Geochemistry, Mineralogy and Microbiology of Molybdenum in Mining-Affected Environments

Abstract

:1. Introduction

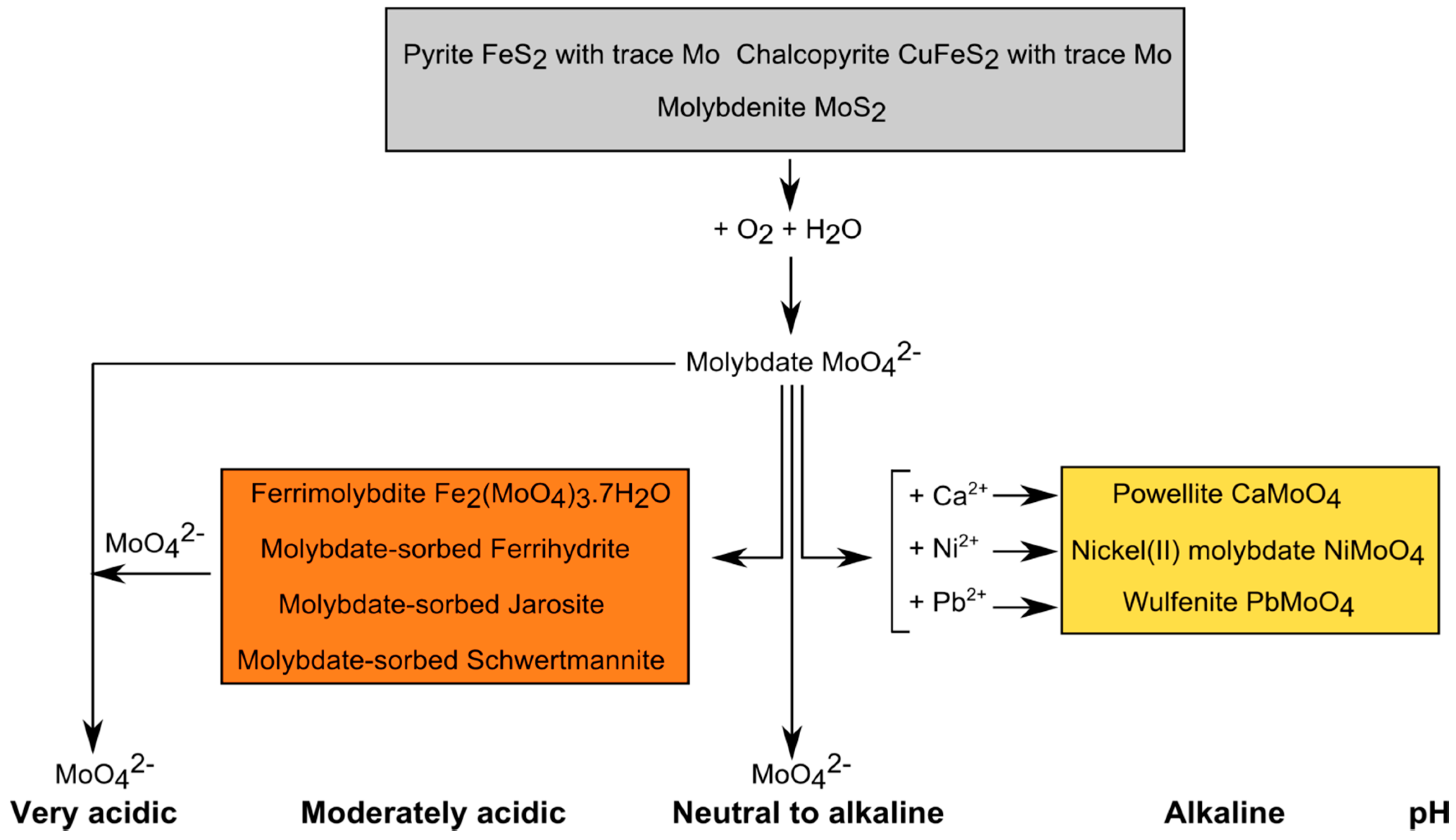

2. Geochemistry of Molybdenum in Mine Wastes

2.1. Molybdenum in Mine Waste Waters

2.2. Molybdenum in Tailings and Mining-Affected Soils and Sediments

2.3. Molybdenum in Mining-Affected Plants

3. Mineralogy of Mo in Mine Wastes

4. Microbiology of Molybdenum in Mine Wastes

5. Geochemical-Mineralogical-Microbiological Controls on Molybdenum Mobility in Mining-Affected Environments

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kropschot, S.J. Molybdenum—A Key Component Of Metal Alloys. USGS Mineral Resources Program Fact Sheet 2009-3106; 2010. Available online: https://pubs.usgs.gov/fs/2009/3106/ (accessed on 23 January 2018).

- International Molybdenum Association (IMOA). Molybdenum Ore Reserves. Available online: http://www.imoa.info/molybdenum/molybdenum-ore-reserves.php (accessed on 9 November 2017).

- Polyak, D.E. Molybdenum. Available online: https://minerals.usgs.gov/minerals/pubs/commodity/molybdenum/mcs-2017-molyb.pdf (accessed on 16 October 2017).

- National Academy of Sciences. Recommended Dietary Allowances, 10th ed.; National Academy Press: Washington, DC, USA, 1989. [Google Scholar]

- Smedley, P.L.; Kinniburgh, D.G. Molybdenum in natural waters: A review of occurrence, distributions and controls. Appl. Geochem. 2017, 84, 387–432. [Google Scholar] [CrossRef]

- Chudy, K.; Marszałek, H.; Kierczak, J. Impact of hard-coal waste dump on water quality—A case study of Ludwikowice Kłodzkie (Nowa Ruda Coalfield, SW Poland). J. Geochem. Explor. 2014, 146, 127–135. [Google Scholar] [CrossRef]

- Sánchez España, J.; González Toril, E.; López Pamo, E.; Amils, R.; Diez Ercilla, M.; Santofimia Pastor, E.; San Martín-Ứriz, P. Biogeochemistry of a hyperacidic and ultraconcentrated pyrite leachate in San Telmo mine (Iberian Pyrite Belt, Spain). Water Air Soil Pollut. 2008, 194, 243–257. [Google Scholar] [CrossRef]

