Sustainable Machining: MQL Technique Combined with the Vortex Tube Cooling When Turning Martensitic Stainless Steel X20Cr13

Abstract

:1. Introduction

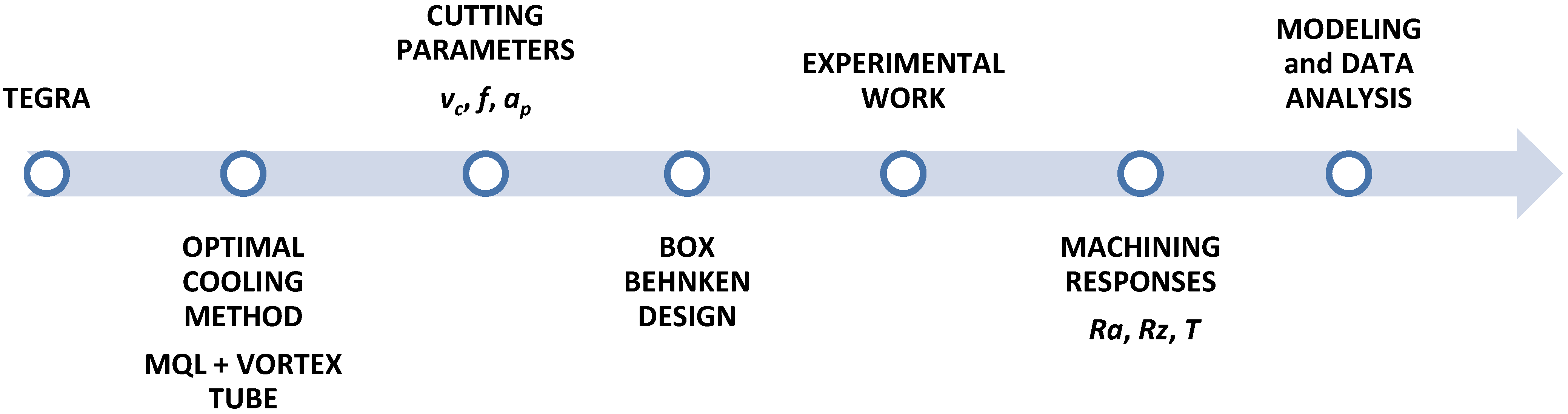

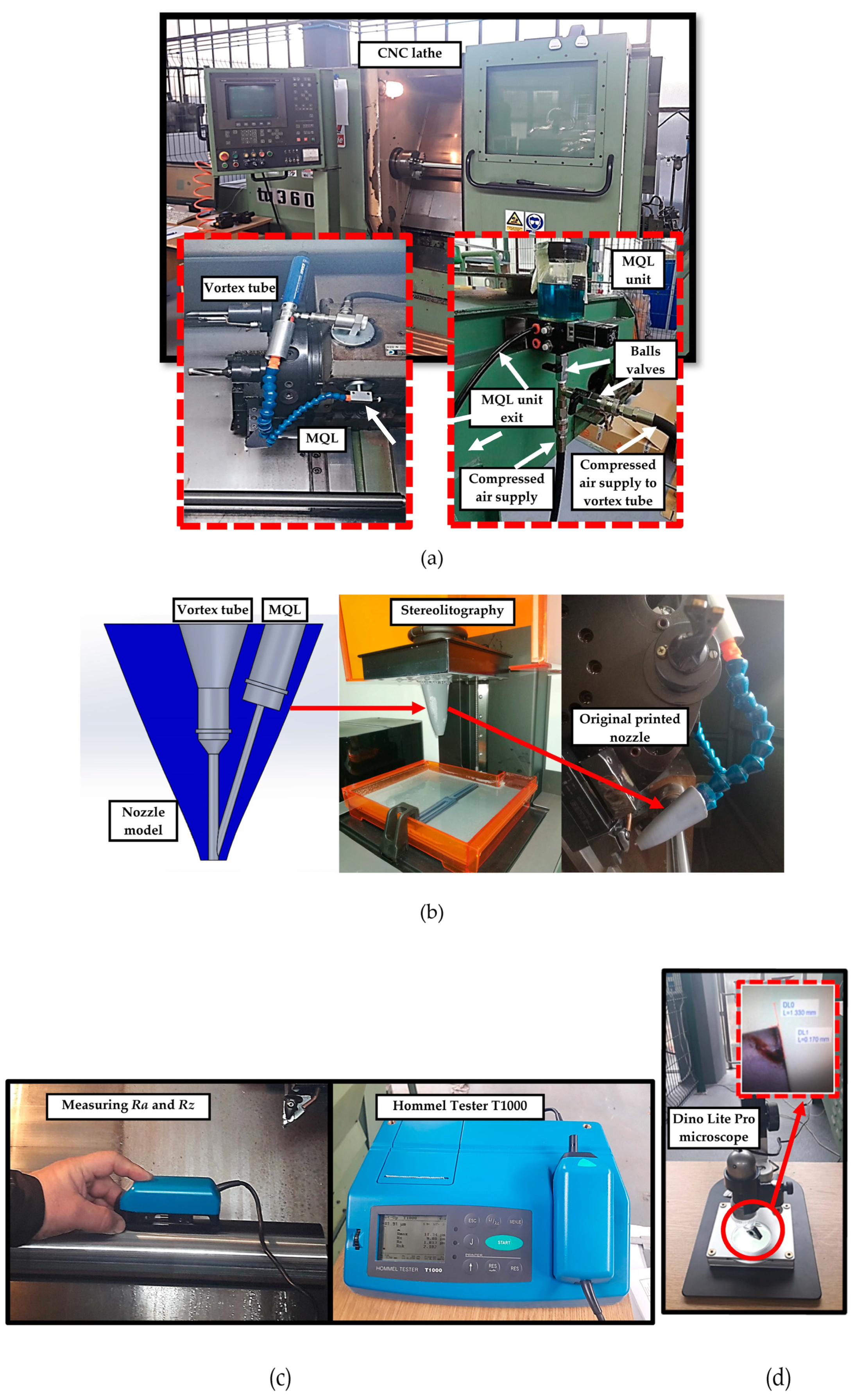

2. Experimental Part—Turning of Martensitic Stainless Steel

2.1. Material, Methods and Equipment

2.2. Results and Discussion

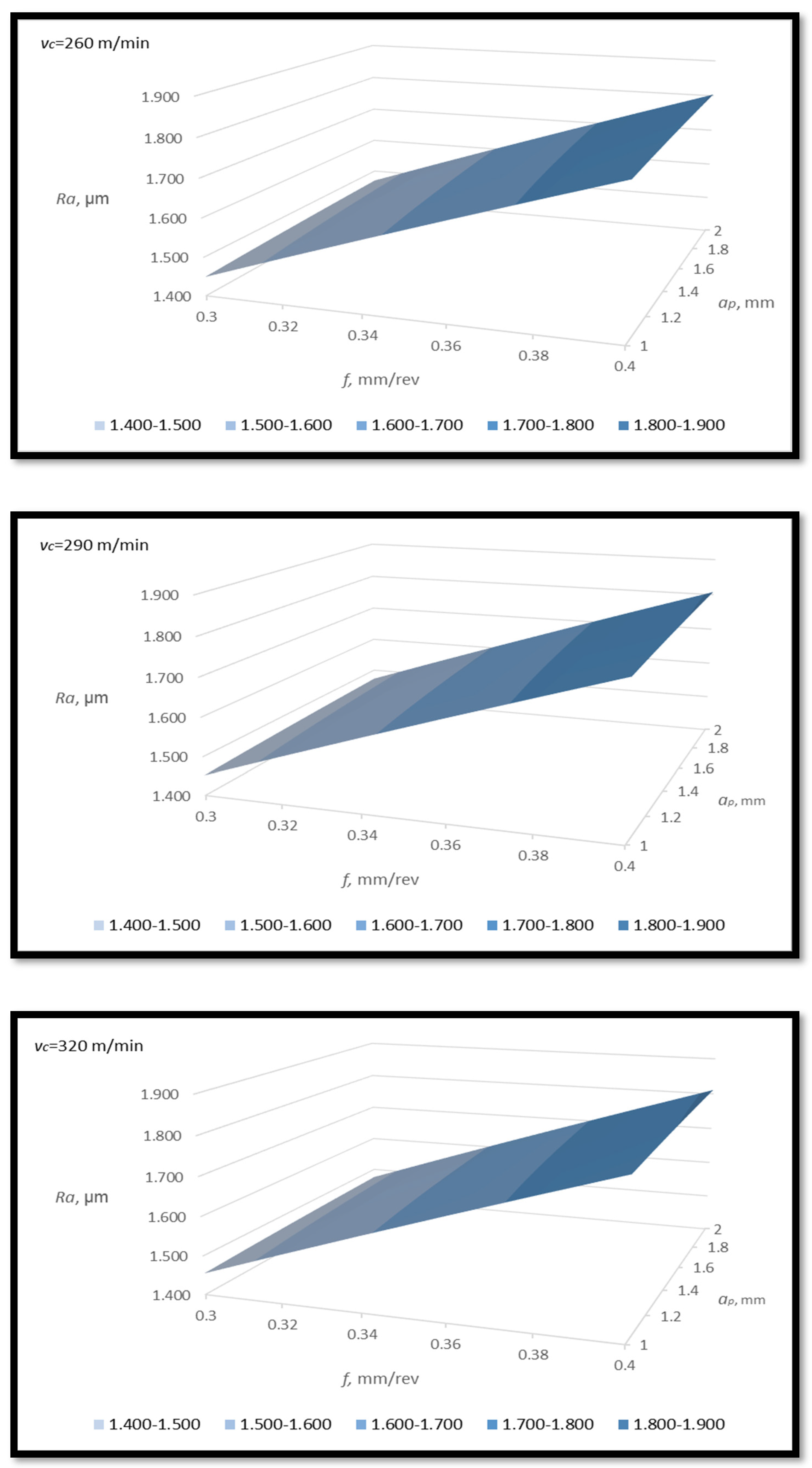

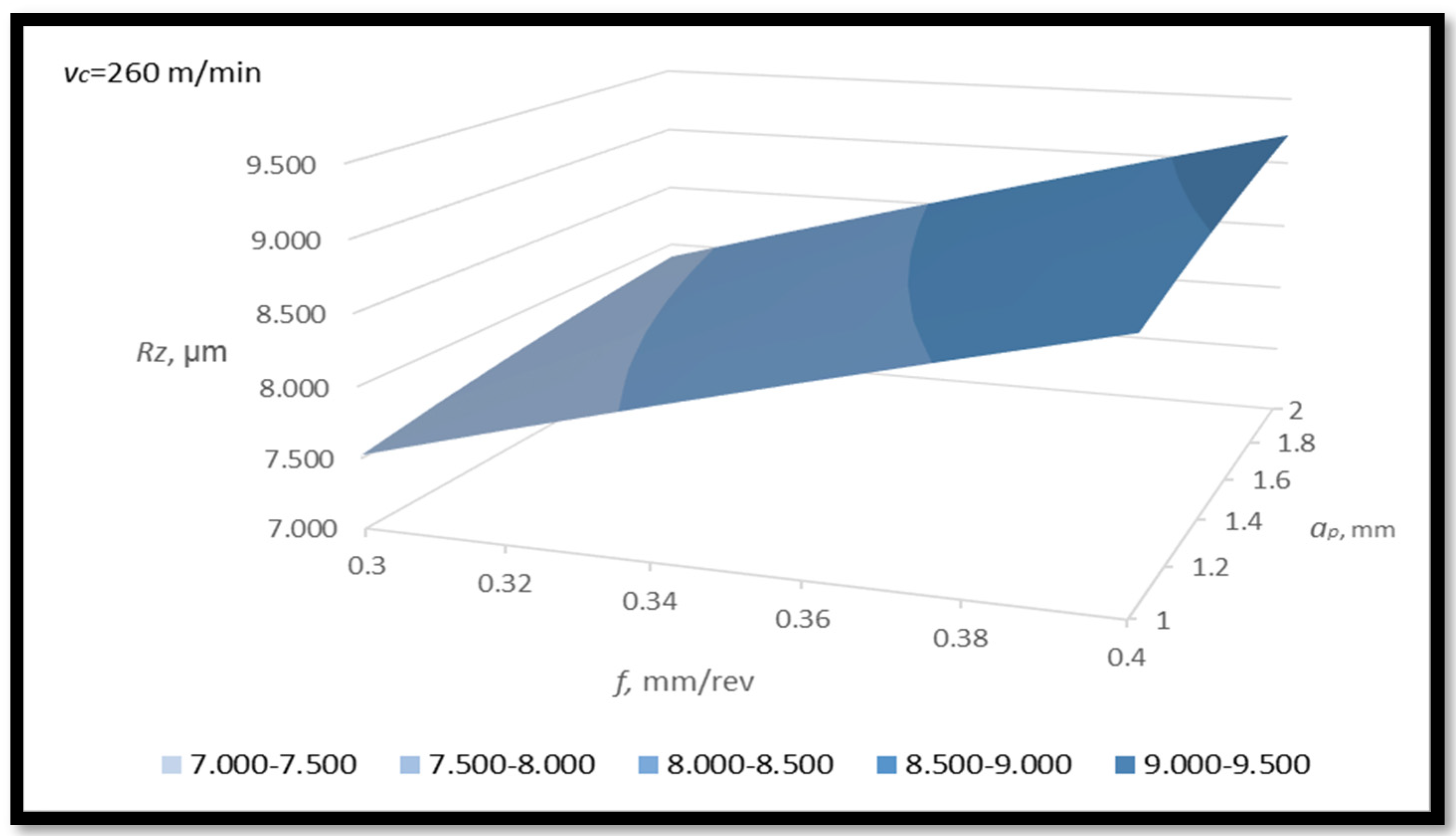

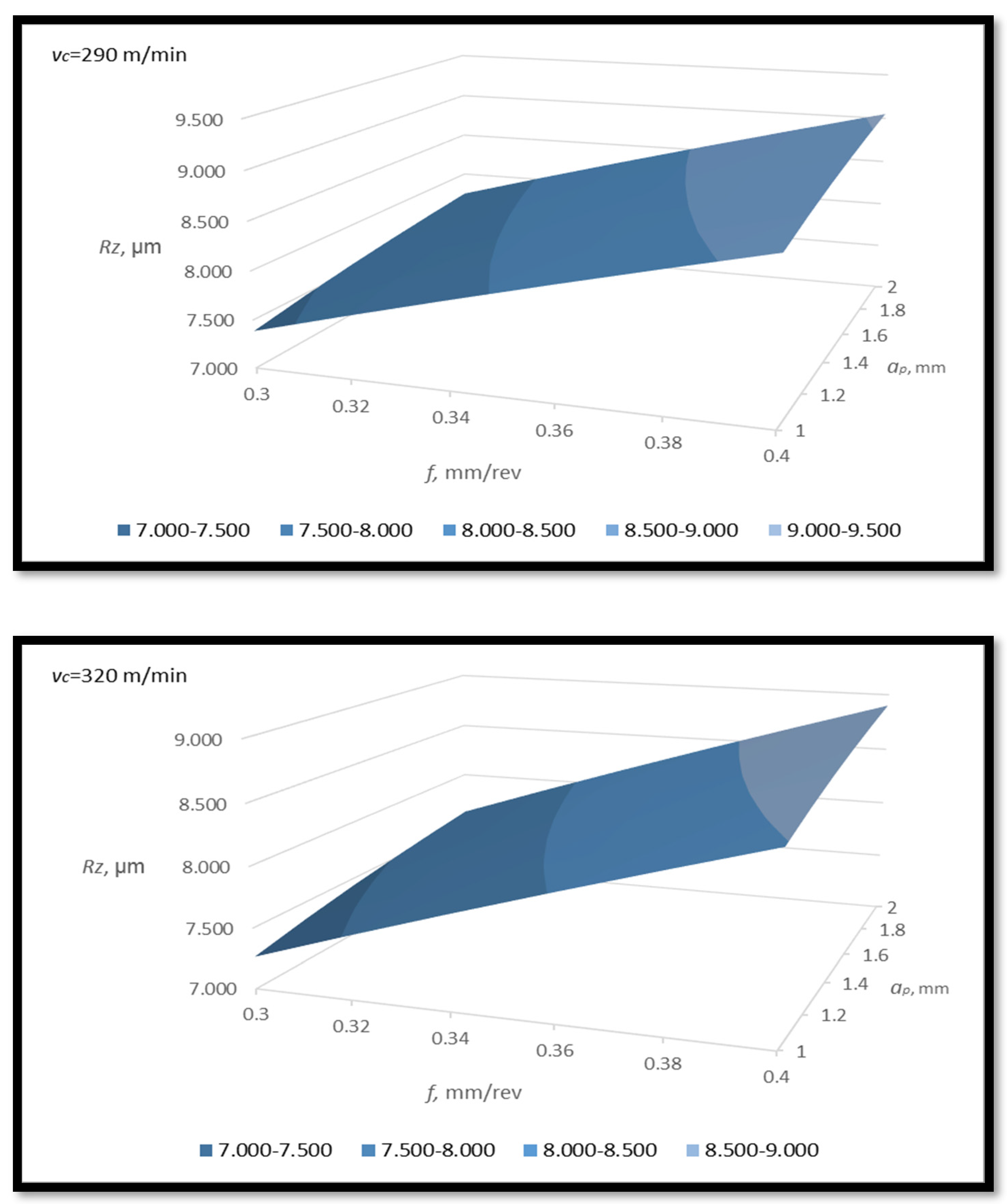

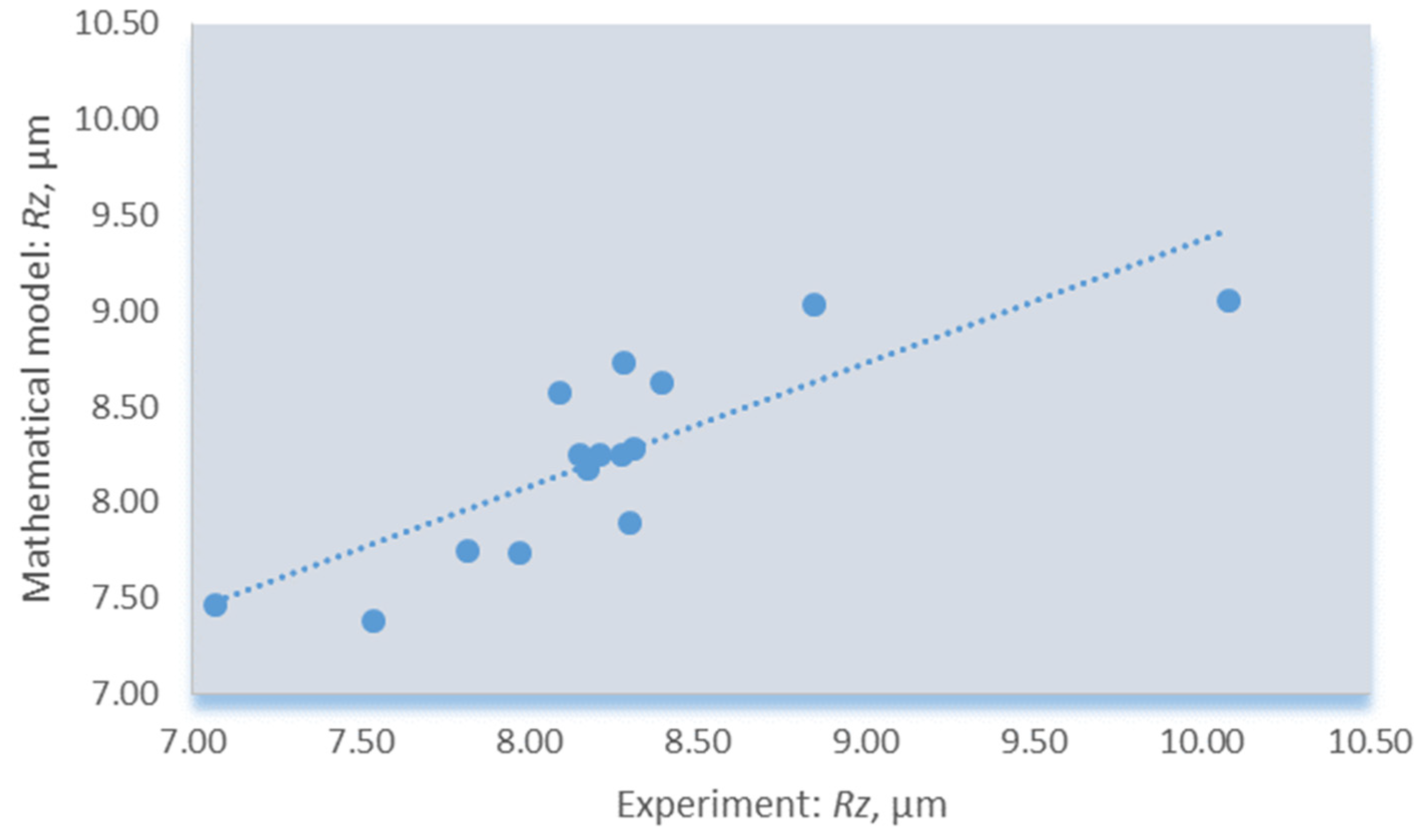

2.2.1. Analysis of Surface Roughness

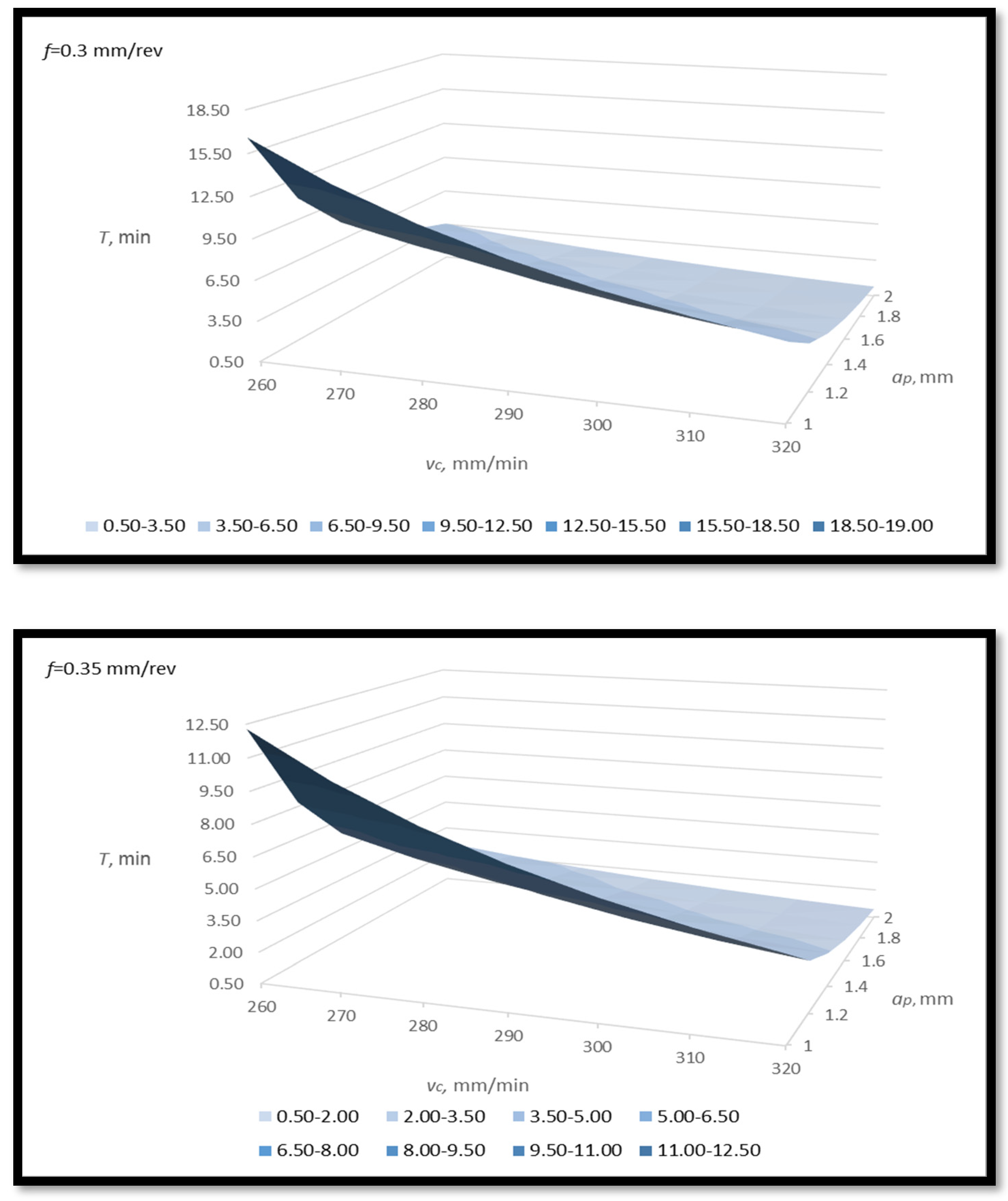

2.2.2. Analysis of Tool Life

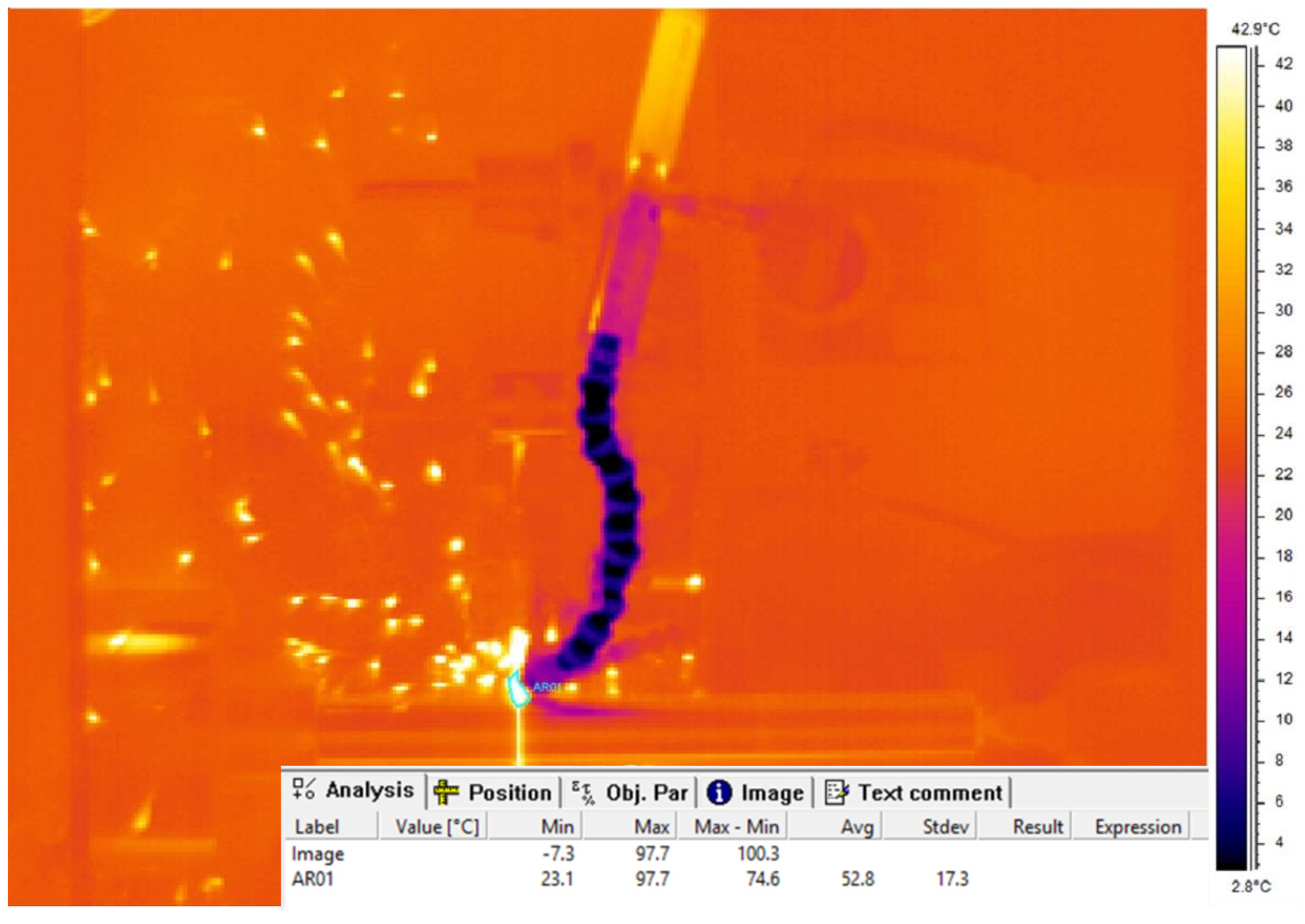

2.2.3. The Effect of the Vortex Tube on Lowering the Temperature

3. Conclusions

- The implementation of the experiments made it possible to consider the insufficiently researched MQL lubrication technique supported by vortex tube cooling when turning martensitic stainless steel X20Cr13. Based on the analysis of the impact on machinability, the mathematical models are defined.

- Models provide a reliable basis for optimizing the turning of martensitic stainless steel X20Cr13 in the MQL + vortex cooling condition.

