Influential Factors in Transportation and Mechanical Properties of Aeolian Sand-Based Cemented Filling Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Aeolian Sand

2.1.2. Fly Ash

2.1.3. Cement

2.1.4. Lime–Slag

2.2. Cemented Filling Material Preparation and Performance Test

2.3. Microstructural Analysis

3. Results and Discussion

3.1. Analysis of Factors Affecting Macroscopic Properties of Cemented Filling Materials

3.1.1. Effects of Fly Ash Content on Properties of Filling Material

Effect of Fly Ash Content on Transportation Properties of Filling Material

Effect of Fly Ash Content on Mechanical Properties of Filling Material

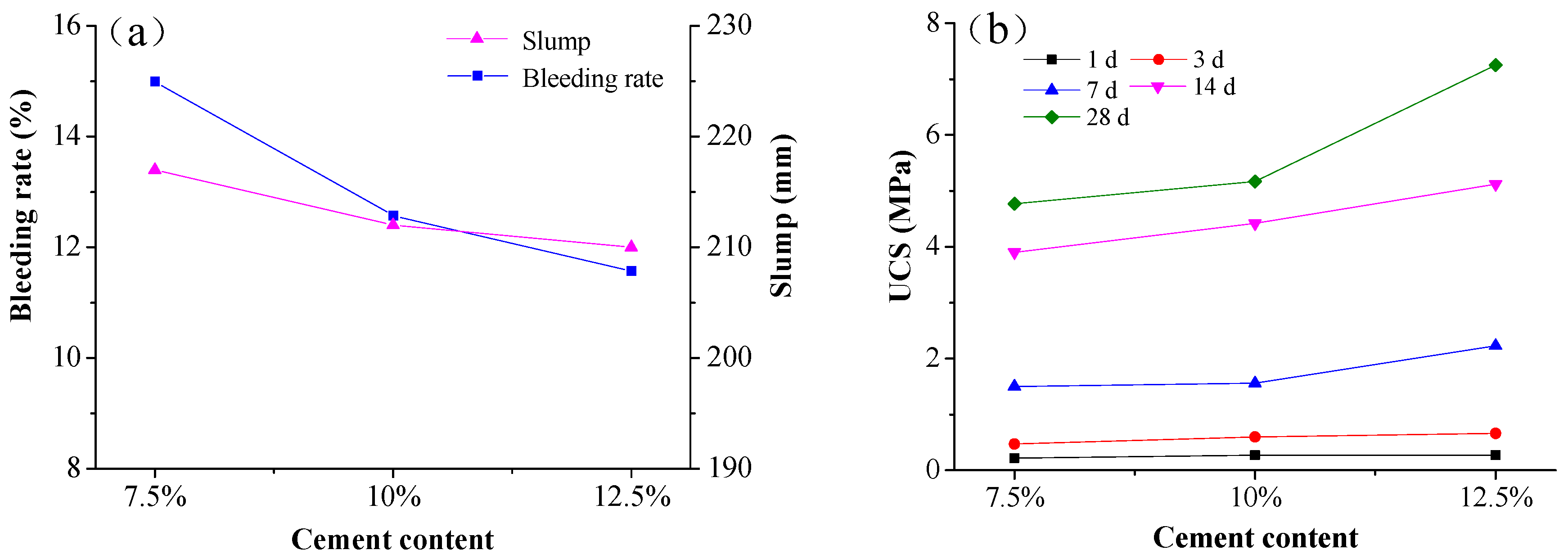

3.1.2. Effects of Cement Content on Properties of Filling Material

Effect of Cement Content on Transportation Properties of Filling Material

Effect of Cement Content on Mechanical Properties of Filling Material

3.1.3. Effects of Lime–Slag Content on Properties of Filling Material

Effect of Lime–Slag Content on Transportation Properties of Filling Material

Effect of Lime–Slag Content on Mechanical Properties of Filling Material

3.1.4. Effects of Concentration on Properties of Filling Material

Effect of Concentration on Transportation Properties of Filling Material

Effect of Concentration on Mechanical Properties of Filling Material

3.2. Feasibility Analysis of Cemented Filling Material Based on Aeolian Sand

3.3. Developing Characteristics of Early Microstructure in Filled Object

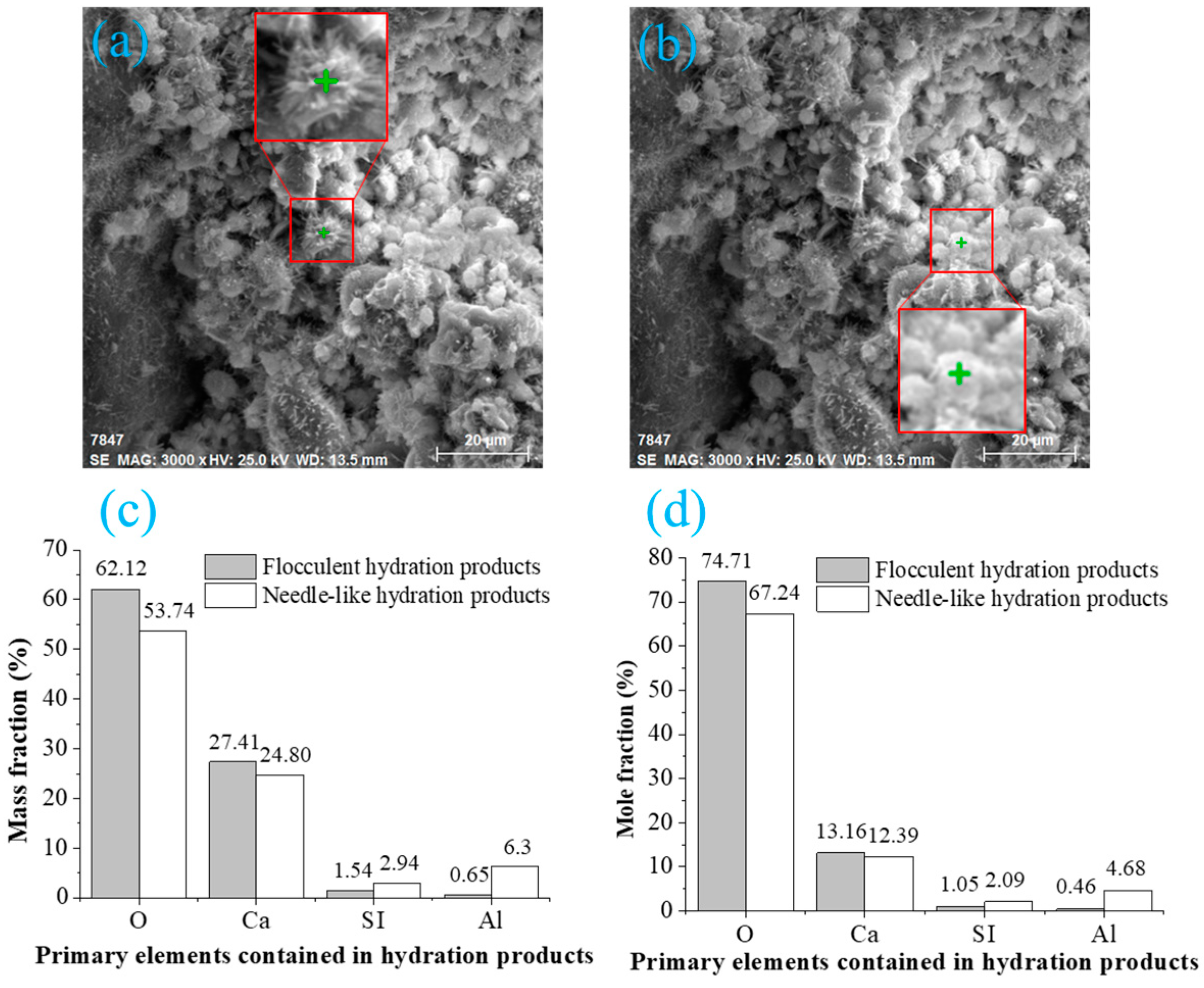

3.3.1. Results of SEM Analysis

Filled Object for a Curing Time of 3 Days