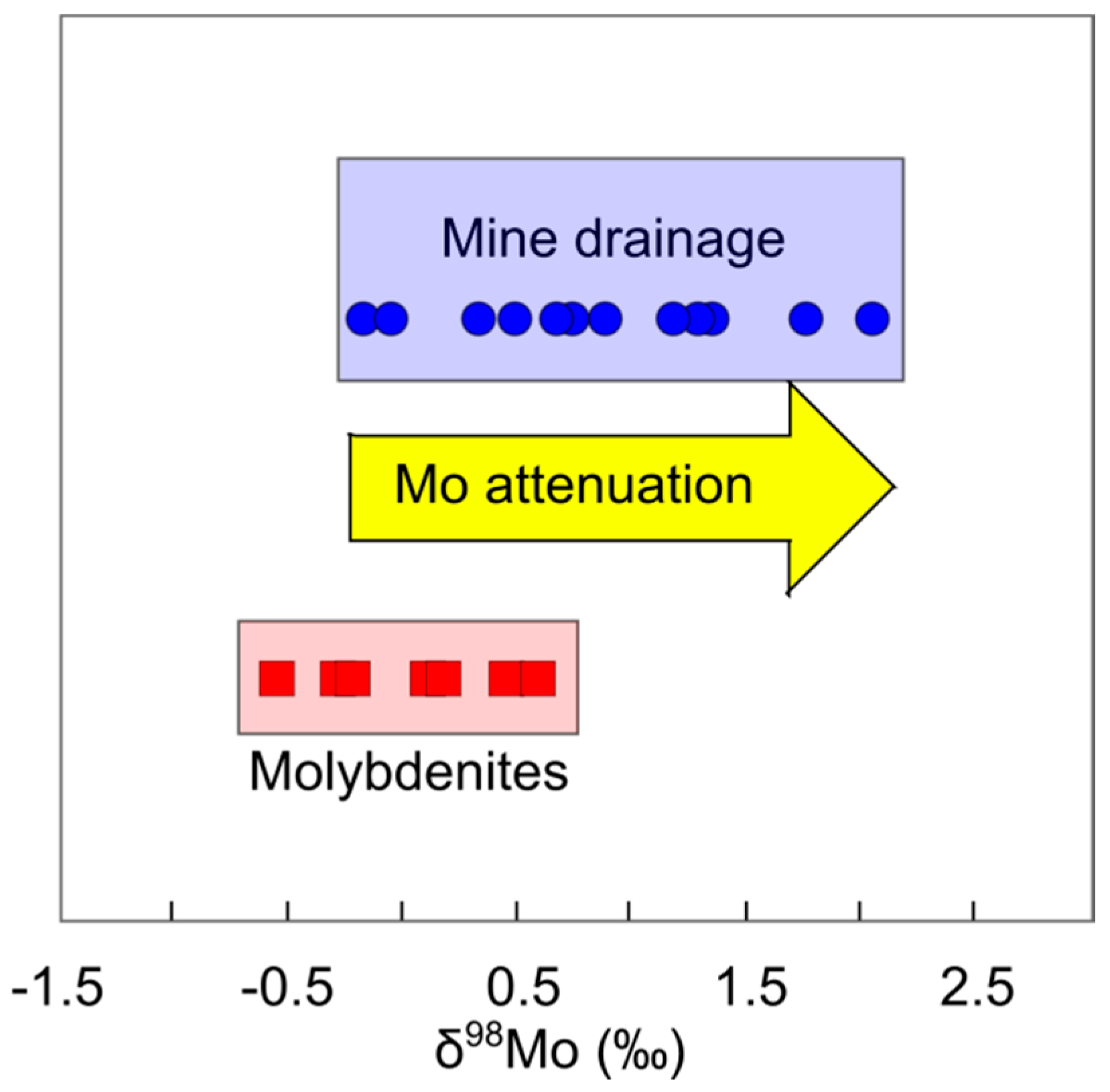

- Skierszkan, E.K.; Mayer, K.U.; Weis, D.; Beckie, R.D. Molybdenum and zinc stable isotope variation in mining waste rock drainage and waste rock at the Antamina mine, Peru. Sci. Total Environ. 2016, 550, 103–113. [Google Scholar] [CrossRef] [PubMed]

- Smuda, J.; Dold, B.; Spangenberg, J.E.; Pfeifer, H.-R. Geochemistry and stable isotope composition of fresh alkaline porphyry copper tailings: Implications on sources and mobility of elements during transport and early stages of deposition. Chem. Geol. 2008, 256, 62–76. [Google Scholar] [CrossRef]

- Lindsay, M.B.J.; Moncur, M.C.; Bain, J.G.; Jambor, J.L.; Ptacek, C.J.; Blowes, D.W. Geochemical and mineralogical aspects of sulfide mine tailings. Appl. Geochem. 2015, 57, 157–177. [Google Scholar] [CrossRef]

- Parviainen, A.; Isoaari, P.; Loukola-Ruskeeniemi, K.; Nieto, J.M.; Gervilla, F. Occurrence and mobility of As in the Ylöjärbi Cu-W-As mine tailings. J. Geochem. Explor. 2012, 114, 36–45. [Google Scholar] [CrossRef]

- Wurl, J.; Mendez-Rodriguez, L.; Acosta-Vargas, B. Arsenic content in groundwater from the southern part of the San Antonio-El Triunfo mining district, Baja California Sur, Mexico. J. Hydrol. 2014, 518, 447–459. [Google Scholar] [CrossRef]

- Alakangas, L.; Öhander, B.; Lundberg, A. Estimation of temporal changes in oxidation rates of sulphides in copper mine tailings at Laver, Northern Sweden. Sci. Total Environ. 2010, 408, 1386–1392. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Sillanpää, M.; Gjessing, E.T.; Peräniemi, S.; Vogt, R.D. Environmental impact of mining activities on the surface water quality in Tibet: Gyama valley. Sci. Total Environ. 2010, 408, 4177–4184. [Google Scholar] [CrossRef] [PubMed]

- Miller, C.A.; Peucker-Ehrenbrink, B.; Walker, B.D.; Marcantonio, F. Re-assessing the surface cycling of molybdenum and rhenium. Geochim. Cosmochim. Acta 2011, 75, 7146–7179. [Google Scholar] [CrossRef]

- Emerson, S.R.; Huested, S.S. Ocean anoxia and the concentrations of molybdenum and vanadium in seawater. Mar. Chem. 1991, 34, 177–196. [Google Scholar] [CrossRef]