- The temperature of the outlet cold air flow was approximately −8 °C. The use of the vortex tube under the MQL + vortex tube condition achieved an additional drop in temperature at the tool –workpiece interface by −38.1 °C.

- Finally, the MQL lubrication technique with vortex tube cooling can be recommended for the turning of martensitic stainless steel X20Cr13. It has been confirmed that the use of conventional MWFs can be excluded when turning martensitic stainless steels. Furthermore, this alternative cooling technique has a positive effect on two aspects of sustainability: the environment and health protection.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kostadin, T.; Cukor, G.; Jakovljevic, S. Analysis of corrosion resistance when turning martensitic stainless steel X20Cr13 under chilled air-cooling. Adv. Prod. Eng. Manag. 2017, 12, 105–114. [Google Scholar] [CrossRef] [Green Version]

- Sterpin Valic, G.; Cukor, G.; Jurkovic, Z.; Brezocnik, M. Multi-criteria optimization of turning of martensitic stainless steel for sustainability. Int. J. Simul. Model. 2019, 18, 632–642. [Google Scholar] [CrossRef] [PubMed]

- Wen, K.-L.; Chang, T.-C.; You, M.-L. The grey entropy and its application in weighting analysis. In Proceedings of the 1998 IEEE International Conference on Systems, Man, and Cybernetics, San Diego, CA, USA, 14 October 1998; pp. 1842–1844. [Google Scholar]

