Abstract

A method for robotized cable winding of the Uppsala University Wave Energy Converter generator stator has previously been presented and validated. The purpose of this study is to present and validate further developments to the method: automated stand-alone equipment for the preparation of the winding cables. The cable preparation consists of three parts: feeding the cable from a drum, forming the cable end and cutting the cable. Forming and cutting the cable was previously done manually and only small cable drums could be handled. Therefore the robot cell needed to be stopped frequently. The new equipment was tested in an experimental robot stator cable winding setup. Through the experiments, the equipment was validated to be able to perform fully automated and robust cable preparation. Suggestions are also given on how to further develop the equipment with regards to performance, robustness and quality. Hence, this work represents another important step towards demonstrating completely automated robotized stator cable winding.

1. Introduction

Cable winding has previously been suggested as an alternative method for robust, efficient and facilitated stator winding for large electric machines [1,2,3]. An application where cable winding is used is in the linear direct-drive generator used in the Uppsala University (UU) Wave Energy Converter (WEC) concept [4], commercialized by the spin-off company Seabased Industry AB. The most recent UU WEC version, representing the third design generation, is using a nine-sided and about 2 m long cable wound stator, see Figure 1. In this concept, farms of numerous WEC units are to be deployed offshore. With this approach, the fluctuating power outputs from single units are aggregated and smoothened, thereby improving the utilization and the economic efficiency of the complete system [5,6]. Hence, large-scale production, preferably combined with investments in automated manufacturing in order to enable local production [7], could be utilised to achieve successful commercialization. Further, it has been identified that the promotion of renewables in general will increase the use of distributed electric energy generation system [8], with multiple smaller units often using medium to large sized generators. Hence, automated manufacturing methods developed for the UU WEC generator are likely to have further applications.

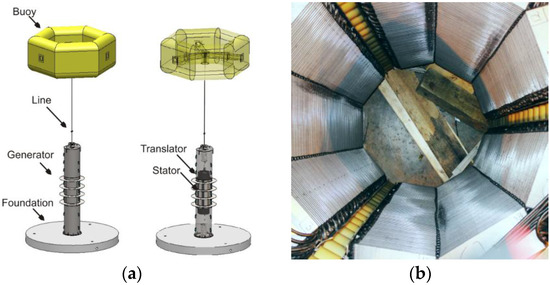

Figure 1.

(a) The UU WEC concept explained: a point-absorbing buoy coupled via a line to the translator, i.e., the moving part of the generator, and thus moving vertically inside the stator as the generator is mounted on a concrete gravity foundation and placed on the seabed; (b) A photo of the stator inside the UU WEC generator hull before the translator is mounted.

Fully automated assembly of conventional stators is widely used today, in particular for smaller machines, and has been stressed to provide not only low production costs but also both flexibility and high quality [9,10]. Cable stator winding, on the other hand, is a much less common winding technology, mainly used in larger machines and have so far only been performed manually [11]. In previous work a robotized solution for automated cable winding has been suggested and evaluated [3,12,13]. The most recent such robot cell prototype [13] included equipment for automatic cable feeding from a small cable drum to two industrial robots, equipped with cable feeder tools, to wind a short UU WEC stator, see Figure 2a. A bottleneck was however that the winding cables needed to be prepared manually. This preparation included forming the cable end to a tip, so that it did not get stuck while being fed through the stator, and cutting the cable to the desired length. Manual cable end forming was achieved by heating up the cable end insulation using a heat gun, pulling the insulation out over the end threads of the cable and forming it to a tip either using gloves or by pressing it into a cast. This process took about 45 s per cable end. A manual cable cutter tool was used to cut the cable. Another bottleneck was that only small cable drums, holding about 25 m cable, could be handled. For reference, winding of one complete third generation UU WEC stator did require about 300 cable end preparations, about 150 cable cuts and about 3000 m cable in total. Hence, together these two bottlenecks did lead to a frequent need for manual work inside the cell since many cable ends needed to be prepared and a lot of cable was required. During both these operations the robot cell was stopped, which affected the achievable productivity of the cell considerably. This suggested the need for a fully automated equipment to feed the cable from a larger cable drum, form the cable ends and cut the cable to the desired lengths and has therefore been prioritized.

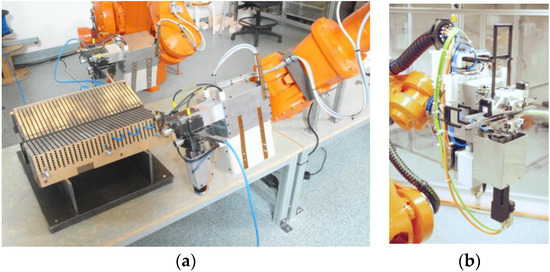

Figure 2.

(a) Two industrial robots, equipped with cable feeder tools, demonstrating automated stator cable winding in a previous experimental setup at Uppsala University; (b) The industrial robot model and robot cable feeder tool version used in the experiments presented in this work.

Electric and hydraulic cable drum and reel feeder equipment for unwinding a cable and cutting a cable to specified lengths exist on the market today, but would need to be adjusted to fit the automated robot cell. In particular, the robotized cable winding application requires precise cable feeding lengths with a fast, synchronized and fully integrated control as well as a precise delivery of the cable to the robots. Other applications with some similarities are automatic cable winches for remotely operated or autonomous sub-sea vehicles and automated filament winding systems [14,15,16]. However, neither of these solutions could be used directly for this application. It was therefore decided to develop new custom-made equipment that was as simple as possible. No suitable or similar existing equipment has been found in the literature or on the market to prepare the cable end. Commercially available cable hoses were considered, but could not be used mainly due to the fact that they build too much on the diameter and structure of the cable end. However, a principal method for automated cable end preparation has earlier been suggested for integration in robotized stator winding of the UU WEC generator [17].

The aim of the work presented in this article has been to design, construct and validate automated stand-alone equipment for the preparation of winding cable which can be integrated into a robotized stator cable winding cell. In the following, the experimental setup and methods are presented in Section 2, the final equipment design is presented in Section 3, the experimental results are presented in Section 4, the results are discussed in Section 5 and the conclusions are presented in Section 6.

2. Experimental Setup and Methods

To validate the constructed prototype cable preparation equipment, an experimental setup for robotized cable winding at UU was used. This setup included an ABB IRB4400/60 kg M2000 S4C+ robot equipped with a new cable feeder tool, see Figure 2b above. The robot cable feeder tool was of the same principal design as the tool presented in [13]. In the experiments, a 25 mm2 PVC-insulated multi-thread installation cable with an approximate outer diameter of 9.3 mm was used, i.e., the cable used in the most recent UU WEC version. The cable was delivered on standard plastic cable drums with a 600 mm outer diameter, a 250 mm inner diameter, a 75 mm centrum hole diameter and a 470 mm outer width. Each drum carried about 250 m of cable. The cable length on the drum was limited in order to facilitate manual handling of the drum.

To begin with, preparing a cable for robotized cable winding was divided into three sub-tasks, which could be solved with separate equipment:

- To feed cable from the cable drum

- To prepare the cable end

- To cut the cable to the desired length

For each of these sub-tasks, separate equipment was designed. The equipment design was based on the results and experience of the work mentioned above. Using a 3D-CAD computer software environment, the equipment mechanisms and dimensions could be validated directly against the 3D models of the industrial robot, the cable feeder tool, the cable drum and the cable itself. To minimize the idea-to-prototype-time and to limit the investment cost, mostly parts that were either standard available components, including all actuators and sensors, machined or 3D-printed plastic components made in-house or machined flat aluminium components which were screwed and assembled together in-house were used. The developed prototype was connected to and controlled by an ABB AC500 Programmable Logic Controller (PLC) and tested in the experimental setup presented above. The equipment was adjusted and calibrated until a satisfying solution was found. During the experiments, critical process parameters were logged by the PLC with a 10 Hz sampling frequency. The logging included output parameters from the cable feeder tools and the industrial robot, such as the applied cable feed force, the cable feed velocity and the linear velocity of the robot tool centre point.