- Greber, N.D.; Mäder, U.; Nägler, T. Experimental dissolution of molybdenum-sulphides at low oxygen concentrations: A first-order approximation of late Archean atmospheric conditions. Earth Space Sci. 2015, 2, 173–180. [Google Scholar] [CrossRef] [Green Version]

- World Health Organization (WHO). Molybdenum in Drinking Water; Background Document for Development of WHO Guidelines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2011. [Google Scholar]

- Xu, N.; Braida, W.; Christodoulatos, C.; Chen, J. A Review of Molybdenum Adsorption in Soils/Bed Sediments: Speciation, Mechanism, and Model Applications. Soil Sediment Contam. 2013, 22, 912–929. [Google Scholar] [CrossRef]

- Matthies, R.; Sinclair, S.A.; Blowes, D.W. The zinc stable isotope signature of waster rock drainage in the Canadian permafrost region. Appl. Geochem. 2014, 48, 53–57. [Google Scholar] [CrossRef]

- Aykol, A.; Budakoglu, M.; Kumral, M.; Gultekin, A.H.; Turhan, M.; Esenli, V.; Yavuz, F.; Orgun, Y. Heavy metal pollution and acid drainage from the abandoned Balya Pb-Zn sulfide Mine, NW Anatolia, Turkey. Environ. Geol. 2003, 45, 198–208. [Google Scholar] [CrossRef]

- U.S. Department of the Interior. Water Quality Criteria: Report of the National Technical Advisory Committee to the Secretary of the Interior; Federal Water Pollution Control Administration: Washington, DC, USA, 1968.

- SEPA & AQSIQ (State Environmental Protection Administration of the P.R. China & General Administration of Quality Supervision, Inspection and Quarantine of the P.R. China). Chinese National Standards GB 3838-2002: Environmental Quality Standards for Surface Water; Ministry of environmental protection of the People's Republic of China: Beijing, China, 2002. (In Chinese)

- CCME. Canadian Environmental Quality Guidelines; Canadian Council of Ministers of the Environment: Ottawa, ON, Canada, 2007. Available online: http://www.ccme.ca/en/resources/canadian_environmental_quality_guidelines/index.html (accessed on 8 August 2017).

- U.S. EPA. Standards for Remedial Actions at Inactive Uranium Processing Sites, Federal Register; 40 CFR Part 192; U.S. Environmental Protection Agency: Washington, DC, USA, 1987.

- Rudnick, R.L.; Gao, S. Composition of the continental crust. In Treatise on Geochemistry, 1st ed.; Elsevier: Amsterdam, The Nederland, 2003. [Google Scholar]

- Farago, M.E.; Cole, M.; Xiao, X.; Vaz, M.C. Preliminary assessment of metal bioavailability to plants in the Neves Corvo area of Portugal. Chem. Spec. Bioavail. 1992, 4, 19–27. [Google Scholar] [CrossRef]

- Favas, P.J.C.; Pratas, J.; Gomes, M.E.P.; Cala, V. Selective chemical extraction of heavy metals in tailings and soils contaminated by mining activity: Environmental implications. J. Geochem. Explor. 2011, 111, 160–171. [Google Scholar] [CrossRef]

- Candeias, C.; Melo, R.; Ávila, P.F.; Ferreira da Silva, E.; Salgueiro, A.R.; Teixeira, J.P. Heavy metal pollution in mine-soil-plant system in S. Francisco de Assis—Panasqueira mine (Portugal). Appl. Geochem. 2014, 44, 12–26. [Google Scholar] [CrossRef]

- Khorasanipour, M.; Esmaeilzadeh, E. Environmental characterisation of Sarcheshmeh Cu-smelting slag, Kerman, Iran: Application of geochemistry, mineralogy and single extraction methods. J. Geochem. Explor. 2016, 166, 1–17. [Google Scholar] [CrossRef]

- Khorasanipour, M.; Tangestani, M.H.; Naseh, R.; Majmohammadi, H. Hydrochemistry, mineralogy and chemical fractionation of mine and processing wastes associated with porphyry copper mines: A case study from the Sarcheshmeh mine, Iran. Appl. Geochem. 2011, 26, 714–730. [Google Scholar] [CrossRef]

- Sima, M.; Dold, B.; Frie, L.; Senila, M.; Balteanu, D.; Zobrist, J. Sulfide oxidation and acid mine drainage formation within two active tailings impoundments in the Golden Quadrangle of the Apuseni Mountains, Romania. J. Hazard. Mat. 2011, 189, 624–639. [Google Scholar] [CrossRef] [PubMed]

- Dold, B.; Fontboté, L. Element cycling and secondary mineralogy in porphyry copper tailings as a function of climate, primary mineralogy, and mineral processing. J. Geochem. Explor. 2001, 74, 3–55. [Google Scholar] [CrossRef]

- Smuda, J.; Dold, B.; Spangenberg, J.E.; Friese, K.; Kobek, M.R.; Bustos, C.A.; Pfeifer, H.-R. Element cycling during the transition from alkaline to acidic environment in an active porphyry copper tailings impoundment, Chuquicamata, Chile. J. Geochem. Explor. 2014, 140, 23–40. [Google Scholar] [CrossRef]

- Kelm, U.; Helle, S.; Matthies, R.; Morales, A. Distribution of trace elements in soils surrounding the El Teniente porphyry copper deposit, Chile: The influence of smelter emissions and a tailings deposit. Environ. Geol. 2009, 57, 365–376. [Google Scholar] [CrossRef]

- Pérez Rodríguez, N.; Engström, E.; Rodushkin, I.; Nason, P.; Alakangas, L.; Öhander, B. Copper and iron isotope fractionation in mine tailings at the Laver and Kristineberg mines, northern Sweden. Appl. Geochem. 2013, 32, 204–215. [Google Scholar] [CrossRef]

- Holmström, H.; Salmon, U.J.; Carlsson, E.; Petrov, P.; Öhlander, B. Geochemical investigations of sulfide-bearing tailings at Kristineberg, northern Sweden, a few years after remediation. Sci. Total Environ. 2001, 273, 111–133. [Google Scholar] [CrossRef]

- Langedal, M. Dispersion of tailings in the Knabeåna-Kvina drainage basin, Norway, 1: Evaluation of over bank sediments as sampling medium for regional geochemical mapping. J. Geochem. Explor. 1997, 58, 157–172. [Google Scholar] [CrossRef]