- Brinksmeier, E.; Meyer, D.; Huesmann-Cordes, A.G.; Herrmann, C. Metalworking fluids—Mechanisms and performance. CIRP Ann. Manuf. Technol. 2015, 64, 605–628. [Google Scholar] [CrossRef] [Green Version]

- Lawal, S.A. A review of application of vegetable oil-based cutting fluids in machining non-ferrous metals. Indian J. Sci. Technol. 2013, 6, 3951–3956. [Google Scholar] [CrossRef]

- Sampaio, M.A.; Machado, A.R.; Laurindo, C.A.H.; Torres, R.D.; Amorim, F.L. Influence of minimum quantity of lubrication (MQL) when turning hardened SAE 1045 steel: A comparison with dry machining. Int. J. Adv. Manuf. Technol. 2018, 98, 959–968. [Google Scholar] [CrossRef]

- Uysal, A.; Demiren, F.; Altan, E. Applying minimum quantity lubrication (MQL) method on milling of martensitic stainless steel by using nano MoS2 reinforced vegetable cutting fluid. Procedia Soc. Behav. Sci. 2015, 195, 2742–2747. [Google Scholar] [CrossRef] [Green Version]

- Meena, A.; El Mansori, M. Study of dry and minimum quantity lubrication drilling of novel austempered ductile iron (ADI) for automotive applications. Wear 2011, 271, 2412–2416. [Google Scholar] [CrossRef]