The experiments with the complete equipment were repeated approximately 150 times, of which about 100 times with the final fully calibrated equipment. About half of the prepared cable ends were tested in actual robot or manual winding experiments. The insulation pull-out sub-process of the cable end preparation sub-task was validated with the final equipment by pulling out the insulation over 20 cable ends while repeating the automatic pull-out length control process 20 times for each cable. Assuming that the average value of the 20 pull-out length measurements was equivalent to the actual pulled length for each cable, the repeatability and performance of the of the insulation pull-out equipment could be evaluated. Furthermore, the repeatability of the insulation pull-out length measurements was evaluated by comparing the deviation from average for all 400 measurements. From this, the standard deviations for the actual insulation pull-out length and for the insulation pull-out measurements could be calculated. The cable insulation pull-out measurement equipment was also validated through manual measurements of the actual pull-out length using a calliper.

3. The Final Equipment Design

To construct the prototype cable preparation equipment was a repetitive task, where both the equipment and the control system were adjusted and completed numerous times before a satisfying solution was found. In this section, the final prototype equipment and the control system design are presented separately for the three defined sub-tasks. All equipment was connected to and fully controlled by the PLC, apart from the robot movements which were programmed on the robot controller but including all actuators, drives and sensors. This meant that the equipment could be completely controlled and supervised in the PLC. Since all equipment was supposed to be used frequently in the intended cable winding application and highly robust results were required, the PLC was also programmed to supervise how much critical components were actually used. Thus, service intervals could be set and the PLC could warn the operator when service or replacement of these components were needed. The basic requirements that the equipment should fulfil are defined based on previous work and winding experience. Common requirements for all three sub-tasks are presented in Table 1.

Table 1.

Basic requirements for all cable preparation equipment, including priority level; level A requirements are necessary to fulfil, level B requirements should be aimed to be fulfilled and level C requirements are desired but not critical.

3.1. Feeding Cable from the Cable Drum

This section present the final prototype cable drum feeding equipment. First, the defined specific requirements on the equipment are presented in Table 2. In the following, the equipment design is presented in Section 3.1.1 and the corresponding control system is presented in Section 3.1.2.

Table 2.

Specific requirements for the cable drum feeding equipment, including priority level; level A requirements are necessary to fulfil, level B requirements should be aimed to be fulfilled and level C requirements are desired but not critical.

3.1.1. Prototype Design

In designing the new drum feeding equipment, the solution used in earlier work [13] was first evaluated. In this previous solution, cable was delivered to the robot cable feeder tool using a separate cable feeder tool mounted on the drum feeding equipment. An advantage with this solution was that a cable feeder tool design similar to that for the robot cable feeder tool could be used, thus providing the required feed control while also saving design and programming time. In this solution, the cable was pulled from the drum by the feeder tool, through four guiding rollers and a circular air blow nozzle, which was used to blow off dirt from the cable. The drum was rotating freely around a vertical axis. A major drawback of this design was that the maximum cable length which could be handled by the equipment was limited by the low feeding force provided by the cable feeder tool. Furthermore, as the feeding was frequently started and stopped by the feeder tool, cable slack was typically created between the drum and the feeder tool, both when the feeding was accelerated and when it was stopped, as the drum was rotating freely. When the feeding was started from standstill, the drum would typically start to rotate with a jerk as the cable was tensed and then accelerate to a too high velocity, making the cable slack again and so on. This uneven motion was aggravated further as the cable occasionally came off the drum unevenly when falling downwards on the drum. The resulting uneven drum rotational velocity created an uneven force on the feeder tool, with high feed force peaks.

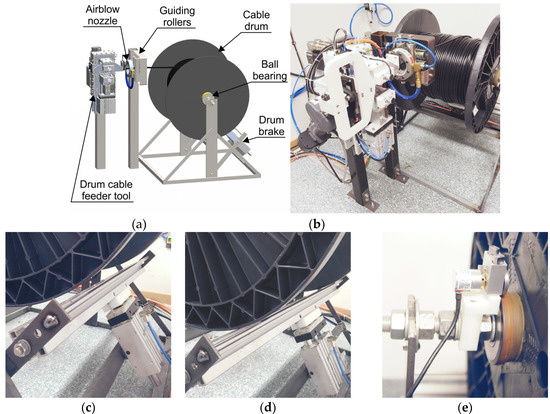

For the new equipment, it was decided that the advantages with the previous drum feeding solution outweighed the drawbacks described above and that these could be solved. Therefore, a new cable feeder tool, similar to the robot mounted cable feeder tool described above, was constructed. The main differences between the robot cable feeder tool described in [13] and the new drum cable feeder tool was (a) that the step motor previously used in the feed mechanism was replaced with a servo motor; (b) that the feeding wheels were closed by a double-acting guided linear pneumatic cylinder instead of a step motor coupled ball screw; (c) that it was not possible to open the cable guiding system and (d) that the new tool was designed to be fully controlled by the PLC. The cable feeding force delivered by the new tool was theoretically about 90 N nominal and about 150 N peak, while the servo motor drive provided better motion control and supervision than the previous motor drive. To reduce the required feeding force, the new cable drum was mounted with ball-bearings on a fixed horizontal axis. Hence the rotational frictional losses were reduced considerably. The horizontal axis holding up the cable drum consisted of a threaded rod fixed with special nuts against and resting on two steel plates. Two ball bearings with conical shaped outer surfaces were mounted on the opposite drum sides on the threaded rod and fixed against the drum with nuts, thus holding it on the threaded rod. In order to supervise the rotational velocity and acceleration of the drum, a miniature measuring wheel system with an incremental rotational sensor was mounted with nuts on the threaded rod at one side of the drum, against the rotating outer surface of the ball bearing. Hence, the measuring system was easily removed from the drum axis, the drum and the axis were easily lifted off together and the drum was easily unmounted from the axis and vice versa. Moreover, to minimize the cable slack, and consequently the peak feeding forces, a simple variable force drum brake was constructed and mounted on the drum frame. The brake, having some conceptual similarities with the disc clutch brake in [15], consisted of an aluminium profile being pushed against the two thin outer envelope surfaces of the drum, thus creating a frictional force between the two surfaces and braking the drum rotation. A double-acting guided linear pneumatic cylinder was used as actuator. The actuator operation was controlled by a pneumatic 3/2 way NC solenoid valve. The movement velocity was calibrated manually in both directions using throttle valves on the actuator side and the push force was adjusted with a proportional pneumatic valve. A damping power spring and two small retracting tension springs were mounted between the actuator and the aluminium profile and a Hall Effect sensor was mounted on the cylinder to verify when the brake was released. Two additional Hall Effect sensors were mounted, with some offset relative to each other, higher up on the cylinder to verify when the brake was closed. Finally, it was decided to keep the guiding rollers and the circular air blow nozzle mounted between the drum and the drum feeder. The air blow nozzle was again controlled by a pneumatic NC solenoid valve, but the pressure of the supplied compressed air was now manually calibrated with a pressure regulator. The final version of the complete drum feeding equipment is shown in Figure 3.

Figure 3.

(a) A 3D-CAD model of the final complete drum feeding equipment design and its main components, note that the miniature drum rotation measurement equipment is placed on the opposite side of the drum; (b) A photo of the final complete drum feeding equipment, including the cable cutting equipment; (c) A close-up photo of the drum brake while being released; (d) A close-up photo of the drum brake while being activated; (e) A close-up photo of the drum axis ball bearing and the miniature drum rotation measurement system.

3.1.2. Control System

The control system of the cable feeding equipment was simultaneously developed with the prototype equipment. To begin with, as the drum cable feeder tool servo motor drive was connected to the PLC, it was possible to directly control and supervise the servo motor from the PLC. Since the feeding mechanism servo motor drive of the robot cable feeder tool was connected to the PLC in the same way, it was possible to synchronize the feeding of the two tools. Furthermore, the cable feeding—in particular the acceleration and deceleration phases—could be adjusted precisely in order to limit the maximum force that the feeder was subjected to as the drum feeding was started from standstill. Since the servo motor, in contrast to the step motor used before, did not allow motor slip, a too high or jerky feeding force automatically raised an error from the drive in the PLC. When drum feeding was activated by the control system, the circular air blow nozzle was automatically activated simultaneously, using its solenoid valve, to blow dirt off from the cable.