- Lindsay, M.B.J.; Condon, P.D.; Jambor, J.L.; Lear, K.G.; Blowes, D.W.; Ptacek, C.J. Mineralogical, geochemical, and microbial investigation of a sulfide-rich tailings deposit characterized by neutral drainage. Appl. Geochem. 2009, 24, 2212–2221. [Google Scholar] [CrossRef]

- Garrido, T.; Mendoza, J.; Arriagada, F. Changes in the sorption, desorption, distribution, and availability of copper, induced by application of sewage sludge on Chilean soils contaminated by mine tailings. J. Environ. Sci. 2012, 24, 912–918. [Google Scholar] [CrossRef]

- Haque, N.; Peralta-Videa, J.R.; Jones, G.L.; Gill, T.E.; Gardea-Torresdey, J.L. Screening the phytoremediation potential of desert broom (Baccharis sarothroides Gray) growing on mine tailings in Arizona, USA. Environ. Pollut. 2008, 153, 362–368. [Google Scholar] [CrossRef] [PubMed]

- Wang, L. Geochemical modelling for predicting potential solid phases controlling the dissolved molybdenum in coal overburden, Powder River Basin, WY, U.S.A. Appl. Geochem. 1994, 9, 37–43. [Google Scholar] [CrossRef]

- Miller, M.; Gosar, M. Characteristics and potential environmental influences of mine waste in the area of the closed Mežica Pb-Zn mine (Slovenia). J. Geochem. Explor. 2012, 112, 152–160. [Google Scholar] [CrossRef]

- International Mineralogical Association. Available online: https://www.ima-mineralogy.org (accessed on 30 June 2017).

- Abrosimova, N.; Gaskova, O.; Loshkareva, A.; Edelev, A.; Bortnikova, S. Assessment of the acid mine drainage potential of waste rocks at the Ak-Sug porphyry Co-Mo deposit. J. Geochem. Explor. 2015, 157, 1–14. [Google Scholar] [CrossRef]

- Yu, C.; Xu, S.; Gang, M.; Chen, G.; Zhou, L. Molybdenum pollution and speciation in Never River sediments impacted with Mo mining activities in western Liaoning, northeast China. Int. J. Environ. Res. 2011, 5, 205–212. [Google Scholar]

- Petrunic, B.M.; Al, T.A. Mineral/water interactions in tailings from a tungsten mine, Mount Pleasant, New Brunswick. Geochim. Cosmochim. Acta 2005, 69, 2469–2483. [Google Scholar] [CrossRef]

- Jiangang, F.; Kaida, C.; Hui, W.; Chao, G.; Wei, L. Recovering molybdenite from ultra fine waste tailings by oil agglomerate flotation. Miner. Eng. 2012, 39, 133–139. [Google Scholar] [CrossRef]

- Xu, S.; Yu, C.; Hiroshiro, Y. Migration behaviour of Fe, Cu, Zn, and Mo in alkaline tailings from Lanjiagou porphyry molybdenum deposits, northeast China. Mem. Fac. Eng. Kyushu Univ. 2010, 70, 19–31. [Google Scholar]

- Langedal, M. Dispersion of tailings in the Nabeåna-Kvain drainage basin, Norway, 2: Mobility of Cu and Mo in tailings-derived fluvial sediments. J. Geochem. Explor. 1997, 58, 173–183. [Google Scholar] [CrossRef]

- Wedepohl, K.H. Molybdenum 42. In Handbook of Geochemistry II-2; Springer-Verlag Berlin Heidelberg: New York, NY, USA, 1978; ISBN 978-3-642-65935-5. [Google Scholar]

- Conlan, M.J.W. Attenuation mechanisms for molybdenum in neutral rock drainage. Master Thesis, University of British Columbia, Vancouver, BC, Canada, 2009. [Google Scholar]

- Conlan, M.J.W.; Mayer, K.U.; Blaskovich, R.; Beckie, R.D. Solubility controls for molybdenum in neutral rock drainage. Geochem. Explor. Environ. Anal. 2012, 12, 21–32. [Google Scholar] [CrossRef]

- Essilfie-Dughan, J.; Pickering, I.J.; Hendry, M.J.; George, G.N.; Kotzer, T. Molybdenum speciation in uranium mine tailings using X-ray absorption spectroscopy. Environ. Sci. Technol. 2011, 45, 455–460. [Google Scholar] [CrossRef] [PubMed]

- Hayes, J.R.; Grosvenor, A.P.; Rowson, J.; Hughes, K.; Frey, R.A.; Reid, J. Analysis of the Mo speciation in the JEB tailings management facility at McClean Lake, Saskatchewan. Environ. Sci. Technol. 2014, 48, 4460–4467. [Google Scholar] [CrossRef] [PubMed]

- Blanchard, P.E.R.; Hayes, J.R.; Grosvenor, A.P. Investigating the geochemical model for molybdenum mineralization in the JEB tailings management facility at McClean Lake, Saskatchewan: An X-ray absorption spectroscopy study. Environ. Sci. Technol. 2015, 49, 6504–6509. [Google Scholar] [CrossRef] [PubMed]

- Dold, B.; Fontboté, L. A mineralogical and geochemical study of element mobility in sulfide mine tailings of Fe oxide Cu-Au deposits from the Punta del Cobre belt, northern Chile. Chem. Geol. 2002, 189, 135–163. [Google Scholar] [CrossRef]

- Petrunic, B.M.; Al, T.A.; Weaver, L. A transmission electron microscopy analysis of secondary minerals formed in tungsten-mine tailings with an emphasis on arsenopyrite oxidation. Appl. Geochem. 2006, 21, 1259–1273. [Google Scholar] [CrossRef]

- Petrunic, B.M.; Al, T.A.; Weaver, L.; Hall, D. Identification and characterization of secondary minerals formed in tungsten mine tailings using transmission electron microscopy. Appl. Geochem. 2009, 24, 2222–2233. [Google Scholar] [CrossRef]

- Huston, D.L.; Sie, S.H.; Suter, G.F.; Cooke, D.R.; Both, R.A. Trace elements in sulfide minerals from eastern Australian volcanic-hosted massive sulfide deposits; Part I, Proton microprobe analyses of pyrite, chalcopyrite, and sphalerite, and Part II, Selenium levels in pyrite; comparison with delta 34 S values and implications for the source of sulfur in volcanogenic hydrothermal systems. Econ. Geol. 1995, 90, 1167–1196. [Google Scholar] [CrossRef]