- Hadad, M.; Hadi, M. An investigation on surface grinding of hardened stainless steel S34700 and aluminum alloy AA6061 using minimum quantity of lubrication (MQL) technique. Int. J. Adv. Manuf. Technol. 2013, 68, 2145–2158. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Krolczyk, G.M.; Mandal, U.K.; Mondal, S.P. Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 8, 249–280. [Google Scholar] [CrossRef] [Green Version]

- Said, Z.; Gupta, M.; Hegab, H.; Arora, N.; Khan, A.M.; Jamil, M.; Bellos, E. A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int. J. Adv. Manuf. Technol. 2019, 105, 2057–2086. [Google Scholar] [CrossRef]

- Singh, T.; Singh, P.; Dureja, J.S.; Dogra, M.; Singh, H.; Bhatti, M.S. A review of near dry machining/minimum quantity lubrication machining of difficult to machine alloys. Int. J. Mach. Mach. Mater. 2016, 18, 213–251. [Google Scholar] [CrossRef]

- Ngo, M.T.; Tran, M.D.; Tran, T.L.; Vu, L.H.; Tran, B. Ngoc. Investigation of Machining Performance of MQL and MQCL Hard Turning Using Nano Cutting Fluids. Fluids Spec. Issue Fluid Flows Nanoscale 2022, 7, 143. [Google Scholar] [CrossRef]

- Pradeep, K.G.; Saravanan, P.; Samuel, R.D.; Shuhaib, H.; Varun, R.S.; Naveen, R. Optimization of jet position and investigation of the effects of multijet MQCL during end milling of Ti-6Al-4V. J. Manuf. Process. 2021, 64, 392–408. [Google Scholar] [CrossRef]

