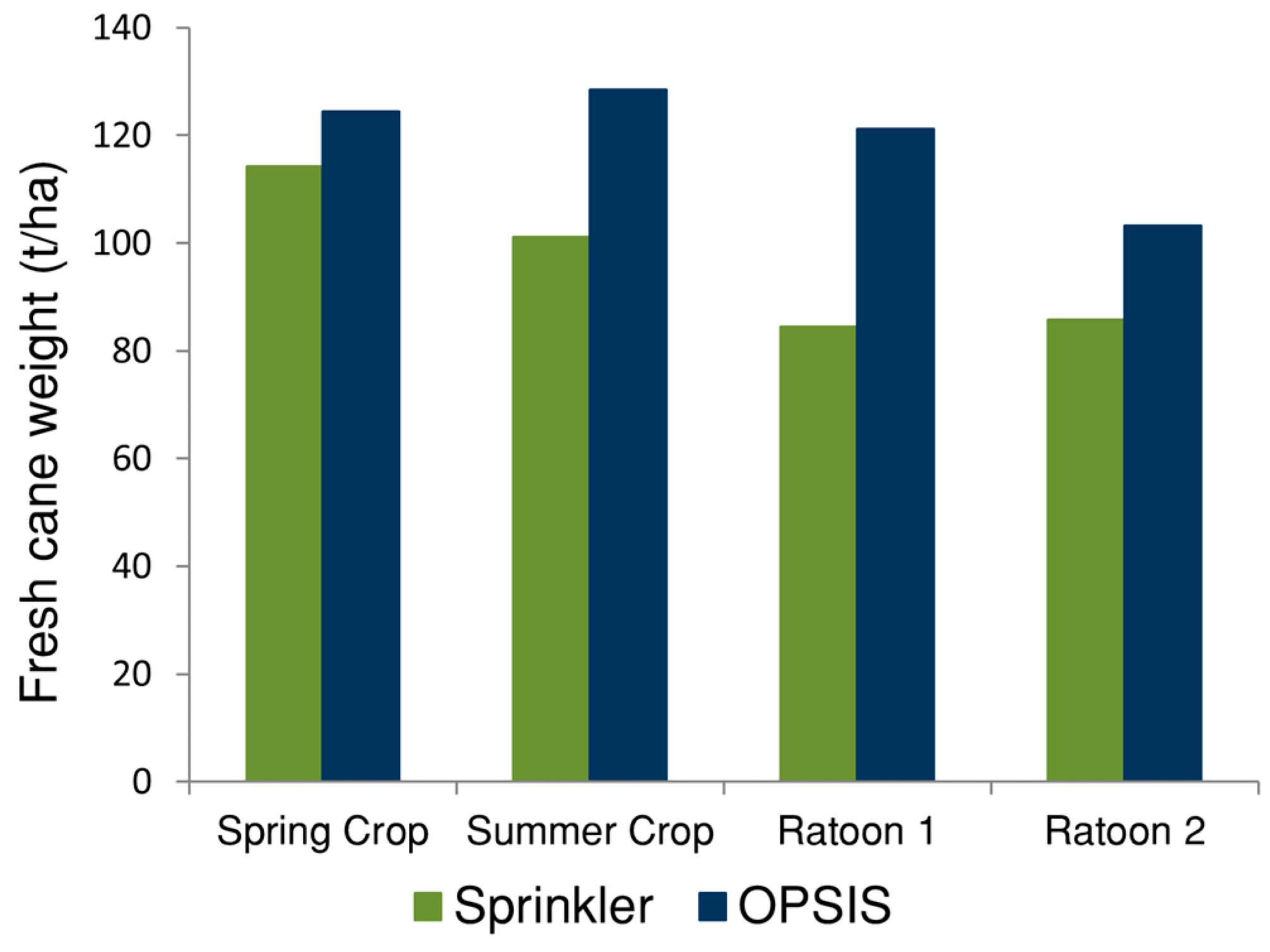

3.3. Fresh Cane Yield

3.4. Millable Cane Length

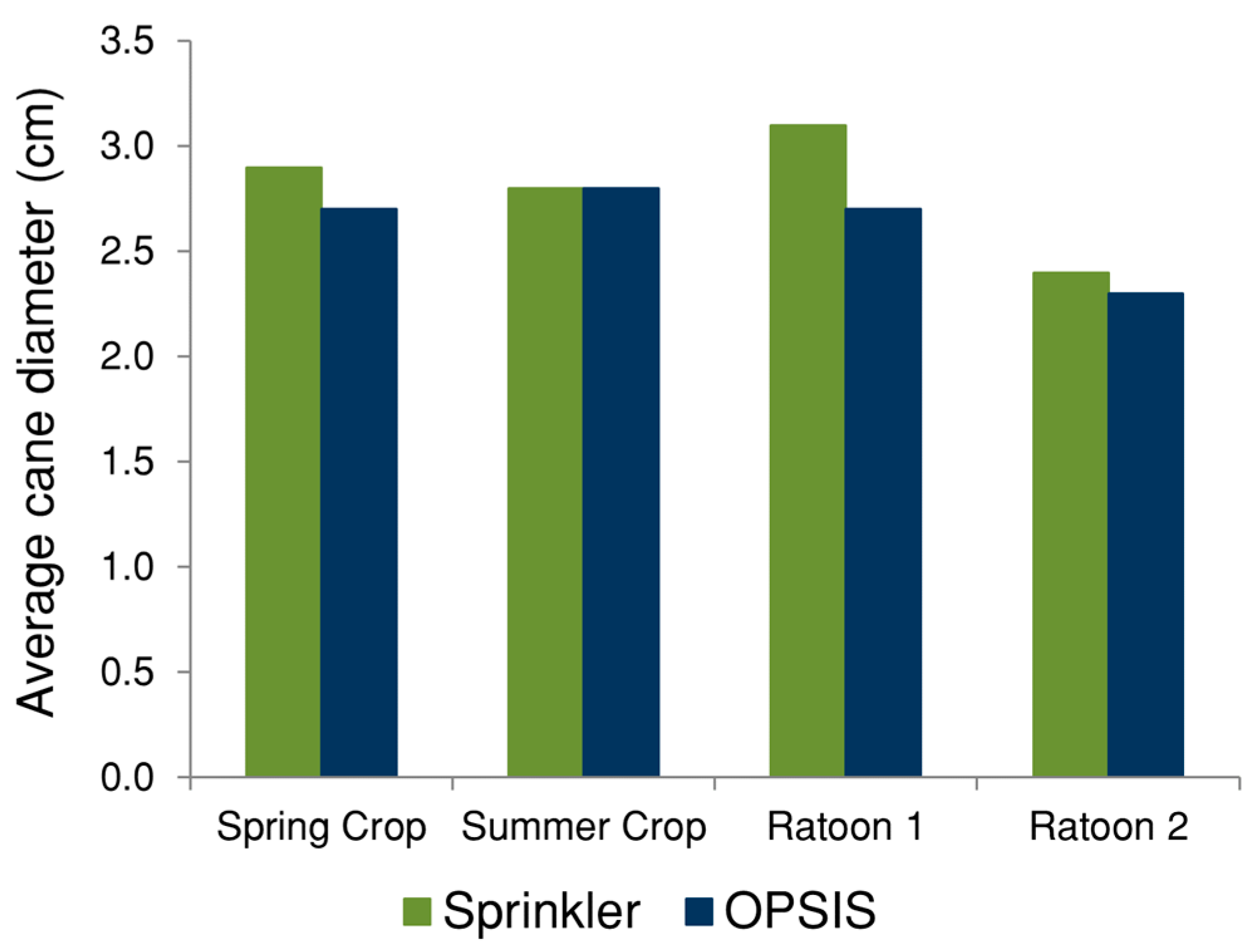

3.5. Cane Diameter at Maturity

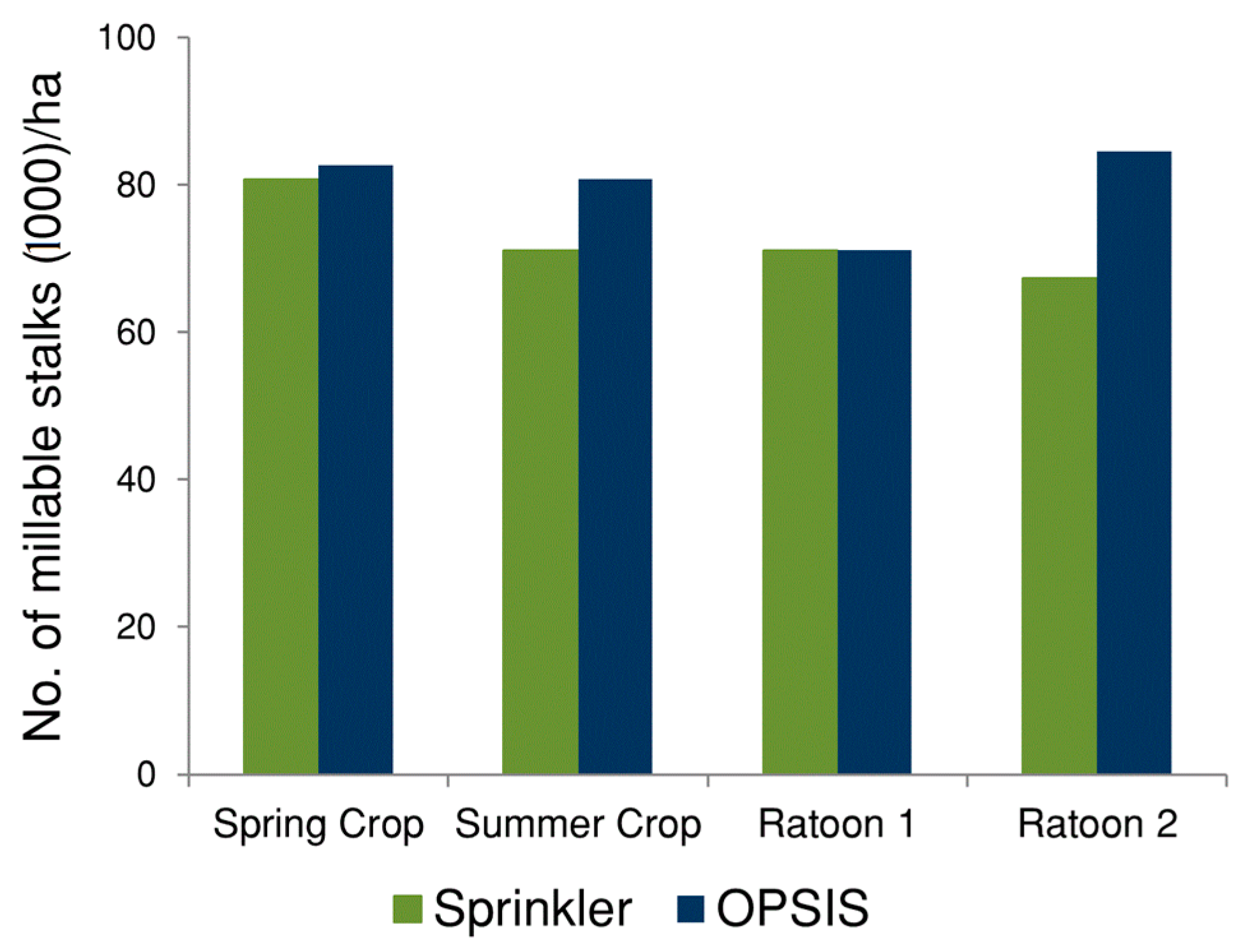

3.6. Number of Millable Stalks

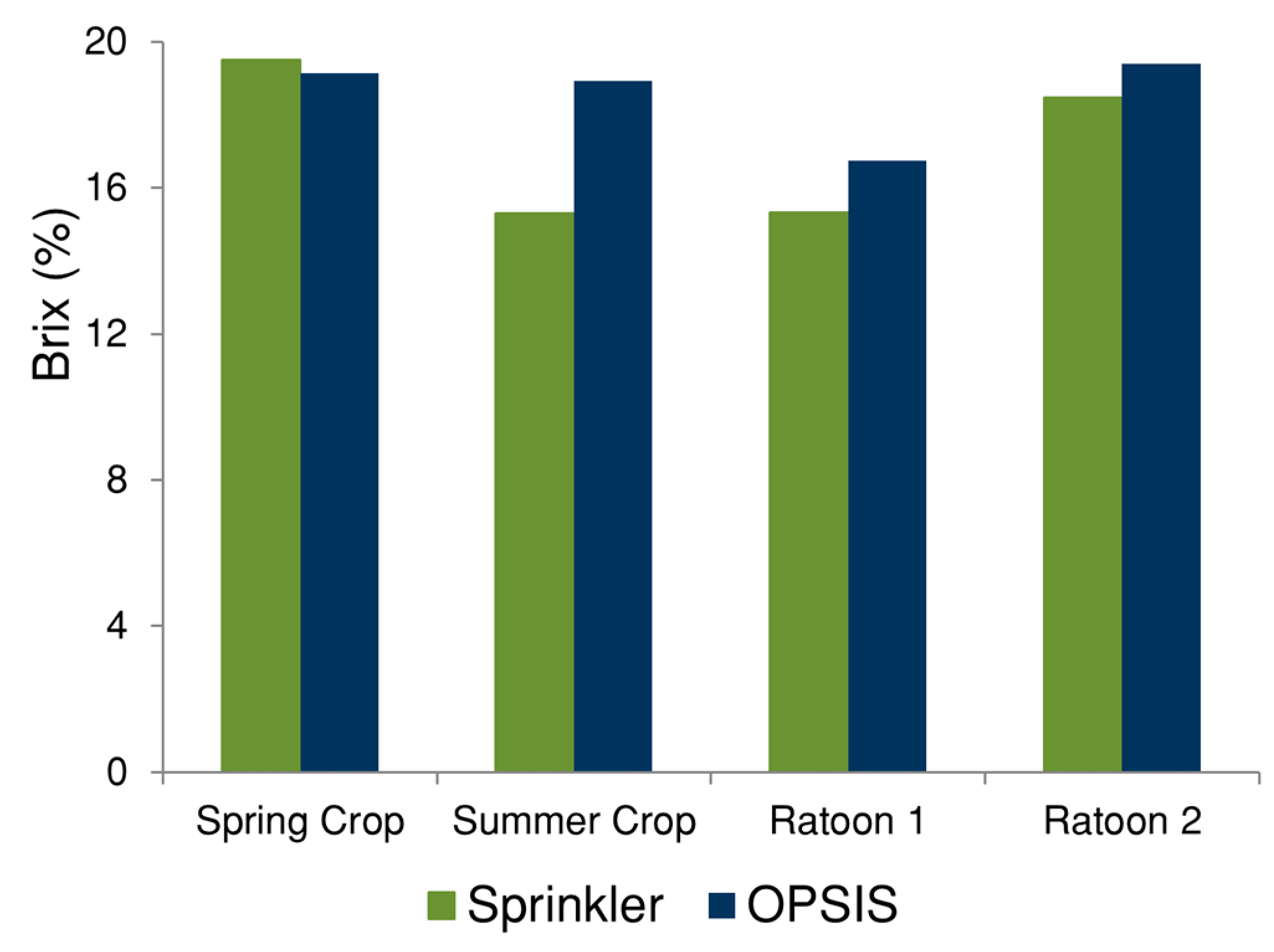

3.7. Brix Value

3.8. Irrigation Water Use

3.9. Water Use Efficiency

4. Discussion

4.1. Crop Yield

4.2. Water Use Efficiency

5. Conclusions

6. Recommendations

Author Contributions

Conflicts of Interest

References

- Knox, J.W.; Rodríguez Díaz, J.A.; Nixon, D.J.; Mkhwanazi, M. A preliminary assessment of climate change impacts on sugarcane in Swaziland. Agric. Syst. 2010, 103, 63–72. [Google Scholar] [CrossRef] [Green Version]