Filled Object for a Curing Time of 7 Days

3.3.2. Results of Energy Dispersive Spectrometer (EDS) Analysis

3.3.3. EDS Spot Element Testing of Hydration Products in Filled Objects for a Curing Time of 7 Days

3.3.4. EDS Surface Element Testing of Hydration Products in Filled Objects for Various Curing Times

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Jiang, H.; Deng, X.; Ju, F. Prediction of the Height of the Water-Conducting Zone Above the Mined Panel in Solid Backfill Mining. Mine Water Environ. 2014, 33, 317–326. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.; Sun, Q.; Gao, R.; Germain, D.; Abro, S. Surface subsidence control theory and application to backfill coal mining technology. Environ. Earth Sci. 2015, 74, 1439–1448. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Y.; Wang, M.; Tian, F.; Ao, J. Effect of mining subsidence on soil erosion in mountainous area of the Loess Plateau. Trans. Chin. Soc. Agric. Eng. 2014, 30, 228–235. [Google Scholar]

- Yan, H.; Zhang, J.; Zhou, N.; Zhang, S.; Dong, X. Shaft failure characteristics and the control effects of backfill body compression ratio at ultra-contiguous coal seams mining. Environ. Earth Sci. 2018, 77, 458. [Google Scholar] [CrossRef]

- Zhou, N.; Han, X.; Zhang, J.; Li, M. Compressive deformation and energy dissipation of crushed coal gangue. Powder Technol. 2016, 297, 220–228. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Taheri, A.; Zhang, W.; Wu, Z.; Song, W. Properties and application of backfill materials in coal mines in china. Minerals 2019, 9, 53. [Google Scholar] [CrossRef]