- Rashid, R.A.; Murad, M.N.; Hamidon, R.; Shariffuddin, S.; Ali, M.A.M. Experimental investigation of machining parameter on hole quality in drilling Ti-6Al-4V. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 1st International Conference on Science, Engineering and Technology (ICSET), Penang, Malaysia, 27 February 2020. [Google Scholar] [CrossRef]

- Saberi, A.; Rahimi, A.R.; Parsa, H.; Ashrafijou, M.; Rabiei, F. Improvement of surface grinding process performance of CK45 soft steel by minimum quantity lubrication (MQL) technique using compressed cold air jet from vortex tube. J. Clean. Prod. 2016, 131, 728–738. [Google Scholar] [CrossRef]

- Dureja, J.S.; Singh, R.; Singh, T.; Singh, P.; Dogra, M.; Bhatti, M.S. Performance evaluation of coated carbide tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. Green Technol. 2015, 2, 123–129. [Google Scholar] [CrossRef] [Green Version]

- Leppert, T. The effects of cooling and lubrication on tool wear in turning 316L steel. In Proceedings of the 2011 IEEE International Conference on Management and Service Science (MASS), Wuhan, China, 12–14 August 2011; pp. 1–4. [Google Scholar]

- Leppert, T. Surface layer properties of AISI 316L steel when turning under dry and with minimum quantity lubrication conditions. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 617–631. [Google Scholar] [CrossRef]