- Candeias, C.; Ferreria da Silva, E.; Salgueiro, A.R.; Pereira, H.G.; Reis, A.P.; Patinha, C.; Matos, J.X.; Ávila, P.H. The use of multivariate statistical analysis of geochemical data for assessing the spatial distribution of soil contamination by potentially toxic elements in the Aljustrel mining area (Iberian Pyrite Belt, Portugal). Environ. Earth Sci. 2011, 62, 1461–1479. [Google Scholar] [CrossRef]

- Vaughan, D.J.; Craig, J.R. Mineral Chemistry of the Metal Sulfides; Cambridge University Press: Cambridge, UK, 1978; ISBN 978-0-521-21489-6. [Google Scholar]

- Lottermoser, B. Mine Wastes: Characterization, Treatment and Environmental Impacts, 1st ed.; Springer: Berlin, Germany, 2003; ISBN 978-3-662-05133-7. [Google Scholar]

- Foord, E.E.; Shawe, D.R. The Pb-Bi-Ag-Cu-(Hg) chemistry of galena and some associated sulfosalts. A review and some new data from Colorado California and Pennsylvania. Can. Mineral. 1989, 27, 363–382. [Google Scholar]

- Spiridonov, E.M.; Kachalovskaya, V.M.; Chvileva, T.N. Thallium-bearing hakite, a new fahlore variety. Trans. USSR Acad. Sci. Earth Sci. Sect. 1988, 290, 206–208. [Google Scholar]

- Khorasanipour, M.; Eslami, A. Determination of elements leachability from Sarcheshmeh Porphyry Copper Mine Tailings: Application of toxicity characteristic leaching procedure. Environ. Process. 2014, 1, 387–403. [Google Scholar] [CrossRef]

- Khorasanipour, M.; Tangestani, M.H.; Naseh, R.; Hajmohammadi, H. Chemical fractionation and contamination intensity of trace elements in stream sediments at the Sarcheshmeh Porphyry Copper Mine, SE Iran. Mine Water Environ. 2012, 31, 199–213. [Google Scholar] [CrossRef]

- Dzombak, D.A.; Morel, F.M.M. Surface Complexation Modeling: Hydrous Ferric Oxide; Wiley: New York, NY, USA, 1990. [Google Scholar]

- Parks, G.A. The isoelectric points of solid oxides, solid hydroxides, and aqueous hydroxo complex systems. Chem. Rev. 1965, 65, 177–198. [Google Scholar] [CrossRef]

- Khorasanipour, M.; Eslami, A. Hydrogeochemistry and contamination of trace elements in Cu-porphyry mine tailings: A case study from the Sarcheshmeh Mine, SE Iran. Mine Water Environ. 2014, 33, 335–352. [Google Scholar] [CrossRef]

- Khorasanipour, M. Environmental mineralogy of Cu-porphyry mine tailings, a case study of semi-arid conditions, Sarcheshmeh mine, SE Iran. J. Geochem. Explor. 2015, 153, 40–52. [Google Scholar] [CrossRef]

- Holmström, H.; Ölander, B. Layers rich in Fe- and Mn-oxyhydroxides formed at the tailings-pond water interface, a possible trap for trace metals in flooded mine tailings. J. Geochem. Explor. 2001, 74, 189–203. [Google Scholar] [CrossRef]

- Romero, A.; González, I.; Galán, E. Estimation of potential pollution of waste mining dumps at Peña del Hierro (Pyrite Belt, SW Spain) as a base for future mitigation actions. Appl. Geochem. 2006, 21, 1093–1108. [Google Scholar] [CrossRef]

- Carlson, L.; Bigham, J.M.; Schwertmann, U.; Kyek, A.; Wagner, F. Scavenging of As from acid mine drainage by schwertmannite and ferrihydrite: A comparison with synthetic analogues. Environ. Sci. Technol. 2002, 36, 1712–1719. [Google Scholar] [CrossRef] [PubMed]

- Acero, P.; Ayora, C.; Torrentó, C.; Nieto, J.-M. The behaviour of trace elements during schwertmannite precipitation and subsequent transformation into goethite and jarosite. Geochim. Cosmochim. Acta 2006, 16, 4130–4139. [Google Scholar] [CrossRef]

- Antelo, J.; Fiol, S.; Gondar, D.; López, R.; Arce, F. Comparison of arsenate, chromate and molybdate binding on schwertmannite: Surface adsorption vs anion-exchange. J. Colloid Interface Sci. 2012, 386, 338–343. [Google Scholar] [CrossRef] [PubMed]

- Antelo, J.; Fiol, S.; Gondar, D.; Pérez, C.; López, R.; Arce, F. Cu(II) incorporation to schwertmannite: Effect on stability and reactivity under AMD conditions. Geochim. Cosmochim. Acta 2013, 119, 149–163. [Google Scholar] [CrossRef]

- Bryner, L.C.; Anderson, R. Microorganisms in leaching sulfide minerals. Ind. Eng. Chem. 1957, 49, 1721–1724. [Google Scholar] [CrossRef]

- Bryner, L.C.; Beck, J.V.; Davis, D.B.; Wilson, D.G. Microorganisms in leaching sulfide minerals. Ind. Eng. Chem. 1954, 46, 2587–2592. [Google Scholar] [CrossRef]

- Bryner, L.C.; Jameson, A.K. Microorganisms in leaching sulfide minerals. Appl. Microbiol. 1958, 6, 281–287. [Google Scholar] [PubMed]

- Duncan, D.W.; Walden, C.C.; Trussell, P.C.; Lowe, E.A. Recent advances in the microbiological leaching of sulfides. AIME Trans. 1967, 238, 122–128. [Google Scholar]

- Tuovinen, O.H.; Kelly, D.P. Biology of Thiobacillus ferrooxidans in relation to the microbiological leaching of sulphide ores. Z. Allg. Mikrobiol. 1972, 12, 311–346. [Google Scholar] [CrossRef] [PubMed]

- Imai, K.; Sugio, T.; Tsuchida, T.; Tano, T. Effect of heavy metal ions on the growth and iron-oxidising activity of Thiobacillus ferrooxidans. Agric. Biol. Chem. 1975, 39, 1349–1354. [Google Scholar] [CrossRef]