- Santos, D.L.; Sentelhas, P.C. Climate change scenarios and their impact on the water balance of sugarcane production areas in the State of São Paulo, Brazil. Ambi-Agua Taubaté 2012, 7, 7–17. [Google Scholar] [CrossRef]

- Carvalho, M.; Serralheiro, R.; Corte-Real, J.; Valverde, P. Implications of climate variability and future trends on wheat production and crop technology adaptations in southern regions of Portugal. Water Util. J. 2015, 9, 13–18. [Google Scholar]

- Zhao, D.; Li, Y.R. Climate change and sugarcane production: Potential impact and mitigation strategies. Int. J. Agron. 2015. [Google Scholar] [CrossRef]

- Mazibuko, N.W.; Greenfield, P.L.; Johnston, M.A. The effect of different furrow irrigation regimes on infiltration and sugarcane yield at Ubombo. Proc. S. Afr. Sugar Technol. Assoc. 2002, 76, 196–206. [Google Scholar]

- Narayanamoorthy, A. Economics of drip irrigation in sugarcane cultivation: Case study of a farmer from Tamil Nadu. Indian J. Agric. Econ. 2005, 60, 235–248. [Google Scholar]

- Brouwer, C.; Heibloem, M. Principles of irrigation water needs. In Irrigation Water Management Training Manual; Food and Agriculture Organization (FAO): Rome, Italy, 1986. [Google Scholar]

- Shukla, S.K.; Lal, M. Productivity and economics of sugarcane based production systems in subtropical India. Indian J. Agron. 2003, 48, 16–19. [Google Scholar]