- Elmunafi, M.H.S.; Kurniawan, D.; Noordin, N.Y. Use of castor oil as cutting fluid in machining of hardened stainless steel with minimum quantity of lubricant. Procedia CIRP 2015, 26, 408–411. [Google Scholar] [CrossRef] [Green Version]

- Pereira, O.; Rodrigez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Jamaludin, A.S.; Hosokawa, A.; Furumoto, T.; Koyano, T.; Hashimoto, Y. Study on the effectiveness of Extreme Cold Mist MQL system on turning process of stainless steel AISI 316. IOP Conf. Ser. Mater. Sci. Eng. 2018, 319, 012054. [Google Scholar] [CrossRef]

- Liu, N.; Liu, B.; Jiang, H.; Wu, S.; Yang, C.; Chen, Y. Study on vibration and surface roughness in MQCL turning of stainless steel. J. Manuf. Process. 2021, 65, 343–353. [Google Scholar] [CrossRef]

- Singh, T.; Dureja, J.S.; Dogra, M.; Bhatti, M.S. Machining performance investigation of AISI 304 austenitic stainless steel under different turning environments. Int. J. Automot. Mech. Eng. 2018, 15, 5837–5862. [Google Scholar] [CrossRef]

- Boswell, B.; Voges, E. The effect of combined cold air and minimum liquid cooling on end milling. In Proceedings of the 2011 International Conference on Mechanical, Industrial, and Manufacturing Engineering (MIME2011), Information Engineering Research Institute, Melbourne, Australia, 15 January 2011; pp. 54–57. [Google Scholar]

- Cukor, G.; Šterpin-Valić, G.; Kostadin, T.; Fabić, M. Sustainable turning of martensitic stainless steel. Trans. FAMENA 2019, 43, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Liew, P.J.; Hashim, U.S.; Rahman, M.N.A. Effect of chilled air coolant on surface roughness and tool wear when machining 2205 duplex stainless steel. J. Adv. Manuf. Technol. 2017, 11, 61–68. [Google Scholar]

- Veić, M.; Jozić, S.; Bajić, D. Surface roughness modelling in super duplex stainless steel turning. Eng. Model. 2018, 31, 19–34. [Google Scholar] [CrossRef] [Green Version]

- BSSA: General Principles of Machining Stainless Steels. Available online: http://www.bssa.org.uk/topics.php?article=192 (accessed on 10 April 2021).

- Veldhuis, S.C.; Fox-Rabinovich, G.S.; Shuster, L.S. Coolants and lubricants in metal cutting. In Handbook of Lubrication and Tribology, 2nd ed.; Totten, G.E., Ed.; CRC Press: Boca Raton, FL, USA, 2006; Volume I. [Google Scholar]

- Godderis, L.; Deschuyffeleer, T.; Roelandt, H.; Veulemans, H.; Moens, G. Exposure to metalworking fluids and respiratory and dermatological complaints in a secondary aluminium plant. Int. Arch. Occup. Environ. Health 2008, 81, 845–853. [Google Scholar] [CrossRef]

- Burton, C.M.; Crook, B.; Scaife, H.; Evans, G.S.; Barber, C.M. Systematic review of respiratory outbreaks associated with exposure to water-based metalworking fluids. Ann. Occup. Hyg. 2012, 56, 374–388. [Google Scholar] [CrossRef] [PubMed]

- Sujová, E. Contamination of the working air via metalworking fluids aerosols. Eng. Rev. 2012, 32, 9–15. [Google Scholar]

- Byrne, G.; Dornfeld, D.; Denkena, B. Advancing cutting technology. CIRP Ann. Manuf. Technol. 2003, 52, 483–507. [Google Scholar] [CrossRef] [Green Version]

- Dixit, U.S.; Sarma, D.K.; Davim, J.P. Environmentally Friendly Machining; Springer: Boston, MA, USA, 2012. [Google Scholar]

- 2000/532/EC: COMMISSION DECISION of 3 May 2000 Replacing Decision 94/3/EC Establishing a List of Wastes Pursuant to Article 1(a) of Council Directive 75/442/EEC on Waste and Council Decision 94/904/EC Establishing a List of Hazardous Waste Pursuant to Article 1(4) of Council Directive 91/689/EEC on Hazardous Waste (Notified under Document Number C (2000) 1147). Available online: https://op.europa.eu/hr/publication-detail/-/publication/239a2785-9115-4e06-adae-66c8e08a5a42/language-hr/format-PDF (accessed on 15 April 2021).

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj (accessed on 15 April 2021).

- BGI/GUV-I 718, E. Minimum Quantity Lubrication for Machining Operations; DGUV: Berlin, Germany, 2010. [Google Scholar]

- Pusavec, F.; Kramar, D.; Krajnik, P.; Kopac, J. Transitioning to sustainable production—Part II: Evaluation of sustainable machining technologies. J. Clean. Prod. 2010, 18, 1211–1221. [Google Scholar] [CrossRef]

- Hong, S.Y.; Zhao, Z. Thermal aspects, material considerations and cooling strategies in cryogenic machining. Clean Technol. Environ. Policy 1999, 1, 107–116. [Google Scholar] [CrossRef]

- Davim, J.P. Sustainable Manufacturing; ISTE Ltd.: Hoboken, NJ, USA; John Wiley & Sons, Inc.: London, UK, 2010. [Google Scholar]

- De Vera, G. The Ranque-Hilsch Vortex Tube. 2010. Available online: https://www.academia.edu/1646175/The_Ranque-Hilsch_Vortex_Tube (accessed on 17 November 2019).

- Skerlos, S.J.; Hayes, K.F.; Clarens, A.F.; Zhao, F. Current Advances in Sustainable Metalworking Fluids Research. Int. J. Sustain. Manuf. 2008, 1, 180–202. [Google Scholar] [CrossRef] [Green Version]

- Thornburg, J.; Leith, D. Size distribution of mist generated during metal machining. Appl. Occup. Environ. Hyg. 2000, 15, 618–628. [Google Scholar] [CrossRef] [PubMed]

- Pavić, A. Tehnologija—Obrada Odvajanjem Čestica; Veleučilište u Karlovcu: Karlovac, Croatia, 2013. [Google Scholar]

- EN ISO 4287:2008/A1:2010; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters—Amendment 1: Peak Count Number (ISO 4287:1997/Amd 1:2009; EN ISO 4287:1998/A1:2009). German Institute for Standardization: Berlin, Germany, 2010.