The drum brake was controlled by setting the desired normal force between the brake profile and the drum in the PLC. Knowing the relation between the air pressure and the actuator push force, the desired normal force was then translated to the corresponding required air pressure in the PLC and sent to the built-in control system in the proportional valve. A feedback signal from the proportional valve to the PLC provided the actual air pressure delivered to the cylinder, which was then translated to the actual normal force value of the brake. The signal from the incremental rotational sensor was connected to a fast counter input on the PLC and the result was translated into rotational degrees of the drum. This value was then differentiated to get the rotational velocity of the drum, which was then in turn differentiated to get the rotational acceleration of the drum. With the variables to control and supervise the brake and the drum rotation ready, the brake operation could be programmed. It was decided from experience that the brake should be possible to operate in in four different ways:

- To be completely released

- To quickly stop the drum when rotating

- To stop the drum from starting to rotate by itself

- To slide against the drum and thus counteract the drum rotation

The first brake operation was the most straightforward. To release the brake, and hence allow the drum to rotate freely, the desired value of the normal force was set to zero and the brake was deactivated using its solenoid valve. The system was then waiting for the lower cylinder Hall Effect sensor to confirm that the pneumatic actuator had been pulled back completely. The second brake operation, to stop the drum when rotating, was also rather straightforward. Here, the desired value of the normal force was first set to 500 N and the brake was activated using its solenoid valve. The control system then supervised the actual rotational velocity of the drum. As soon as the drum rotation was completely stopped, the desired value of the normal force was lowered to 100 N and the system waited for the actual brake force to reach this value. The third brake operation was identical to the last part of the second brake operation: here the normal brake force was directly set to 100 N. The fourth brake operation was the most sensitive one requiring the most calibration. The idea was to make the brake slide with a rather low normal force against the drum in order to avoid a jerky drum rotation during feeding. However the drum should preferably not be braked when the drum feeding was initiated and accelerated, since that could cause high snap loads on the drum feeder tool if the cable was not completely tensed beforehand. The solution was to start with the brake released while supervising the rotation of the drum. As soon as the drum started to rotate and reached a rotational velocity corresponding to about 10% of the ordered drum cable feeder tool cable feed velocity, the desired value of the normal brake force was adjusted to 150 N and the brake was activated using its solenoid valve. This normal force was higher than the normal brake force used for brake slipping and was used to position the brake profile against the drum surface more quickly. Immediately when the upper cylinder Hall Effect sensors indicated that the brake had been closed—typically before the set normal brake force was reached—the desired value of the normal brake force was adjusted to about 60 N, i.e., the normal brake force value that had been decided experimentally to be suitable for brake slipping, and the control system waited for the set normal force to be reached. The brake then remained in sliding operation until another brake operation was ordered. To estimate the cable feed off velocity from the drum, the diameter of the outer cable layer on the drum was approximated knowing the drum and cable dimensions and the approximated amount of cable currently on the drum. The amount of cable on the drum was continuously calculated and updated by the PLC as the cable was fed from or to the drum using the drum cable feeder tool and the outer drum cable layer diameter approximation was simultaneously updated. The cable drum feed off velocity could thus be calculated continuously from the current drum rotational velocity. To determine if the brake was closed, the digital signals from the three cylinder Hall Effect sensors were supervised by the PLC. The status of the brake was set to close if one or both of the two upper sensors were active while the status was set to open if the lower sensor was active or if the middle sensor was inactivated while the upper sensor was already inactive. Another advantage with the slide brake operation was that it enabled a quicker full drum brake while being in the sliding brake mode compared to starting with the brake released. To maintain the equipment performance, the PLC was programmed to supervise how many times the brake was activated and how long it had been used in total to slide-brake the against the drum.

3.2. Preparing the Cable End

This section presents the final prototype cable end preparation equipment. First, the defined specific requirements on the equipment are presented in Table 3. In the following, the equipment design is presented in Section 3.2.1 and the corresponding control system is presented in Section 3.2.2.

Table 3.

Specific requirements for the cable end preparation equipment, including priority level; level A requirements are necessary to fulfil, level B requirements should be aimed to be fulfilled and level C requirements are desired but not critical.

3.2.1. Prototype Design

As mentioned above, a pre-study on automated cable end preparation has previously been done at UU [17]. Since the results from this pre-study were very promising, it was decided to use them as a base for designing the new completely automated cable end preparation equipment. For reference, a summary of the method and equipment suggested in the pre-study is given in the following paragraph.

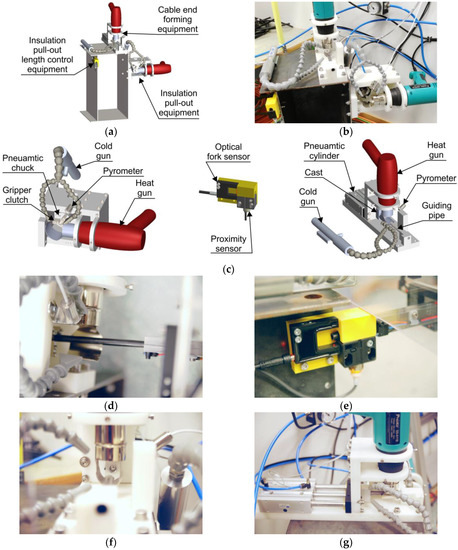

The referred pre-study suggested a complete robotized system, with inspiration from the corresponding manual process and the previous developed robotized cable winding cell [13], where the preparation was performed by an industrial robot with an attached cable feeder tool in two main sub-process steps:

- The cable insulation was stretched out over the threads at the cut cable end

- The stretched out cable end insulation was heated up and formed in a cast

Separate side equipment was used to pull out the cable end insulation and to form the cable end. To begin with, the cable end was positioned by the robot inside a pneumatic three-finger chuck at the insulation pull-out equipment. The cable end was then grabbed by the chuck with three teethed gripper clutches. Next, the robot was moved about 100 mm straight back following the cable from the chuck. The free cable part between the chuck and the robot tool was then heated up at a distance of about 50 mm from the cable end to about 130 °C using a heat gun with an attached reflector nozzle. Consequently, the cable insulation became formable so that it could be stretched out about 5 mm over the cable end threads by pulling the cable backwards with the robot cable feeder tool. The cable was then released from the chuck and moved by the robot to a separate circular air blow nozzle for cooling. Next, after cooling, the cable end was fed back into the robot tool and moved by the robot to the forming side equipment. Here, the cable was fed by the robot feeder tool into and through a 120 mm long guiding steel pipe, so that the cable end was sticking out about 20 mm at the far end of the pipe. The cable end was then heated up to about 130 °C using another heat gun with an attached reflector nozzle. Immediately after the cable end had been heated up, an aluminium cast was pushed against the cable end using a double-acting guided linear pneumatic cylinder as actuator. The cable end insulation was thus closed and formed over the end threads. The purpose of the steel pipe was to provide space for the heat gun being attached to the actuator, as the actuator was pushed forward. Finally, the cast was moved back and the cable end was again moved by the robot to the circular air blow nozzle for cooling. In the pre-study, suggestions were also made for further developments regarding sensor integration for automated process control. All equipment was designed in a 3D-CAD environment and the complete process was simulated with an industrial robot holding a cable feeder tool, using offline industrial robot programming and simulation computer software. Prototype gripper clutches and casts were constructed and key processes, such as heating up the cable with a heat gun, gripping the cable end with the three-finger chuck and forming the cable end using a cast, were manually tested.