- Inman-Bamber, N.G.; Smith, D.A. Water relations in sugarcane and response to water deficits. Field Crop. Res. 2005, 92, 185–202. [Google Scholar] [CrossRef]

- Skocaj, D.M.; Hurney, A.P.; Inman-Bamber, N.G.; Schroeder, B.L.; Everingham, Y.L. Modeling sugarcane yield response to applied nitrogen fertilizer in a wet tropical environment. Proc. Aust. Soc. Sugar Cane Technol. 2013, 35, 1–9. [Google Scholar]

- Carr, M.K.V.; Knox, J.W. The water relations and irrigation requirements of sugarcane (Saccharum officinarum): A review. Exp. Agric. 2011, 47, 1–25. [Google Scholar] [CrossRef]

- Mudima, K. Socio-economic impact of smallholder irrigation development in Zimbabwe: A case study of five successful irrigation schemes. In Private Irrigation in sub-Saharan Africa; Proceedings of Regional Seminar on Private Sector Participation and Irrigation Expansion in sub-Saharan Africa; Sally, H., Abernethy, C.L., Eds.; International Water Management Institute, Food and Agriculture Organization of the United Nations and ACP-EU Technical Centre for Agricultural and Rural Cooperation: Colombo, Sri Lanka, 2002; pp. 21–30. ISBN 9290904941. [Google Scholar]

- Lecler, N.L.; Jumman, A. Irrigated sugarcane production functions. Proc. S. Afr. Sugar Technol. Assoc. 2009, 82, 604–607. [Google Scholar]