- Rahim, E.A.; Dorairaju, H. Evaluation of mist flow characteristic and performance in Minimum Quantity Lubrication (MQL) machining. Measurement 2018, 123, 213–225. [Google Scholar] [CrossRef]

- Amiril, S.A.S.; Rahim, E.A.; Hishamudin, A.Z. Effect of nozzle distance and cutting parameters on MQL machining of AISI 1045. In Proceedings of the International Conference on Mechanical and Manufacturing Engineering (ICME2018), Johor, Malaysia, 16–17 July 2018; Volume 1150. [Google Scholar] [CrossRef]

- Veerabhadrarao, M.; Patil, B.T.; Shaikh, V.A.; Sudhakar, D.S.S. Contribution of Factors such as Machining Parameters, MQL Nozzle Orientation (Angle & Distance) and MQL Nano-Fluid Type on Surface Finish of Turned Steel Work-Pieces Using DOE Approach. Mater. Sci. Forum 2019, 1019, 181–193. [Google Scholar] [CrossRef]

| Fe, % | C, % | Si, % | Mn, % | P, % | S, % | Cr, % | Mo, % | Ni, % | V, % | Nb, % | Cu, % |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 85.85 | 0.236 | 0.352 | 0.683 | 0.044 | 0.023 | 11.97 | 0.125 | 0.299 | 0.053 | 0.07 | 0.195 |

| Yield Strength Rp0,2, MPa | Tensile Strength Rm, MPa | Elongation A5, % | Contraction Z, % | Hardness HB |

|---|---|---|---|---|

| 750 | 881 | 16.36 | 47 | 272 |

| Parameter | Coded Symbols | Levels | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Cutting speed vc, m/min | X1 | 260 | 290 | 320 |