In the new equipment, the same three-finger chuck was used to grab the cable end in the insulation pull-out equipment but an updated gripper clutch design was used to improve the grip on the cable end. To be able to grab the cable with a higher and more evenly distributed force, the teeth of the new clutches were tilted slightly inwards at the top side and the clutch grip width was reduced. Furthermore, the material of the clutches was changed to stainless steel, the mechanical tolerances were refined and the teeth were sharper. The actuator operation was, as before, controlled by a pneumatic 3/2 way NC solenoid valve and two throttle valves were added on the actuator side to manually calibrate the movement velocity of the actuator in both directions. Two Hall Effect sensors were also added to the actuator to verify when the clutches were opened and closed respectively. To heat up the cable insulation, a similar heat gun with attached reflector nozzle was used. Compared to the pre-study solution, the power supply of the heat gun was however wired through a NO relay and, as suggested for further developments in the pre-study, a pyrometer was used to measure the surface temperature of the cable inside the heat gun reflector nozzle. A new cooling equipment, a pneumatic point cooling cold gun with dual point hose nozzles, was chosen. With this solution, the cable could be cooled down more effectively directly inside the heat gun reflector nozzle. This also assured that the stretched out insulation would not deform while being moved to separate cooling equipment as could happen with the previous setup. The cold gun nozzles were directed to opposite sides of the cable surface and the cold gun was controlled with a pneumatic NC solenoid valve while the pressure of the supplied compressed air was calibrated manually using a pressure regulator. For the second sub-process step, to form the cable end, the same guiding pipe, pneumatic cylinder and cast setup as in the pre-study were used as well as a similar heat gun with attached reflector nozzle. The actuator operation was again controlled by a pneumatic 3/2 way NC solenoid valve and two throttle valves were added to the actuator to manually calibrate the movement velocity in both directions. Two Hall Effect sensors were also added to the actuator to verify when the cast was pushed forward completely and pulled back completely. As with the new insulation pull-out equipment, the power supply of the heat gun was wired through a NO relay, a pyrometer was used—as suggested for further developments in the pre-study—to measure the surface temperature of the cable inside the heat gun reflector nozzle and a pneumatic point cooling cold gun with dual point hose nozzles was added to cool down the cable insulation inside the heat gun reflector nozzle. The cold gun was controlled by a pneumatic NC solenoid valve and the pressure of the supplied compressed air was calibrated manually using a pressure regulator.

In the initial experiments with the new equipment it became clear that to achieve a successful forming of the cable end, the cable end insulation pull length is critical. Automatic supervision of the pulled length was not straightforward. Two alternatives could be to use a laser triangulation sensor to measure the distance to the thread ends relative to the distance to the insulation, as suggested in the previous work, or an active vision system for 3D inspection. However this measurement might be challenging to perform in a robust way since the copper end threads will not be exactly evenly axially distributed after the insulation has been pulled out. Therefore an alternative solution was used in this work: a separate, less expensive, cable insulation pull-out length measurement equipment. This equipment consisted of an optical fork sensor and a cylindrical shielded proximity sensor mounted on a 3D-printed plastic base component. To measure the pulled length, the robot positioned its cable feeder tool at the measurement equipment and slowly fed the cable end into the equipment. Here, the cable end first passed close to the measuring surface of the proximity sensor, which was mounted perpendicularly to the cable. Hence, the proximity sensor did indicate the position of the end copper threads inside the cable end. As the cable was fed further, it passed the LED beam of the optical fork sensor, which indicated the position of the cable insulation end. These two positions could then be used to calculate the pulled insulation length. Further, since the initial experiments with the described equipment indicated high and uniform quality, it was decided that automatic inspection of the prepared cable ends could be managed without in the prototype equipment.

The final version of the complete cable end preparation equipment was mounted on a steel frame and is shown in Figure 4.

Figure 4.

(a) A 3D-CAD model of the final complete cable end preparation equipment design and its sub-equipment; (b) A photo of the final complete cable end preparation equipment; (c) 3D-CAD models of the final cable end preparation sub-equipment design and their main components ; (d) A close-up photo of the cable gripped inside the insulation pull-out equipment; (e) A photo of the cable inside the insulation pull-out length control equipment; (f) A close-up photo of the end forming equipment with the cast in its back position; (g) A photo of the end forming equipment with the cast in its front position.

3.2.2. Control System

The control system of the cable end preparation equipment was simultaneously developed with the prototype equipment. To begin with, the initial experiments with the new equipment showed that the cable end was bent after being cut. The bend was not considerable, but sufficient to potentially affect the cable end preparation process. Therefore, a cable end straightening sub-process was added before the cable insulation pull-out sub-process: the cable end was gripped with a higher normal force by the robot cable feeder tool and then fed back and forth between its feeding wheels. A side effect of this operation was that the cable insulation was already pushed out over the cable end threads about 1 mm before the actual insulation pull-out sub-process was started.

The control of the cable end insulation pull-out equipment was straightforward. As the cable end had been positioned and fed by the robot inside the chuck, the chuck was closed using its solenoid valve and the system then waited for the inner chuck Hall Effect sensor to confirm that the clutches had been closed around the cable. Next, the robot was moved back following the cable and the heat gun was activated using its relay while the cable temperature was supervised with the pyrometer. When the temperature reached 130 °C, the heat gun was turned off using its relay and the robot cable feeder tool immediately pulled back the cable 6 mm with a rather high normal grip force. The pull distance was experimentally decided in order to achieve in total about 5 mm insulation pull-out. After the insulation had been pulled, the cold gun was activated using its solenoid valve. The cable temperature was supervised with the same pyrometer and the cooling continued until the cable temperature dropped to 35 °C. Then the cold gun was turned off using its solenoid valve and the chuck was opened using its solenoid valve. The system then waited for the outer chuck Hall Effect sensor to confirm that the clutches had been opened so that the cable was released, before the cable end was fed back into the robot tool. To maintain the equipment performance, the PLC was programmed to supervise how many times the cable end was gripped by the clutches.

As the cable end insulation had been pulled, the robot moved its feeder tool to the insulation pull-out length measurement equipment. In this sub-process, the relative cable fed length difference between when the end threads were first detected by the proximity sensor and when the insulation end was first detected by the optical fork sensor was registered by the PLC. Through experiments with cable ends with different pulled end insulation lengths, the control system was set up and calibrated so that the registered relative cable fed length difference was translated to the actual pulled cable insulation length. The measured actual pull-out length value was compared in the PLC to the desired value, 5.0 mm. If the actual length was not shorter than 4.5 mm and not longer than 6.5 mm the cable end was passed. The limits were decided from cable end forming experiments with cable ends with different pulled insulation lengths. If the cable end failed the control, the operator could choose either to overrun the test result so that the preparation process continued anyway or to order the cable to be automatically cut off and removed after which the complete end preparation process would automatically restart.

Finally, the robot moved its feeder tool to the insulation forming equipment. Here, the cable end was fed through the guiding tube so that 40 mm cable was sticking out on the other side. The heat gun was then activated using its relay while the cable temperature was supervised with the pyrometer. When the temperature reached 140 °C the heat gun was turned off using its relay. The heated cable end was then immediately and quickly fed back into the guiding tube by the feeder tool after which the cast was quickly moved forward against the guiding tube end with the actuator using its solenoid valve. As soon as the outer cylinder Hall Effect sensor confirmed that the cast had reached its outer position, the cable was quickly fed forward 18 mm by the feeder tool with a rather high normal grip force. Thus, the heated cable end was pushed into the cast, where the end insulation was melted together and formed a closed, rounded top around the end threads of the cable. This method, to push the cable into the cast instead of pushing the cast against the cable, gave smoother cable end forms since the cable end could not be pushed against the edges of the cast. After forming and simultaneously passively cooling the cable end for 3 s in the cast, the cast was moved back by the actuator using its solenoid valve. When the inner cylinder Hall Effect sensor confirmed that the cast had been fully pulled back, the robot feeder tool fed the cable forward 27 mm, back to the position inside the reflector nozzle on the heat gun, and the cold gun was activated using its solenoid valve. The cable temperature was again supervised with the pyrometer and the cooling continued until the cable temperature dropped to 35 °C. Then the cold gun was turned off using its solenoid valve and the robot feeder tool fed the cable back into the tool.

3.3. Cutting the Cable

This section presents the final prototype cable cutting equipment. First, the defined specific requirements on the equipment are presented in Table 4. In the following, the equipment design is presented in Section 3.3.1 and the corresponding control system is presented in Section 3.3.2.

Table 4.

Specific requirements for the cable cutting equipment, including priority level; level A requirements are necessary to fulfil, level B requirements should be aimed to be fulfilled and level C requirements are desired but not critical.