- McGuire, P.J.; Holden, J.R.; McDougall, A. Irrigation Systems. In Irrigation of Sugarcane Manual; Holden, J.R., McGuire, P.J., Eds.; BSES Limited: Queensland, Australia, 2010; pp. 13–23. [Google Scholar]

- Torres, J.S.; Campos, A.; Cruz, D.M. Irrigating sugarcane with very low furrow inflow rates. Proc. Int. Soc. Sugar Cane Technol. 2010, 27, 1–4. [Google Scholar] [CrossRef]

- Young, M.; Klose, S.L.; Jupe, M.; Morris, J.; Kaase, G. Impact of Volumetric Water Pricing for Sugarcane Comparing Furrow vs. Surge Irrigation in the Lower Rio Grande Valley. FARM Assistance Focus, April 2006. Available online: http://agrilife.org/farmassistance/files/2013/08/2006-4.pdf (accessed on 8 November 2017).

- El-Berry, A.M.; El Ebaby, F.G.; Hassan, S.S.; Fattouh, S.M. Performance of locally developed surface irrigation in sugarcane production. Misr J. Agric. Eng. 2006, 23, 169–191. [Google Scholar]

- Hanafy, M.; Mahrous, A.; El Garib, M.Z. Water requirements for irrigated sugarcane under trickle irrigation systems. Misr J. Agric. Eng. 2008, 25, 1343–1357. [Google Scholar]

- Pires, R.C.M.; Barbosa, E.A.A.; Arruda, F.B.; Silva, T.J.A.; Sakai, E.; Landell, M.G.A. Subsurface Drip Irrigation in Different Planting Spacing of Sugarcane; Geophysical Research Abstracts. In Proceedings of the EGU General Assembly, Vienna, Austria, 22–27 April 2012. [Google Scholar]

- Shinde, P.P.; Deshmukh, A.S. Sugarcane nutrition through rain gun sprinkler irrigation. Proc. Int. Soc. Sugar Cane Technol. 2007, 26, 481–484. [Google Scholar]

- Dinka, M.O. Evaluating the adequacy performance of sprinkler irrigation systems at Finchaa sugar cane plantation, Eastern Wollega zone (Ethiopia). Irrig. Drain. 2016, 65, 537–548. [Google Scholar] [CrossRef]

- Mahesh, R.; Asoka, R.N.; Archana, H.A. Performance of surface and subsurface drip fertigation on yield and water use efficiency of sugarcane. In Proceedings of the 2nd World Irrigation Forum, Chiang Mai, Thailand, 6–8 November 2016. [Google Scholar]

- Kaushal, A.; Patole, R.; Singh, K.G. Drip irrigation in sugarcane: A review. Agric. Rev. 2012, 33, 211–219. [Google Scholar]

- Dlamini, M. Experience with drip irrigation on smallholder sugarcane irrigation schemes in Swaziland. Proc. S. Afr. Sugar Technol. Assoc. 2005, 79, 463–472. [Google Scholar]

- Gunarathna, M.H.J.P.; Sakai, K.; Nakandakari, T.; Kazuro, M.; Onodera, T.; Kaneshiro, H.; Uehara, H.; Wakasugi, K. Optimized subsurface irrigation system (OPSIS): Beyond traditional subsurface irrigation. Water 2017, 9, 599. [Google Scholar] [CrossRef]

- Rubel, F.; Kottek, M. Observed and projected climate shifts 1901–2100 depicted by world maps of the Köppen-Geiger climate classification. Meteorol. Z. 2010, 19, 135–141. [Google Scholar] [CrossRef]

- Kubotera, H. The factors and assumed mechanisms of the hardening of Red Soils and Yellow Soils in subtropical Okinawa Island, Japan. JARQ 2006, 40, 197–203. [Google Scholar] [CrossRef]

- De Sousa, R.T.X.; Korndörfer, G.H.; Brem Soares, R.A.; Fontoura, P.R. Phosphate fertilizers for sugarcane used at pre-planting (Phosphorus fertilizer application). J. Plant Nutr. 2015, 38, 1444–1455. [Google Scholar] [CrossRef]