- Yong, N.K.; Oshima, M.; Blake, R.C.; Sugio, T. Isolation and some properties of an iron-oxidising bacterium Thiobacillus ferrooxidans resistant to molybdenum ion. Biosci. Biotech. Biochem. 1997, 61, 1523–1526. [Google Scholar] [CrossRef]

- Bosecker, K. Bioleaching: Metal solubilization by microorganisms. FEMS Microbiol. Rev. 1997, 20, 591–604. [Google Scholar] [CrossRef]

- Bondici, V.F.; Lawrence, J.R.; Khan, N.H.; Hill, J.E.; Yergeau, E.; Wolfaardt, G.M.; Warner, J.; Korber, D.R. Microbial communities in low permeability, high pH uranium mine tailings: Characterization and potential effects. J. Appl. Microbiol. 2013, 114, 1671–1681. [Google Scholar] [CrossRef] [PubMed]

- Bondici, V.F.; Khan, N.H.; Swerhone, G.D.W.; Dynes, J.J.; Lawrence, J.R.; Yergeau, E.; Wolfaardt, G.M.; Warner, J.; Korber, D.R. Biogeochemical activity of microbial biofilms in the water column overlying uranium mine tailings. J. Appl. Microbiol. 2014, 117, 1079–1094. [Google Scholar] [CrossRef] [PubMed]

- Kauffman, J.W.; Laughlin, W.C.; Baldwin, R.A. Microbiological treatment of uranium mine waters. Environ. Sci. Technol. 1986, 20, 243–248. [Google Scholar] [CrossRef] [PubMed]

- Levine, V.E. The reducing properties of microorganisms with special reference to selenium compounds. J. Bacteriol. 1925, 10, 217–263. [Google Scholar] [PubMed]

- Capaldi, A.; Proskauer, B. Beiträge zur Kenntniss der Säurebildung bei Typhus-bacillen und Bacterium coli. Med. Microbiol. Immunol. 1896, 23, 452–474. [Google Scholar] [CrossRef]

- Othman, A.R.; Bakar, N.A.; Halmi, M.I.E.; Johari, W.L.W.; Ahmad, S.A.; Jirangon, H.; Wyed, M.A.; Shukor, M.Y. Kinetics of molybdenum reduction to molybdenum blue by Bacillus sp. Strain A. rzi. BioMed Res. Int. 2013, 2013, 371058. [Google Scholar] [CrossRef] [PubMed]

- Sabullah, M.K.; Rahman, M.F.; Ahmad, S.A.; Sulaiman, M.R.; Shukor, M.S.; Shamaan, N.A.; Shukor, M.Y. Isolation and characterization of a molybdenum-reducing and glyphosate-degrading Klebsiella oxytoca Strain Saw-5 in soils from Sarawak. Agrivita 2016, 38, 1–13. [Google Scholar] [CrossRef]

- Khan, A.; Halmi, M.I.E.; Shukor, M.Y. Isolation of Mo-reducing bacterium in soils from Pakistan. J. Environ. Microbiol. Toxicol. 2014, 2, 38–41. [Google Scholar]

- Othman, A.R.; Abu Zeid, I.M.; Rahman, M.F.; Ariffin, F.; Shukor, M.Y. Isolation and characterization of a molybdenum-reducing and orange G-decolorizing Enterobacter sp. strain Zeid-6 in soils from Sudan. Bioremediat. Sci. Technol. Res. 2015, 3, 13–19. [Google Scholar]

- Mansur, R.; Gusmanizar, N.; Roslan, M.A.H.; Ahmad, S.A.; Shukor, M.Y. Isolation and characterisation of a molybdenum-reducing and metanil yellow dye-decolourising Bacillus sp. strain Neni-10 in soils from west Sumatera, Indonesia. Trop. Life Sci. Res. 2017, 28, 69–90. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.A.; Shukor, M.Y.; Shamaan, N.A.; MacCormack, W.P.; Syed, M.A. Molybdate reduction to molybdenum blue by an Antarctic bacterium. BioMed Res. Int. 2013, 2013, 871941. [Google Scholar] [CrossRef] [PubMed]

- Abo-Shakeer, L.K.A.; Ahmad, S.S.; Shukor, M.Y.; Shamaan, N.A.; Syed, M.A. Isolation and characterization of a molybdenum-reducing Bacillus pumilus strain Ibna. J. Environ. Microbiol. Toxicol. 2013, 1, 9–14. [Google Scholar]

- Halmi, M.I.E.; Zuhainis, S.W.; Yusof, M.T.; Shaharuddin, N.A.; Helmi, W.; Shukor, Y.; Syed, M.A.; Ahmad, S.A. Hexavalent molybdenum reduction to Mo-Blue by a sodium-dodecyl-sulfate-degrading Klebsiella oxytoca Strain DRY14. BioMed Res. Int. 2013, 2013, 384541. [Google Scholar] [CrossRef] [PubMed]

- Goldberg, S.; Forster, H.S.; Godfrey, C.L. Molybdenum adsorption on oxides, clay minerals, and soils. Soil Sci. Soc. Am. J. 1996, 60, 425–432. [Google Scholar] [CrossRef]

- Xu, N.; Christodoulatos, C.; Braida, W. Adsorption of molybdate and tetrathiomolybdate onto pyrite and goethite: Effect of pH and competitive anions. Chemosphere 2006, 62, 1726–1735. [Google Scholar] [CrossRef] [PubMed]

| Mine | Ore Type | Mine Activity | Type | Mean or Range Mo Concentration (µg/L) | Reference |

|---|---|---|---|---|---|

| 13 historic mines within the San Antonio-El Triunfo district, Mexico | Au-Ag-Pb-Zn-As | 1878–1911 | Groundwater | <5–150 | Wurl et al. [12] |

| Ylöjärvi mine, Finland | Cu-W-As | 1943–1966 | Groundwater 8.4 m from tailings surface | 32.3 | Parviainen et al. [11] |

| Laver mine, Sweden | Cu-Ag-Au | 1936–1946 | Gräbergsbäcken brook, 2004–2005, dissolved fraction (<0.22 μm) | 0.3 | Alakangas et al. [13] |

| Gyama Cu-polymetallic plant, central Tibet | Cu-polymetallic | mid-15th century; 1990–present | River water | 0.6–9.7 | Huang et al. [14] |