3.3.1. Prototype Design

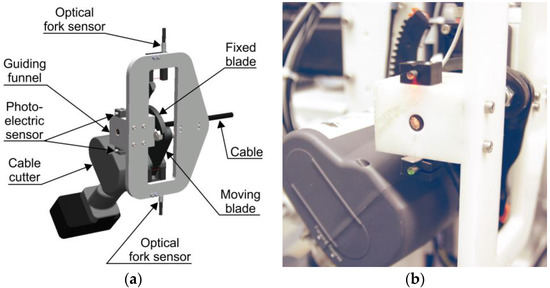

In designing the new cable cutting equipment, different cable cutters—both manual and driven versions—were investigated and tested. Since a multi-thread winding cable was used, the cable was easily flattened to some extent when cut, making the cut cable end a bit oval. To minimize this effect, the cutting blades of the cutter should preferably be curved around the cable and not larger than necessary. On the other hand, the cutter should not be too small, since it must be possible to feed the cable through the open cutter without risk hitting the blades. Furthermore, since the cutter should be mounted between the drum cable feeder tool and the robot cable feeder tool, the cutter blades should be thin. Finally, the cutter should preferably be easy to control from the PLC. With these aspects in mind, an electric battery-powered cable cutter, a BC520 sold by Nelco Contact AB in Sweden, was chosen. The cutter had one stationary blade and one moveable blade cogged on the outside and geared to a DC motor. A trigger button was used to activate cutting and the cutting direction was set with a switch. Both the button and the switch were placed on the tool handle. In order to be able to control the cutter from the PLC, the button and the switch were replaced with relays. The operation of the cutting direction relays was to switch the polarity of the electrical supply to the DC motor driving the cutter, hence switching the motor rotation direction and thereby the cutting direction. In manual operation, the user was supposed to stop the operation of the cutter before the movable cutting blade cogged out in either direction. Here, to supervise the position of the moveable cutter blade, two optical fork sensors were used to detect when the cutter was completely opened and closed respectively. To guarantee constant full cutting force and velocity and to eliminate the need for frequent battery recharging, the battery of the cutter was replaced with an AC/DC plug-in power supply powered from a standard 230 VAC wall socket.

The cable cutter was mounted with the cutter blades positioned directly after the feeding end of the cable guiding system of the cable feeder tool on the drum feeding equipment, allowing the cable to be fed through the cutter. In order to catch and direct the cut end of the cable from the drum into the robot cable feeder tool, a short and wide plastic funnel was mounted directly after the cutter blades. The tight mounting of the cable cutter between the drum cable feeder tool and the funnel made it impossible for an operator’s fingers to reach inside the blades. At the end of the narrow side of the guiding funnel, the funnel went over to a short circular guiding hole from where the cable could be guided into the robot cable feeder tool. At the end of this guiding hole, a side-facing through-beam photoelectric sensor with built-in amplifier was installed to supervise if the cable was sticking out from the hole.

Figure 5.

(a) A 3D-CAD model of the final complete cable cutting equipment design and its main components; (b) A close-up photo of the final complete cable cutting equipment.

3.3.2. Control System

The control system of the cable cutting equipment was simultaneously developed with the prototype equipment. To begin with, three necessary operation modes for the cable cutter were identified:

- To perform a complete cable cut

- To immediately stop the cable cutter movement regardless of current operation

- To reset the cable cutter

In order to perform a cable cut, the PLC needed to be able to confirm that cable was in position inside the cutter. This information was provided by the drum cable feeder tool and the photoelectric through-beam sensor, together confirming that the cable was present on both sides of the cutter. Furthermore, the PLC also had to verify that the cutter blades were opened, which was done with the upper optical fork sensor. With these requirements fulfilled, the cutting could be started. To begin with, the cable feeder tool was ordered to release its grip on the cable. This allowed the cable to move in its axial direction while being cut, thus eliminating the axial forces that would otherwise occur between the cable and the cutting blades as the cable was moving slightly in its radial direction while being cut. If not eliminated, these forces could impair the quality of the cut, deform the cable end and also increase the wear and tear of the equipment. Next, the cutter operation direction was set to forward and cutting was activated using its relays. Hence, the cutter blades were closed and the cable was cut. As soon as the lower optical fork sensor detected the moving cutter blade—which was when the cut had been completed—the cutting movement was stopped using the relay. The control system then waited one second for the cutting movement to be decelerated to standstill before the cutter direction was reversed and cutting was reactivated using the relays. This opened the cutter blades. This time the upper optical fork sensor was used to detect when the cutter had been completely opened so that the cutting movement could be stopped using the relay. Finally, the cable feeder tool was programmed to retake its grip on the cable. The second operation mode, to immediately stop the cable cutter, was programmed to stop and override all other cable cutter operation modes. To stop the cutting, the relay triggering the cutting was simply deactivated. This operation did not represent a safe stop, but was sufficient for the control system to stop the cutting if required due to e.g., an error in the control system process supervision. The third operation mode, to reset the cutter, was used to open the cutter blades if they had stopped in a half or fully closed position. To achieve this, the cutter operation direction was set to reverse and cutting was activated using the relays. Then, as soon as the upper optical fork sensor detected the moving cutter blade, the cutting movement was stopped using the relay. To maintain the equipment performance, the PLC was programmed to supervise how many cuts the cable cutter performed.

Finally, the cable cutter equipment needed to be able to remove the end of the cut off cable from the guiding funnel. The first approach to solve this problem was to push out the cut cable end with the remaining cable using the drum cable feeder tool. However, this solution was not robust enough, since the two cable ends could end up beside each other and be squeezed inside the guiding funnel. Instead, it was decided to use the robot feeder tool to pull out the cut cable from the guiding hole while using the photoelectric through-beam sensor to confirm that the cable had been fully pulled out.

4. Experimental Results

As the constructed equipment reached the final prototype version, the performance was evaluated against the requirements presented above. In this section, the results from these experiments are presented for the three previously defined sub-tasks. All constructed equipment was fully controlled by the PLC and experimentally validated to be compatible with robotized cable winding of the UU WEC generator stator. Moreover, all process cycle times were reduced in the presented equipment, without compromising on the quality or robustness of the results. The estimated total cost for each sub-equipment—including estimations of the actual costs for in-house component manufacturing, but excluding costs for design, assembly, programming and calibration work as well as costs for the industrial robot, the robot cable feeder tool and the PLC equipment—are presented in Table 5.

Table 5.

Total cost estimations for the constructed prototype sub-equipment.

4.1. Feeding Cable from the Cable Drum

As required, the drum cable feeder equipment was experimentally validated to be able to deliver cable from the specified drum to the robot cable feeder tool. It was easy to replace the cable drum, even though two persons were required to manually lift the new drum. With the new design, the cable drum could rotate with negligible resistance as the cable was fed off it. Slack on the cable was reduced with the drum brake. The control system was able to quickly and effectively release the brake, to completely stop the drum when rotating and to stop the drum from starting to rotate by itself. The sliding brake function could be controlled as expected, even though it was not able to completely prevent cable slack during feeding. Hence, the jerky drum rotation with oscillating cable feed forces was significantly reduced but not eliminated. Especially with little cable on the drum combined with lower cable feeding velocities, the drum rotation could still be jerky. All drum brake operations were experimentally validated in numerous experiments with varying amounts of cable on the drum and different cable feed velocities. In low feed velocities—around 100–200 mm/s—the feeding system worked very well, with low peak feed forces. In higher feed velocities—up to 500 mm/s was tested—more slack was sometimes created on the cable as it took longer to stop the cable drum from higher velocities. Furthermore, the peak feed forces from tensing cable slack were also higher at higher feed velocities since the cable drum was then accelerated faster to higher velocities. At lower feed velocities, the peak feed forces were handled well by the drum cable feeder tool. The corresponding results for higher feed velocities were also promising. However, especially with a lot of cable on the drum, the peak feed forces at higher feed velocities could occasionally not be handled by the drum cable feeder tool servo motor. This would then cause a fatal follow error in the servo motor drive. The experiments showed that the sliding brake operation needed to be carefully calibrated for good performance. The drum feeding could be fully synchronized with the robot cable feeder tool feeding. Negligible wear was noticed on the drum brake components and the cable drum during the experiments.