- Bates, D.; Maechler, M.; Bolker, B.; Walker, S. Fitting linear mixed-effects models using lme4. J. Stat. Softw. 2015, 67, 1–48. [Google Scholar] [CrossRef]

- R Core Team R. A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2016. [Google Scholar]

- Venables, W.N.; Ripley, B.D. Modern Applied Statistics with S, 4th ed.; Springer: New York, NY, USA, 2002; ISBN 0-387-95457-0. [Google Scholar]

- Mendiburu, F.D. Agricolae: Statistical Procedures for Agricultural Research. 2016. R Package Version 1.2-4. Available online: https://CRAN.R-project.org/package=agricolae (accessed on 12 October 2017).

- Johari, D.; Srivastava, R.P.; Singh, S.P.; Agarwal, M.L.; Singh, G.P. Effect of moisture stress on growth, yield and juice quality of sugarcane. Coop. Sugar 1998, 30, 15–18. [Google Scholar]

- Ramesh, P.; Mahadevaswamy, M. Effect of formative phase drought on different classes of shoots, shoot mortality, cane attributes, yield and quality of four sugarcane cultivars. J. Agron. Crop. Sci. 2000, 185, 249–258. [Google Scholar] [CrossRef]

- Chen, G.F.; Tang, Q.; Li, Y.; Huang, Y.; Liu, B.; Lin, X.; Huang, H. Effects of Sub-soil Drip Fertigation on Sugarcane in Field Conditions. Sugar Tech 2012, 14, 418–421. [Google Scholar] [CrossRef]

- Mahesh, R.; Asoka, R.N. Influence of source of fertilizers and fertilizer levels on tillers production, shoot population, number of millable canes and yield of sugarcane under subsurface drip fertigation. Trends Biosci. 2015, 8, 1095–1099. [Google Scholar]

- Levitt, J. Responses of Plants to Environmental Stresses; Academic Press: New York, NY, USA, 1972. [Google Scholar]

- Bendigeri, A.V.; Hapse, D.G.; Tiwari, U.S. Physiological behavior of different sugarcane varieties for moisture stress. In Proceedings of Deccan Sugar Technologists Association; Deccan Sugar Technologists Association: Maharashtra, India, 1986; pp. A217–A238. [Google Scholar]

- Juan, T.; Jinchuan, G.; Jianqiang, W.; Wei, P.; Yang, B.; Kai, H.; Lingzu, H.; Weixiong, W.; Jinhua, S. Photosynthetic characteristics of sugarcane under different irrigation modes. Trans. CSAE 2016, 32, 150–158. (In Chinese) [Google Scholar] [CrossRef]

- McCormick, A.J.; Cramer, M.D.; Watt, D.A. Sink strength regulates photosynthesis in sugarcane. New Phytol. 2006, 171, 759–770. [Google Scholar] [CrossRef] [PubMed]

- Sivanappan, R.K. Chapter 7. Advanced Technologies for sugarcane Cultivation under Micro Irrigation: Tamil Nadu. In Sustainable Micro Irrigation Principles and Practices; Goyal, M.R., Ed.; Apple Academic Press: Waretown, NJ, USA, 2014; pp. 121–145. [Google Scholar]

- De Silva, A.L.C.; de Costa, W.A.J.M. Varietal Variation in Growth, Physiology and Yield of Sugarcane under Two Contrasting Water Regimes. Trop. Agric. Res. 2004, 16, 1–12. [Google Scholar]

- Basnayake, J.; Jackson, P.A.; Inman-Bamber, N.G.; Lakshmanan, P. Sugarcane for water-limited environments. Genetic variation in cane yield and sugar content in response to water stress. J. Exp. Bot. 2012, 63, 6023–6033. [Google Scholar] [CrossRef] [PubMed]