| Balya mine, Turkey | Pb-Zn-Ag | early 1880s–late 1940s | Kocacay river water arid | 1.12; 1.28 | Aykol et al. [21] |

| San Telmo mine, Iberian Pyrite Belt, Spain | Cu | 1970–1989 | Acid mine drainage, leachate, pH 0.16–0.82 | 10,400 | Sánchez-España et al. [7] |

| Antamina mine, Peru | Cu-Zn-Mo | 2002–present | Mine drainage, pH 2.2–8.4, median 7.9 | 10–13,900 | Skierszkan et al. [8] |

| Machalí, Cachapoal Province, Chile | Cu porphyry | 1819–present | Tailings impoundment channel water | 2670–3900 | Smuda et al. [9] |

| Nickel Rim mine, Sudbury, Canada | Ni-Cu | 1953–1958 | Tailings pore water | <0.005 | Lindsay et al. [10] |

| Ylöjärvi mine, Finland | Cu-W-As | 1943–1966 | Tailings pore water | 1.28–209 | Parviainen et al. [11] |

| Greens Creek mine, Alaska, USA | Zn-Ag-Pb-Au | 1989–1993; 1996–present | Vadose zone pore-water; tailings pore-water | <5–15; <5–1900 | Lindsay et al. [10] |

| Sherridon mine, Manitoba, Canada | Zn-Cu-Au-Ag | 1930–1932; 1937–1951 | Tailings pore water | <5–1100 | Lindsay et al. [10] |

| Nowa Ruda Coalfield mine, Poland | Coal | n.r. | Deionised water extracts of mine waste | 2,332,000 | Chudy et al. [6] |

| Guideline values for Mo | |||||

| Type of limit | Value (µg/L) | Organisation | Reference | ||

| Drinking water | 70 | World Health Organization | WHO [18] | ||

| Irrigation water in all soils | 5 | US Department of the Interior | US Department of the Interior [22] | ||

| Surface water | 70 | SEPA & AQSIQ, China | SEPA & AQSIQ [23] | ||

| Protection of aquatic life in freshwater | 73 | Canada | CCME [24] | ||

| Groundwater standard for inactive uranium mines | 100,000 | US EPA | US EPA [25] | ||

| Mine | Ore Type | Mine Activity | Type | Mean Concentration (mg/kg) | Reference |

|---|---|---|---|---|---|

| Apuseni mine, Romania | Au-Ag-Te epithermal | 1986–2006 | Primary non-oxidised tailings | 12 | Sima et al. [32] |

| Carén tailings impoundment, Machalí, Cachapoal Province, Chile | Cu porphry | 1819–present | Cemented tailings | 101 | Smuda et al. [9] |

| La Andina mine, Chile | Cu porphyry | 1970–1980 | Tailings in E2 impoundment | 278 | Dold and Fontboté [33] |

| Chuquicamata mine, Chile | Cu porphyry | n.r. | Fresh tailings solids | 260 | Smuda et al. [34] |

| Caletones smelter and unused Baraho, Chile | Cu-Mo porphyry | 16th century; 1905–present | Tailings sediments | 179 | Kelm et al. [35] |

| Laver mine, Sweden | Cu-Au-Ag | 1936–1946 | Oxidized zone tailings (0–99 cm); unoxidised zone tailings (100–130 cm) | 38.3; 24.3 | Perez Rodriguez et al. [36] |

| San Telmo mine, Iberian Pyrite Belt, Spain | Cu | 1970–1989 | Tailings | 148 | Sánchez-España et al. [7] |

| Gyama valley, central Tibet | Cu-polymetallic | Mid-15th century; 1990–present | Tailings | 3985 | Huang et al. [14] |

| Kristineberg mine, Sweden | Cu-Zn | Unknown–early 1950s | Oxidized tailings; unoxidized tailings | 17.7; 24 | Holmstrom et al. [37] |

| Knaben mine, Sweden | Mo | 1918–1973 | Tailings pond | 51 | Langedal [38] |

| Greens Creek mine, Alaska, USA | Zn-Ag-Pb-Au | 1989–1993; 1996–present | Tailings | 49.5–76.3 | Lindsay et al. [39] |

| Mine | Ore Type | Mine Activity | Type | Mean or Range Concentration (mg/kg) | Reference |

|---|---|---|---|---|---|

| 6th Region of Chile | Cu | n.r. | Soil 2 km from tailings impoundment | 74 | Garrido et al. [40] |

| Sarcheshmeh mine, Iran | Cu | Unknown–present | Top 0–5 cm soil around slag dump | 19.4–138.6 | Khorasanipour & Esmaeilzadeh [30] |

| Neves Corvo mine, Portugal | Cu-Pb-Zn | 1988–present | Soils <250 m from mine | 3.76 | Farago et al. [27] |

| Globe-Miami mining district, Arizona, USA | Cu and other metals | n.r. | Soil | 112 | Haque et al. [41] |

| Powder River Basin, Wyoming, USA | Coal | n.r. | Soil near mine sites | 13.5–20 | Wang [42] |

| Ervedosa mine, Portugal | Sn-As | Phoenician, Roman, 1928–1969 | Mine tailings and soils | 5.91 | Favas et al. [28] |

| Panasqueira mine, Spain | Sn-W | 1896–present | Rhizosphere soil | 0.6 | Candeias et al. [29] |

| Knaben Mo mines, Sweden | Mo | 1918–1973 | Top section of overbank sediments | 137 | Langedal [38] |

| Knaben Momines, Sweden | Mo | 1918–1973 | 0–25 cm floodplain sediments | 60 | Langedal [38] |

| Knaben Mo mines, Sweden | Mo | 1918–1973 | Sandbars | 93 | Langedal [38] |

| Gyama Cu-polymetallic plant, central Tibet | Cu-polymetallic | mid-15th century; 1990–present | Sediment | 9.1–20.1 | Huang et al. [14] |

| Mezica mining district, Slovenia | Pb-Zn | 300 years up to 1995 | River sediments | 130 | Miller & Gosar [43] |

| Sarcheshmeh mine, Iran | Cu | n.r. | Sediment associated with concentration plant effluents | 1950 | Khorasanipour et al. [31] |

| Mine | Ore Type | Type | Mean or Range Mo Concentration (mg/kg) | Reference |

|---|---|---|---|---|

| Globe-Miami mining district, Arizona, USA | Cu and other metals | Roots of desert broom (Baccharis sarothroides) | 73.9 | Haque et al. [41] |