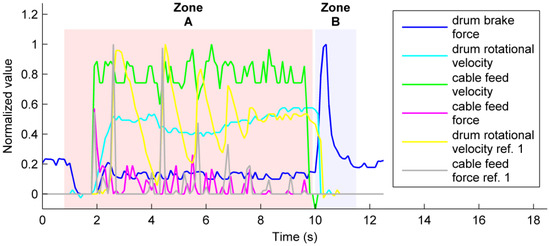

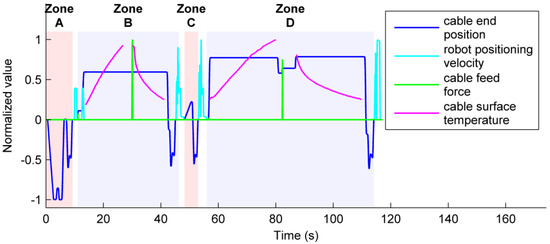

In Figure 6, the brake operation is demonstrated in terms of the normalized actual values of the brake force, the drum velocity and the cable feed velocity from the drum cable feeder tool, for a short typically smooth drum feeding operation. The displayed operation started with the brake being released after approximately 1 s. Next, after about 2 s, cable feeding was initiated and the drum started to rotate. Shortly after, the drum brake was activated. The drum cable feeder cable feed velocity was quickly accelerated to its desired velocity, while the drum reached its corresponding rotational velocity and the drum brake reached its desired brake force after about 2.5 s. After about 10 s the drum feeding was quickly stopped. The drum brake was then used to stop the drum rotation by raising the drum brake force to its full stop force. As soon as the drum had been completely stopped, the drum brake force was reduced again. During this complete operation, the cable feed force had its highest peak when the drum feeding was accelerated from standstill. During feeding, the feed force was oscillating but only with low peak forces. Furthermore, in the same figure, the corresponding drum rotational velocity and cable feed force are shown for a typically jerky corresponding drum feed operation. From the figure, it can been noted that in the jerky operation example the drum started to rotate slightly later and was then first accelerated very fast to a high rotational velocity, causing a high peak cable feed force, before the velocity dropped to almost standstill again. This acceleration and deceleration sequence was repeated a few times with decreasing amplitudes until the velocity reached a more steady level. The cause for this jerky drum feed was most likely that there was slack on the cable between the drum and the drum feeder tool as the feeding was started. The peak feed forces during feeding, as the drum is accelerated, were significantly higher than the corresponding peak feed force needed to accelerate the drum feeding and much higher than the corresponding peak forces during feeding for the smooth operation example.

Figure 6.

Normalized actual values of the drum brake force, the drum rotational velocity, the cable feed velocity and the cable feed force during a short smooth drum feeding process. For reference, the corresponding drum rotational velocity and cable feed force are also shown for a jerky short drum feed process, referred to in the figure as “ref. 1”. Zone A highlights the sliding brake sub-process and Zone B highlights the full brake sub-process. The actual maximum absolute values shown in the figure are 474 N drum brake force, 73 degrees/s drum rotational velocity, 124 mm/s cable feed velocity and 42 N cable feed force.

4.2. Preparing the Cable End

The cable end preparation equipment was experimentally validated to be able to prepare a cut end of the specified cable according to the end form requirements and without any additive materials. The complete process cycle time for preparing one cable end, including moving the robot to and from the equipment, was about 115 s. In Table 6, this cycle time is approximately divided and presented per sub-process.

Table 6.

The complete cable end preparation process cycle time approximately divided per sub-process, including total active time for the heat and cold guns during the pull-out and forming sub-processes.

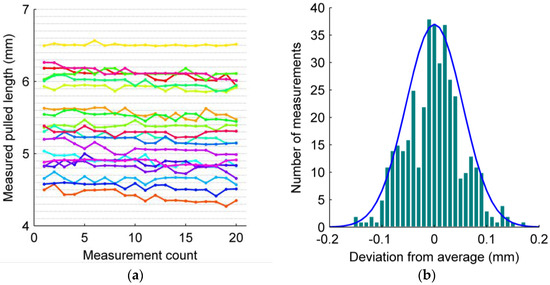

Straightening the cable end took about 10 s, pulling out the cable insulation took about 35 s, controlling the pull length took about 5 s, forming the cable end took about 60 s and the remaining time was used for positioning the robot tool between the different sub-stations.

In the cable insulation pull-out equipment, it was not possible to achieve completely consistent pull-out lengths. By estimate, less than one out of ten of the cables failed the insulation pull-out length control equipment, typically by one or two tenths of a millimetre. However, in almost all of these cases, the length control result was overridden by the operator so that the cable end preparation could continue anyway. Analysis of the 400 cable pull-out length measurements indicated that the variation of both the pulled insulation length and the automatic measurements were normally distributed. The calculated confidence intervals for the pulled cable insulation lengths and the cable insulation pull-out measurements for different confidence levels are presented in Table 7. The actual values of all the measurements are presented per cable in Figure 7a, while Figure 7b presents a histogram of the deviation from average for all 400 measurements together with the corresponding normal distribution. It was difficult to achieve well defined high accuracy manual measurements of the pulled cable insulation lengths using a calliper, because neither the end insulation nor the end threads were completely even. However, comparing these measurement results to the automatically performed measurements indicated good correlation. The maximum feed force required to pull out the cable insulation was estimated, from the logged robot cable feeder tool feed force values, to 100 N.

Table 7.

Confidence intervals for the pulled cable insulation lengths and the cable insulation pull-out measurements for different confidence levels, based on analysis of 400 measurements.

Figure 7.

(a) The actual values of all 400 automatic cable end insulation pull-out measurements, presented per cable, where each colored line represents one cable; (b) A histogram of the deviation from the cable average for all 400 automatic cable end insulation pull-out measurements, together with the corresponding normal distribution.

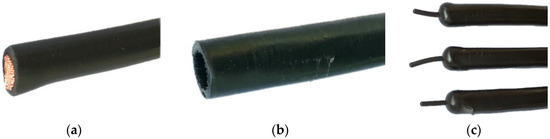

In the cable end forming equipment, the cable end was given a spherical, smooth and uniform shape. The strands of the end threads were completely covered, while both edges and diameter deviations were negligible in relation to the intended winding application. None of the cable ends formed on the cables which passed the pull-out length control were failed by manual inspection or in the following winding experiments. A few cable ends formed on cables which had been failed in the pull-out length control, were visually judged not to fulfil the form requirements so well. However, only one of these cable ends in the end failed in the following winding experiments. In this single case, the end threads were not completely covered by the formed end insulation, probably due to a too short pulled insulation length. The maximum robot cable feeder tool feed force required to push the cable end into—and thereby form the cable end inside—the cast was estimated, again from the logged cable feeder tool feeding force values, to be lower than the maximum force required to pull out the cable insulation. As the cable end was formed in the cast an additional insulation tip—about one millimetre in diameter and a few millimetres long—was formed at the cable end in the air outlet in the bottom of the cast. It was experimentally validated that this tip did not disturb the intended winding process. Furthermore, the experiments showed that the pull-out and forming process needed to be carefully calibrated together for good performance. No significant wear was noticed on the toothed chuck gripper clutches. Figure 8 shows a typical cable end after being cut, after the insulation has been pulled out and after the end has been formed.

Figure 8.

(a) A cable end after being cut; (b) A cable end after the end insulation has been pulled; (c) A cable end after being formed.

Figure 9 shows the normalized actual values of the cable end fed distance relative to the feeding end of the robot cable feeder tool cable guiding system, the absolute non-directional linear positioning velocity for the tool centre point of the feeding end of the robot cable feeder tool cable guiding system, the feed force applied to the cable by the robot cable feeder tool and the cable end temperature during the complete cable end preparation process. The displayed operation started with the cable end straightening sub-process, where the cable end was fed back into the cable feeder tool and straightened between the feeding wheels. When the straightening was finished, after about 7 s, the robot cable feeder tool performed a homing cable search sequence, where the cable end was fed back into and detected inside the feeder tool, in order to readjust to the actual cable end position. Next, after about 9 s, the cable feeder tool was positioned by the robot at the insulation pull-out equipment. The cable end was fed into and gripped by the chuck and the feeder tool was then moved away from the chuck following the cable. The heat gun was activated after about 14 s. The desired high cable temperature was reached after about 27 s. The heat gun was then switched off and the cable feeder tool gripped the cable with a high normal force before pulling the cable. Thus, the end insulation was pulled out after about 30 s, and the cold gun was immediately activated. The desired low cable temperature was reached after about 41 s. Thereafter, the cold gun was switched off, the cable feeder tool performed another homing cable end search sequence and the feeder tool was positioned by the robot at the insulation pull-out length measurement equipment. After about 48 s, the pull-out length measurement was started as the cable end was slowly fed into the measurement equipment by the robot feeder tool. When the measurement was completed, the feeder tool performed another homing cable search sequence and was then positioned by the robot at the end-forming equipment. After about 57 s, the cable end was fed into the forming equipment and the heat gun was activated. As the desired high cable temperature was reached after about 80 s, the cable was fed back into the guiding pipe by the feeder and the cast was quickly pushed forward. Next, after about 82 s, the cable end was pushed into the form by the feeder tool. A few seconds was given for the cable end to form and cool down inside the cast, before the cast was moved back and the cable was fed forward slightly so that the cold gun could be activated after about 87 s. The desired low cable temperature was reached after about 110 s. Finally, the cable was retracted from the forming equipment and another homing cable end search sequence was performed before the cable feeder tool was moved away from the equipment by the robot.