| Feed rate f, mm/rev | X2 | 0.3 | 0.35 | 0.4 |

| Depth of cut ap, mm | X3 | 1 | 1.5 | 2 |

| Experiment Number | X1 | X2 | X3 |

|---|---|---|---|

| 1 | −1 (260) | −1 (0.3) | 0 (1.5) |

| 2 | 1 (320) | −1 (0.3) | 0 (1.5) |

| 3 | −1 (260) | 1 (0.4) | 0 (1.5) |

| 4 | 1 (320) | 1 (0.4) | 0 (1.5) |

| 5 | −1 (260) | 0 (0.35) | −1 (1) |

| 6 | 1 (320) | 0 (0.35) | −1 (1) |

| 7 | −1 (260) | 0 (0.35) | 1 (2) |

| 8 | 1 (320) | 0 (0.35) | 1 (2) |

| 9 | 0 (290) | −1 (0.3) | −1 (1) |

| 10 | 0 (290) | 1 (0.4) | −1 (1) |

| 11 | 0 (290) | −1 (0.3) | 1 (2) |

| 12 | 0 (290) | 1 (0.4) | 1 (2) |

| 13 | 0 (290) | 0 (0.35) | 0 (1.5) |

| 14 | 0 (290) | 0 (0.35) | 0 (1.5) |

| 15 | 0 (290) | 0 (0.35) | 0 (1.5) |

| Experiment Number | Output Responses | ||

|---|---|---|---|

| Ra, μm | Rz, μm | T, min | |

| 1 | 1.556 | 7.97 | 7.5 |

| 2 | 1.349 | 7.07 | 2.45 |

| 3 | 1.774 | 8.85 | 2.81 |

| 4 | 1.777 | 8.28 | 1.31 |

| 5 | 1.606 | 8.18 | 13.7 |

| 6 | 1.767 | 8.30 | 3.8 |

| 7 | 1.582 | 8.09 | 2.87 |

| 8 | 1.685 | 8.31 | 1.13 |

| 9 | 1.415 | 7.54 | 7.486 |

| 10 | 1.718 | 8.39 | 8.39 |

| 11 | 1.490 | 7.82 | 2.19 |

| 12 | 1.844 | 10.08 | 1.02 |

| 13 | 1.685 | 8.28 | 2.83 |

| 14 | 1.623 | 8.15 | 2.94 |

| 15 | 1.651 | 8.21 | 2.91 |

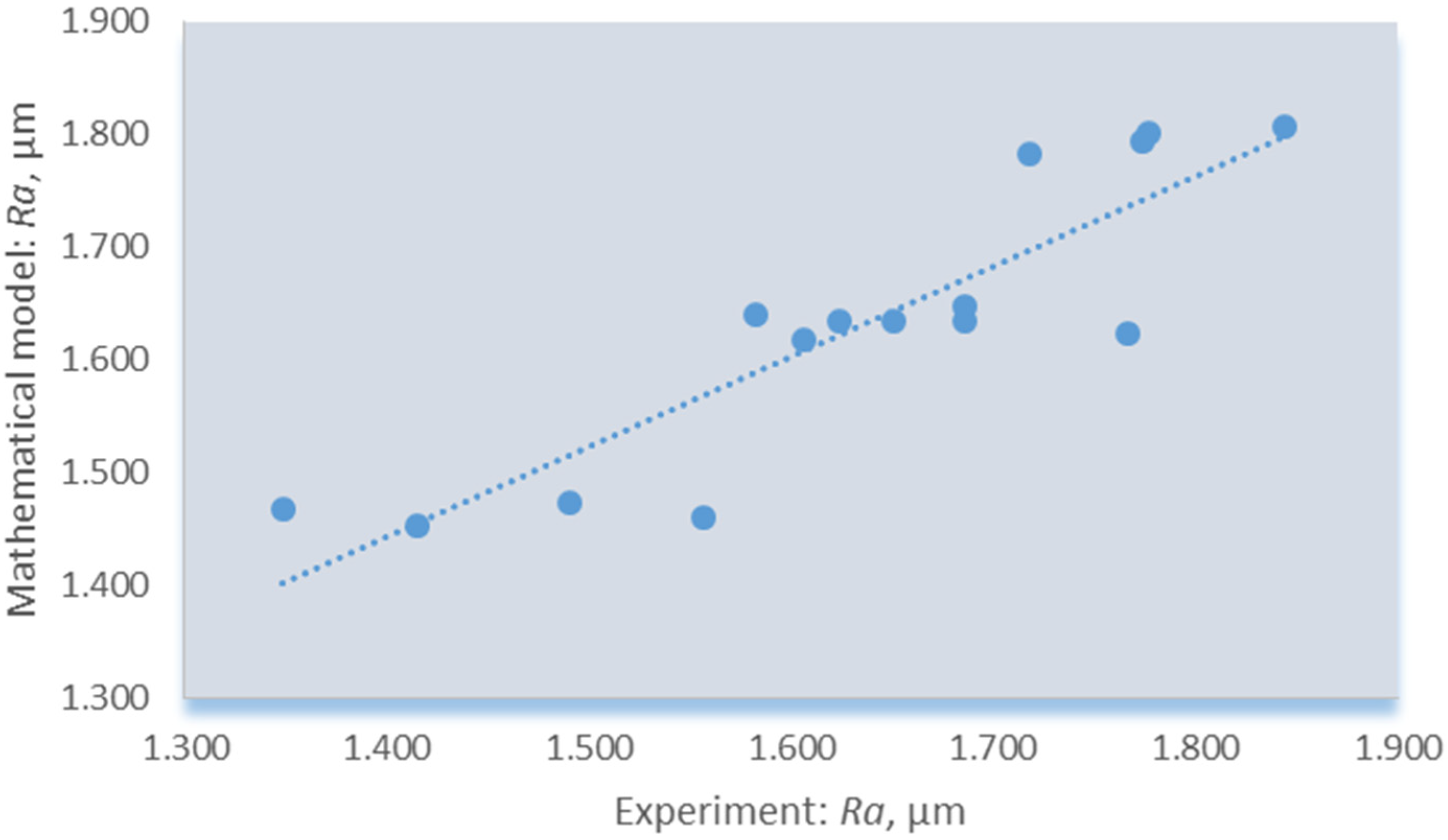

| Regression Statistics | ||||||

|---|---|---|---|---|---|---|

| Multiple R | 0.883 | |||||

| R Square | 0.779 | |||||

| Adjusted R Square | 0.719 | |||||

| Standard Error | 0.047 | |||||

| Observations | 15 | |||||

| ANOVA | ||||||

| df | SS | MS | F | Significance F | ||

| Regression | 3 | 0.085 | 0.028 | 12.959 | 0.00062344 | |

| Residual | 11 | 0.024 | 0.002 | |||

| Total | 14 | 0.109 | ||||

| Coefficients | Standard Error | t Stat | p-value | Lower 95% | Upper 95% | |

| Intercept | 1.118 | 0.909 | 1.230 | 0.244 | −0.882 | 3.118 |

| vc | 0.020 | 0.159 | 0.128 | 0.901 | −0.329 | 0.370 |

| f | 0.713 | 0.115 | 6.219 | 6.5 × 10−5 | 0.460 | 0.965 |

| ap | 0.020 | 0.047 | 0.430 | 0.675 | −0.040 | 0.178 |

| Experiment Number | Experiment Ra, μm | Mathematical Model Ra, μm | Residue |

|---|---|---|---|

| 1 | 1.556 | 1.461 | 0.095 |

| 2 | 1.349 | 1.467 | −0.118 |

| 3 | 1.774 | 1.793 | −0.019 |

| 4 | 1.777 | 1.801 | −0.024 |

| 5 | 1.606 | 1.617 | −0.011 |

| 6 | 1.767 | 1.624 | 0.143 |

| 7 | 1.582 | 1.640 | −0.058 |

| 8 | 1.685 | 1.647 | 0.039 |

| 9 | 1.415 | 1.452 | −0.037 |

| 10 | 1.718 | 1.783 | −0.065 |

| 11 | 1.490 | 1.472 | 0.018 |

| 12 | 1.844 | 1.808 | 0.037 |

| 13 | 1.685 | 1.634 | 0.051 |

| 14 | 1.623 | 1.634 | −0.011 |

| 15 | 1.651 | 1.634 | 0.017 |

| Regression Statistics | ||||||

|---|---|---|---|---|---|---|

| Multiple R | 0.825 | |||||

| R Square | 0.681 | |||||

| Adjusted R Square | 0.593 | |||||

| Standard Error | 0.049 | |||||

| Observations | 15 | |||||

| ANOVA | ||||||

| df | SS | MS | F | Significance F | ||

| Regression | 3 | 0.056 | 0.019 | 7.812 | 0.005 | |

| Residual | 11 | 0.026 | 0.002 | |||

| Total | 14 | 0.082 | ||||

| Coefficients | Standard Error | t Stat | p-value | Lower 95% | Upper 95% | |

| Intercept | 3.609 | 0.949 | 3.801 | 0.003 | 1.519 | 5.699 |

| vc | −0.169 | 0.166 | −1.018 | 0.330 | −0.534 | 0.196 |

| f | 0.541 | 0.120 | 4.522 | 0.001 | 0.278 | 0.805 |

| ap | 0.069 | 0.049 | 1.397 | 0.190 | −0.040 | 0.178 |

| Experiment Number | Experiment Rz, μm | Mathematical Model Rz, μm | Residue |

|---|---|---|---|

| 1 | 7.97 | 7.74 | 0.24 |

| 2 | 7.07 | 7.47 | −0.40 |

| 3 | 8.85 | 9.04 | −0.19 |

| 4 | 8.28 | 8.73 | −0.45 |

| 5 | 8.18 | 8.18 | 0.00 |

| 6 | 8.30 | 7.89 | 0.40 |

| 7 | 8.09 | 8.58 | −0.49 |

| 8 | 8.31 | 8.28 | 0.03 |

| 9 | 7.54 | 7.38 | 0.15 |

| 10 | 8.39 | 8.63 | −0.23 |

| 11 | 7.82 | 7.75 | 0.07 |

| 12 | 10.08 | 9.05 | 1.03 |

| 13 | 8.28 | 8.25 | 0.02 |

| 14 | 8.15 | 8.25 | −0.10 |

| 15 | 8.21 | 8.25 | −0.04 |

| Regression Statistics | ||||||

|---|---|---|---|---|---|---|

| Multiple R | 0.971 | |||||

| R Square | 0.943 | |||||

| Adjusted R Square | 0.928 | |||||

| Standard Error | 0.203 | |||||

| Observations | 15 | |||||

| ANOVA | ||||||

| df | SS | MS | F | Significance F | ||

| Regression | 3 | 7.532 | 2.511 | 60.974 | 3.85101 × 10−7 | |

| Residual | 11 | 0.453 | 0.0411 | |||

| Total | 14 | 7.985 | ||||

| Coefficients | Standard Error | t Stat | p-value | Lower 95% | Upper 95% | |

| Intercept | 27.876 | 3.950 | 7.058 | 2.10546 × 10−5 | 19.183 | 36.570 |

| vc | −4.930 | 0.691 | −7.139 | 1.89581 × 10−5 | −6.450 | −3.410 |

| f | −1.950 | 0.498 | −3.914 | 0.002415885 | −3.046 | −0.854 |

| ap | −2.222 | 0.206 | −10.804 | 3.39625 × 10−7 | −2.674 | −1.769 |

| Experiment Number | Experiment T, min | Mathematical Model T, min | Residue |

|---|---|---|---|

| 1 | 7.5 | 6.74 | 0.76 |

| 2 | 2.45 | 2.42 | 0.03 |

| 3 | 2.81 | 3.85 | −1.04 |

| 4 | 1.31 | 1.38 | −0.07 |

| 5 | 13.7 | 12.29 | 1.41 |

| 6 | 3.8 | 4.42 | −0.62 |

| 7 | 2.87 | 2.63 | 0.24 |

| 8 | 1.13 | 0.95 | 0.18 |

| 9 | 7.49 | 9.69 | −2.21 |

| 10 | 8.39 | 5.53 | 2.86 |

| 11 | 2.19 | 2.08 | 0.11 |

| 12 | 1.02 | 1.19 | −0.17 |

| 13 | 2.83 | 2.91 | −0.08 |

| 14 | 2.94 | 2.91 | 0.03 |

| 15 | 2.91 | 2.91 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šterpin Valić, G.; Kostadin, T.; Cukor, G.; Fabić, M. Sustainable Machining: MQL Technique Combined with the Vortex Tube Cooling When Turning Martensitic Stainless Steel X20Cr13. Machines 2023, 11, 336. https://doi.org/10.3390/machines11030336

Šterpin Valić G, Kostadin T, Cukor G, Fabić M. Sustainable Machining: MQL Technique Combined with the Vortex Tube Cooling When Turning Martensitic Stainless Steel X20Cr13. Machines. 2023; 11(3):336. https://doi.org/10.3390/machines11030336

Chicago/Turabian StyleŠterpin Valić, Graciela, Tihana Kostadin, Goran Cukor, and Marko Fabić. 2023. "Sustainable Machining: MQL Technique Combined with the Vortex Tube Cooling When Turning Martensitic Stainless Steel X20Cr13" Machines 11, no. 3: 336. https://doi.org/10.3390/machines11030336