- Zhou, N.; Li, M.; Zhang, J.; Gao, R. Roadway backfill method to prevent geohazards induced by room and pillar mining: A case study in Changxing coal mine, China. Nat. Hazards Earth Syst. Sci. 2016, 16, 2473–2484. [Google Scholar] [CrossRef]

- Deng, X.J.; Klein, B.; Hallbom, D.J.; Wit, B.D.; Zhang, J.X. Influence of Particle Size on the Basic and Time-Dependent Rheological Behaviors of Cemented Paste Backfill. J. Mater. Eng. Perform. 2018, 27, 3478–3487. [Google Scholar] [CrossRef]

- Feng, G.R.; Ren, Y.F.; Zhang, X.Y.; Guo, Y.X.; Kang, L.X. The activating experimental research of fly ash for mining filling material in Tashan Mine. J. China Coal Soc. 2011, 36, 732–737. [Google Scholar]

- Ercikdi, B.; Cihangir, F.; Kesimal, A.; Deveci, H.; Alp, İ. Utilization of industrial waste products as pozzolanic material in cemented paste backfill of high sulphide mill tailings. J. Hazard. Mater. 2009, 168, 848–856. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.X.; Lan, M.; Xiao, S.Y.; Guo, H.Q. Damage failure of cemented backfill and its reasonable match with rock mass. Trans. Nonferrous Met. Soc. China 2015, 25, 954–959. [Google Scholar] [CrossRef]

- Wu, J.; Feng, M.; Chen, Z.; Mao, X.; Han, G.; Wang, Y. Particle size distribution effects on the strength characteristic of cemented paste backfill. Minerals 2018, 8, 322. [Google Scholar] [CrossRef]

- Huynh, L.; Beattie, D.A.; Fornasiero, D.; Ralston, J. Effect of polyphosphate and naphthalene sulfonate formaldehyde condensate on the rheological properties of dewatered tailings and cemented paste backfill. Miner. Eng. 2006, 19, 28–36. [Google Scholar] [CrossRef]