Figure 9.

Normalized actual values of the fed cable end distance, the robot positioning velocity, the cable feed force and the cable surface temperature during a complete cable end preparation process. Zone A highlights the straightening sub-process, Zone B highlights the insulation pull-out sub-process, Zone C highlights the pull-out length control sub-process and Zone D highlights the end forming sub-process. The actual maximum absolute values shown in the figure are 162.5 mm fed cable end distance, 505 mm/s robot positioning velocity, 81 N cable feed force and 140 °C cable surface temperature. Note that the cable temperature is only shown when the cable is heated up or cooled down. The cable end position values are integrated from the logged cable feed velocity values and slightly adjusted to be consistent with the actual cable feed lengths.

4.3. Cutting the Cable

The cable cut equipment was experimentally validated to be able to cut the cable between the drum cable feeder tool and the robot cable feeder tool according to the shape requirements in a robust way. The achieved cut was fairly straight and even, see Figure 8a above, and was experimentally validated to be an adequate starting point for the cable end preparation process. As described in Section 3.2.2 above, the cable end was bent while being cut, but this bend was however readjusted with the straightening sub-process in the cable end forming equipment. The cable cutter control system was validated to perform all three identified required operations: to cut the cable, to immediately stop the cutting and to reset the cutter. The cable guiding funnel was able to catch a cable end being fed through the cutter and direct it into the robot cable feeder tool. It was also experimentally validated that the robot held cable feeder tool could be used to pull out the cut cable from the equipment with verification from the photoelectric through-beam sensor in a robust way. The complete process cycle time for cutting a cable, including releasing the drum cable feeder tool grip before and retaking the grip after the cutting, was about 20 s. The cable cutter cutting operation alone took about 14 s. No significant wear was noticed on the cutter blades.

5. Discussion

Through the experiments presented above, the constructed final prototype of the cable preparation equipment was experimentally validated to be able to deliver cables for robotized cable winding according to the specified requirements. The results from these experiments were consistent with the conclusions and assumptions from earlier work [3,13,17] and the presented processes were judged to be robust with uniform results. The flexibility of the method has not been validated. However, it is likely that the equipment could be modified to handle cables with reasonable different dimensions. Further work would be required to determine if the equipment can be modified to handle other cable types, such as cables with fewer threads or other insulation thickness or material.

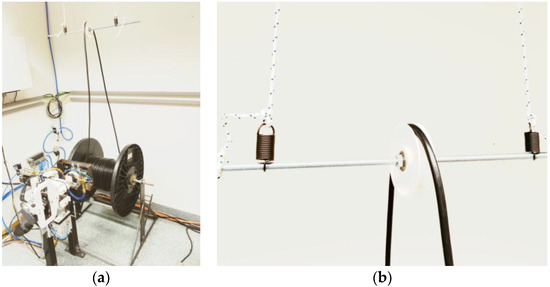

Since the equipment is supposed to be used very frequently in a fully automated robotized cable winding setup where failures might be very costly, some modifications of the equipment are recommended to further improve the quality of the processes before taking the equipment into production. Especially, the oscillating drum cable feed forces—occurring due to cable slack between the cable drum and the cable drum feeder in the cable feeding equipment—should be handled in a more effective way. It was very hard to eliminate all cable slack in the equipment completely. Some reasons for this were the direct coupling between the drum cable feeder tool and the drum, the high and varying—depending on the amount of cable on the drum—moment of inertia of the cable drum, the unprecise and not very quick adjustment of the normal brake force, the not insignificantly uneven outer envelope surfaces of the cable drum and the varying—depending on if the brake profile was static or sliding against the drum—frictional coefficient between the drum surface and the brake profile surface. Calibrating the drum brake to eliminate cable slack with varying feeding velocities and amount of cable on the drum was especially difficult. At low feed velocities and with little cable on the drum, it might actually be better to completely release the brake. With these difficulties in mind, it might be worth investigating adding cable tensing equipment between the cable drum and the drum cable feeder tool. This equipment should preferably not only be designed to prevent cable slack, but also to smoothen snap cable pull forces as the drum rotation is accelerated by ramping the cable tension. For example, the cable could be tensed against a spring damped line wheel. A simple, not calibrated, passive pilot prototype of such a system—where the cable was fed over a spring damped line wheel hinged over the cable drum—was preliminary tested with the presented equipment, see Figure 10. This test showed that the constructed prototype did not reduce the cable slack. However it did significantly reduce the peak cable pull forces, while on the other hand requiring more overall cable pulling force to pull the cable over the line wheel. Thus, the results from the pilot prototype did justify further investigation. A similar simple but more controlled cable tensing equipment solution is to guide the cable horizontally between three line wheels, where the cable is guided over the middle line wheel which is mounted above the other two line wheels and vertically springy downwards. In this way, the damping of the middle wheel can be supervised in order to decide the cable tension, as in [14]. However, the best solution would probably be to combine cable tensing equipment and cable tension supervision with an additional motor driving the cable drum, similar to how it is done in [16]. The drum motor solution could then be designed to eliminate cable slack completely, to allow feeding cable back to the drum and to eliminate the need for a separate drum brake. On the other hand, this would be a more complicated and expensive solution and effort must be made to not make it complicated to change the drum. A second recommendation is to increase the available feeding force from the drum equipment cable feeder tool. Thus, the drum feeding equipment would be able to handle higher forces while pulling the drum. This would probably not only make the process more robust, but could also enable higher cable feed velocities and allow for the use of drums with more cable. A third modification, intended to increase the robustness of the cable end preparation equipment, is to add automatic inspection of the final shape of the prepared cable end. This could be done using e.g., an active 3D vision system [18]. The smoothness and uniformity of the prepared cable end should then be inspected.

Figure 10.

(a) A photo of the used simple passive pilot cable tensing prototype equipment mounted on the drum feeding equipment; (b) A close-up photo of the used simple passive pilot cable tensing prototype equipment.

Comparing the estimated cycle time for manual cable end preparation with the cycle time result for automated cable end preparation indicate that manual preparation is much faster. However, it should be kept in mind that the automated preparation can be performed within the robot winding process, without stopping the cell operation or adding any extra waiting time. It is also likely that the cable ends prepared with the automated equipment are more uniform. Furthermore, if the end preparation affects the total cycle time for robotized cable winding too much, it could instead be performed with an additional separate robot inside the cable winding production cell simultaneously with the actual winding process. For the 400 experimental cable insulation pull-out length measurements it was observed that the measured lengths were generally decreasing slightly during the 20 measurements, see Figure 7a. The average decrease between the first and the last measurement was about 0.09 mm, while the average decrease between the average value of the first ten measurements and the average value of the last ten measurements was about 0.06 mm. Possible explanations for this decrease were probably that the cable was fed back and forth between the feeding wheels of the robot cable feeder tool between the measurements or that the cable insulation which was not heated and cooled during the pull-out sub-process had also been stretched out and was therefore still slowly returning to its original shape or that the cable end temperature dropped further during the measurements, or a combination of these. Hence, taking this decrease into account, the repeatability of the automatic pull-out length measurement equipment could in fact be even more precise than indicated from the calculated normal distribution. However, the pull-out length measurement repeatability was already sufficient in relation to the determined acceptable pull length interval. Regarding the standard deviation result for the average pulled cable insulation lengths, a not negligible part of the pulled cable ends would be failed with regards to the selected acceptable pulled length limits. This result was judged to be acceptable for the intended application, since robustness was prioritized. Nevertheless, a more consistent pulled length would of course increase the cell productivity and reduce the cable waste if integrated in a complete robot cable winding cell. It would be worth investigating if the cable ends which failed the insulation pull-out length control could be automatically modified instead of cutting them off and restarting the process. Extending the pulled length could probably be done by repeating the automatic insulation pull-out process, but with a shorter cable pull length. Reducing the pulled length on the other hand could probably be done by slowly pushing the cable end, with a low feed force, against a flat surface using the robot cable feeder tool. Concerning the manual control measurements of the pulled cable insulation lengths, it was noticed that the result did differ slightly depending on how the calliper was directed both against the end insulation and against the end threads. With this in mind, it is in fact likely that the automatic measurement method presented here could provide more robust and reliable results, since these measurements were always taken on the same side of the cable end in relation to the previous insulation pull-out process. If desired, automatic measurements could also easily be taken from the other sides of the cable within the same equipment by rotating the robot cable feeder tool.