- Surendran, U.; Jayakumar, M.; Marimuthu, S. Low cost drip irrigation: Impact on sugarcane yield, water and energy saving in semiarid tropical agro ecosystem in India. Sci. Total Environ. 2016, 573, 1430–1440. [Google Scholar] [CrossRef] [PubMed]

- Shrivastava, A.K.; Srivastava, A.K.; Solomon, S. Sustaining sugarcane productivity under depleting water resources. Curr. Sci. 2011, 101, 748–754. [Google Scholar]

- Abdel Wahab, D.M. Introduction of fertigation in sugarcane production for optimization of water and fertilizers use. Agric. Sci. 2014, 5, 945–957. [Google Scholar] [CrossRef]

- Inman-Bamber, N.G. Sugarcane water stress criteria for irrigation and drying off. Field Crops Res. 2004, 89, 103–114. [Google Scholar] [CrossRef]

- Smit, M.; Singles, A.; Antwerpen, R.V. Differences in canopy development of two sugarcane cultivars under conditions of water stress: Preliminary results. Proc. S. Afr. Sugar Technol. Assoc. 2004, 78, 149–152. [Google Scholar]

- Kumawat, P.D.; Kacha, D.J.; Dahima, N.U. Effect of crop geometry and drip irrigation levels on sugarcane in South Saurashtra region of India. Indian J. Agric. Res. 2016, 50, 366–369. [Google Scholar] [CrossRef]

- Motiwale, M.P.; Singh, A.B. Effect of Trash Mulch in Economy of Water and Fertilizer Use in Sugarcane; Annual Report; Indian Institute of Sugarcane Research: Lucknow, India, 1971; pp. 23–24. [Google Scholar]

- Oliviera, F.C.; Singels, A. Increasing water use efficiency of irrigated sugarcane production in South Africa through better agronomic practices. Field Crops Res. 2015, 176, 87–98. [Google Scholar] [CrossRef]

- Gupta, R.; Singh, P.R. Water management strategies for sustainable socio-economic development of sugarcane farmers. Agric. Eng. Today 2015, 39, 11–19. [Google Scholar]

| Planting Season | Crop Type | Planting Date | Harvesting Date | Rainfall (mm) | Max. T (°C) | Min. T (°C) | Cumulative SR (MJ/m2) |

|---|---|---|---|---|---|---|---|

| Spring | Main crop | April 2013 | March 2014 | 2234 | 15.5–34.8 | 10.3–28.9 | 5460 |

| First ratoon crop | January 2015 | 3599 | 14.9–33.9 | 9.8–28.8 | 4595 | ||

| Second ratoon crop | January 2016 | 2303 | 12.5–33.8 | 6.1–28.8 | 5499 | ||

| Summer | Main crop | October 2013 | January 2015 | 4529 | 14.9–33.9 | 9.8–28.8 | 6604 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gunarathna, M.H.J.P.; Sakai, K.; Nakandakari, T.; Momii, K.; Onodera, T.; Kaneshiro, H.; Uehara, H.; Wakasugi, K. Optimized Subsurface Irrigation System: The Future of Sugarcane Irrigation. Water 2018, 10, 314. https://doi.org/10.3390/w10030314

Gunarathna MHJP, Sakai K, Nakandakari T, Momii K, Onodera T, Kaneshiro H, Uehara H, Wakasugi K. Optimized Subsurface Irrigation System: The Future of Sugarcane Irrigation. Water. 2018; 10(3):314. https://doi.org/10.3390/w10030314

Chicago/Turabian StyleGunarathna, M. H. J. P., Kazuhito Sakai, Tamotsu Nakandakari, Kazuro Momii, Tsuneo Onodera, Hiroyuki Kaneshiro, Hiroshi Uehara, and Kousuke Wakasugi. 2018. "Optimized Subsurface Irrigation System: The Future of Sugarcane Irrigation" Water 10, no. 3: 314. https://doi.org/10.3390/w10030314