- Deng, X.; Klein, B.; Tong, L.; de Wit, B. Experimental study on the rheological behavior of ultra-fine cemented backfill. Constr. Build. Mater. 2018, 158, 985–994. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Song, W. Evaluation of viscosity, strength and microstructural properties of cemented tailings backfill. Minerals 2018, 8, 352. [Google Scholar] [CrossRef]

- Xu, W.; Cao, P.; Tian, M. Strength development and microstructure evolution of cemented tailings backfill containing different binder types and contents. Minerals 2018, 8, 167. [Google Scholar] [CrossRef]

- Taheri, A.; Tatsuoka, F. Small– and large–strain behaviour of a cement–treated soil during various loading histories and testing conditions. Acta Geotech. 2015, 10, 131–155. [Google Scholar] [CrossRef]

- Taheri, A.; Tatsuoka, F. Stress–strain relations of cement-mixed gravelly soil from multiple-step triaxial compression test results. Soils Found. 2012, 52, 748–766. [Google Scholar] [CrossRef]

- Niroshan, N.; Yin, L.; Sivakugan, N.; Veenstra, R.L. Relevance of SEM to Long-Term Mechanical Properties of Cemented Paste Backfill. Geotech. Geol. Eng. 2018, 36, 2171–2187. [Google Scholar] [CrossRef]

- Cao, S.; Song, W.; Yilmaz, E. Influence of structural factors on uniaxial compressive strength of cemented tailings backfill. Constr. Build. Mater 2018, 174, 190–201. [Google Scholar]

- Deng, X.J.; Zhang, J.X.; Zhou, N.; Wit, B.D.; Wang, C.T. Upward slicing longwall-roadway cemented backfilling technology for mining an extra-thick coal seam located under aquifers: A case study. Environ. Earth Sci. 2017, 76, 789. [Google Scholar] [CrossRef]

- Yu, Y. Development for the New Backfilling Cementing Materials and Research on Its Properties in Coal Mine. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, June 2017. [Google Scholar]

- Wang, Q.; Jin, W.U. The impact of embedded length on bond performance between fly ash concrete and steel bars. Sichuan Build. Sci. 2013, 38, 179–182. [Google Scholar]

- Yang, J.; Fan, N.; Meishu, J.I. Experimental study on recycled concrete bonding performance of different fly ash replacement rate. Concrete 2013, 39, 36–39. [Google Scholar]

- Gu, Q. Mixing Proportion of Paste-like Filling Material based on Back-propagation Neural Network. Met. Mine 2016, 45, 40–43. [Google Scholar]

- Liang, Q.U.; Chen, D.X.; Yang, X.B.; Wang, Y.D. Test on filling characteristics of mixed aggregate of waste rock and copper slag tailings in Jinchuan Mine. Ind. Miner. Process. 2018, 47, 51–54. [Google Scholar]

- Maohui, L.I.; Yang, Z.; Qian, G.; Wang, Y. Discussion on exploitation of new backfilling cementing materials with unclassified tailings and associated hydration mechanisms. J. Hohai Univ. 2015, 43, 335–340. [Google Scholar]

- Yang, B.; Yang, J.; Yu, Y.; Li, D.; Jiang, B.; Cheng, K. Study on proportioning test of a new cementing filling material and hydration mechanism. J. Min. Sci. Technol. 2017, 2, 475–481. [Google Scholar]

- Jie, L.; Zhang, F.; Gang, L.; Ma, Y.; Hua, T.; Zhang, J.; Le, L. The Study on Modification of Quicklime to Fly Ash-Gypsum Composites. Non-Met. Mines 2016, 39, 52–54. [Google Scholar]

- Zhao, Y.; Soltani, A.; Taheri, A.; Karakus, M.; Deng, A. Application of Slag–Cement and fly ash for strength development in cemented paste backfills. Minerals 2019, 9, 22. [Google Scholar] [CrossRef]

- Li, T.; He, X.; Xie, H.; Zhou, X. Experimental study on composite admixture of electrolytic manganese residue-quicklime-low grade fly ash. New Build. Mater. 2007, 34, 66–69. [Google Scholar]