| Shoots | 105.8 | |||

| Neves Corvo mine, Portugal | Cu-Pb-Zn | Quercus leaves | 0.29–1.1 | Farago et al. [27] |

| Quercus twigs | 0.34–0.98 | |||

| Cistus tops | 0.35–1.08 |

| Mineral | Composition | References |

|---|---|---|

| Ferrihydrite | (Fe3+)2O3·0.5H2O | Essilfie-Dughan et al. [54]; Hayes et al. [55]; Blanchard et al. [56] |

| Ferrimolybdite | Fe2(MoO4)3·7H2O | Langedal [50]; Hayes et al. [55]; Blanchard et al. [56] |

| Jorsidite | MoS2 | Dold and Fontboté [33]; Dold and Fontbotè [57] |

| Molybdenite | MoS2 | Abrosimova et al. [45]; Sima et al. [32]; Smuda et al. [9,34]; Yu et al. [46]; Langedal [50]; Khorasanipour et al. [31]; Petrunic and al [47]; Petrunic et al. [58]; Blanchard et al. [56] |

| Molybdite | MoO3 | Abrosimova et al. [45] |

| Nickel(II) molybdate | NiMoO4 | Essilfie-Dughan et al. [54] |

| Powellite | CaMO4 | Conlan et al. [53]; Langedal [50]; Hayes et al. [55]; Blanchard et al. [56] |

| Tugarinovite | MoO2 | Abrosimova et al. [45] |

| Wulfenite | PbMoO4 | Conlan et al. [53]; Petrunic et al. [58]; Petrunic [59] |

| Mineral | Composition | References |

|---|---|---|

| Fe oxyhydroxides | FeOOH | Favas et al. [28]; Holmstrom and Ohlander [72]; Romero et al. [63]; Khorasanipour et al. [31]; Khorasanipour and Eslami [66] |

| Pyrite | FeS2 | Lindsay et al. [39]; Candeias et al. [61]; Khorasanipour et al. [31]; Khorasanipour and Eslami [66,70]; Khorasanipour [71] |

| Chalcopyrite | CuFeS2 | Khorasanipour and Eslami [66,70]; Khorasanipour et al. [31]; Khorasanipour [71] |

| Jarosite | KFe3(OH)6(SO4)2 | Romero et al. [73]; Smuda et al. [34]; Khorasanipour [71] |

| Schwertmannite | Fe8O8(OH)6(SO4)·nH2O | Dold and Fontboté [33] |

| Langedal [50] | Dold and Fontboté [33] | Khorasanipour et al. [31] | |||||

|---|---|---|---|---|---|---|---|

| Fraction: Reagents | Mineral Attribution | Fraction: Reagents | Mineral Attribution | Fraction: Reagents | |||

| (1) | Bioavailable: 30 mL 0.01 M BaCI2 | (1) | Water soluble: 1 g of sample into 50 mL of deionized H20, shake for 1 h | water-soluble sulfates, e.g., gy, bonattite, chalcantite | (1) | Water soluble: 1 g of air dried solid sample into 50 mL of de-ionized H2O and shaken for 2 h at room temperature | |

| (2) | Adsorbed/ion exchangeable: 30 mL 1 M NH4OA | (2) | Exchangeable: 1 M NH4-Acetate pH 4.5, shake for 2 h at room temperature | ca, vermiculite-type-mixed-layer, exchangeable ions | (2) | Exchangeable: 1 M NH4OAc at pH 7, continuous shaking for 2 h at room temperature | |

| (3) | Acid-soluble or carbonates: at room temperature with a 50 mL buffered acetic acid/sodium acetate solution (adjusted to pH 5 with HOAc) for 4 h, with continuous stirring. | ||||||

| (4) | Reducible: 40 mL oxalic acid /ammonium oxalate | ||||||

| (3) | Fe(III)oxy-hydroxides: 0.2 M NH4-oxalate pH 3.0, shake for 1 h in darkness | sh, 2-line fh, secondary jt, MnO2 | (5) | amorphous Fe oxides: 50 mL of 0.2 M NH4 oxalate (NH4C2O4), adjusted to pH 3 with 0.2-M oxalic acid (H2C2O4), and shaken for 4 h in darkness at ambient temperature. | |||

| (4) | Fe(III)oxides: 0.2 M NH4-oxalate pH3.0, heat in water bath 80°C for 2 h | gt, jt, Na-jt, hm, mt, higher ordered fh | (6) | crystalline Fe oxide phases: 50 mL of 0.2 M NH4C2O4, adjusted to pH 3.3 with a 0.1-M solution of ascorbic acid, at 100 °C for 30 min. | |||

| (3) | Oxidisable: (a) 10 mL 30% H202; (b) 40 mL 1 M NH4OAc | Sulfides, organic matter | (5) | Organics and secondary Cu-sulfides: H2O2 35%, heat in water bath for 1h | organic, cv, cc-, dg | (7) | Oxidisable (organic matter): 30% H2O2 (adjusted to pH 2 by use of 0.02-M HNO3), and continuously shaken for 3 h at 85 °C. |

| (6) | Primary sulfides: Combination of KClO3 and HCl, followed by 4 M HNO3 boiling | py, cp, cc, bn, sl, gn, tt, cb, op, stbp | (8) | Primary sulfides: combination of KClO3 and HCl, followed by 4 M HNO3 at boiling point. | |||

| (5) | Residual: 2.6 mL HCI + 0.9 mL HNO3 | Micas, amphiboles | (7) | Residual: HNO3, HF, HClO4, HCl digestion | Silicates | (9) | Residual: digestion with HNO3, HClO4, HF and HCl. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frascoli, F.; Hudson-Edwards, K.A. Geochemistry, Mineralogy and Microbiology of Molybdenum in Mining-Affected Environments. Minerals 2018, 8, 42. https://doi.org/10.3390/min8020042

Frascoli F, Hudson-Edwards KA. Geochemistry, Mineralogy and Microbiology of Molybdenum in Mining-Affected Environments. Minerals. 2018; 8(2):42. https://doi.org/10.3390/min8020042

Chicago/Turabian StyleFrascoli, Francesca, and Karen A. Hudson-Edwards. 2018. "Geochemistry, Mineralogy and Microbiology of Molybdenum in Mining-Affected Environments" Minerals 8, no. 2: 42. https://doi.org/10.3390/min8020042