Even though no significant wear was noticed on the equipment during the experiments, well defined service intervals—for example for sharping the blades of the cable cutter and the teeth of the chuck grip clutches—are likely to be required to maintain the quality of the cable end preparation. Defining these intervals correctly would probably require supervision of the equipment during long term operation. In general, further and preferably long term experiments in a complete automated robot cable winding setup are recommended to fully evaluate and further develop the presented equipment. If such experiments show that the prepared cable end suffers hard from wear during a full winding process, a possible solution could be to use the equipment, with minor adjustments, to cut off the worn cable end and prepare a new end on the same cable during the winding process. Wear on the cable end after the winding process is finished can be neglected since the cable end will then be cut off. The cable winding process, as described in [3], requires the winding cables to be prepared in both ends, since two robot pairs perform winding in opposite directions on the stator using the same cable. To prepare such cables, the other end of the cut cable must be delivered to the robot cable feeder tool as well. This is not possible in the equipment presented here and has not been taken into account in this work. Furthermore, it is likely that the process cycle times can be reduced further, both by optimizing the present process and by equipment optimizations, since this has not been the highest priority in this work. For example, in Table 6 it is shown that heating and cooling of the cable insulation during the cable end preparation forming sub-process took about twice as long as the corresponding heating and cooling during the insulation pull-out sub-process. It is likely, however, that these slower operations can be sped up by guiding the hot and cold airflows more efficiently to the cable end.

Some additional ideas for minor improvements of the equipment came up during the experiments. To begin with, when it comes to controlling the drum brake, a more precise estimation of the actual brake force could be provided either by measuring the actual force using a load cell sensor or by measuring the compression of the brake spring. Furthermore, it could be interesting to investigate if the cable end forming quality was affected by the magnitude of the force used to push the cable end into the cast during the cable end preparation forming sub-process. This could be achieved by reprogramming the robot cable feeder tool to push the cable into the cast with a specified feed force instead of as was done now, namely to feed the cable forward a specified distance into the cast. The bending of the cable end created during the cutting process was indeed fixed with the implemented cable end straightening process. However, the short cable insulation length that was simultaneously pushed out over the cable end threads during this operation was observed to vary a bit. This meant an extra unwanted uncertainty was added to the total pulled out cable insulation length. To eliminate this uncertainty, the cable cutter would need to be adjusted to eliminate the bending. Two solutions for this could be to change to a cable cutter with two moving blades, meeting in the middle, or to adjust the mounting of the cable cutter so that the cutter could move in the radial direction of the cable while cutting. Alternatively, the insulation pull-out length control equipment could be used also between the cable end straightening sub-process and the cable insulation pull-out sub-process, thus allowing the later sub-process to adapt to the actual insulation length which has already been pushed out.

6. Conclusions

In the work presented above, equipment for automated cable preparation for robotized stator cable winding has been designed, constructed, tested and validated. The preparation include delivering cable from a cable drum to a robot held cable feeder tool, forming the cable end to a tip and cutting the cable to the desired length. The results were robust, correlated well with earlier theoretical and experimental results and fulfilled the identified requirements, especially for lower drum cable feed velocities. Hence, the work represents another important step towards demonstrating completely automated robotized stator cable winding. However, to achieve robust drum feeding at higher velocities, especially if larger drums should be used, cable tensing equipment is recommended to be added to the drum feeding equipment. It is likewise recommended to increase the available drum cable feeder tool feed force and to add automatic machine vision inspection of the prepared cable end. Adding a motor to drive the cable drum itself should be considered as well. Even though the results are very promising, further long term tests in a full scale robotized cable winding setup are required to fully investigate the robustness of the equipment. Furthermore, it is likely that the equipment presented in this work could be adjusted and calibrated to handle different cable dimensions and possibly also other similar cable types.

Acknowledgments

The authors are thankful to Vargöns Smältverk for contributing to the funding of this study.

Author Contributions

E.H. and M.L. conceived and designed the project; E.H. designed, assembled and calibrated the equipment, performed the experiments, analysed the data and wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest. The funding sponsors had no role in the design of the study; in the collection, the analyses, or the interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Leijon, M.; Dahlgren, M.; Walfridsson, L.; Li, M.; Jaksts, A. A recent development in the electrical insulation systems of generators and transformers. IEEE Electr. Insul. Mag. 2001, 17, 10–15. [Google Scholar] [CrossRef]

- Metwally, I.A.; Radwan, R.M.; Abou-Elyazied, A.M. Powerformers: A breakthrough of high-voltage power generators. IEEE Potentials 2008, 27, 37–44. [Google Scholar] [CrossRef]

- Hultman, E.; Leijon, M. Utilizing cable winding and industrial robots to facilitate the manufacturing of electric machines. Robot. Comput.-Integr. Manuf. 2013, 29, 246–256. [Google Scholar] [CrossRef]

- Parwal, A.; Remouit, F.; Hong, Y.; Francisco, F.; Castelucci, V.; Hai, L.; Ulvgard, L.; Li, W.; Lejeskorg, E.; Baudoin, A.; et al. Wave energy research at Uppsala University and the Lysekil Research Site, Sweden: A status update. In Proceedings of the 11th European Wave and Tidal Energy Conference, Nantes, France, 6–11 September 2015; pp. 6–11. [Google Scholar]

- Engström, J.; Eriksson, M.; Göteman, M.; Isberg, J.; Leijon, M. Performance of large arrays of point absorbing direct-driven wave energy converters. J. Appl. Phys. 2013, 114, 204502. [Google Scholar] [CrossRef]

- Sjolte, J.; Tjensvoll, G.; Molinas, M. Power collection from wave energy farms. Appl. Sci. 2013, 3, 420–436. [Google Scholar] [CrossRef]

- Bogue, R. Europe fights back with advanced manufacturing and assembly technologies. Assem. Autom. 2012, 32, 312–317. [Google Scholar] [CrossRef]

- Pepermans, G.; Driesen, J.; Haeseldonckx, D.; Belmans, R.; D’haeseleer, W. Distributed generation: Definition, benefits and issues. Energy Policy 2005, 33, 787–798. [Google Scholar] [CrossRef]

- Kirkhoff, J. Processes and design considerations for automatic assembly of electric motor stators. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Technology Conference, Indianapolis, IN, USA, 25 September 2003; pp. 79–88. [Google Scholar]

- Morreale, P. Electric motor and generator manufacturing myths. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing Expo, Nashville, TN, USA, 22–24 October 2007; pp. 413–417. [Google Scholar]

- Alfredson, S.; Hernäs, B.; Bergström, H. Assembly of generators with rated voltage higher than 100 kV. In Proceedings of the 2000 International Conference on Power Systems Technology, Perth, Australia, 4–7 December 2000; Volume 1, pp. 189–193. [Google Scholar]

- Hultman, E.; Leijon, M. Six-Degrees-of-Freedom (6-DOF) Work Object Positional Calibration Using a Robot-Held Proximity Sensor. Machines 2013, 1, 63–80. [Google Scholar] [CrossRef]