- Bo, Y.; Kang, T.; Kang, J.; Chen, Y. Experimental and Mechanistic Research on Enhancing the Strength and Deformation Characteristics of Fly-Ash-Cemented Filling Materials Modified by Electrochemical Treatment. Energy Fuels 2018, 32, 3614–3626. [Google Scholar]

- Shao, Y.; Guo, L.; Chen, Y.; Hou, G. Determination of conveying parameters of coarse aggregate paste filling slurry pipeline based on annular tube test. Nonferrous Met. 2018, 70, 20–23. [Google Scholar]

- Ouellet, S.; Bussière, B.; Aubertin, M.; Benzaazoua, M. Characterization of cemented paste backfill pore structure using SEM and IA analysis. Bull. Eng. Geol. Environ. 2008, 67, 139–152. [Google Scholar] [CrossRef]

- Ouyang, X.; Ye, G.; Breugel, K.V. Experimental and numerical evaluation of mechanical properties of interface between filler and hydration products. Constr. Build. Mater. 2017, 135, 538–549. [Google Scholar] [CrossRef]

- Joseph, S.; Bishnoi, S.; Van Balen, K.; Cizer, Ö. Modeling the effect of fineness and filler in early-age hydration of tricalcium silicate. J. Am. Ceram. Soc. 2016, 100, 1178–1194. [Google Scholar] [CrossRef]

| Samples | Na2O | MgO | Al2O3 | SiO2 | K2O | CaO | Fe2O3 | Others |

|---|---|---|---|---|---|---|---|---|

| AS | 2.22 | 1.3 | 8.75 | 67.49 | 2.86 | 5.78 | 4.35 | 7.25 |

| FA | 1.31 | 1.62 | 26.69 | 41.29 | 0.94 | 8.73 | 5.21 | 14.21 |

| Test Group | Test No. | Concentration (Solid Content) [wt. %] | Water Content [wt. %] | Solids Content Composition [wt. %] | |||

|---|---|---|---|---|---|---|---|

| Fly Ash | Cement | Lime Slag | Aeolian Sand | ||||

| A | A1 | 72 | 28 | 42.5 | 12.5 | 5 | 40 |

| A2 | 72 | 28 | 47.5 | 12.5 | 5 | 35 | |

| A3 | 72 | 28 | 52.5 | 12.5 | 5 | 30 | |

| B | B1 | 72 | 28 | 47.5 | 7.5 | 5 | 40 |

| B2 | 72 | 28 | 47.5 | 10 | 5 | 37.5 | |

| B3 | 72 | 28 | 47.5 | 12.5 | 5 | 35 | |

| C | C1 | 72 | 28 | 47.5 | 12.5 | 0 | 40 |

| C2 | 72 | 28 | 47.5 | 12.5 | 5 | 35 | |

| C3 | 72 | 28 | 47.5 | 12.5 | 10 | 30 | |

| D | D1 | 72 | 28 | 47.5 | 12.5 | 5 | 35 |

| D2 | 74 | 26 | 47.5 | 12.5 | 5 | 35 | |

| D3 | 76 | 24 | 47.5 | 12.5 | 5 | 35 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, N.; Ma, H.; Ouyang, S.; Germain, D.; Hou, T. Influential Factors in Transportation and Mechanical Properties of Aeolian Sand-Based Cemented Filling Material. Minerals 2019, 9, 116. https://doi.org/10.3390/min9020116

Zhou N, Ma H, Ouyang S, Germain D, Hou T. Influential Factors in Transportation and Mechanical Properties of Aeolian Sand-Based Cemented Filling Material. Minerals. 2019; 9(2):116. https://doi.org/10.3390/min9020116

Chicago/Turabian StyleZhou, Nan, Haobin Ma, Shenyang Ouyang, Deon Germain, and Tao Hou. 2019. "Influential Factors in Transportation and Mechanical Properties of Aeolian Sand-Based Cemented Filling Material" Minerals 9, no. 2: 116. https://doi.org/10.3390/min9020116